A kind of low temperature granulation method of solid sodium lactate

A low-temperature granulation and sodium lactate technology, applied in the separation/purification of carboxylic acid compounds, can solve the problems of only 17% thermal efficiency utilization rate of dry hot air, difficult process, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

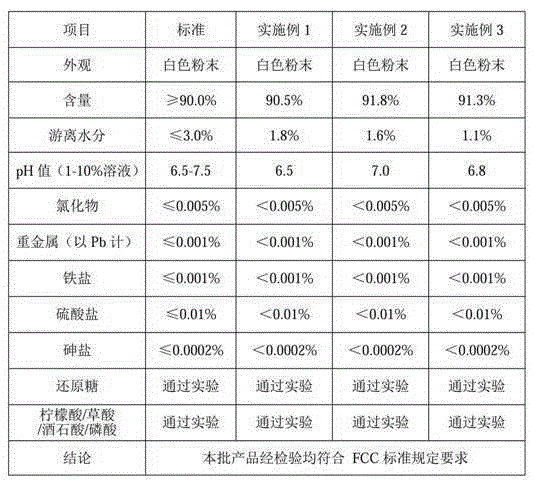

Examples

Embodiment 1

[0021] A low-temperature granulation method of solid sodium lactate, comprising the following steps:

[0022] 1) The sodium lactate solution is evaporated under reduced pressure using a wiped film evaporator. Before evaporation, the content of sodium lactate is 40wt%. Controlled at 0.04MPa, the concentration process can be completed within 5 minutes;

[0023] 2) Press the concentrated solution into the rotary centrifugal spray granulator through compressed air. At this time, the temperature of the concentrated solution is 91°C, so that the concentrated solution is sprayed downward from the high-speed rotating disk on the upper part of the granulator. , the speed of the centrifugal disc is 10,000 rpm; at the same time, the cold air of 5°C is introduced from the top of the granulator synchronously to control the ventilation volume, and the temperature is not higher than 45°C when the cold air is drawn out from the lower side of the granulator; the liquid droplets Cool and solid...

Embodiment 2

[0025] A low-temperature granulation method of solid sodium lactate, comprising the following steps:

[0026] 1) Evaporate the sodium lactate solution under reduced pressure using a wiped film evaporator. The content of sodium lactate before evaporation is 46wt%. When evaporating, the jacket heating steam of the wiped film evaporator is 0.25MPa. When evaporating, the temperature inside the wiped film evaporator is controlled at 92°C, and the pressure is controlled at a negative pressure of 0.045MPa. The concentration process can be completed within 5 minutes Finish;

[0027] 2) Introduce the concentrated solution into the centrifugal spray granulator. At this time, the temperature of the concentrated solution is 91°C, so that the concentrated solution is sprayed downward from the rotating centrifugal disc of the granulator. Cool air at 10°C is introduced from the top of the granulator, and the ventilation volume is controlled. When the cold air is drawn out from the lower sid...

Embodiment 3

[0029] A low-temperature granulation method of solid sodium lactate, comprising the following steps:

[0030] 1) Evaporate the sodium lactate solution under reduced pressure using a wiped film evaporator. Before evaporation, the content of sodium lactate is 47wt%. , the pressure is controlled at a negative pressure of 0.05MPa;

[0031] 2) Introduce the concentrated solution into the centrifugal spray granulator. At this time, the temperature of the concentrated solution is 91°C, so that the concentrated solution is sprayed downward from the rotating centrifugal disc of the granulator. Cool air at 14°C is introduced above the granulator to control the ventilation rate. When the cold air is drawn out from the lower side of the granulator, the temperature is not higher than 45°C; after heat exchange between the cold air and the concentrated solution, solid crystalline powder of sodium lactate is formed and falls into the chassis. , Complete the granulation of solid sodium lactat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com