Two ends straight through type all glass vacuum heat collection tube of solar energy

A solar heat collection tube, straight-through technology, applied in the field of double-ended straight-through all-glass vacuum solar heat collection tubes, can solve the problems of heat transfer medium and impurities in the tube, inability to fully utilize heat energy, and low reliability, etc., to achieve High thermal efficiency and thermal energy utilization rate, full utilization of thermal energy, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

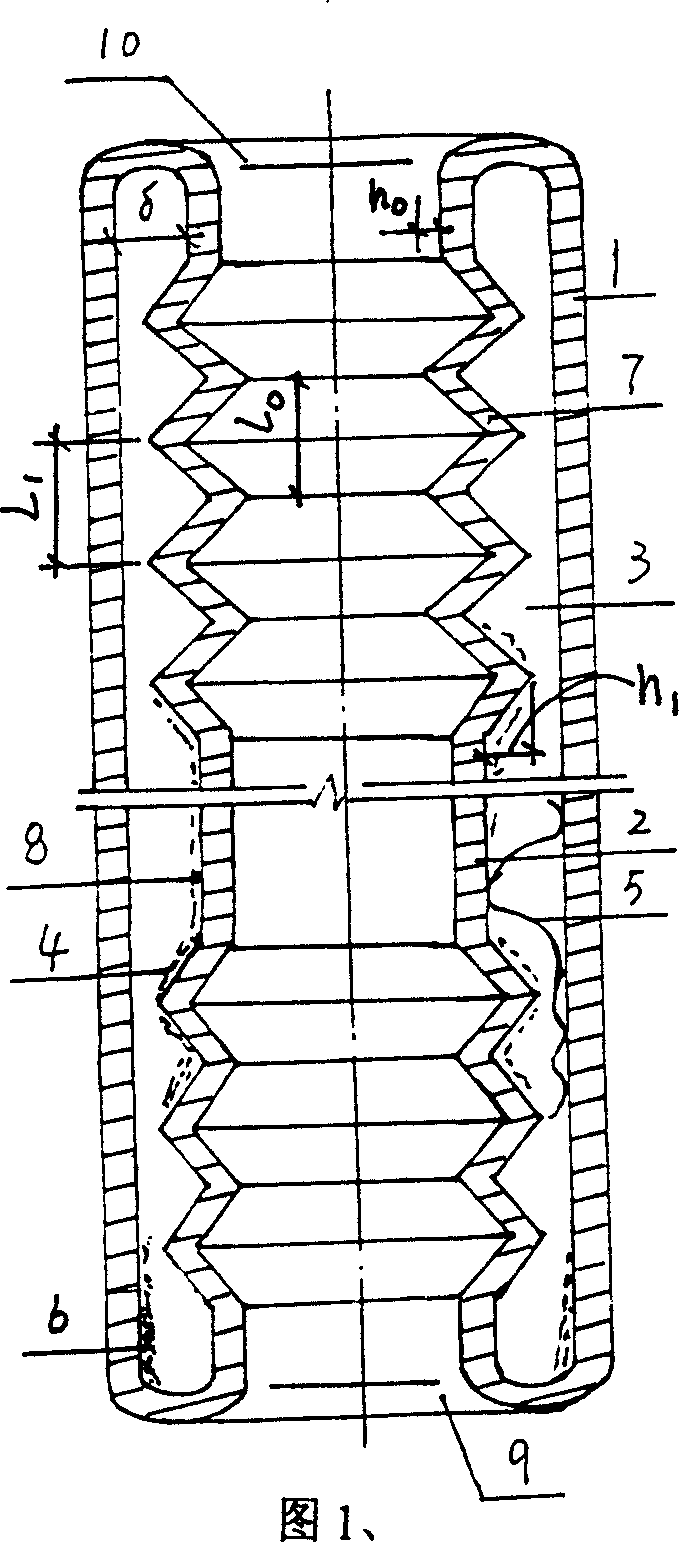

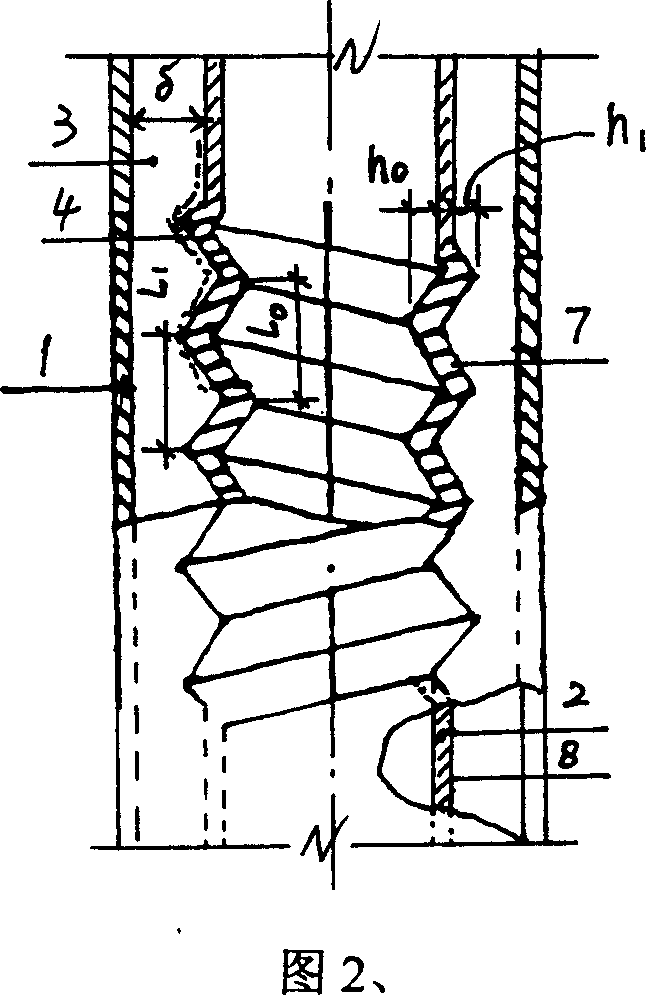

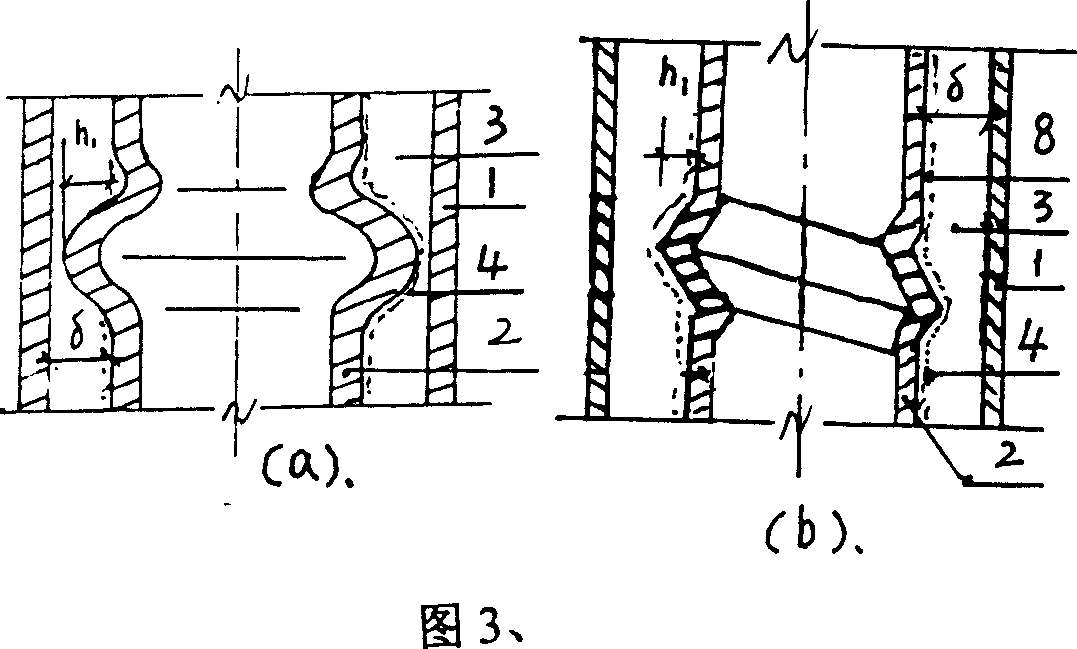

[0013] In conjunction with the attached drawings, it is further explained in detail; in the figure, 1 shows the outer glass tube, 4 shows the absorbing coating, 5 shows the elastic support, 6 shows the getter, and 9 and 10 respectively show the inlet and outlet of the heat transfer medium in the tube. Export.

[0014] As shown in Figures 1 and 2, the corrugated body or threaded body of the inner glass tube 2 is distributed in a continuous or discontinuous group of corrugations 7, and each group of corrugations 7 contains at least one annular corrugation body , generally containing 1 to 6 ring wave protrusions.

[0015] As shown in Figure 1, there is one or two group-shaped wave protrusions 7 near one end of the inner glass tube 2, or one or two assembled wave protrusions 7 are respectively provided at its two ends, the wave protrusions Body 7 is a corrugated or threaded body.

[0016] As shown in FIG. 2 , there are 1 to 4 group-shaped corrugations 7 in the middle of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com