Patents

Literature

156results about How to "Improve interface bonding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

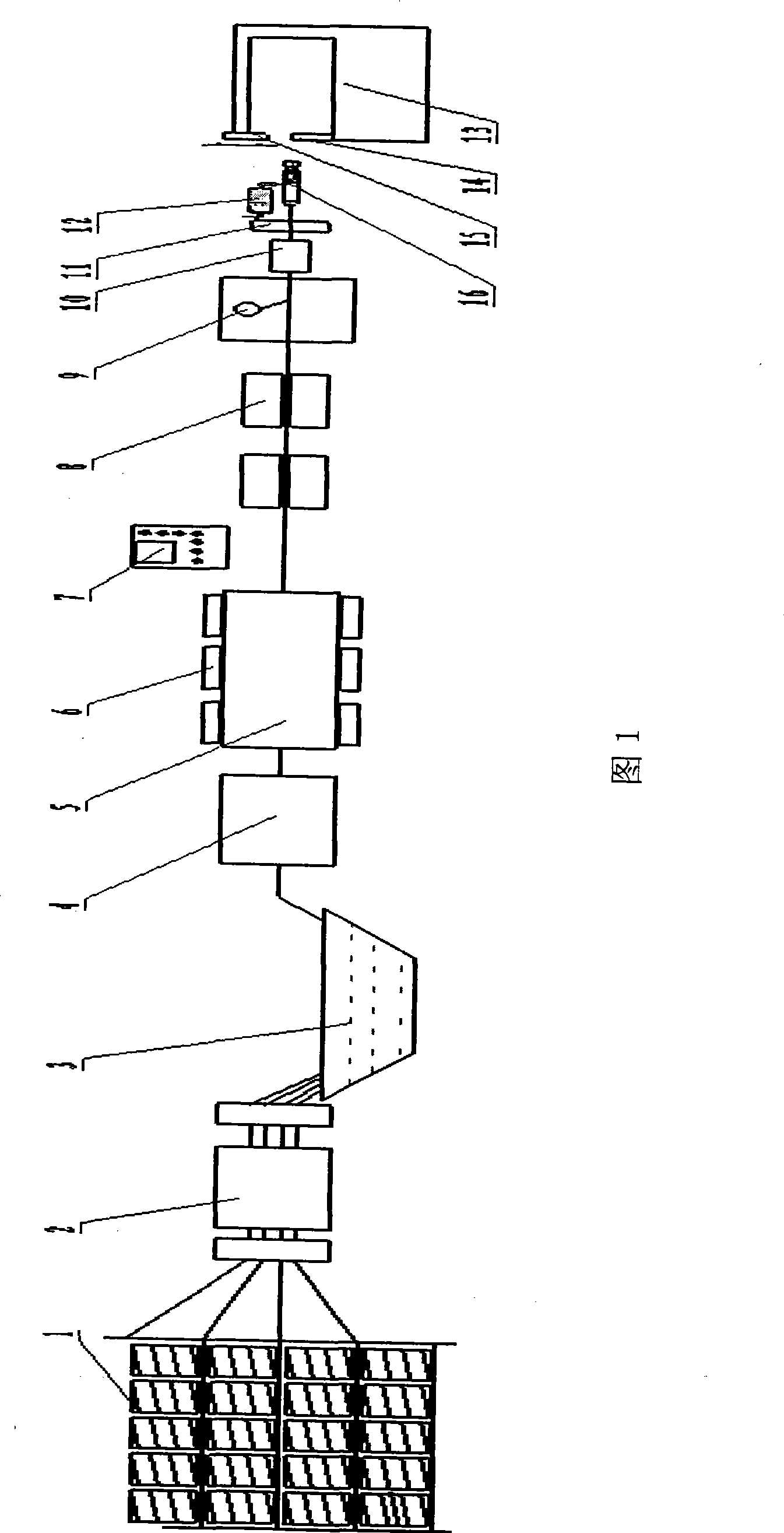

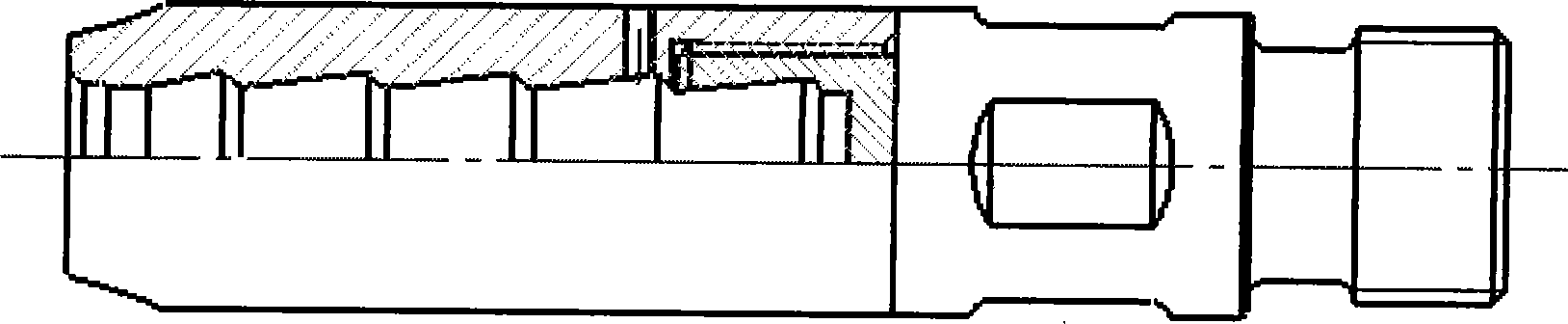

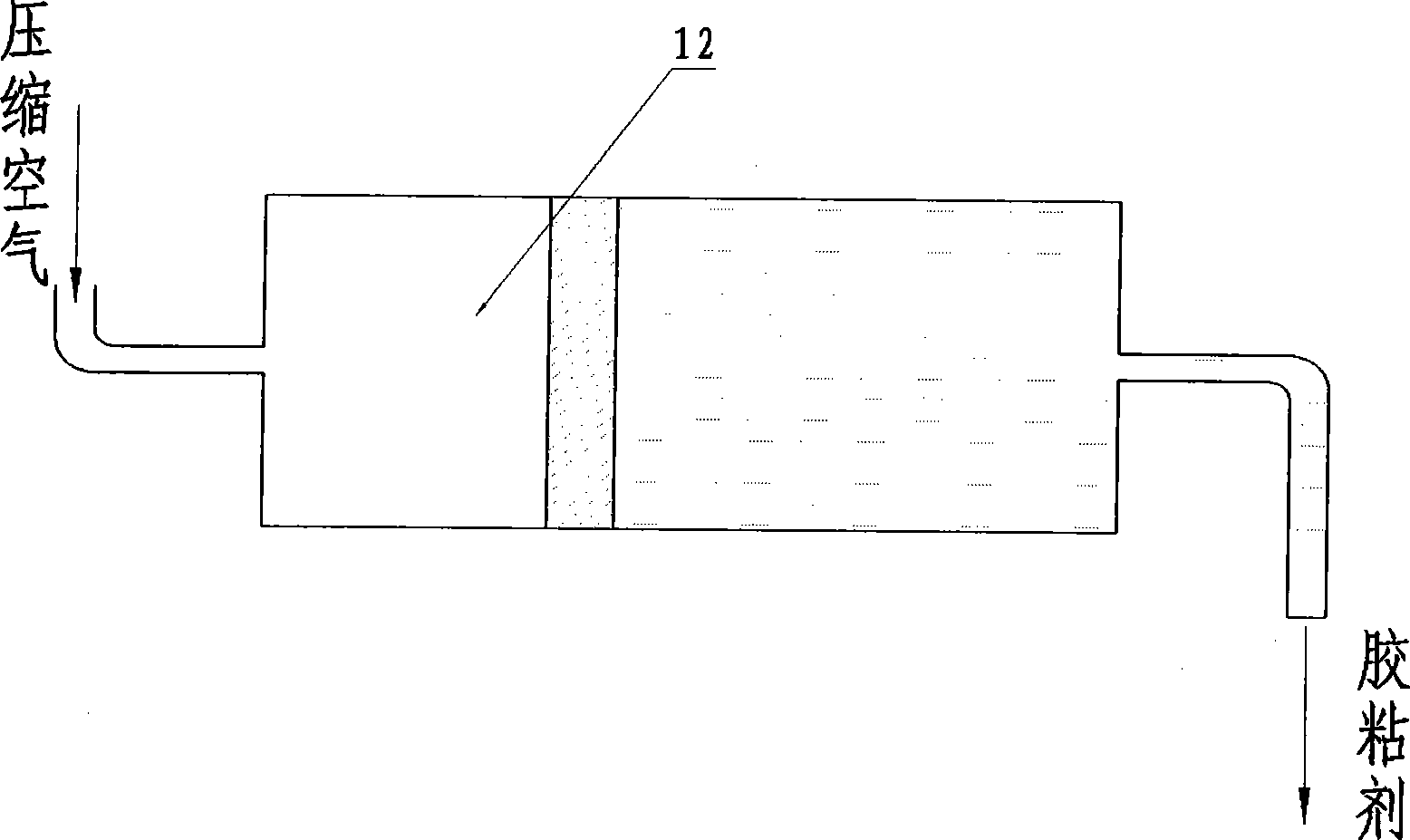

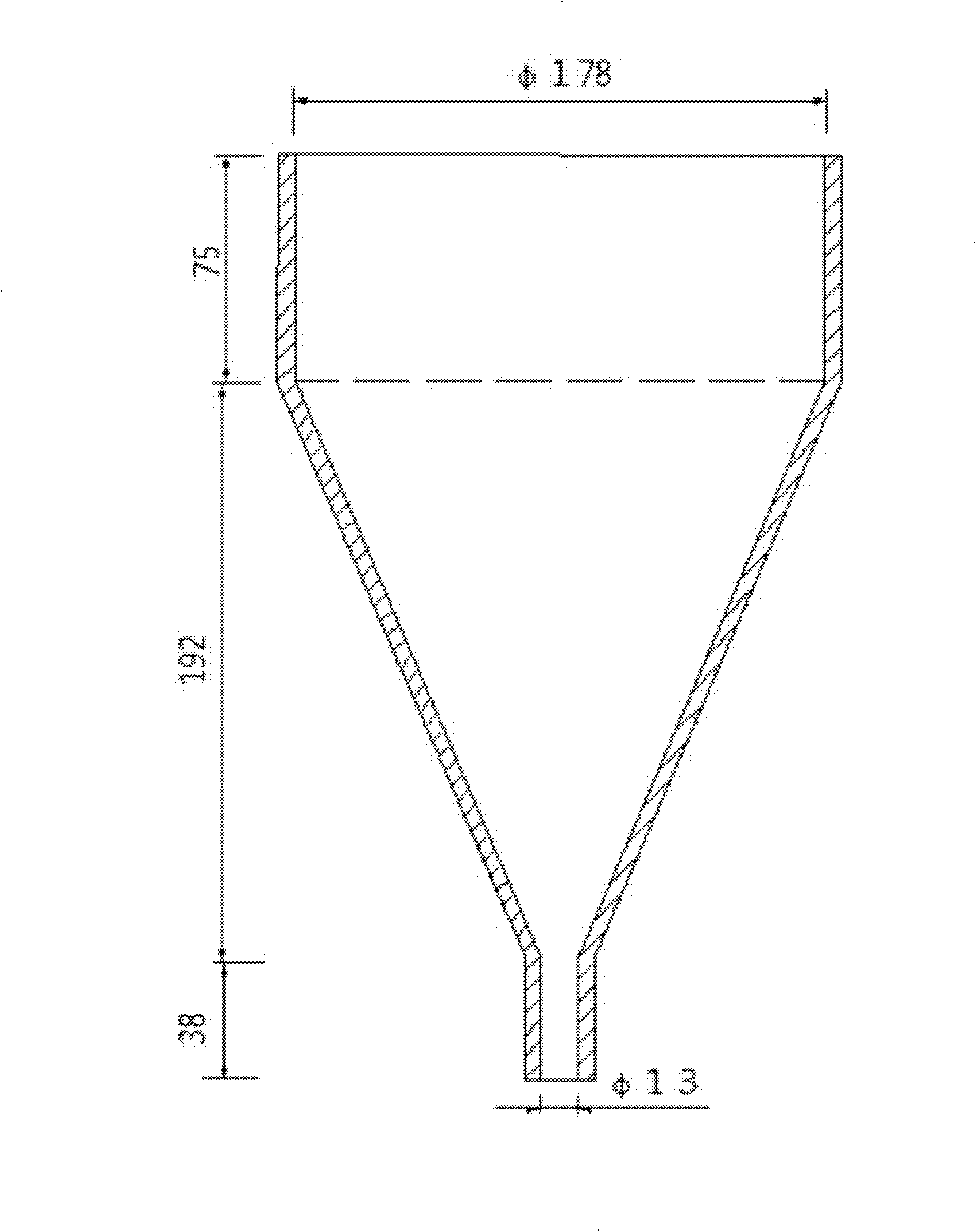

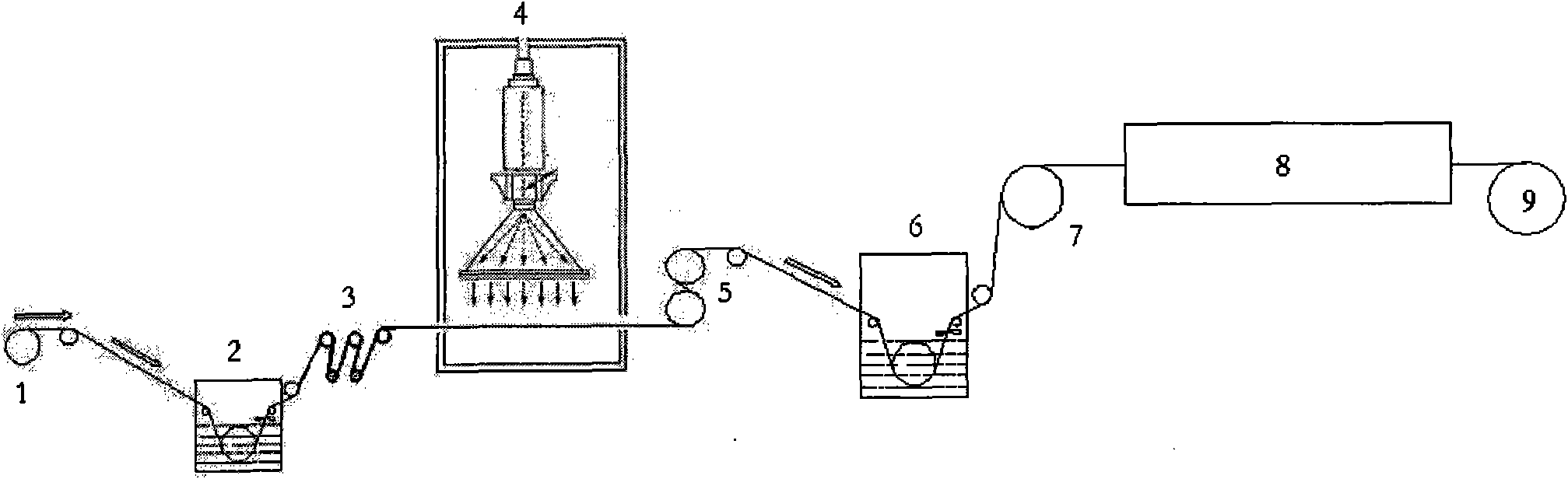

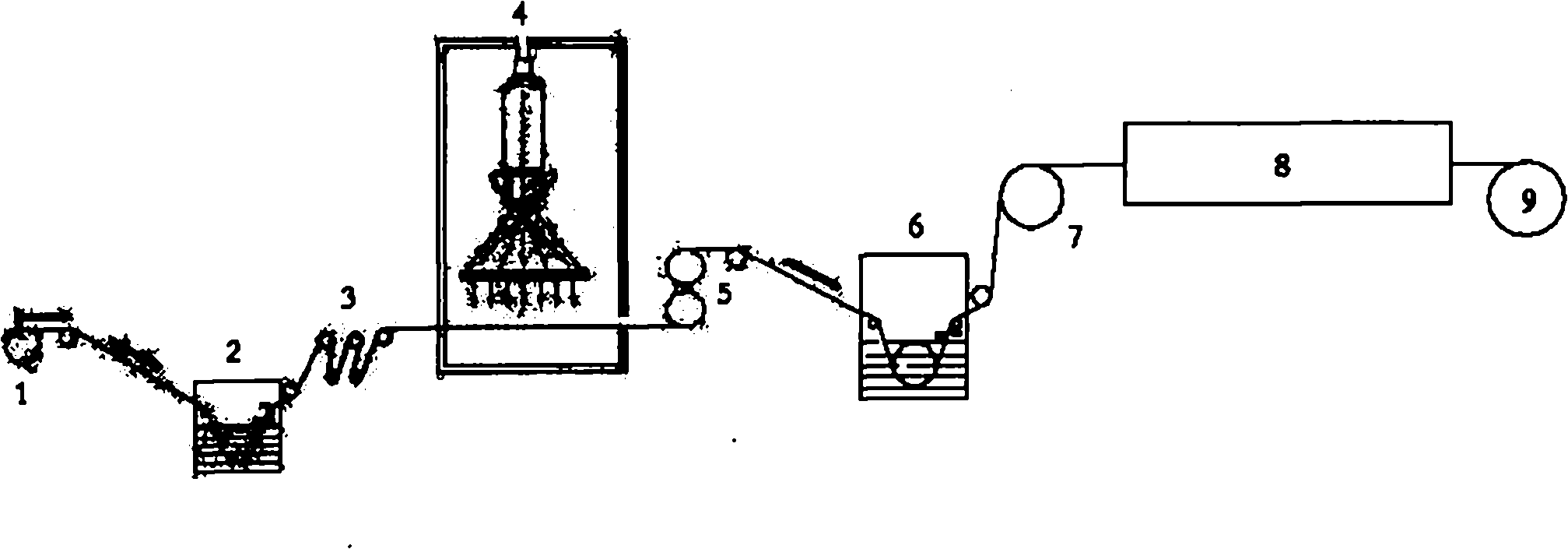

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

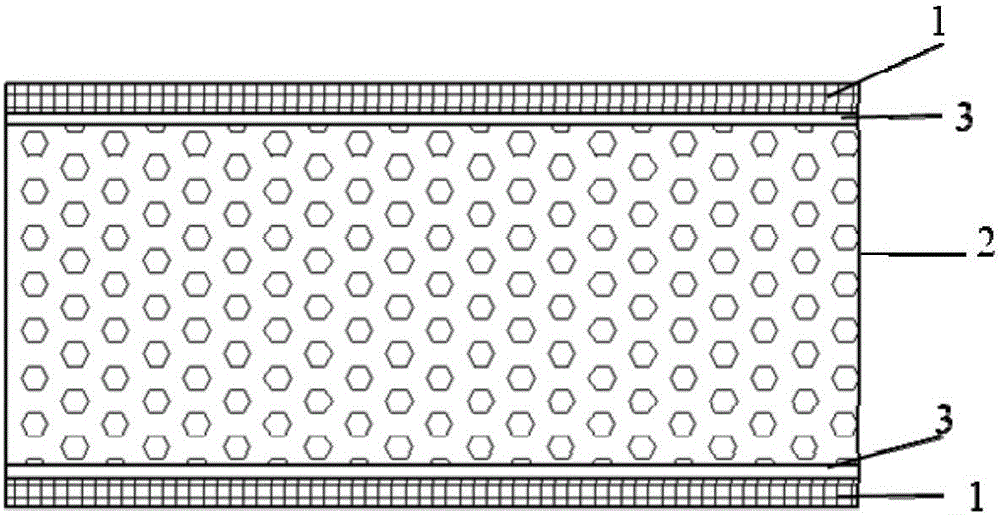

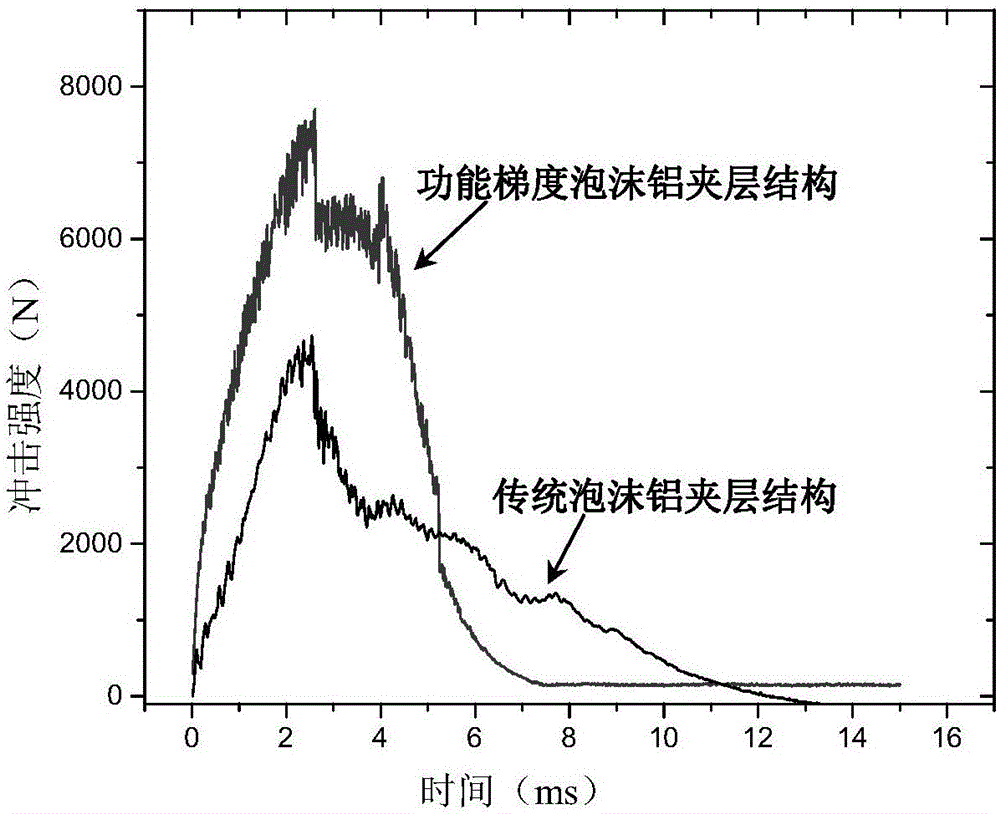

Foamed aluminum sandwich structure composite material and preparing method thereof

ActiveCN106273902AImprove the interface bonding strengthSmall difference in coefficient of thermal expansionSynthetic resin layered productsVehicle componentsFiberEpoxy

The invention provides a foamed aluminum sandwich structure composite material and a preparing method thereof. The foamed aluminum sandwich structure composite material comprises a foamed aluminum core material, a toughening interface layer and skin, wherein the toughening interface layer is located between the foamed aluminum core material and the skin, the toughening interface layer is made of an epoxy resin composite material, and the epoxy resin composite material is composed of an epoxy resin matrix, a toughening agent, a diluent, hollow microspheres, chopped fiber, a curing agent and an accelerant; pores in the surface of the foamed aluminum core material is filled with the epoxy resin composite material to form the toughening interface layer. According to the technical scheme, the toughening interface layer is formed between the composite material skin and the foamed aluminum core material by means of multi-component low-density epoxy filling adhesive, and interface bonding strength can be effectively improved; by means of the skin designed based on functional gradient, the interface bonding property of the foamed aluminum sandwich structure in a humid and hot environment is improved, and the impact resistance of the foamed aluminum sandwich structure is improved.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

Surface preservative treatment method for aviation aluminium alloy material

InactiveCN102586775AImprove corrosion resistanceImprove interface bonding performanceAnti-corrosive paintsMetallic material coating processesCvd grapheneChemical bond

The invention discloses a method for forming one layer of sol-gel coating with a compact reticular crosslinking structure on the surface of the aviation aluminium alloy substrate material. The coating and an atom on the surface of the aluminium alloy substrate material can be firmly combined by the action of a chemical bond, and the coating has good adhesive force on the substrate material. In the method, graphene is added in a coating ingredient to participate in the crosslinking structure, and therefore the anti-corrosion capability of the coating is enhanced. The coating prepared by the method has strong anti-corrosion capability and adhesive force on the surface of aviation aluminium alloy. In addition, the coating has good chemical stability and thermal stability and can resist the influence on the coating because of an external acid and alkaline environment and temperature variation. The method is simple, is convenient to operate, has low requirement on equipment, is environmentally friendly and is free from pollution.

Owner:SHANGHAI JIAO TONG UNIV +1

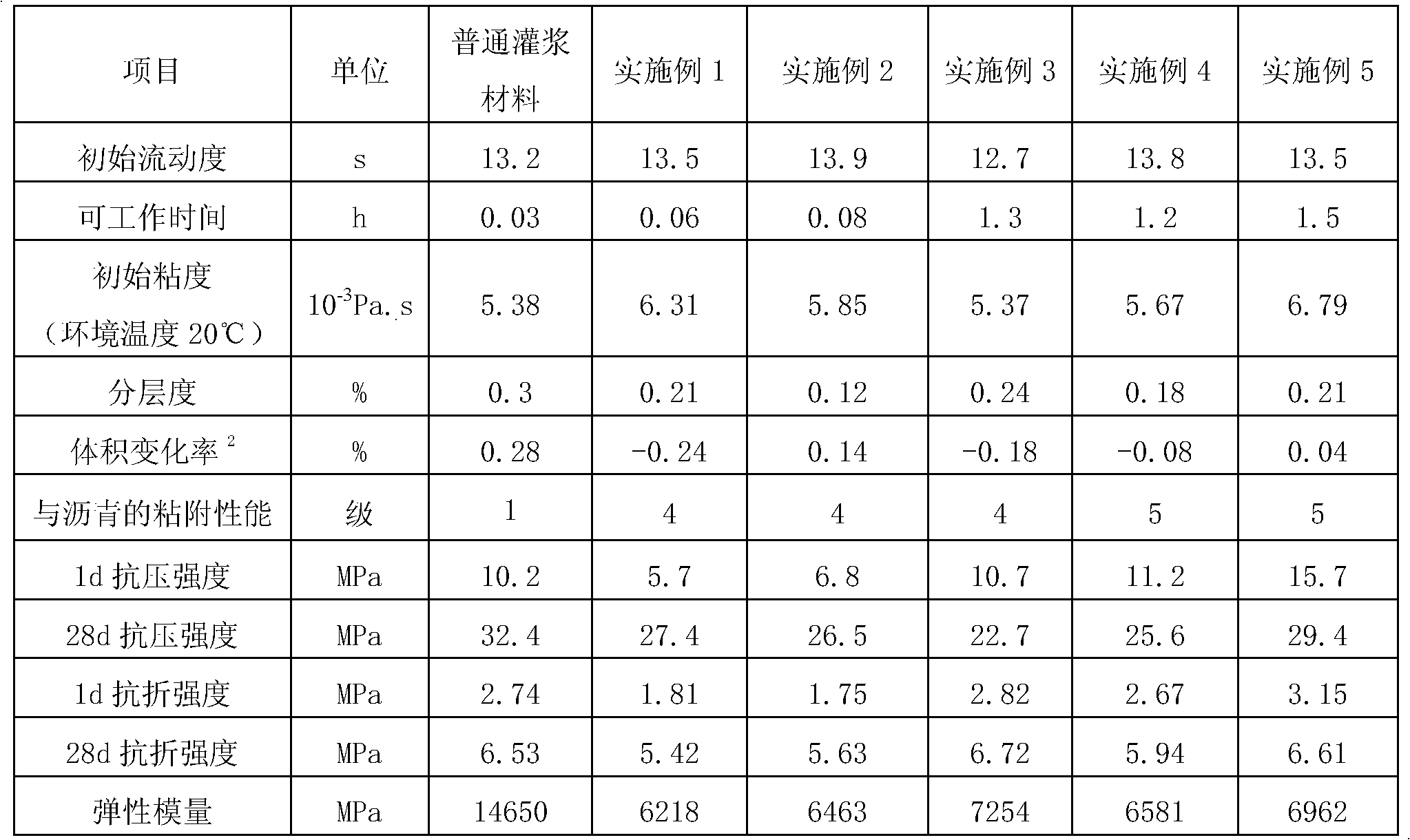

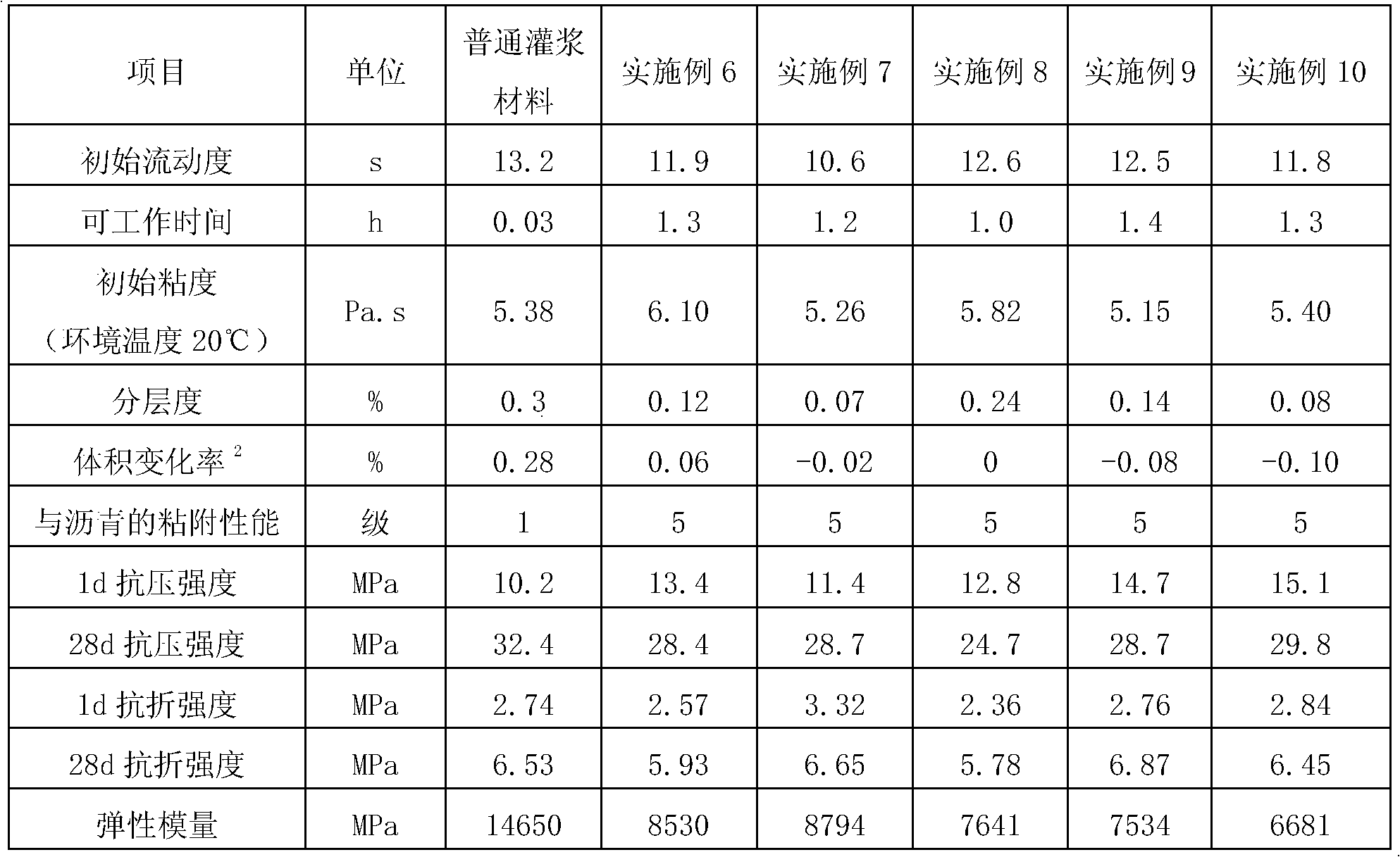

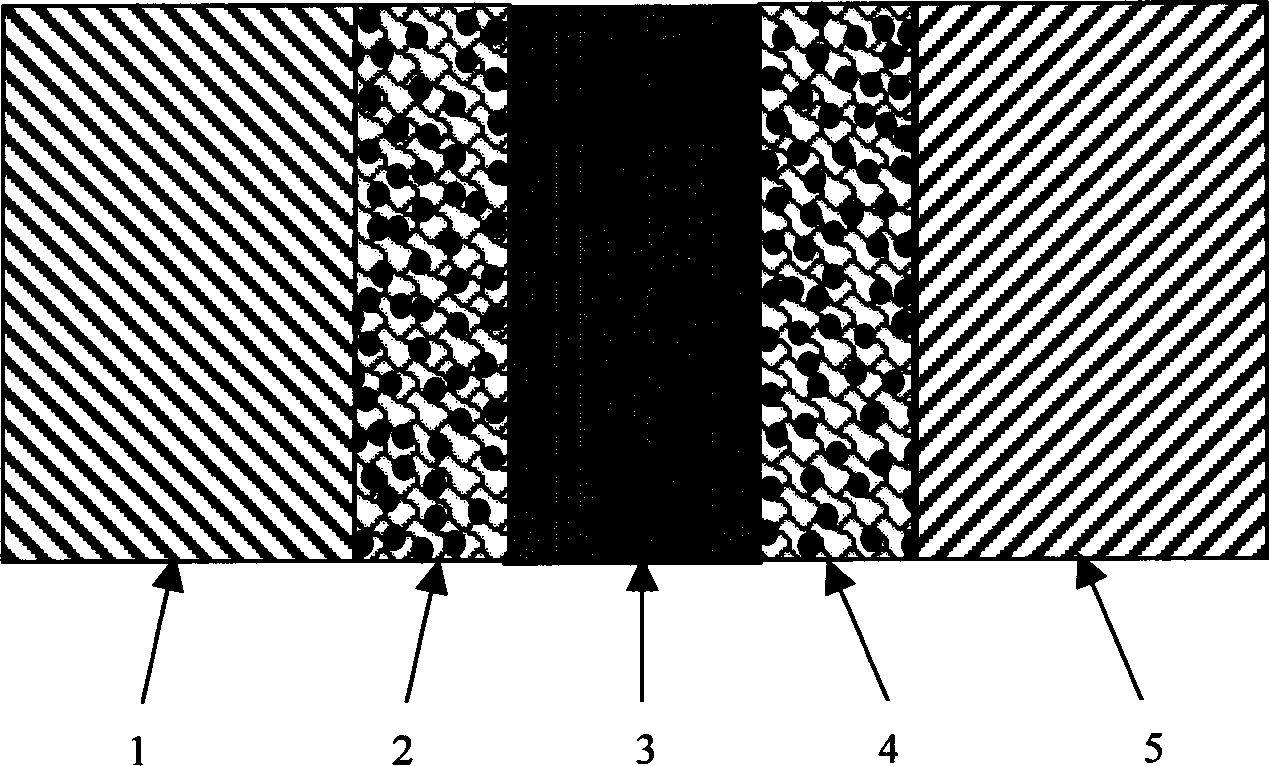

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

Membrane electrode for proton exchange membrane fuel cell and producing method thereof

InactiveCN1773755AImprove interface bonding performanceImprove stabilityCell electrodesFiberElectrical conductor

A film electrode used on proton exchange film fuel cell consists of five layers as middle layer of total F proton exchange film, two external layers of catalytic layers and two layers of diffusion layers outside of two external layers. Its preparing method includes embedding nanofibre proton conductor network in catalytic layer, preparing a layer of nanofibre proton conductor multiple film on total F proton exchange film surface by static spinning technique, coating ink containing catalyst in proton conductor fibre, drying and heat rolling to obtain film electrode containing nanofibre proton conductor network in catalytic layer.

Owner:SHANGHAI JIAO TONG UNIV

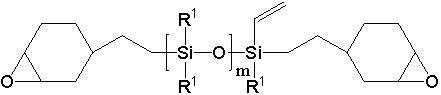

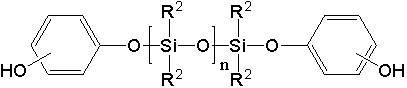

Rapid-curing conductive adhesive composition and method for preparing same

ActiveCN101851478ACompact structureImprove interface bonding performanceEpoxy resin adhesivesElectrically-conducting adhesivesMetal catalystSolvent

The invention relates to a rapid-curing conductive adhesive composition and a method for preparing the same. The composition comprises (A) a silicon-containing epoxy resin, (B) polysiloxane containing phenolic groups, (C) a latent curing accelerator, (D) a metal catalyst, (E) a reaction velocity regulator and (F) a filler, wherein the molecule of the silicon-containing epoxy resin at least comprises one ethylene and two 3,4-epoxy cyclohexyl groups; and the molecule of the polysiloxane at least comprises two oxyphenol groups. When used for electric conduction and / or heat conduction and adhesion of chips or devices in micro-electronics, electronics and optoelectronics industries, the adhesive composition has the advantages of reducing the corrosion of the base material and improving the adhesion and the conductivity, along with no solvent and rapid curing.

Owner:黄文迎 +1

Polypropylene composite capable of resisting thermal oxidizing aging

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

Carbon fiber bundle and method for producing same

ActiveCN102597360AImprove interface bonding performanceCarbon fibresCoatingsFiber bundlePolymer science

Disclosed is a carbon fiber bundle in which an amino group-containing modified polyolefin resin adheres to a carbon fiber bundle and the amount of the amino group-containing modified polyolefin resin adhering to the carbon fiber bundle is 0.2-5.0% by mass. The carbon fiber bundle is able to be produced by having 0.2-5.0% by mass of an amino group-containing modified polyolefin resin adhere to the surface of a carbon fiber bundle. The carbon fiber bundle exhibits excellent interfacial adhesion to polyolefin resins, especially to polypropylene resins, and is useful for the reinforcement of polyolefin resins. Also disclosed is a method for producing the carbon fiber bundle.

Owner:MITSUBISHI CHEM CORP

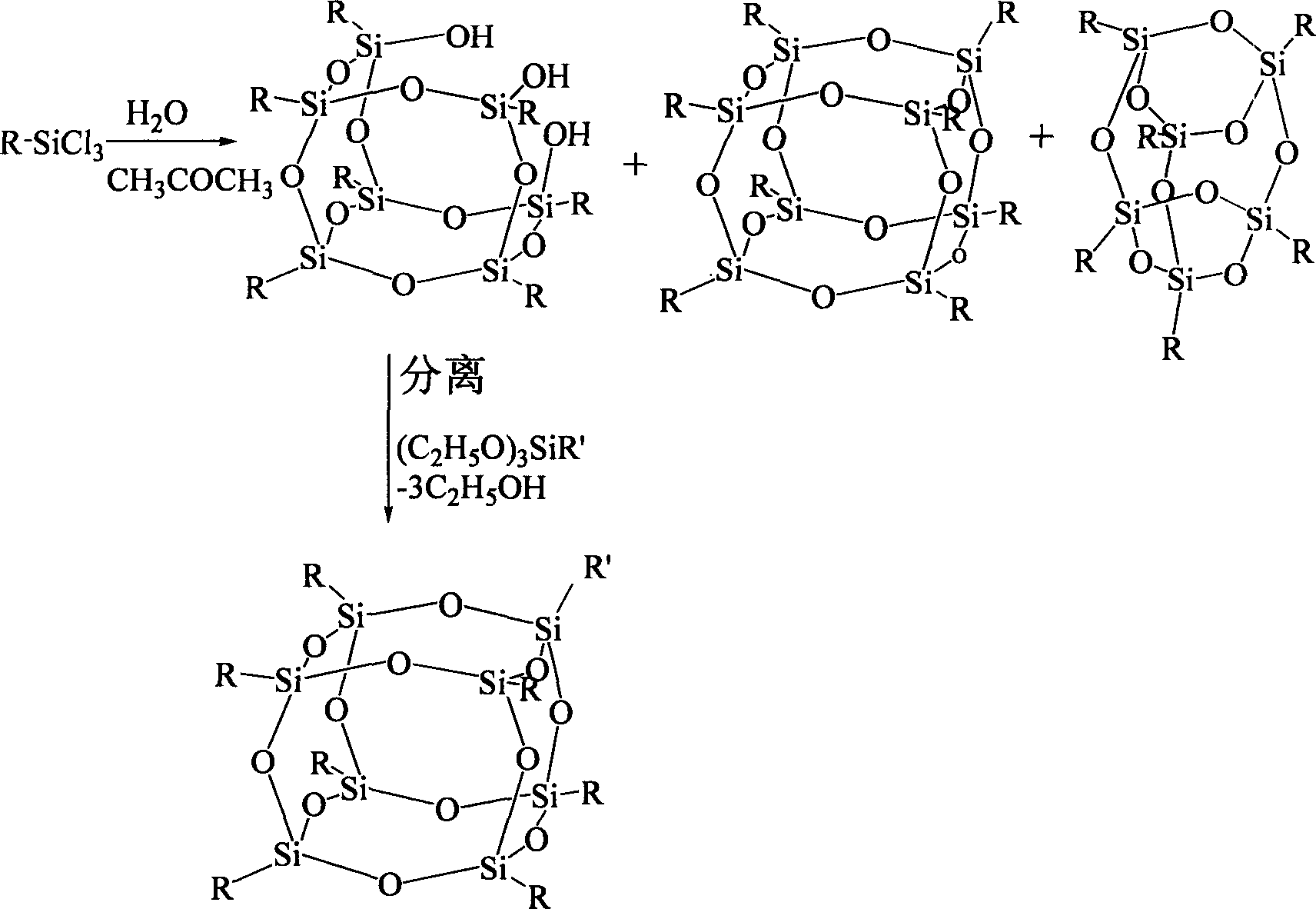

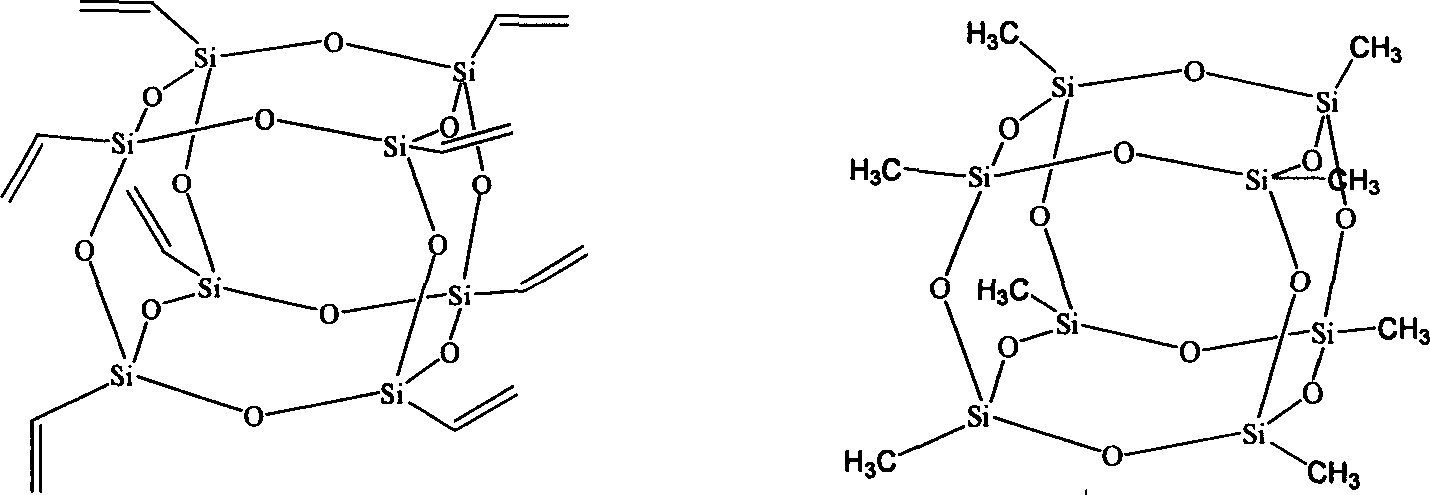

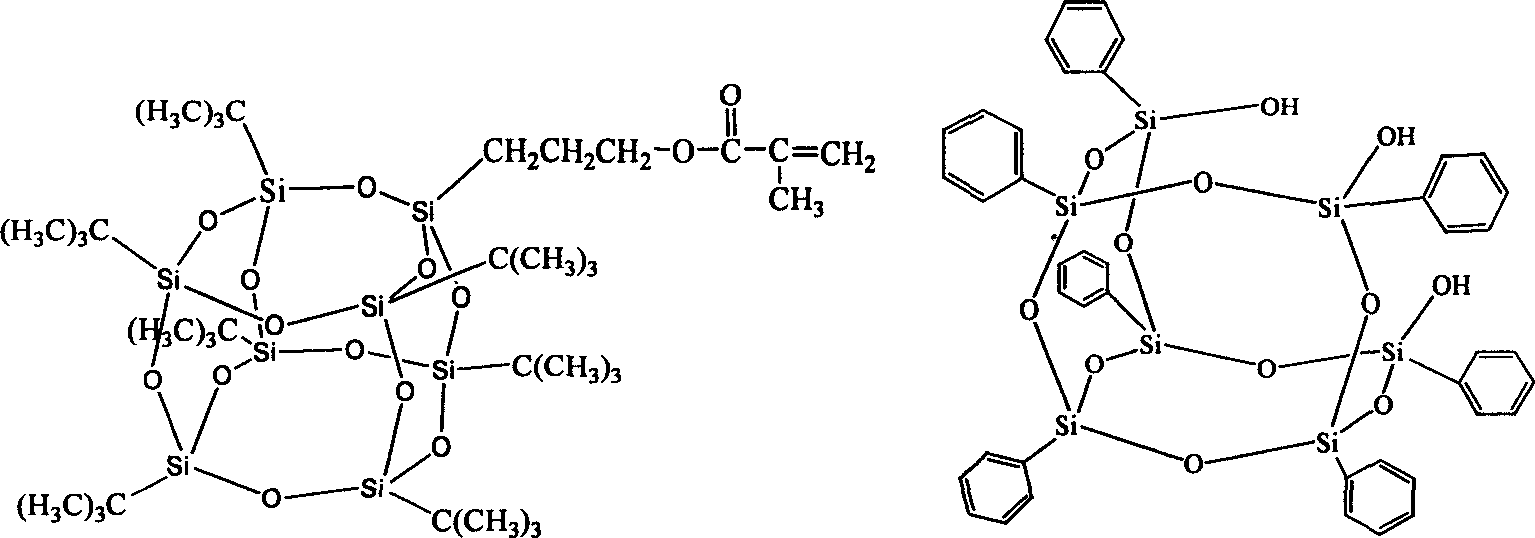

Carbon fiber modifying coating and its preparation method

ActiveCN1730744AImprove interface bonding performanceImprove heat resistanceArtificial filament chemical after-treatmentCarbon fibersSurface roughness

The carbon fiber modified coating and its preparation process belongs to the field of composite material interface modification technology, and aims at making the interface between carbon fiber and polymer in the composite material maintain unchanged and the composite material reaching predicted use performance. The carbon fiber modified coating is cage sesquisiloxane coating prepared through eliminating original coating in the surface of carbon fiber, soaking in cage sesquisiloxane solution to form cage sesquisiloxane coating on the surface of fiber, and stoving. The present invention introduces single functional group matching the resin structure to the surface of carbon fiber. By means of modifying the surface of carbon fiber with POSS coating of different functional groups, the present invention has raised resin wettability, increased surface roughness and greatly raised interface adhering performance of composite material while maintaining carbon fiber strength unchanged.

Owner:HARBIN INST OF TECH

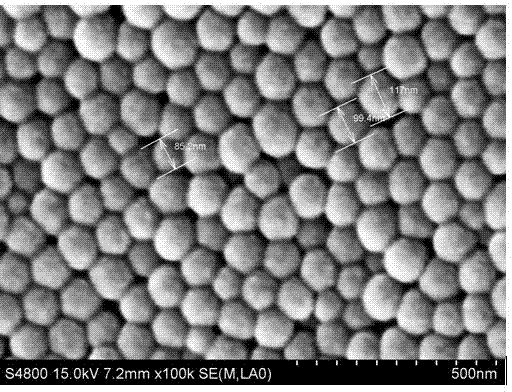

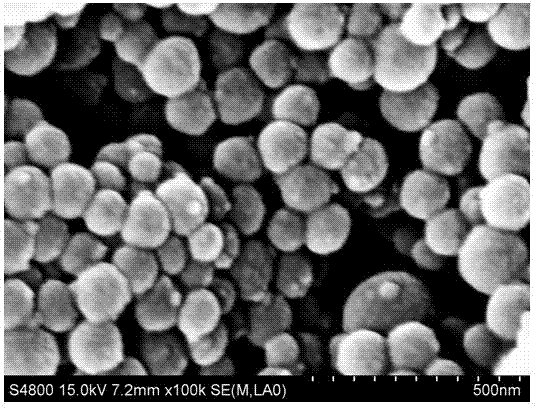

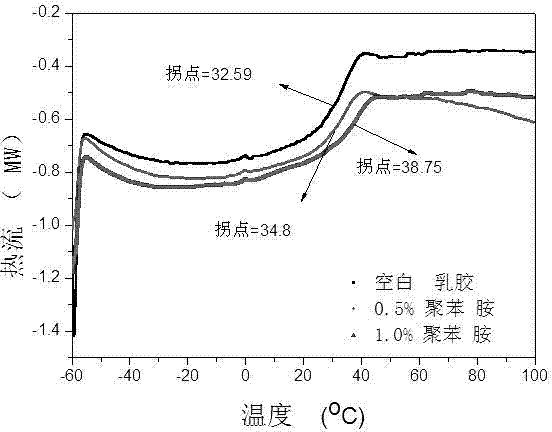

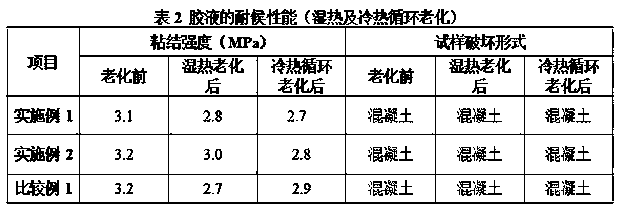

Preparation method of bonding polyaniline on surfaces of styrene-acrylate copolymer emulsion particles

The invention discloses a preparation method of bonding polyaniline on surfaces of styrene-acrylate copolymer emulsion particles, relating to the field of preparation of styrene-acrylate emulsion which is chemically modified on the surface of conductive polyaniline. The styrene-acrylate emulsion containing a phosphoric acid functional group is firstly prepared by adopting a miniemulsion polymerization method, and then a suspension and dispersion solution which bonds the polyaniline on the surfaces of the styrene-acrylate copolymer emulsion particles is prepared by aniline in-situ oxidation polymerization. The functional emulsion obtained by the method disclosed by the invention has the following advantages: the polyaniline is dispersed in the styrene-acrylate copolymer emulsion in a molecular size; and excellent interface bonding force exists between the polyaniline and a matrix of a styrene-acrylate copolymer due to electrostatic interaction.

Owner:YANGZHOU UNIV

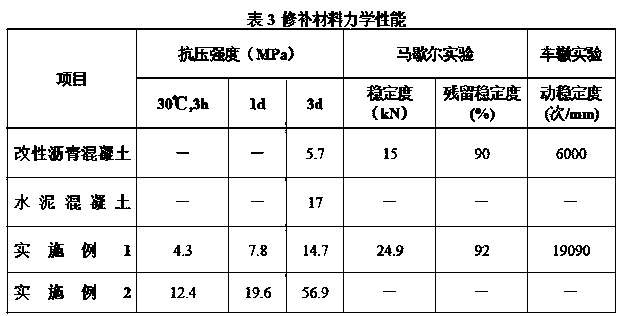

Weather-proof and quick-drying pavement damage repairing material and preparation method thereof

ActiveCN103964747AImprove aging resistanceEnhance the destructive effectWeather resistanceHindered amine light stabilizers

The invention discloses a weather-proof and quick-drying pavement damage repairing material which comprises the following raw materials in parts by mass: 100 parts of epoxy resin, 5-20 parts of a reactive diluent, 10-40 parts of a filler, 40-90 parts of a curing agent, 0.5-1.5 part of a hindered amine light stabilizer and aggregate, wherein the ratio of the mass of the aggregate to the total mass of components in a group A and the total mass of the components in a group B is 2 to 1-10 to 1. The invention further discloses a preparation method of the repairing material. The repairing material is solidified at a normal temperature, is good in weather resistance, quick in solidification, prominent in interface adhering performance, wide in application scope, simple and convenient to construct and operate, and long in service life.

Owner:广东建科交通工程质量检测中心有限公司

High-dehydration curing plugging agent and preparation method thereof

The invention provides a high-dehydration curing plugging agent. The high-dehydration curing plugging agent is characterized by comprising the following components in parts by weight: 25-70 parts of fly ash or coke ash or lime fly ash or coal cinder, 40-75 parts of gypsum, 10-25 parts of sodium soil or pottery clay or calcium soil, 10 parts of paper fiber or leather fiber, 3-6 parts of sodium silicate or magnesium silicate or aluminum silicate or silicon oxide, 5-15 parts of calcium chloride or lime or calcium carbonate and 1.6-6 parts of sodium hydroxide. The plugging agent is a novel plugging material, water is added into the plugging agent and stirred by virtue of a stirrer to obtain a mixture, the mixture is pumped into the leakage formation, the plugging agent is rapidly dehydrated to form a cured product and thus the leakage formation is plugged and the difficult problem that the compressive strength after the leakage formation is plugged by the general plugging agent is not high is solved.

Owner:JIANGXI PINGXIANG ANHUA BIOTECH

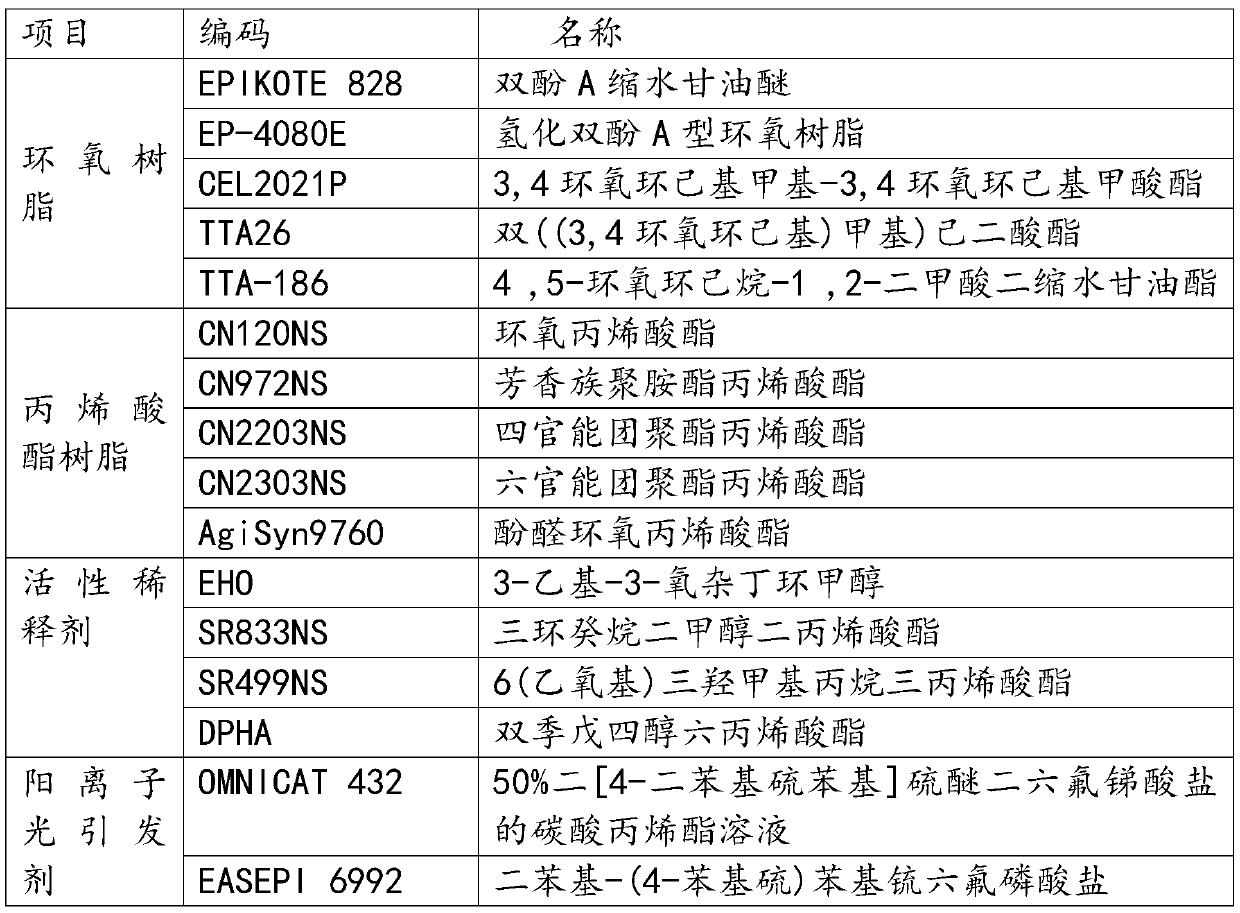

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

Wholly-aromatic polymer fiber with high compound property and preparing method thereof

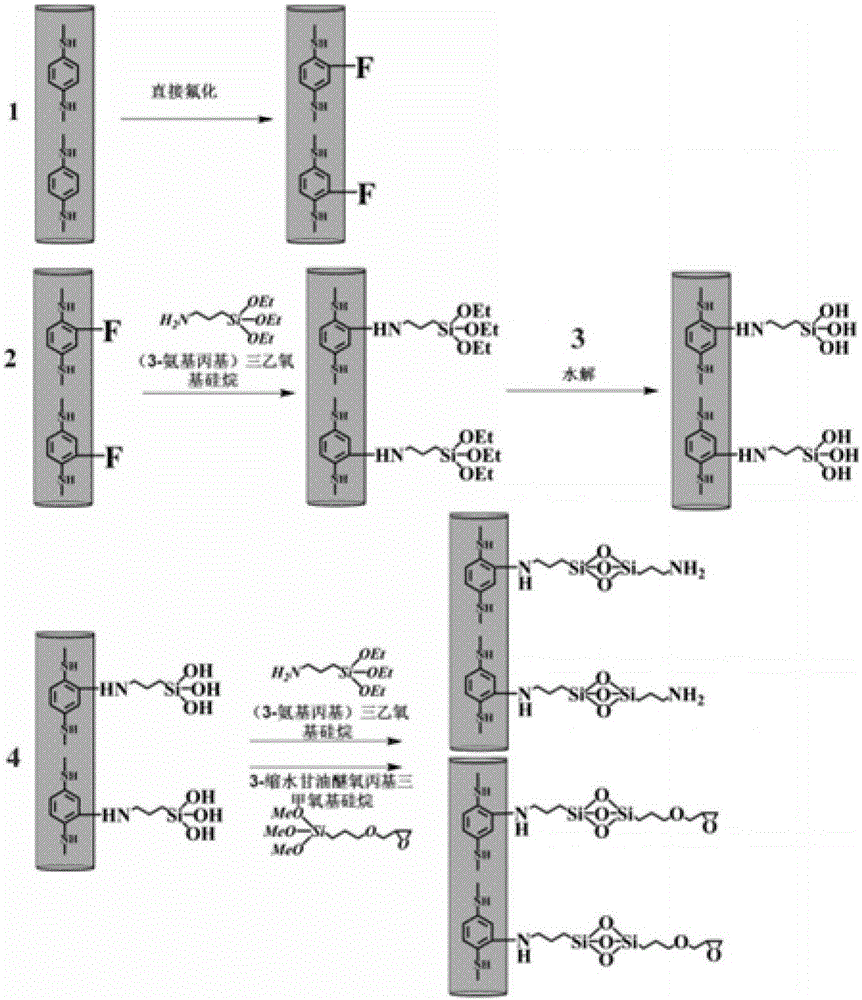

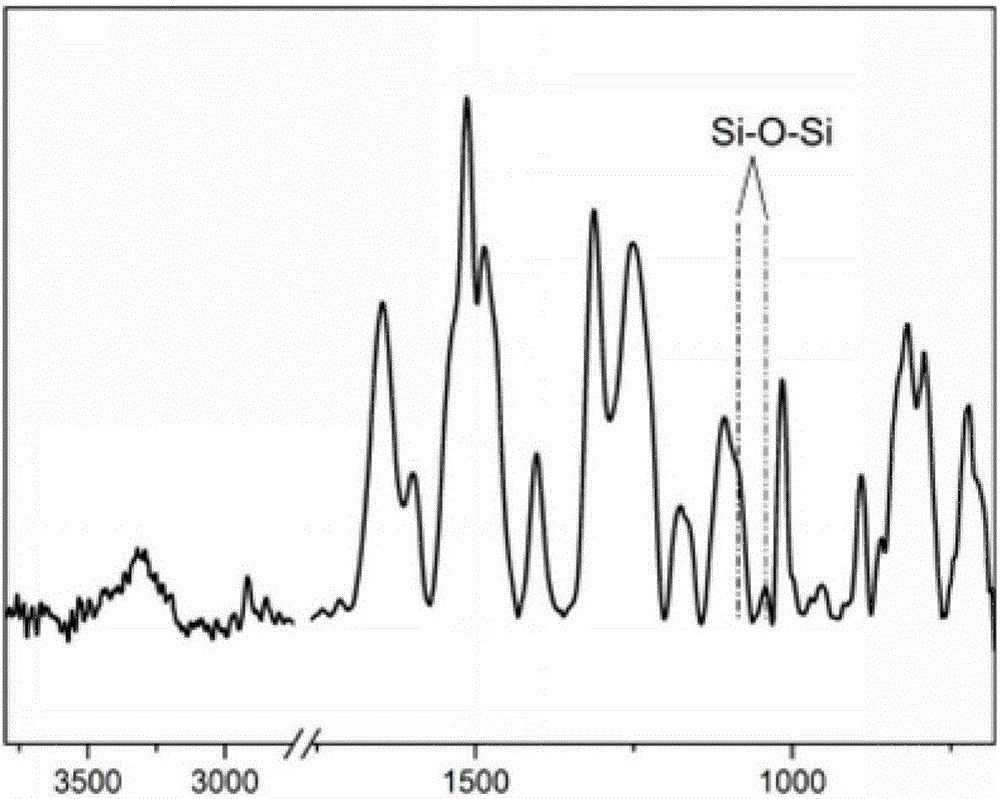

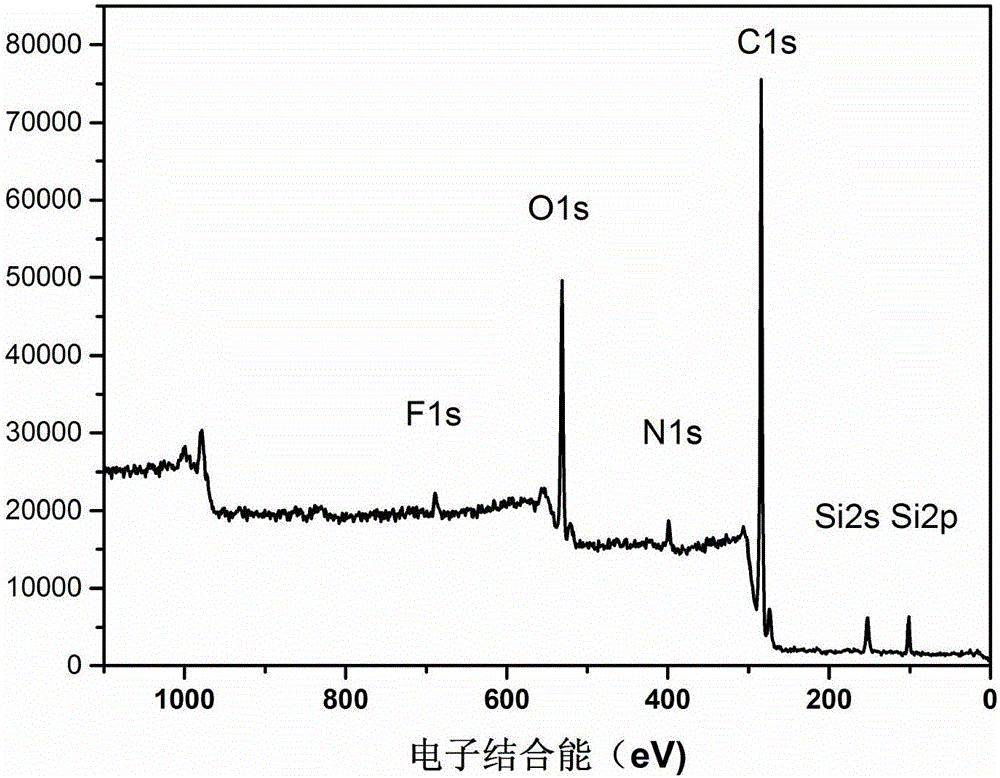

The invention discloses wholly-aromatic polymer fiber with high compound property. Wholly-aromatic polymer fiber obtained through direct fluorinated surface treatment is treated with a silane coupling agent containing amino group firstly, then hydrolysis is conducted with acid aqueous solution, and then treatment is conducted with a silane coupling agent containing amino group, epoxy group or allyl group to obtain the wholly-aromatic polymer fiber with high compound property. The surface of the fiber contains the active groups capable of reacting with matrix resin. It is found through infrared display that a Si-O-Si peak exists at the position of 1000-1100 cm<-1>, and a Si element energy spectrum peak exists at the position of 103.6 eV binding energy of an X-ray photoelectron spectroscopy diagram. Through chemical bonding of the massive active groups including amino group, epoxy group and allyl group on the surface of the fiber, the fiber can be connected with matrix resin or a curing agent system of the matrix resin through a powerful covalent bond, the bonding capacity between the fiber and the matrix resin is improved greatly, and low fluorination degree and high compound property are realized.

Owner:SICHUAN UNIV

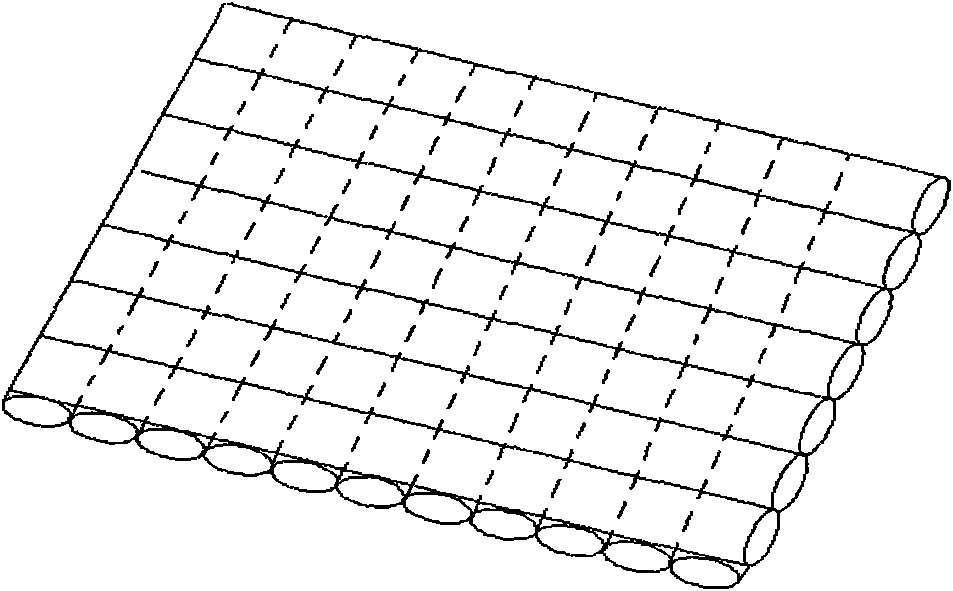

Method for producing composite non-woven cloth material from irradiated ultrahigh molecular weight polyethylene fiber

InactiveCN102400284AImprove interface bonding performanceReduce dosageFibre typesNon-woven fabricsTectorial membraneFiber

The invention relates to a method for producing a composite non-woven fabric material from irradiated ultrahigh molecular weight polyethylene (UHMWP) fiber. The method comprises the following steps of: (1) spreading a plurality of strands of ultrahigh molecular weight polyethylene fiber in parallel by using a guide roller after passing through a buncher, and impregnating the fiber in a grafting liquid; (2) irradiating the fiber impregnated in the grafting liquid to realize grafting, and sending the fiber into a glue dipping groove; (3) processing glue on double surfaces of adhesive-containing filament bundles by using parallel scrappers, and drying the filament bundles to obtain a one-way non-woven fabric; (4) producing composite non-woven fabric sheets or coils to obtain a composite non-woven fabric material. Compared with the prior art, the method has the advantages that an electron beam irradiation grafting technology is introduced into a UD cloth production method in the invention, so that the UHMWP fiber can be grafted and modified through mutual irradiation, and interfacial adhesive performances of the fiber and the adhesive can be improved; and therefore, the consumption of the adhesive is reduced during the production of the one-way non-woven fabric, application of a protective film is eliminated, and finally surface density of the composite non-woven fabric material is reduced.

Owner:SURREY HI TECH INC +1

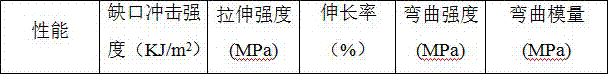

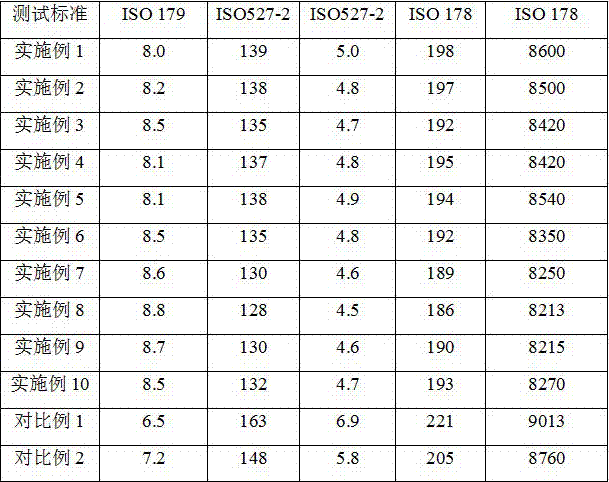

LCP/PBT/PET ternary alloy material and preparation method thereof

InactiveCN107383807AStrong impact resistanceHigh tensile strengthPolytetramethylene terephthalatePolybutylene

The invention relates to the technical field of a high-molecular material, and more specifically relates to a LCP / PBT / PET ternary alloy material and a preparation method thereof. The LCP / PBT / PET ternary alloy material comprises the following raw materials in parts by weight: 10-40 parts of a liquid crystal polymer, 10-40 parts of polybutylene telephthalate, 10-40 parts of polyethylene glycol terephthalate, 5-40 parts of glass fiber, 3-15 parts of a compatilizer, 3-15 parts of a fire retardant, 0.1-0.5 parts of an anti-oxidant, 0.2-2 parts of a lubricant and 1-2 parts of a modifier. The ternary alloy material has the excellent mechanical properties of toughness, impact strength, tensile strength and bending strength, and has the advantages of good fireproof performance, good heat resistance, low water absorption, good size stability, high crystallization efficiency, good moulding performance, good processing performance, low cost, and high usage value.

Owner:广东壹豪新材料科技股份有限公司

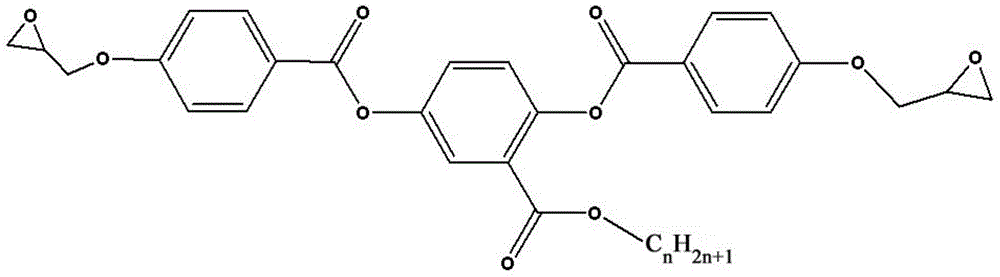

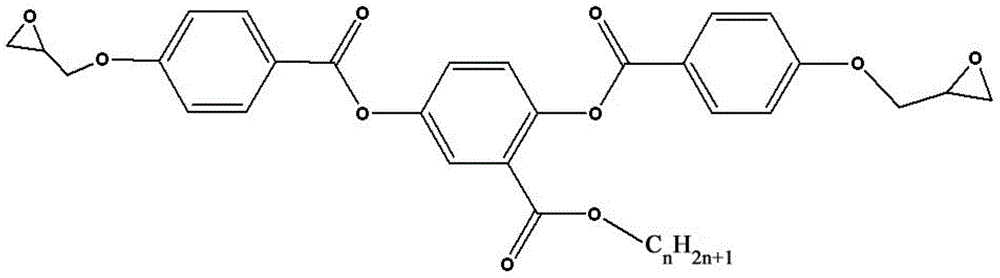

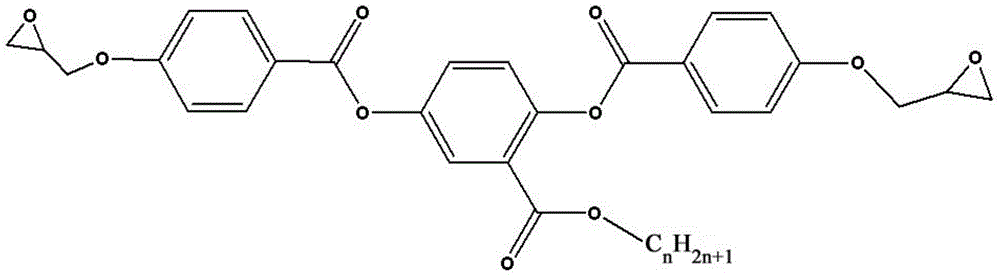

Liquid crystal epoxy resin - carbon fiber composite material and preparation method thereof

The invention belongs to the preparation field of shape memory polymers, specifically discloses a liquid crystal epoxy resin-carbon fiber composite material with shape memory properties and a preparation method thereof. The preparation method of the liquid crystal epoxy resin-carbon fiber composite material comprises three steps: (1) carbon fiber surface treatment; (2) composite material mixture preparation; and (3) curing for forming. According to the preparation method, carbon fiber is used for modifying of liquid crystal epoxy resin with branched chains, the cost can be reduced, and the thermodynamic properties of the material can be improved; and the liquid crystal epoxy resin-carbon fiber composite material prepared by the preparation method has the shape memory property, is high in response rate, is high in recovery stress, and can be applied to the technical field of biomedicine, aerospace and other sciences.

Owner:SICHUAN HUASON ELECTRONICS TECH

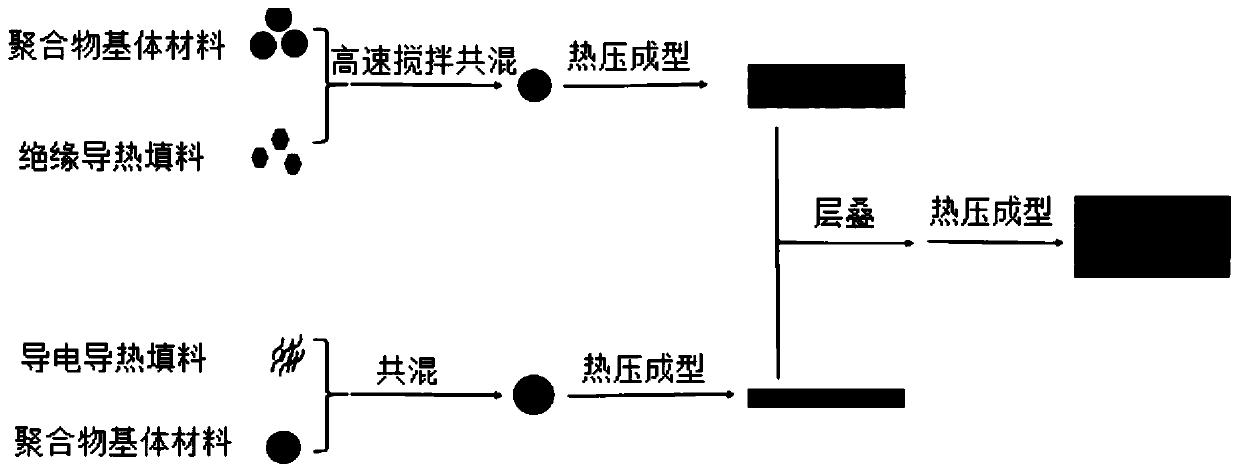

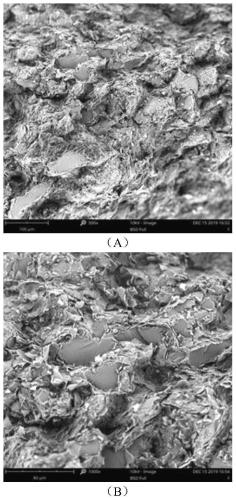

Insulating heat-conducting polymer composite material with frequency selective electromagnetic shielding and preparation method thereof

ActiveCN111391440AImprove thermal conductivityImprove shielding effectSynthetic resin layered productsLaminationElectromagnetic shieldingPolymer composite materials

The invention provides an insulating heat-conducting polymer composite material with frequency selective electromagnetic shielding, the material comprises an insulating heat-conducting layer and two conductive heat-conducting layers, and the two conductive heat-conducting layers are respectively located at two sides of the insulating heat-conducting layer to form an integrated sandwich structure;the insulating heat-conducting layer comprises a polymer matrix and an insulating heat-conducting filler, the insulating heat-conducting filler is selectively distributed at the interface of polymer particles to form an insulating heat-conducting network, each conductive heat-conducting layer comprises a polymer matrix and conductive heat-conducting filler, the conductive heat-conducting filler isdistributed in the polymer matrix to form a conductive heat-conducting network, and the polymer matrix of the insulating heat-conducting layer and the polymer matrix of the conductive heat-conductinglayers have the same composition; the material has frequency selective electromagnetic shielding performance and is insulated in the electromagnetic shielding direction. The frequency selective electromagnetic shielding function is given to an existing heat conduction electromagnetic shielding material, and the new requirements for selective electromagnetic shielding, heat conduction, insulationand the like of the heat conduction electromagnetic shielding material at present can be better met.

Owner:SICHUAN UNIV

Environment-friendly atmospheric pressure wood assembly adhesive

InactiveCN105219307AGood adhesionHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementEngineering

The invention relates to an environment-friendly atmospheric pressure wood assembly adhesive which comprises a component A and a component B, wherein the component B is a cross-linking agent; the component A is prepared from the following raw materials in parts by weight: 3-5 parts of polyvinyl alcohol, 20-40 parts of a polyvinyl acetate emulsion, 20-40 parts of a vinyl acetate-ethylene copolymerization emulsion, 0.3-0.5 part of a pH buffer agent, 0.1-0.3 part of nano particles, 0.05-0.2 part of a dispersing agent, 0.1-0.3 part of an antifoaming agent, 0.1-0.5 part of a preservative, 0.1-0.5 part of a wetting agent, 0.1-0.5 part of a flatting agent and 20-30 parts of water. The used polymer and auxiliary ingredients belong to chemicals which are low in toxicity, friendly to environment and beneficial to clean production; the environment-friendly atmospheric pressure wood assembly adhesive does not contain harmful components such as formaldehyde, and is an environment-friendly adhesive.

Owner:JIANGSU QIYANLI PAINT CO LTD

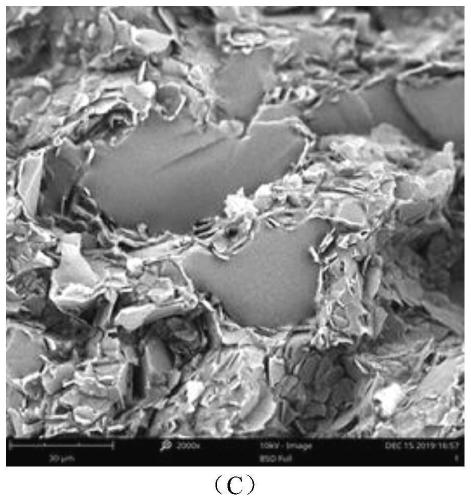

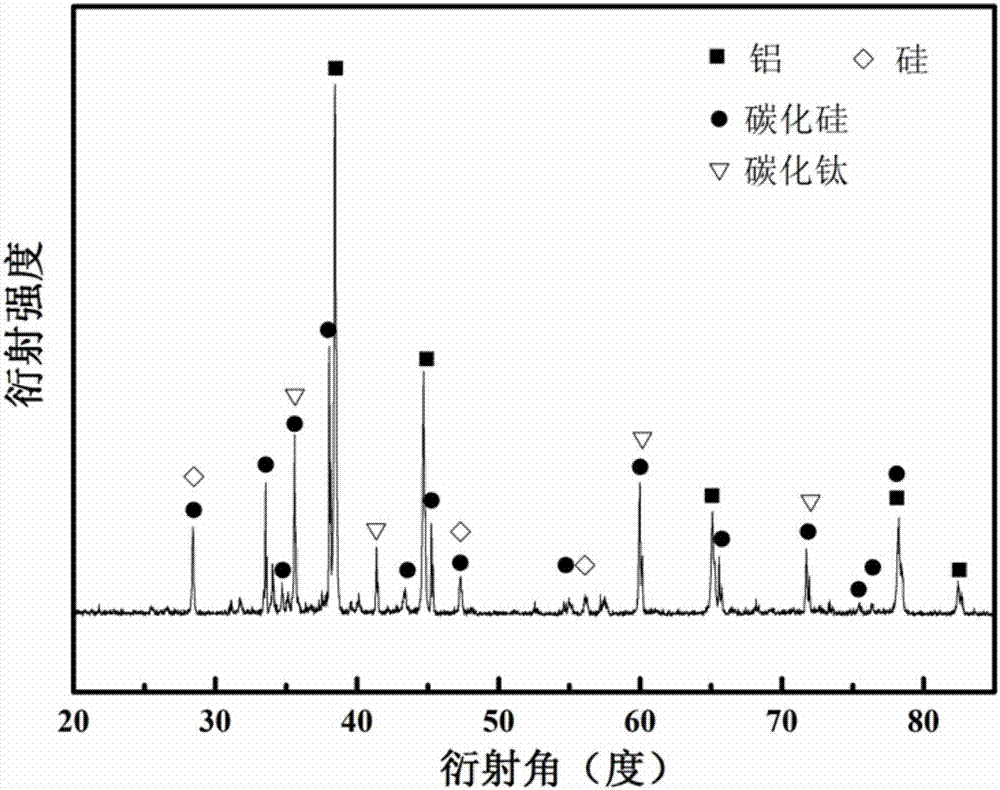

Preparation method for high-volume-fraction SiC reinforced Al-base composite material

ActiveCN106917009AGood wettabilityImprove interface bonding performanceInterfacial reactionPowder metallurgy

The invention discloses a preparation method for a high-volume-fraction SiC reinforced Al-base composite material. The preparation method comprises the steps of SiC powder oxidation treatment, TiO2 sol preparation, SiC powder surface coating, high-temperature calcination under a reducing atmosphere, mixing, forming, Ar atmosphere protection sintering and cooling. The preparation process is simple, the interface bonding between SiC particles and molten metal Al is effectively improved, an adverse interfacial reaction is avoided, the defect that the density is not high as a powder metallurgy method is adopted traditionally is overcome, and the finally prepared SiC particle reinforced Al-base composite material is excellent in performance, for example, the flexure strength ranges from 181.7 Mpa to 203.5 Mpa, the density ratio ranges from 91.0 % to 95.3 %, and the volume fraction is 56.5 %.

Owner:WUHAN UNIV OF TECH

Preparation method of magnesium alloy surface hydroxyapatite composite coating

InactiveCN109183127AImprove adsorption capacityInduced growthAnodisationPharmaceutical delivery mechanismMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method of a magnesium alloy surface hydroxyapatite composite coating. The preparation method comprises the steps that the magnesium alloy surface is subjected togrinding, polishing and micro-arc oxidation treatment in sequence, soaked in polydopamine-modified hydroxyapatite dispersion liquid, subjected to heat preservation at 100-120 DEG C for 0.5-1h and taken out, the surface is cleaned with distilled water, dried and soaked in the polydopamine-modified hydroxyapatite dispersion liquid again, the operation is repeated for 3-5 times, and the hydroxyapatite composite coating is formed on the magnesium alloy surface. Since micro-arc oxidation treatment is carried out on the magnesium alloy surface with no oxidation layer, the hydroxyapatite composite coating with the good interface binding performance is formed on the outer surface of the polydopamine-modified hydroxyapatite, and the corrosion resistance and tissue compatibility of magnesium alloy are improved.

Owner:长沙瑞联材料科技有限公司

High-toughness bismaleimide resin material and preparation method thereof

ActiveCN106585047ASolve the problem of obvious viscosity increaseImprove other mechanical propertiesSynthetic resin layered productsLaminationHeat resistanceMechanical property

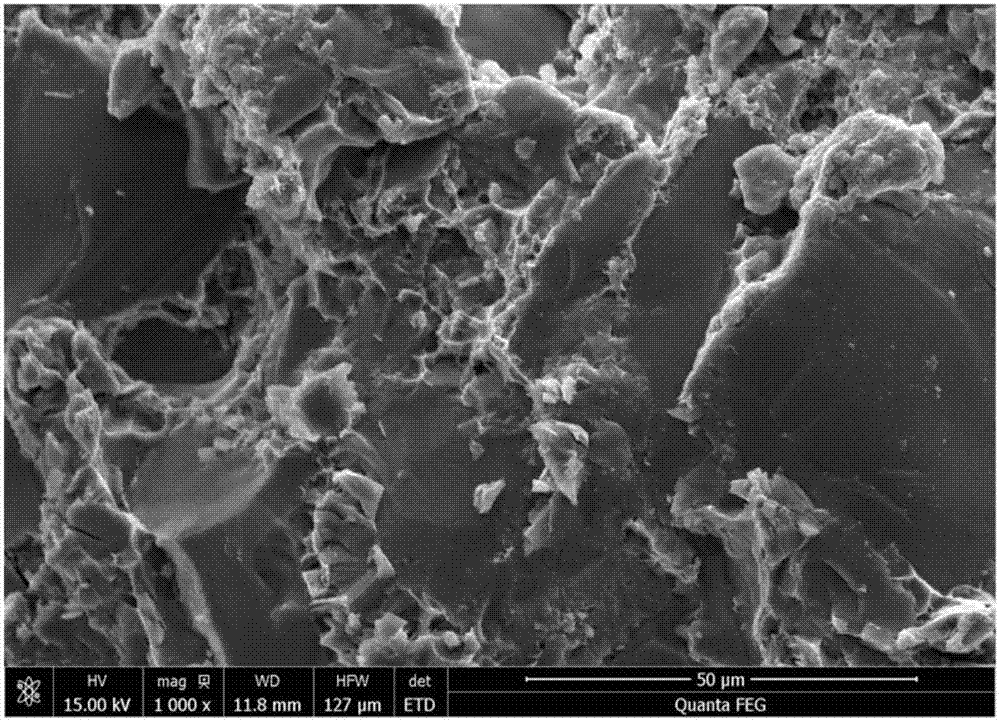

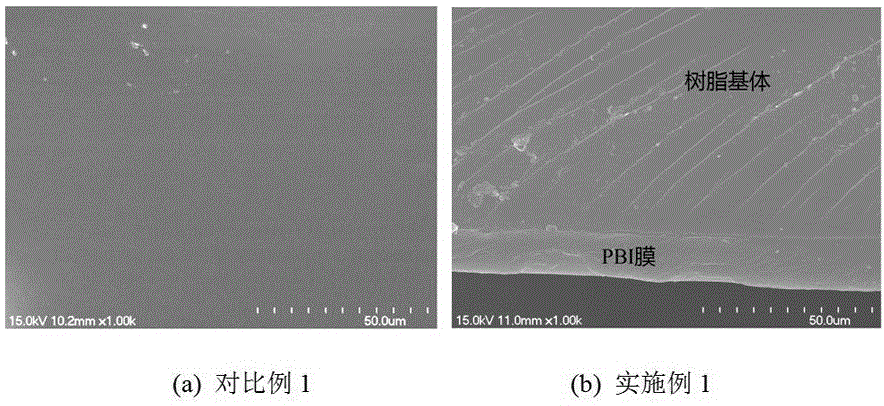

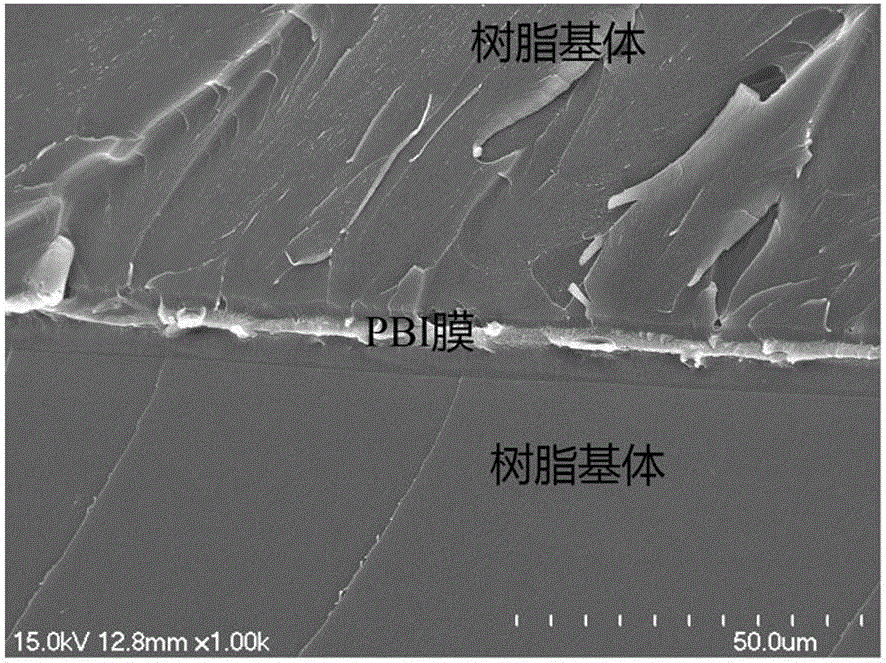

The invention relates to a high-toughness bismaleimide resin system and a preparation method thereof. With bismaleimide, an allyl compound and thermoplastic polybenzimidazole (PBI) as raw materials, a PBI film is prepared, and the PBI film and a bismaleimide / allyl compound resin system prepolymer thin plate are laid in an intersection manner, and the bismaleimide / allyl compound resin system material containing the PBI film is obtained through heat curing treatment. The prepared material can obtain outstanding impact resistance after a small amount of PBI film is inserted, and has the heat resistance and other mechanical properties all higher than or not lower than those of the bismaleimide / allyl compound resin system inserted without the PBI film; the material system has obvious application value in the fields of aviation, aerospace and other high-performance composite materials.

Owner:SUZHOU UNIV

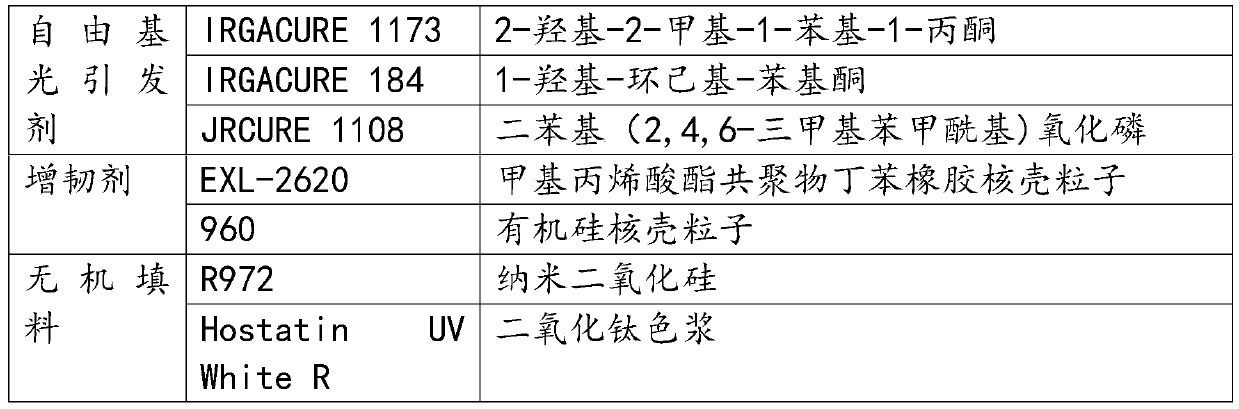

Dual-curing adhesive and preparation method thereof

InactiveCN111892891AAvoid mutual destructionStable network structureNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

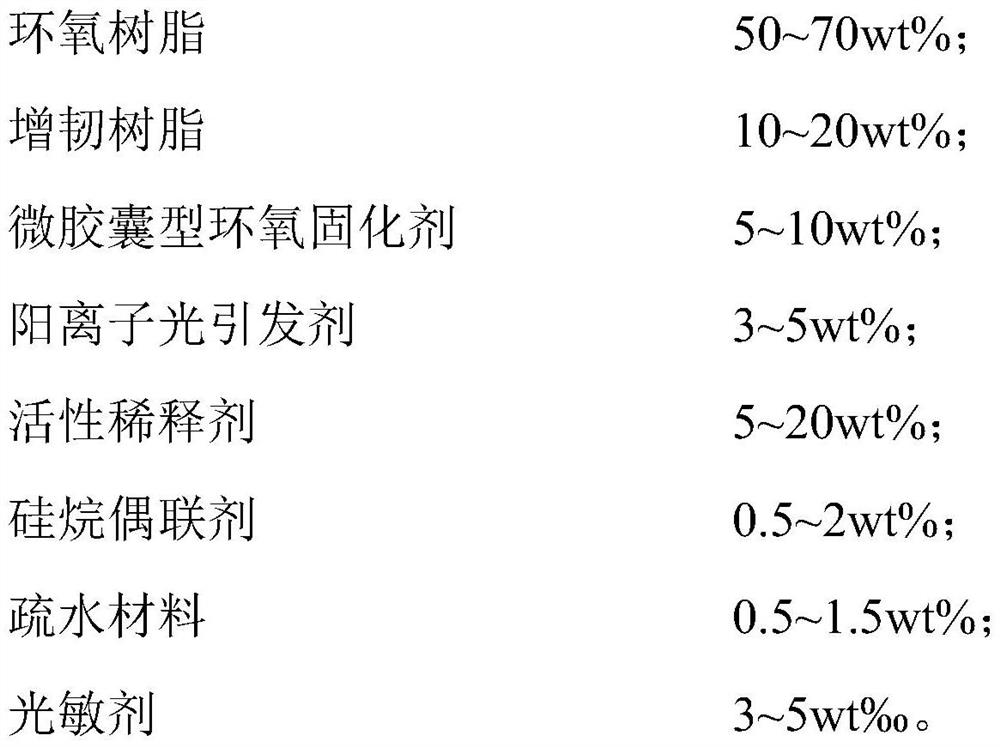

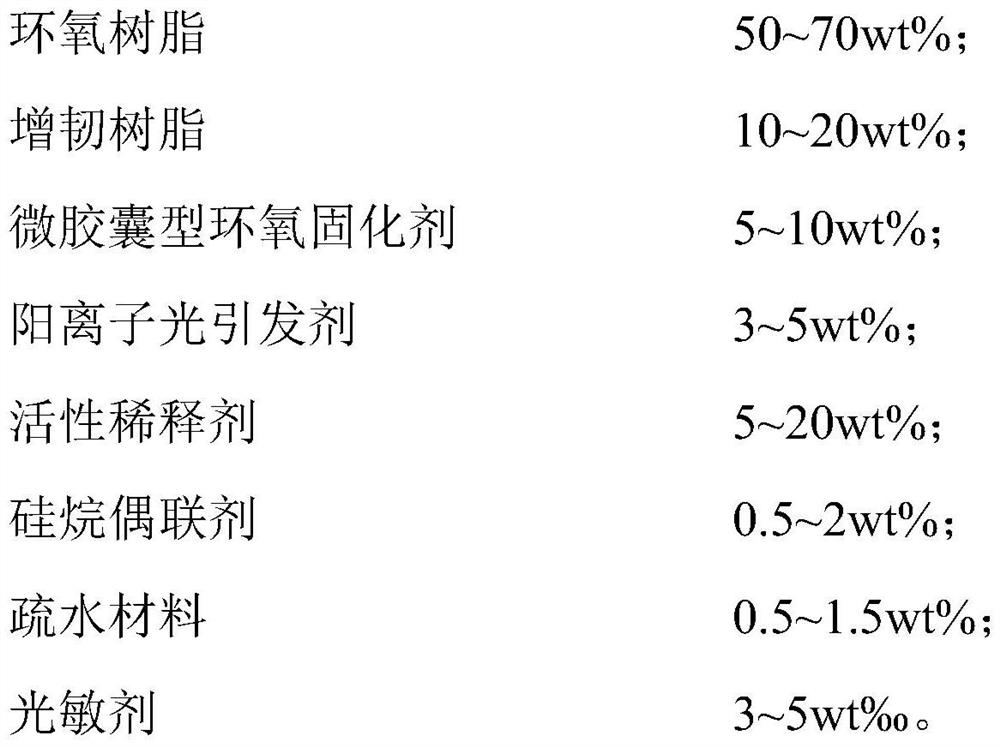

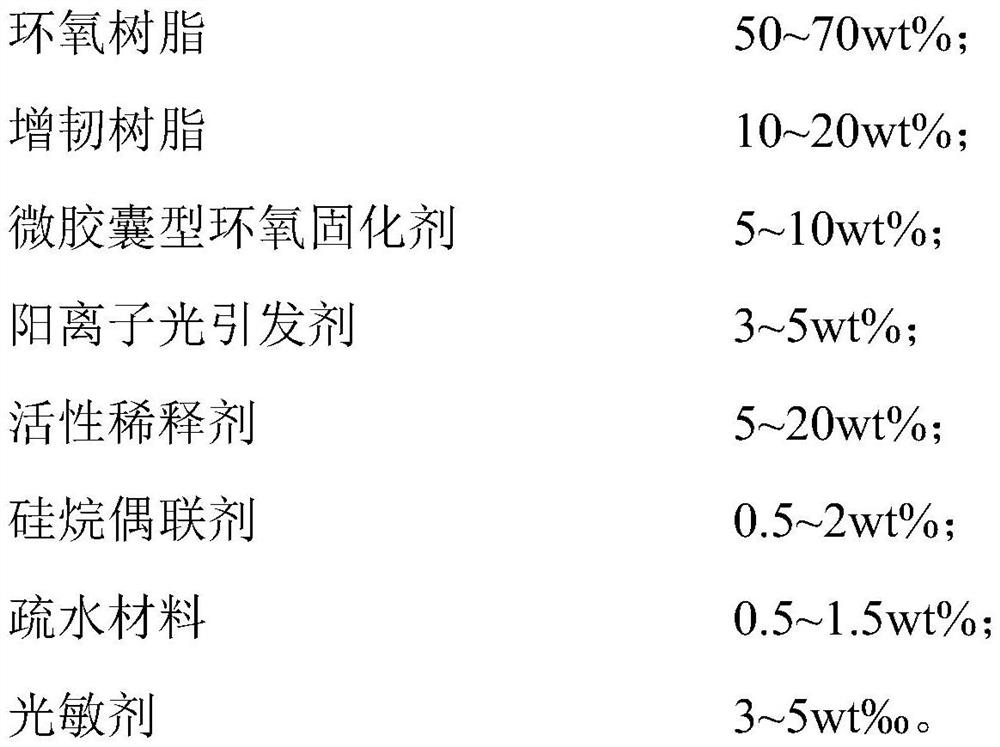

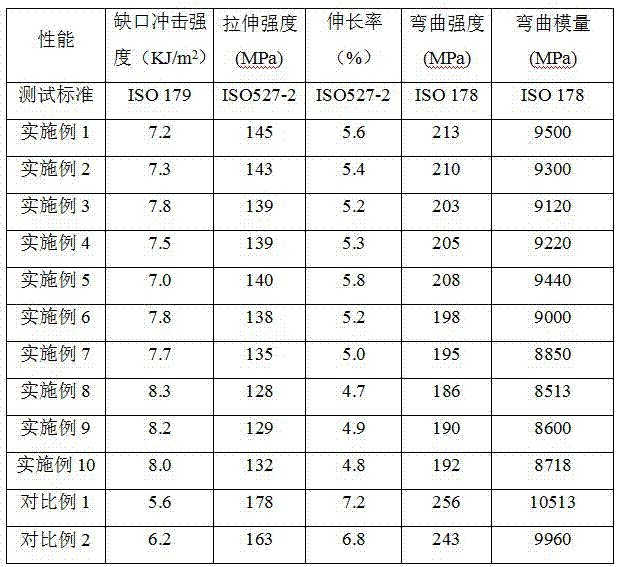

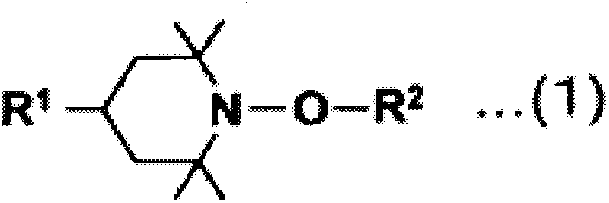

The invention belongs to the technical field of adhesives, in particular to a dual-curing adhesive. According to the fact that the total mass of the raw materials of the dual-curing adhesive is 100%,the dual-curing adhesive comprises 50 to 70 wt% of epoxy resin, 10 to 20 wt% of toughening resin, 5 to 10 wt% of a microcapsule type epoxy curing agent, 3 to 5 wt% of a cationic photoinitiator, 5 to 20 wt% of an active diluent, 0.5 to 2 wt% of a silane coupling agent, 0.5 to 1.5 wt% of a hydrophobic material and 0.3 to 0.5 wt% of a photosensitizer. The dual-curing adhesive has dual-curing effectsof light curing and heat curing, and can form a more stable network structure so that the interface bonding effect is improved, and the cured adhesive has excellent water resistance and gas resistance, and meanwhile, the temperature resistance is improved.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Thermoplastic polar polymer/laminated clay nanometer composite material and its preparation method

The invention provides a process for preparing thermoplastic polar polymer / laminated clay nano composite material which comprises, using thermoplastic polar polymer, laminated clay, intercalator, and disperse medium as raw material, reacting the laminated clay with intercalator (I) and intercalator (II), obtaining modified laminated clay, then mixing the modified laminated clay with thermoplastic polar polymer. The prepared nano composite material has good combination property.

Owner:ZHENGZHOU UNIV

Method for improving interface adhesion between glass aggregate and asphalt by using nanometer iron oxide

The invention discloses a method for improving the interface adhesion between glass aggregate and asphalt by using nanometer iron oxide. The nanometer iron oxide is used to improve the interface adhesion between glass aggregate and asphalt in order to improve the glass aggregate utilization rate and realize good adhesion, good durability, small energy consumption and no pollution to environment. The method comprises the following steps: 1, cleaning and drying the glass aggregate for later use; 2, preparing a nanometer iron oxide solution, immersing the glass aggregate in step 1 in the nanometer iron oxide solution, and taking out and drying the glass aggregate after the surface of the glass aggregate is completed infiltrated with the nanometer iron oxide solution; and 3, immersing the glass aggregate obtained in step 2 in hot matrix asphalt to make the surface of the glass aggregate completely wrapped with the matrix asphalt.

Owner:CHANGAN UNIV

PA6/PC/ PBT ternary alloy material and preparation method thereof

ActiveCN107365494AImprove toughnessGood dimensional stabilityPolytetramethylene terephthalateCrack resistance

The invention relates to the technical field of polymer materials, in particular to a PA6 / PC / PBT ternary alloy material and a preparation method of the PA6 / PC / PBT ternary alloy material. The ternary alloy material comprises the following raw materials in parts by weight: 20 to 80 parts of PA6 resin, 10 to 70 parts of PC, 10 to 30 parts of polybutylene terephthalate, 5 to 30 parts of glass fibers, 2 to 15 parts of compatibilizers, 0.1 to 1 part of an antioxidant and 0.1 to 1 part of a lubricant. The PA6 / PC / PBT ternary alloy material disclosed by the invention has high performances of toughness, dimensional stability, corrosion resistance, stress cracking resistance, oil resistance, mechanical strength and the like, and is high in molding performance, excellent in processability, low in cost and high in use value, and the preparation method is simple, convenient to operate and control, stable in quality, high in production efficiency, low in production cost and suitable for large-scale industrial production.

Owner:广东壹豪新材料科技股份有限公司

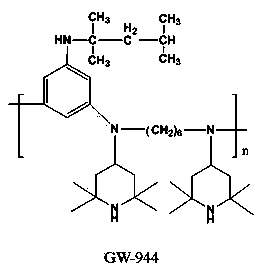

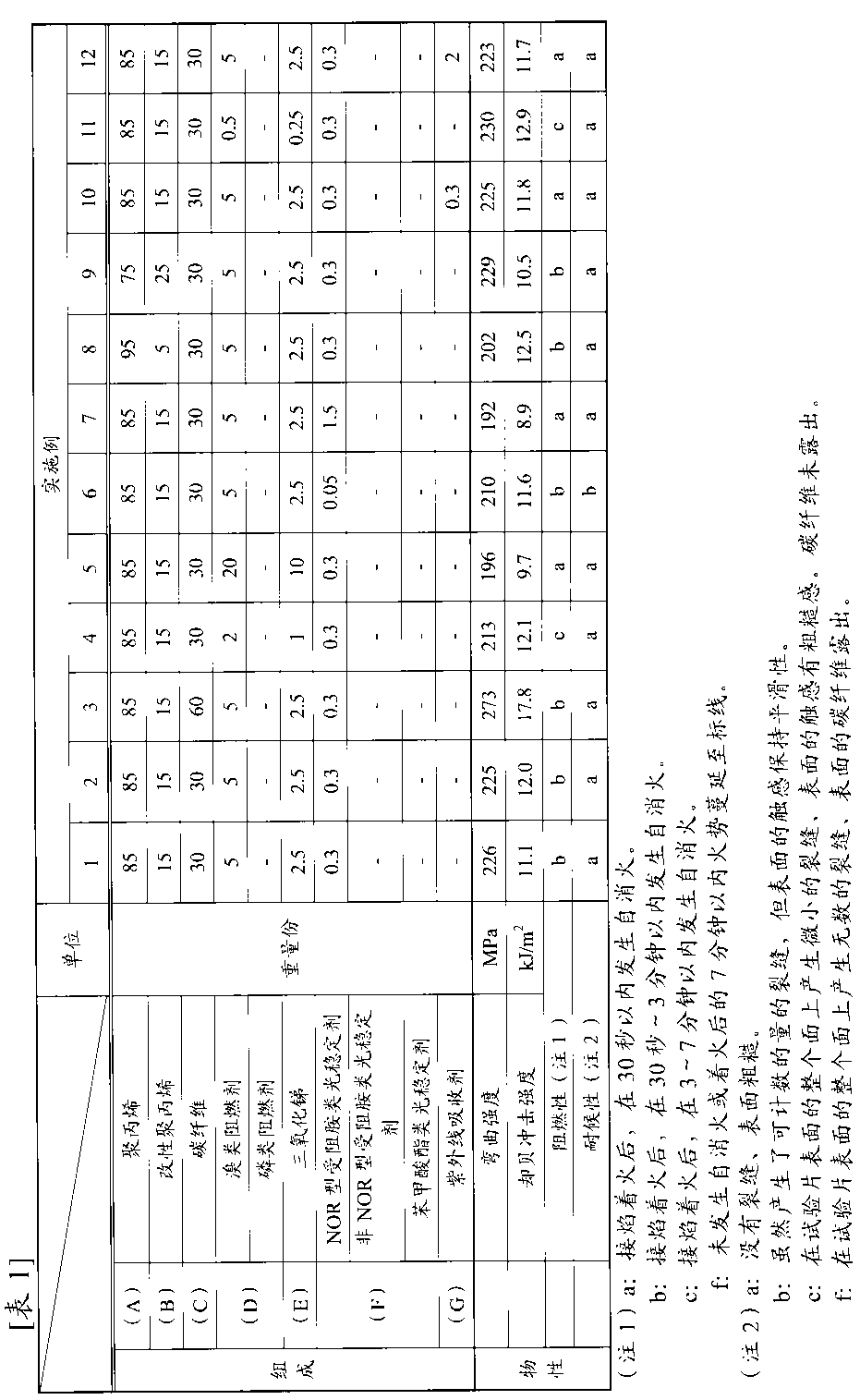

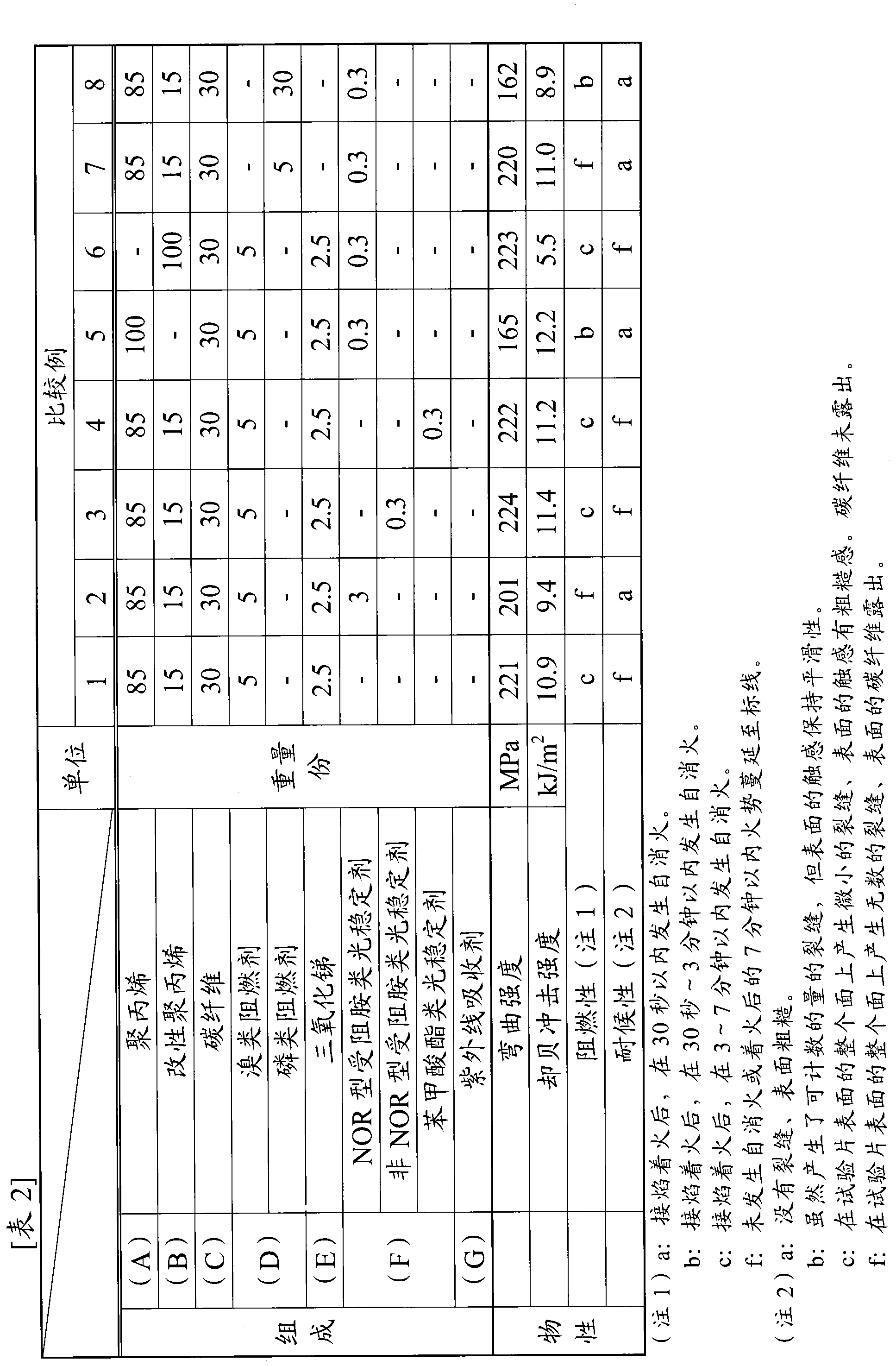

Carbon-fiber reinforced polypropylene resin composition, molding material, and molded articles

The invention relates to a carbon-fiber reinforced polypropylene resin composition. The carbon-fiber reinforced polypropylene resin composition is obtained by blending 100 parts by weight of the total of (A) a polypropylene resin and (B) a modified polypropylene resin with 8 to 70 parts by weight of (C) carbon fiber, 0.4 to 25 parts by weight of (D) a brominated flame retardant, 0.2 to 12.5 parts by weight of (E) an antimony oxide compound, and 0.05 to 2 parts by weight of (F) an amino-ether type hindered amine light stabilizer. Thus, the present invention provides: a carbon-fiber reinforced polypropylene resin composition which combines excellent flame retardance, excellent weather resistance and excellent mechanical characteristics; a molding material; and molded articles.

Owner:TORAY IND INC

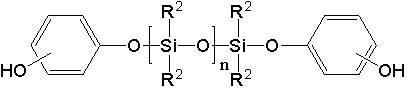

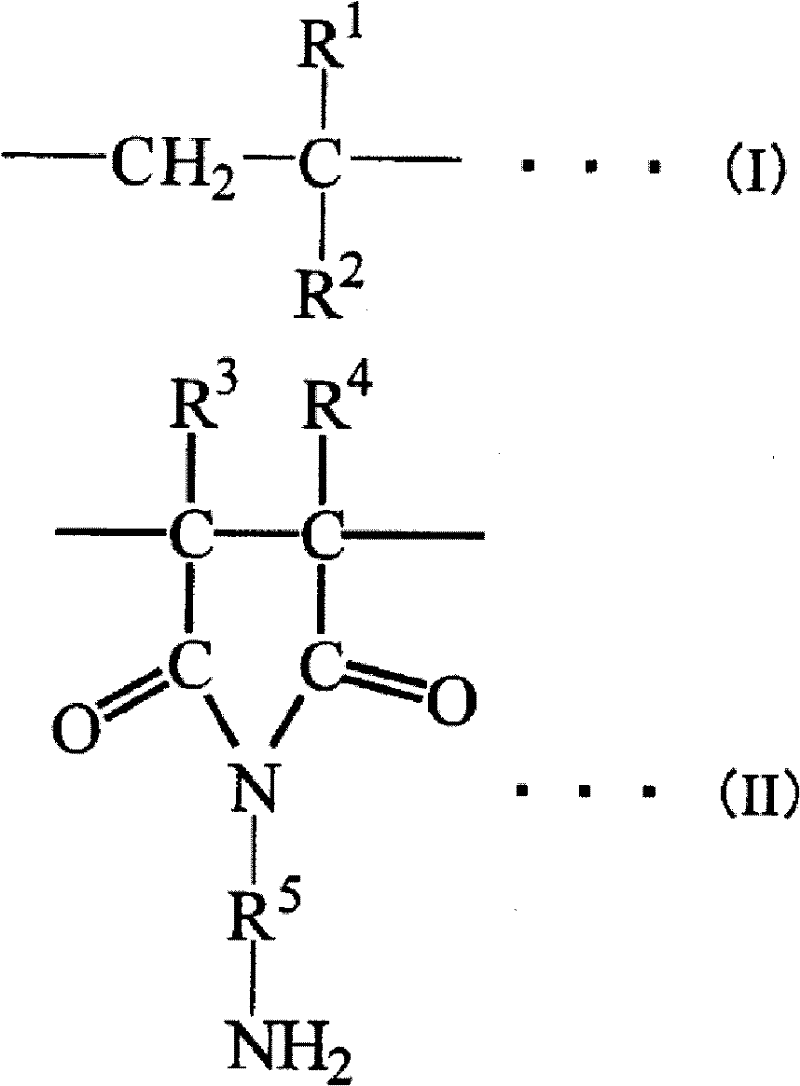

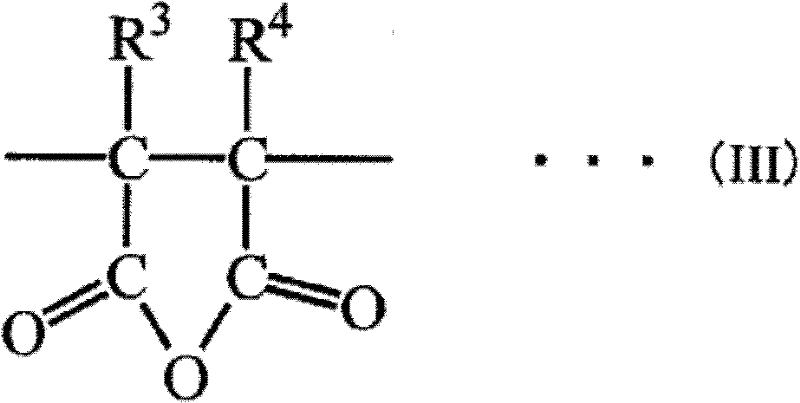

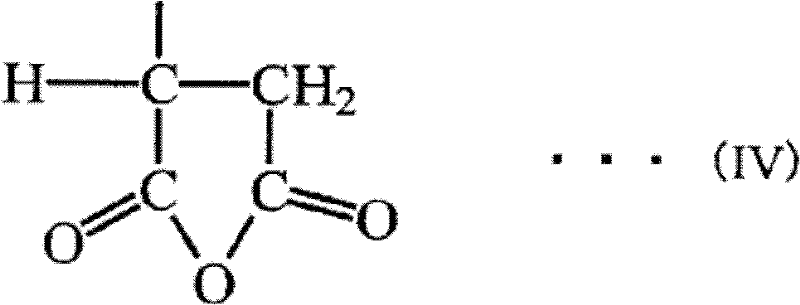

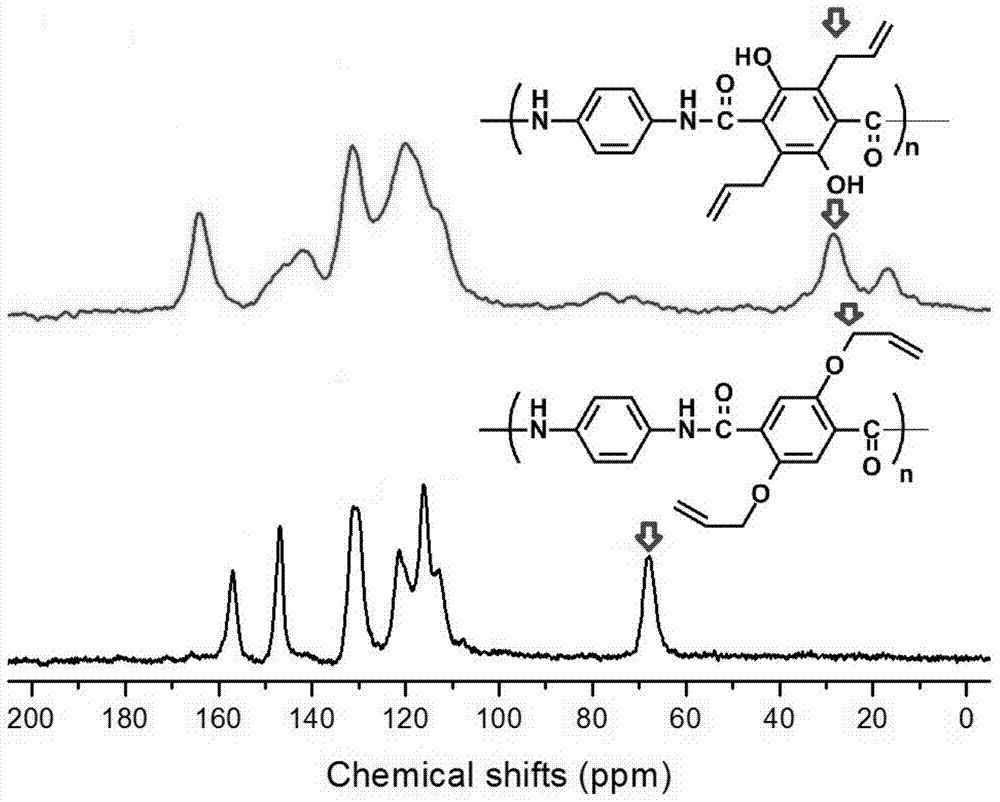

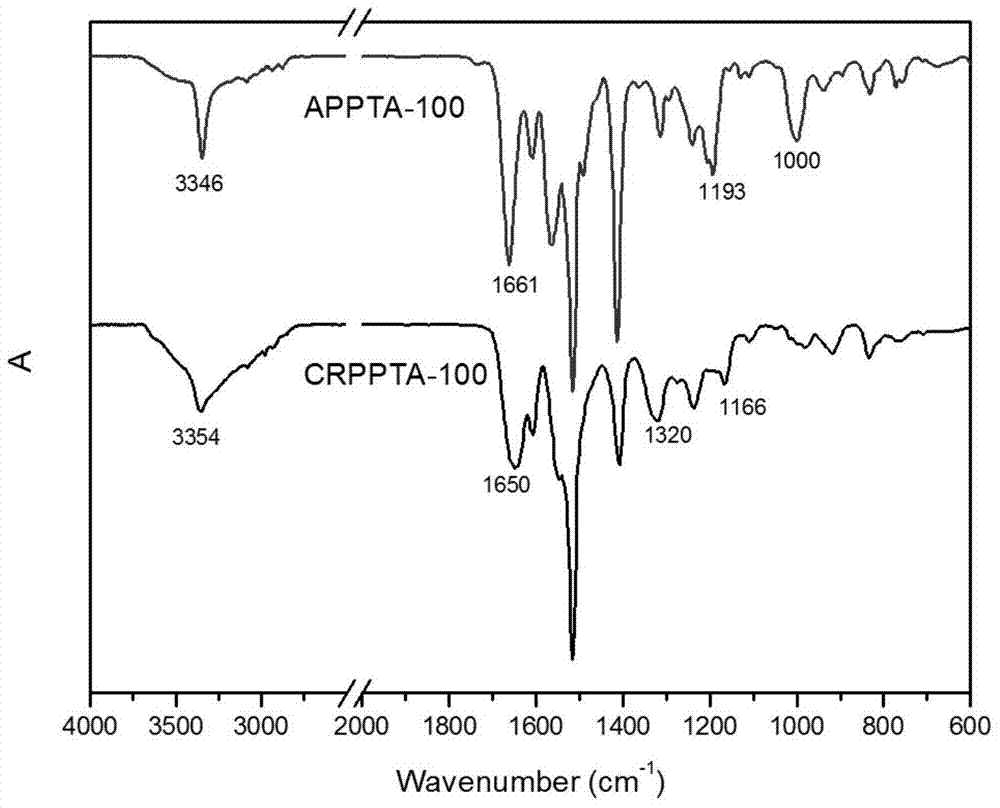

Aromatic polyamide resin containing hydroxyl group and allyl group, preparation method and application thereof

The invention discloses aromatic polyamide resin containing a hydroxyl group and an allyl group, a preparation method and an application thereof, wherein a repeated structure unit of the resin is represented as the formula I. In the aromatic polyamide resin, the hydroxyl group and the allyl group are introduced on a molecular chain of aromatic polyamide at the same time to form covalent bonds by reaction between a double bond of the allyl group and other materials. By means of introduction of a phenolic hydroxyl group, active forces between the molecular chains are enhanced by increasing the polarity of the aromatic polyamide, and meanwhile, by means of control of the contents of the two groups in the polymer, adjustment and control of a composite capability of aromatic polyamide fiber with other materials is achieved. The polymer represented as the formula I is good in thermal-stability. The hydroxyl group and the allyl group are easy to interact with epoxy resin, rubber and the like, thereby enhancing interlace adhesive performance. The aromatic polyamide resin may be employed as reinforced fibers of a sizing agent and can be used for developing an aromatic polyamide reinforced composite material being excellent in material interface composite performance.

Owner:PEKING UNIV

Preparation method of epoxy acrylate ultraviolet cured coating

InactiveCN104559686AImprove interface bonding performanceImprove dispersionEpoxy resin coatingsPhotoinitiatorPliability

The invention belongs to the field of coatings, and in particular relates to a modified epoxy acrylate ultraviolet cured coating and a preparation method thereof. The preparation method comprises the following steps: adding epoxy resin and modified titanium dioxide / attapulgite nano composite powder containing an epoxy group coupling agent into an active diluent, then adding acrylic acid, a catalyst and a polymerization inhibitor, and heating to perform epoxy ring-opening reaction to obtain titanium dioxide / attapulgite modified epoxy acrylate; and adding a photoinitiator, a leveling agent and a defoaming agent into the modified epoxy acrylate, and mixing uniformly to obtain the ultraviolet cured coating. According to the preparation method, the dispersity of the titanium dioxide / attapulgite in epoxy acrylic resin is improved, and the mechanical properties including ageing resistance, impact resistance, flexibility and the like of an epoxy acrylate coating layer are greatly improved.

Owner:CHANGZHOU UNIV

Preparation method for graphene oxide treated hybrid chopped fiber reinforced polyether sulfone composite material

The invention belongs to the technical field of fiber reinforced thermoplastic composite materials, and particularly relates to a preparation method for a graphene oxide treated hybrid chopped fiber reinforced polyether sulfone composite material. The preparation method specifically comprises the following steps: blending, washing and drying fiberglass and carbon fibers; preparing an aqueous solution of graphene oxide at a certain concentration; adding the aqueous solution of graphene oxide into the hybrid fibers; drying the hybrid fibers treated with graphene oxide in a drying oven to remove water; mixing the treated hybrid short fibers and polyether sulfone particles, and performing melting, extrusion and granulation to prepare the hybrid chopped fiber reinforced polyether sulfone composite material. According to the method, the bonding strength of an interface of the fibers of the prepared composite material and polyether sulfone resin is strong, equipment adopted for a preparation process is simple, convenient to operate and low in energy consumption and cost, and the composite material has excellent mechanical performance and strength designability.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com