Capstan crab gear shift sleeve

A technology for shifting clutches and winches, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of reducer or system damage, inconvenient operation, improper operation, etc., and achieve friction reduction, easy operation, and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

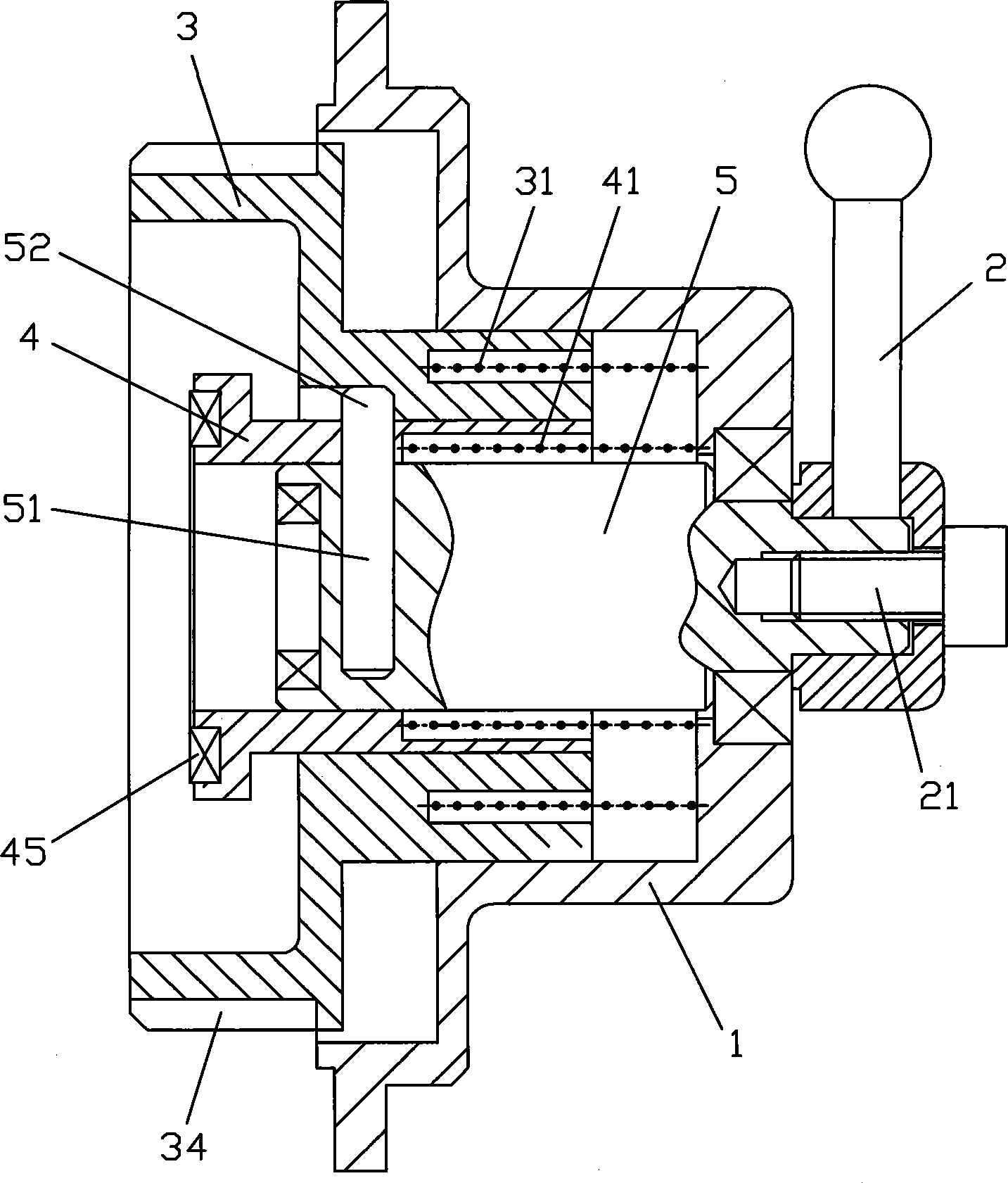

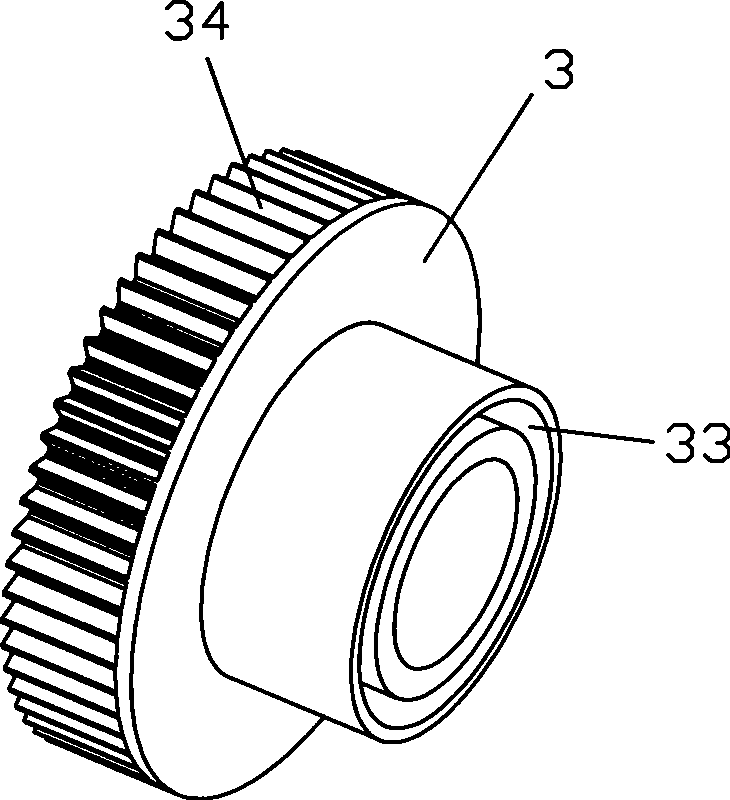

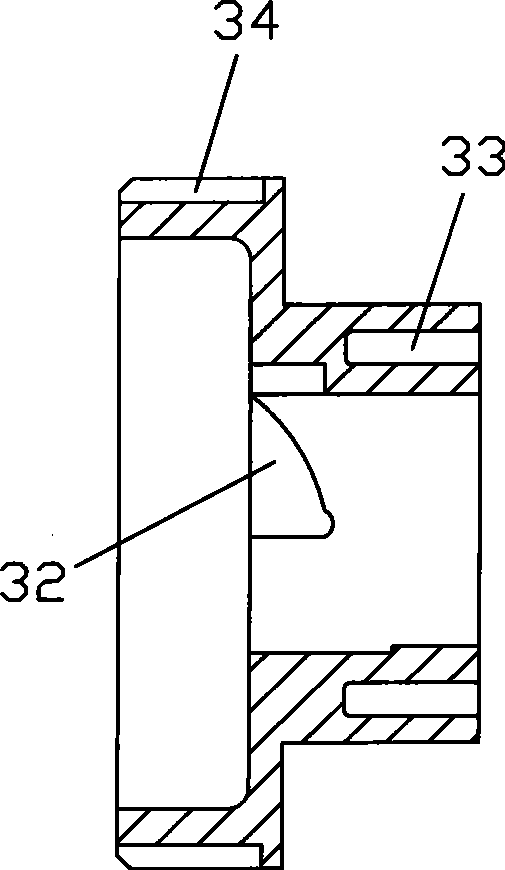

[0029] Such as Figure 1 to Figure 7 As shown, the winch shift clutch of the present invention includes a housing 1 and a handle 2. The housing 1 is provided with a clutch camshaft 3, and the clutch camshaft 3 is connected with a shift camshaft 4 and a shift clutch shaft. 5. The cam surfaces on the clutch camshaft 3 and shift camshaft 4 are sequentially linked and fitted. The clutch camshaft 3 is provided with a cam curved surface I32, the shift camshaft 4 is provided with a cam curved surface II42, and the shift camshaft 4 is also provided with an annular curved surface 43 connected with the cam curved surface II42. The position of the cam curved surface I32 is corresponding, and the cam curved surface I32, the cam curved surface II42 and the torus curved surface 43 are all 1 / 4 circular arcs. A clutch return spring 31 is provided between the clutch cam gear shaft 3 and the housing 1, and the clutch cam gear shaft 3 is provided with an annular slot 33. One end of the clutch r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com