Preparation method of bonding polyaniline on surfaces of styrene-acrylate copolymer emulsion particles

A technology of acrylate and particle surface, which is applied in the field of preparation of chemically modified styrene-acrylic latex on the surface of conductive polyaniline, which can solve the problems affecting the anti-corrosion, conductivity and anti-fouling performance of polyaniline, and achieve excellent interface adhesion and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 50 grams of phosphoric acid-containing functional styrene-acrylic latex prepared by the above process, add 0.15 grams of aniline, stir with a mechanical stirrer for 20 minutes, and evenly add dropwise an aqueous solution containing 0.4 grams of ammonium persulfate for 2 hours at an ambient temperature of 10°C.

[0035] After the dropwise addition, the ice-bath stirring was continued for 20 h to obtain a suspension dispersion of polyaniline (polyaniline accounted for 0.5% by weight of the copolymer) bound to the surface of the styrene-acrylate copolymer latex particles.

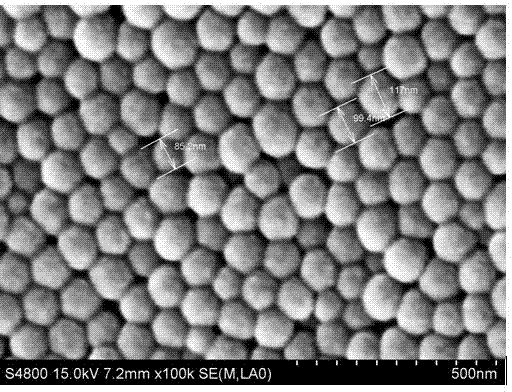

[0036] The scanning electron microscope picture of the styrene-acrylic acid ester copolymer latex particle containing phosphoric acid functional group prepared by this process is as follows figure 1 As shown, the polymer presents a regular spherical shape with a particle size of 100±15 nm.

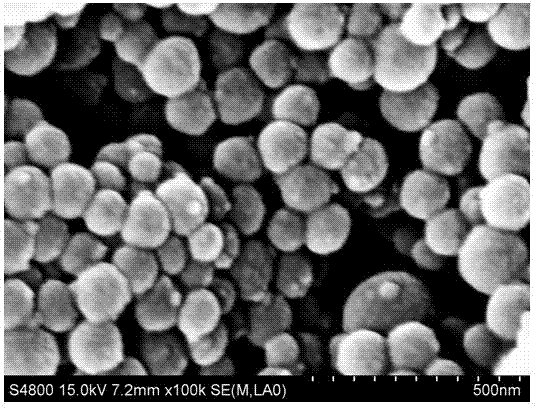

[0037] Such as figure 2 As shown in the scanning electron microscope picture of polyaniline bonded to the...

Embodiment 2

[0039] Weigh 50 grams of phosphoric acid-containing functional styrene-acrylic latex prepared by the above process, add 0.3 grams of aniline, stir with a mechanical stirrer for 20 minutes, and evenly drop an aqueous solution containing 0.8 grams of ammonium persulfate for 3 hours at an ambient temperature of 0°C.

[0040] After the dropwise addition, the ice-bath stirring was continued for 15 hours to obtain a suspension dispersion of polyaniline (polyaniline accounted for 1% by weight of the copolymer) bound to the surface of the styrene-acrylate copolymer latex particles.

[0041] The aqueous solution of the oxidant ammonium persulfate added dropwise can adopt potassium persulfate, H 2 o 2 、KIO 3any of the alternatives.

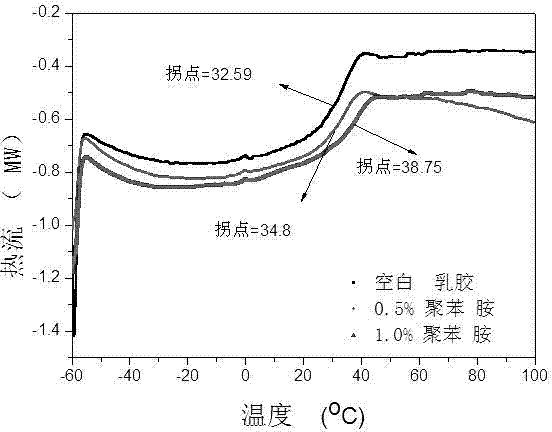

[0042] image 3 Compared the DSC of styrene-acrylate copolymer latex films containing phosphoric acid functional groups and polyaniline with different contents bound to the surface of styrene-acrylate copolymer latex particles, the results showed tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com