High-strength high-toughness anticorrosion high-temperature bearing/pinion steel and preparation method thereof

A high-temperature bearing, high-strength and high-toughness technology, applied in the field of bearing gear steel, can solve the problems of low toughness, poor tempering resistance, and unsatisfactory, and achieve high toughness and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

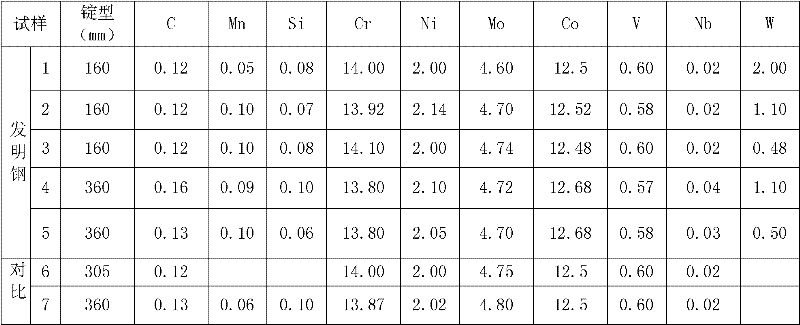

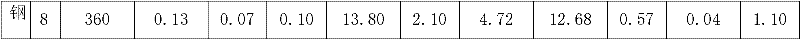

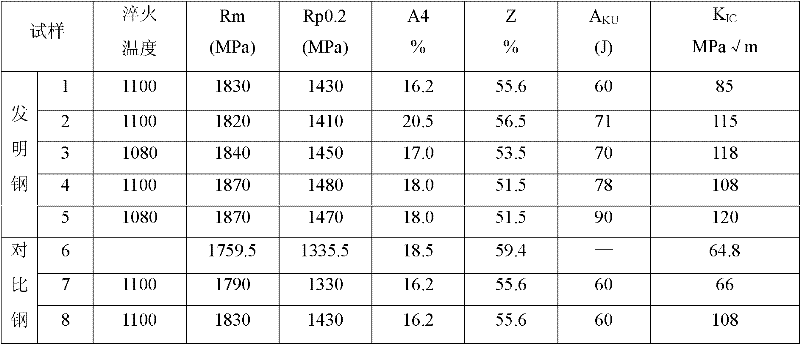

[0024] Vacuum induction furnace smelting and vacuum consumable remelting were used to smelt 5 furnaces of invention steel and 2 furnaces of comparison steel. Three consumable ingot types were used. The chemical composition is shown in Table 1. Table 2 is a comparison table of the mechanical properties of the invention steel and the comparison steel,

[0025] Table 1 Invention Steel and Comparative Steel Chemical Composition Scope (%)

[0026]

[0027]

[0028] It can be seen from Table 2 that compared with US Patent US5424028, the strength and fracture toughness index K IC Significantly improved, when the W content in the invented steel reaches 0.48% to 2.0%, the tensile strength Rm reaches 1820, K IC Both exceed 85MPa√m, and the highest reaches 120MPa√m. The W content in the inventive steel is kept within the range of 0.48% to 1.10%, K IC All over 100MPa√m, impact energy A KU Both exceed 70J, and the highest reaches 90J. Adding more than 1% W can improve the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com