Castable Furnace Structure of a Cylindrical Rotary Heat Equipment

A furnace body structure and castable technology, which is applied in the field of cylindrical rotary heat equipment, can solve the problems of inability to quickly repair in a small area, lack of overall strength of the kiln lining, and low utilization rate of thermal efficiency, so as to prevent movement and displacement, The effect of increasing residence time and improving thermal efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

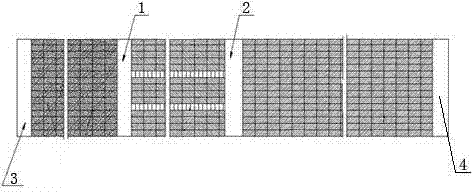

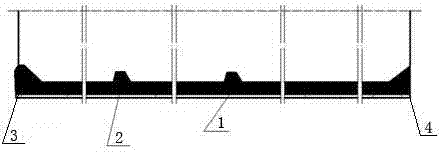

[0027] As shown in the figure, the castable furnace body structure of a cylindrical rotary heat equipment divides the furnace body into three areas: the low-temperature feed section, the high-temperature thermal reaction section, and the outlet orifice. The low-temperature feed section and the high-temperature thermal reaction section A retaining ring is set at the boundaries of the three areas of the section and the outlet orifice, and the retaining ring protrudes from the kiln lining, so that when the material enters a different temperature zone, the material retaining ring protrudes to the blocking function to make the material turn over and change the running track; The material retaining ring completes different functions according to different temperature sections of the thermal equipment: the material retaining ring set at the boundary between the low temperature section and the high temperature section is the high temperature boundary material retaining ring 1, from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com