Novel commercial vehicle lead-acid storage battery with long service life

A lead-acid battery, long-life technology, applied in the direction of lead-acid batteries, lead-acid battery construction, batteries, etc., can solve the problems of poor vibration resistance, low-temperature starting performance of batteries, short service life, etc., to improve low-temperature starting performance , Prevent the phenomenon of electricity deficiency, improve the effect of hydrogen evolution and oxygen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

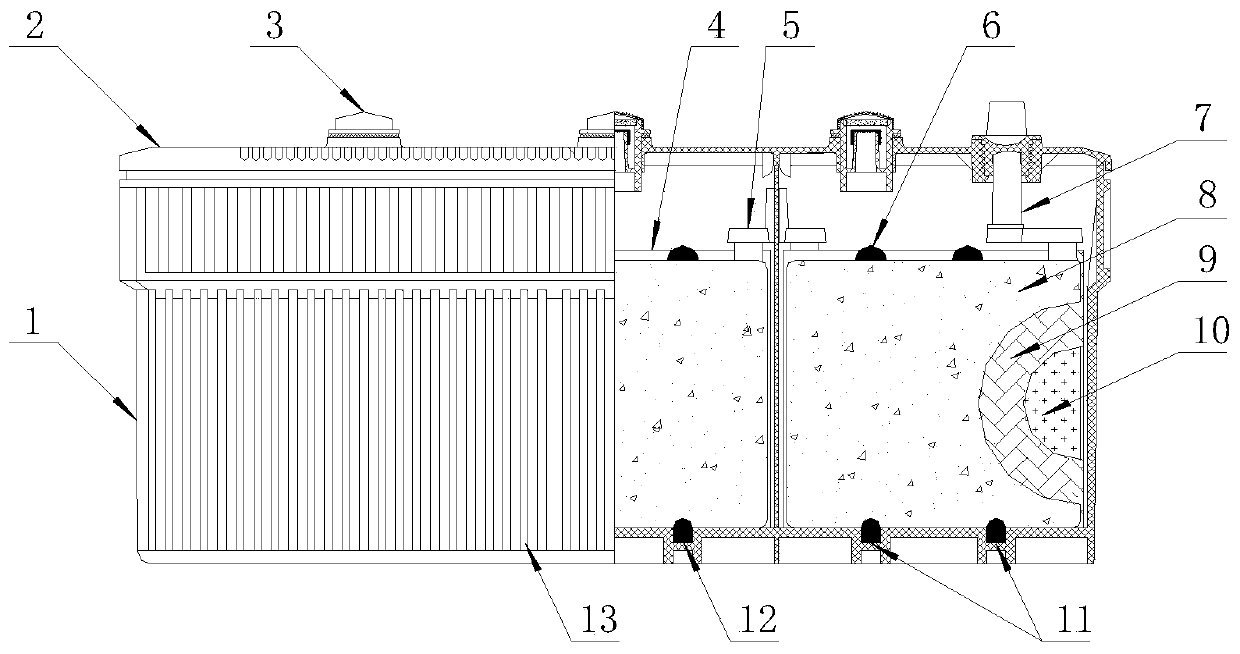

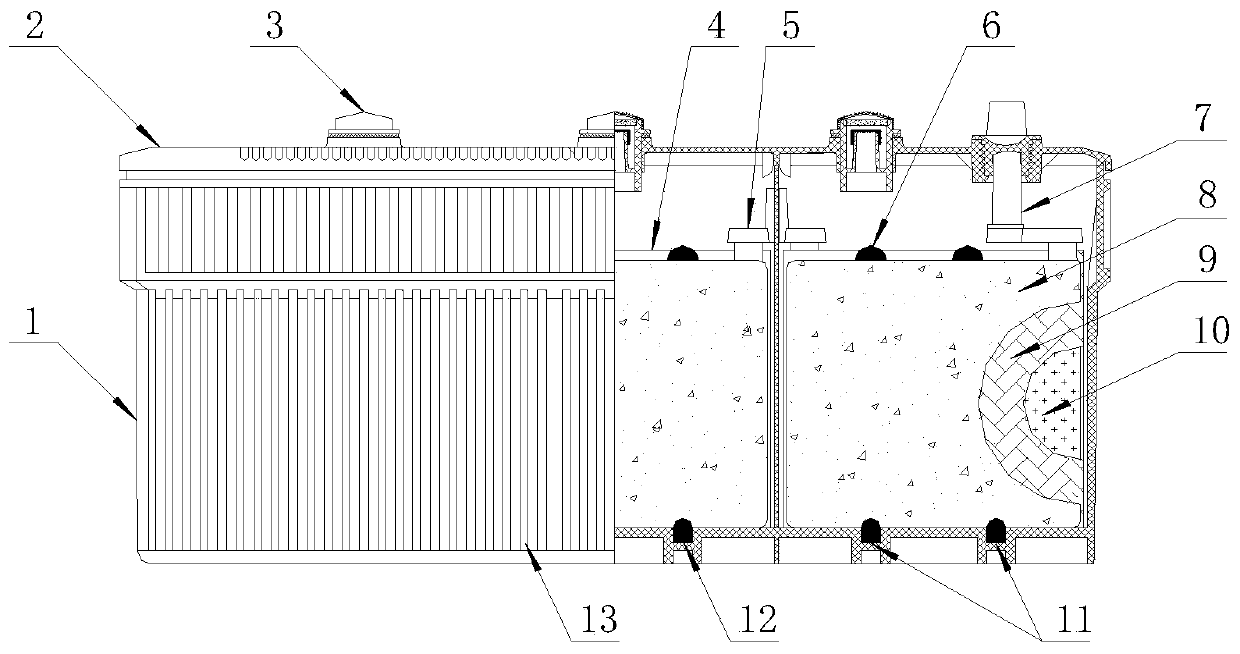

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] Such as figure 1 As shown, a new type of long-life commercial vehicle lead-acid battery, including battery tank 1, battery cover 2, safety valve 3, pole group 4 and electrolyte, battery tank 1 and battery cover 2 are injection molded by reinforced PP plastic, both Bonded together by heat sealing; each pole group 4 is connected in series by through-wall welding; the safety valve 3 is fixed on the liquid injection hole of the battery cover 2 by thread sealing; the wall thickness of the battery tank 1 and the battery cover 2 is 3.5mm, and the battery If the thickness of the longitudinal reinforcing rib 13 on the outer wall of the tank 1 is 3mm, the inside of the cavity formed by the battery tank 1 and the battery cover 2 can withstand a positive pressure of 65kPa; the bottom of each cavity of the battery tank 1 is provided with two glue retention grooves 11, When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com