Electric vehicle waste heat utilization variable-frequency thermal pump air conditioning system and method thereof

A technology of heat pump air conditioners and electric vehicles, which is applied in the field of automobile air conditioners, can solve the problems of unable to meet the heating needs of automobiles, consume large electric energy, and shorten the mileage of electric vehicles, so as to ensure normal operation and service life, save energy, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

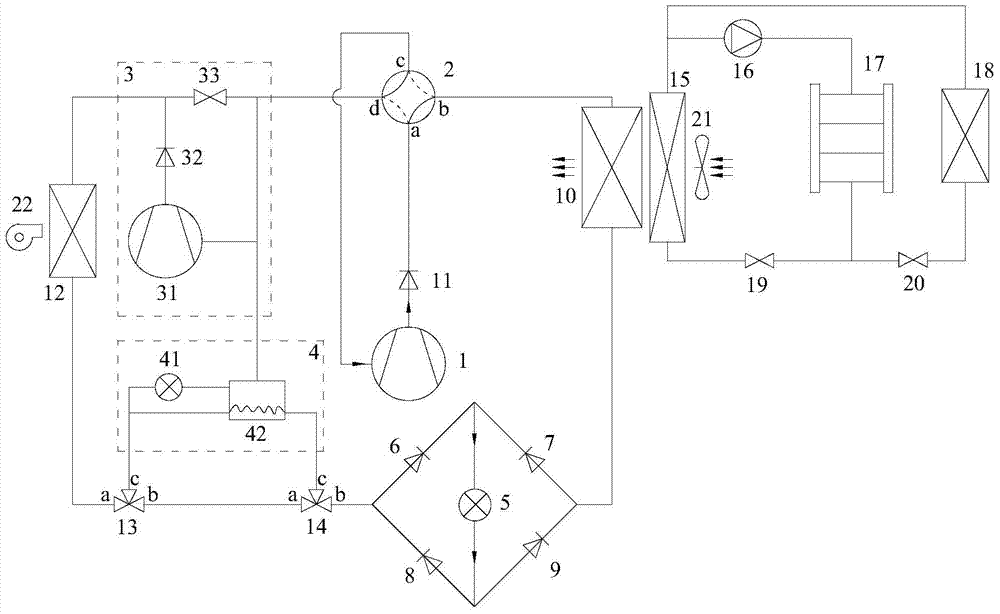

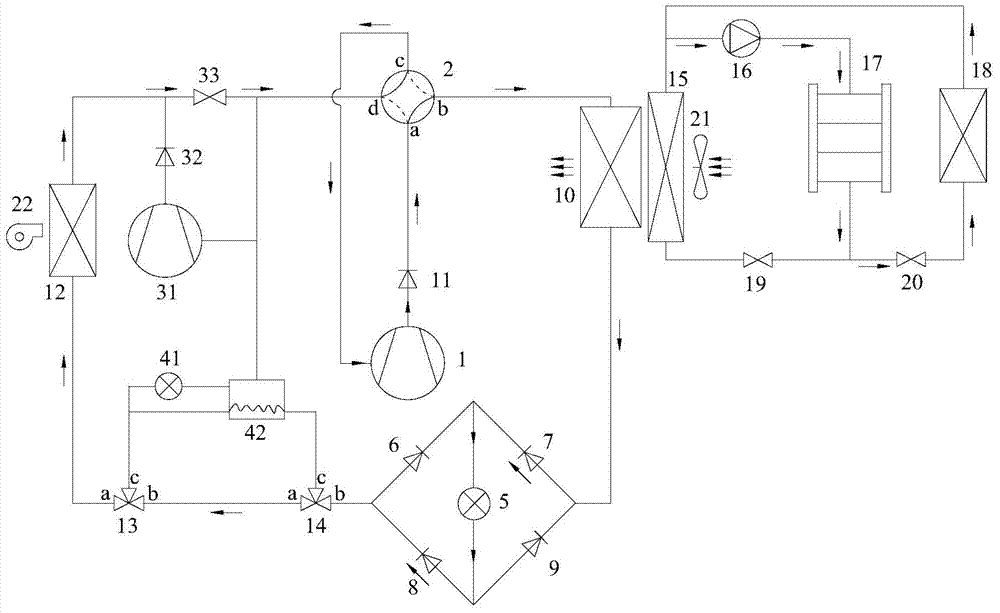

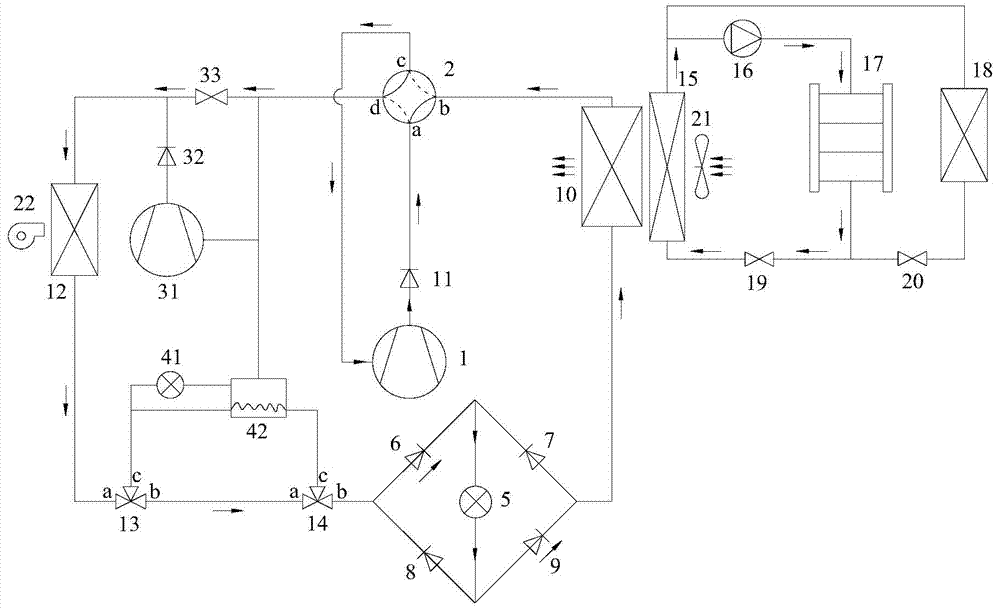

[0047] like figure 1 shown. The electric vehicle waste heat utilization frequency conversion heat pump air conditioning system of the present invention includes a refrigerant circulation circuit and a waste heat recovery circuit that can automatically switch between single-stage and double-stage compression according to environmental conditions; the refrigerant circulation circuit includes a low-pressure stage compressor 1, a first Check valve 11, four-way reversing valve 2, interior heat exchanger 12, exterior heat exchanger 10, first interior fan 22, exterior fan 21, main expansion valve 5, second one-way valve 6, The third one-way valve 7, the fourth one-way valve 8, the fifth one-way valve 9, the first three-way solenoid valve 13, the second three-way solenoid valve 14, the high-pressure stage compressor assembly 3 and the intercooler assembly 4;

[0048] The waste heat recovery circuit includes a waste heat recovery radiator 15, a waste heat discharge radiator 18, an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com