Carbon-fiber reinforced polypropylene resin composition, molding material, and molded articles

A polypropylene resin and molding material technology, which is applied in the field of carbon fiber reinforced polypropylene resin materials, can solve problems such as heat resistance, deterioration, discoloration and mechanical properties, and achieve good interface adhesion, good flame retardancy and weather resistance, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

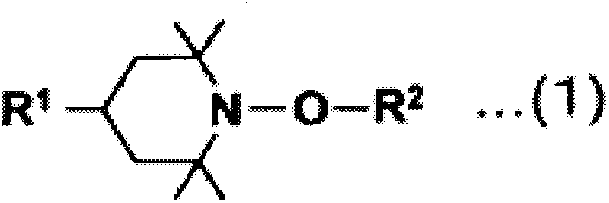

Method used

Image

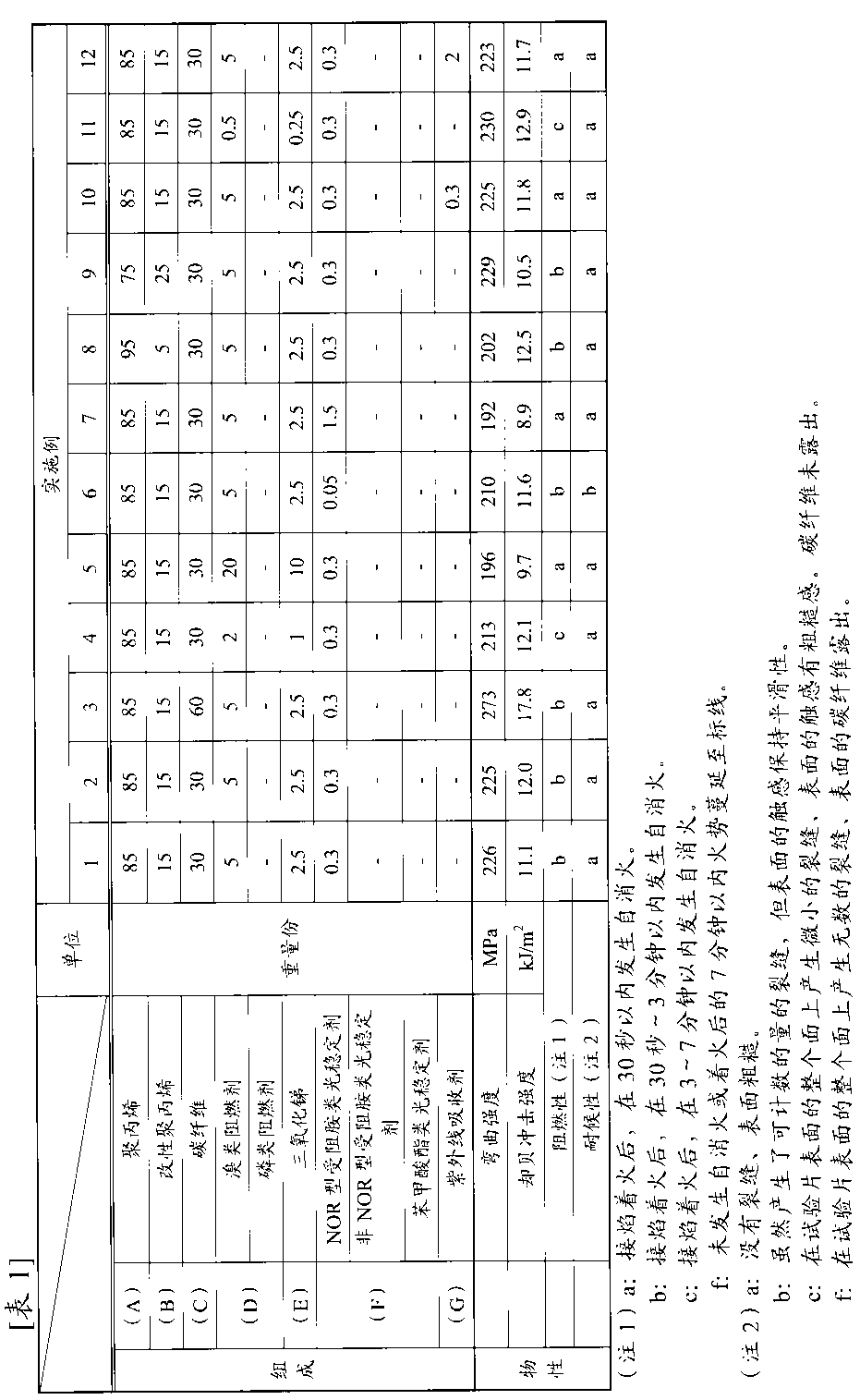

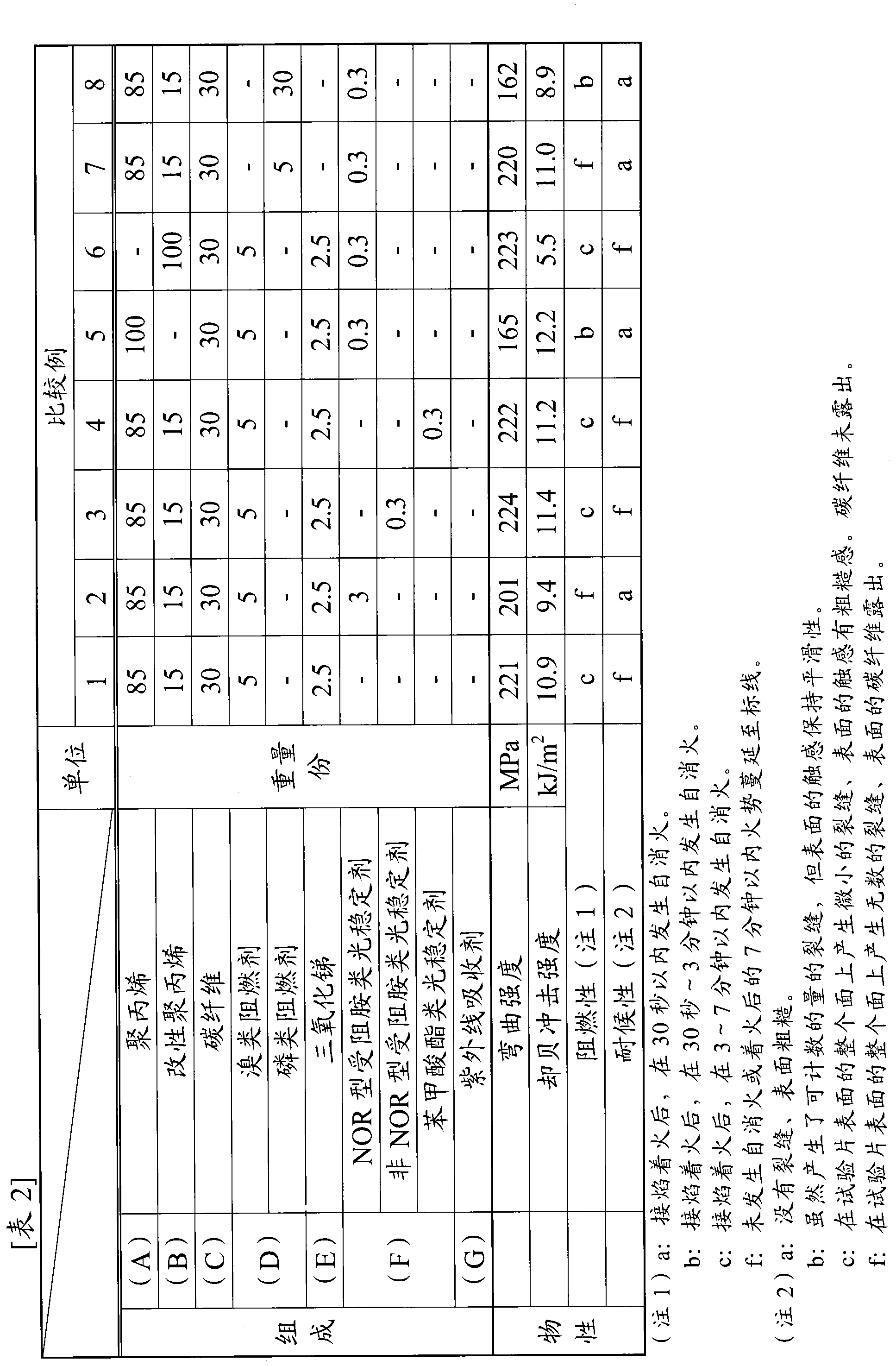

Examples

Embodiment 1

[0122] Using the TEX-30α twin-screw extruder made by JSW (screw diameter 30mm, die diameter 5mm, barrel temperature 220°C, screw rotation speed 150rpm), the weight ratio (A) / (B)=85 / 15 A mixture obtained by mixing pellets of (A) polypropylene resin (Prime PolyproJ105G resin manufactured by Prime Polymer Co., Ltd.) and (B) maleic acid-modified polypropylene resin (ADMER QE840 manufactured by Mitsui Chemicals Co., Ltd.), ( D) Brominated flame retardant (Nonnen PR-2 manufactured by Maruhishi Petrochemical Co., Ltd.), (E) antimony trioxide (manufactured by Showa Chemical Co., Ltd.), (F) amino ether type hindered amine light stabilizer (Tinuvin 123 manufactured by BASF Japan Co., Ltd.), while degassing through the downstream vacuum vent, the molten resin was ejected from the die, and the resulting strand was cooled and then cut with a cutter to obtain melt-kneaded pellets.

[0123] In addition, using a long-fiber-reinforced resin pellet manufacturing device provided with a coating ...

Embodiment 2

[0131]Using a long-fiber-reinforced resin pellet manufacturing device provided with a coating die for molten resin at the discharge front end of a single-screw extruder, set the cylinder temperature of the extruder to 220°C, and supply a weight ratio of ( A) / (B)=85 / 15 for (A) polypropylene resin (Prime Polypro J105G resin manufactured by Prime Polymer Co., Ltd.) and (B) maleic acid-modified polypropylene resin (manufactured by Mitsui Chemicals Co., Ltd. ADMER QE840), (D) brominated flame retardant (Nonnen PR-2 manufactured by Maruhishi Petrochemical Co., Ltd.), (E) antimony trioxide (manufactured by Showa Chemical Co., Ltd.), ( F) Amino ether type hindered amine light stabilizer (Tinuvin 123 manufactured by BASF Japan Co., Ltd.) was melted at a screw speed of 200 rpm, and the (C) carbon fiber obtained in the reference example was supplied to the die (diameter 3 mm), the resin-coated tow is cooled, and cut into pellets with a length of 10 mm by a granulator, and the molding mat...

Embodiment 3

[0138] When dry-blending the melt-kneaded granules and the long-fiber granules, dry-blending is carried out so that the composition of (C) carbon fibers is 60 parts by weight relative to the total amount of the above-mentioned components (A) and (B) of 100 parts by weight, Other than that, molding evaluation was performed in the same manner as in Example 1. The evaluation results are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com