Device for receiving prefabricated frame and sliding on variable slope slideway and application method thereof

A technology of sliding device and slope-changing slideway, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of difficult to control the jacking direction, the surface of the slideway is damaged, and the jacking force consumption is large, so as to avoid The effect of mutual destruction, speeding up the jacking speed, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

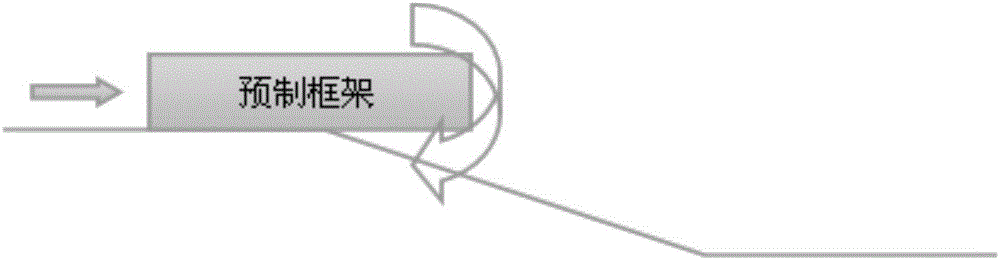

[0035] The Changsha Xiangfu Road high culvert project passes under the Beijing-Guangzhou Railway. The construction plan adopts prefabrication in the working pit outside the railway subgrade, and then the overhead railway is jacked into place according to the design.

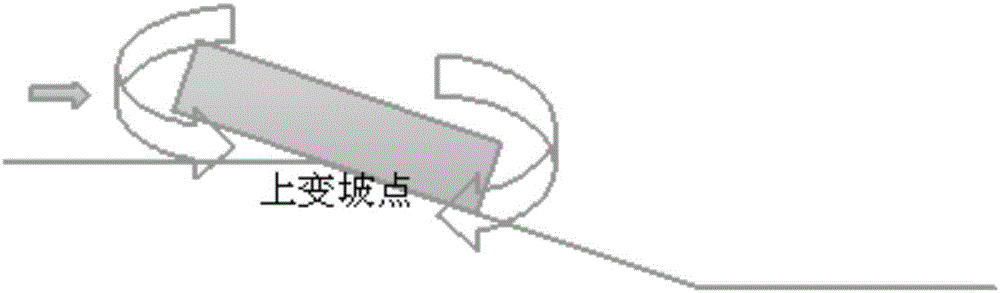

[0036] After the off-line prefabrication of the prefabricated frame 9 was completed, it was found that the actual elevation of the upstream drainage culvert did not match the design—the elevation of the upstream flow surface was lower than the design flow elevation of the newly built iron-related culvert, resulting in the failure of the prefabricated frame 9 to drain water after it was completed according to the design. In order to solve the problem of culvert drainage, it is necessary to lower the design elevation of the culvert in the railway-related section. After calculation, the elevation drops by 65cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com