Patents

Literature

86results about How to "High thermal efficiency utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

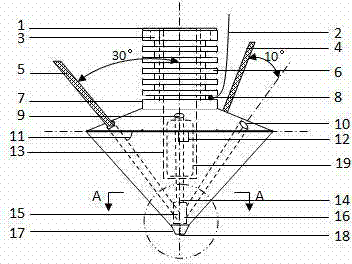

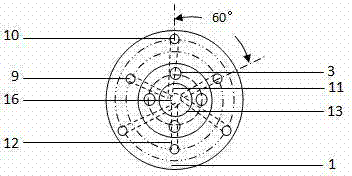

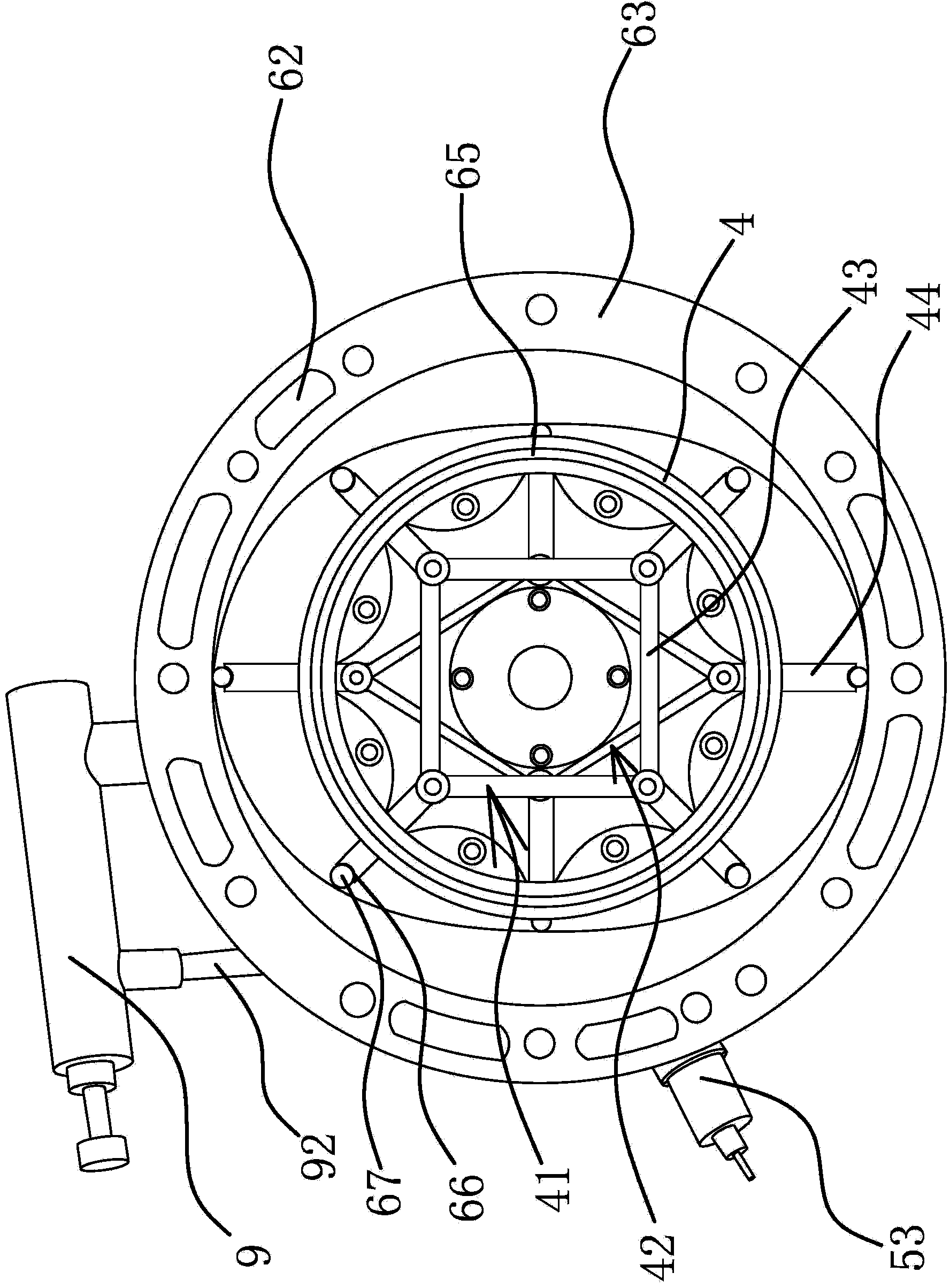

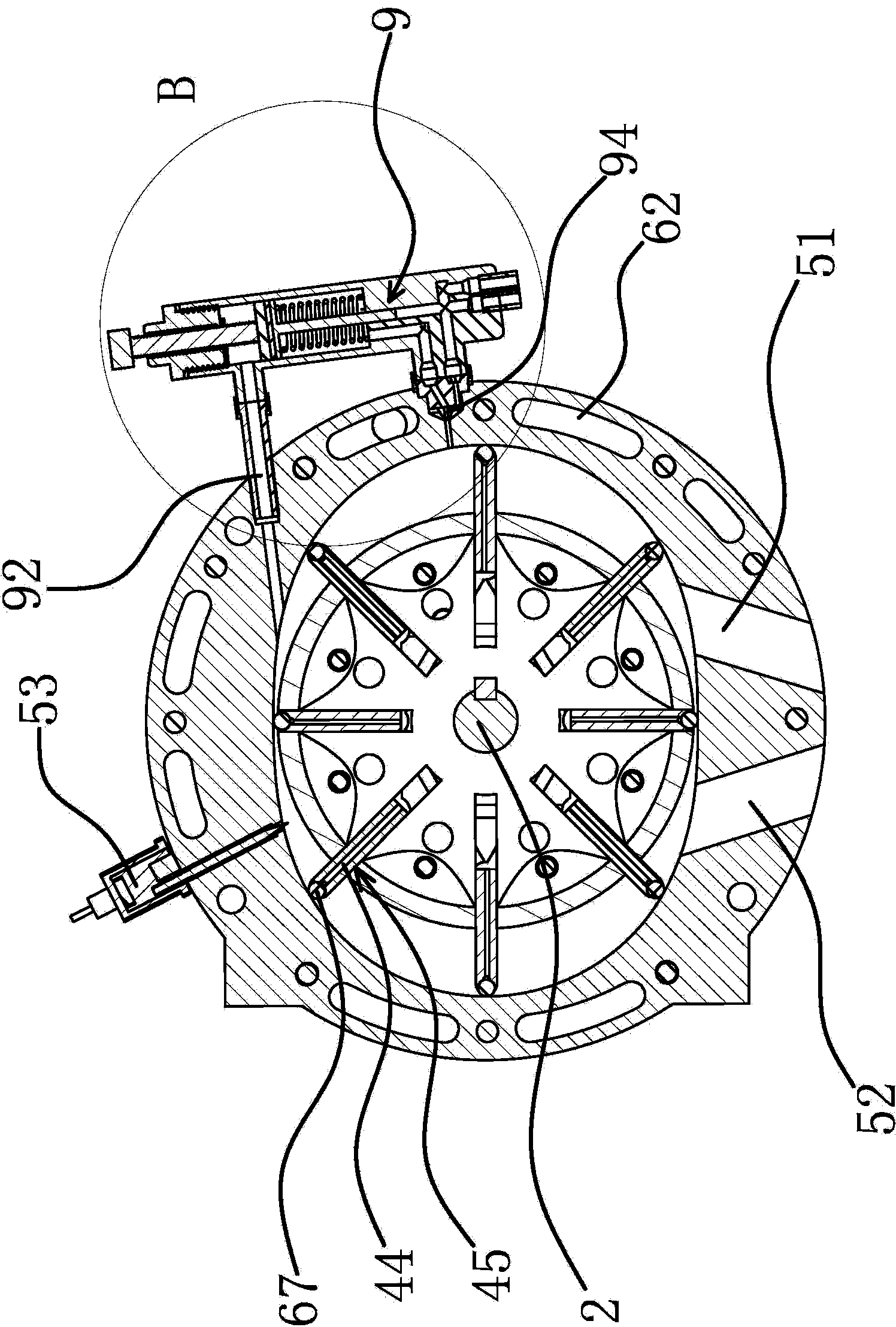

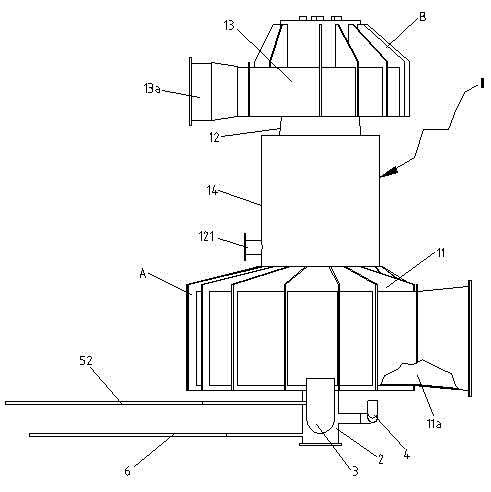

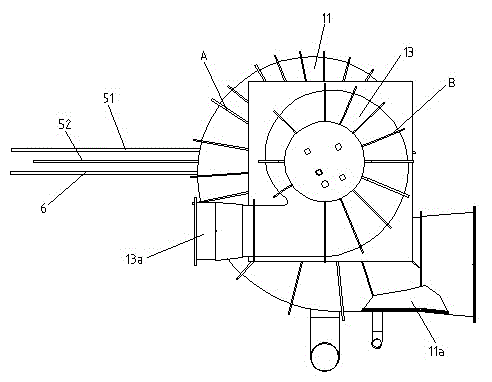

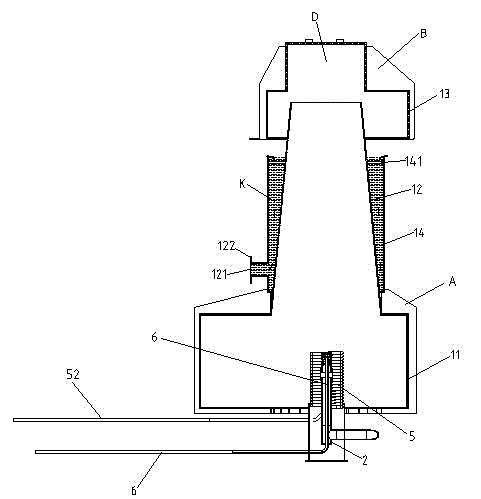

Six-channel aggregation-fusion type squeezing nozzle for fused deposition modeling type color three-dimensional printer

ActiveCN104742364AHigh thermal efficiency utilizationImprove energy efficiencyComputer printingControl system

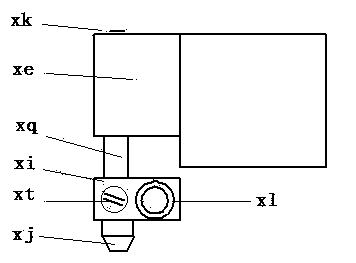

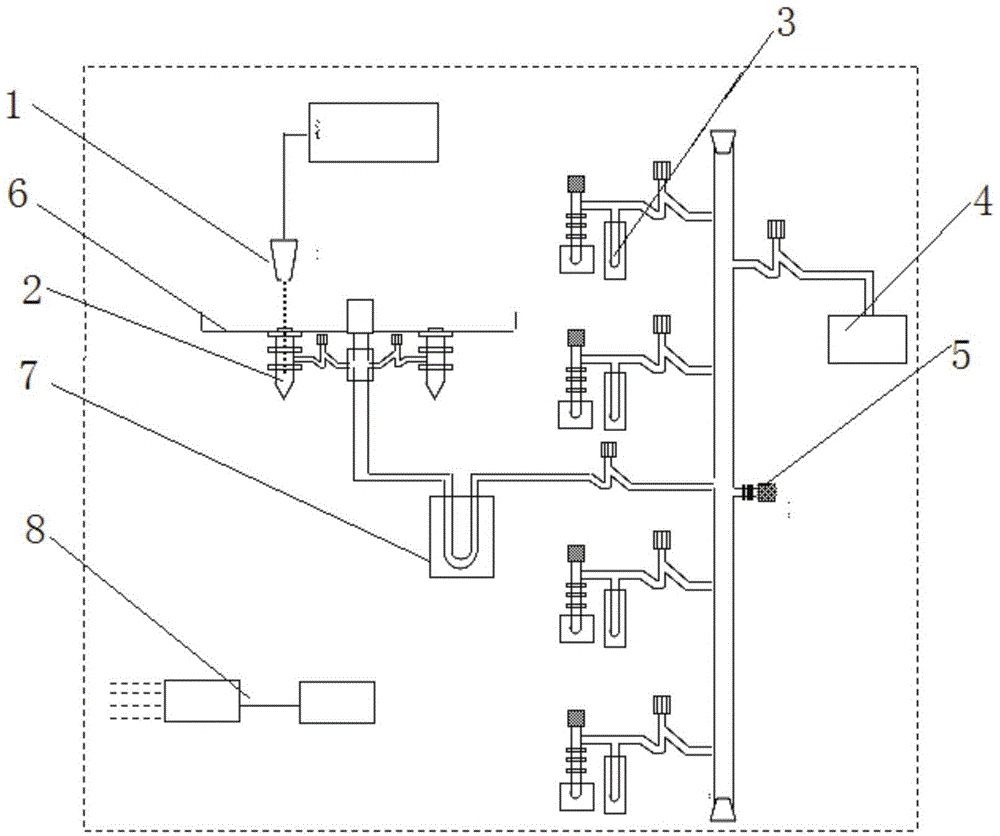

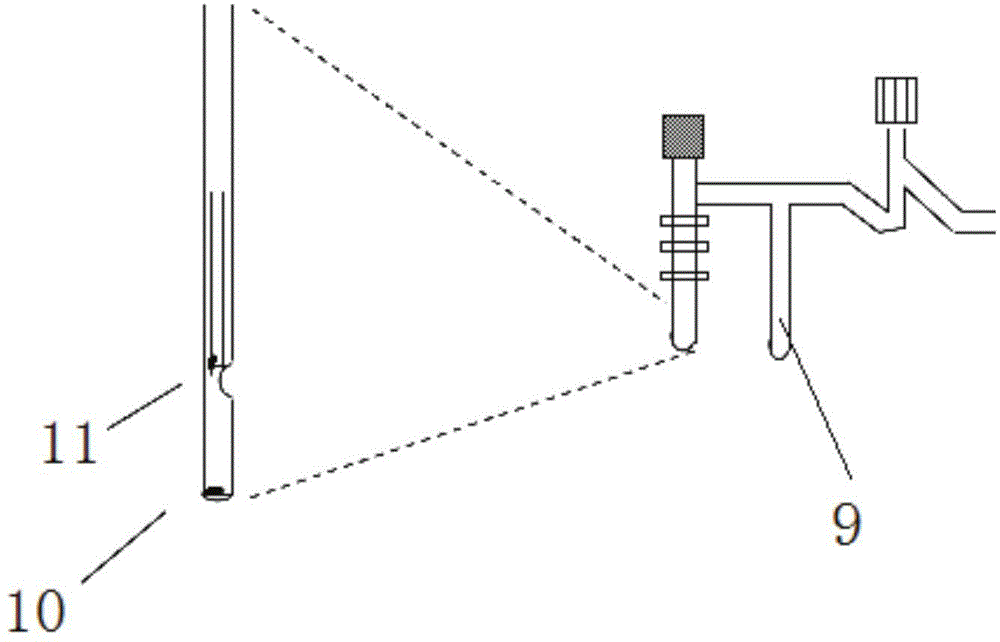

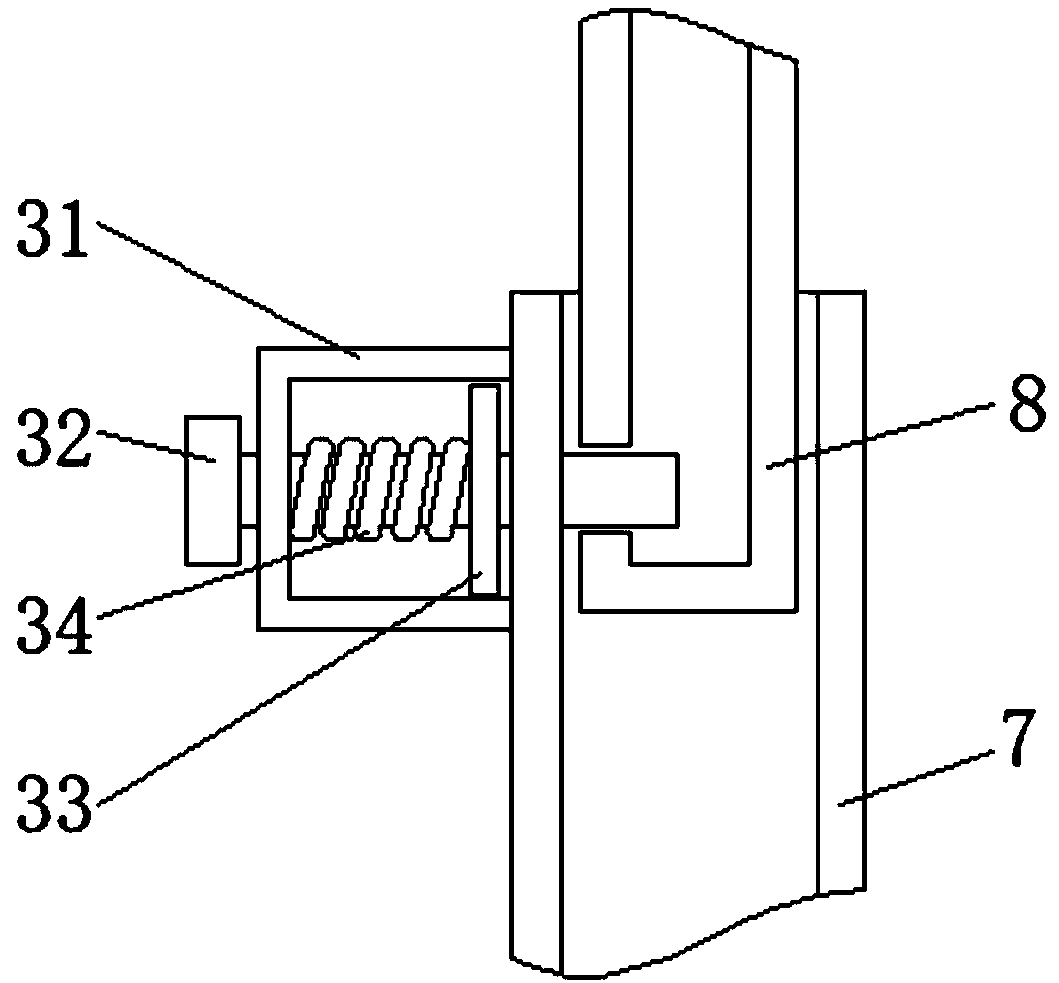

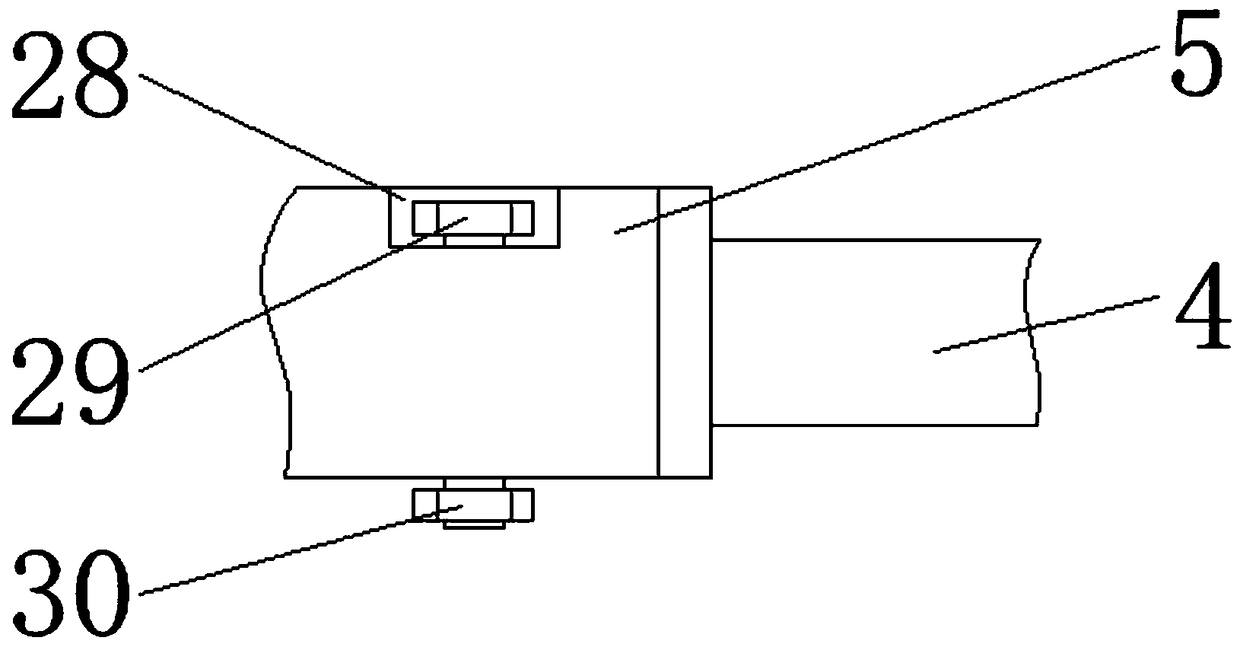

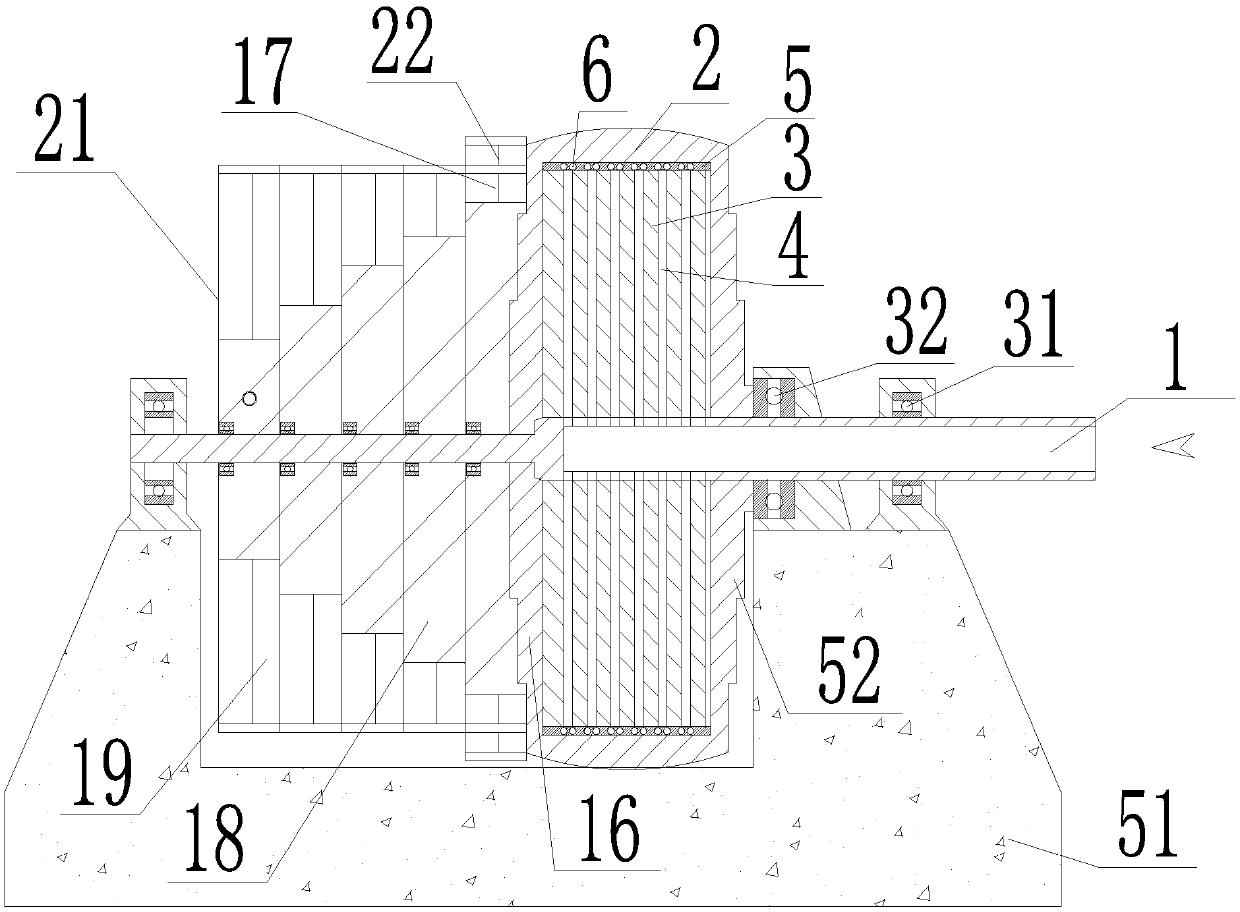

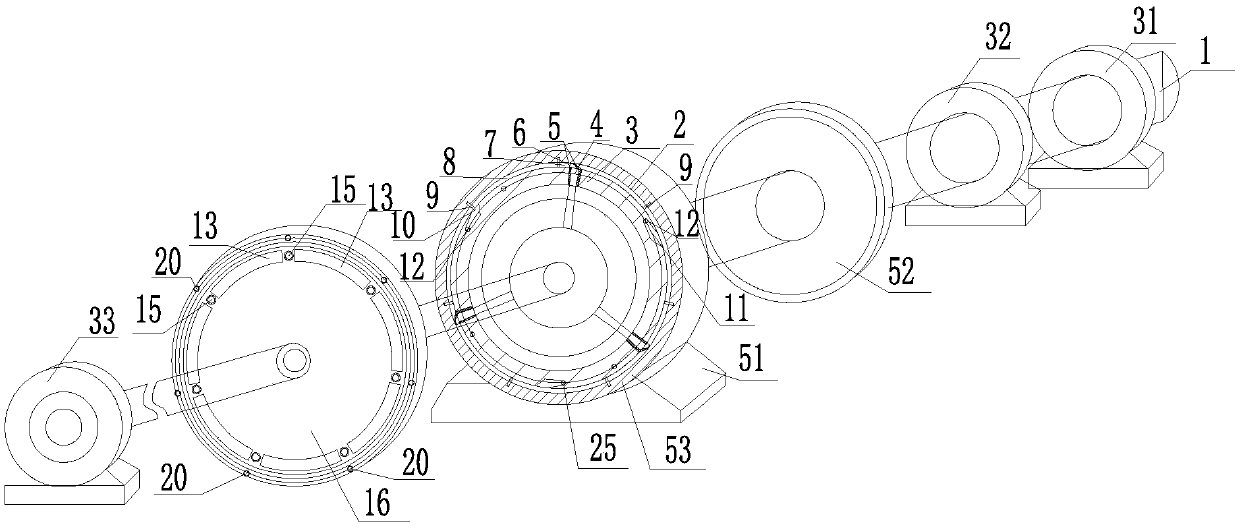

The invention discloses a six-channel aggregation-fusion type squeezing nozzle. The squeezing nozzle is provided with six thread inlets and one thread outlet and is suitable for a fused deposition modeling type (FDM) all-true color three-dimensional printer control system capable of achieving precision printing. Raw material printing threads of each color can be fused without a temperature difference in a nozzle aggregation fusion mixing and stirring cavity in a process of printing a color three-dimensional stereoscopic workpiece, the colored threads are extruded, a thread outlet caliber can be changed, and printing, all true color and high precision can be achieved. Accordingly, the mechanical strength of the printed workpiece reaches the mechanical strength index of the material, maintenance and replacement are convenient, resources are saved, energy consumption is reduced, the cost is reduced, and the nozzle is simple in structure, stable and reliable.

Owner:辽宁重彩立体打印机有限公司

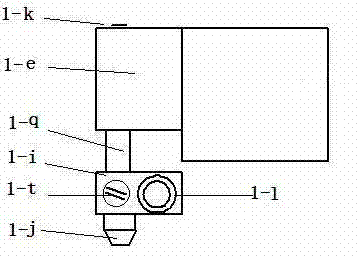

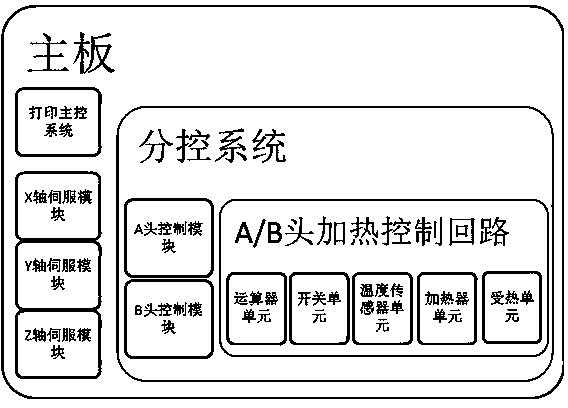

Control system for stackable multi-color-head three-dimensional printer capable of realizing precision printing

ActiveCN103448247AGuaranteed printing qualityEliminate the assembly processControl systemComputer printing

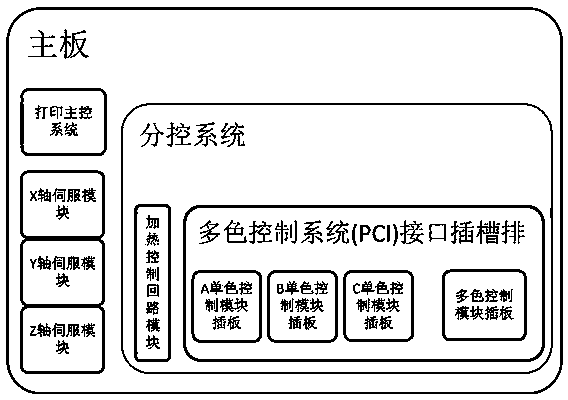

The invention discloses a control system for a stackable multi-color-head three-dimensional printer capable of realizing precision printing. A plurality of color heads of the stackable multi-color-head three-dimensional printer are used for separating hardware parts of a control loop and a heating control loop of each wire feeding pump from a motherboard to form a modular plug-board structure capable of easily ensuring the symmetry consistency; the modular plug-board structures are respectively plugged into interface slots of a heating system and a multi-color control system on the motherboard; by virtue of the symmetry consistency of technical indexes and parameter values of each wire feeding pump, multi-color fuse wires can be fused without temperature difference in a sprayer nozzle when a multi-color-head three-dimensional workpiece is printed, color wires are extruded, and high printing precision is realized. The mechanical strength of the printed workpiece reaches mechanical strength indexes of a material. Meanwhile, the control system is convenient to maintain and replace, simple in structure, stable and reliable; resources are saved, and the energy consumption and the cost are reduced.

Owner:辽宁重彩立体打印机有限公司

Solar energy underground cross-season heat-storing method

InactiveCN101539335ASimple processEasy constructionOther heat production devicesSolar heat devicesSolar energy storageMixed materials

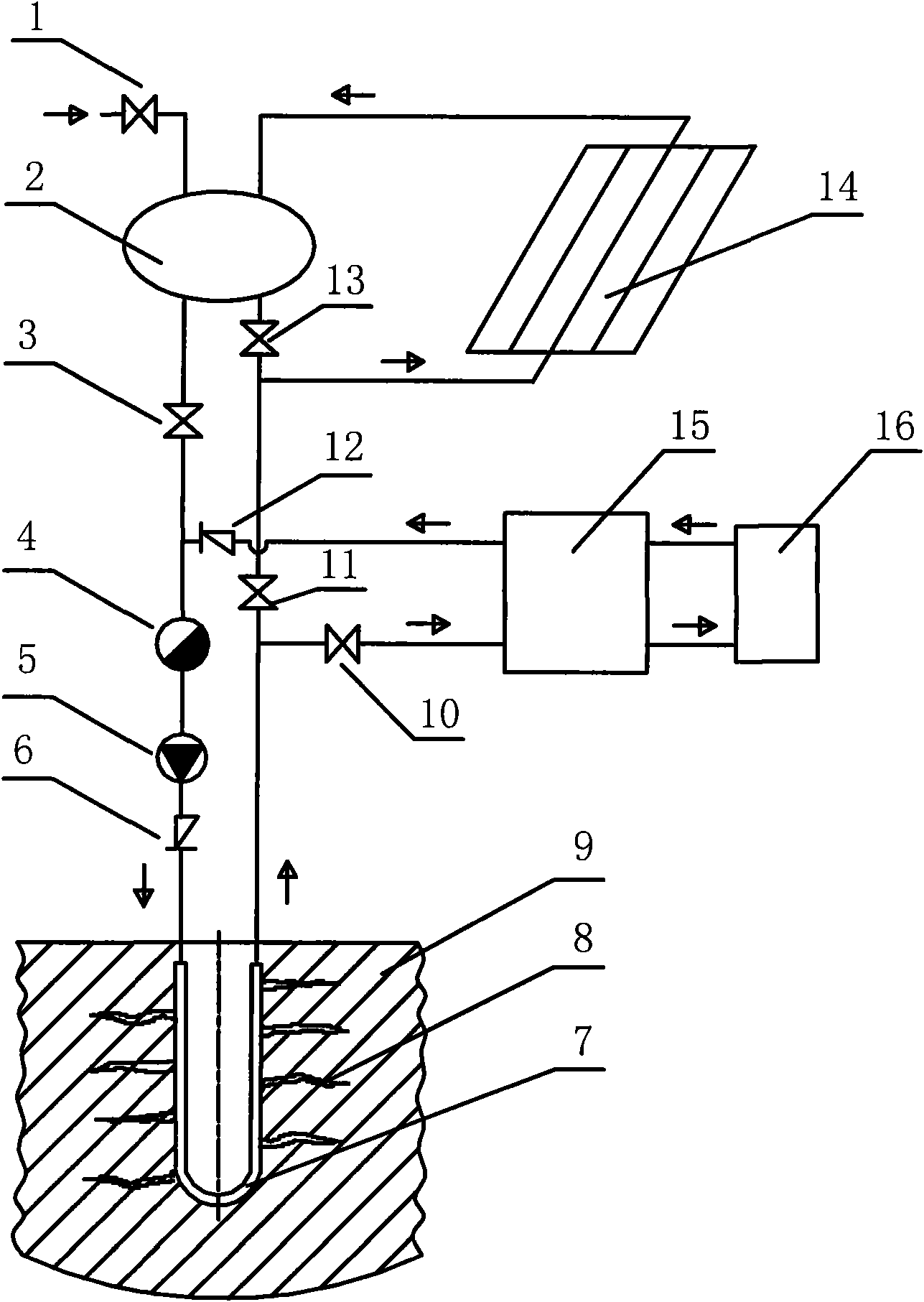

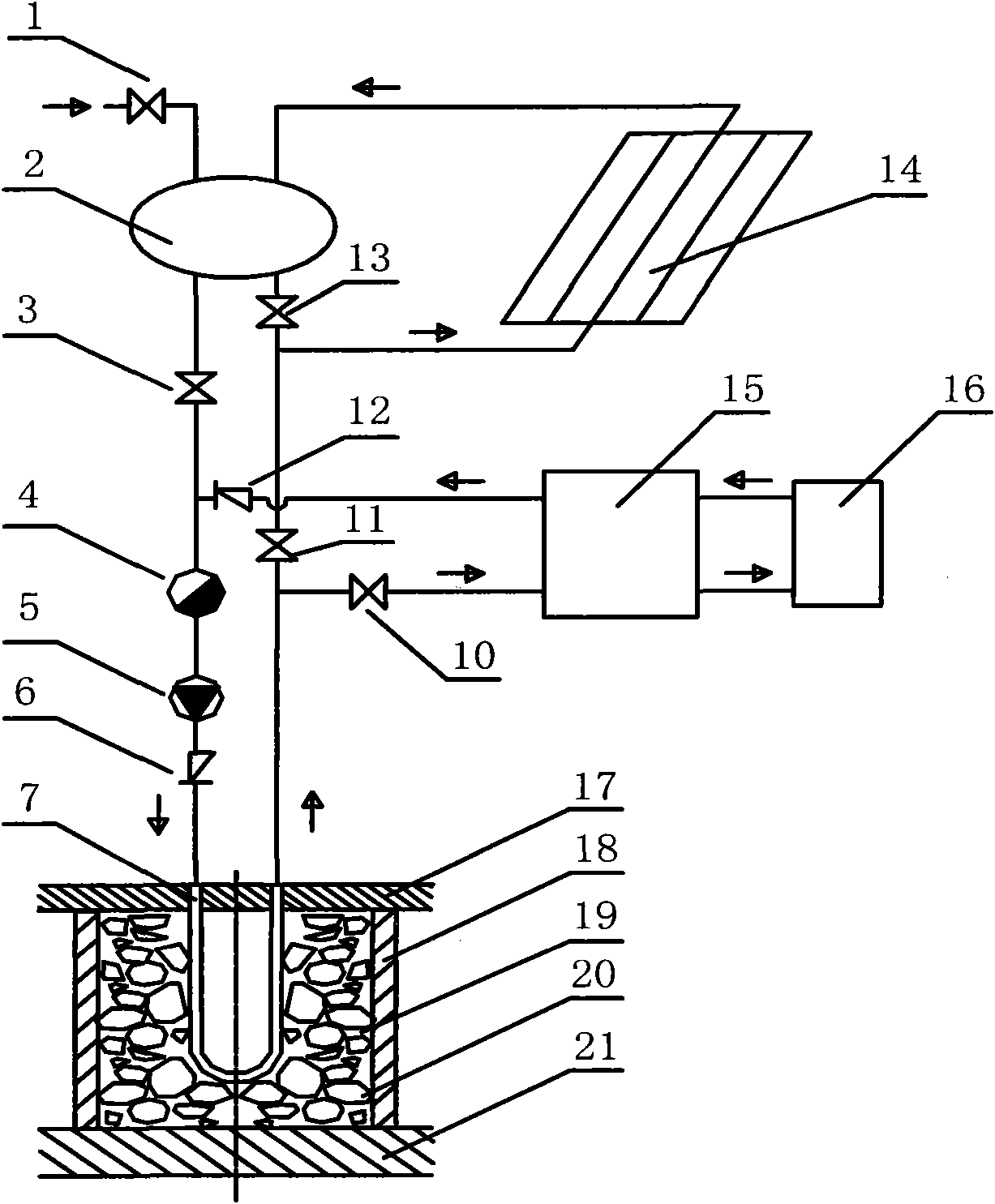

The invention relates to a solar energy underground cross-season heat-storing method. In a clay stratum region, a high pressure jet grouting technique is used for injecting high-thermal conductivity mixed materials into the clay stratum around a heat exchanger with high pressure so as to form a high thermal conductivity heat-storing body and fast store the solar energy into the soil by the heat exchanger; in a stratum region with high water permeability, a jet grouting method is used for injecting water-tight heat-insulated slip casting with high pressure so as to form a loop of sealed continuous water-tight heat-insulated purdah; the earth surface is covered by the clay to form a underground heat-storing sealed storehouse; and the heat exchanger which is arranged in the storehouse is used for continuously storing the solar energy into the soil. The invention can effectively store the solar energy or industrial waste heat into the underground with an underground heat-storing device and the heat exchanger, can extract and use the energy when the heat energy is needed, can store the solar energy or the industrial waste heat into the under ground in the summer and use the energy in the winter, can store the solar energy in the day and use the energy in the night, and has simple technology, simple construction, good heat-storing effect proved by experiment and good utilization ratio of thermal efficiency.

Owner:JILIN UNIV

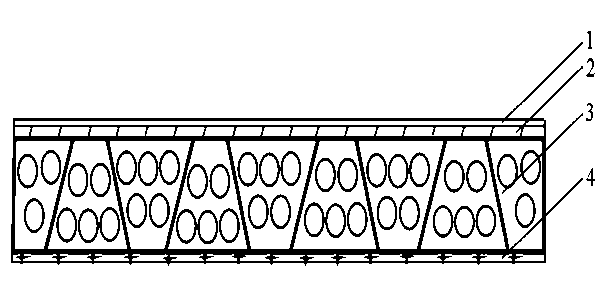

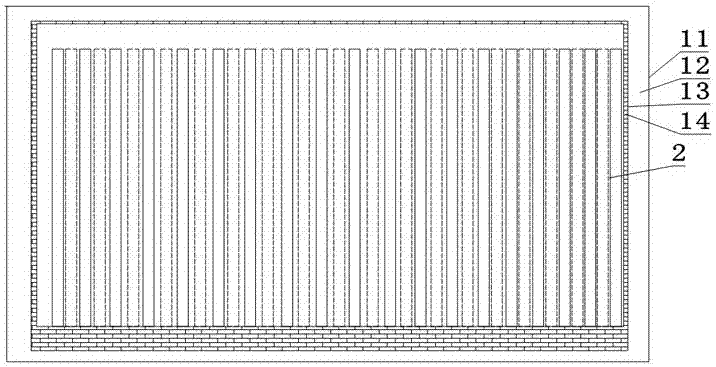

Functional floor heating floor made of alloy materials and preparation method thereof

ActiveCN103541539ASimple preparation processImprove thermal conductivityAntifouling/underwater paintsSynthetic resin layered productsPolymer alloyPolyvinyl chloride

The invention discloses a functional floor heating floor made of alloy materials and a preparation method thereof. The floor heating floor is structurally characterized by being of a four-layer composite structure, wherein the bottom layer is a vacuum coating reflective layer; a backing material layer is arranged on the reflective layer and made of polyvinyl chloride (PVC)-based polymer alloy composite materials; a coextru-lamination decorative layer is arranged on the backing material layer; the backing material layer and the decorative layer are integrally formed to an integral structure through a co-extrusion extrusion process; the top layer is an ultraviolet (UV) processing transparent antibacterial wear-resisting layer. The invention further discloses a method for preparing the functional floor heating floor. The method comprises the following steps of (1) blending and preparing of the backing material layer; (2) online coextru-lamination of the decorative layer and the backing material layer; (3) online embossing processing of the surface of the decorative layer; (4) vacuum coating of the surface of a board; (5) UV antibacterial wear-resisting processing of the surface layer. The method is simple in process progress. The floor heating floor prepared by the method is good in floor heating conductivity, dimension stability, antifouling and environment-friendly performance and using durability.

Owner:安徽圣源橡塑科技有限公司

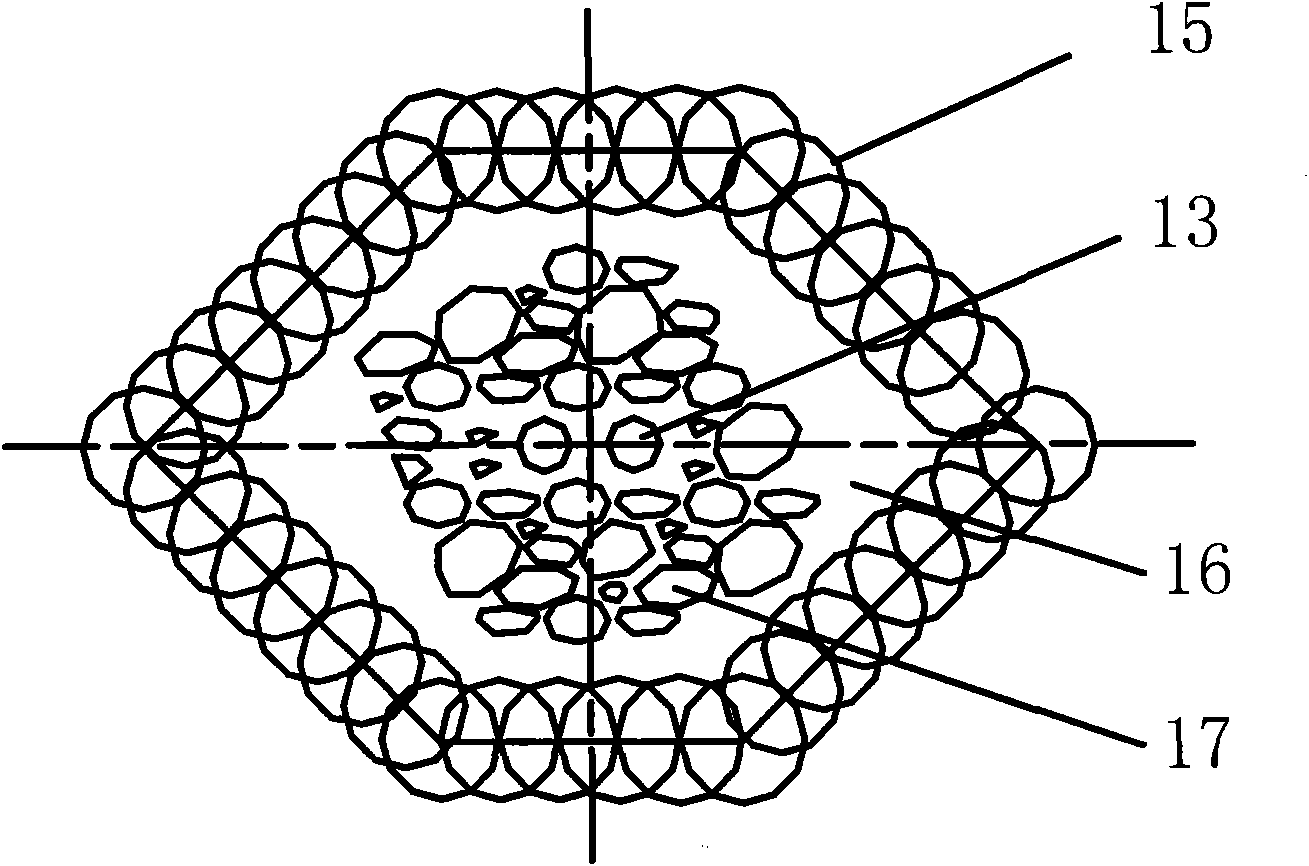

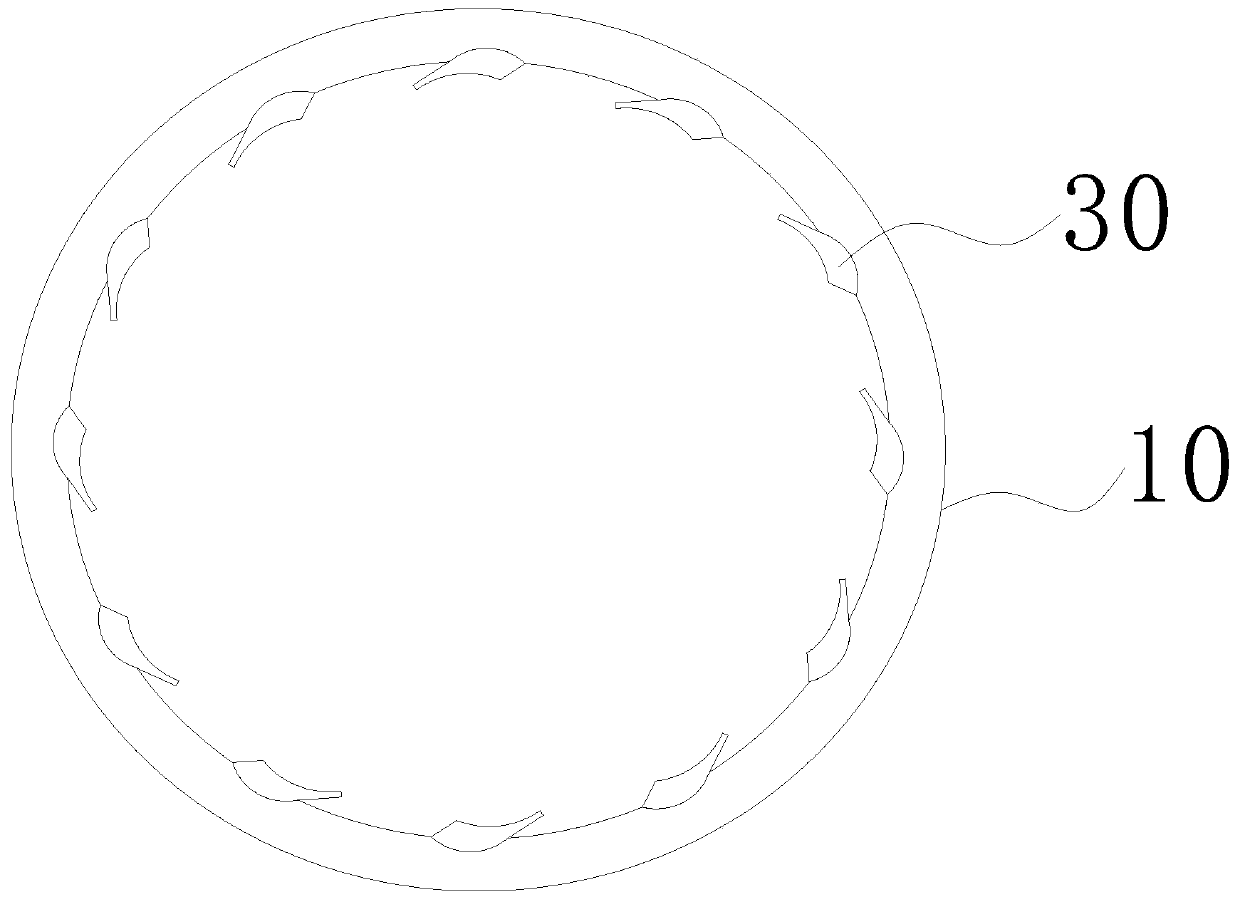

Two ends straight through type all glass vacuum heat collection tube of solar energy

InactiveCN1959293AGuaranteed working lifeTake advantage ofSolar heating energySolar heat devicesDegasserWave form

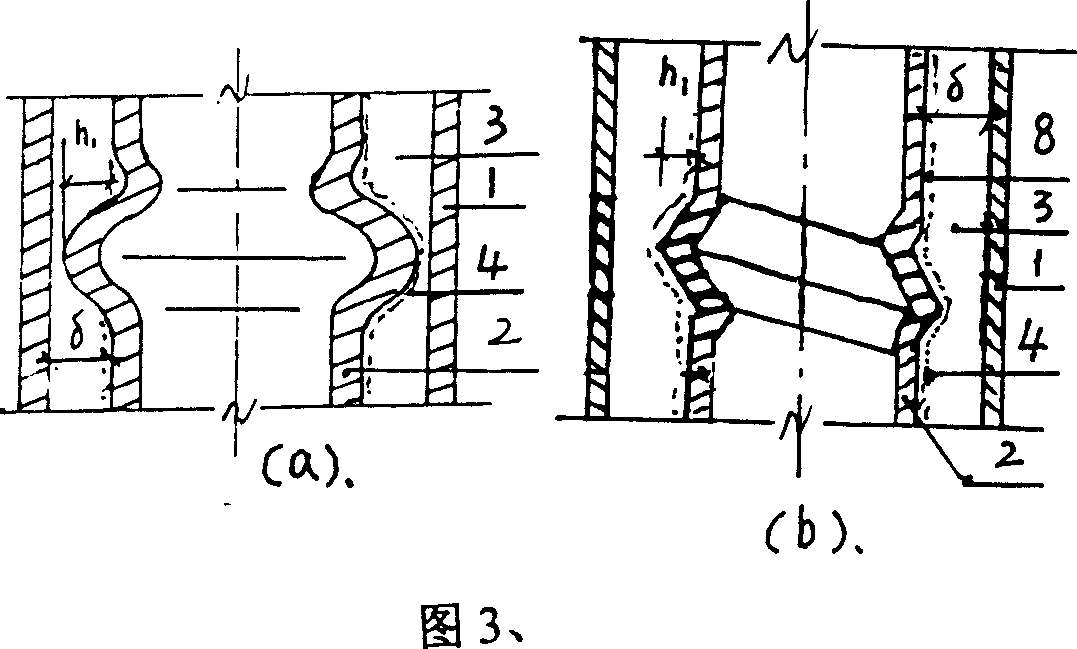

A glass vacuum solar heat collection tube of through two-end type consists of external glass tube, internal tube with corrugated body, absorption coated layer, elastic support and degasser. It is featured as setting space between two said tubes to be vacuum cavity, melt-jointing two ends of two said tubes to be an integral body for sealing two ends with each other and setting circular wave form ledges on internal tube to be distributed in mode of group wave ledges being not continuously set.

Owner:罗赞继 +2

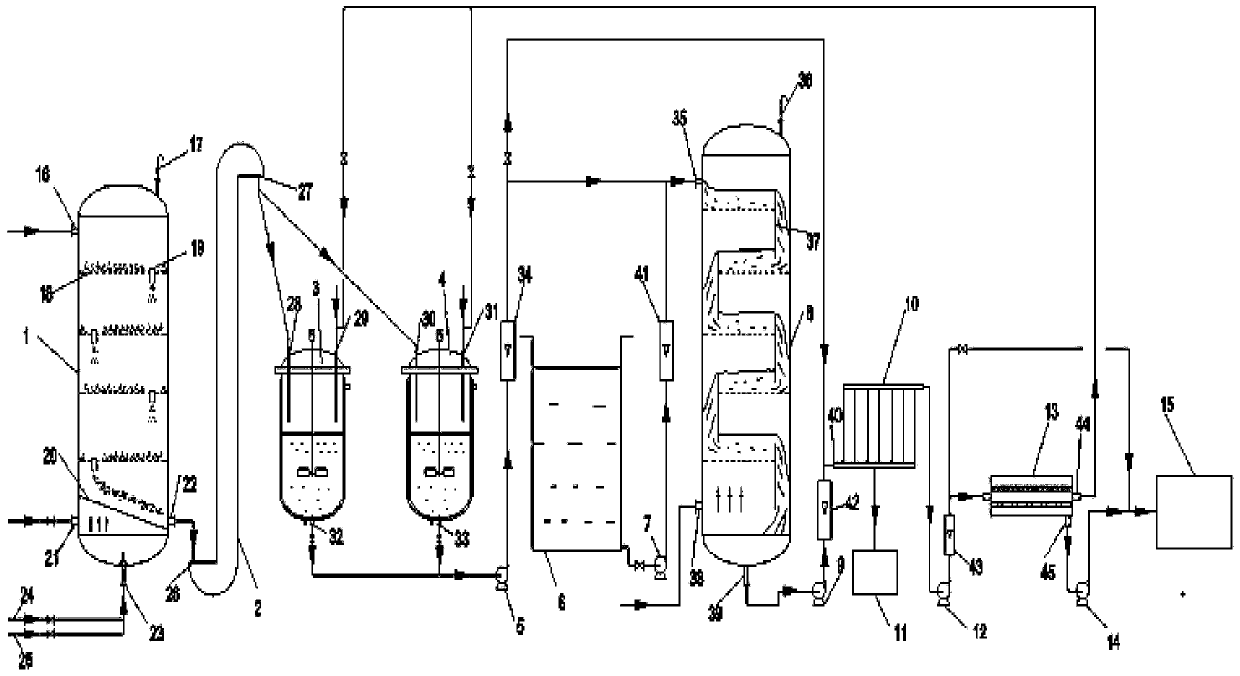

Organic molecule C14 dating sample preparation system and method

InactiveCN103558073APromote combustionBurn fullyPreparing sample for investigationDisplay deviceCopper oxide

The invention relates to the field of scientific research and in particular relates to an organic molecule C14 dating sample preparation system and method. The method comprises the following steps: filling an organic molecule sample into a quartz tube in a vacuumizing environment, adding copper oxide to serve as an oxidizing agent, carrying out laser heating, purifying, directly pouring the purified material into a graphite target synthetic unit filled with iron powder and zinc granules, carrying out a synthetic reaction by adopting a laser heating method, and directly monitoring the synthetic conditions through a pressure monitoring display in the synthetic process, thus accurately obtaining a high-quality graphite target needed for dating. Compared with a traditional sample preparation system, the system disclosed by the invention has the advantages that the laser heating method is introduced on the basis that the reliability is improved, so that the heating is centralized and rapid, and the thermal efficiency is high in utilization rate. The graphite target synthesis and a CO2 combustion system are comprehensively integrated, intermediate links are reduced, pollution is avoided, and the dating reliability is improved. The synthetic reaction conditions are monitored by adopting pressure, and the reaction speed is timely known.

Owner:NORTHWEST UNIV(CN)

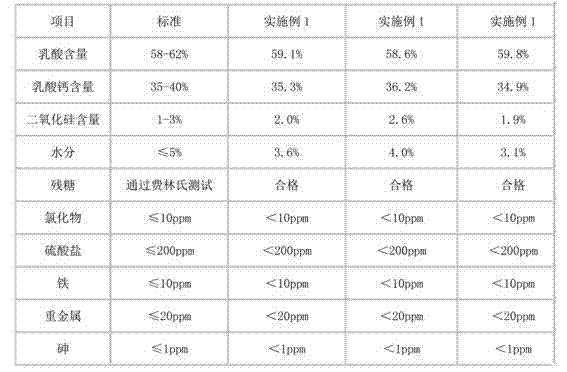

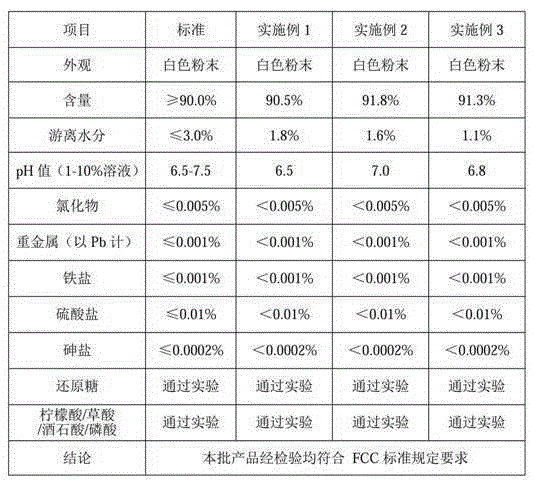

A low-temperature granulating method of powdered lactic acid

ActiveCN104117327AReduce drying energy consumptionReduce energy consumptionGranulation by liquid drop formationCold airThermal energy

A low-temperature granulating method of powdered lactic acid is provided. The method includes following steps: 1) heating 900 parts by weight of lactic acid having a content higher than 99% in a reactor to 90-95 DEG C, adding 97.6 parts by weight of calcium oxide, and adding 2 parts by weight of silicon dioxide powder after the calcium oxide is fully reacted to obtain a mixed solution; and 2) maintaining the temperature of the mixed solution to be higher than 95 DEG C, conveying the material to nozzles at the upper part of a fluidized bed spraying granulator, mixing the material with compressed air having a pressure of 0.2 MPa at the double-layer nozzles, spraying the solution in a vaporific manner, feeding cold air having a temperature of 4-14 DEG C from the lower part of the granulator so that the cold air and the vaporific solution are in contact and subjected to heat exchange, controlling the temperature of the cold air when the cold air is discharged from the upper part to be not higher than 40 DEG C, allowing the vaporific solution to fall to a sieve plate bed under the granulator after the vaporific solution is cooled and cured, and enriching to obtain the powdered lactic acid. By adoption of low-temperature granulating, the production efficiency is high, the thermal energy utilization rate is largely increased, and the method is suitable for popularization and production.

Owner:武汉三江航天固德生物科技有限公司

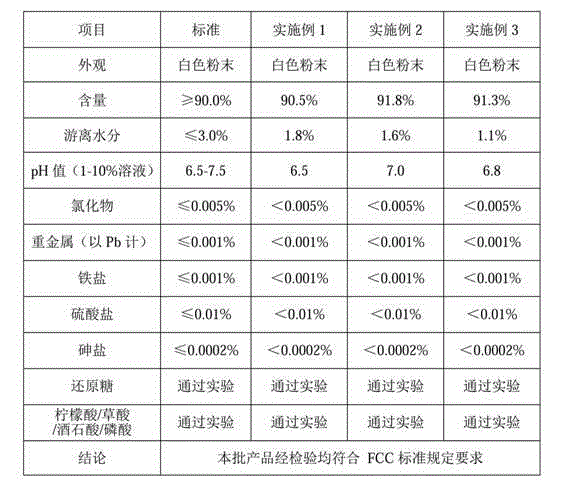

Solid sodium lactate low-temperature granulation method

ActiveCN104130120AGood colorOvercome the disadvantage of easy adhesionCarboxylic compound separation/purificationCold airSpray Granulation

The invention provides a solid sodium lactate low-temperature granulation method. The method comprises the following steps: (1) a sodium lactate solution is subjected to reduced-pressure evaporation by using a thin-film evaporator, wherein sodium lactate content in the solution is increased to 90-92wt% within 5min; and the obtained solution is discharged. During the reduced-pressure evaporation process, the pressure of the jacket heating steam of the thin-film evaporator is controlled at 0.2-0.4MPa, the temperature in the thin-film evaporator is controlled at above 90 DEG C, and the pressure in the thin-film evaporator is controlled at 0.04-0.05MPa; (2) the concentrated solution is pressed into a rotating centrifugation spray granulation machine through compressed air, and the temperature of the concentrated solution is maintained at above 90 DEG C, such that the concentrated solution is spayed as a mist from a high-speed rotation disk on the upper part of the granulation machine; at a same time, cold air with a temperature of 4-15 DEG C is synchronously delivered from above the granulation machine, and the temperature of cold air delivered out from the lower side part of the granulation machine is no higher than 45 DEG C; liquid mist is subjected to heat-exchange with the cold air, and is cooled and solidified, such that sodium lactate solid crystallized powder is obtained. According to the invention, low-temperature granulation is adopted, such that production efficiency is high, and heat energy utilization rate is greatly improved. The method is suitable for popularization and production.

Owner:武汉三江航天固德生物科技有限公司

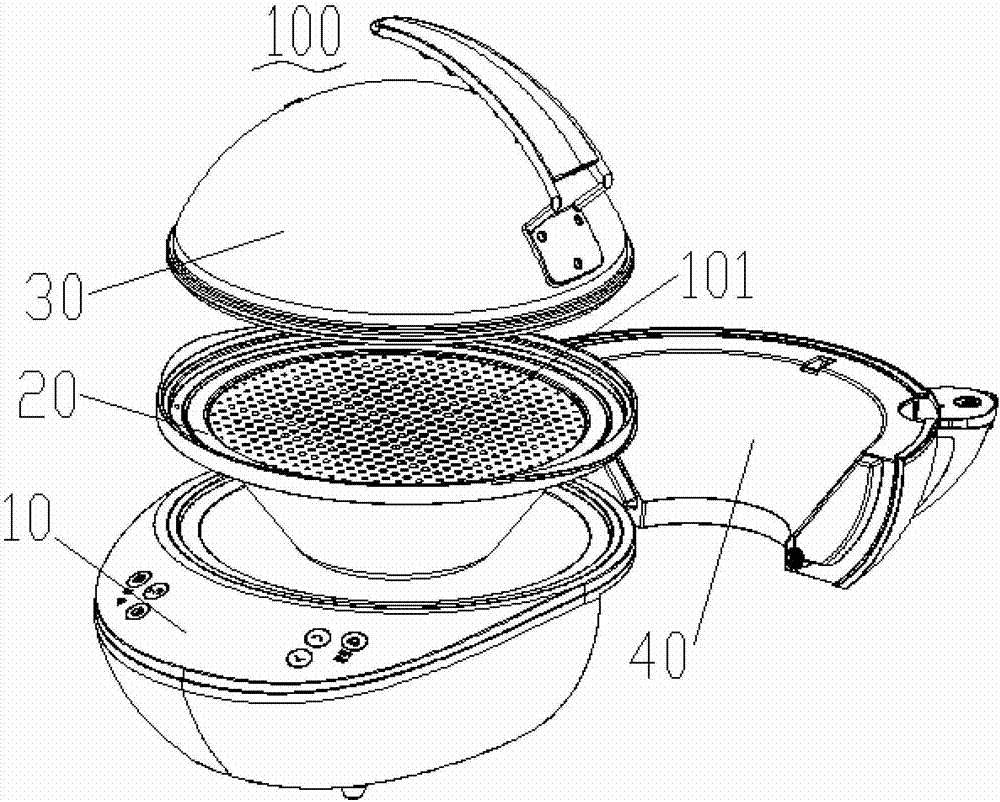

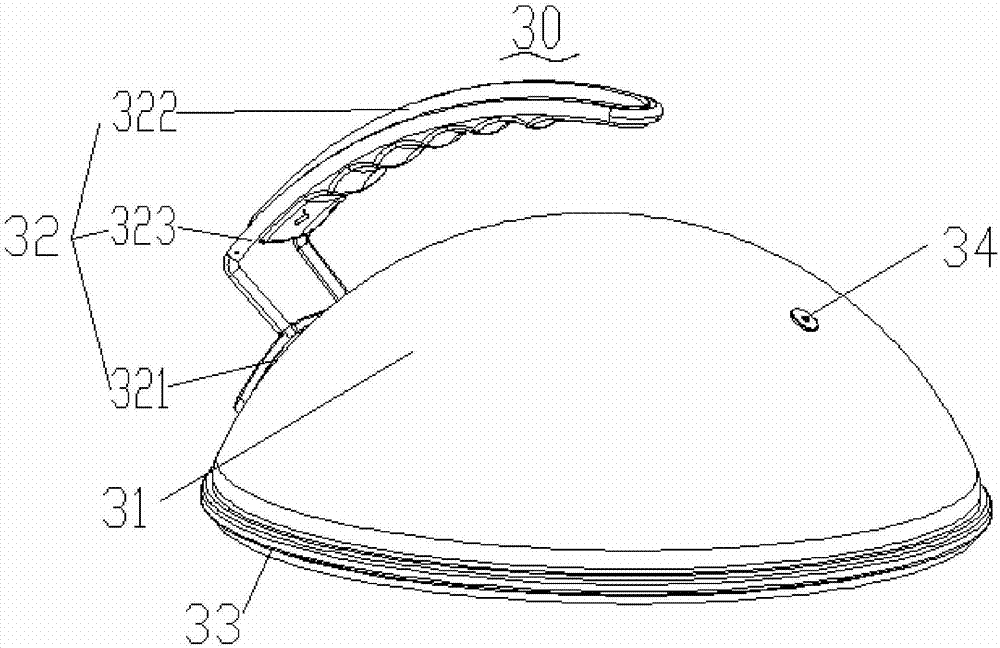

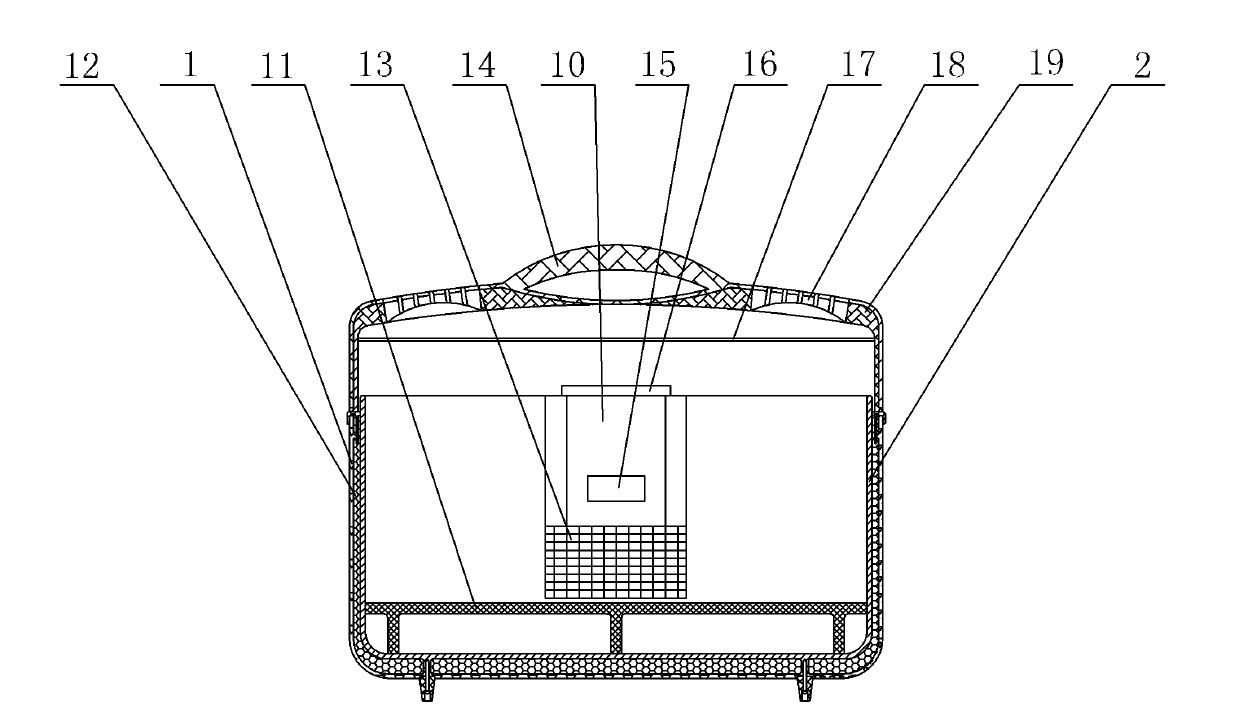

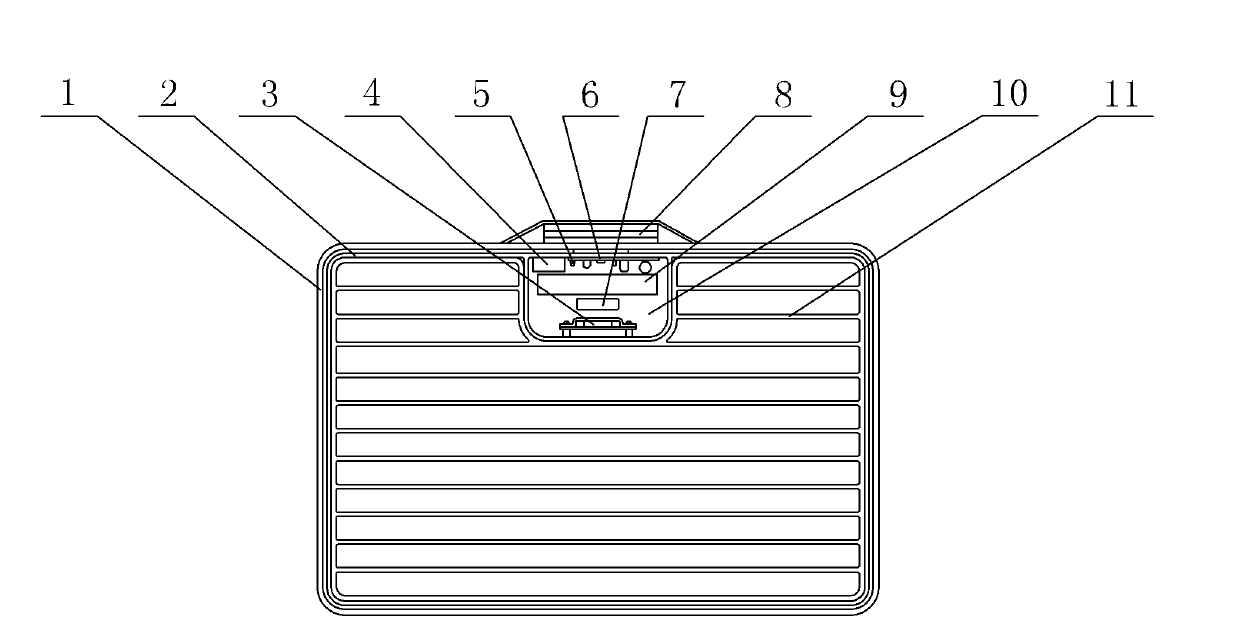

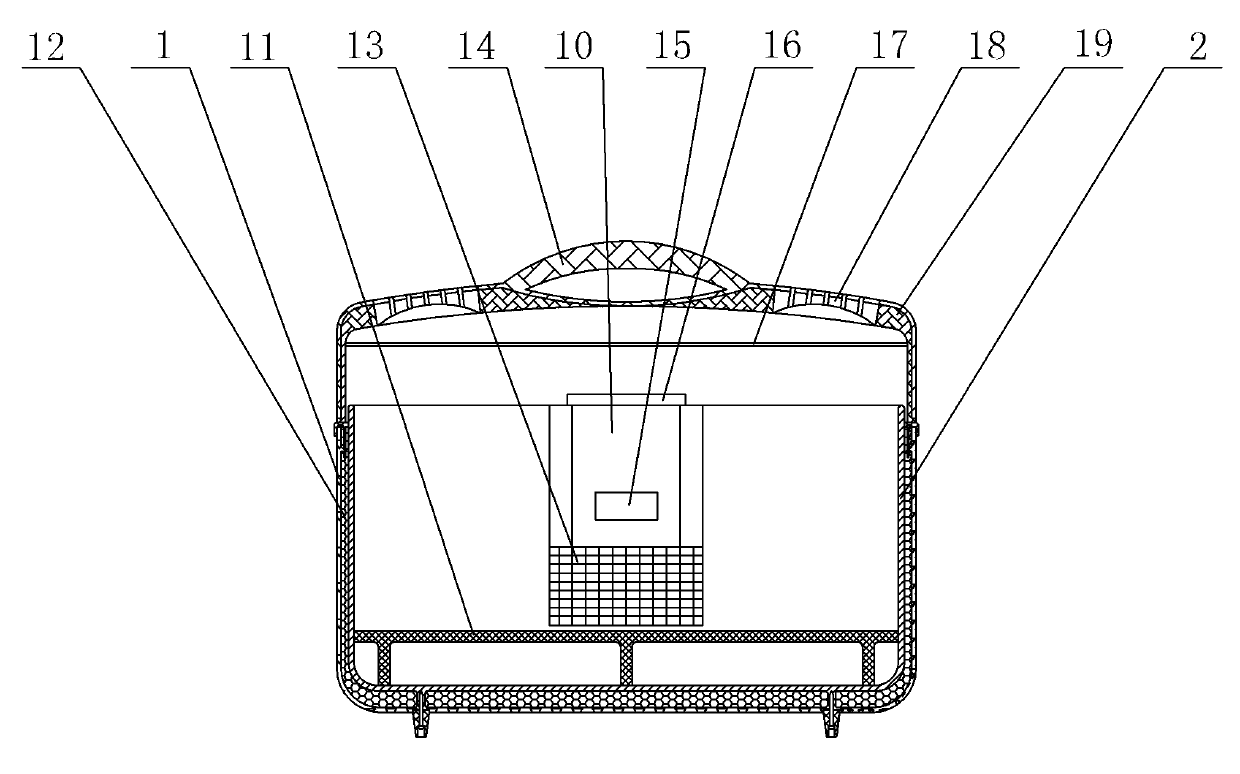

Steam cooker

PendingCN107048987AHigh thermal efficiency utilizationSimple structureCooking-vessel lids/coversSteam cooking vesselsEngineeringControl circuit

A steam cooker comprises a main machine, a cooker body on the main machine and a pot cover covering the cooker body. The cooker cover is of a curved-surface-shaped structure made of a high-borosilicate glass material, and the height of the curved surface is larger than 100 mm; the cooker body is of a conical structure, and the inner diameter of the cooker body is gradually increased from the cooker bottom to a cooker opening; a steam outlet is formed in the cooker bottom of the cooker body, and a switch assembly is arranged on the steam opening so as to control opening and closing of the steam opening. An NTC temperature sensing system and a safety protection switch device are arranged on the main machine, an NTC temperature sensor on the NTC temperature sensing system extends outwards relative to the main machine to be in contact fit with the cooker body, and a trigger rod of the safety protection switch device extends outwards relative to the main machine, so that the on-off control over a control circuit on the main machine can be realized by matching the trigger rod with the cooker body. The steam cooker has the advantages that the structure is simple, the use is convenient, and the use requirements of people for the steam cooker are greatly met.

Owner:NINGBO JIAYIN ELECTRICAL & MECHANICAL TECH CO LTD

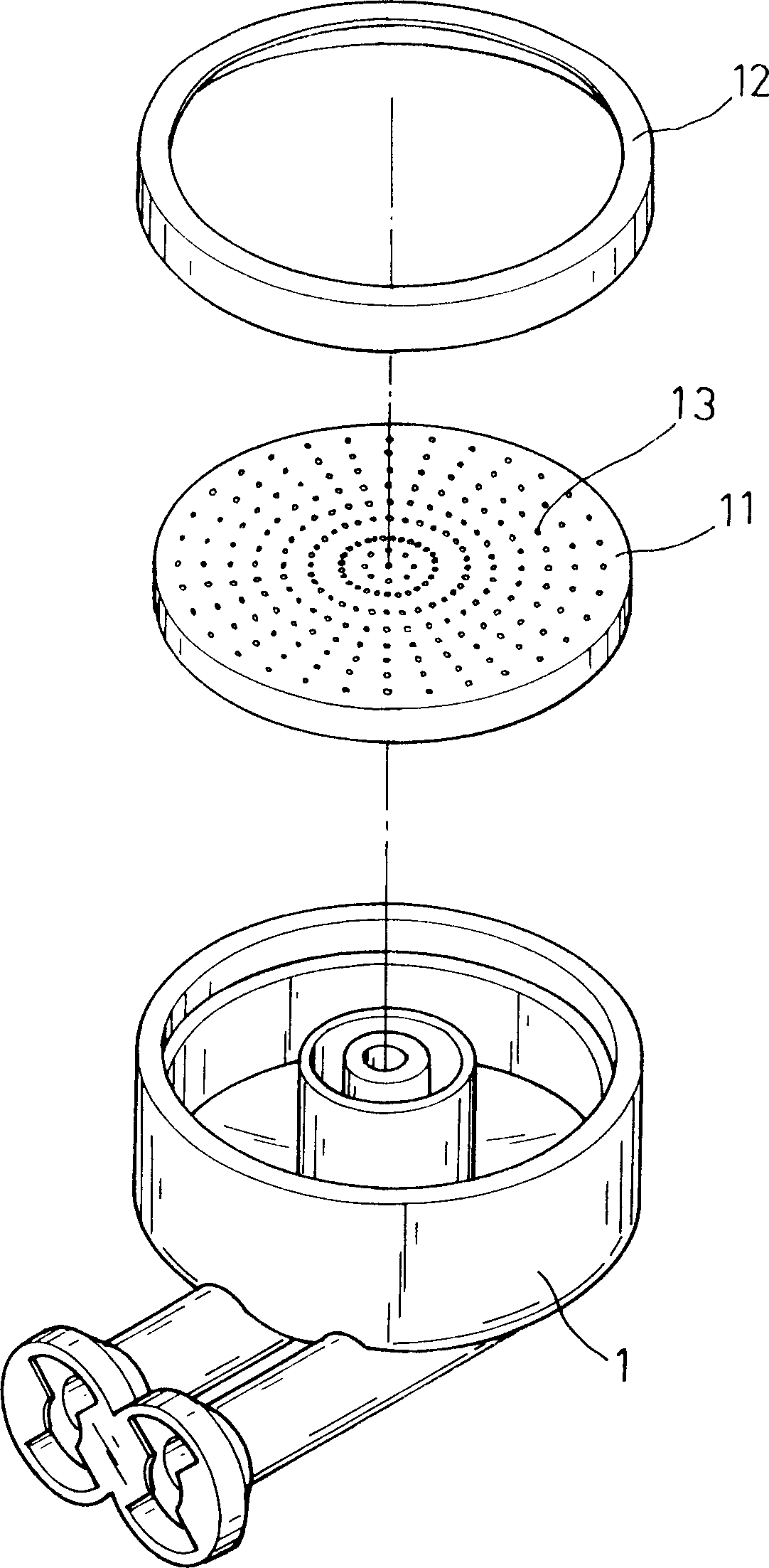

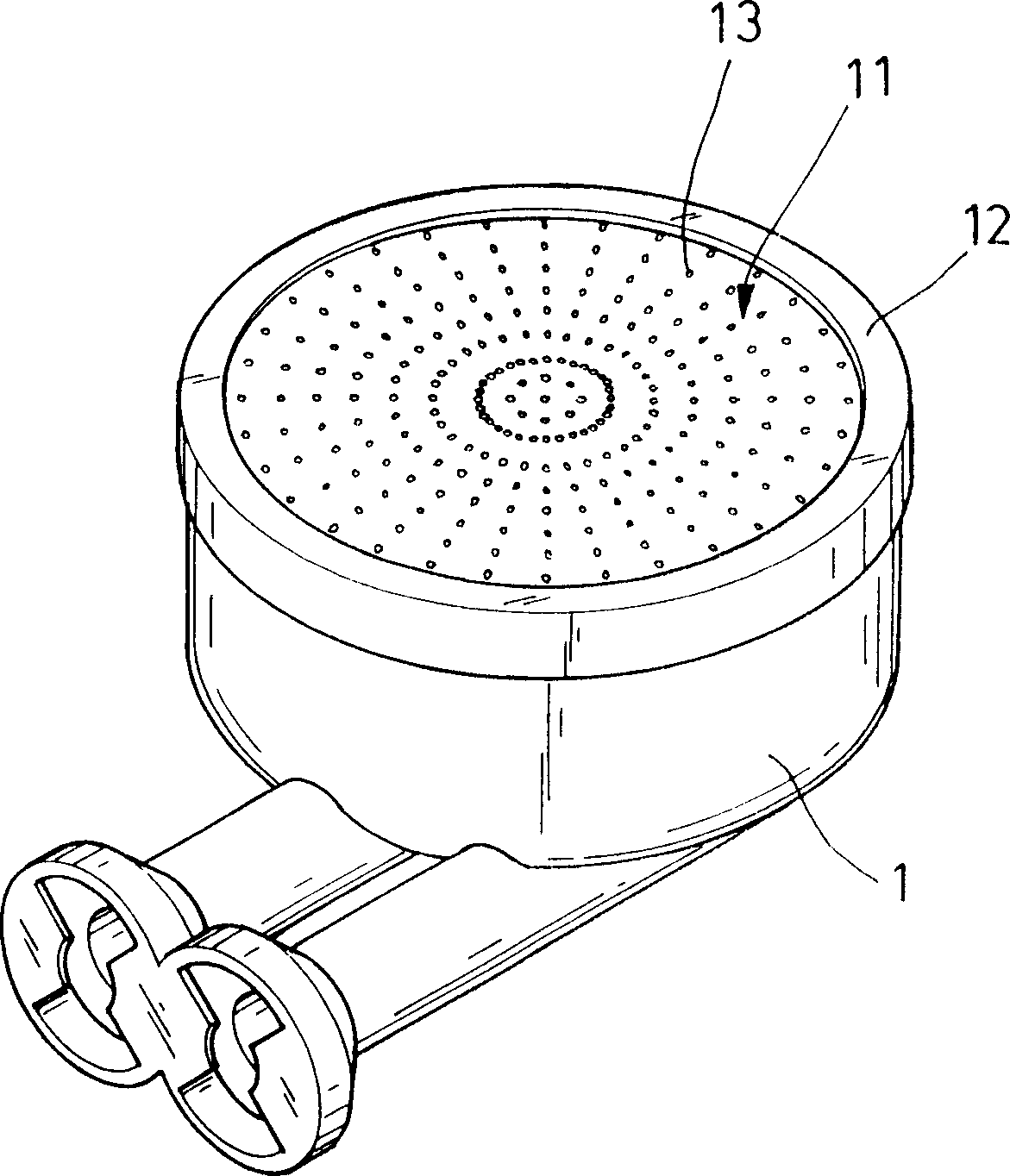

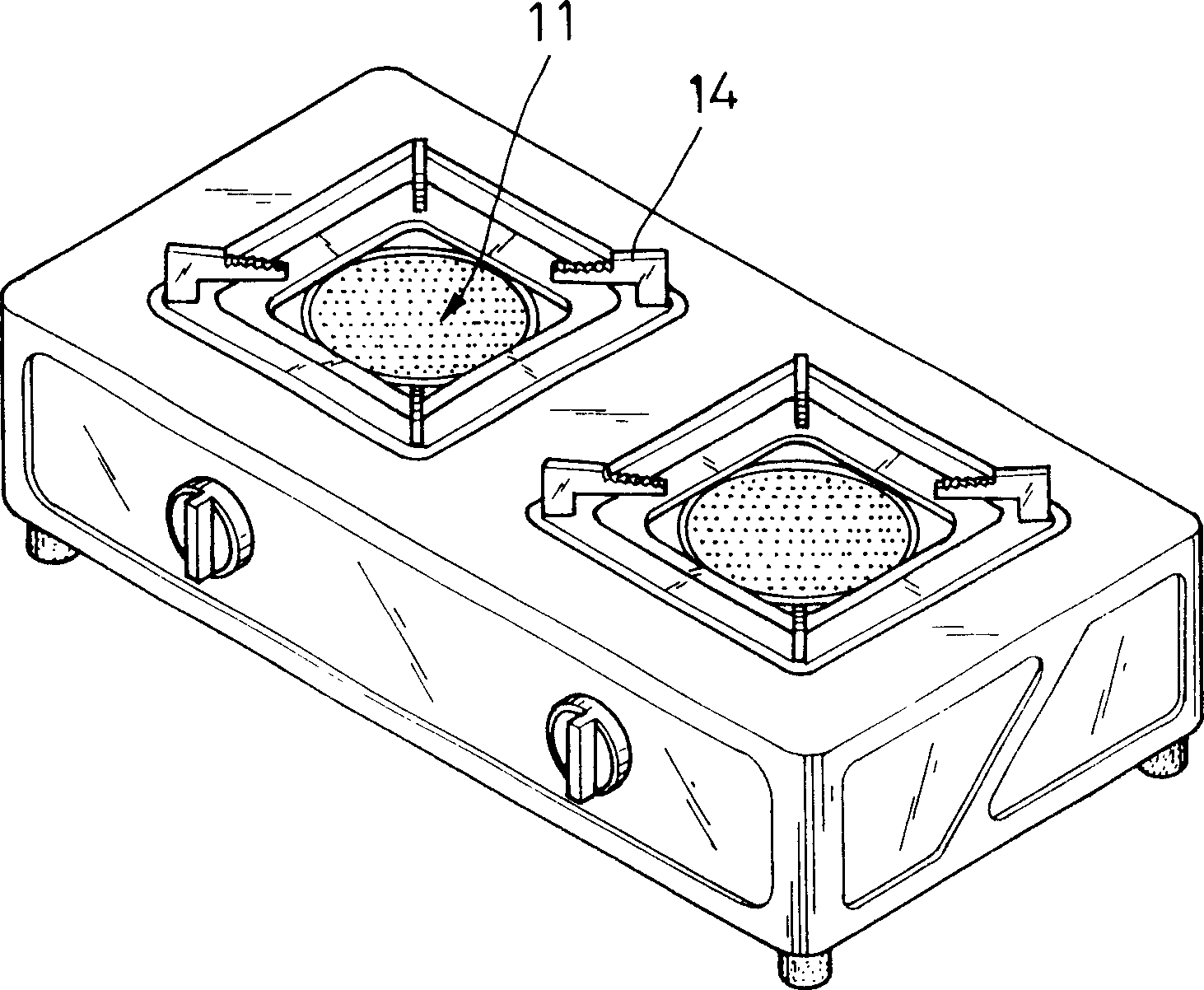

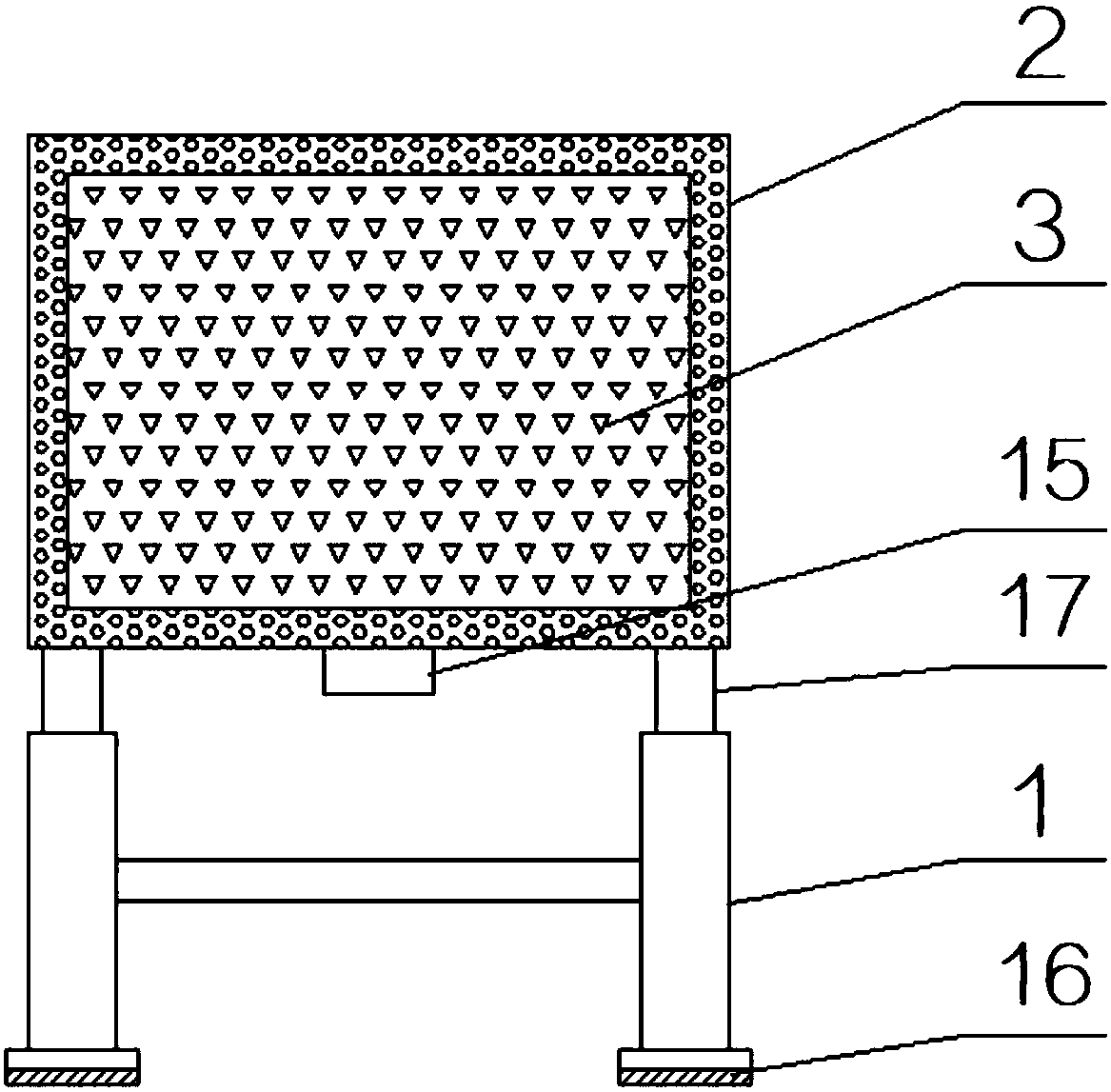

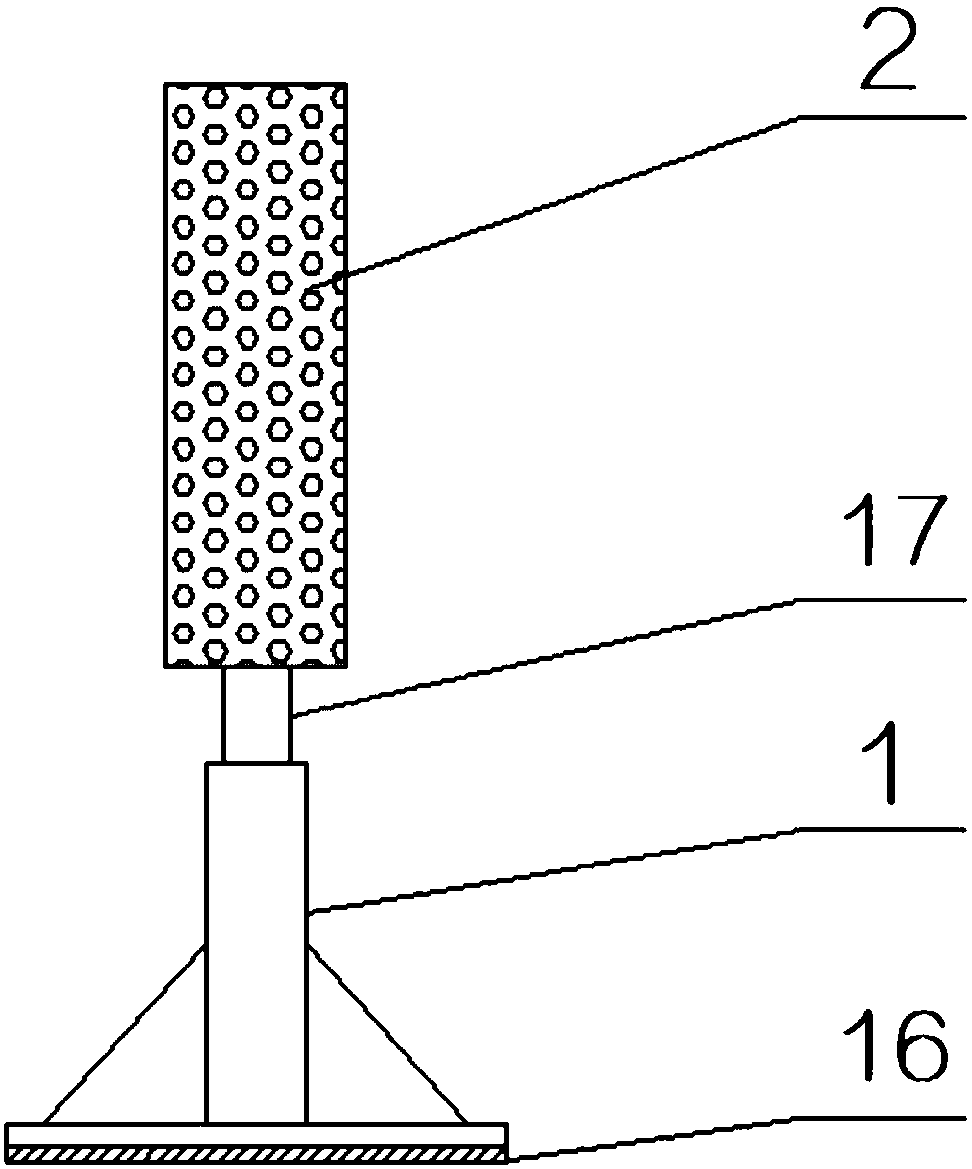

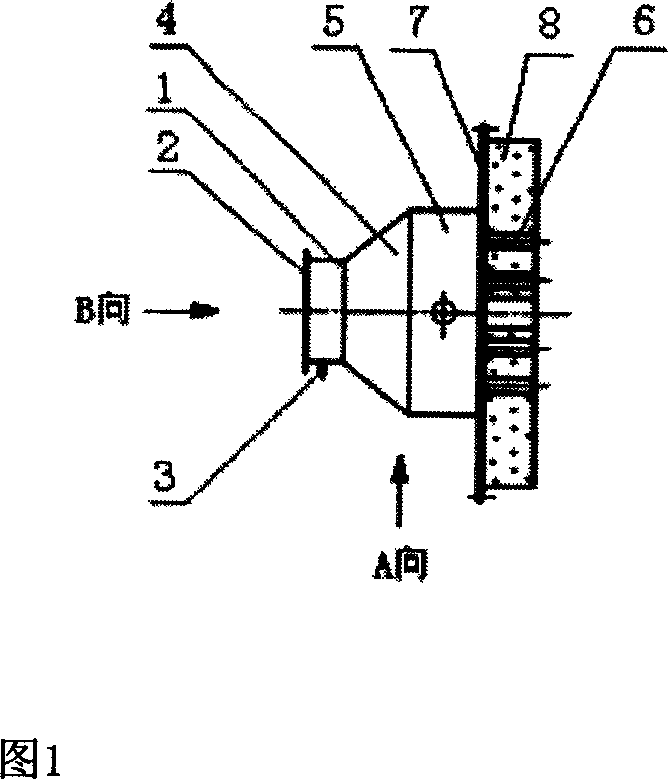

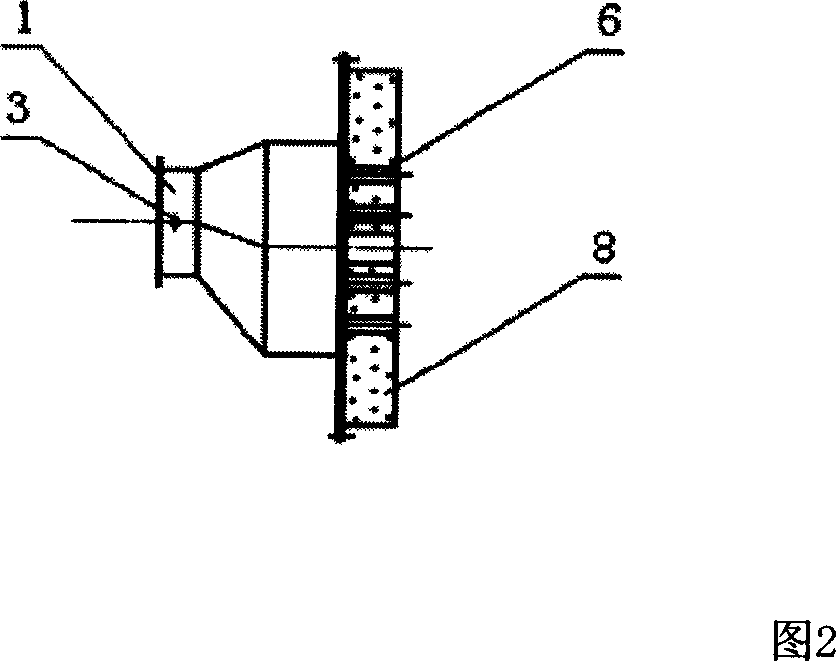

Heat accumulation type energy-saving infrared burner

InactiveCN1501024AMake full use of heat transfer characteristicsHigh thermal efficiency utilizationDomestic stoves or rangesLighting and heating apparatusCombustorHeat conducting

The heat converging energy-saving IR burner includes one burner unit with one IR ceramic plate possessing many small flame holes; one ring frame, which includes upper frame and lower frame set around the burner unit, forms inside annular exhaust passage and has top surface higher than the IR ceramic plate and inner ring surface formed by the inwards inclined top and with several exhaust holes; and exhaust set outside the ring frame. The present invention utilizes heat conducting characteristic fully to reach highest heat efficiency.

Owner:许胜发

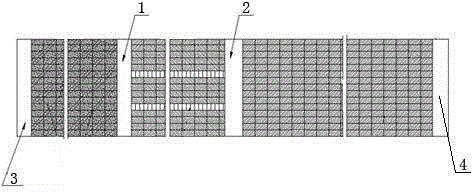

Castable kiln structure of cylindrical heat rotary equipment

Disclosed is a castable kiln structure of cylindrical heat rotary equipment. The castable kiln structure is characterized in that a kiln body is divided into a low-temperature feeding region, a high-temperature heat reaction region and an outlet and flow port. Retaining rings are arranged on regional boundaries of the low-temperature feeding region, the high-temperature heat reaction region and the outlet and flow port. The retaining rings protrude out of a kiln liner, so that the materials are enabled to turn over and change operation orbits through the retaining function of the protrusion height of the retaining rings when materials enter different temperature regions. The shortcomings that the kiln liner shaking during operation of a traditional bricked kiln liner to be separated from a steel casing to produce slip frequency with the same is free of overall strength, the kiln liner can be loosened and disintegrated instantly and cannot be maintained rapidly in a small range, and the like are effectively overcome, so that service life of the cylindrical kiln liner is prolonged by one to several times as compared with that of the bricked kiln liner, working cavities inside the kiln liner can be optionally changed according to technological requirements, damages to certain parts of the kiln liner do not cause affect to the service life of the whole kiln, and rapid maintenance in the small range can be achieved.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

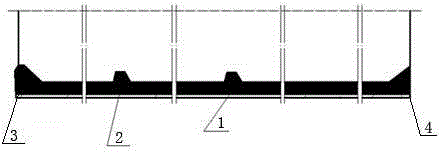

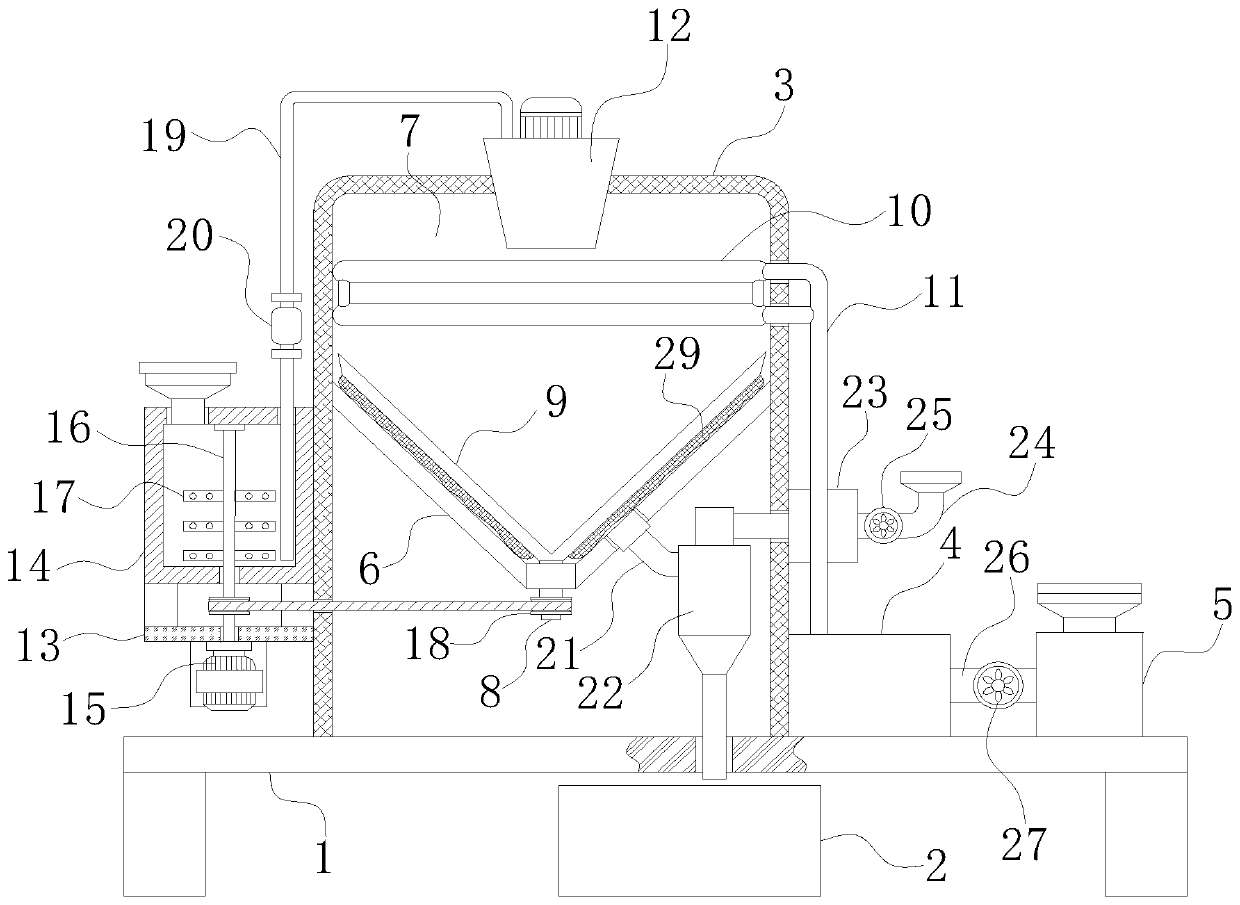

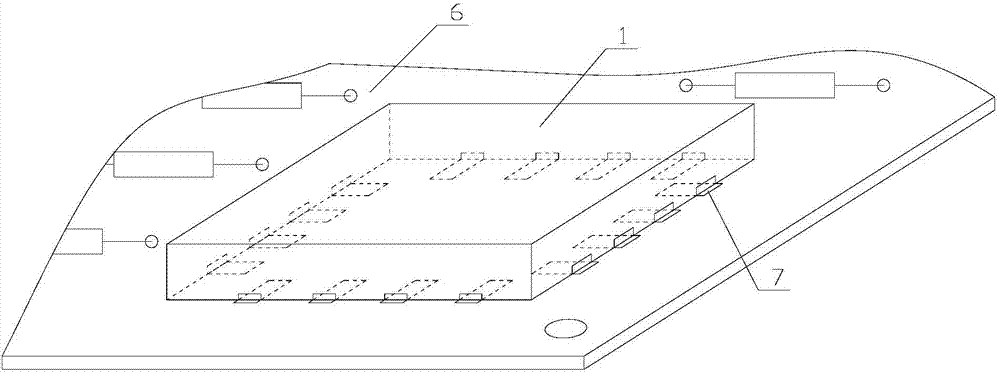

Drying device for preparing glucosamine sulfate double salt

InactiveCN111298464AImprove uniformityIncrease flow rateSugar derivativesEvaporator accessoriesGlucosamine SulfateStructural engineering

The invention relates to the technical field of preparation of glucosamine sulfate double salt, and discloses a drying device for preparing the glucosamine sulfate double salt. The drying device comprises an equipment platform and a receiving box, wherein a drying tower, a heating box and a dehumidifying box are fixedly mounted at the top of the equipment platform in sequence from left to right; bases are fixedly mounted at four corners of the bottom of the equipment platform; a funnel-shaped wall hopper is fixedly mounted on the inner wall of the drying tower; a drying cavity is formed between the top of the wall hopper and the upper end of the inner wall of the drying tower; a rotating rod is rotatably arranged at the bottom of the wall hopper in a penetrating mode; two stirring plates distributed in an equilateral triangle mode are fixed to the top end of the rotating rod; two circular cyclone pipes are fixedly installed at the upper end of the inner wall of the drying cavity and are communicated and fixed with each other through two guide pipes; and the outer circle surfaces of the right sides of the cyclone pipes are communicated with air guide pipes. The drying device of theinvention overcomes the problems that when existing drying equipment is low in efficiency and incapable of realizing thorough drying during preparation and drying and influences product quality.

Owner:JIANGSU SHUANGLIN MARINE BIOLOGICAL PHARM CO LTD

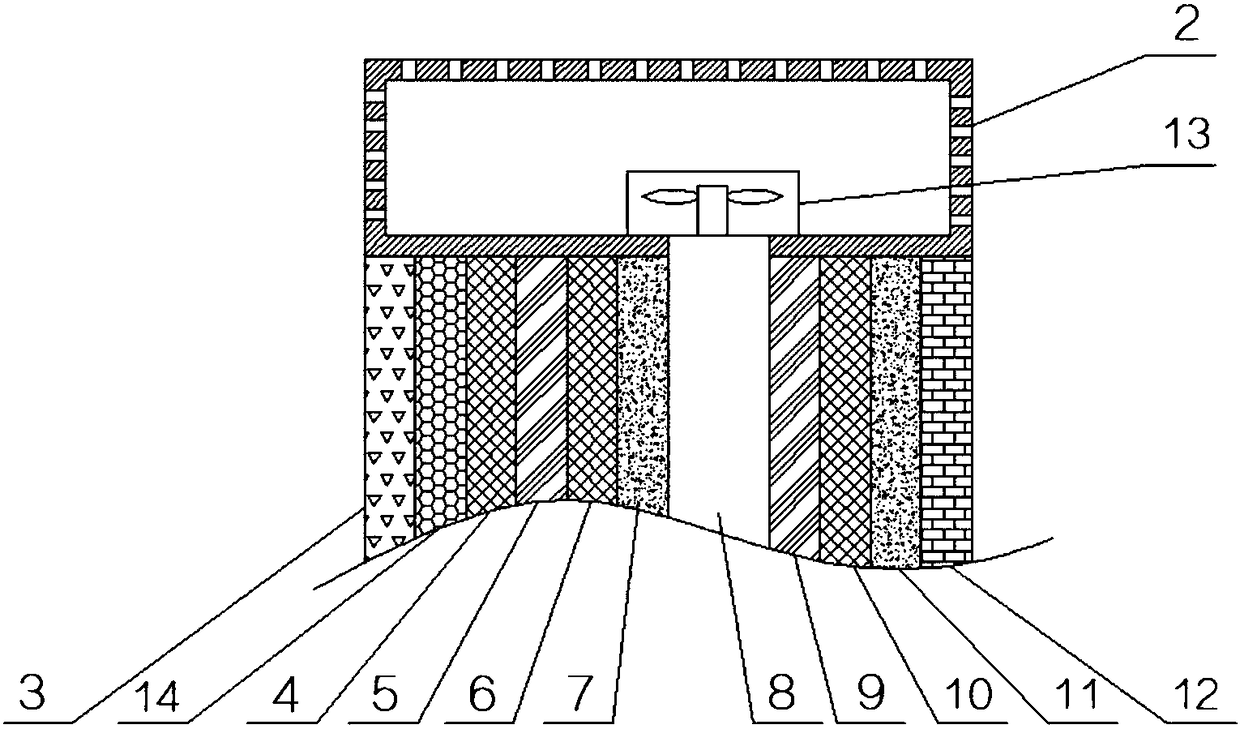

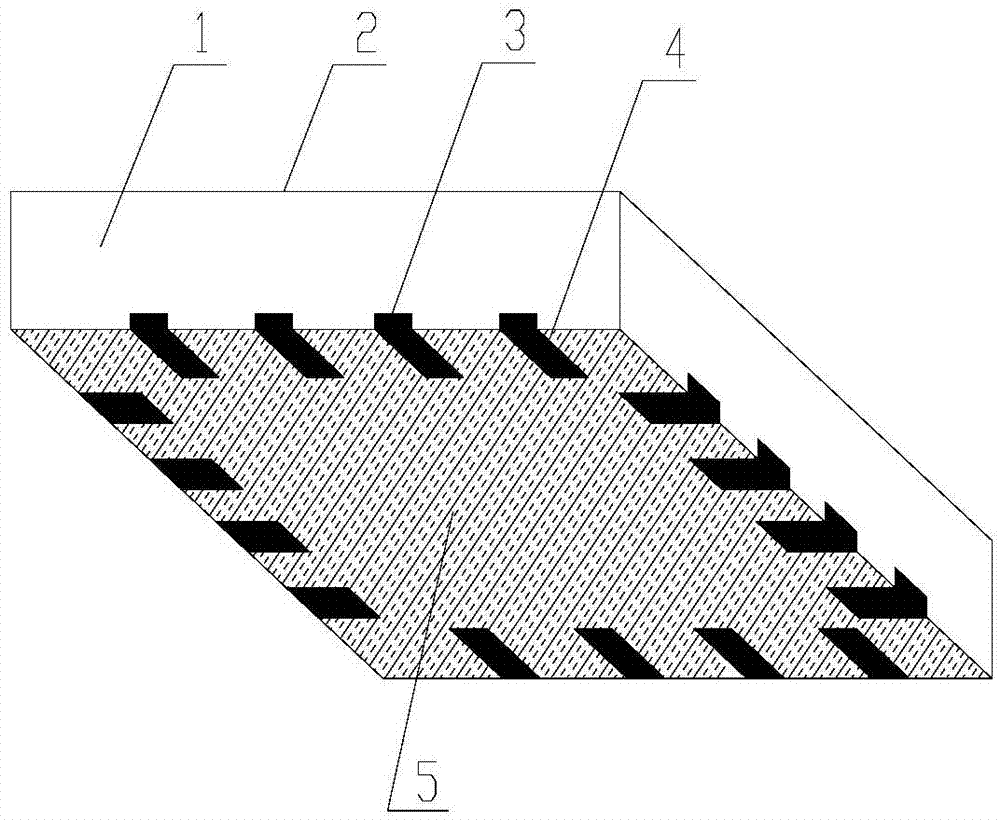

Multilayer rapid temperature rising type electric heater containing graphene and aluminum alloy

InactiveCN108253509AReduce installation costsReduce power consumptionLighting and heating apparatusElectric heating systemElectricityInsulation layer

The invention discloses a multilayer rapid temperature rising type electric heater containing graphene and aluminum alloy. The multilayer rapid temperature rising type electric heater comprises a controller, a bracket, a hollow square frame and a multilayer heating mechanism; the multilayer heating mechanism sequentially comprises an aluminum alloy front plate, a first insulation layer, a first graphene heating film, a second insulation layer, a first heat reflecting and preserving layer, a cavity, a second graphene heating film, a third insulation layer, a second heat reflecting and preserving layer and a rear plate from front to back, and the aluminum alloy front plate is provided with a plurality of ventilation pores; and the side, making contact with the multilayer heating mechanism, of the hollow square frame is provided with an opening, an opening of the hollow square frame is in butt joint with the cavity, and the hollow square frame is internally provided with a plurality of miniature fans. The temperature rising speed of the multilayer rapid temperature rising type electric heater containing the graphene and the aluminum alloy is multiple times higher than that of traditional heating equipment, the heat efficiency and the heat utilization rate are high, the bottleneck that the heating effect is good only with the large graphene area is broken, and the installation costand electricity consumption of graphene heating are reduced.

Owner:江西飞晖科技有限公司

Device used for removing organic impurities in by-product sodium chloride in chlorine chemical process

ActiveCN109956484ASolve the blockageSolve wear and tearAlkali metal halide purificationSlagFluidized bed

The invention belongs to the technical field of chemistry industry, and relates to a device used for removing organic impurities in by-product sodium chloride in chlorine chemical process. The devicecomprises a high temperature oxidation reactor, a dissolving kettle A, a dissolving kettle B, a liquid phase deep oxidation tower, a liquid solid filter, a solid slag tank, and a fine filter which areconnected successively. In application process, firstly, the multilayer fluidized bed type high temperature oxidation reactor is adopted for high temperature oxidation of most organic impurities in by-product sodium chloride, then in the liquid phase deep oxidation tower, residual trace amount organic impurities are subjected to deep oxidation, and a nanofiltration membrane separator is adopted to remove high molecular organic matter impurities further, so that requirements of ionic membrane caustic soda industrial devices on organic impurities in sodium chloride are satisfied. The device islarge in operation flexibility, and high in organic impurity processing efficiency.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

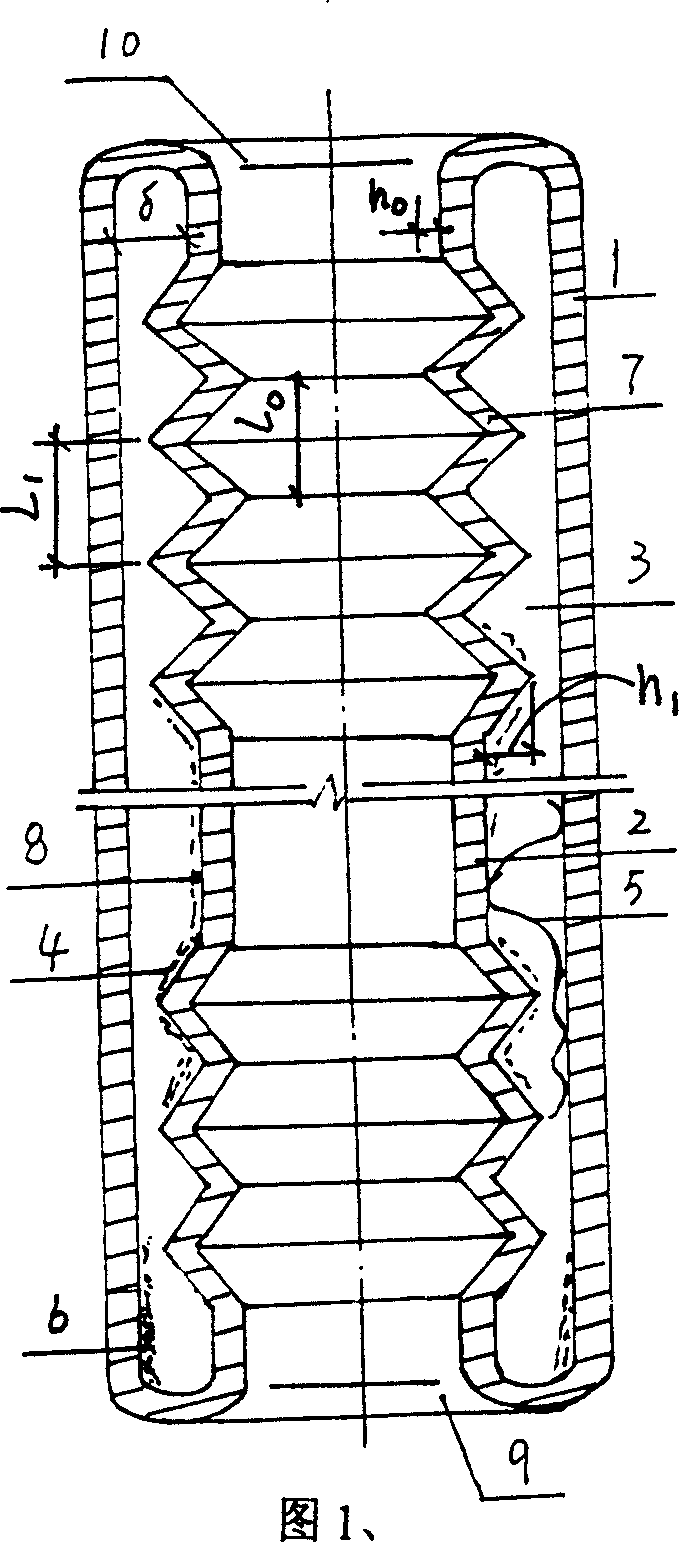

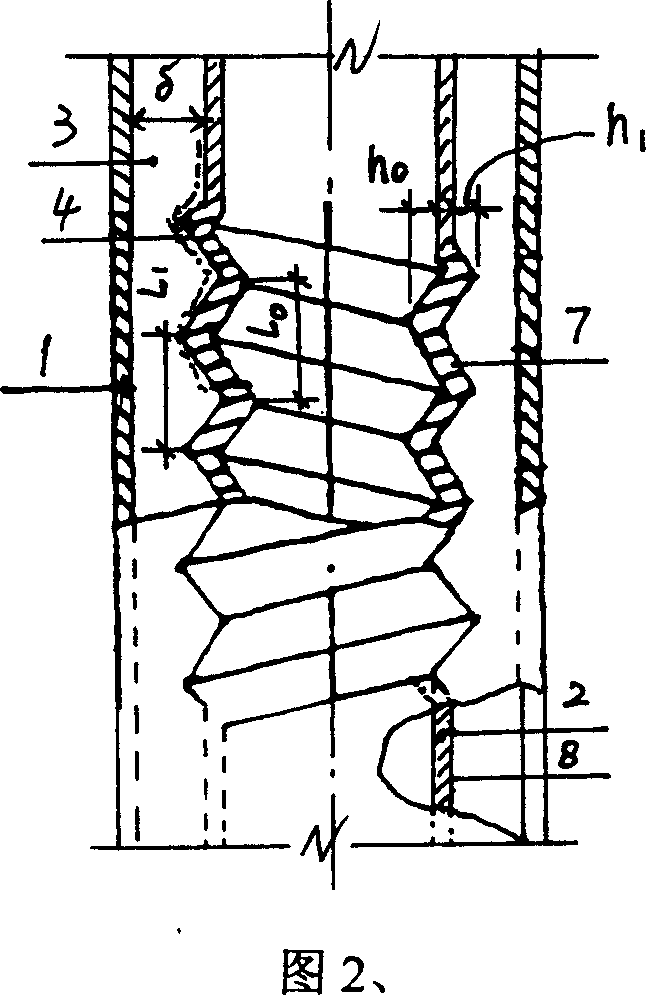

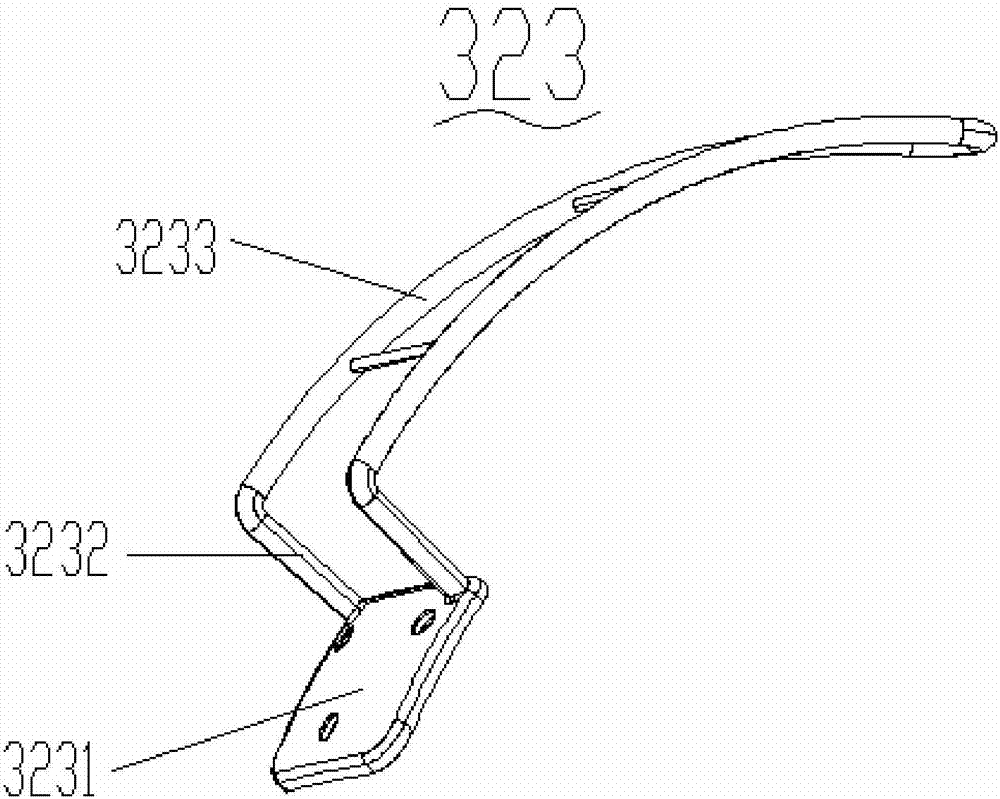

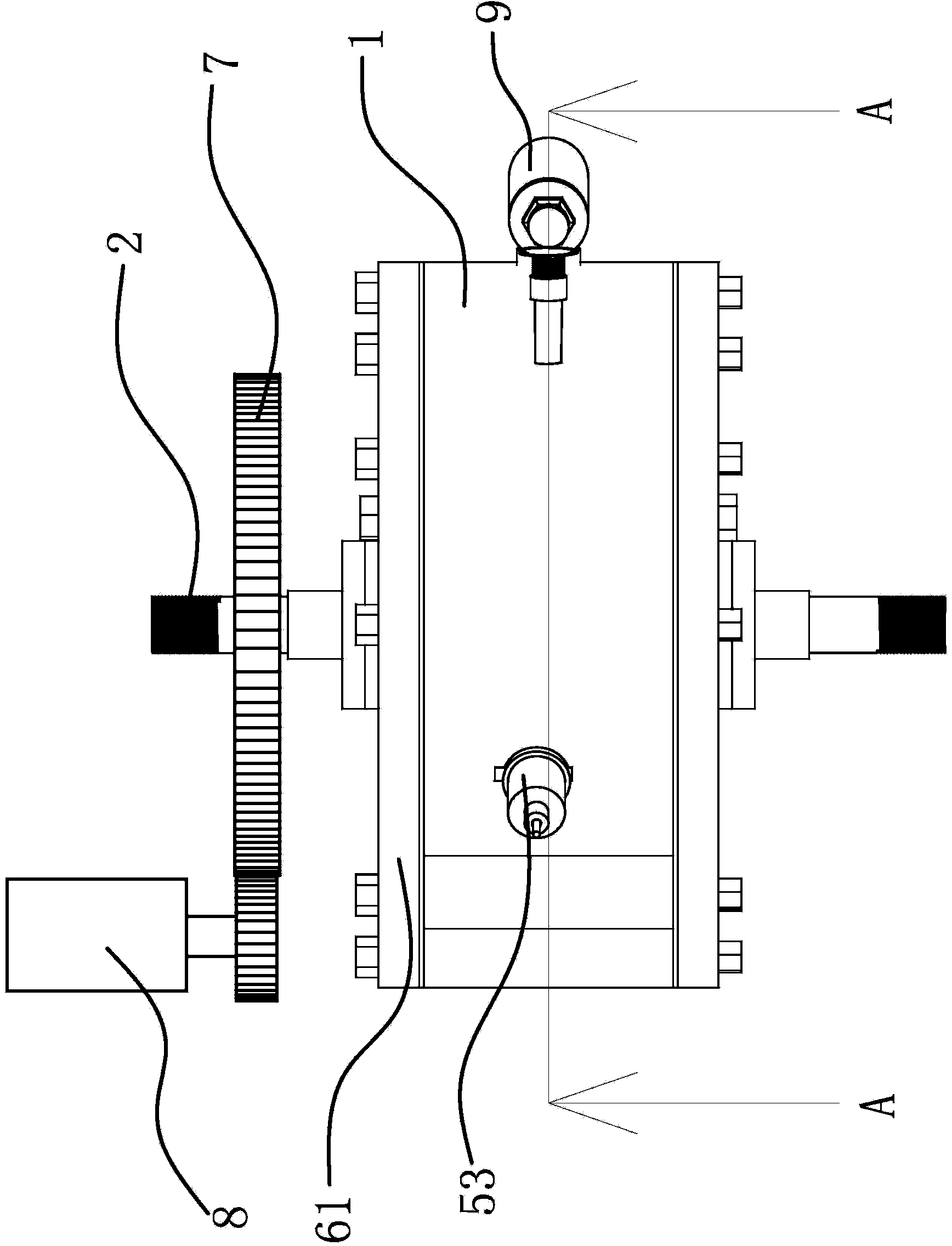

Dual-prism rotor engine

ActiveCN103628977AAvoid complexityAvoid promotional problemsInternal combustion piston enginesPrismEngineering

The invention provides a dual-prism rotor engine, belong to the technical field of machinery and aims to solve the technical problems of low thermal efficiency, high oil consumption and the like existing in the conventional dual-prism rotor engine. The engine comprises a shell and a main shaft, wherein a special-shaped cavity is formed in the shell; a rotor connected with the main shaft is arranged in the special-shaped cavity; the rotor has a hollow structure; the inner cavity of the rotor is provided with a prismatic bracket I and a prismatic bracket I; both the prismatic bracket I and the prismatic bracket II are formed by hinging four equal-length connecting rods end to end; a clapboard is hinged to the joint of every two connecting rods; the rotor is provided with eight sliding chutes which are uniformly distributed on the rotor along a circumferential direction; eight clapboards are inserted into corresponding sliding chutes respectively; the clapboards are radially distributed on the periphery of the main shaft; the clapboards are connected in corresponding sliding chutes in a sliding way, and the sliding chutes are sealed relative to each other; the inner ends of the clapboards are connected with the connecting rods; the outer ends of the clapboards are always pressed against the inner wall of the special-shaped cavity. The dual-prism rotor engine has the advantages of high thermal efficiency, low oil consumption and the like.

Owner:淮北市硕华机械设备有限公司

Immersed combustor

ActiveCN103335310AImprove heating efficiencyReasonable heating efficiencyGaseous fuel burnerCombustorEngineering

The invention discloses an immersed combustor. The combustor comprises a furnace housing, wherein the furnace housing comprises a main combustion cone, a top volute and a cooling water jacket, wherein the main combustion cone is integrally communicated at the top surface of a bottom volute, the top volute is provided with a main tangential air inlet and is fixedly arranged at the upper end of the main combustion cone, and the cooling water jacket encircles the peripheral surface of the main combustion cone and is used for cooling the main combustion cone by circulating water; the bottom volute is internally provided with a combustion nozzle which is respectively connected with an auxiliary air inlet pipe and a fuel supply pipe, a circulation cooling water coiled pipe is sleeved on the periphery of the combustion nozzle, and an inner fuel passageway of the combustion nozzle is provided with an atomizing water pipe which jets water mist outwards to cool the combustion nozzle; a smoke removal channel is formed in the bottom volute in a tangent direction, the furnace housing is immersed and arranged in cooling bath water in such ways of feeding air at the upper part of the furnace housing and discharging smoke at the lower part of the furnace housing, the immersed depth of the furnace housing in the cooling bath water is more than the height of the furnace housing multiplied by one second, and the horizontal plane of the cooling bath water is lower than the edge of the upper opening of the cooling water jacket.

Owner:宁波中能连通机械有限公司

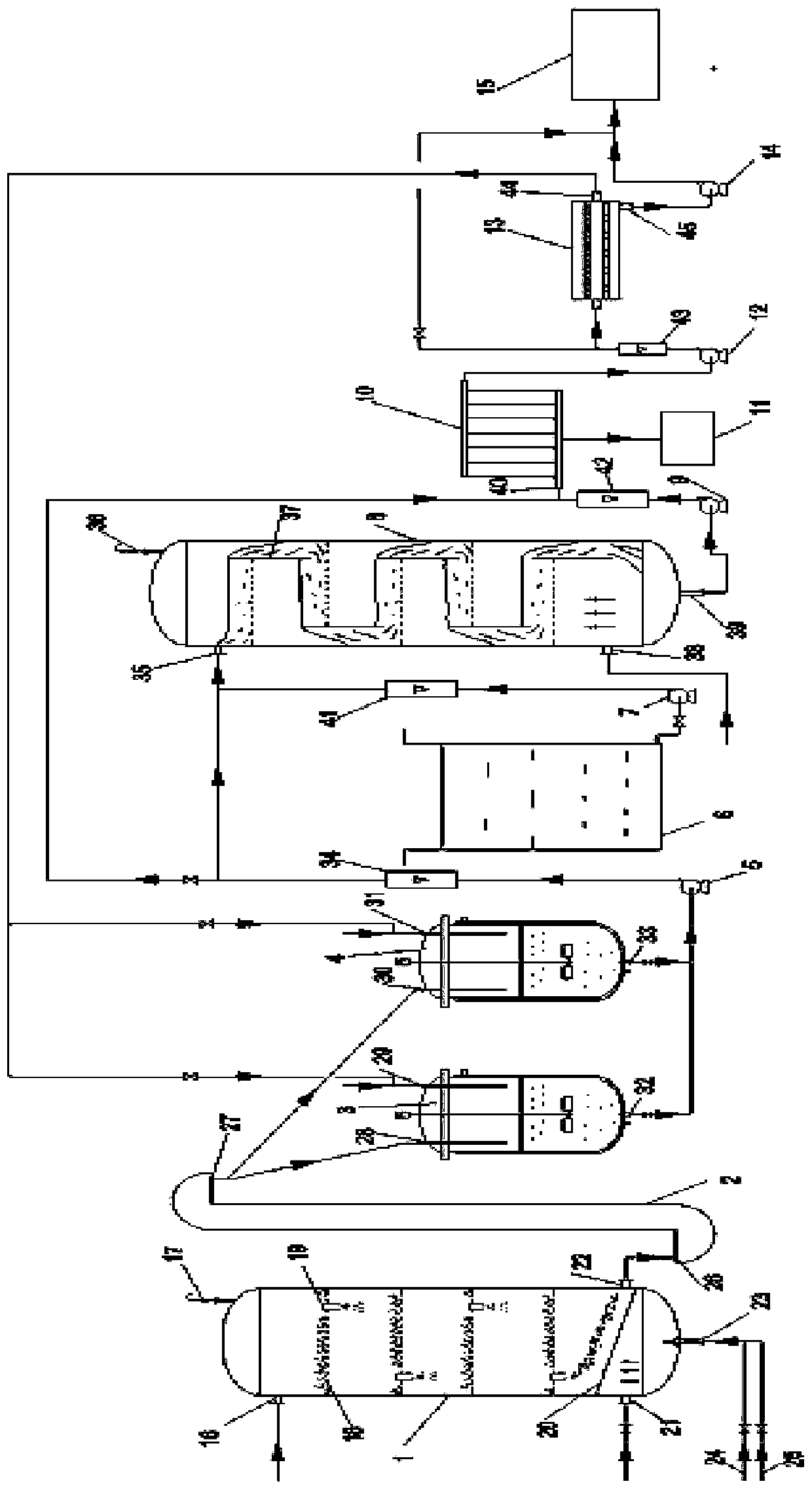

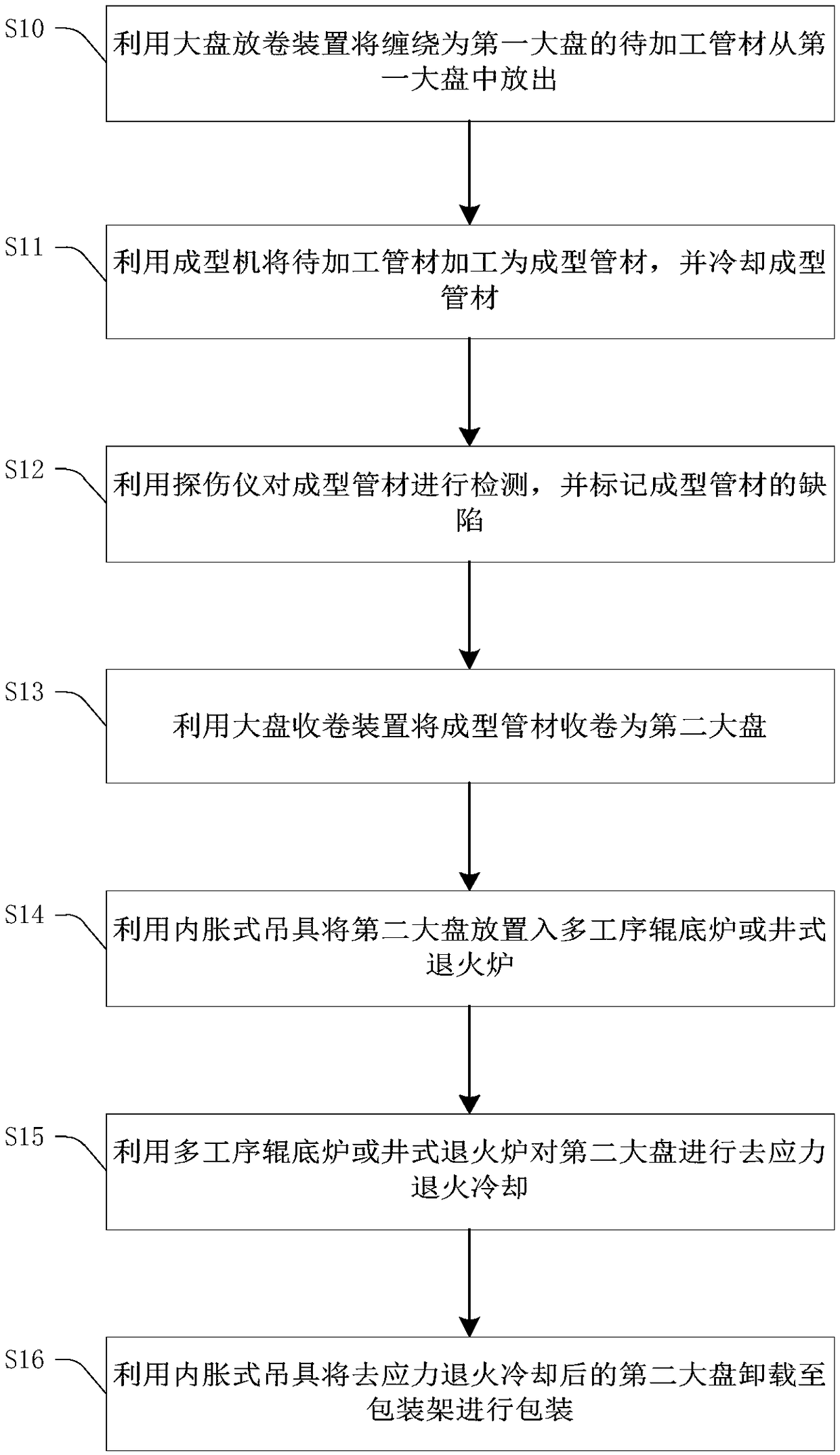

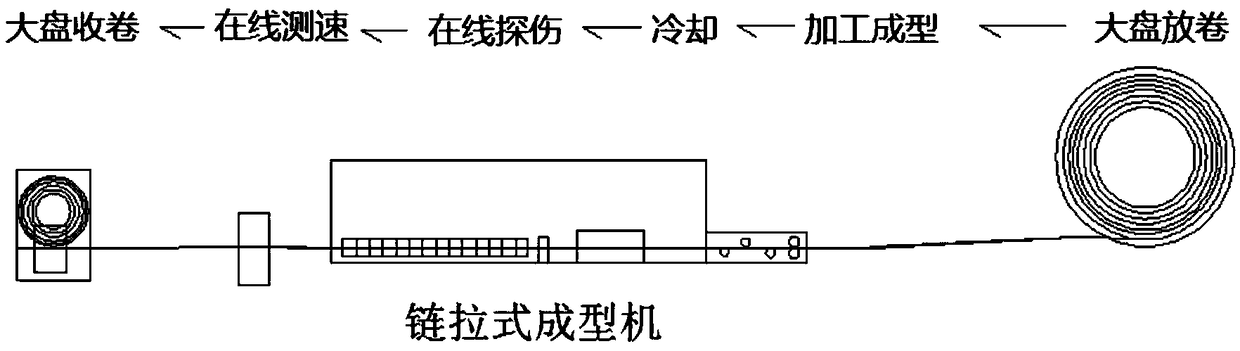

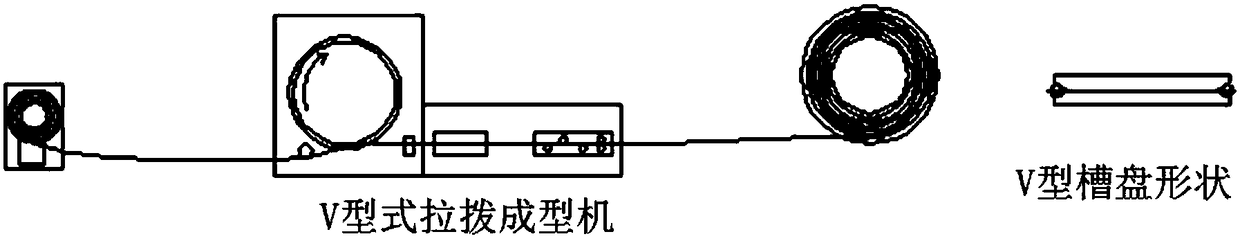

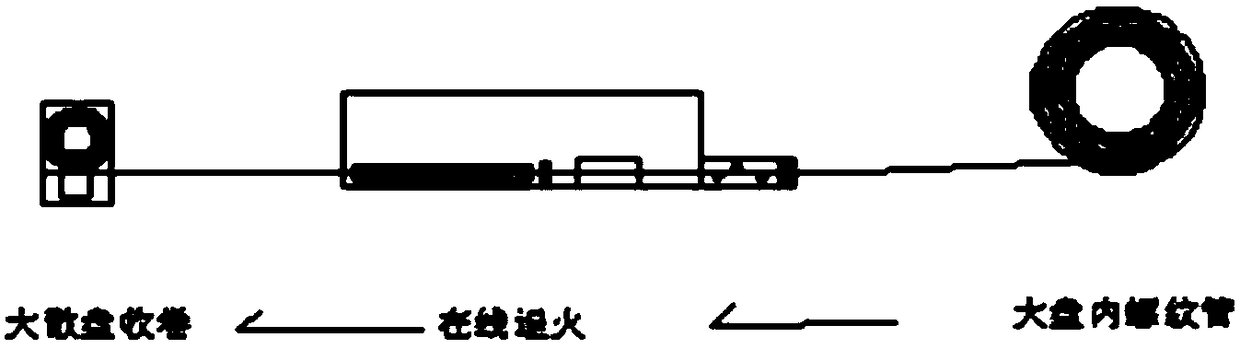

Mosquito-repellent incense type large scattered plate production method and system

The invention relates to the technical field of machining, and provides a mosquito-repellent incense type large scattered plate production method and system. The method comprises the following steps:discharging to-be-machined tubes from a first large plate by a large plate unreeling device; machining the to-be-machined tubes into formed tubes by using a forming machine and cooling the formed tubes; detecting the formed tubes by using a flaw detector and marking flaws; reeling the formed tubes into a second large plate by using a large reeling device, controlling the reeling speed of the largereeling device and the unreeling speed of the large unreeling device to be synchronous by using an encoder in a reeling process; placing the second large plate in a multi-procedure roller hearth furnace or a well annealing furnace by using an internal expansion type hoist; carrying out stress relief annealing and cooling on the second large plate by using the multi-procedure roller hearth furnaceor the well annealing furnace; and unloading the second large plate to a packing pack after stress relief annealing and cooling by using the internal expansion type hoist and packing the second largeplate. The method is simple in production process and high in degree of automation, and the machined mosquito-repellent incense type large scattered plate is uniform in hardness, high in reeling density and convenient to stack and transport.

Owner:冯境铭

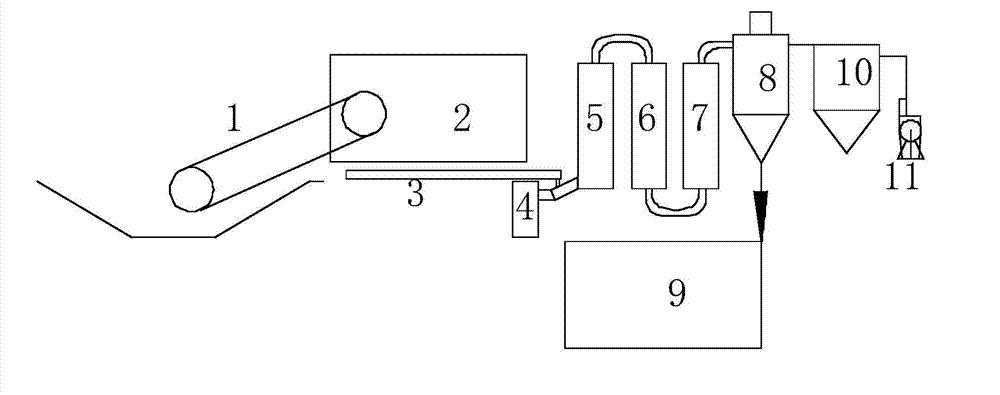

Screening and drying method for wood chips in production of phosphoric acid method activated carbon

InactiveCN103567148AFully contactedReduce consumptionGas current separationDrying gas arrangementsActivated carbonCyclonic separation

The invention discloses a screening and drying method for wood chips in the production of phosphoric acid method activated carbon. Devices used in the method comprise a belt conveyor, a first-stage drum screen, a spiral conveying auger, a blast stove, a first-stage dryer, a second-stage dryer, a third-stage dryer, a cyclone separator, a cloth bag deduster, a draught fan and a second-stage drum screen; the wood chips fall into the first-stage drum belt screen from the belt conveyor, then screened qualified wood chips are fed into an air flow drying system by the spiral conveying auger, hot air generated by the blast stove is led into a hot air pipe by the draught fan and enters the second-stage drum screen after passing the cyclone separator, and the cloth bag deduster is connected behind the cyclone separator; wooden fuel used in the blast stove is burnt with limited oxygen, and 15-20 percent of charring materials can be obtained while heat is generated, so the energy is comprehensively used; the hot air can be fully contacted with the wood chips by the three stages of dryers, so the heat utilization efficiency is high; thinner particles can be removed by the two stages of drum screens, so the consumption of ash content and phosphoric acid in the activated carbon can be reduced.

Owner:安徽金叶碳素科技有限公司

A kind of low temperature granulation method of solid sodium lactate

ActiveCN104130120BGood colorOvercome the disadvantage of easy adhesionCarboxylic compound separation/purificationSpray GranulationCold air

The invention provides a solid sodium lactate low-temperature granulation method. The method comprises the following steps: (1) a sodium lactate solution is subjected to reduced-pressure evaporation by using a thin-film evaporator, wherein sodium lactate content in the solution is increased to 90-92wt% within 5min; and the obtained solution is discharged. During the reduced-pressure evaporation process, the pressure of the jacket heating steam of the thin-film evaporator is controlled at 0.2-0.4MPa, the temperature in the thin-film evaporator is controlled at above 90 DEG C, and the pressure in the thin-film evaporator is controlled at 0.04-0.05MPa; (2) the concentrated solution is pressed into a rotating centrifugation spray granulation machine through compressed air, and the temperature of the concentrated solution is maintained at above 90 DEG C, such that the concentrated solution is spayed as a mist from a high-speed rotation disk on the upper part of the granulation machine; at a same time, cold air with a temperature of 4-15 DEG C is synchronously delivered from above the granulation machine, and the temperature of cold air delivered out from the lower side part of the granulation machine is no higher than 45 DEG C; liquid mist is subjected to heat-exchange with the cold air, and is cooled and solidified, such that sodium lactate solid crystallized powder is obtained. According to the invention, low-temperature granulation is adopted, such that production efficiency is high, and heat energy utilization rate is greatly improved. The method is suitable for popularization and production.

Owner:武汉三江航天固德生物科技有限公司

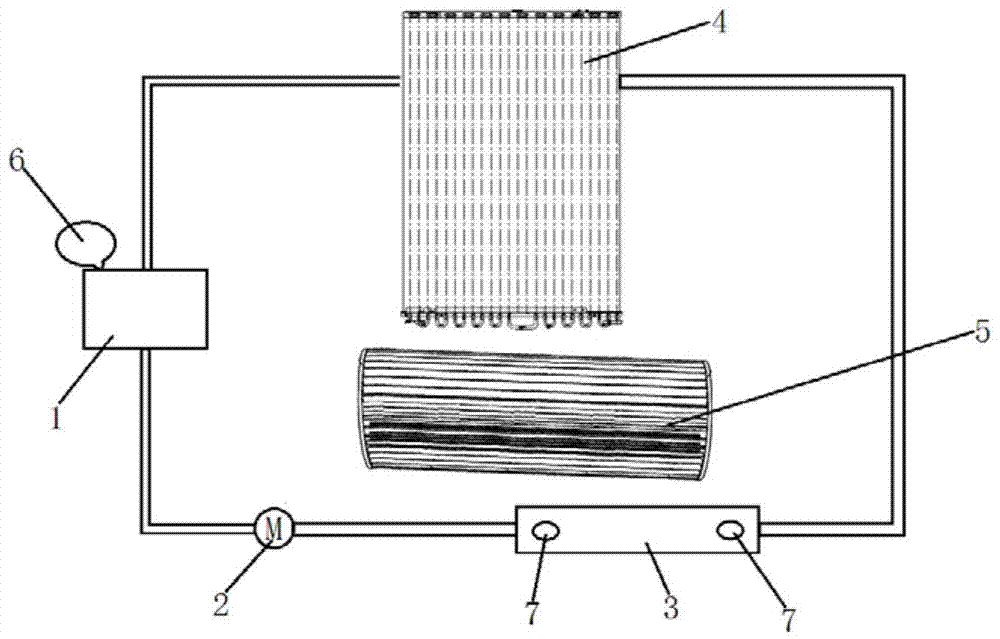

Novel electric radiator

InactiveCN103673049AHigh thermal efficiency utilizationExtended heating rangeLighting and heating apparatusElectric heating systemPlate heat exchangerEngineering

The invention discloses a novel electric radiator. The novel electric radiator comprises a heat exchanger, a liquid storing tank and an electric heating device, wherein liquid in the liquid storing tank is conveyed to the electric heating device for heating through a water pump, the liquid heated through the electric heating device is conveyed to the heat exchanger, the edge of the heat exchanger is provided with cross-flow fan blades which rotate to bring out heat released through heat dissipation of the heat exchanger, and the liquid in the heat exchanger flows back to the liquid storing tank. The heat efficiency use ratio of the electric radiator is high, the structure and principle of a traditional electric radiator are broken through, the warming range is greatly enlarged and not limited to the range where light waves and heat can radiate, and moreover the light and the heat do not directly radiate on the human body, so that a user feels more comfortable when getting warm.

Owner:SUZHOU TAIYANGXUE NEW ENERGY TECH

De-soldering method for elements with bottom terminal packaging

InactiveCN104759726AHeat transfer is direct and rapidShort operating timeSoldering apparatusSilver plateCopper wire

The invention discloses a de-soldering method for elements with bottom terminal packaging and aims at providing a de-soldering method which is short in operation time and capable of not burning elements and printed boards. According to the technical scheme, a silver plated copper wire with the diameter phi in a range of 0.08mm to 0.12mm is used for winding the element body (1) and printed circuit board (6) joint portion for two circles, and the length of the silver plated copper wire is that the silver plated copper wire can wind the element body for at least two circles. The silver plated copper wire is attached to the soldering disc exposure portions of the element body (1) and printed circuit board soldering pad (7) bottom soldering point connection positions and exposed terminal side portions (3) of bottom terminals (4) of the element body (1) to wound all soldering points; the exposed silver plated copper wire is heated directly through electric soldering iron, a certain amount of soldering flux is added at the position of a soldering tip while the silver plated copper wire is heated, heat is transmitted to the bottom terminals and the printed circuit board soldering disc through the silver plated copper wire and the exposed fused soldering flux directly, and all heat is concentrated to the soldering points rapidly, accordingly, the apparatus is taken down.

Owner:CHENGDU KAITIAN ELECTRONICS

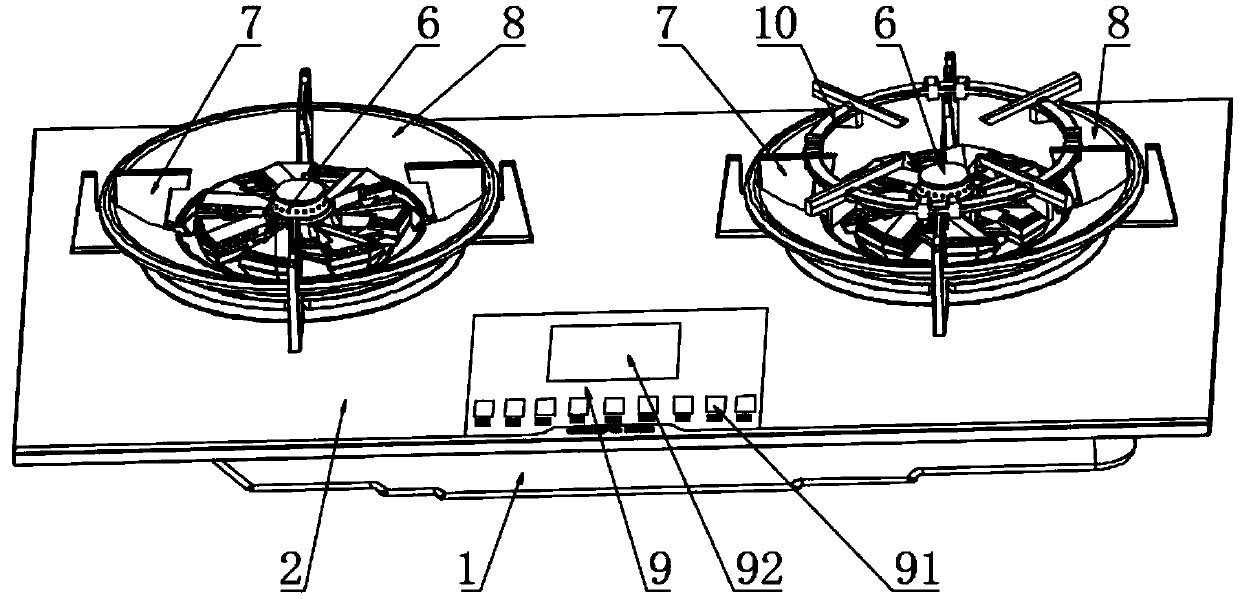

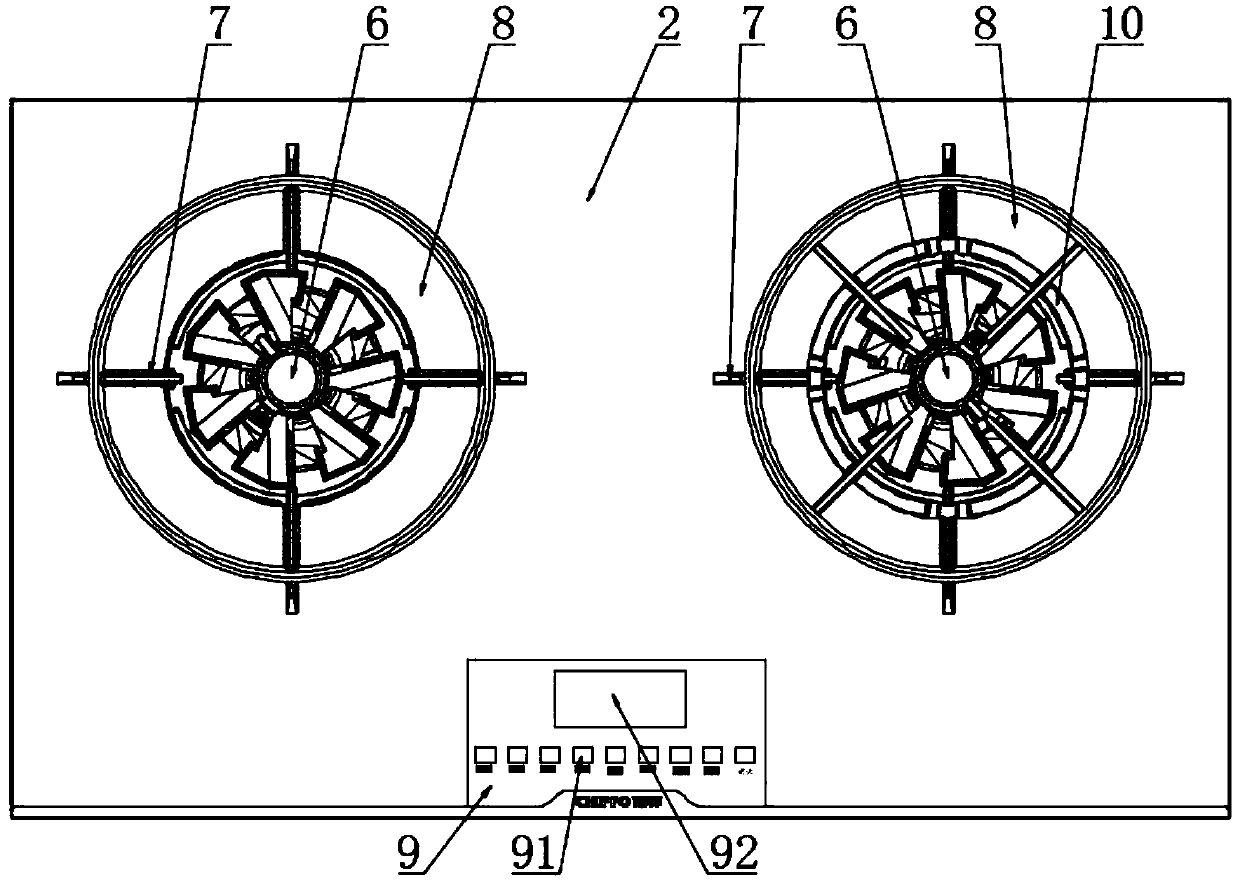

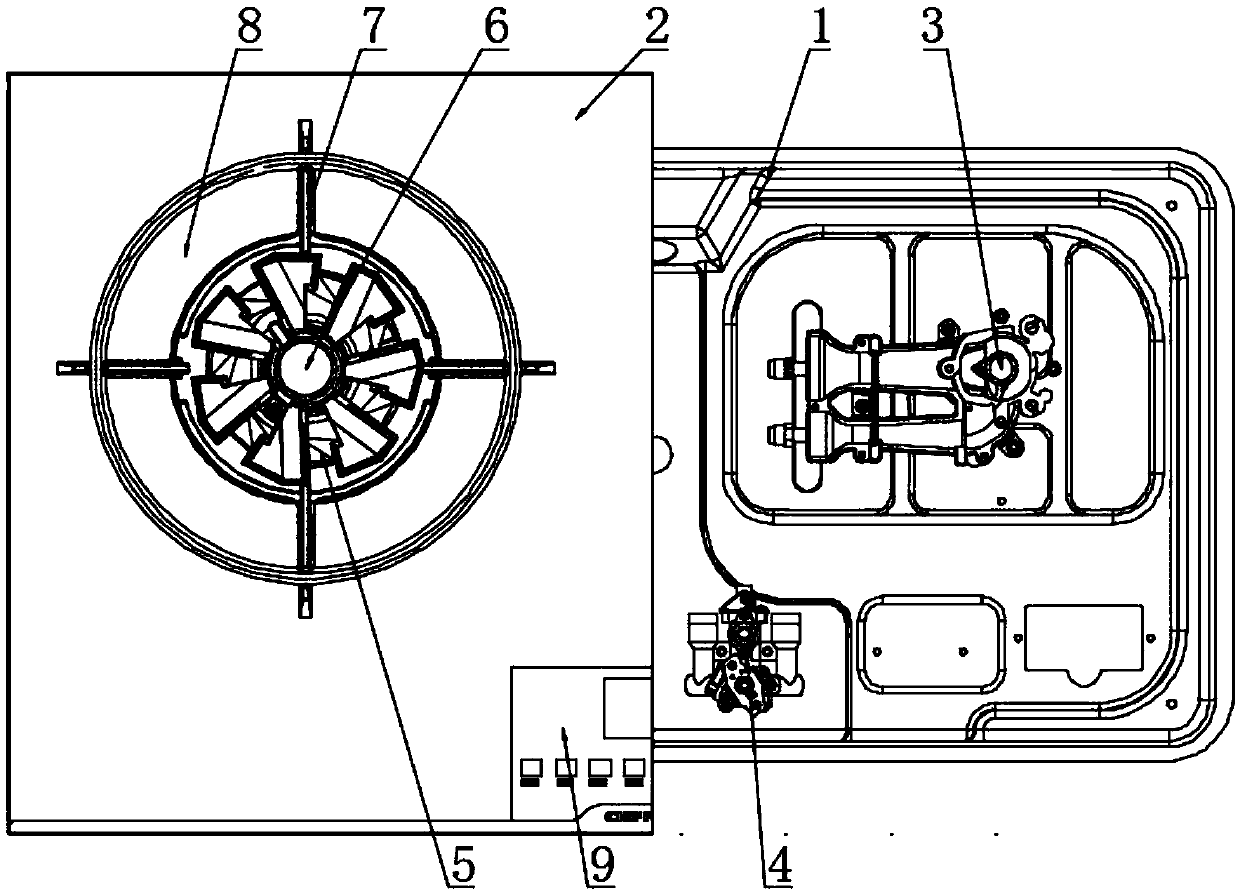

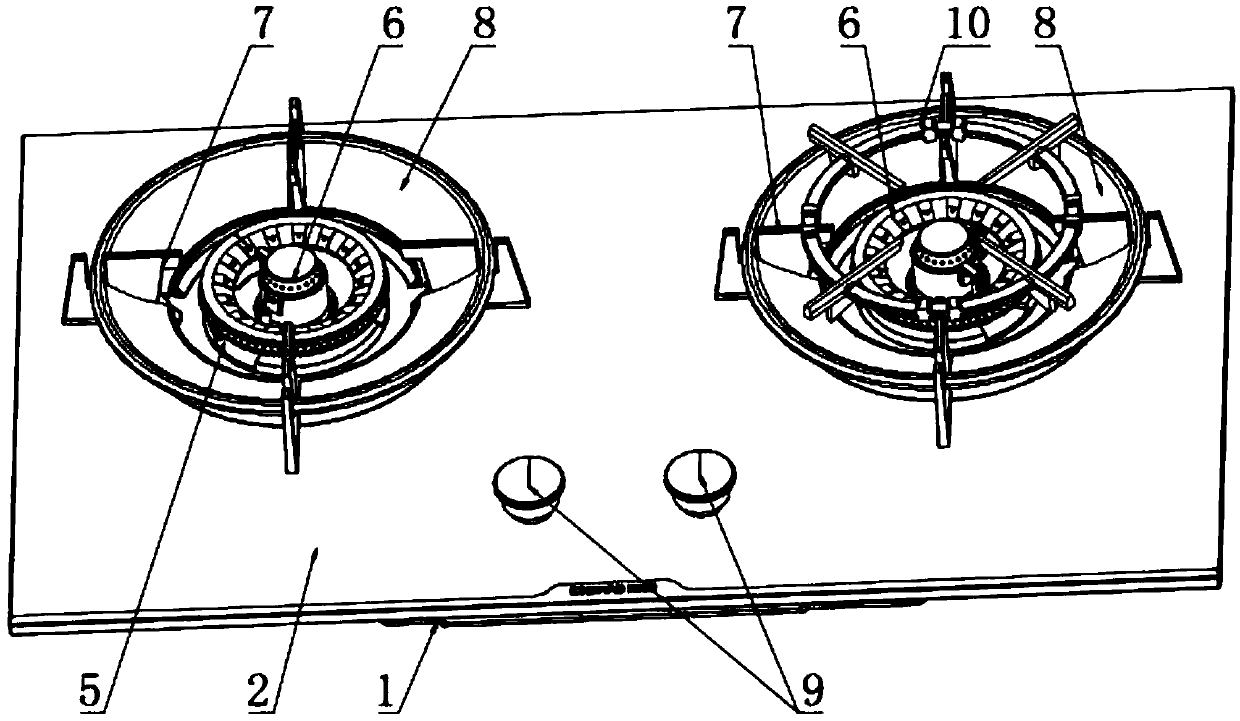

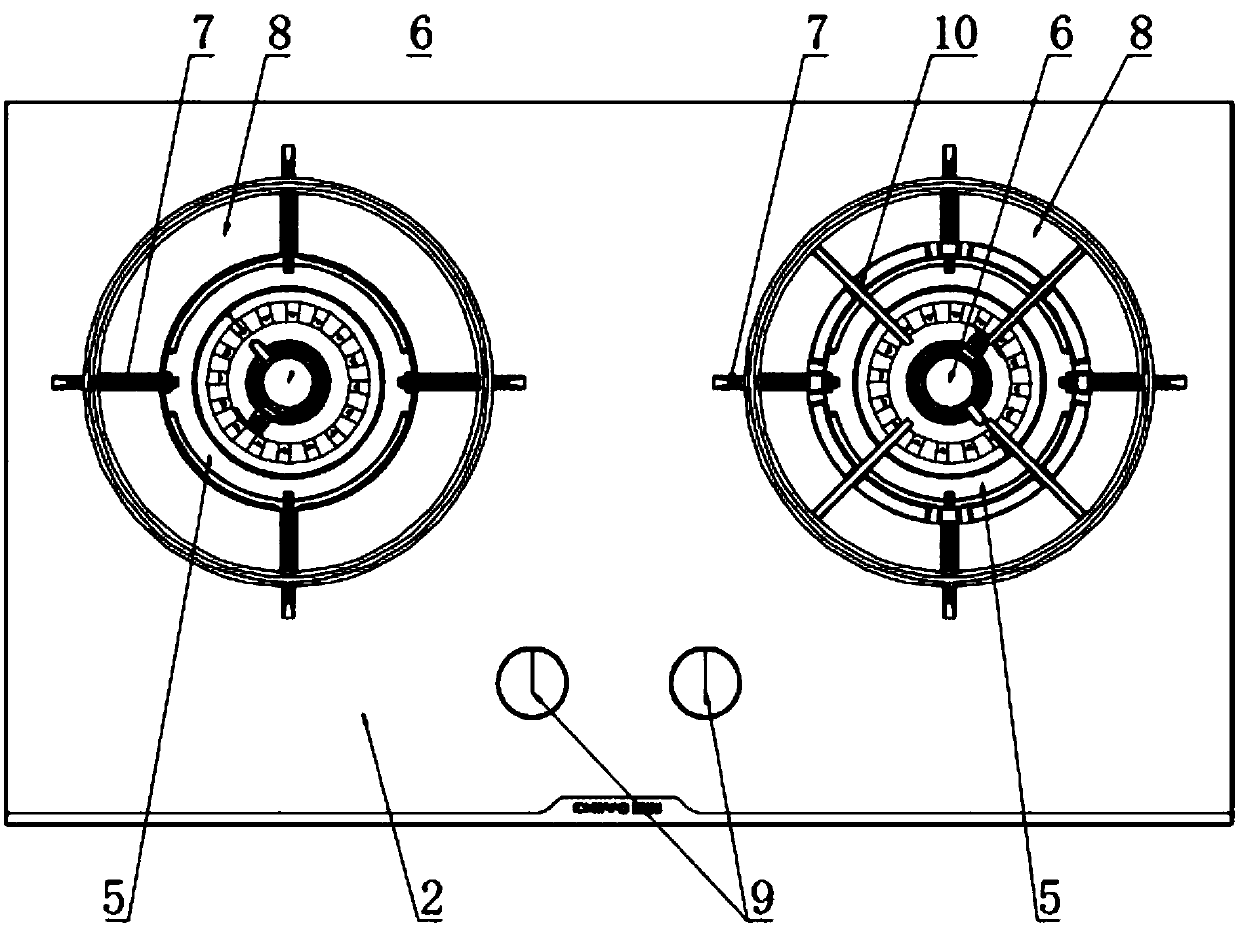

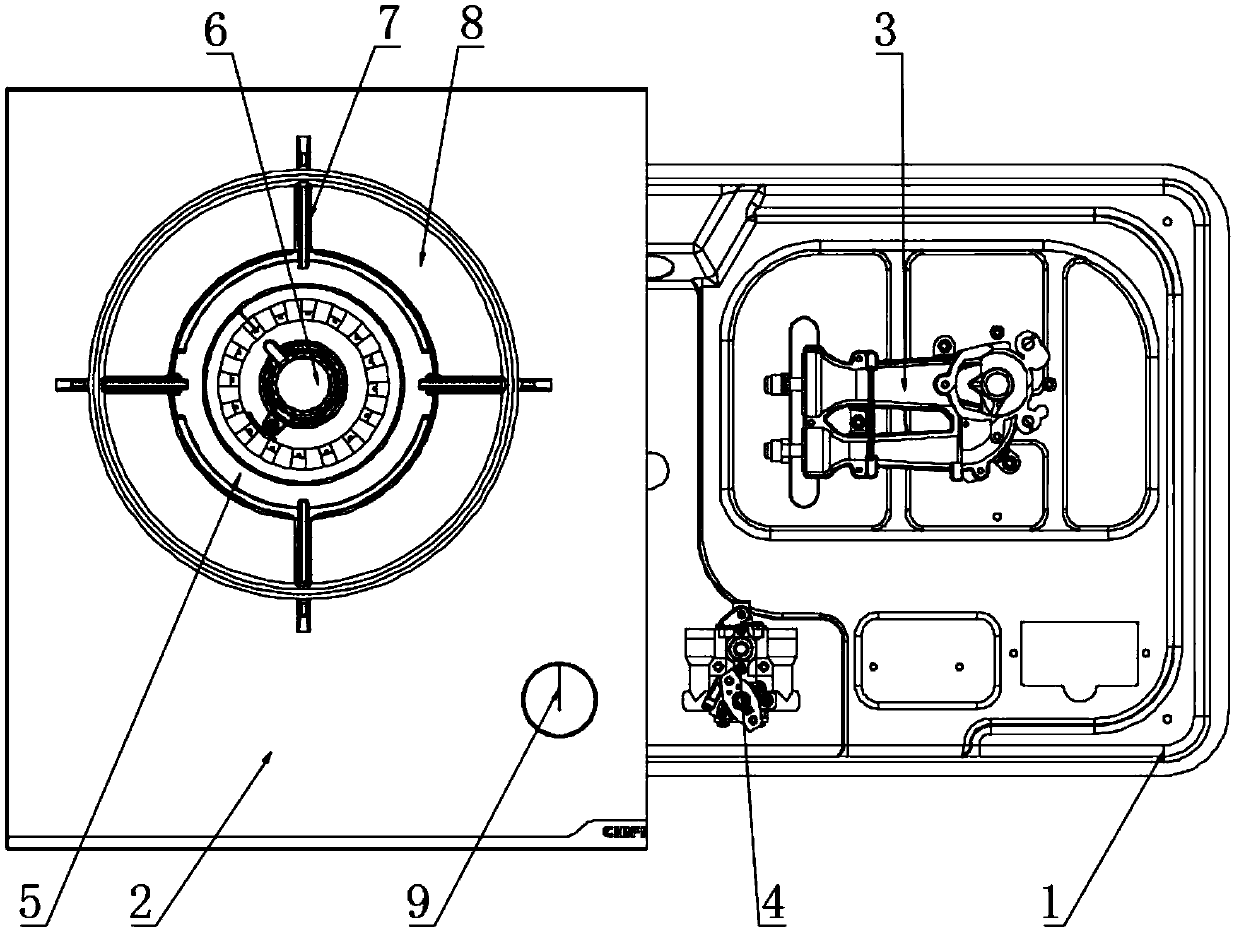

Touch sensitive type stove convenient to wash and high in burning efficiency

PendingCN109595602APlay a role in stabilizing the flameEvenly heatedDomestic stoves or rangesLighting and heating apparatusInterior spaceHigh energy

The invention discloses a touch sensitive type stove convenient to wash and high in burning efficiency. The touch sensitive type stove comprises a bottom shell, a panel, furnace ends, electromagneticvalves, double-layer liquid containing discs, distributors, pot supports I, energy gathering rings, a touch display assembly and a controller. The double-layer liquid containing discs, the distributors, the pot supports I and the energy gathering rings are all coaxially arranged at the upper ends of furnace end holes I. According to the stove, work of the stove is controlled through touch keys, auser only needs to touch the keys by finger, no physical damage or mechanical abrasion is generated, and the requirements of the majority of users, especially young users can be met. By means of the double-layer liquid containing discs, the situation that soup, oil dirt and other liquid flow into internal space of the stove, so that normal use of the stove is affected is avoided; the distributorsare convenient to mount and dismount, secondary air needed by burning can be better supplemented, burning is more sufficient, exhausted carbon monoxide is less, and higher energy saving and environmental protection are achieved; and the energy gathering rings are convenient to mount and dismount, heat losses generated after gas burning can be effectively reduced, and the heat response utilizationrate is increased.

Owner:成都前锋电子有限责任公司

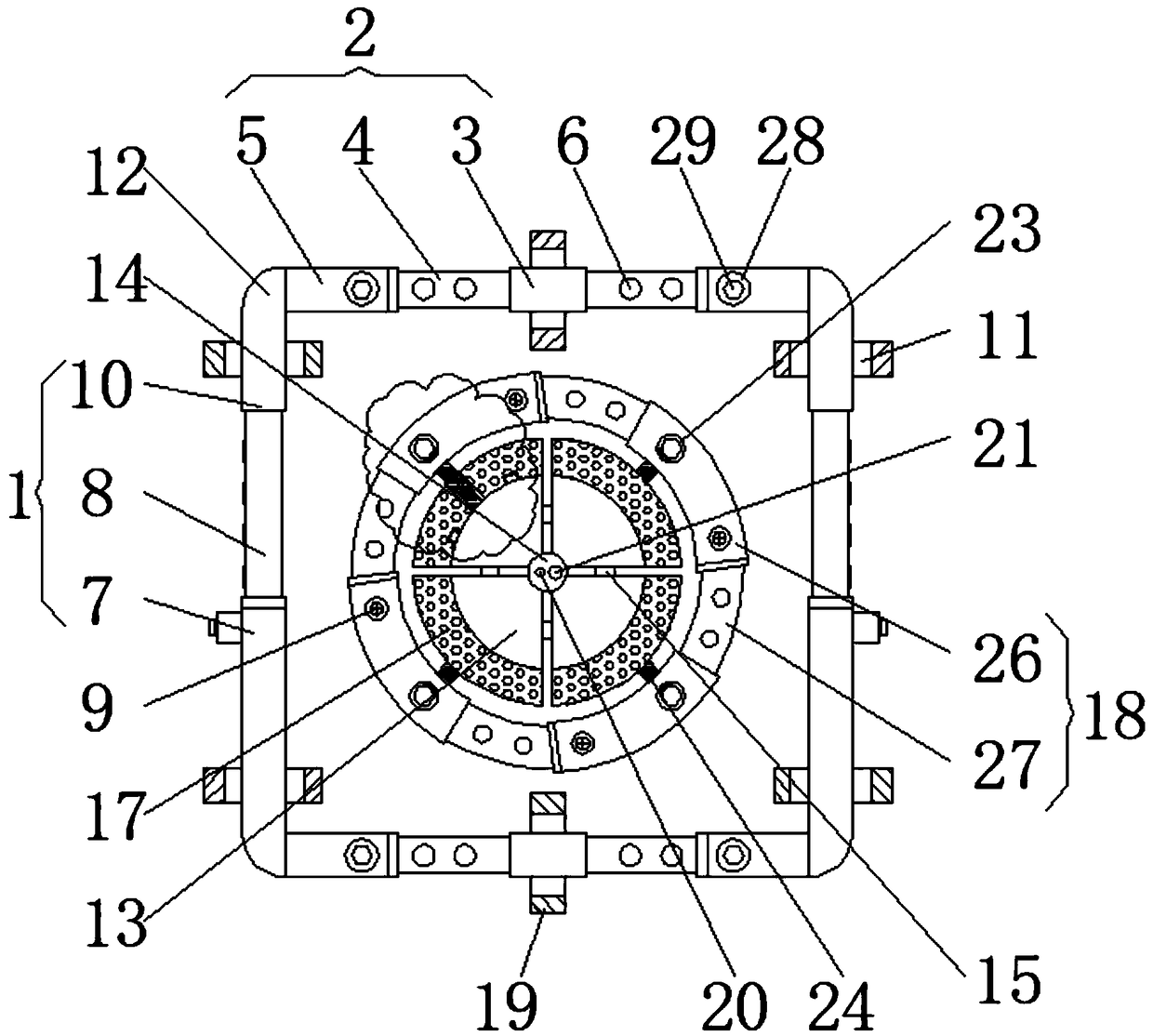

Energy gathering assembly of gas stove

InactiveCN109114599AAvoid dissipationHigh thermal efficiency utilizationDomestic stoves or rangesLighting and heating apparatusThermal energyProcess engineering

The invention relates to the technical field of gas stoves, and discloses an energy gathering assembly of a gas stove. The energy gathering assembly comprises supporting side frames, the number of thesupporting side frames is two, supporting transverse frames are fixedly arranged between the two supporting side frames, the number of the supporting transverse frames is two, the two supporting sideframes and the supporting transverse frames form a supporting frame, each supporting transverse frame comprises a positioning block, the middle part of the positioning block is located in the middlepart of each supporting transverse frame, two sides of the positioning block are respectively fixedly connected with a first inner telescopic rod, and the other end of the first inner telescopic rod is movably connected with a first outer sleeve rod. According to the energy gathering assembly of the gas stove, the energy gathering assembly is positioned and inserted by virtue of a gas hole and anignition hole, then the gas is sprayed by virtue of a gas hole, the gas is ignited by virtue of the ignition hole, the heat-effect heat conduction is performed by virtue of an energy gathering inner disc and an outer disc, the heat-effect energy gathering is performed by virtue of a limiting outer disc, so that the heat dissipation of the fuel gas can be prevented, and an effect of high heat energy fathering efficiency and high heat utilization rate can be achieved.

Owner:刘洪瑞

Pressure gas piston injection type rotary engine system for two-time acting application

PendingCN110872956AImprove utilization efficiencyHigh thermal efficiency utilizationBlade accessoriesCombination enginesRotary engineGas passing

The invention provides a pressure gas (containing steam) piston injection type rotary engine system for two-time acting application. The system is used as a new change of a pressure gas power energy application mode. In the application form of the pressure gas, the mode of acting through pressure or releasing in one-time input is changed, by changing the application structure, the mode of acting twice after the pressure gas is input once is realized, a piston is changed into a complete acting work method of circumference concentric rotation uninterrupted operation under the pressure mode, andpressure gas sent by the piston acts through pressure and then is subjected to second-time turbine release acting application under the storage mode, therefore, the current situation of low application heat efficiency of pressure gas is changed, and a real high-efficiency energy-saving energy application technology is realized and perfected. A new utilization method of the pressure gas in the application field is defined and determined from the aspects of science and technology and practical significance, the full utilization of energy is truly realized, and a more efficient pressure gas internal energy application mode is realized.

Owner:SHANGHAI QUAN ENERGY TECH CO LTD

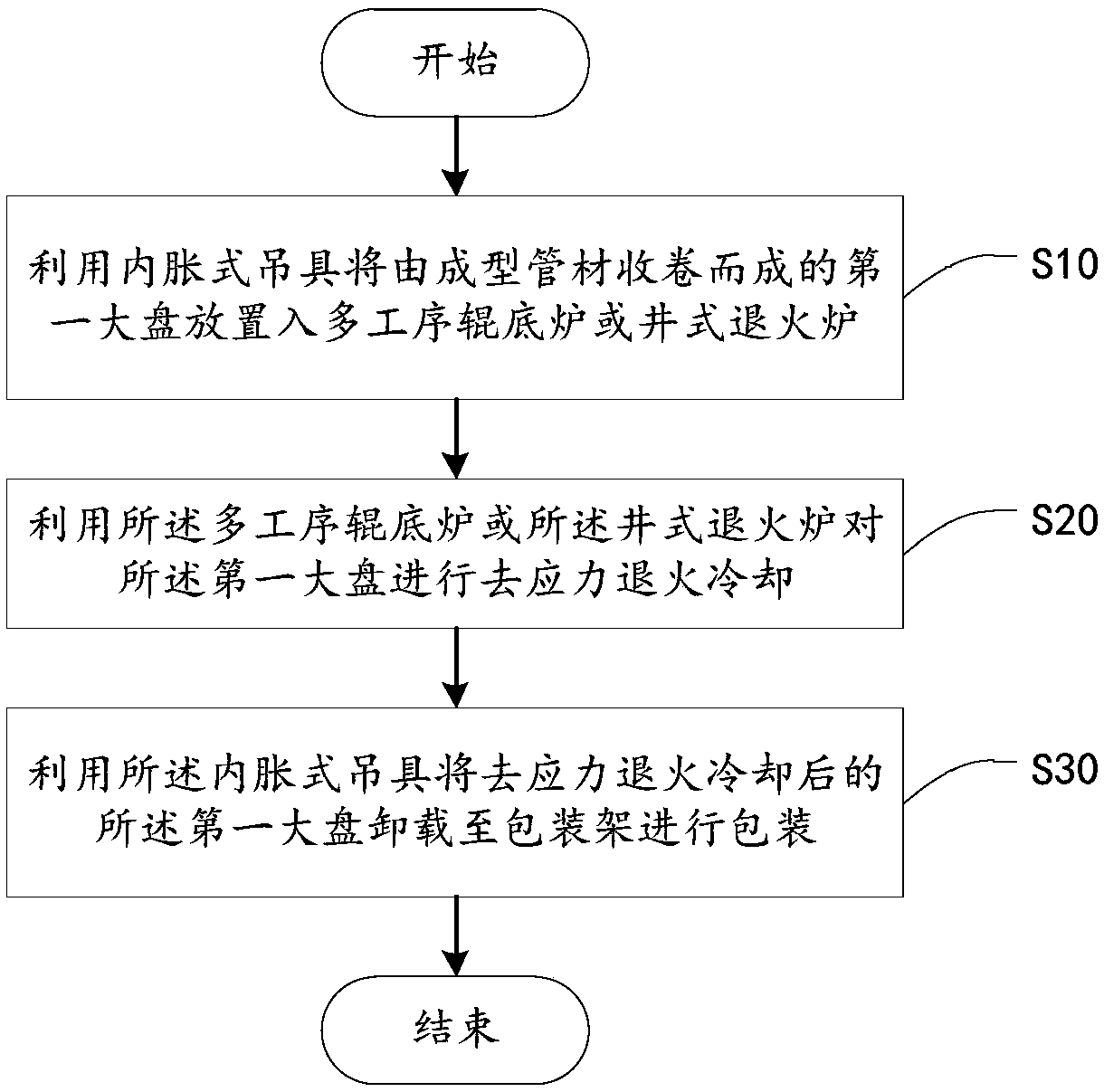

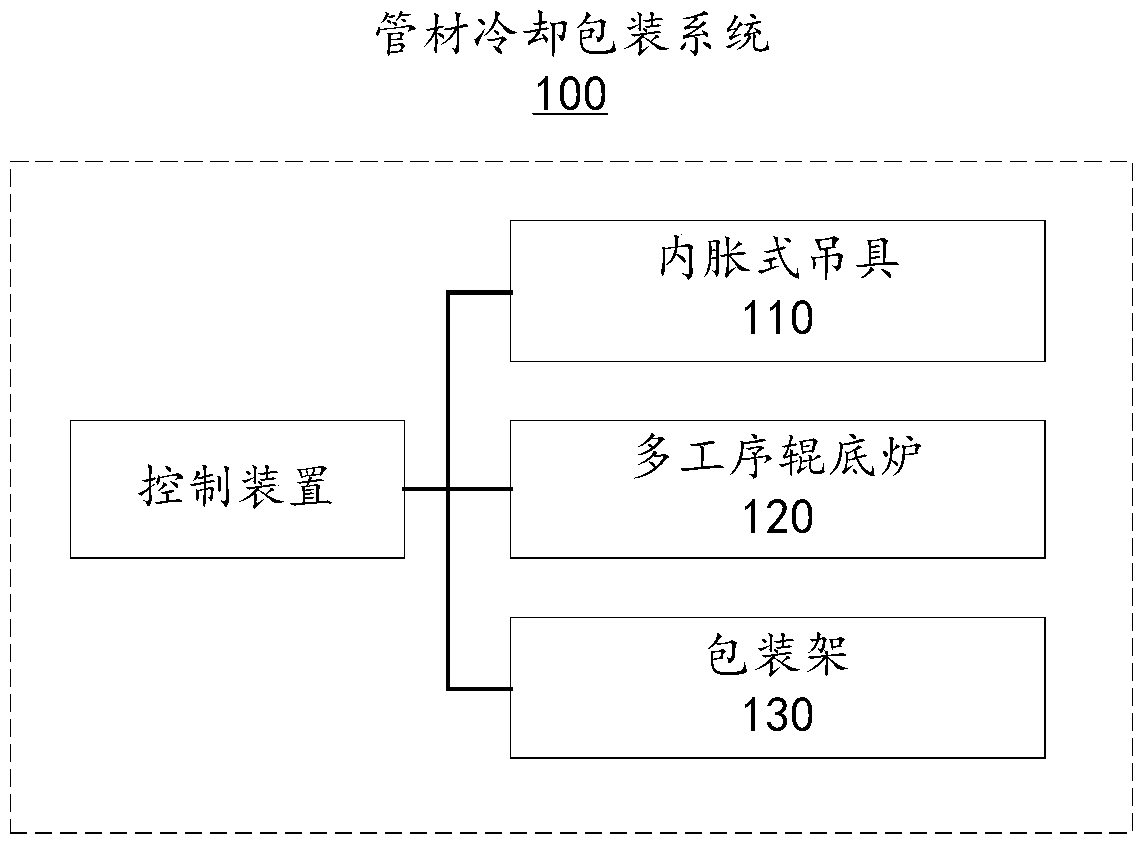

Annealing, cooling and packaging method and system for mosquito-repellent incense type large scattering disc

InactiveCN108950165AImprove packaging qualityImprove packaging efficiencyFurnace typesPackagingEngineeringHardness

The invention provides an annealing, cooling and packaging method and system for a mosquito-repellent incense type large scattering disc, and relates to the technical field of machine machining. The annealing, cooling and packaging method of the mosquito-repellent incense type large scattering disc comprises the steps that an internal expanding type lifting tool is used for placing a first large disc formed through winding of formed pipes into a multi-procedure roller bottom furnace or well type annealing furnace; the multi-procedure roller bottom furnace or well type annealing furnace is usedfor carrying out destressing annealing and cooling on the first large disc; the internal expanding type lifting tool is used for unloading the first large disc obtained after destressing annealing and cooling to a packaging frame to be packaged. The annealing, cooling and packaging method and system for the mosquito-repellent incense type large scattering disc is matched with the internal expanding type lifting tool, the multi-procedure roller bottom furnace or well type annealing furnace and the packaging frame provided by the mosquito-repellent incense type large scattering disc annealing,cooling and packaging system for destressing annealing and cooling on the pipe large disc to obtain the pipe scattering disc with the uniform hardness and the large coiling density, the pipe scattering disc can be subject to stacked transport, the transportation cost is reduced, and meanwhile, the inner cleaning degree of the large scattering disc copper pipe is improved.

Owner:冯境铭

Cooker convenient to clean, easy to adjust and with energy gathering ring

PendingCN109556144AImprove the heating effectPlay a role in stabilizing the flameDomestic stoves or rangesLighting and heating apparatusEngineeringHeat losses

The invention discloses a cooker convenient to clean, easy to adjust and with an energy gathering ring. The cooker comprises a bottom shell, a panel, a burner, a valve body, a double-layer liquid holding disc, a fire distributor, a pan support I, the energy gathering ring and a knob. The double-layer liquid holding disc, the fire distributor, the pan support I and the energy gathering ring are allcoaxially arranged at the upper end of a burner hole I. The fire distributor is installed at a gas outlet of the burner and comprises an outer ring fire distributor and an inner ring fire distributor. The outer ring fire distributor is provided with an inner side burning hole and an outer side burning hole. Work of the cooker is controlled by the traditional mechanical knob, needs of many consumers can be met, and operation and cleaning are more convenient through the mechanical knob especially for middle and old age consumers often using mechanical knobs. Through the double-layer liquid holding disc, soup, oil dirt and other liquids are prevented from flowing into the inner space of the cooker and from influencing normal use of the cooker. The energy gathering ring is convenient to install and detach, heat loss generated after gas burning can be reduced effectively, and the heat utilization rate is increased.

Owner:成都前锋电子有限责任公司

Smoke inlet device of incinerator

InactiveCN1948833AExtended stayIncrease the number of cyclic convective exchangesIncinerator apparatusFlue gasFuel gas

There is disclosed a flue gas inlet device of an incinerator, which consists of a the gas inlet pipe, a flue gas inlet connecting flange, a fuel gas inlet monitoring pipe, a flue gas special pipe, a flue gas pipe, a flue gas inlet fitting pipe and a fitting pipe flange. The flue gas inlet connecting flange and the flue gas inlet monitoring pipe are connected on the flue gas inlet pipe connected with the flue gas special pipe. The flue gas special pipe is connected with the flue gas pipe connected with the fitting pipe flange. The flue gas inlet fitting pipe is connected on the fitting pipe flange and using the refractory pouring material is used for pouring the flue gas inlet fitting pipe and the fitting flange to be an integral one.

Owner:GUIYANG AL-MG DESIGN & RES INST

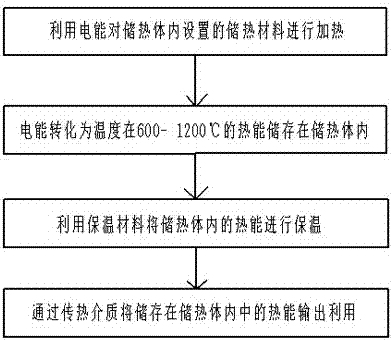

Steel/iron energy storage method

InactiveCN107314696AEasy maintenanceAdjust the number of groups at willHeat storage plantsHeat exchanger casingsThermal energyEngineering

The invention discloses a steel / iron energy storage method. Electric energy is used for heating a heat storage material arranged in a heat storage body; the electric energy is converted to heat energy with a temperature of 600-1200 DEG C to store in the heat storage body; an insulation material is used for insulating the heat storage material in the heat storage body; in the insulation period, the heat energy stored in the heat storage body is stably and controllably output and used; and the heat storage material is steel / iron.

Owner:北京中热能源科技有限公司

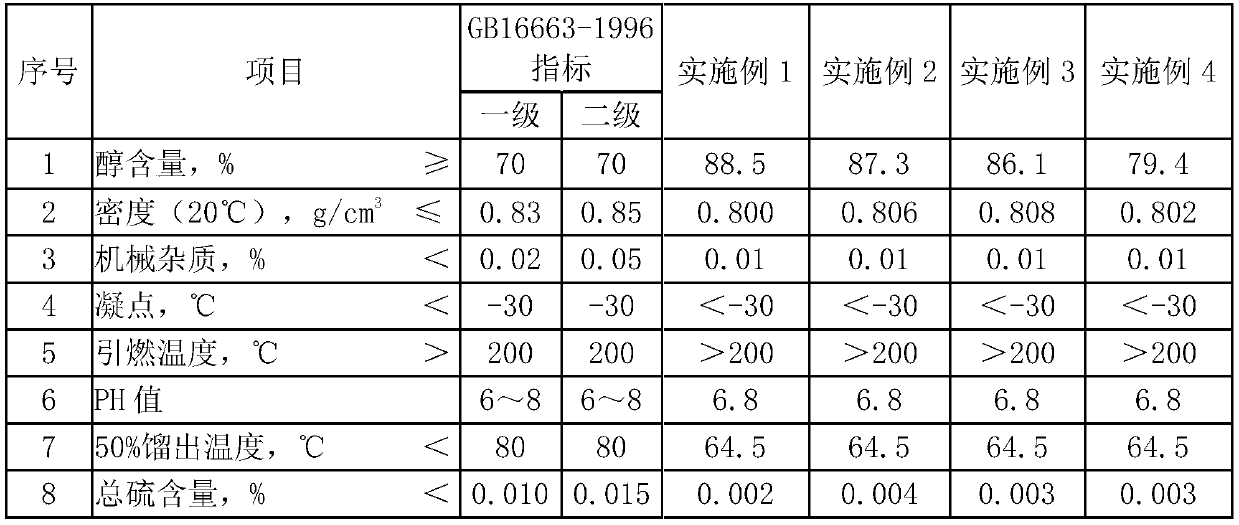

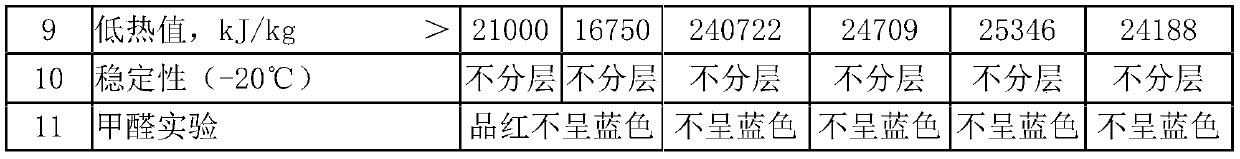

Alcohol-based fuel formed by utilizing waste alcohol azeotrope and preparation method of alcohol-based fuel

InactiveCN109971517AReduce energy consumptionReduce the generation of waste water and other by-productsLiquid carbonaceous fuelsFuel additivesSolventEthyl acetate

The invention relates to the technical field of fuel synthesis, and in particular relates to an alcohol-based fuel formed by utilizing a waste alcohol azeotrope. The alcohol-based fuel comprises the following components: 60-80 parts of methanol, 10-20 parts of an isopropanol-water azeotrope and 5-10 parts of an ethyl acetate-ethanol-water ternary azeotrope. The alcohol-based fuel provided by the invention has high stability and no delamination under the temperature condition of -20 DEG C, and all the indexes meet the requirements of GB 16663-1996 (Alcohol based liquid fuel); and in the field of solvent recovery, under the condition that an azeotrope production amount does not achieve a scale, the method of preparing the alcohol-based fuel by directly using the azeotrope and the methanol asraw materials has more economic advantages, and can reduce energy consumption and reduce unnecessary purification; and the alcohol-based fuel has a high calorific value and high utilization of thermal efficiency, thereby achieving the purpose of resource reuse.

Owner:JIANGSU YINGTIAN CHEM

Shoe drying case

The invention discloses a shoe drying case, which belongs to a household electric appliance. The current shoe drying case cannot be used for drying shoes and disinfecting in the absent of an external power supply. The shoe drying case comprises a case body formed by an upper cover and a lower case body. An inner lining is arranged in the lower case body; a shed frame is arranged in the inner lining; a transverse rod is arranged over the shed frame; and a container is arranged on one side of the inner lining. A storage battery, a control circuit element, a heating element, an ozone generator and a fan are arranged in the container; and the control circuit element, the heating element, the zone generator and the fan are connected in the same loop. A power converting switch is arranged on the inside-outside connecting part of the lower case body corresponding to the control circuit element so that low voltage operation power required for drying and infecting can be provided by a power leading-out end of the battery in the absent of the external heavy power. By the shoe drying case, shoes can be dried and disinfected with or without the external heavy power; the shoes, socks and insoles in the inner lining can be dried; moreover, the shoe drying case can be used for cleaning of indoor air, warm in winter and heat preservation of food.

Owner:SUPERMAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com