Dual-curing adhesive and preparation method thereof

A dual-curing, adhesive technology, used in adhesives, adhesive additives, epoxy resin adhesives, etc., can solve the problems of difficult curing, poor curing effect, and poor temperature resistance in the deep and shadow areas of the cured adhesive. To achieve the effect of improving the interface bonding effect, excellent water resistance and good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The second aspect of the embodiment of the present application provides a method for preparing a dual-curing adhesive, comprising the following steps:

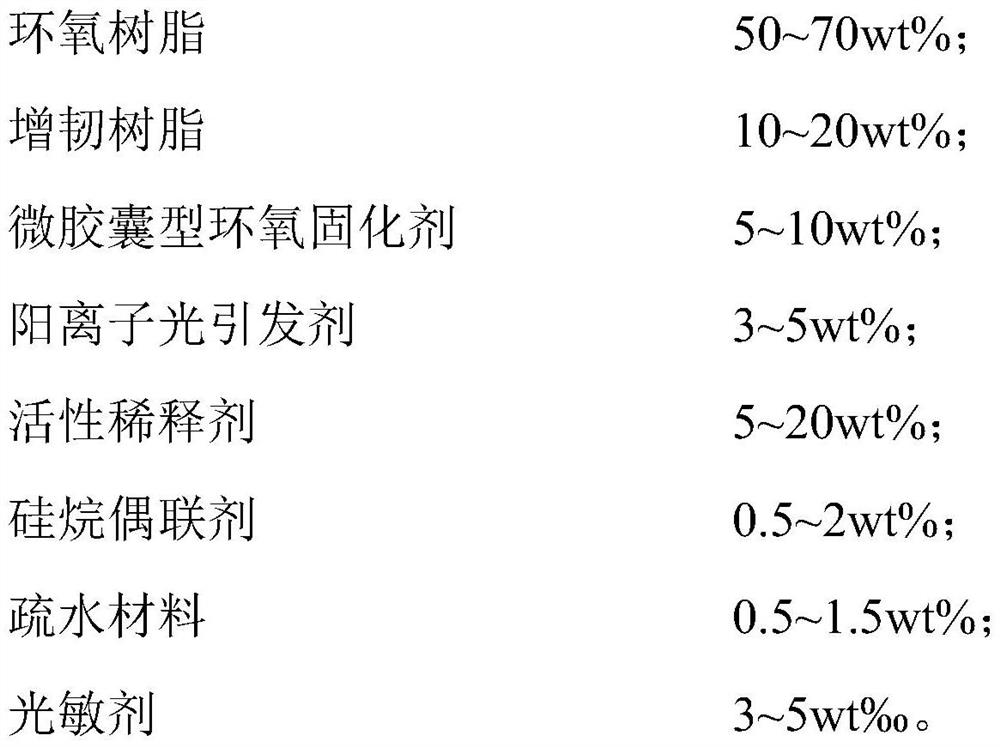

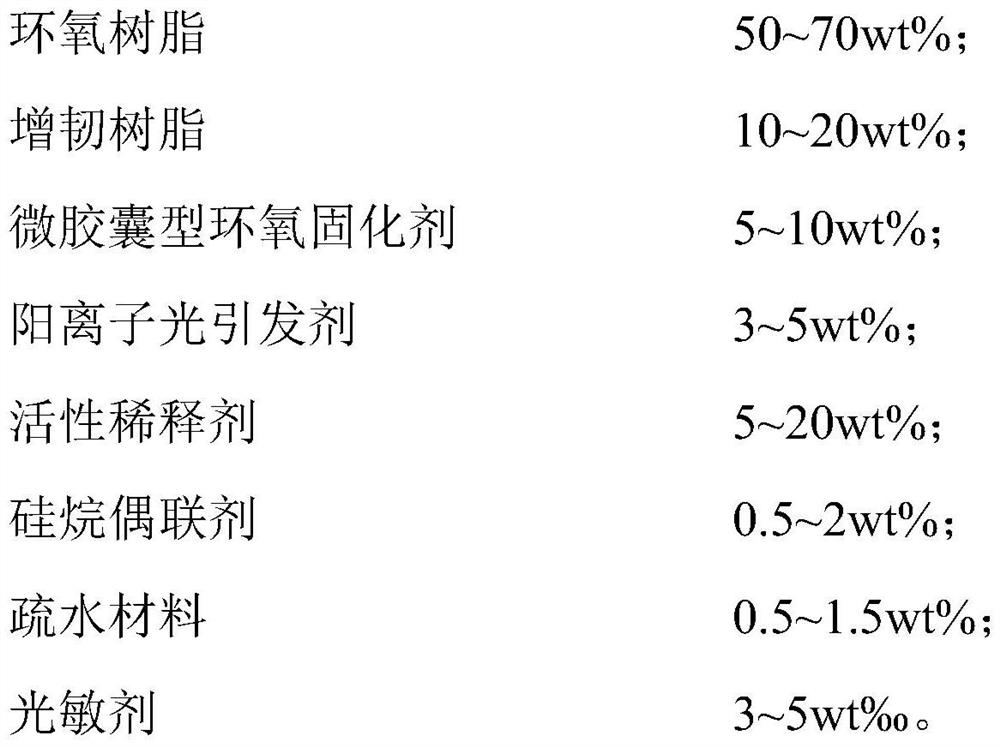

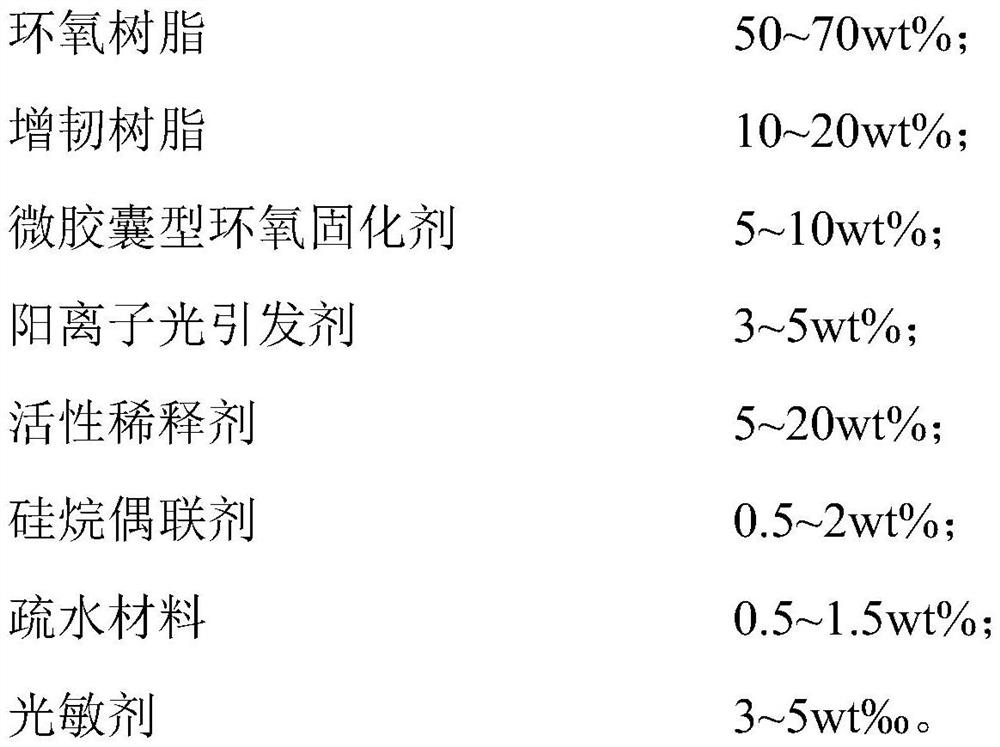

[0035] S10. Taking the total mass of the raw materials of the dual-curing adhesive as 100%, under the condition of no ultraviolet light, 50-70wt% epoxy resin, 10-20wt% toughening resin, 5-10wt% microcapsule epoxy Curing agent, 3-5wt% cationic photoinitiator, 5-20wt% reactive diluent, 0.5-2wt% silane coupling agent, 0.5-1.5wt% hydrophobic material, 3-5wt‰ photosensitizer are mixed to obtain double curing adhesive.

[0036] The preparation method of the dual-curing adhesive provided by the second aspect of the present application, under the condition of no ultraviolet light, by mixing the epoxy resin, toughening resin, microcapsule epoxy curing agent, cationic photoinitiator, active The diluent, the silane coupling agent, the hydrophobic material and the photosensitizer are mixed to form a mixed slurry to obtain a dual-c...

Embodiment 1

[0070] A dual curing adhesive comprising the following preparation methods:

[0071] 1. Preparation of microcapsule epoxy curing agent:

[0072] ① Add 4g of 2-methylimidazole and deionized water into a 250ml flask, stir and dissolve at 80°C (water bath), until the 2-methylimidazole is completely dissolved and becomes clear and transparent; slowly add 6g of PAA until PAA is completely reacted, The solution is a light yellow transparent colloid, and the PAA-2MI aqueous solution is obtained;

[0073] ②Make Span-80 and liquid paraffin into 2% emulsifier solution;

[0074] ③Add 11.5g of emulsifier solution to the PAA-curing agent aqueous solution, and stir and emulsify at a high speed of 50000r / min for 15min;

[0075] ④ After ultrasonically dispersing 1.5g of tetrabutyl titanate and liquid paraffin, add it to the above emulsion, and continue to emulsify at 50000r / min at high speed for 30min;

[0076] ⑤ After emulsification, pour it into a single-necked flask, distill it under re...

Embodiment 2

[0082] A dual curing adhesive comprising the following preparation methods:

[0083] 1. Preparation of microcapsule epoxy curing agent:

[0084] ①Add 5g of diethylenetriamine and deionized water into a 250ml flask, stir and dissolve at 80°C (water bath), until the diethylenetriamine is completely dissolved and becomes clear and transparent; slowly add 6g of PAA until PAA is completely reaction, the solution is a light yellow transparent colloid, and the PAA-2MI aqueous solution is obtained;

[0085] ②Make Span-80 and liquid paraffin into 2% emulsifier solution;

[0086] ③Add 13.5g of emulsifier solution to PAA-curing agent aqueous solution, stir and emulsify at high speed at 4800r / min for 20min;

[0087] ④After ultrasonically dispersing 2g of tetrabutyl titanate and liquid paraffin, add it to the above emulsion, and continue to emulsify at 48000r / min at high speed for 35min;

[0088] ⑤ After emulsification, pour it into a single-necked flask, distill it under reduced pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com