Carbon fiber modifying coating and its preparation method

A technology for modifying coatings and carbon fibers, which is applied in the chemical characteristics of fibers, textiles and papermaking, chemical post-treatment of rayon, etc., and can solve problems such as failure to achieve expected performance, complex and changeable interfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

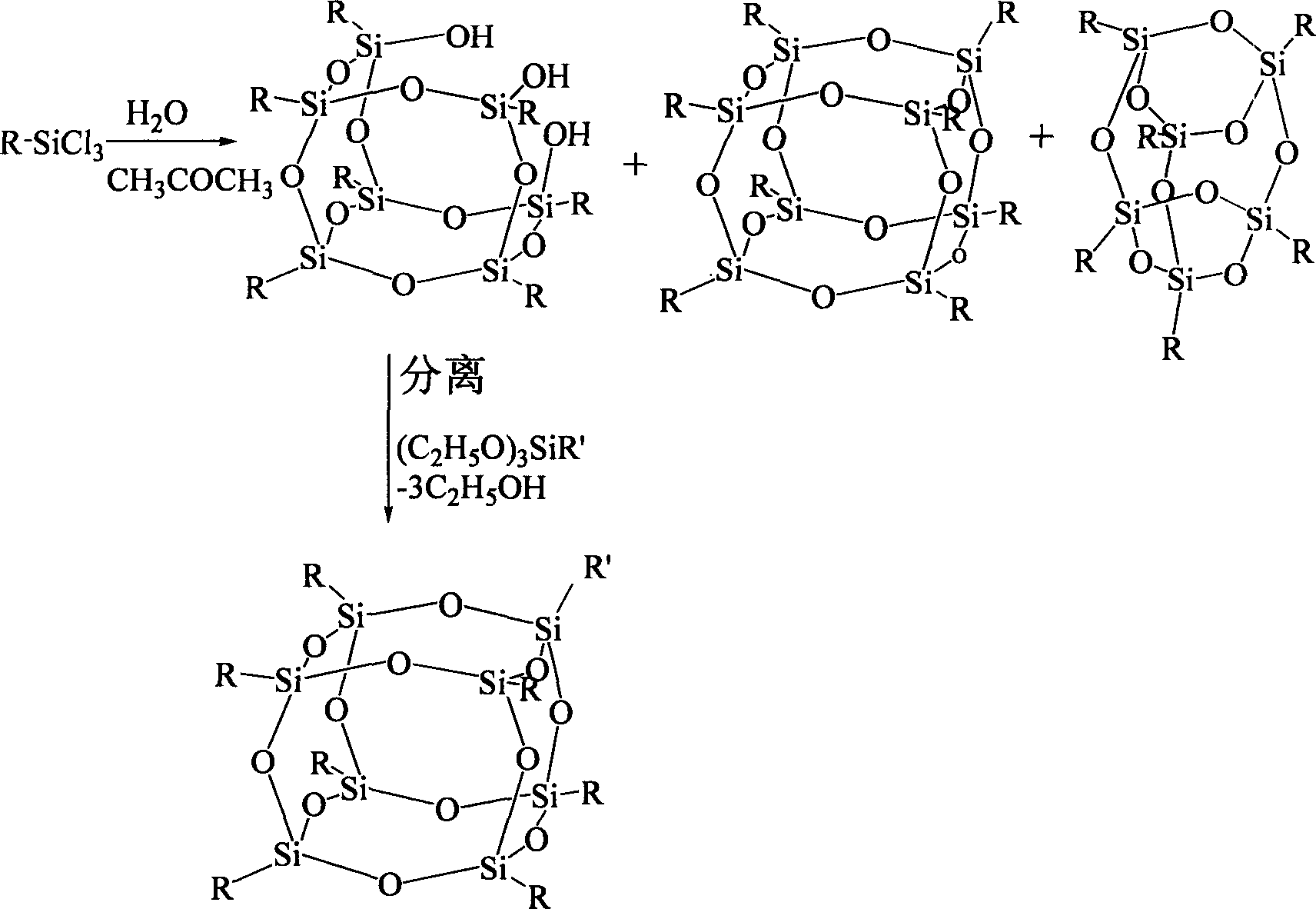

[0010] Embodiment 1: The carbon fiber modified coating in this embodiment is composed of carbon fiber and surface coating, the coating is a cage-type silsesquioxane coating, and the cage-type silsesquioxane coating is coated on the carbon fiber on the outer surface. The thickness of the cage-type silsesquioxane coating in this embodiment is 100-300 nm, wherein the structural formula of the cage-type silsesquioxane is: , where R is H, alkyl, alkenyl, aryl, aralkenyl or derivatives thereof, and R' is an active functional group.

specific Embodiment approach 2

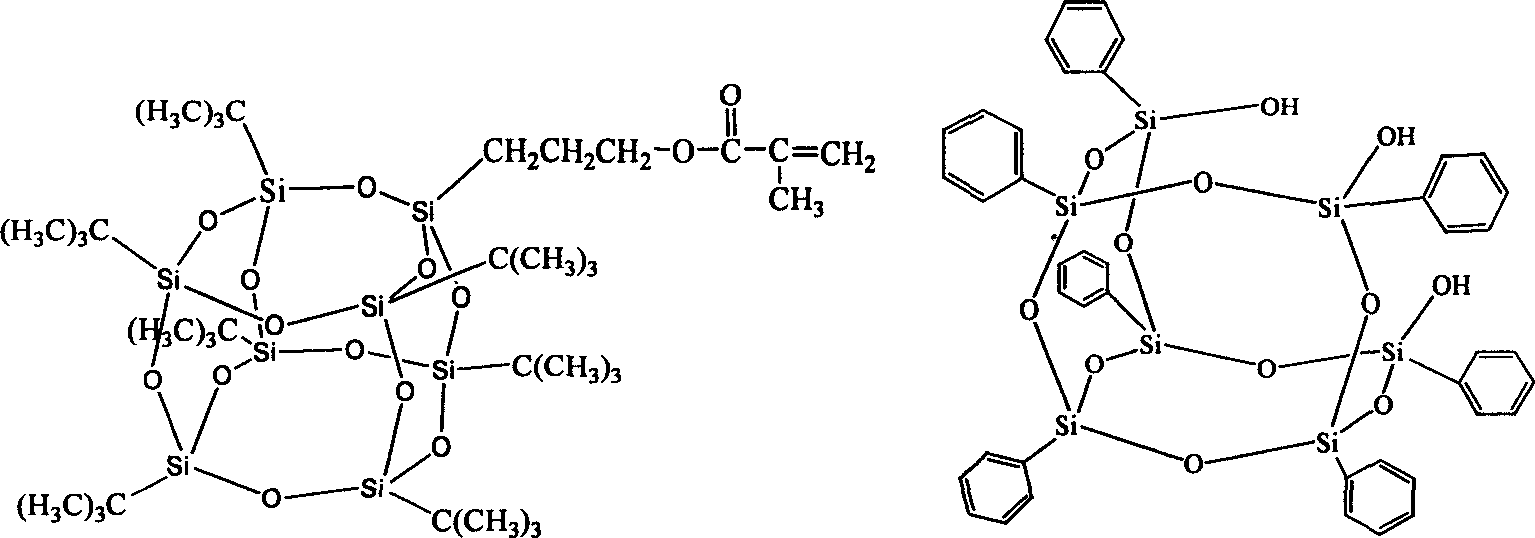

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that R can be cyclohexyl, cyclopentyl or isobutyl; active functional groups can be chlorine, acids, alcohols, amino groups, alkyl groups, acrylates Hydrogen, Epoxy, Styryl, Olefin, Nitrile, Hydrogen, Isocyanate, Bisphenol or Hydroxide.

specific Embodiment approach 3

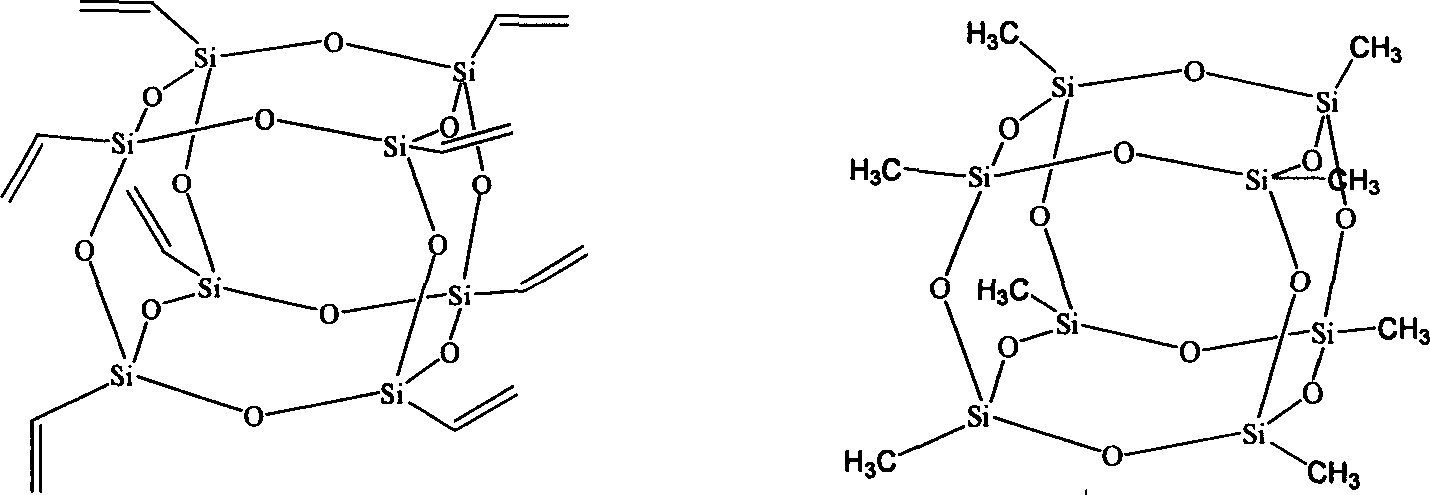

[0012] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 and 2 is that for the carbon fiber and non-polar polyarylene system, this embodiment selects the following four POSS:

[0013]

[0014] a) Octavinyl cage silsesquioxane b) Octamethyl cage silsesquioxane

[0015]

[0016] c) Methacryloxyisobutyl cage silsesquioxane d) Hydroxyphenyl cage silsesquioxane

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Interlaminar shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com