Patents

Literature

63results about How to "Prevent radial deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

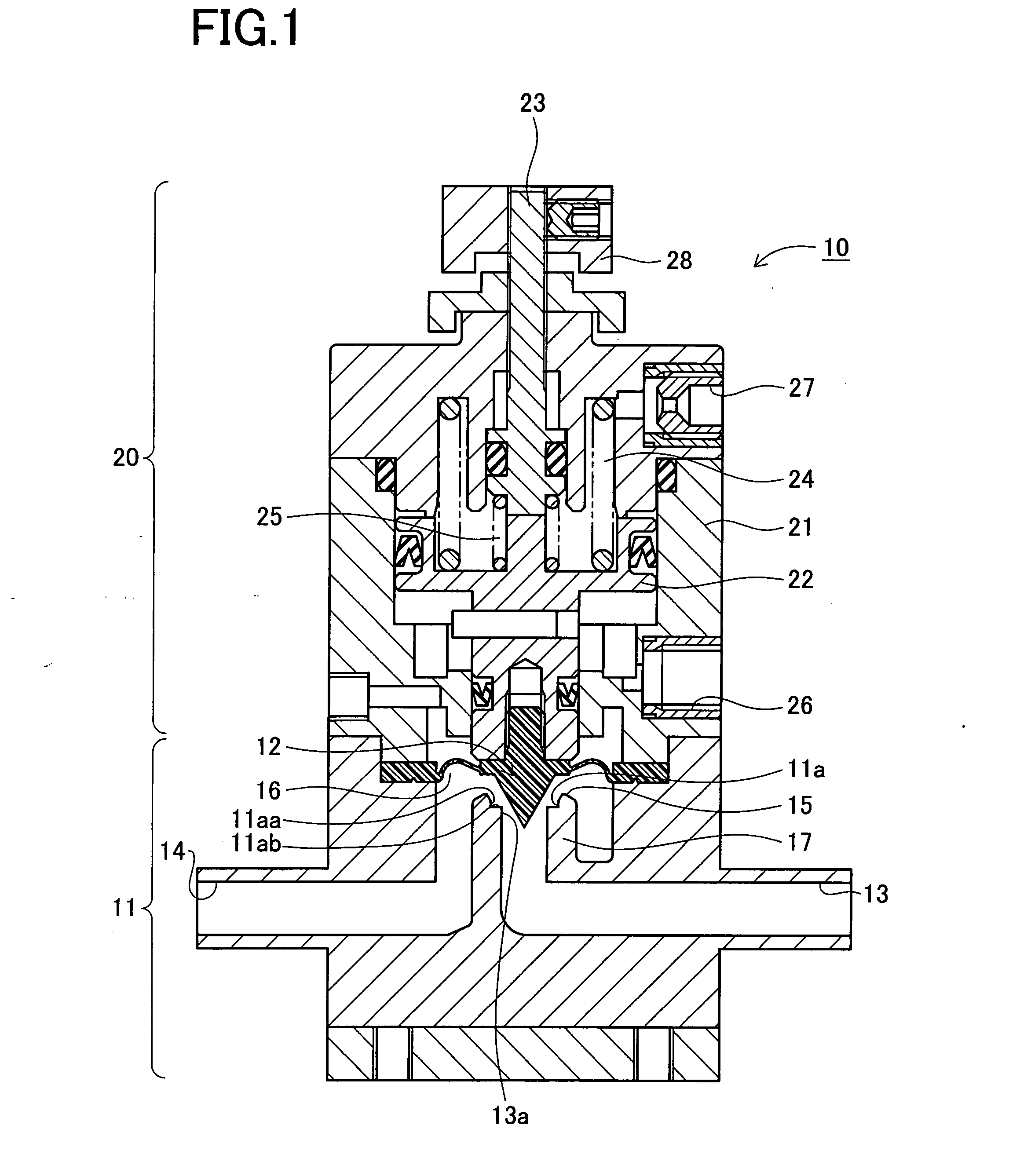

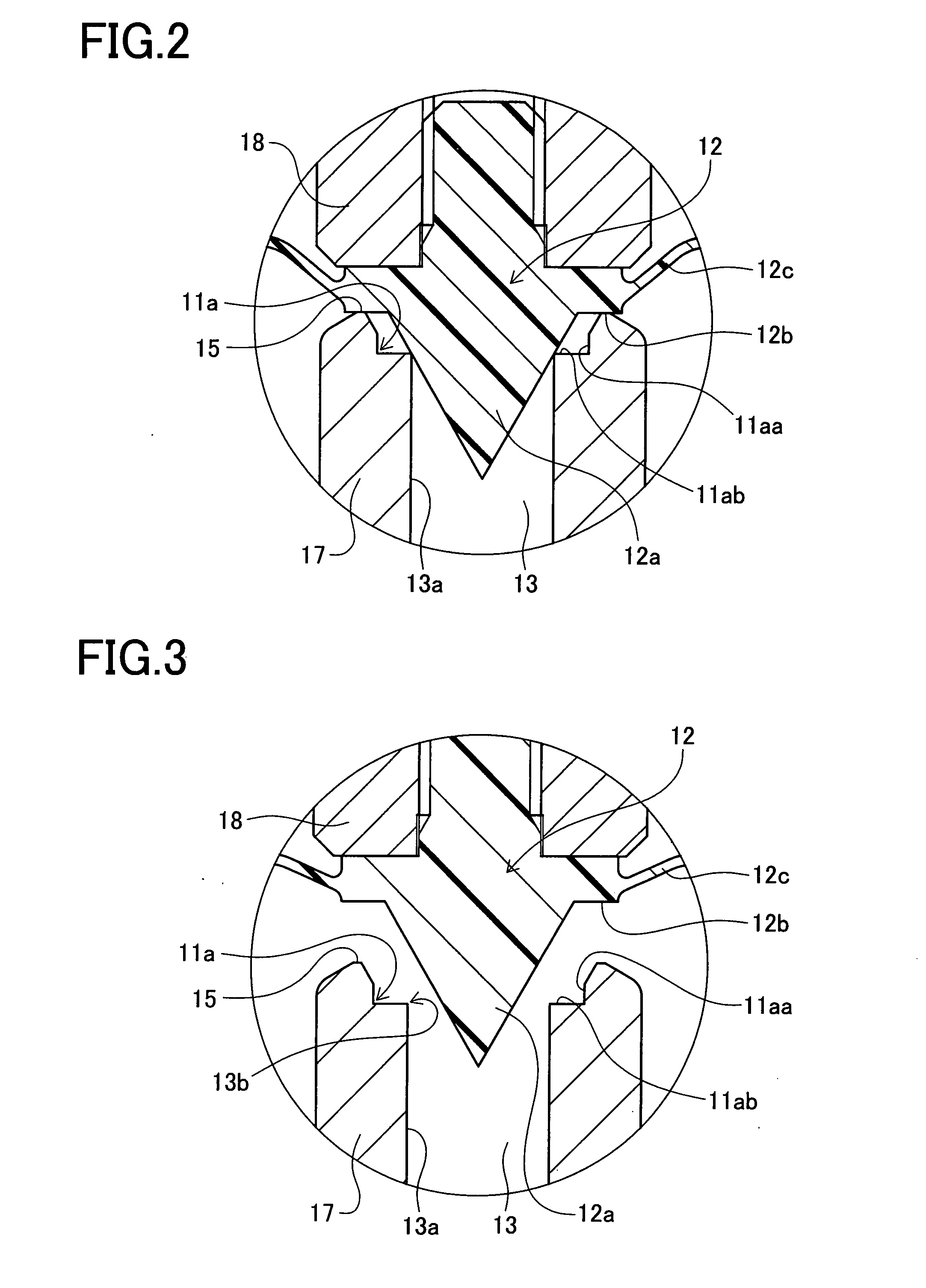

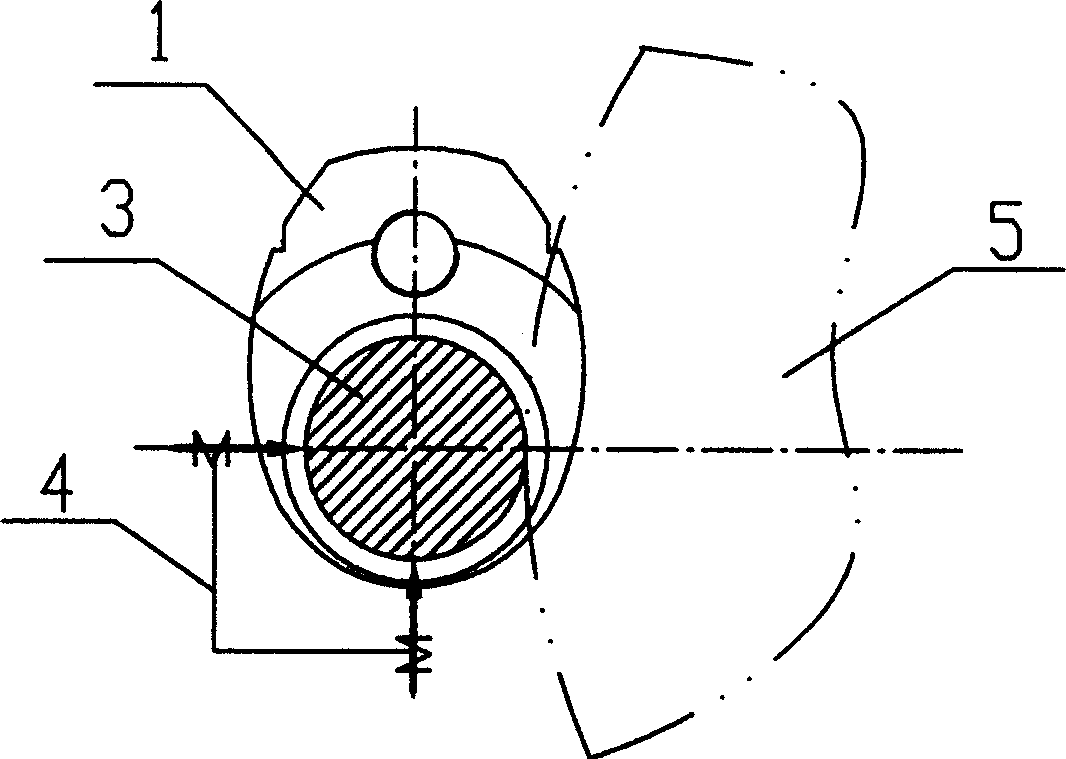

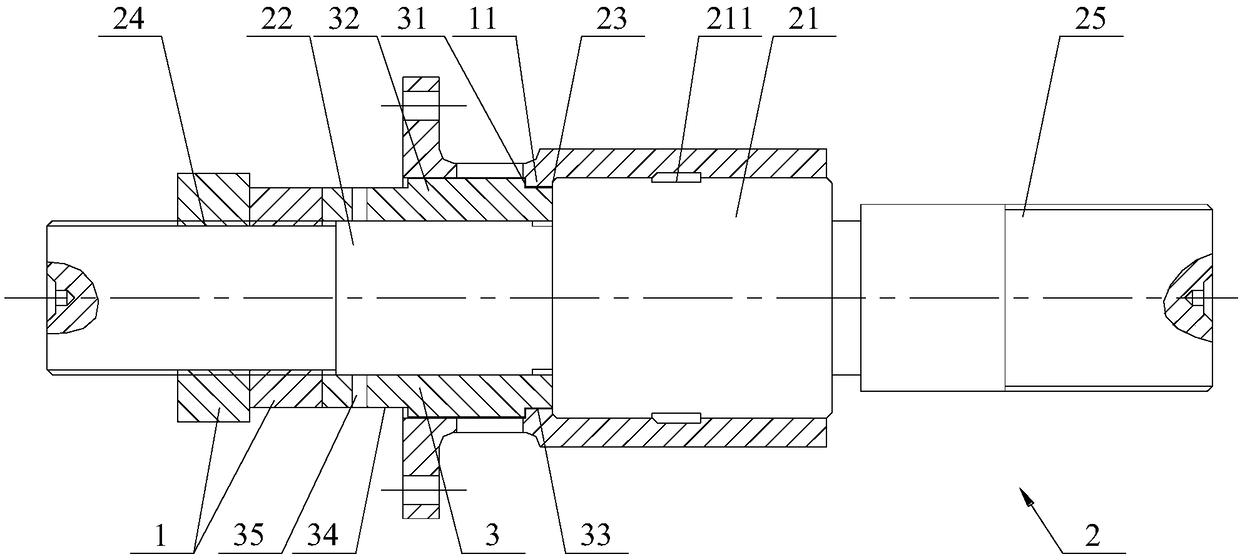

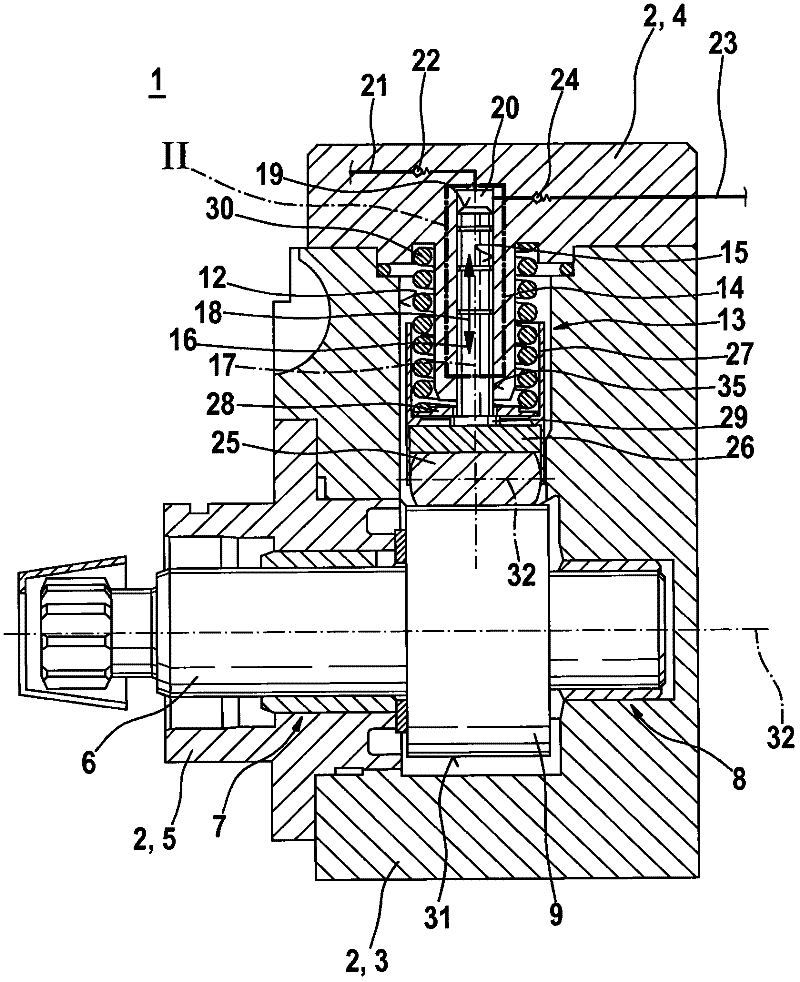

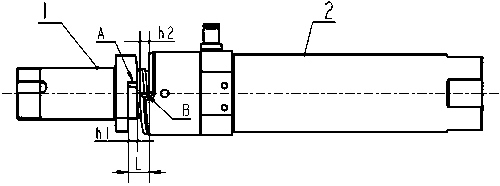

Flow control valve

InactiveUS7537194B2Improve flow stabilityPrevent radial deformationDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

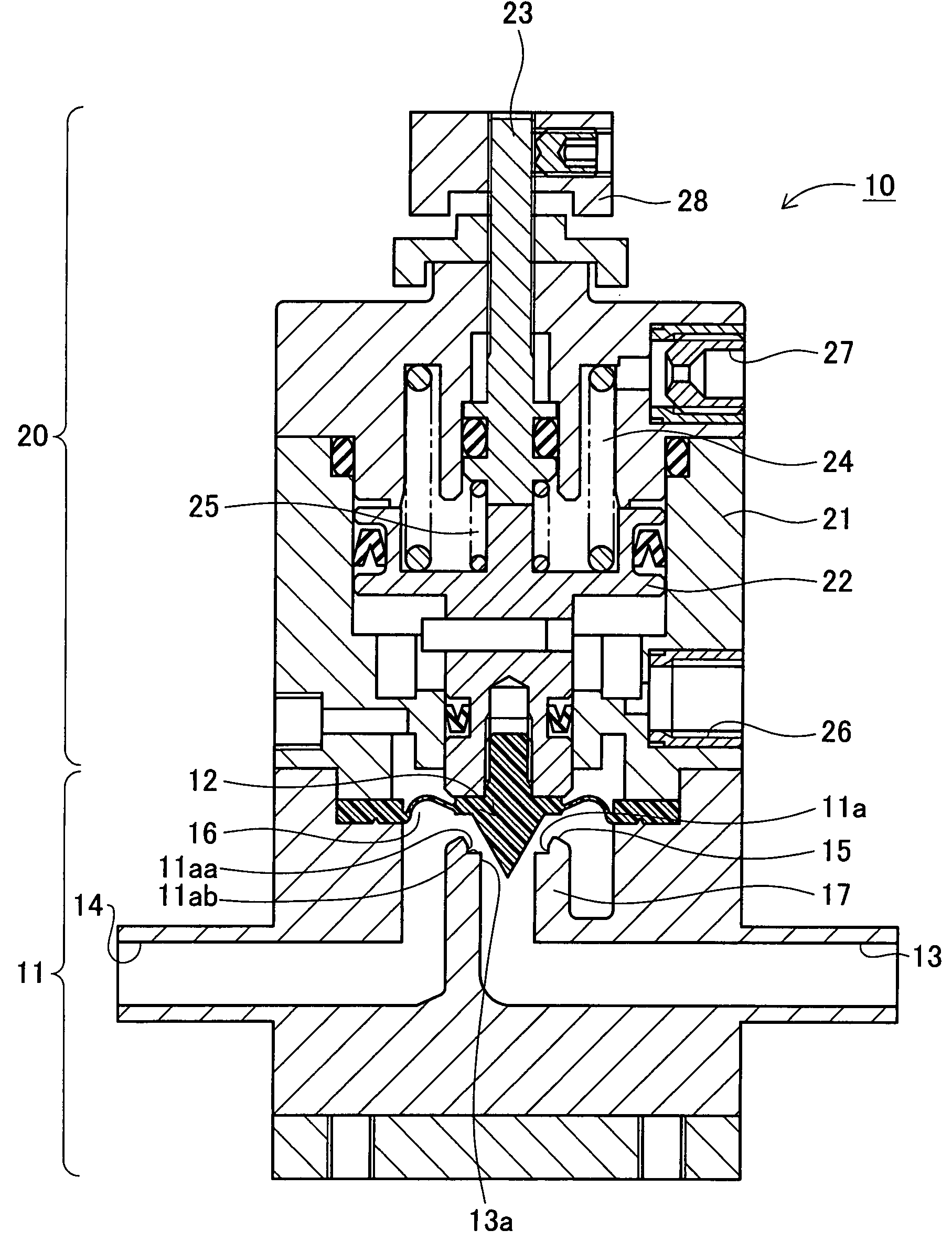

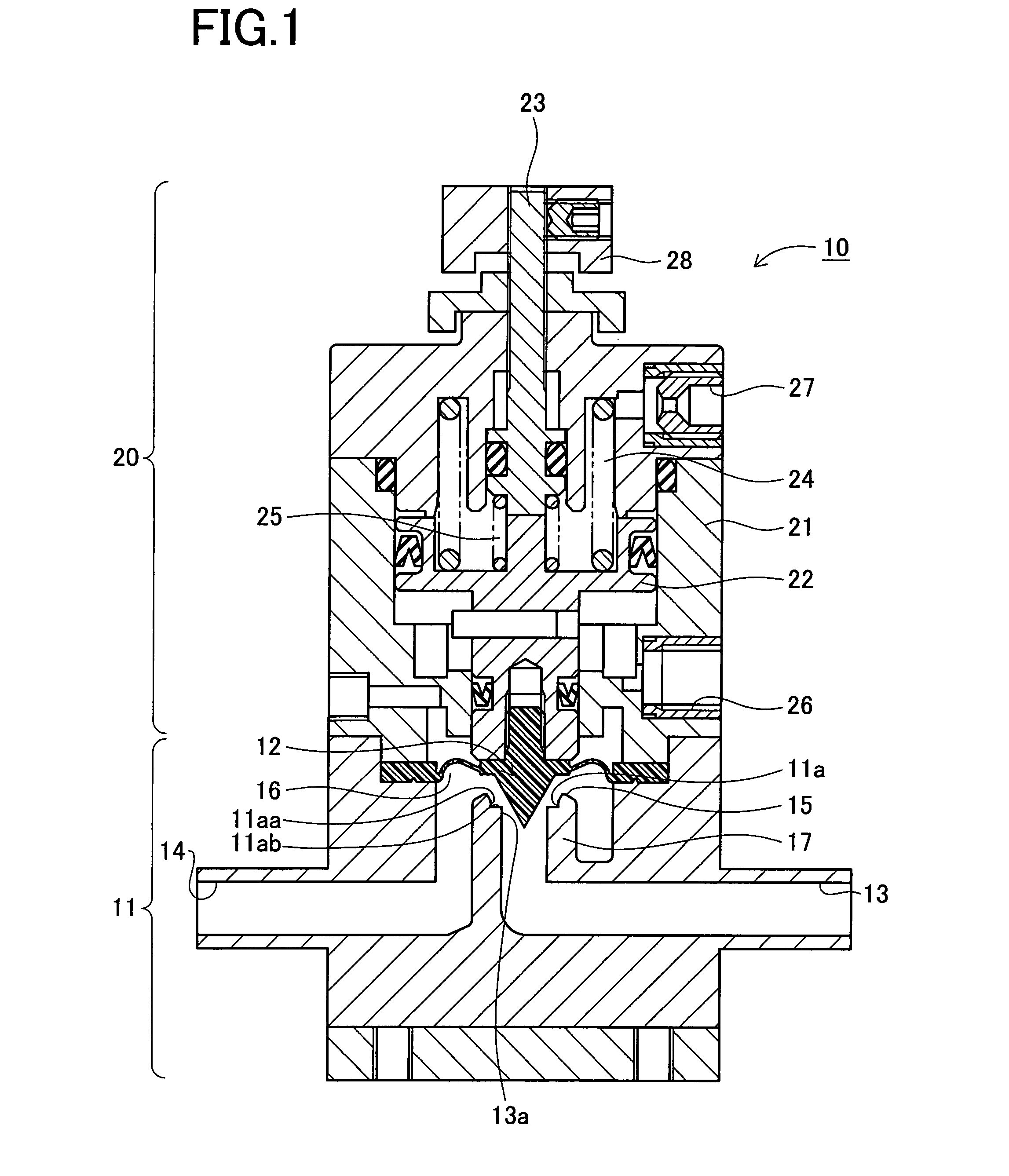

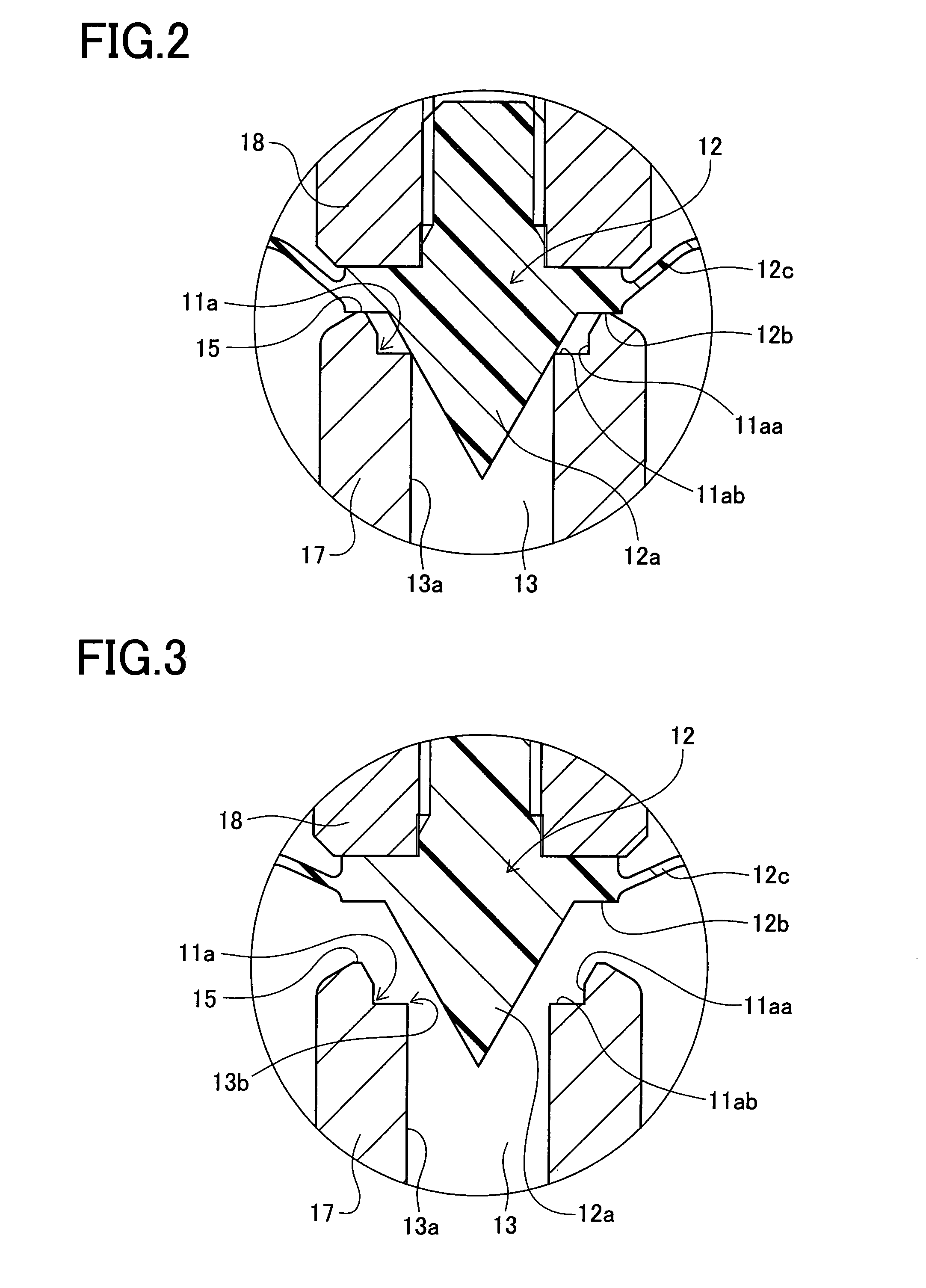

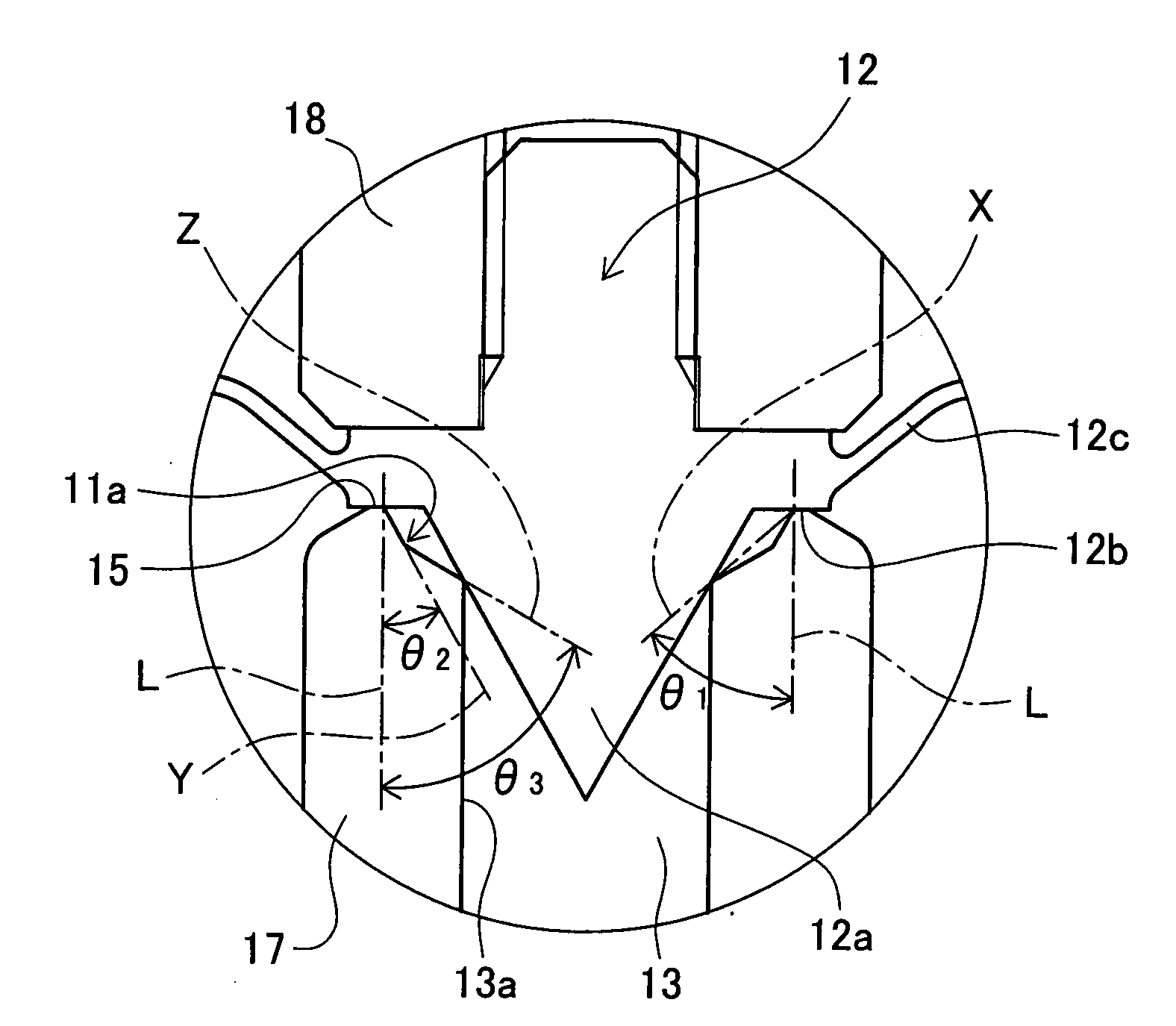

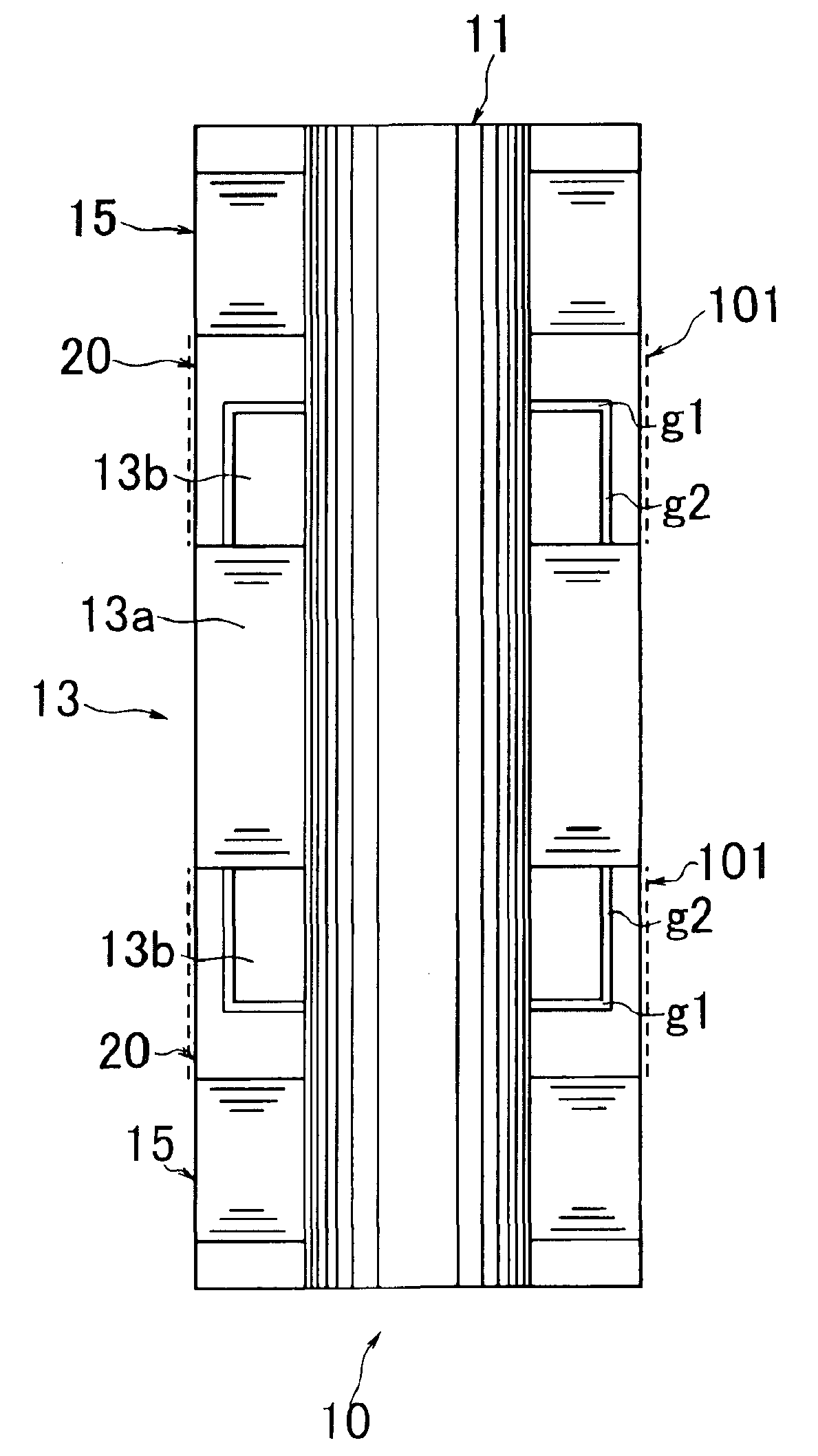

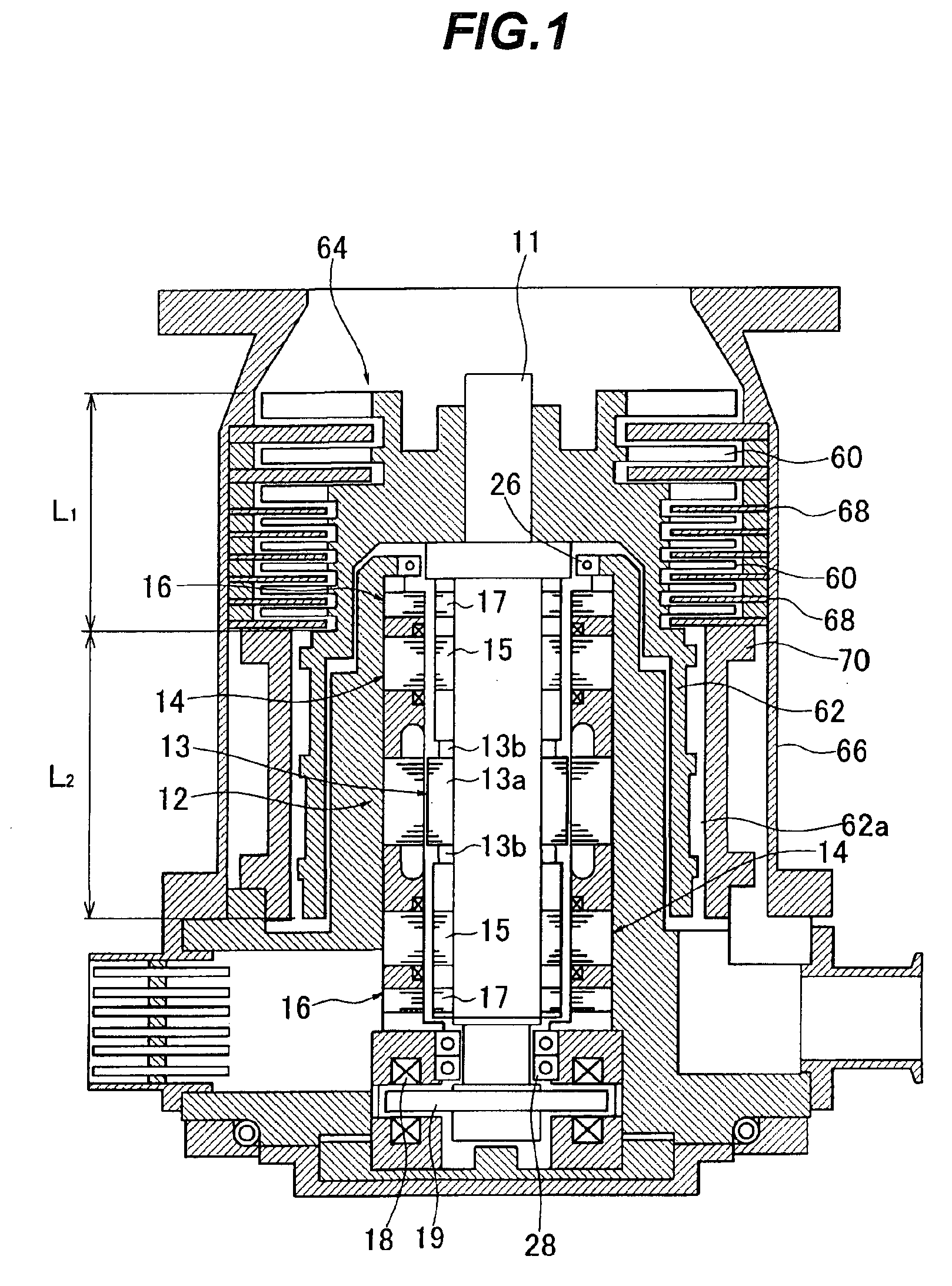

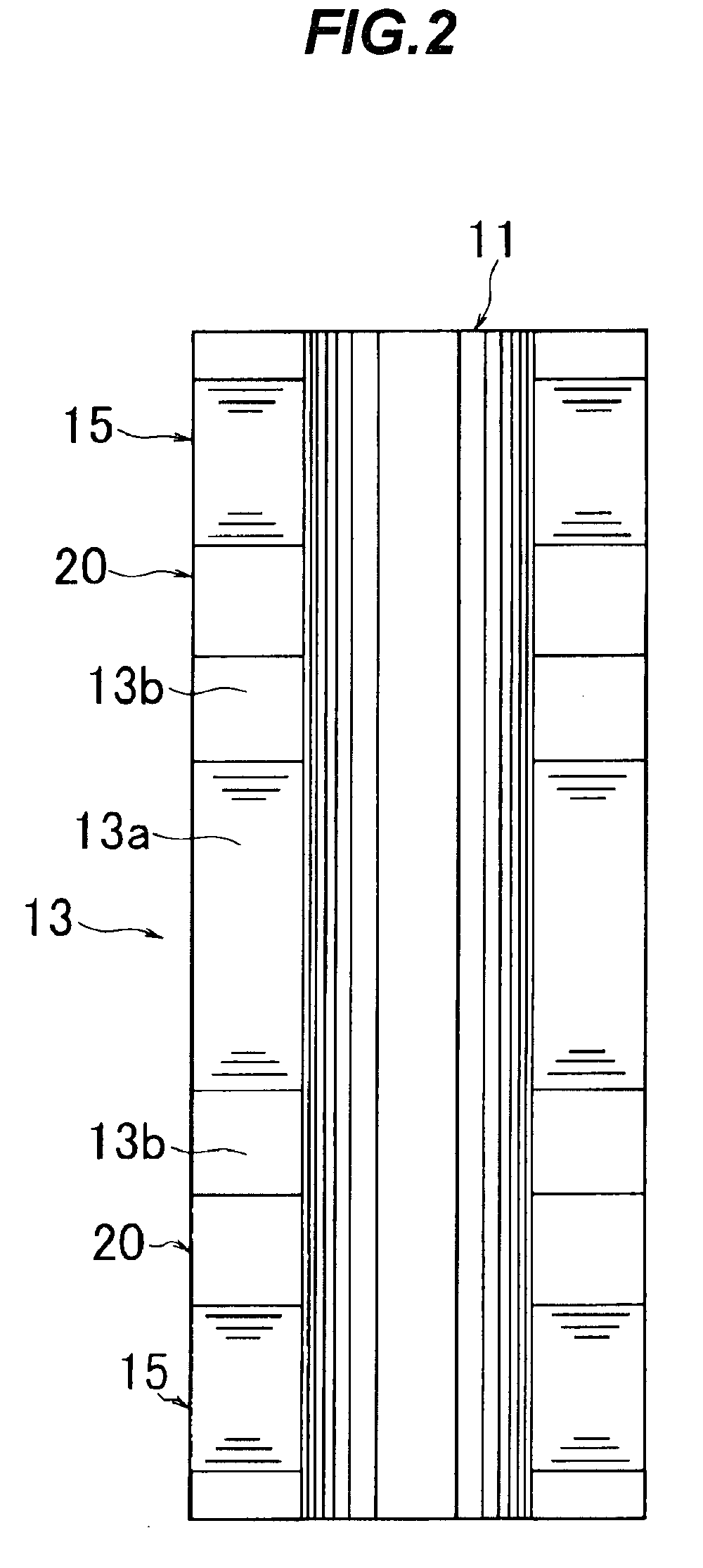

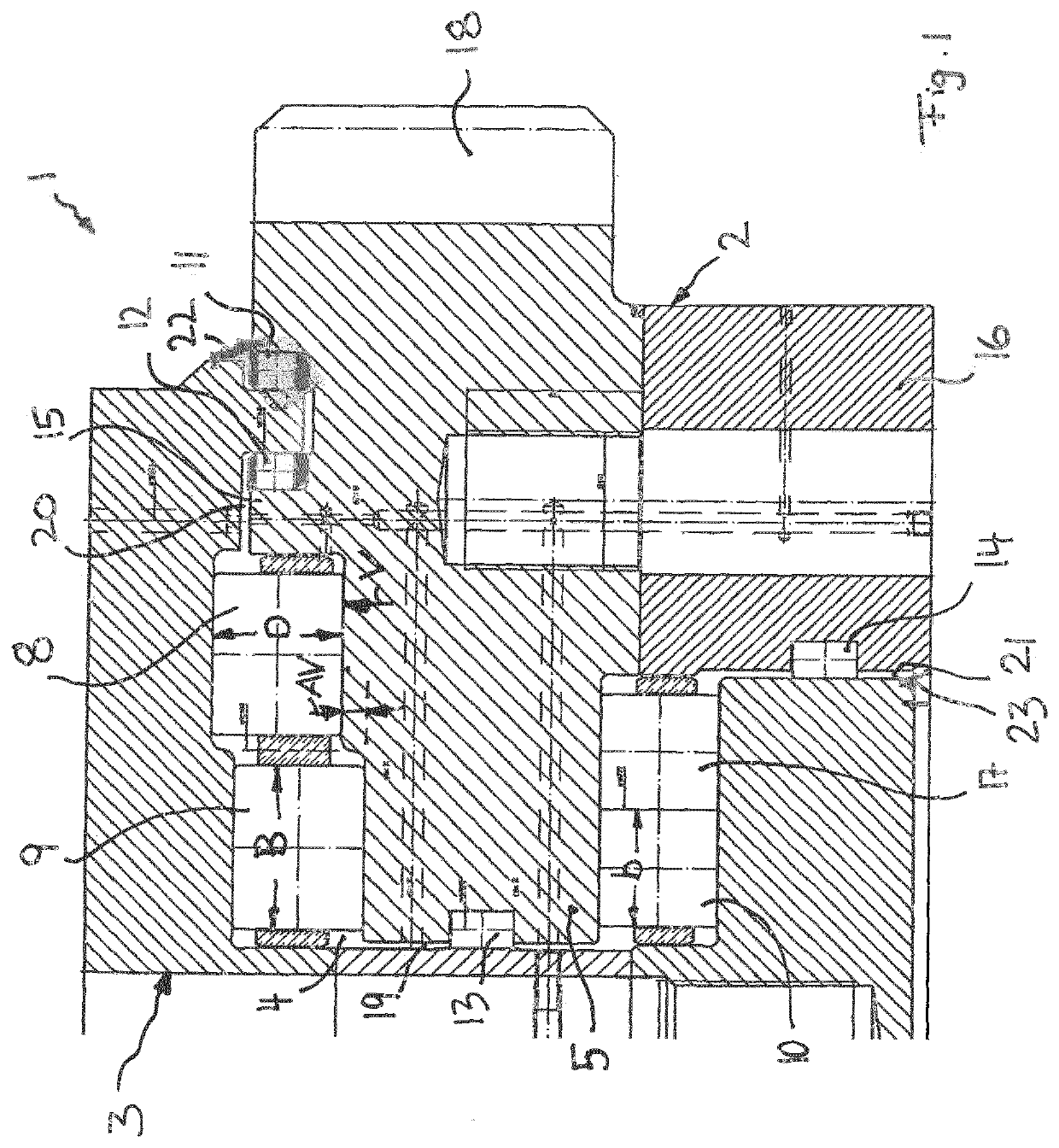

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

Flow control valve

InactiveUS20080001110A1Improve flow stabilityDownsizingDiaphragm valvesOperating means/releasing devices for valvesEngineeringControl valves

A compact flow control valve with high flow stability is arranged to comprises: a valve body made of resin including; a first passage formed in the valve body; a valve port communicating with the first passage; and a valve seat formed around the valve port; a valve element movable into contact with and away from the valve seat; a valve chamber formed around the valve seat; a second passage communicating with the valve chamber; and a flow adjustment rod for adjusting a flow rate of a fluid allowed to flow in the valve chamber, wherein the flow adjustment rod is adjustable in position to change an opening degree of the valve element relative to the valve seat for adjusting the flow rate, and the flow control valve further comprises an annular recess formed in an inner periphery of the valve seat formed surrounding the valve port and configured to prevent radial deformation of the valve port when the valve element is moved into contact with the valve seat.

Owner:CKD

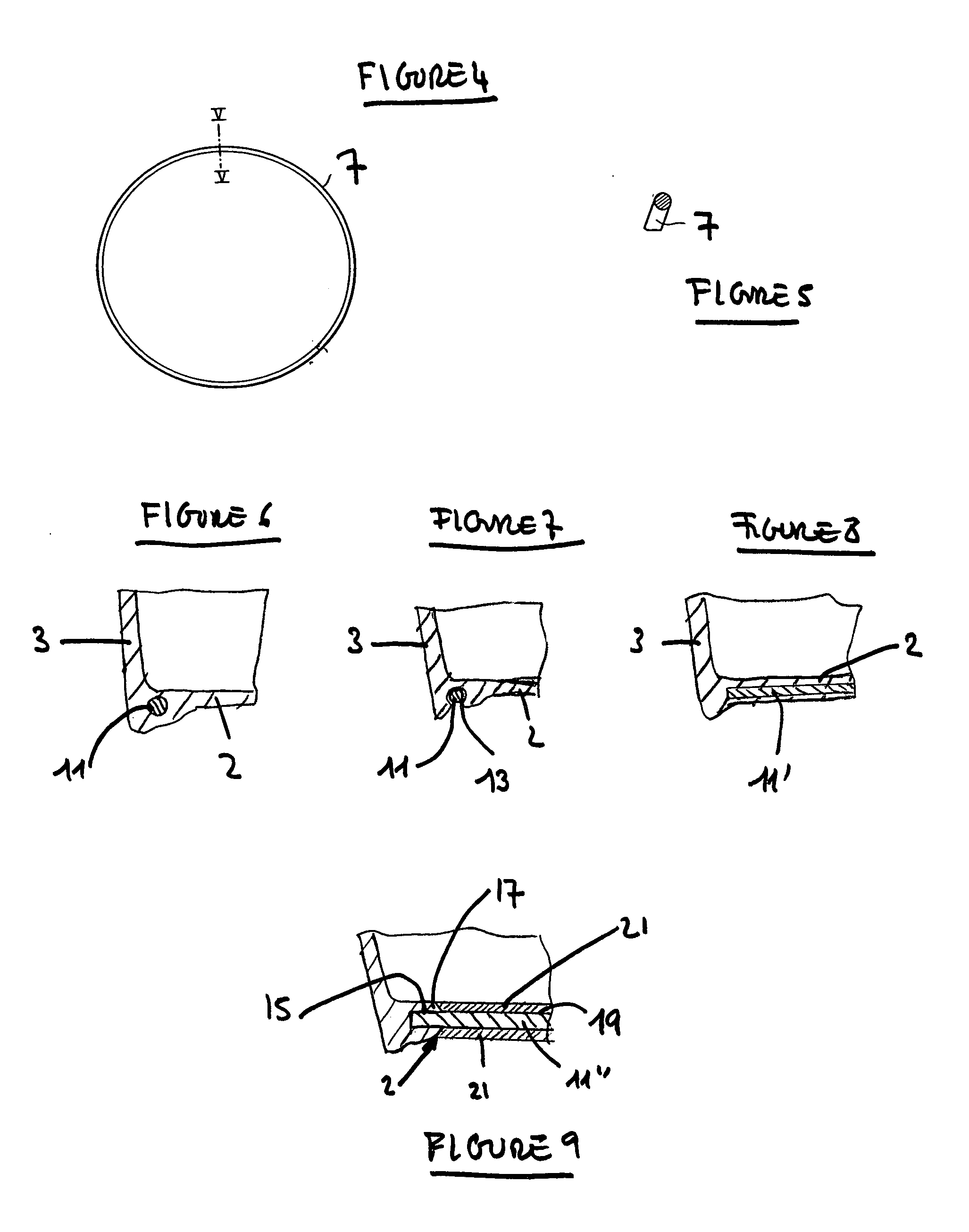

Stiffened flexible mould

InactiveUS20050000960A1StabilityImprove effectArc welding apparatusMachines/enginesEngineeringElastomer

A mould for culinary preparation comprises a hollow tray made from a flexible elastomer material and comprising a side wall, the top end of which forms an opening, and a rigid stiffener. Another stiffener, for example an annular or discoid stiffener is connected to the bottom, close to the junction with the side wall.

Owner:SEB SA

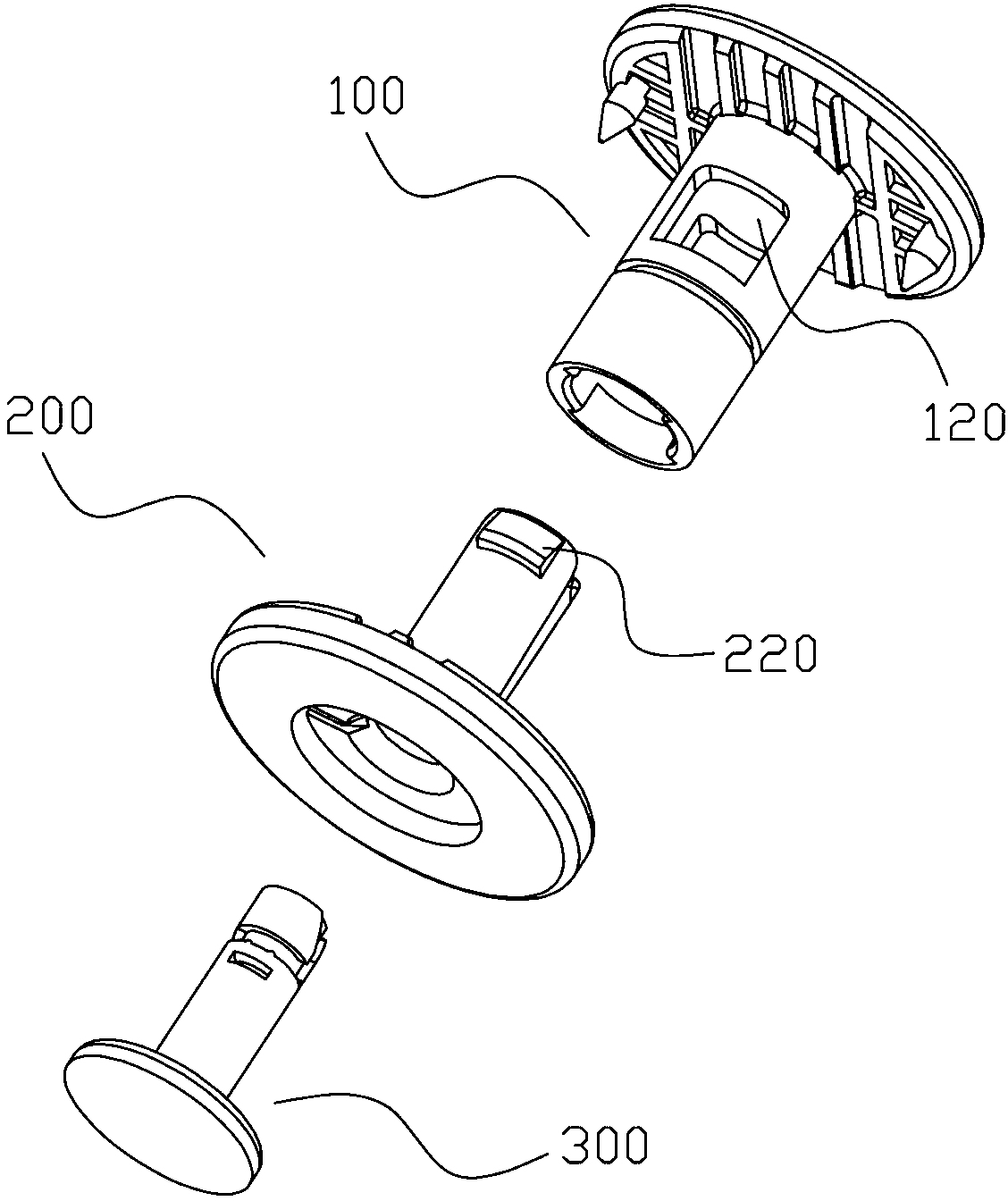

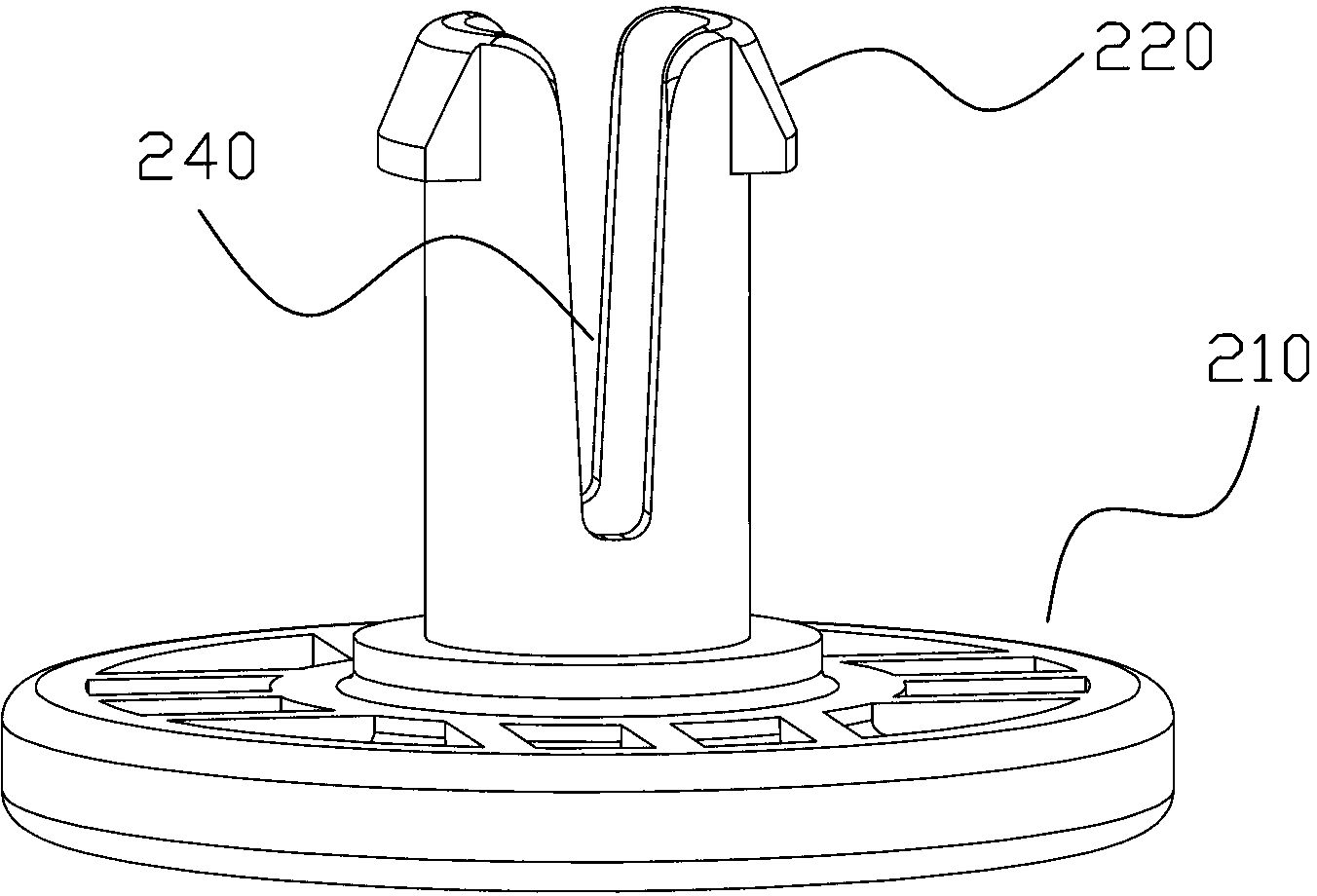

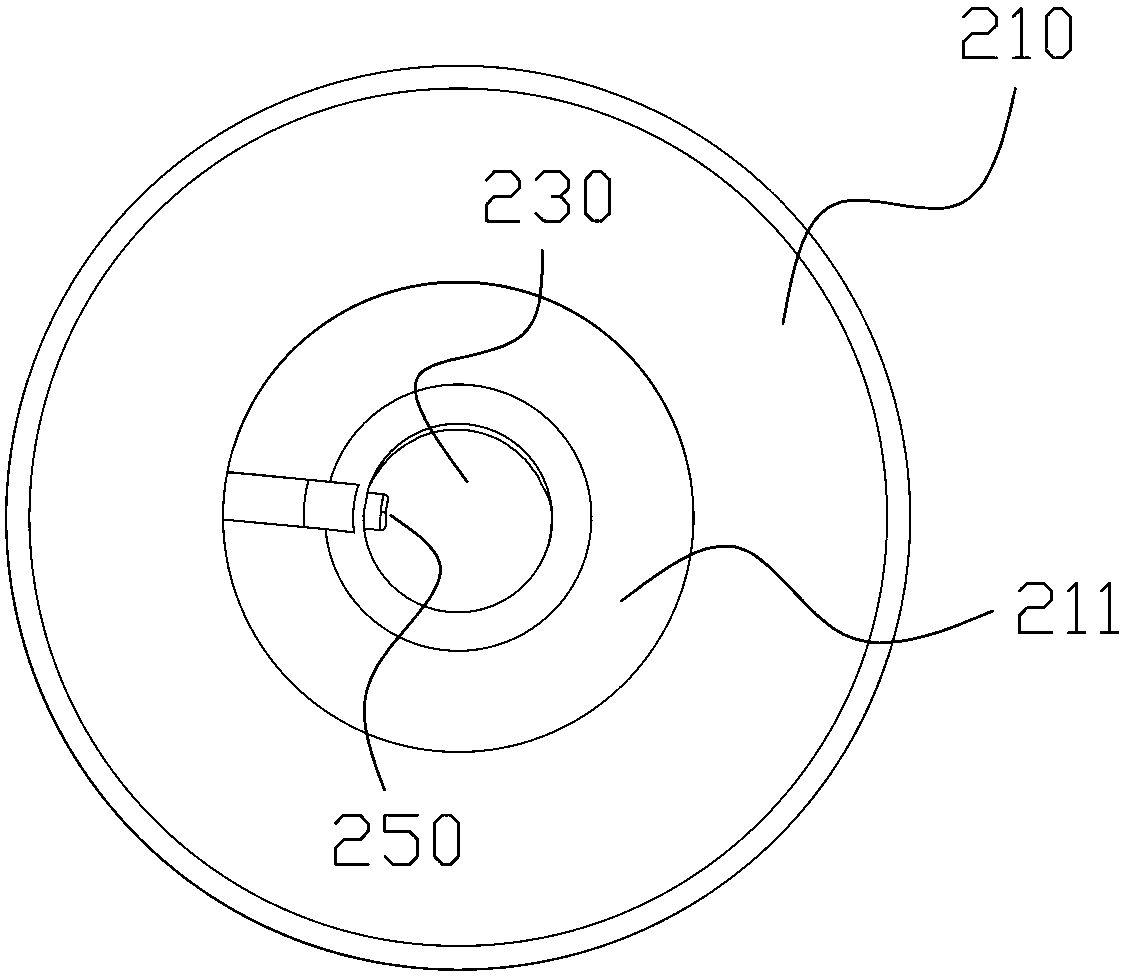

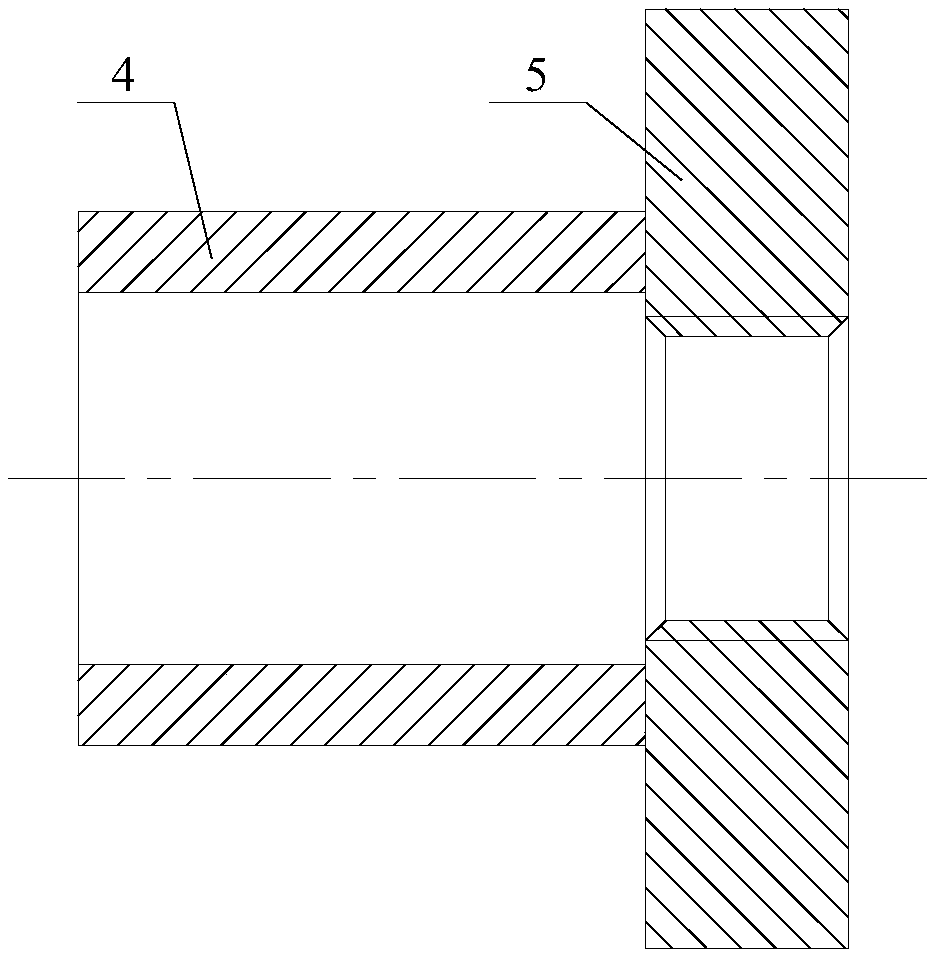

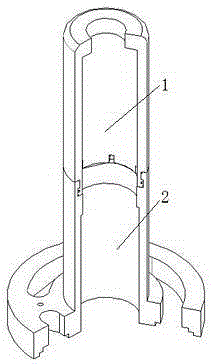

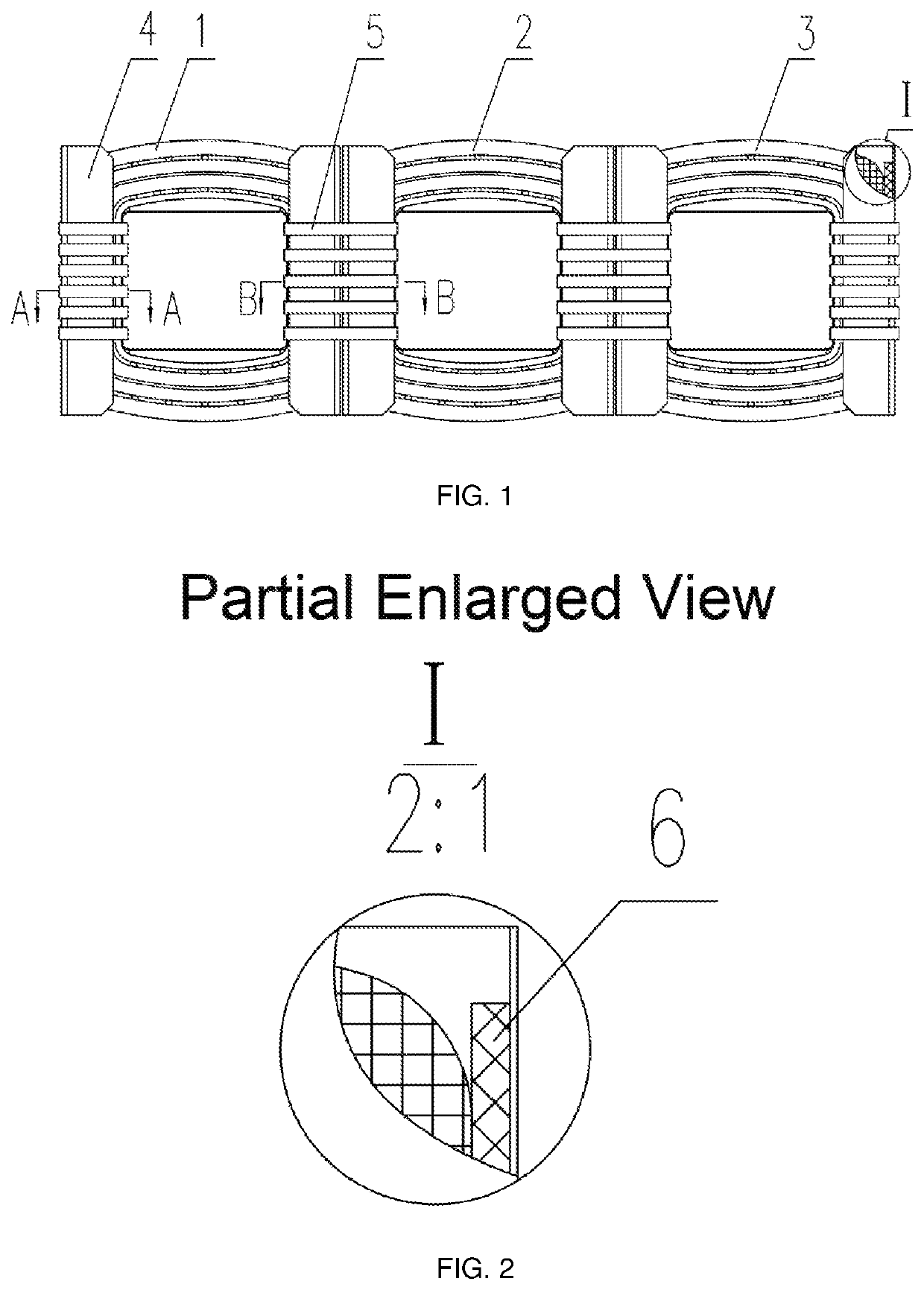

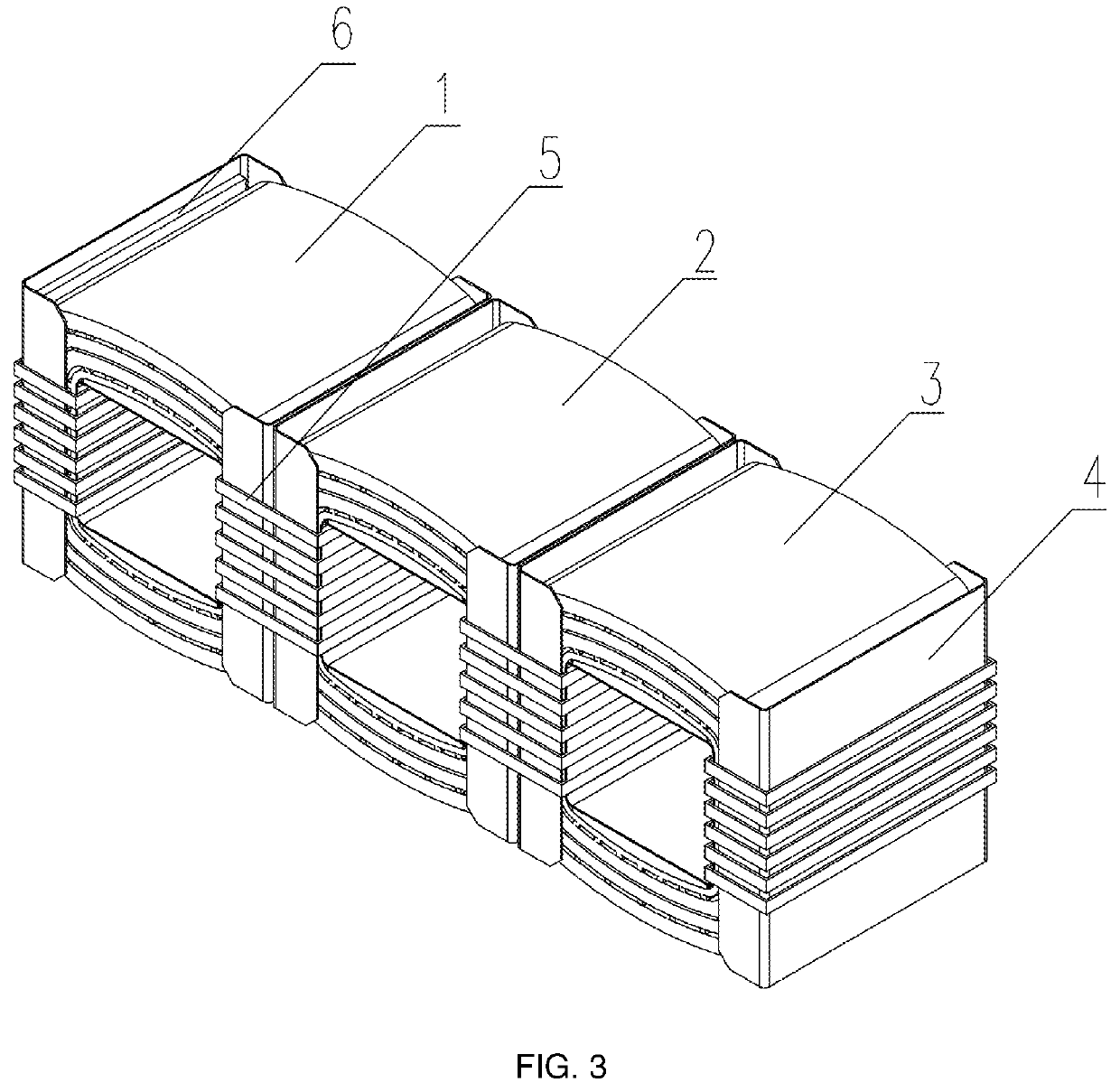

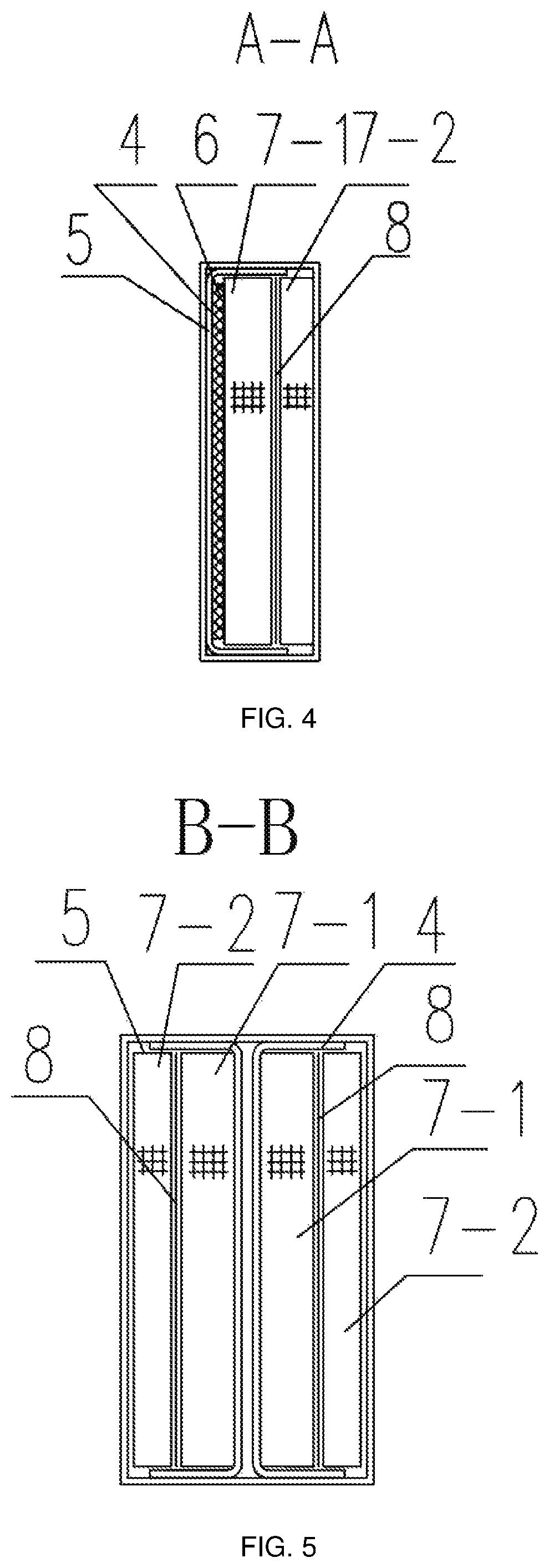

Connecting element for plate connection

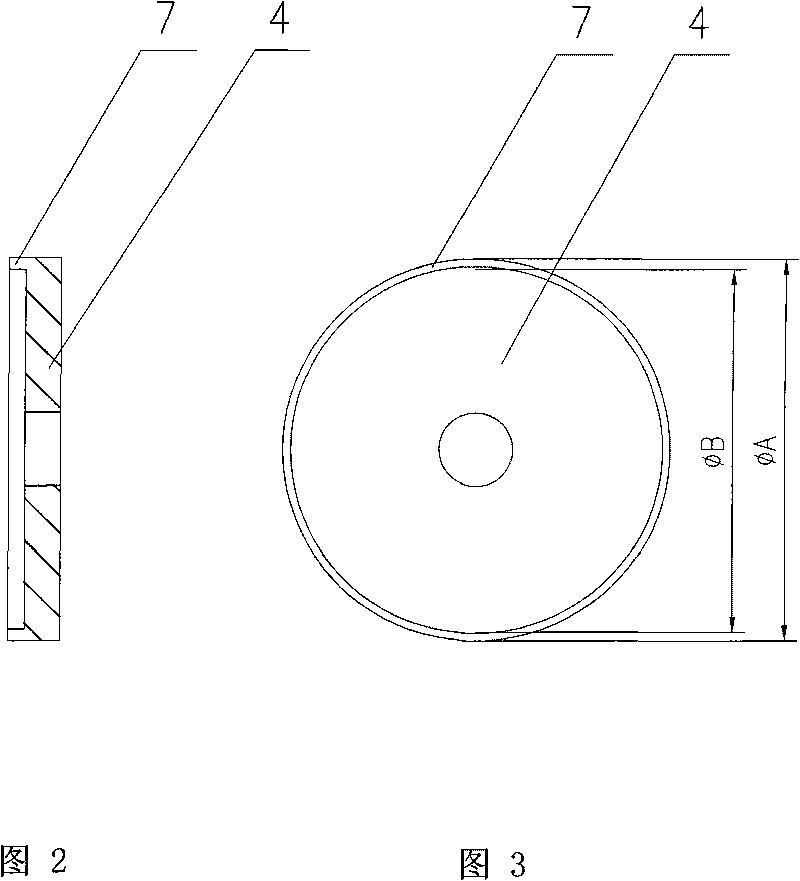

InactiveCN103075399APrevent radial deformation of the front endPrevent radial deformationSheet joiningScrewsEngineeringRadial deformation

The invention discloses a connecting element for plate connection. The connecting element comprises a sleeve tube with a T head and a sleeve rod with a T head, wherein the sleeve rod is inserted and arranged in the sleeve and is buckled with the sleeve tube so that the connecting element is in an I shape, the front end of the sleeve rod is provided with a buckling part, a buckling matching part matched with the buckling part of the sleeve rod is arranged on the tube wall of the sleeve tube, the sleeve rod is provided with a center hole penetrating along an axis line, in addition, a plurality of axial grooves capable of making the front end of the sleeve rod radially deform are arranged in the sleeve rod, the connecting element also comprises an inserting rod, and the inserting rod is axially assembled in the middle hole of the sleeve rod. The inserting rod is assembled in the middle hole of the sleeve rod, the radial deformation of the front end of the sleeve rod can be prevented, the buckling structure between the sleeve rod and the sleeve is tightly locked, and the buckling structure of the sleeve rod and the sleeve can be prevented from loosening. The connecting element has the advantages that the structure is simple, and the assembly is fast and convenient.

Owner:GUANGDONG HHS HEAVY DUTY PACKAGING GRP COMPANY

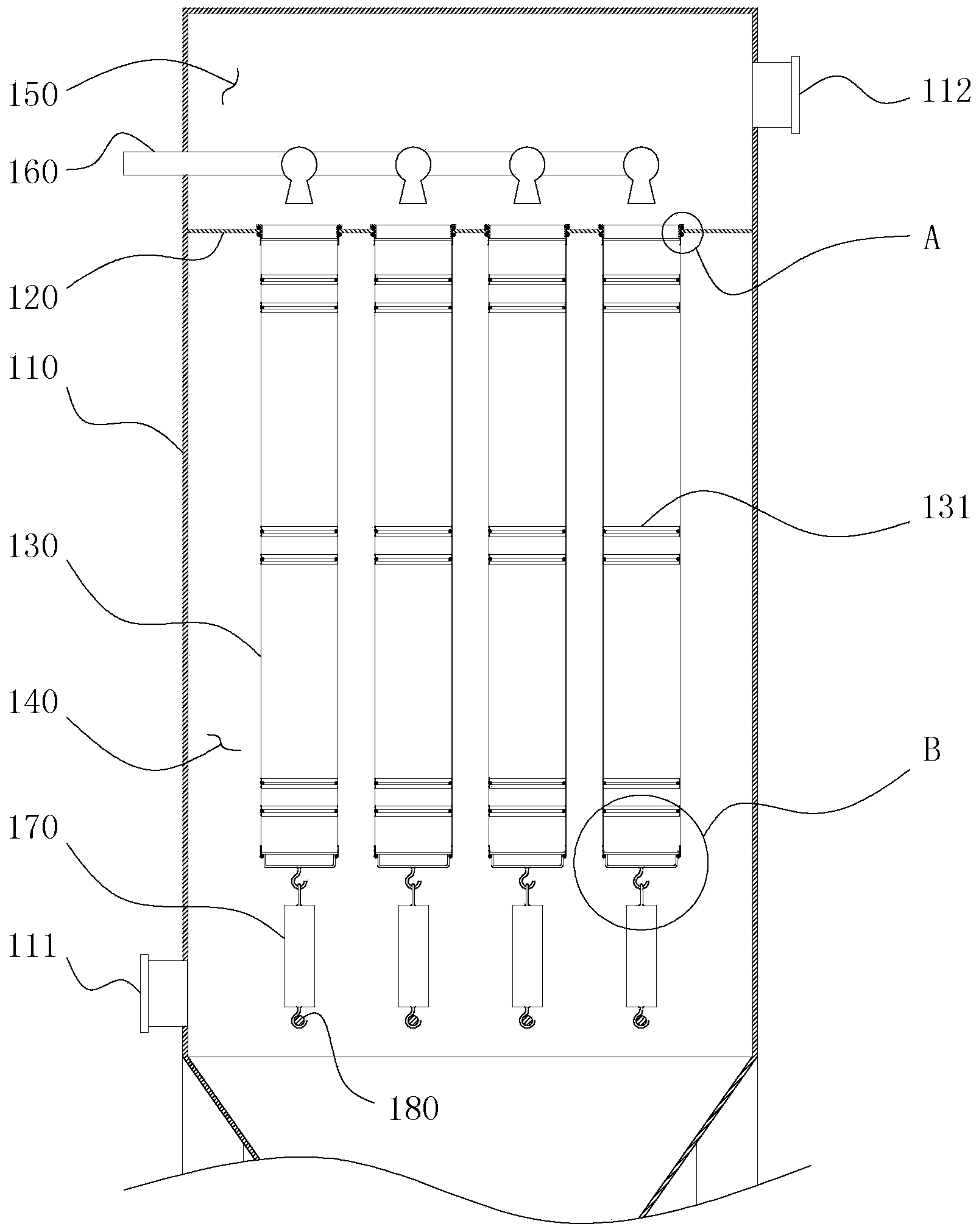

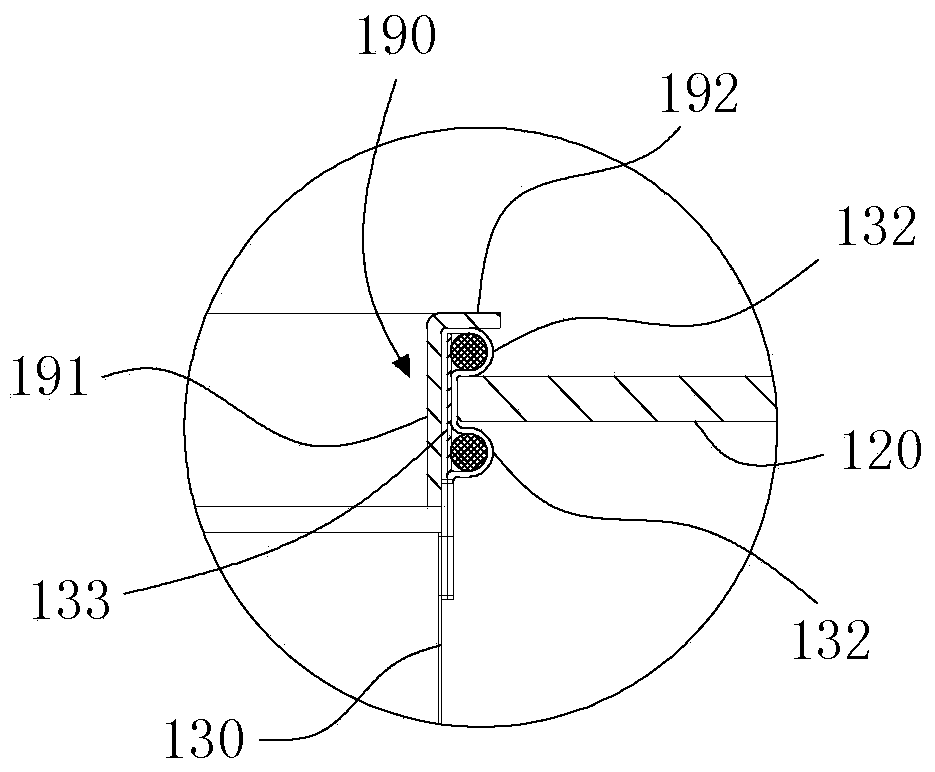

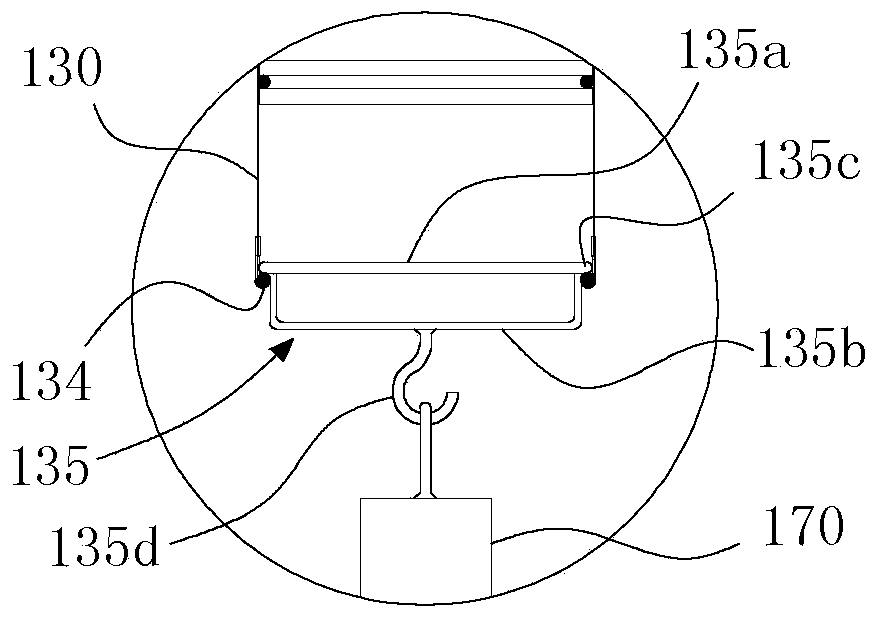

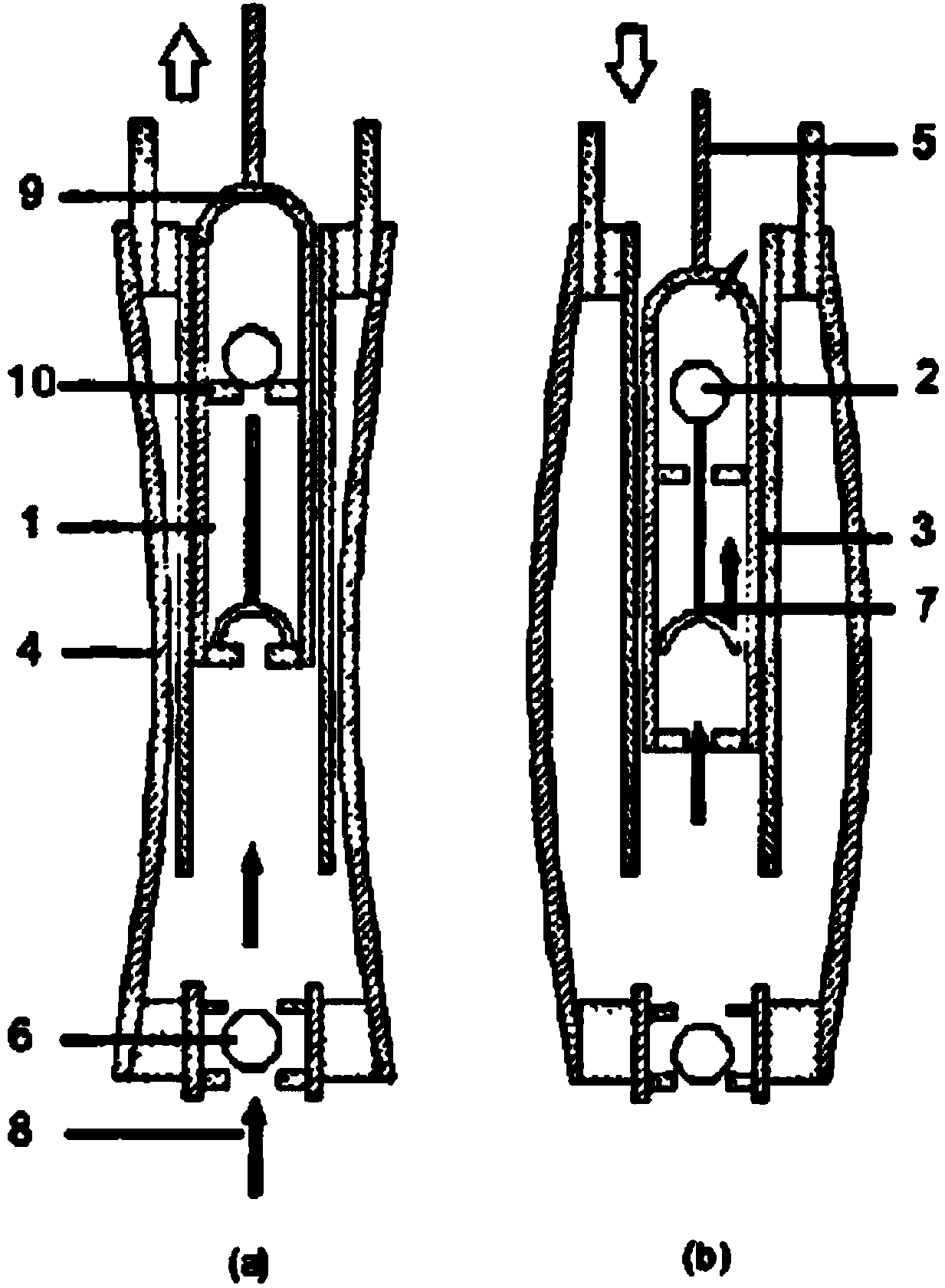

Filter device for separating gas and solid

The invention discloses a filter device which not only can prevent the collision of outer-filter filter bags, but also can improve the ash clearing effect for the filter bag, and is used for separating gas and solid. The filter device comprises a box body, wherein a porous plate is installed in the box body, a plurality of filter units are installed on the porous plate, each filter unit comprises the outer-filter filter bag with an open upper end and a closed lower end, the upper end of the filter bag is installed on the porous plate, an original gas chamber is arranged below the porous plate in the box body, a purified gas chamber is arranged above the porous plate in the box body, the box body is provided with a gas inlet which is communicated with the original gas chamber and an exhaust port which is communicated with the purified gas chamber, a back-flushing device for clearing the ash of each filter bag through the back-flushing airflow is arranged above the box body, the lower end of each filter bag is connected with an elastic drawing device which is used for stretching the filter bag in the axial direction, and the elastic drawing device is connected and elastically tensioned between the filter bag and a fixed component which is arranged below the filter bag and keeps a set distance from the porous plate. By adopting the filter device, the service life of the filter bag can be prolonged, and the ash clearing effect for the filter bag can be improved.

Owner:CHENGDU RUIKELIN ENG TECH

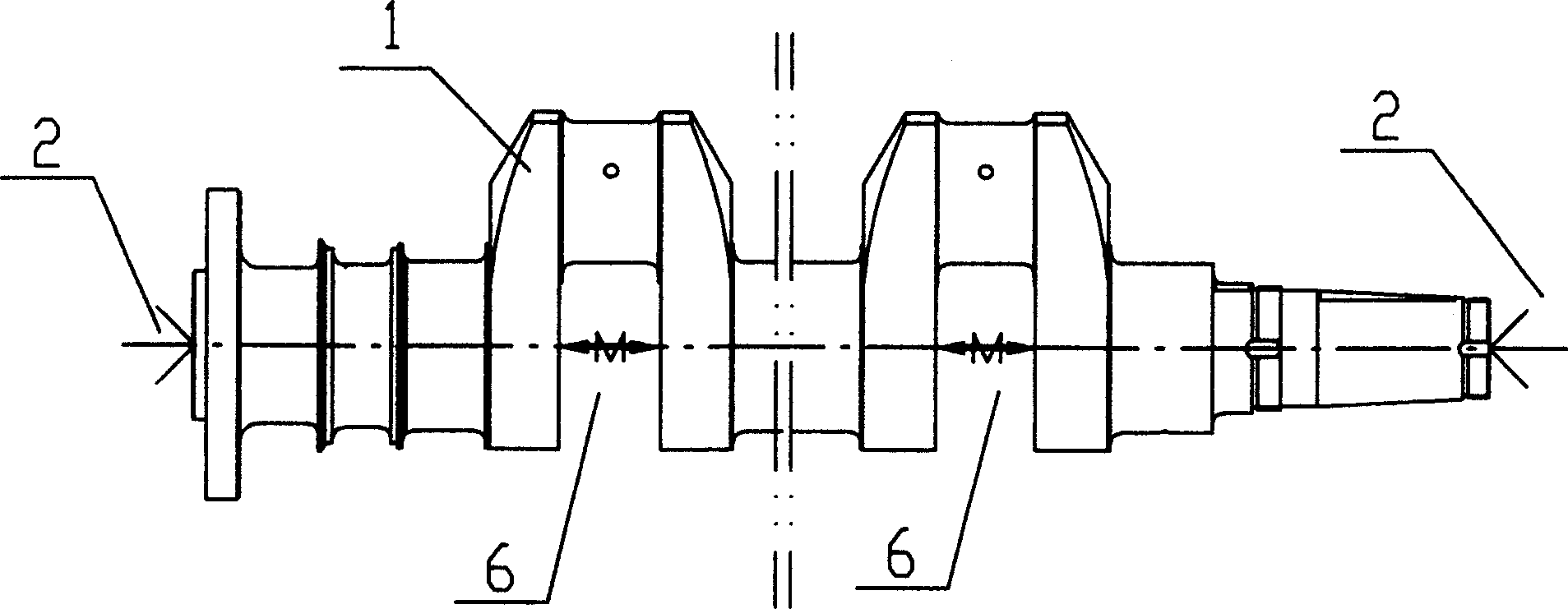

Method for grinding crankshaft of diesel engine accurately

InactiveCN1759987APrevent radial deformationMeet the design requirementsRevolution surface grinding machinesMachining processEngineering

A technology for precisely grinding the crankshaft of diesel engine features that the mainshaft supporting frame can cancel out the gravitation of crankshaft and the push force of abrasive disc to prevent radial deformation and the crank supporter can prevent the axial deformation caused by two centers.

Owner:WEICHAI POWER CO LTD

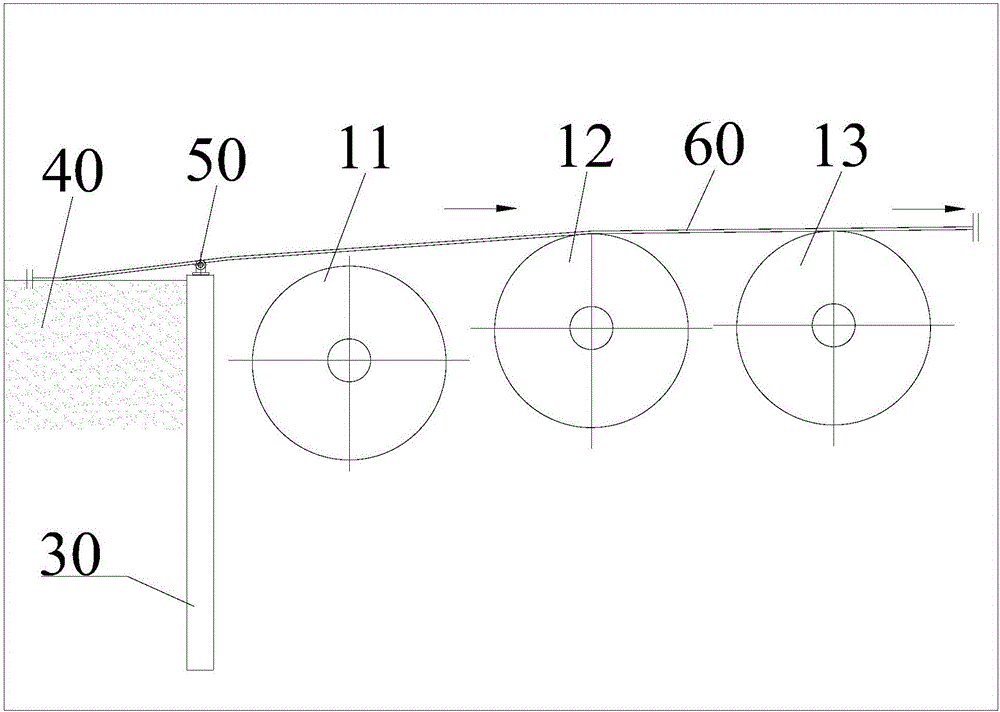

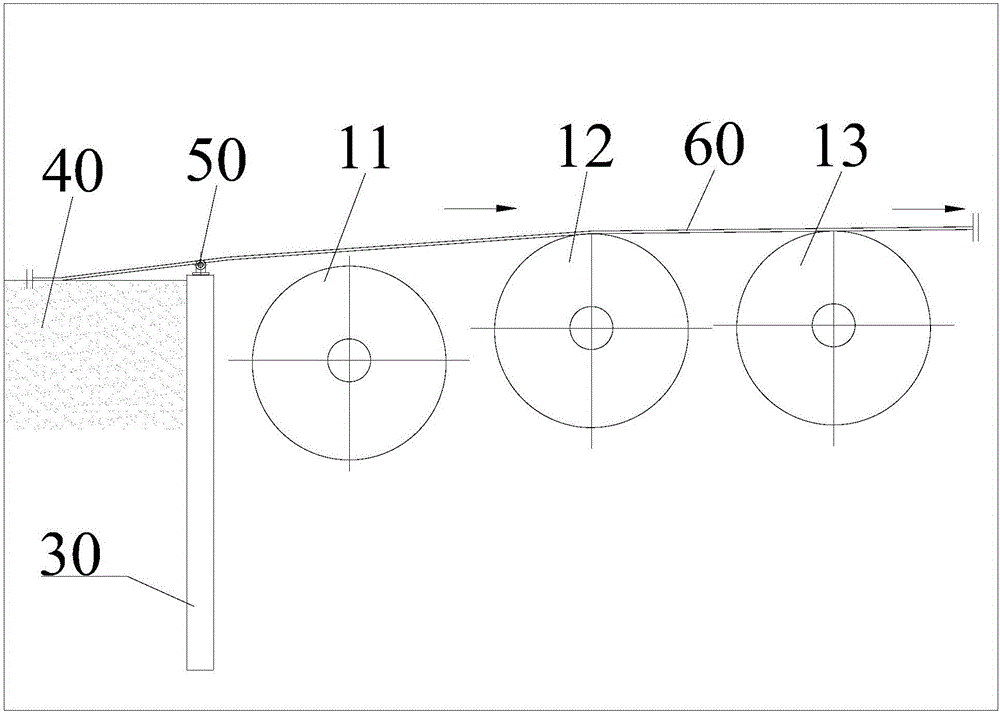

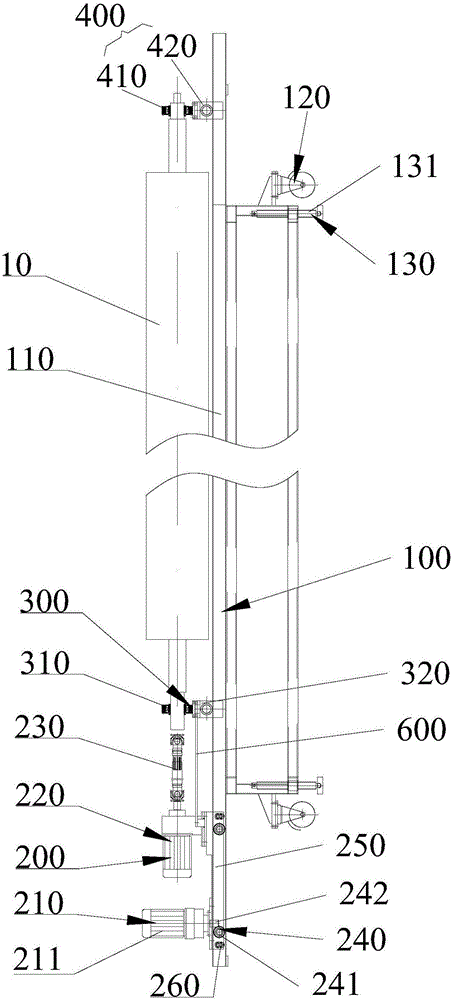

Online transitional roller replacing method

ActiveCN106542723AGuaranteed to workRealize online replacementGlass productionEngineeringGlass manufacturing

The invention belongs to the technical field of glass manufacturing and provides an online transitional roller replacing method. According to the online transitional roller replacing method, a roller replacing trolley is adopted to dismount old transitional rollers from a transitional roller table, and a supporting platform is flush with the old transitional rollers at the same straight line; then the old transitional rollers are dismounted at a vice operation surface, the height of a lifting supporting device is same as that of the supporting platform, the driving ends of the old transitional rollers are installed on a driving end supporting mechanism, and the driven ends of the old transitional rollers are installed on a driven end supporting mechanism; a roller entering and exiting moving mechanism is started to move all the old transitional rollers to the supporting platform automatically; the old transitional rollers are dismounted, and new transitional rollers are installed; then the new transitional rollers rotate automatically under driving of a roller rotating mechanism and are conveyed to the transitional roller table through driving of the roller entering and exiting moving mechanism; and then the new transitional rollers are installed on the transitional roller table and conveyed to suitable positions to work normally. In this way, online replacing of the transitional rollers is achieved, and the situation that radial deformation of the new transitional rollers occurs is avoided, so that normal work of the new transitional rollers is ensured.

Owner:信义超薄玻璃(东莞)有限公司

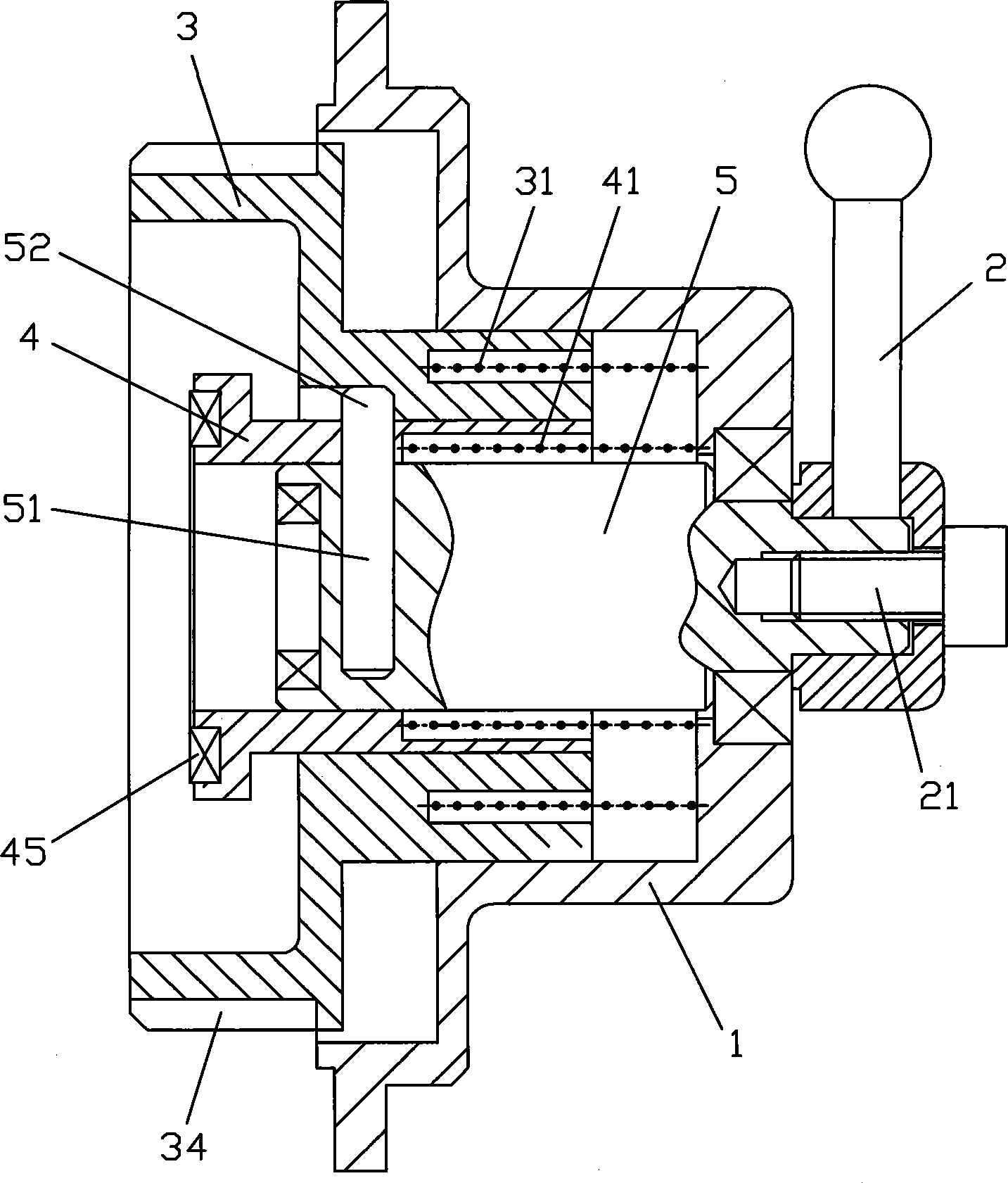

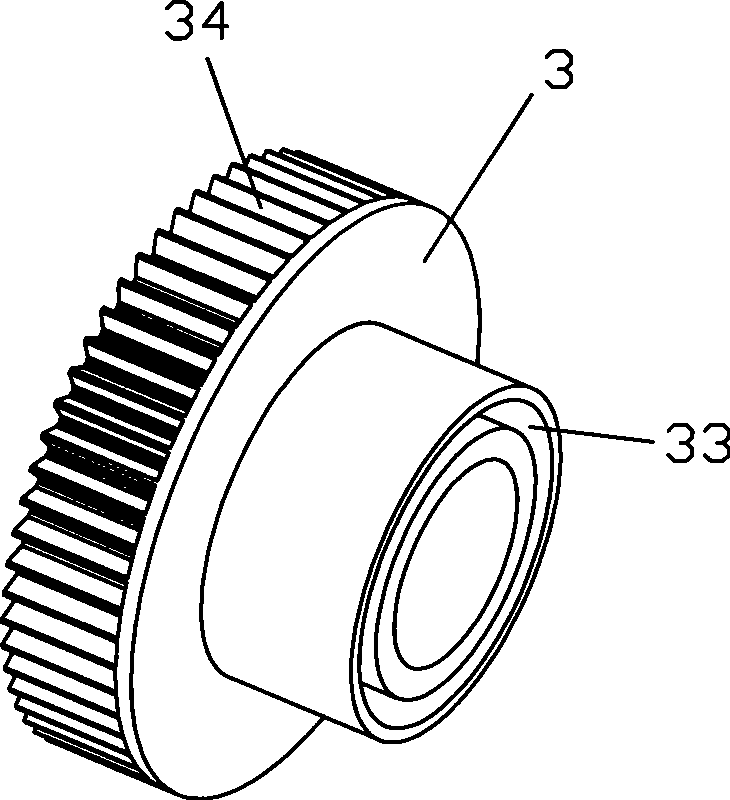

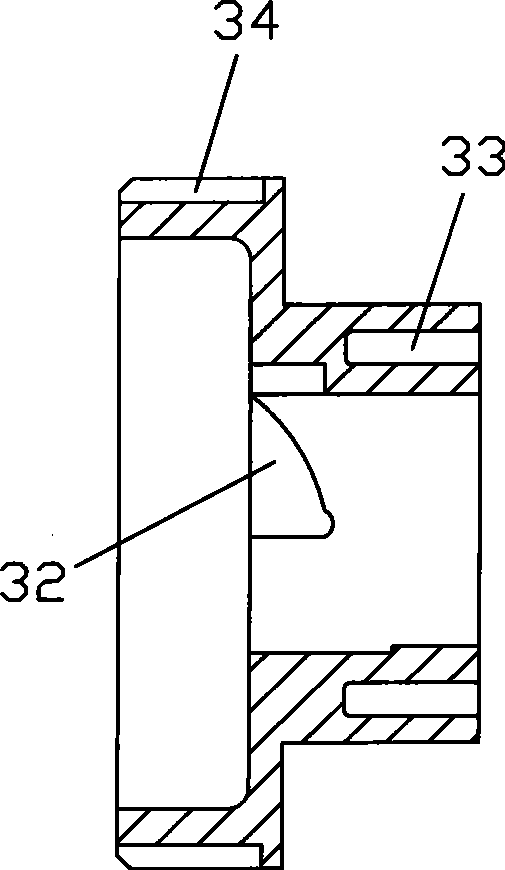

Capstan crab gear shift sleeve

The invention discloses a winch gear-shift clutch, which comprises a shell and a handle, wherein the shell is internally provided with a clutch cam gear shaft; a gear-shift cam shaft and a gear-shift clutch shaft are inserted into the clutch cam gear shaft; the cam curve surfaces on the clutch cam gear shaft and the gear-shift cam shaft are linked to fit in sequence; and a clutch reset spring is arranged between the clutch cam gear shaft and the shell, a gear-shift reset spring is arranged between the gear-shift cam shaft and the shell, the gear-shift clutch shaft is provided with a positioning component sliding on the cam curve surfaces, and the handle is fixedly connected with the gear-shift clutch shaft. The winch gear-shift clutch has the advantages of simple operation and reliable operation, and increases a double-speed function under the conditions that the winch function is not reduced and the ratio of the weight to the pull force of the winch is not reduced. Clutching and gear shifting are integrated, namely gear shifting and clutching share one operating handle; two actions generated by the gear-shift and clutch components are organically combined with the speed reducer; and the winch speed reducer gear automatically carries out separation and mesh. The winch gear-shift clutch has the advantages of convenient and reliable operation, compact structure, low fault rate and long service life.

Owner:ZHEJIANG RUNVA MECHANICAL & ELECTRICAL

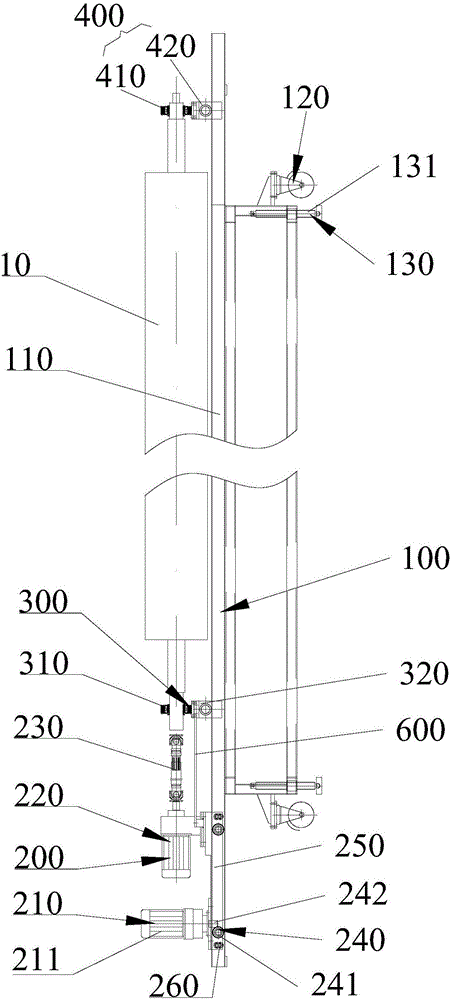

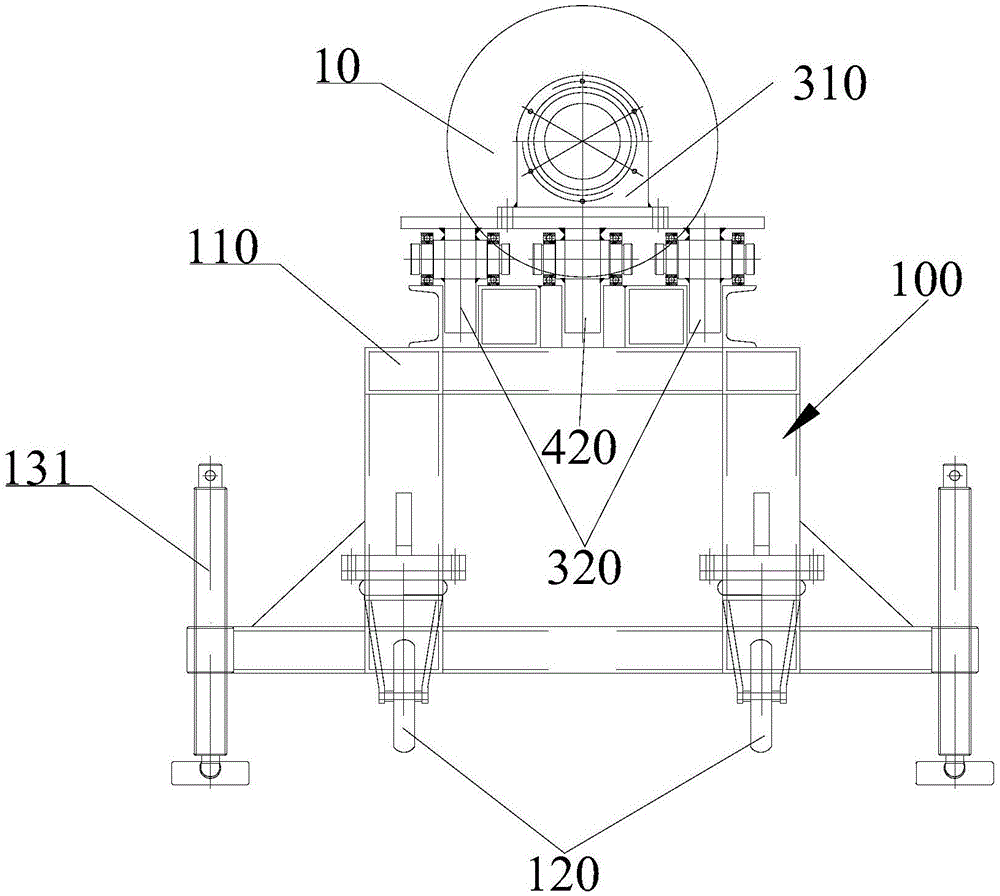

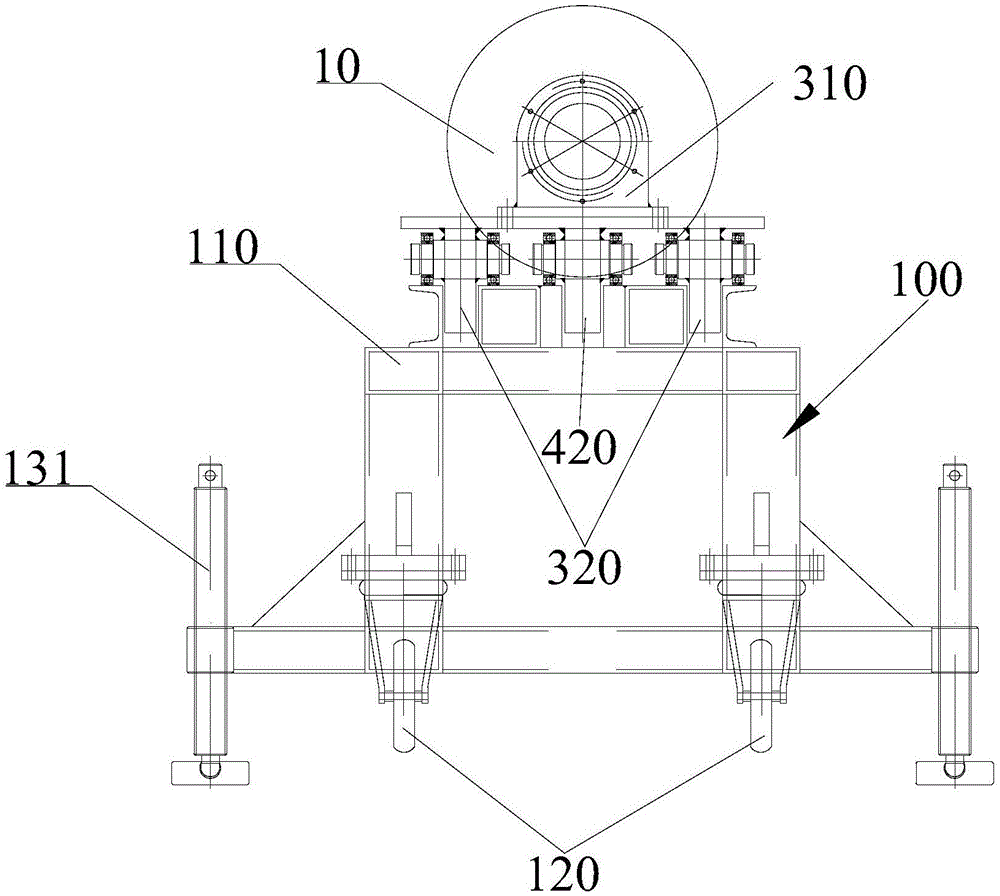

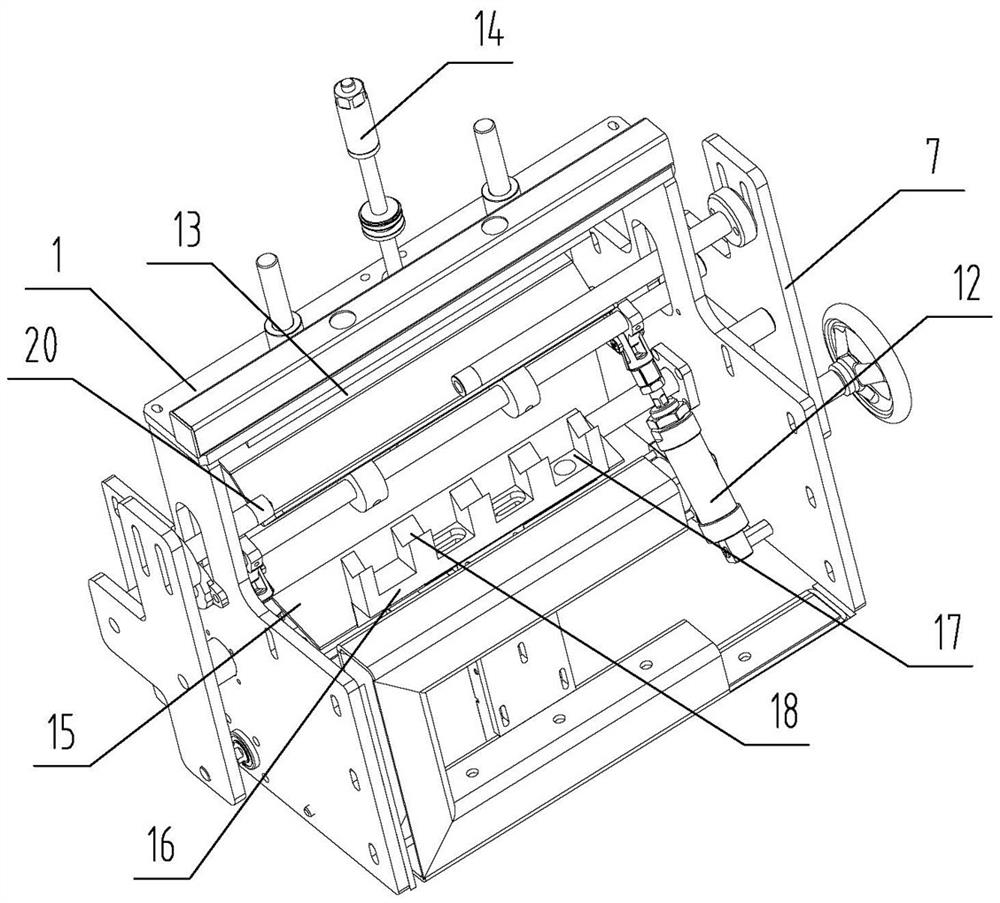

Roller changing carriage with function of online transitional roller changing

ActiveCN106746576AEvenly heatedPrevent radial deformationGlass transportation apparatusPulp and paper industryGlass manufacture

The invention belongs to the technical field of glass manufacture, and aims to provide a roller changing carriage with a function of online transitional roller changing. The roller changing carriage comprises a carriage main body, a movable trolley device, a driving end supporting mechanism and a driven end supporting mechanism, wherein a plurality of universal wheels are fixedly arranged at the bottom of a supporting platform of the carriage main body, so that the roller changing carriage can move freely; the movable trolley device is arranged on the supporting platform, and is driven to move along the supporting platform by virtue of a roller in-out moving mechanism in the movable trolley device, when a transitional roller is fixedly connected to the roller changing carriage under assistance of the driving end supporting mechanism and the driven end supporting mechanism, the transitional roller can move along the supporting platform under driving of the roller in-out moving mechanism to enter and exit a slag box, and can also automatically rotate under driving of a roller rotation mechanism, so that the translational roller can be changed online, and normal production cannot be influenced.

Owner:XINYI GLASS WUHU

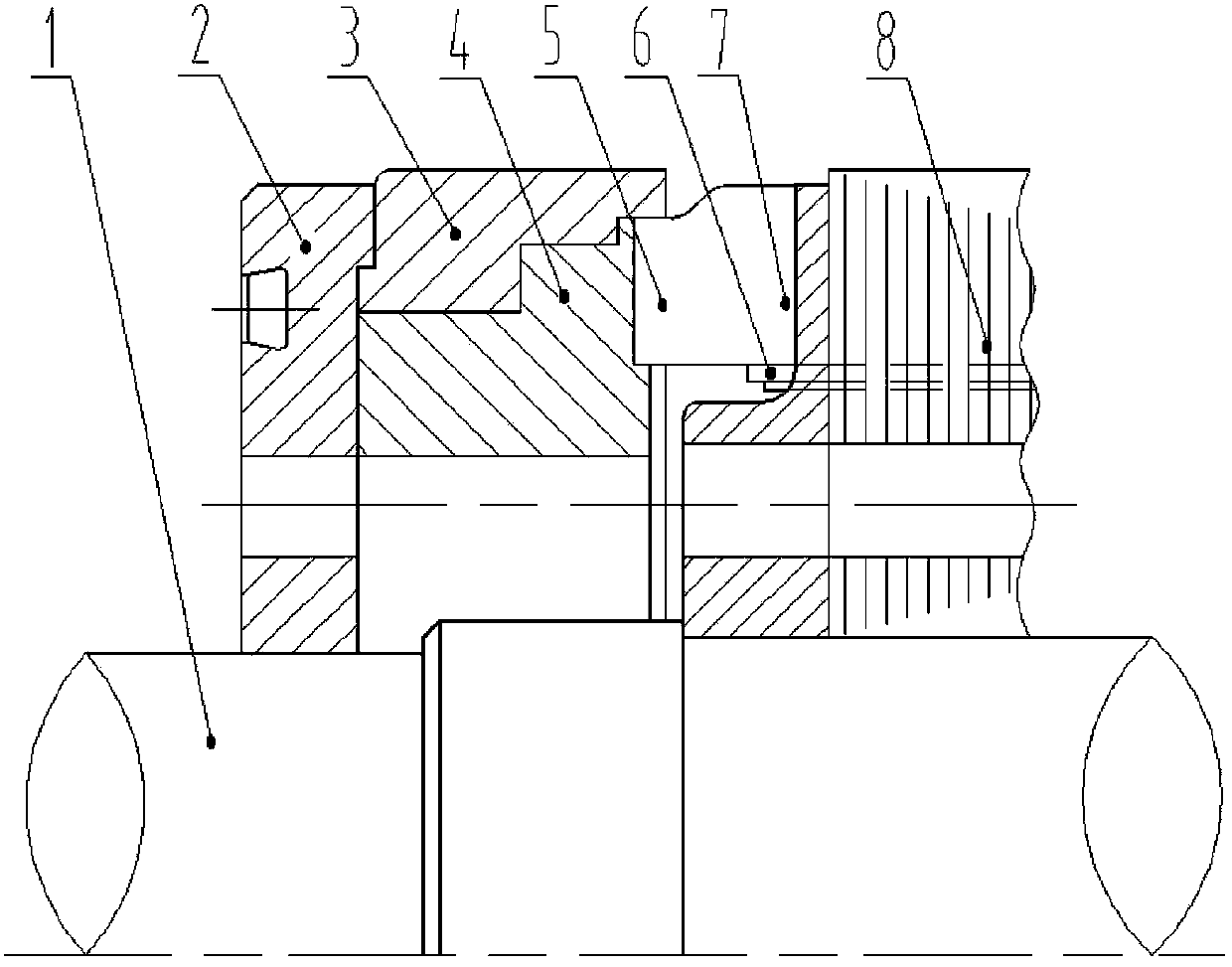

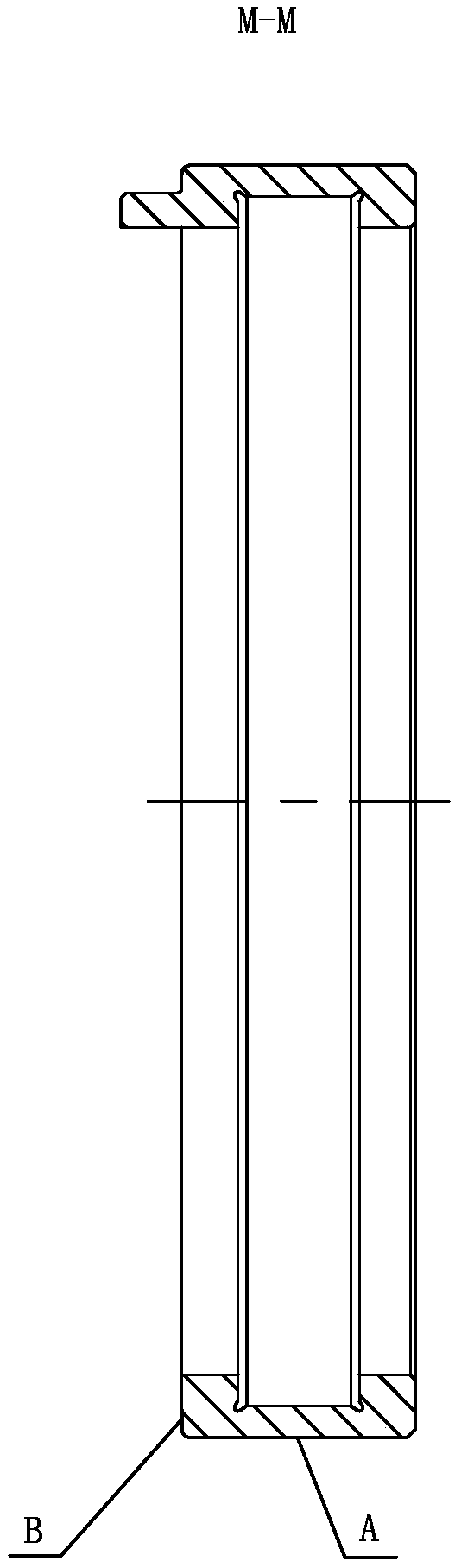

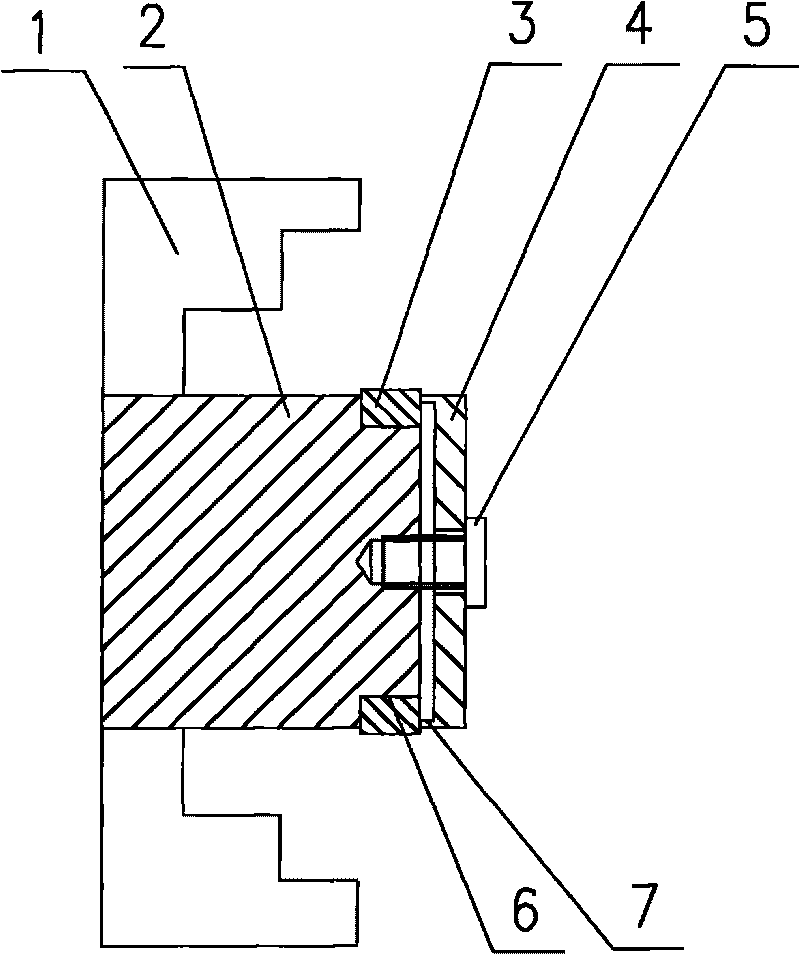

Anti-loose structure for large-sized motor rotator

InactiveCN103427516APrevent radial deformationPrevent axial displacementMagnetic circuit rotating partsAxial displacementElectric machine

The invention discloses an anti-loose structure for a large-sized high speed (more than 1500 revolutions per minute) motor rotor. According to the principle, a high intensity alloy steel protective ring which is designed is sleeved at the outer edge of a rotor end ring in a thermal mode; the outer end of the protective ring achieves axial positioning through a balanced ring which is sleeved on a shaft in a thermal mode and prevents radial displacement of the protective ring through a spigot of the balanced ring; a taper key (6) is embedded at the groove bottom to be tightly wedged after a rotor conducting bar (5) penetrating into a rotor core (8) and the rotor conducting bar is firmly welded to prevent the rotor conducting bar (5) from generating radial looseness inside a groove; certain gaps are reserved between the end ring (4) and a rotor pressing ring (7) to be used for ventilation and heat dissipation. The anti-loose structure for the large-sized high speed motor rotor has the advantages of preventing the conducting bar end portion and the end ring from performing radial deformation caused by centrifugal force, preventing the conducting bar and the end ring from performing axial displacement caused by conducting bar looseness and avoiding breakage bar, open weld and end ring deformation accidents from happening.

Owner:李贤明

Rotary apparatus

InactiveUS20090108703A1Reduce distortionAvoid displacementMagnetic circuit rotating partsAsynchronous induction motorsElectrical conductorInduction motor

A rotary apparatus, in which a rotor can rotate stably when it rotates at a high speed, can rotate at a relatively high speed by the torque of a highly reliable induction motor. The rotary apparatus comprises a rotor shaft and an induction motor. The induction motor includes a motor rotor core fixed to the rotor shaft, conductors disposed in the motor rotor core and a motor end ring for assembling and connecting the conductors, and can rotate the rotor shaft at a high speed by the torque. The rotor shaft is provided with a member that covers the motor end ring.

Owner:EBARA CORP

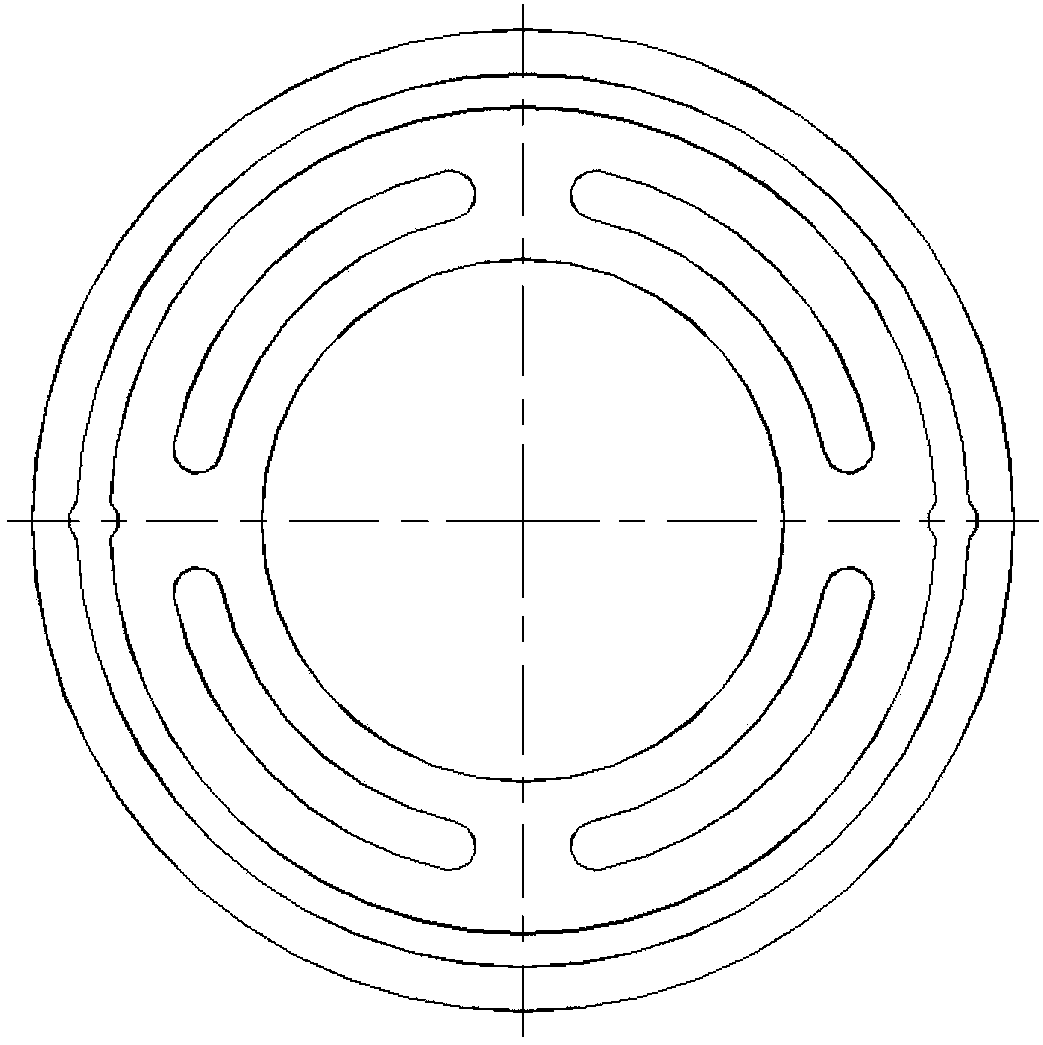

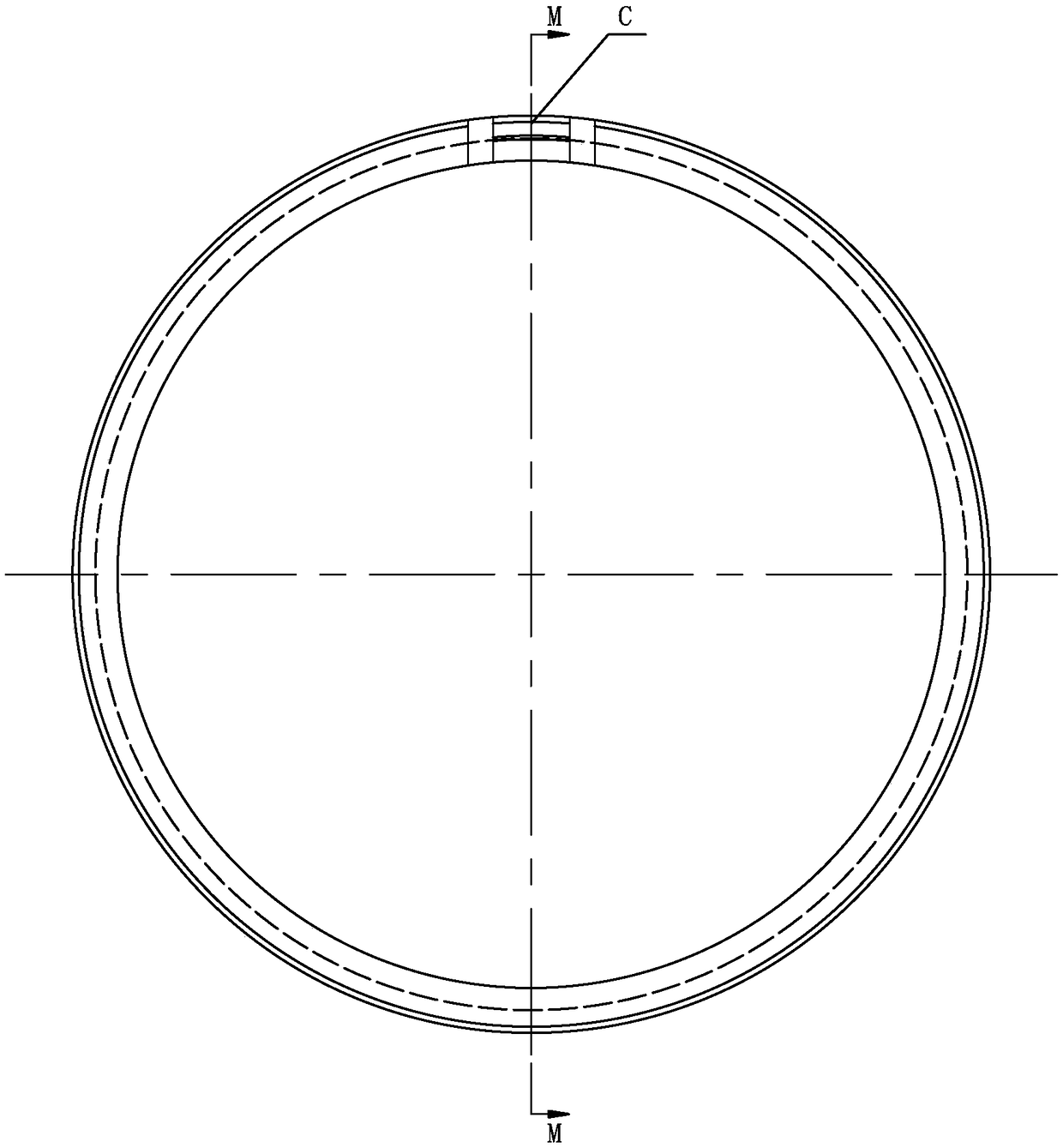

Method for enhancing hard turning circularity of thin-wall annular parts

The invention discloses a method for enhancing the turning circularity of cylindrical surfaces of thin-wall annular parts by controlling flatness of end faces of the thin-wall annular parts and flatness of work faces of clamping positioning pieces of the thin-wall annular parts. The method is characterized in that a positioning manner adopts the combination of end planar location and cylindrical surface dial gauge centering, and a clamping manner adopts the axial clamping of a magnetic chuck or a vacuum chuck. Compared with a manner with a three-jaw chuck for positioning and clamping, the method for positioning, clamping and processing disclosed by the invention can be used for processing the external cylindrical surface, the internal cylindrical surface, the end surfaces and annular channels in the internal and external cylindrical surfaces of the thin-wall annular parts with one clamping and positioning, effectively preventing radial deformation of the thin-wall annular parts during the clamping and processing process, and remarkably improving the turning circularity of the thin-wall annular parts, thereby providing an effective method for ultraprecise turning of thin-wall annular parts such as bearing rings.

Owner:SHANGHAI JIAO TONG UNIV +1

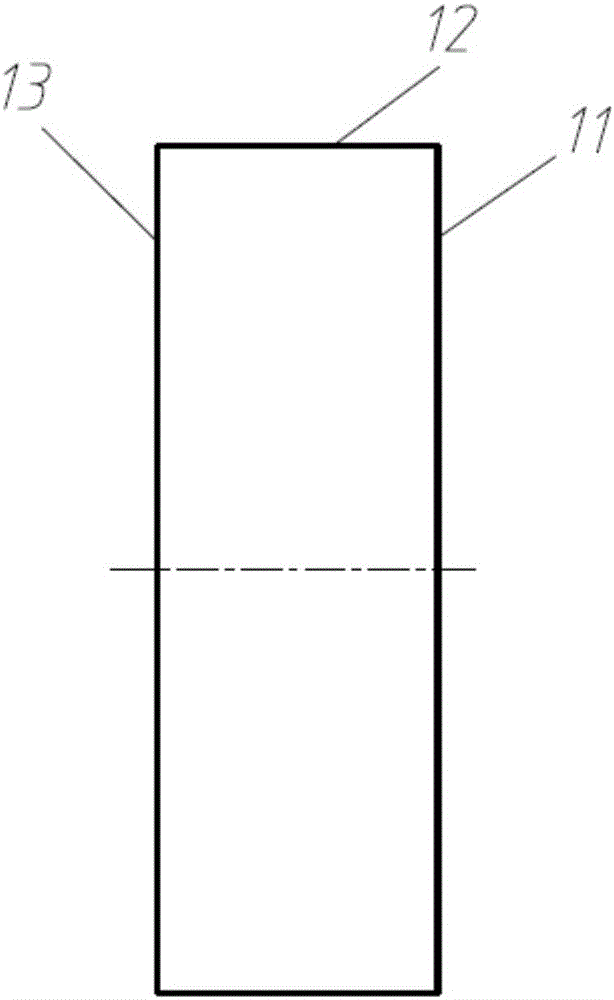

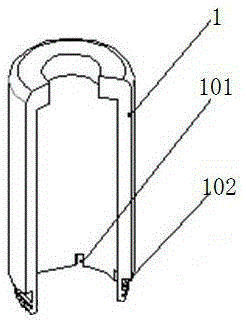

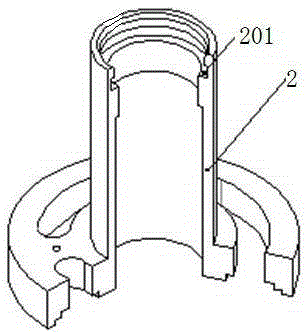

Thin-wall elastic support, and tooling and processing method thereof

ActiveCN109108697APrevent radial deformationGuaranteed yieldPositioning apparatusMetal-working holdersThin walledFastener

The invention discloses a thin-wall elastic support, a tooling of the thin-wall elastic support and a processing method of the thin-wall elastic support. The tooling comprises a processing mandrel, abushing and a fastener, wherein a large diameter section and a small diameter section are sequentially arranged in the middle of the processing mandrel, and a first positioning portion is formed between the large diameter section and the small diameter section, so that one side of a limit portion extending radially from the inner wall of a blank to be machined is axially abutted and positioned against the first positioning portion; the outer diameter dimension of the large diameter section of the processing mandrel is adapted to the inner diameter dimension of a first thin wall section of a finished product located on one side of the limit portion; the bushing is used for sleeving on the small diameter section of the processing mandrel, and the inner shaft end of the bushing is provided with a second positioning part so as to be axially abutted and positioned against the other side of the limit portion; the fastener is removably and fixedly connected with the processing mandrel to restrict the axial relative position of the bushing relative to the processing mandrel. The application of the scheme can effectively improve the precision of the finished product of the thin-wall elasticsupport, so as to further ensure the yield of the product.

Owner:BEIHANG UNIV

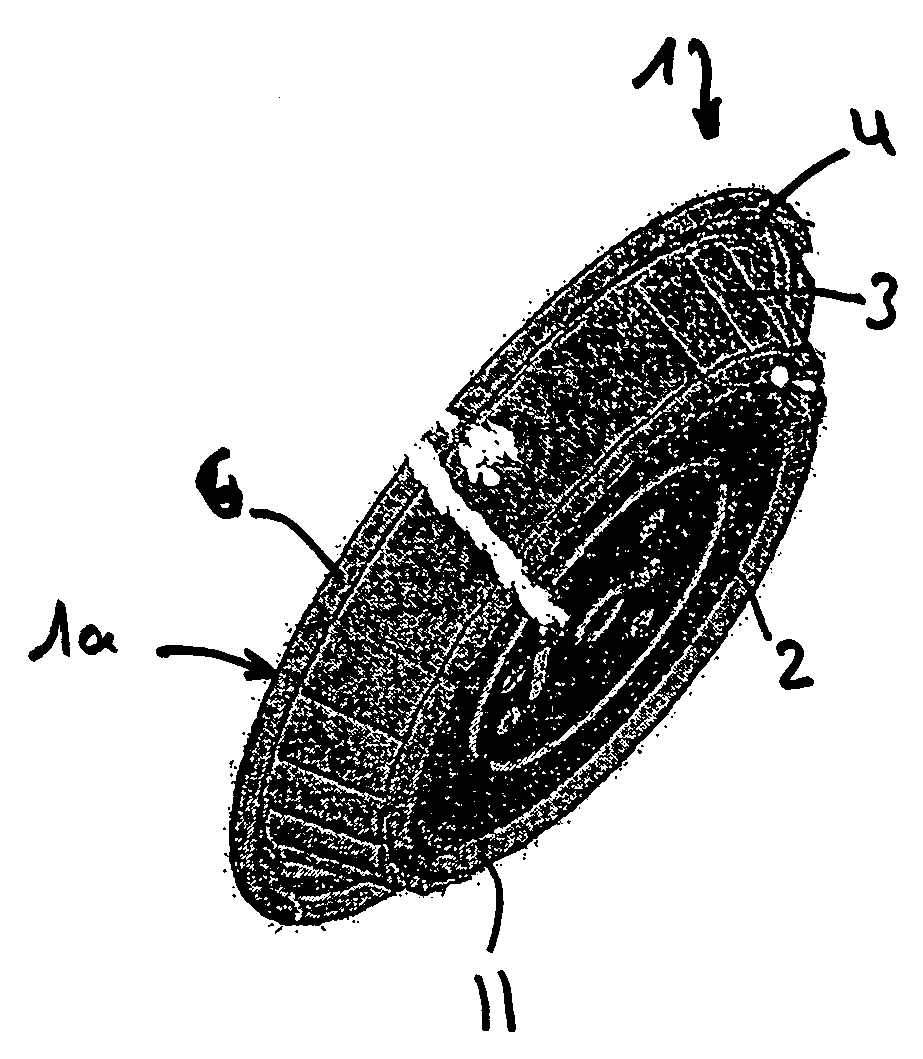

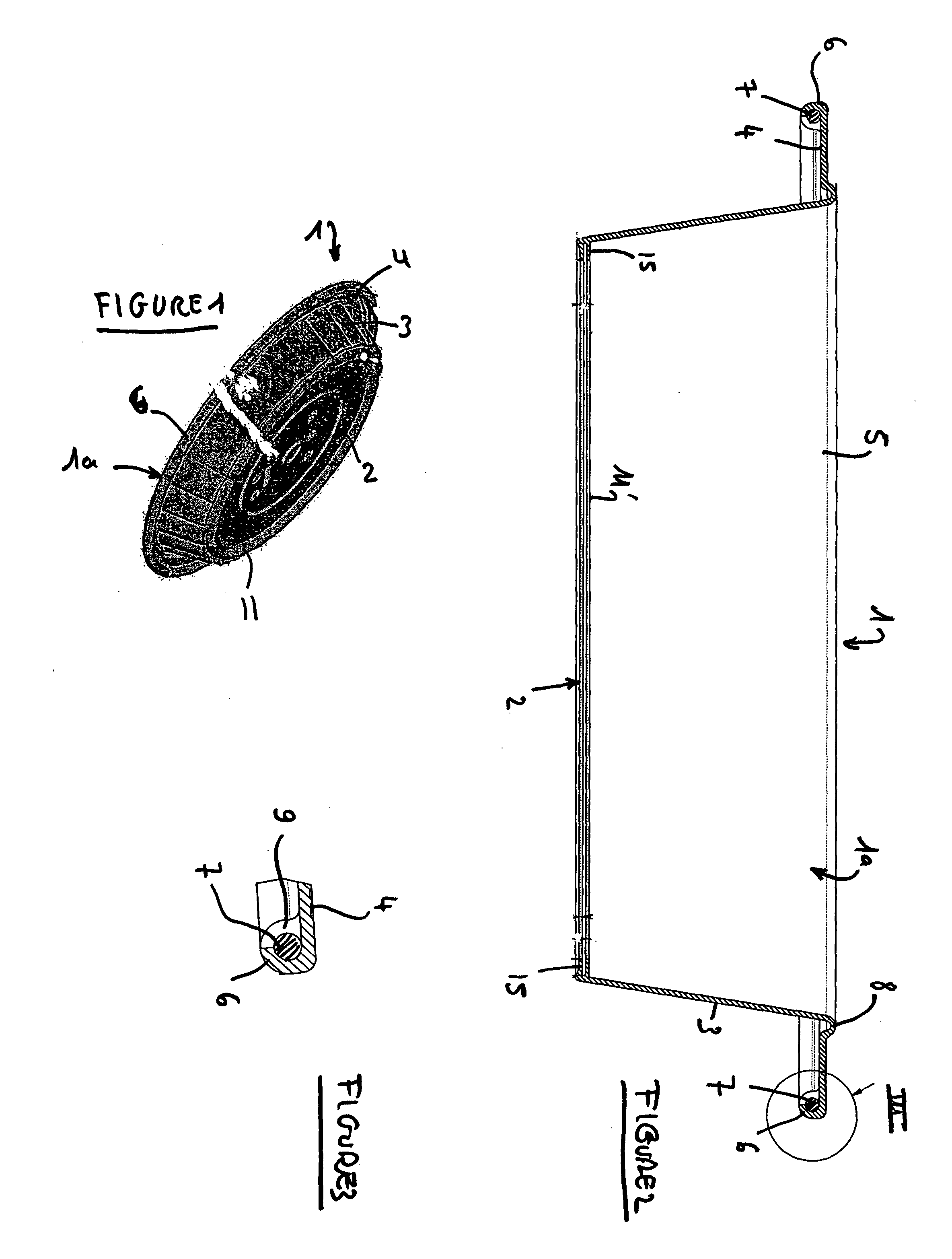

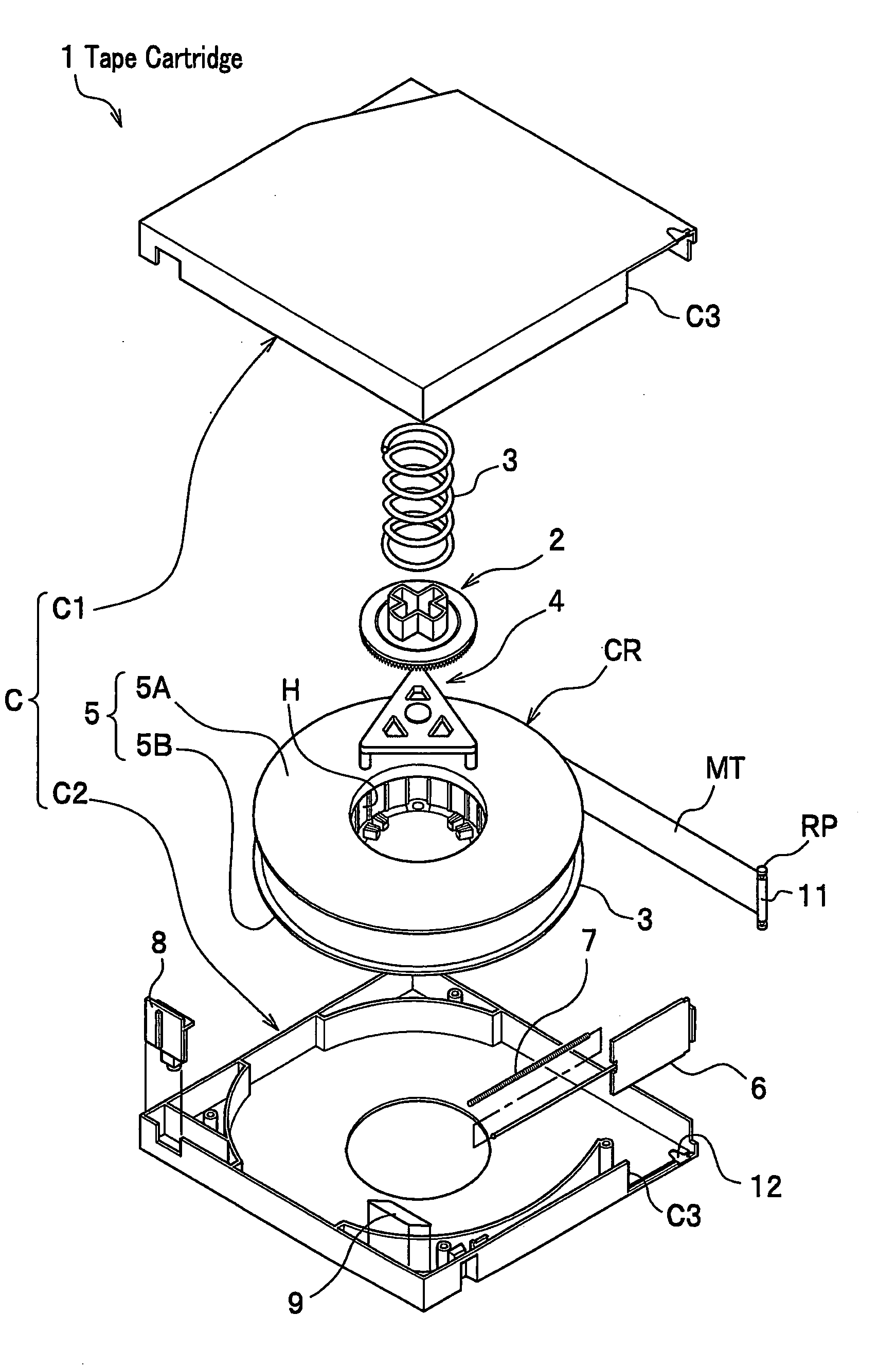

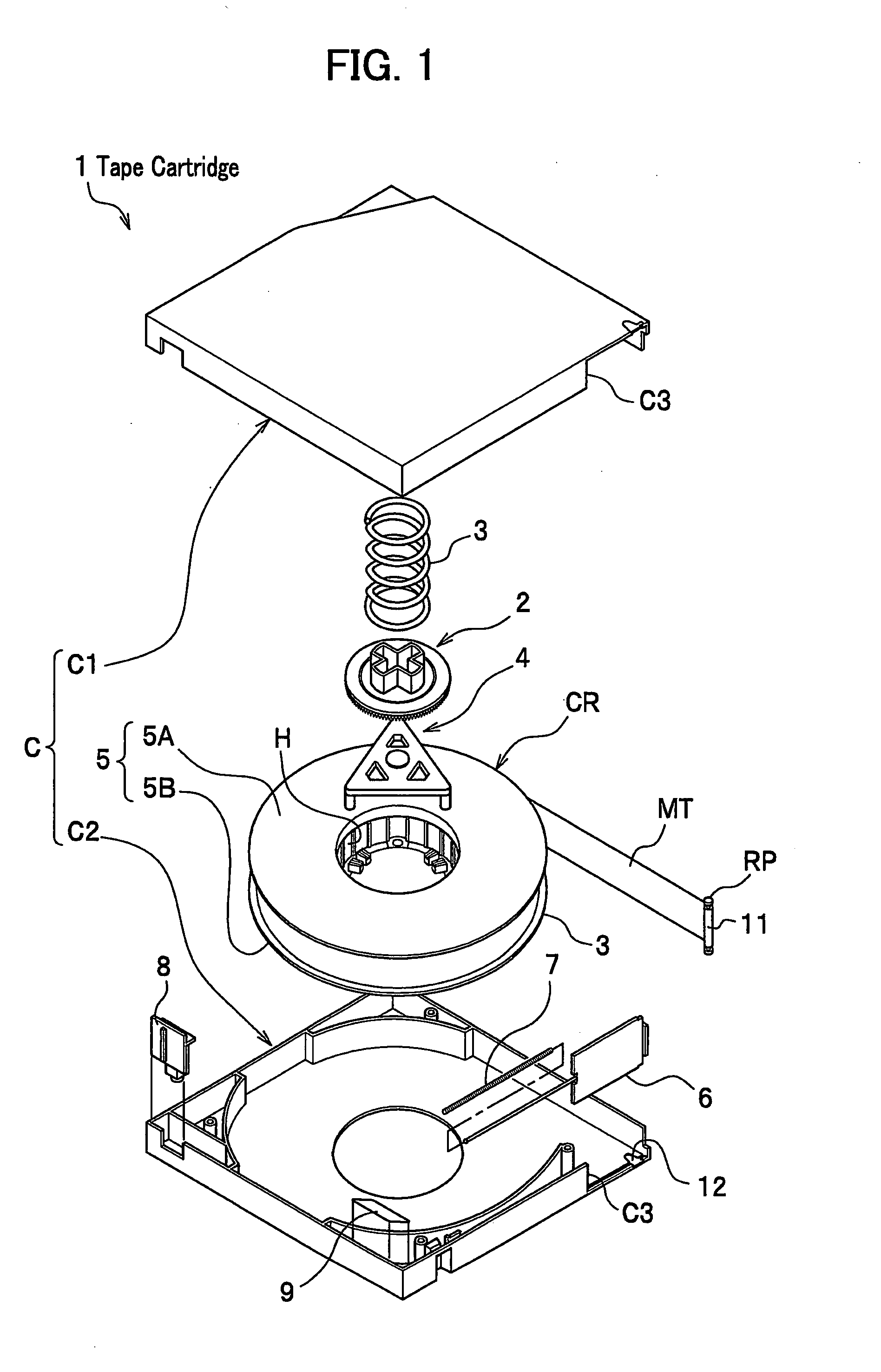

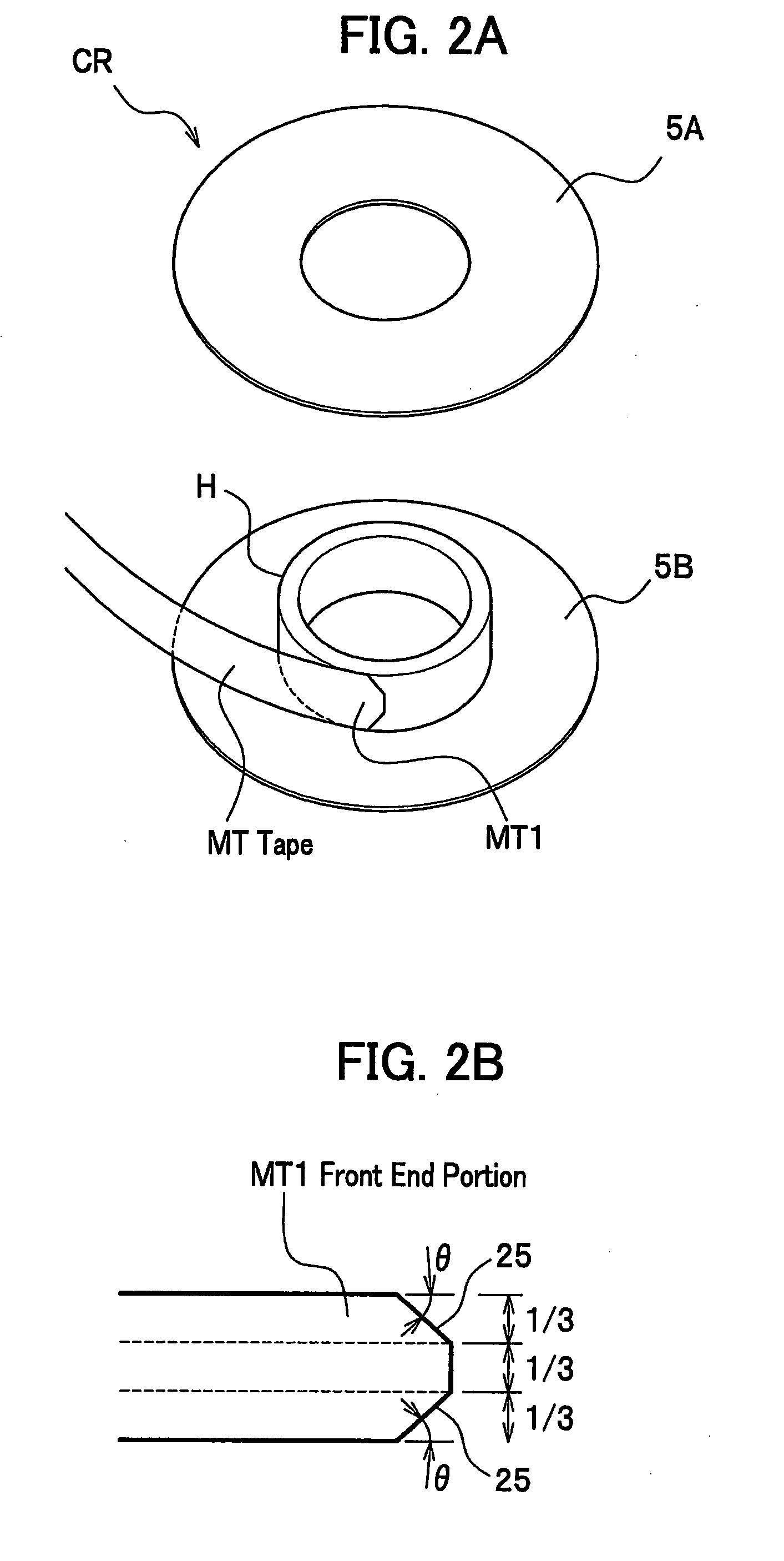

Tape cartridge

ActiveUS20080001013A1Avoid injuryImprove accuracyPicture changing apparatusCarrier storage meansMagnetic tapeEngineering

A tape cartridge including a tape capable of recording and reproducing a high accuracy servo signal, by preventing a deformation of the tape by preventing turning up of a front end portion of a tape when the front end portion is adhered to a reel hub. The tape cartridge includes the tape, a single reel having a reel hub around which the tape is wound and a cartridge case in which the reel is installed, and the front end portion of the tape is adhered to the reel hub, and each corner of the front end portion of the tape is chamfered and chamfers are formed.

Owner:FUJIFILM CORP

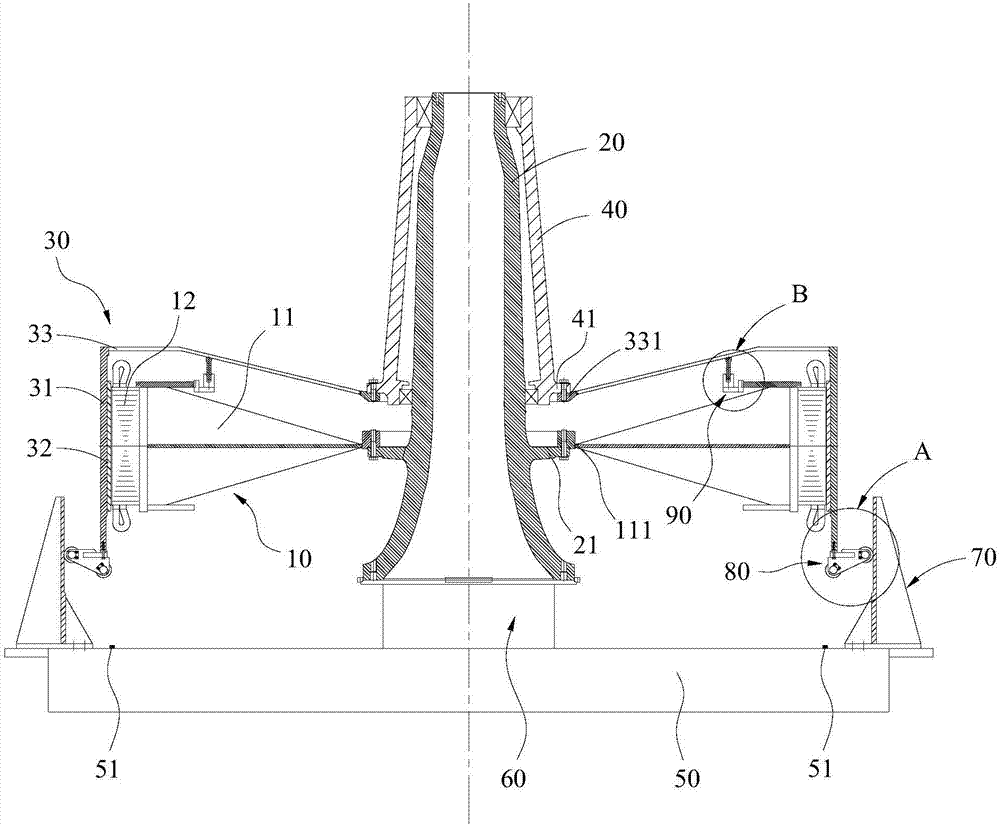

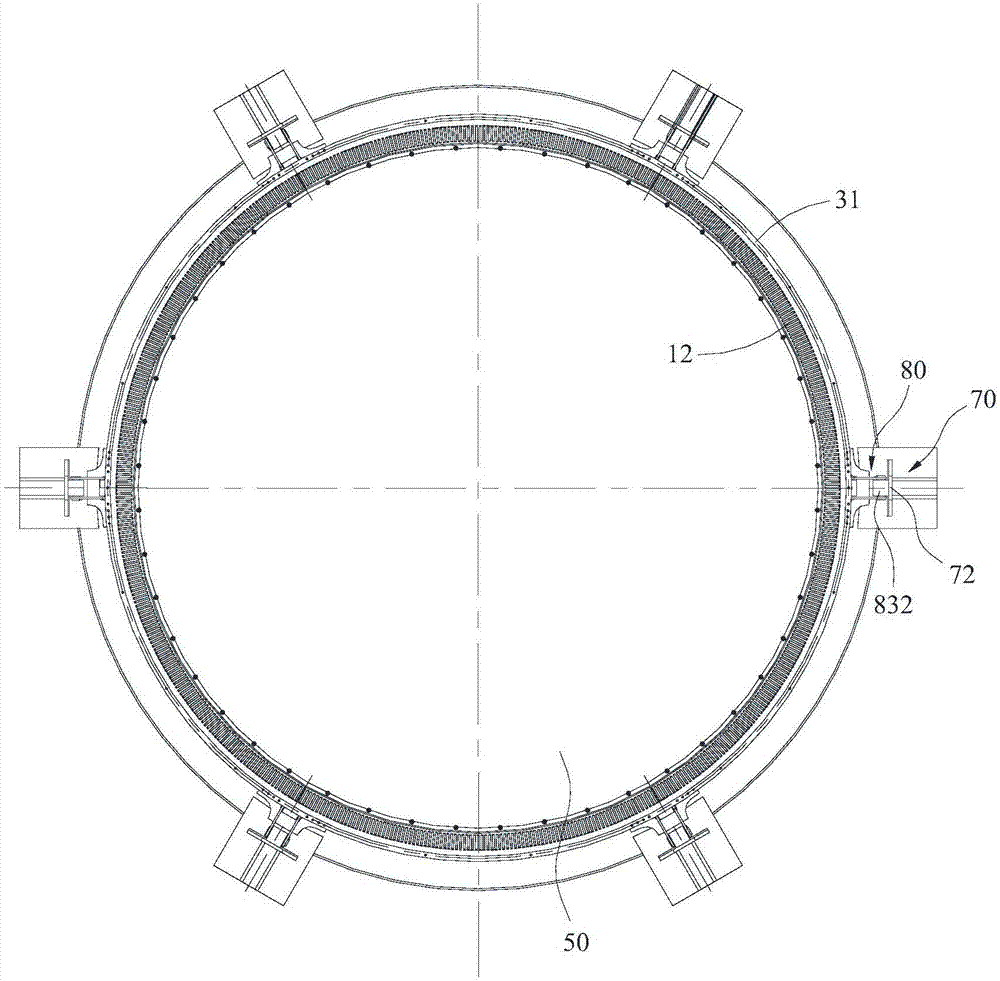

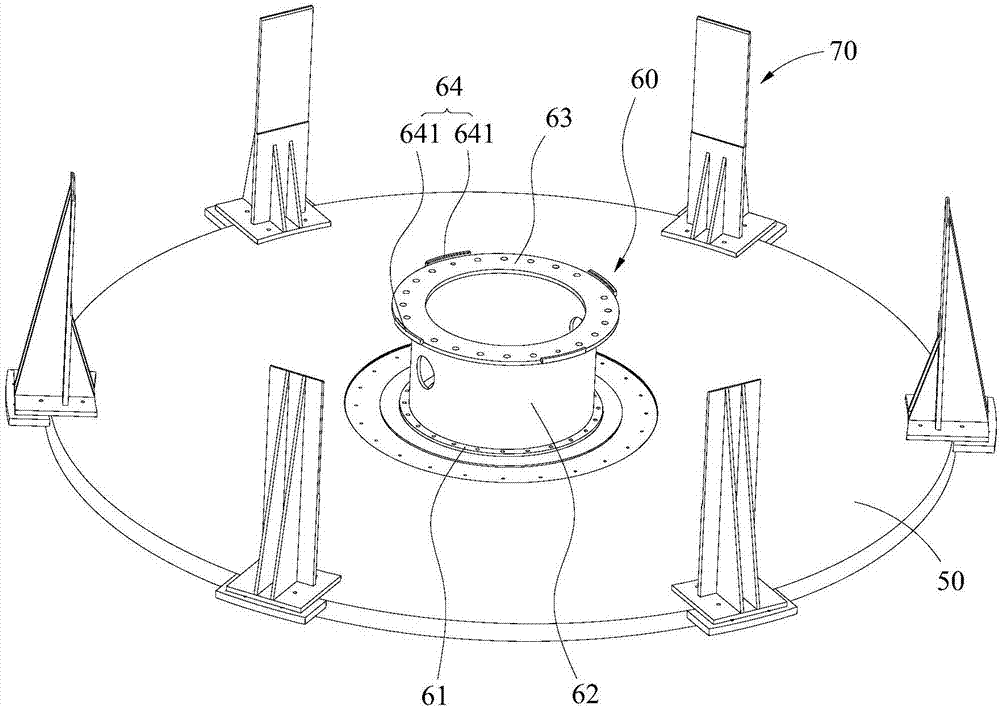

Assembly tool and assembly method of generator

ActiveCN107888037AGuaranteed uniformityPrevent radial deformationManufacturing stator/rotor bodiesMagnetic polesEngineering

The invention provides an assembly tool and an assembly method of a generator. One of a stator and a rotor of the generator is adopted as a sleeved part, and the other one of the stator and the rotorof the generator is adopted as a sleeve part. The assembly tool comprises a limiting device arranged around a predetermined axis and used for defining an assembly space on one side facing the predetermined axis, and a follow-up guide device. The limiting device is provided with a guide surface which faces the assembly space and extends along the predetermined axis. The follow-up guide device comprises a connecting part and a first abutting part connected with the connecting part. When the follow-up guide device is connected with the sleeve part through the connecting part, the first abutting part can extend out of the outside of the sleeve part in the radial direction of the sleeve part. The first abutting part can abut against the guide surface and move along the guide surface, so that anair gap between the sleeve part and the sleeved part is kept constant. Therefore, when the assembly tool disclosed by the embodiment of the invention is used for facilitating the assembling process of the sleeve part and the sleeved part, the uniformity of the air gap between the sleeve part and the sleeved part can be ensured. The deformation of the sleeve part is avoided. Moreover, a rotor magnetic pole and a stator iron core are prevented from being damaged.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

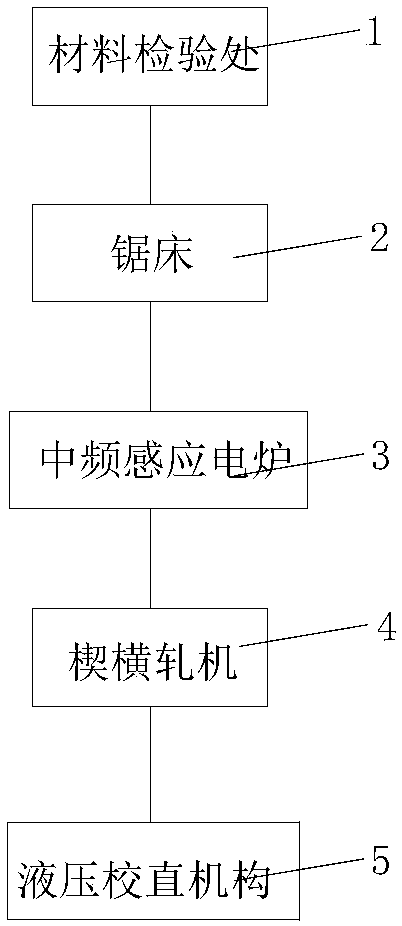

Cross-wedge rolled piece machining device and method

PendingCN107671140AAvoid cutsExtend your lifeMetal sawing devicesOther manufacturing equipments/toolsMachineRoll forming

The invention discloses a cross-wedge rolled piece machining device. The cross-wedge rolled piece machining device comprises a material inspection position, a sawing machine, a medium-frequency induction electric furnace, a cross-wedge rolling mill, a cooling and transporting device and a hydraulic straightening mechanism, wherein a cross-wedge rolled piece sequentially passes through the materialinspection position, the sawing machine, the medium-frequency induction electric furnace, the cross-wedge rolling mill, the cooling and transporting device and the hydraulic straightening mechanism.The invention further provides a cross-wedge rolled piece machining method. The cross-wedge rolled piece machining method comprises the following steps that material inspection is conducted; blankingis conducted, specifically, the sawing machine is used to disintegrate a workpiece; heating is conducted, specifically, a medium-frequency heating furnace is used to conduct heating treatment on the workpiece; rolling forming is conducted, specifically, the cross-wedge rolling mill is used to conduct rolling forming, and then the cooling and transporting device is used to transport the workpiece to the sawing machine and remnant removing is conducted; and straightening is conducted, specifically, a hydraulic straightening machine is used to conduct straightening. The cross-wedge rolled piece machining device has the beneficial effects that positioning disintegration is conducted through the sawing machine, the disintegration precision is improved, the workpiece is prevented from deviatingthrough a positioning device of the cross-wedge rolling mill, the cooling and transporting device enables cooling and transporting to be conducted simultaneously, the time is saved, through the self-made hydraulic straightening mechanism, the straightening precision is high, and the reliability is high.

Owner:安庆市振发汽车锻件有限责任公司

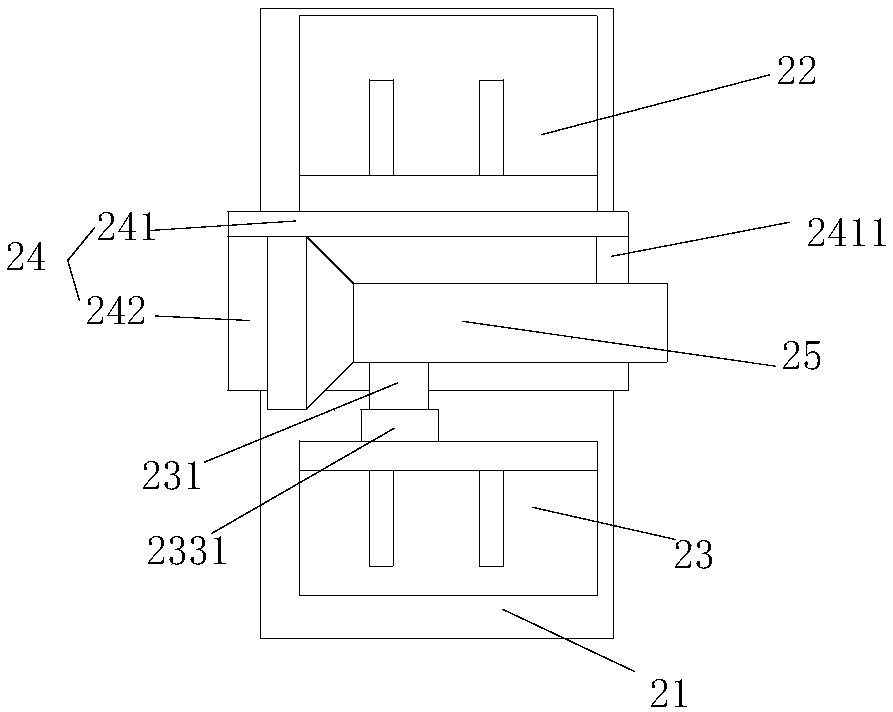

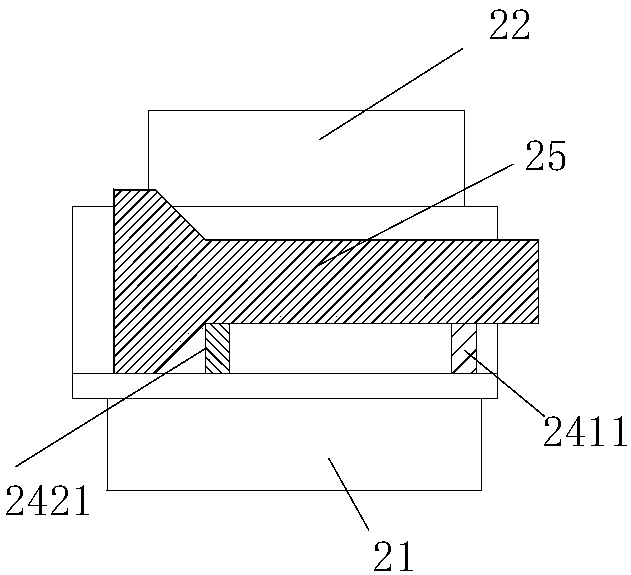

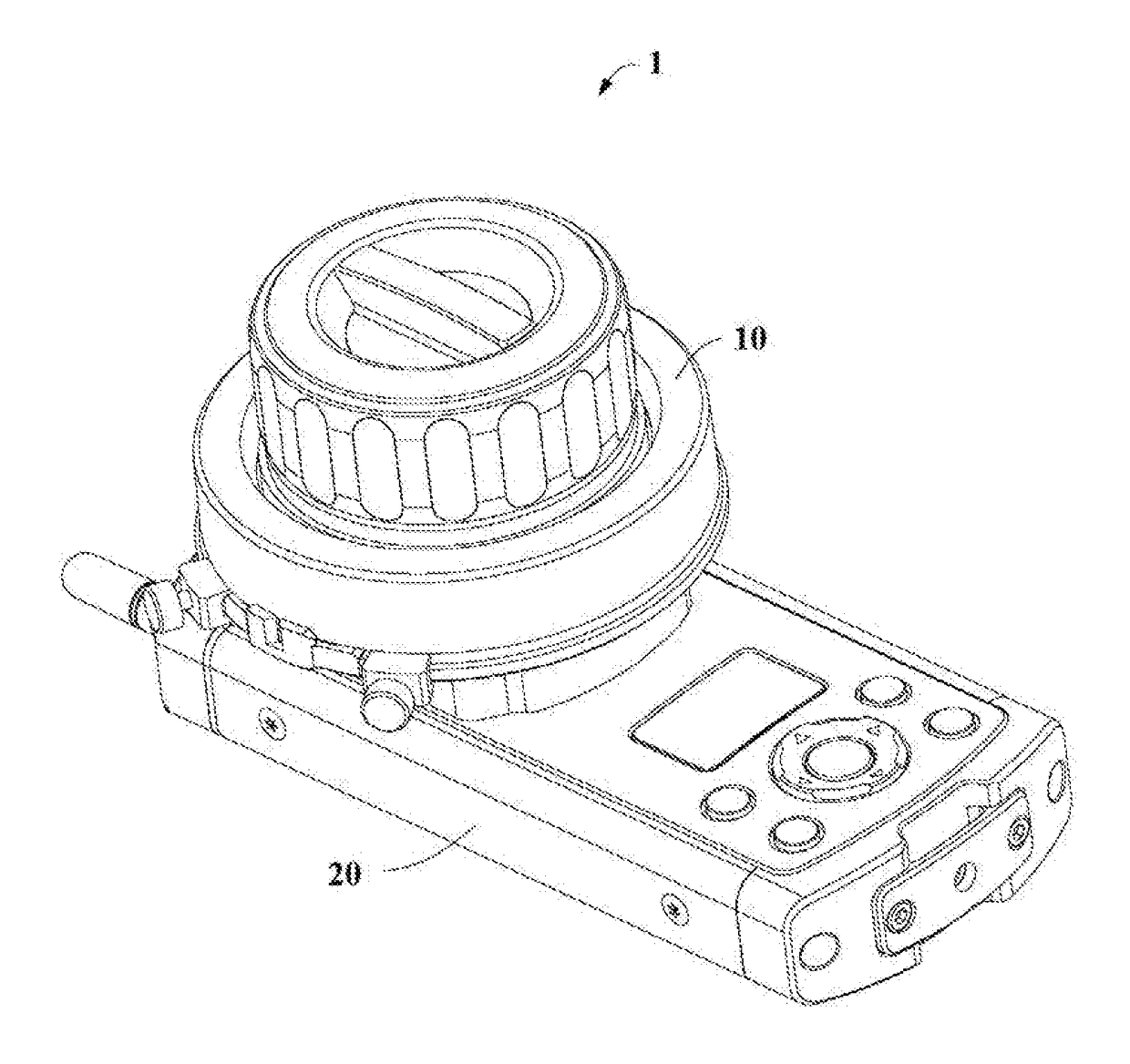

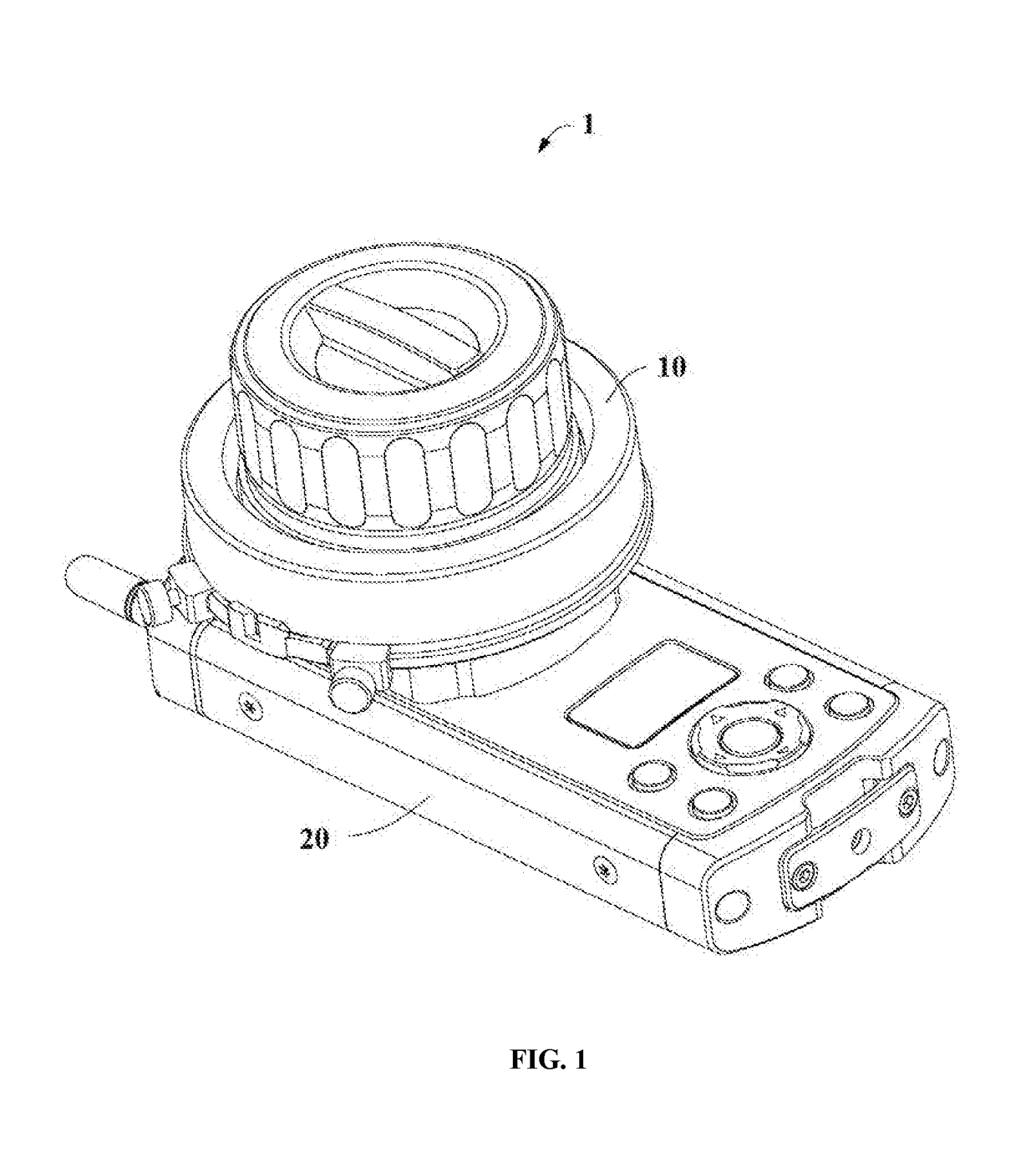

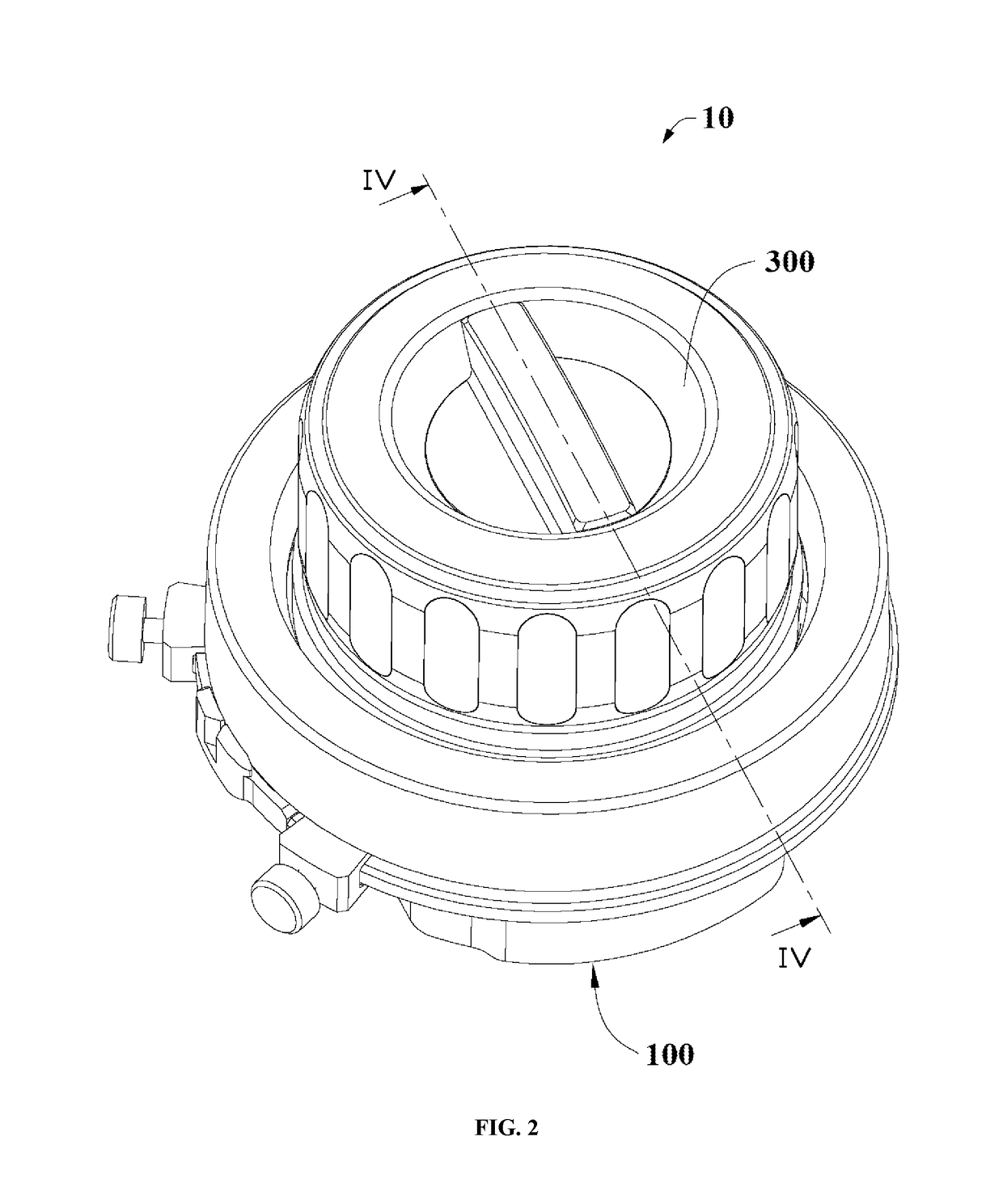

Knob structure and follow focus remote controller using same

ActiveUS20180239387A1Prevent deformationInhibition releaseTelevision system detailsControlling membersEngineering

A knob structure includes a fixed member, a rotational assembly, and a damping element. The fixed member includes a carrying platform. The rotational assembly is rotatably disposed on the fixed member. The damping element is disposed between the carrying platform and the rotational assembly. A contact area between the carrying platform and the damping element is configured to be changed by a rotation of the rotational assembly.

Owner:SZ DJI OSMO TECH CO LTD

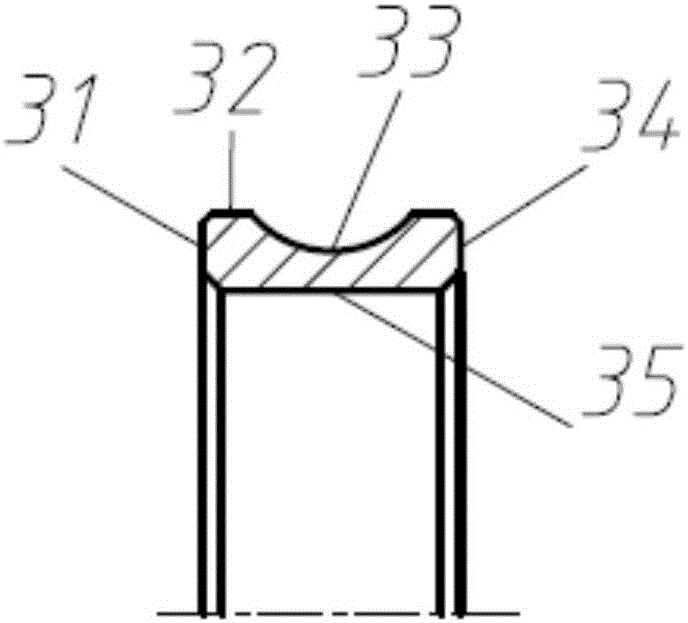

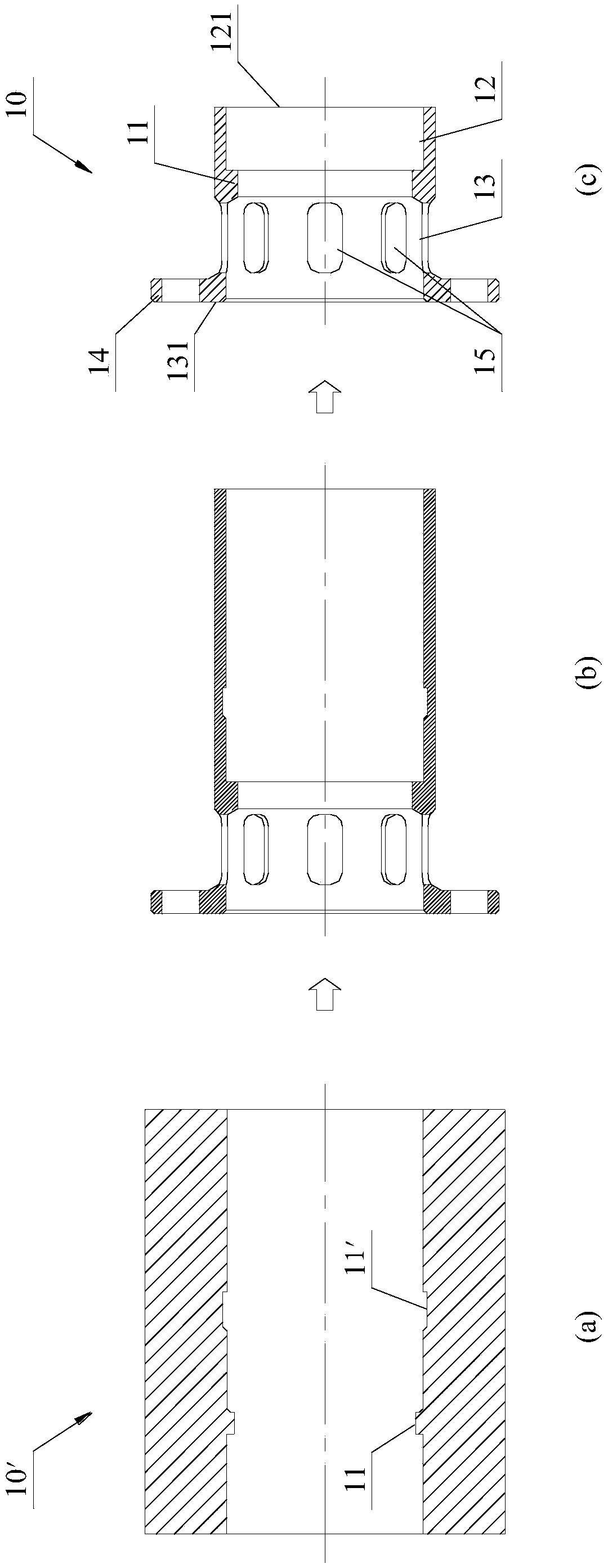

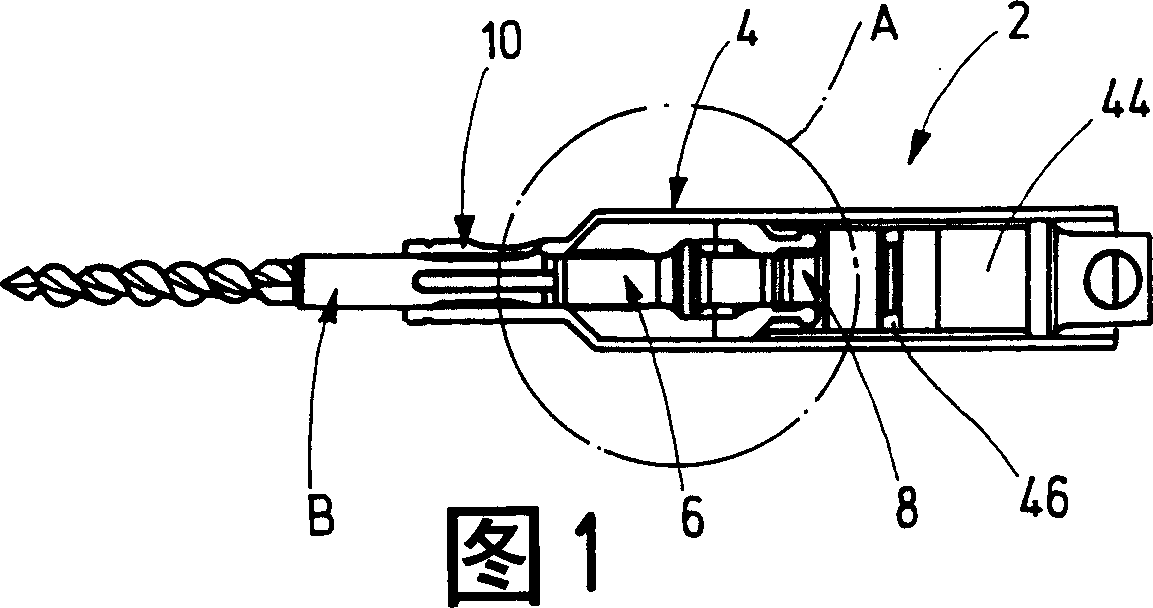

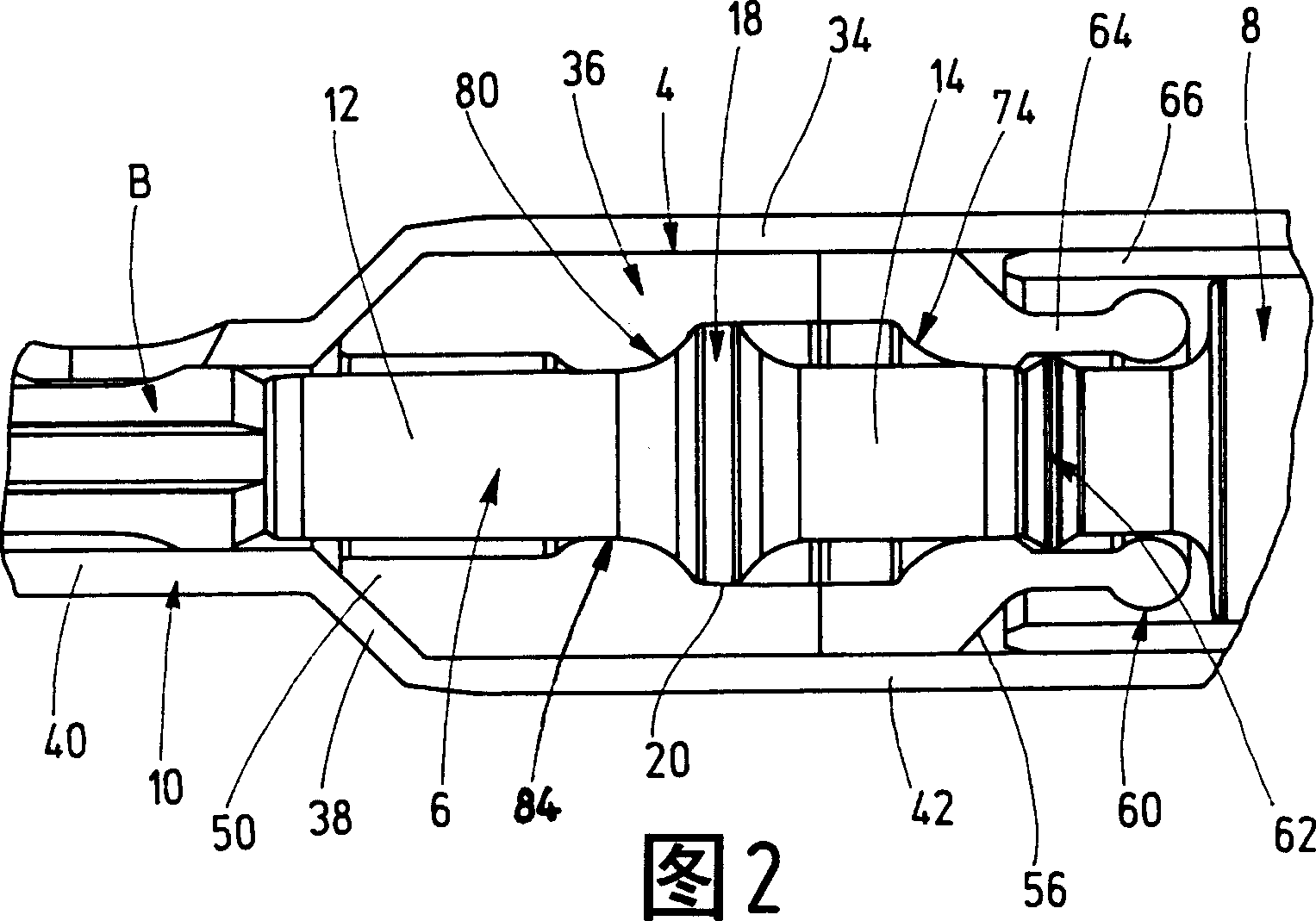

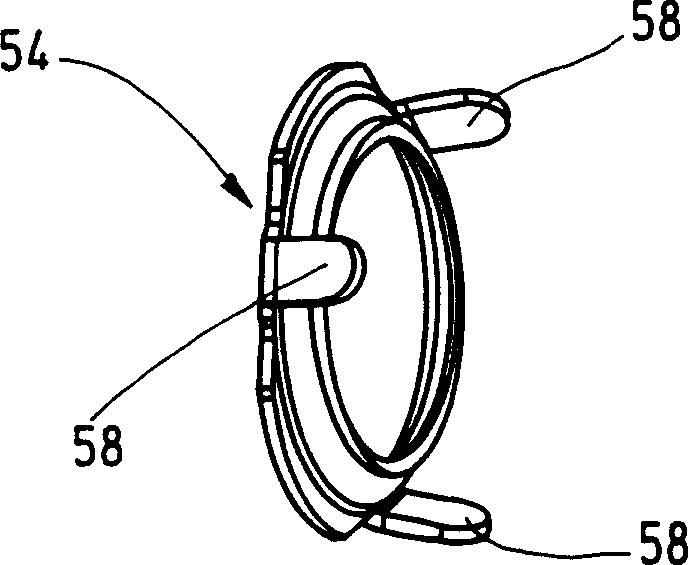

Elastomeric guide-sleeve

InactiveCN1572432AEliminate precision internal machiningReduce noisePortable percussive toolsElastomerDrive motor

The invention relates to a percussion drill and / or a jump bit, comprising a driving motor, a percussion mechanism and a toolholding device (10) for receiving cutters (B); wherein, the percussion mechanism comprises a punch (6) which can do axial movement in a punch guiding device (4) and act on the cutters; the punch guiding device (4) comprises an part (36) with an annular cross section which is made of elastomer material and surrounds the punch (6).

Owner:ROBERT BOSCH GMBH

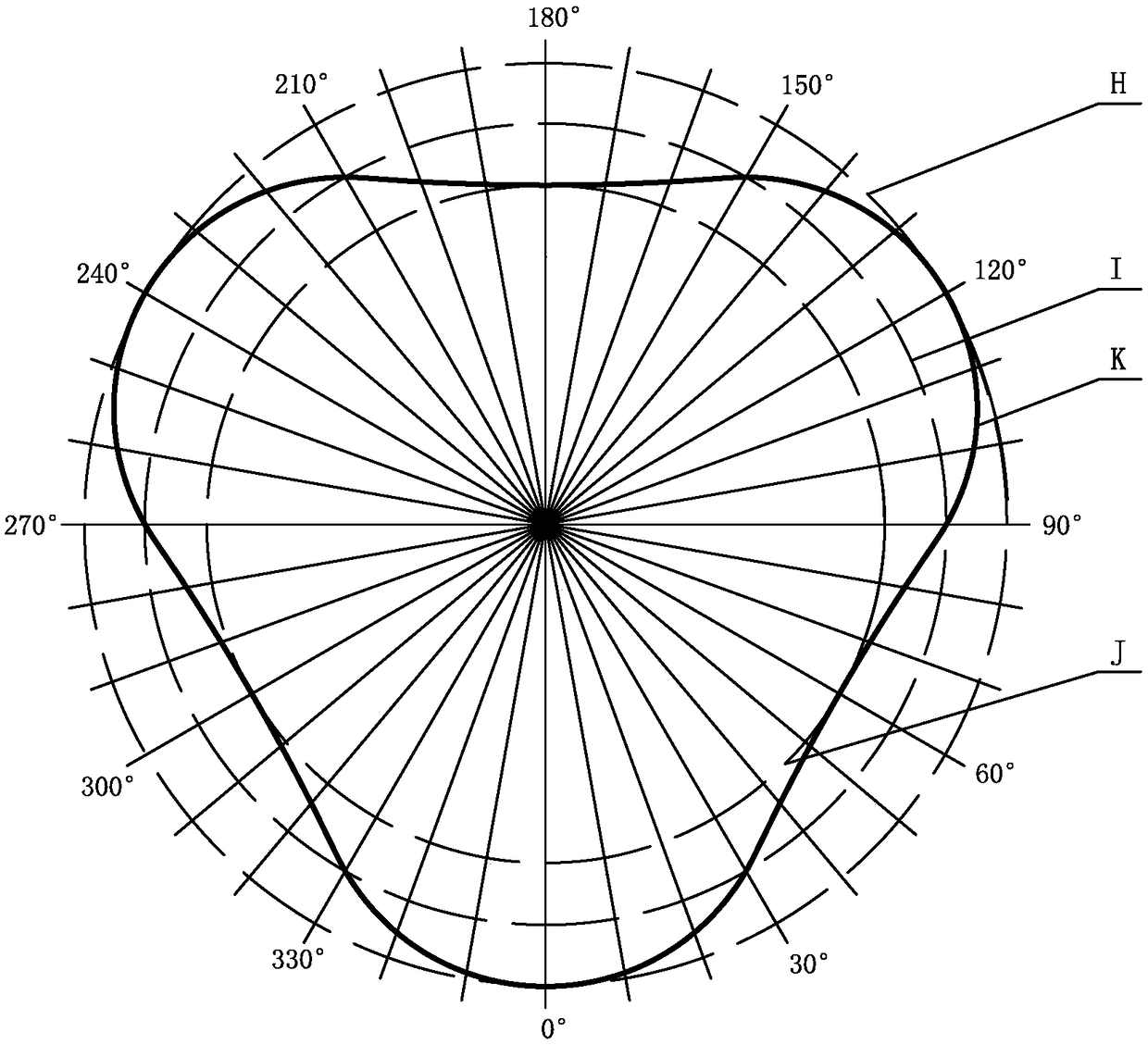

Method for measuring waveform size of bearing three-lobed wave outer raceway

ActiveCN109443290ASolve key problems such as stagnationEasy to useMeasurement devicesDimension measurementEngineering

The invention provides a method for measuring the waveform size of a bearing three-lobed wave outer raceway, and relates to the technical field of geometric quantity measurement and dimension measurement. The method solves the problem that according to an existing three-lobed wave outer raceway, the waveform size of the bearing three-lobed wave outer raceway during the machining process cannot bemeasured. The method comprises the following steps of step one, selecting reference 600 high-precision three-coordinate for measuring; step two, using a reference probe, and selecting a vertical probeand a disc-shaped probe as non-reference probes for measurement; step three, selecting a magnetic suction cup to clamp a workpiece; step 4, verifying the measurement probe; step 5, roughly constructing a coordinate system; step 6, finely constructing the coordinate system for the first time; step 7, finely constructing the coordinate system for the second time; step 8, using a disc probe to scanmeasurement; step 9, converting actual waveform data to a polar coordinate system for outputting 360 point data; step 10, finding the highest and lowest points of the waveform. The method is used formeasuring the waveform size of the bearing three-lobed wave outer raceway.

Owner:AVIC HARBIN BEARING

Machining device of excircle of thin-walled workpiece of motor

InactiveCN101697439ANo effect on mechanical propertiesEffect on mechanical propertiesManufacturing dynamo-electric machinesEngineeringMachining process

The invention relates to a machining device of an excircle of a thin-walled workpiece of a motor, which comprises a three-jaw chuck, wherein the three-jaw chuck is connected with one end of a central spindle, the other end of the central spindle is provided with a positioning step of a thin-walled workpiece to be machined, and the positioning step is connected with a positioning cover plate of the thin-walled workpiece to be machined through a locking bolt. By using the positioning step of the central spindle as a reference, the thin-walled workpiece is respectively positioned by the positioning step and the positioning cover plate of the central spindle and is locked by the locking bolt to enable the thin-walled workpiece to be positioned at the radial direction and the axial direction during the machining so as to ensure the machining concentricity. The invention has simple and compact structure; and the incircle and the excircle of the thin-walled workpiece are positioned and machined by adopting an auxiliary tool with the central spindle, thereby effectively avoiding the workpiece radial deformation caused by the chuck clamping force and causing no influence on the mechanical property of the thin-walled workpiece.

Owner:SEC ELECTRIC MACHINERY

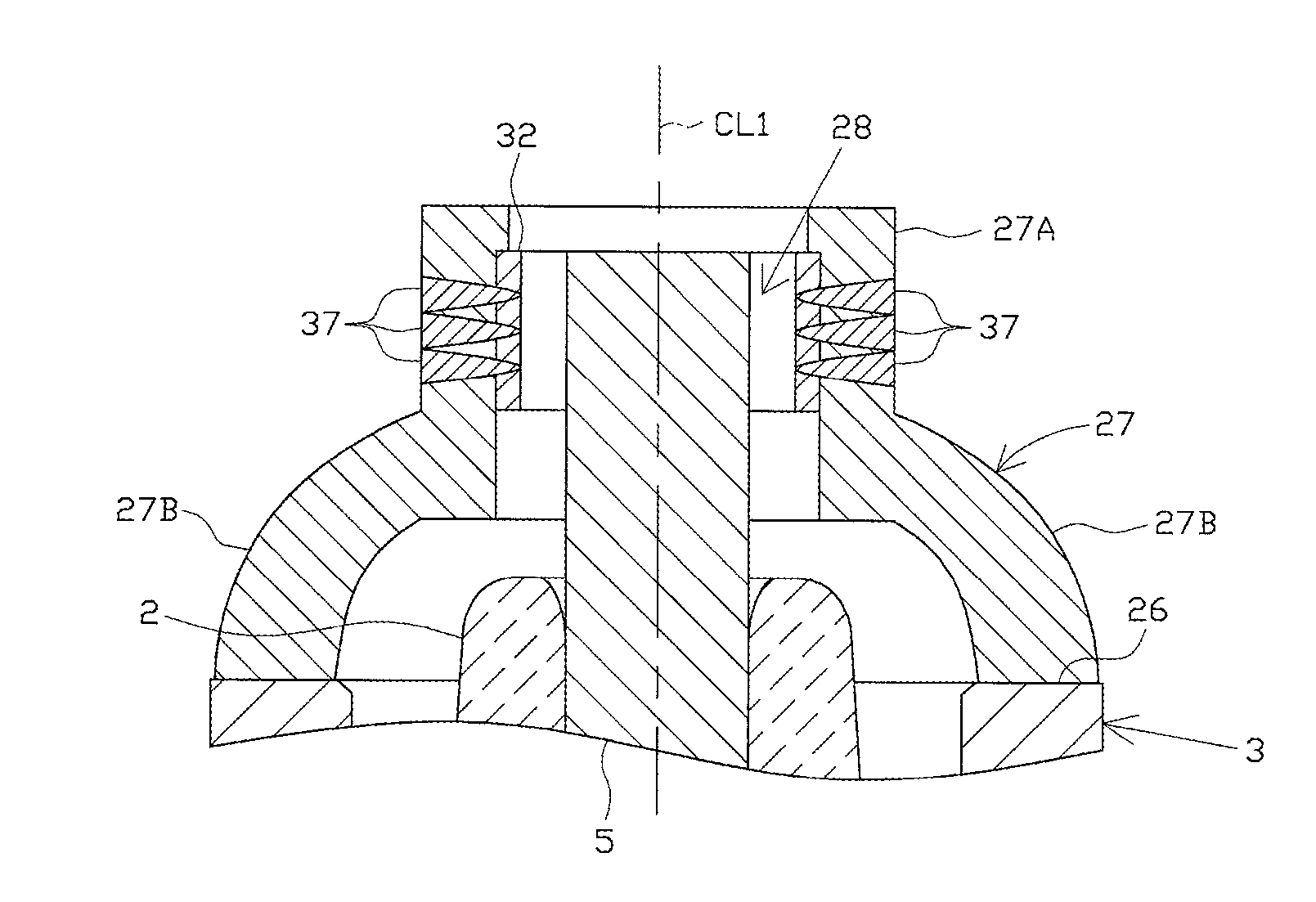

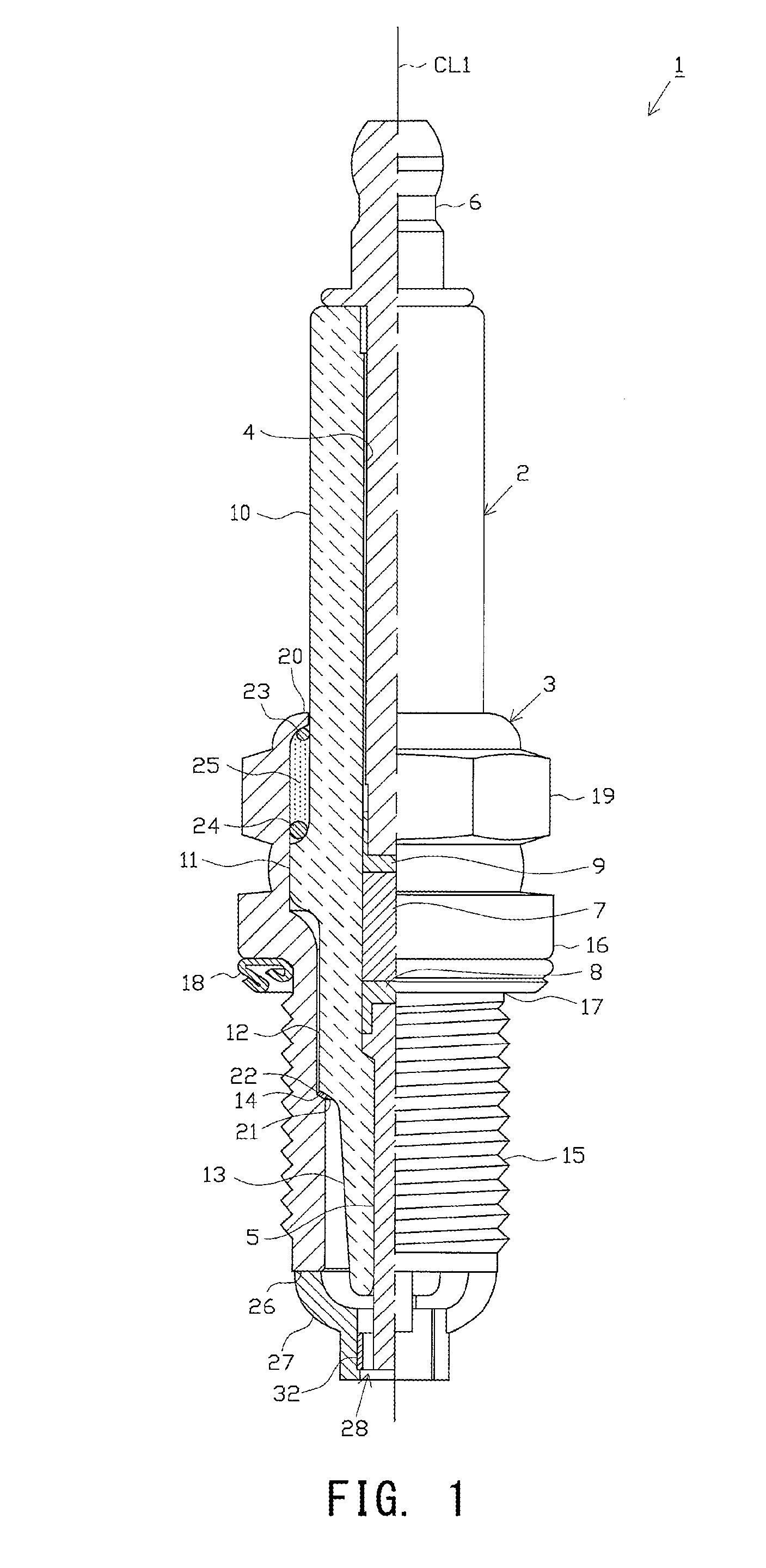

Spark plug

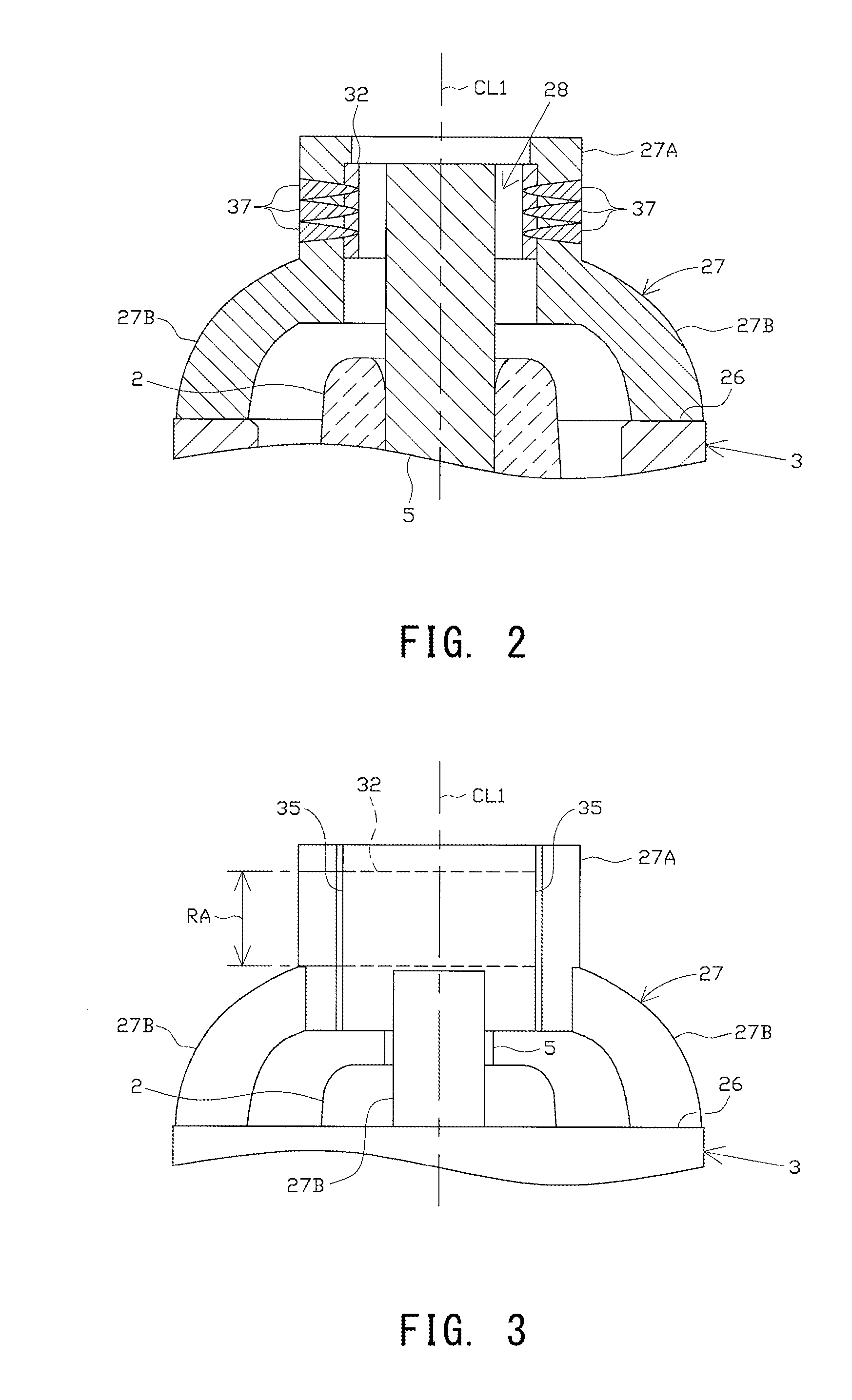

ActiveUS20160141840A1Reduce the differenceAvoid separationSparking plugsSpark dischargeGrounding electrodes

A spark plug (1) includes an insulator (2) having an axial hole (4), a center electrode (5) inserted into the axial hole (4), a metallic shell (3) provided around the insulator (2), a ground electrode (27) whose base end portion is fixed to the metallic shell (3) and which has an annular portion (27A) formed at a forward end portion thereof, the center electrode (5) being disposed radially inward of the annular portion (27A), and an annular tip (32) which is joined to the inner circumference of the annular portion (27A) and which forms a spark discharge gap (28) between the center electrode (5) and the inner circumferential surface of the annular tip (32). Recesses (35) are provided on at least one of the inner and outer circumferences of the annular portion (27A).

Owner:NGK SPARK PLUG CO LTD

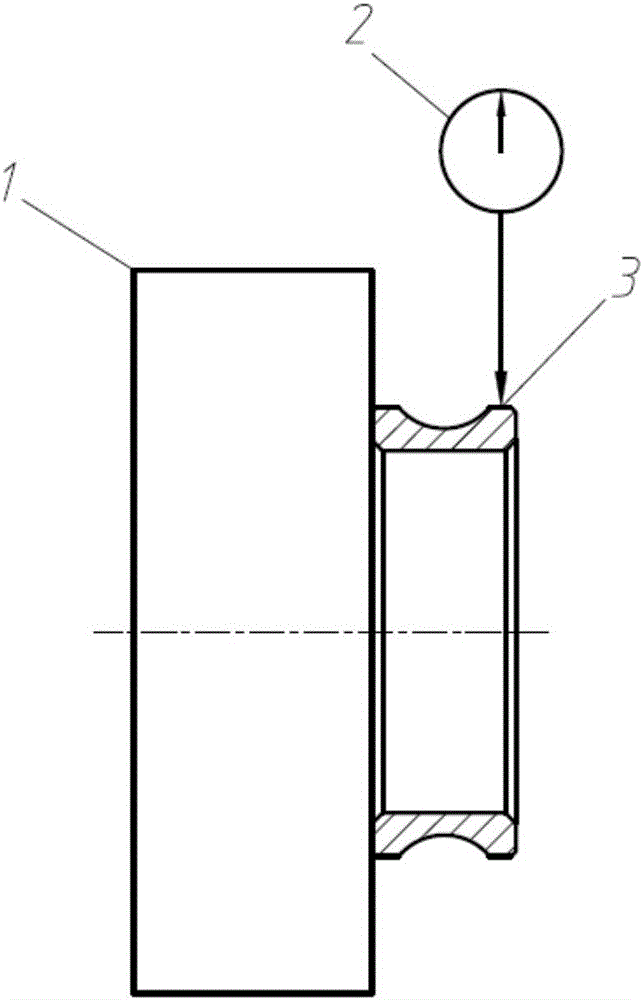

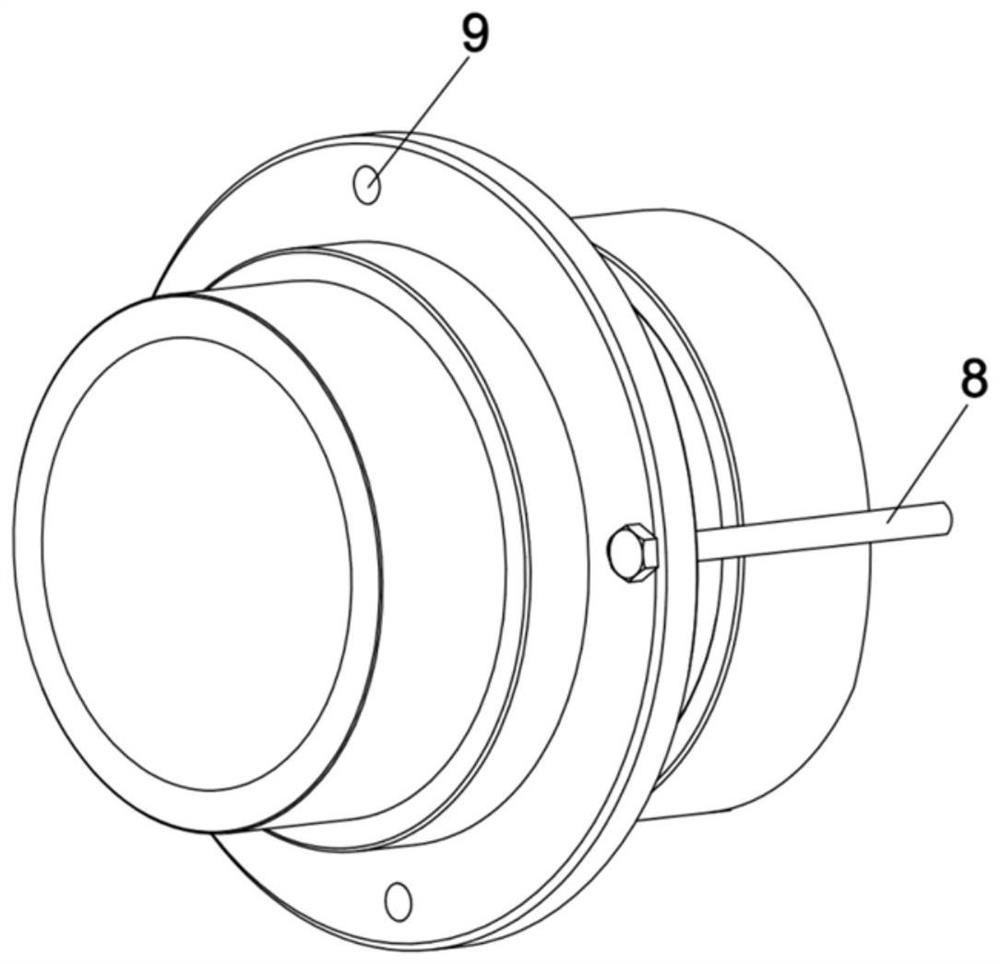

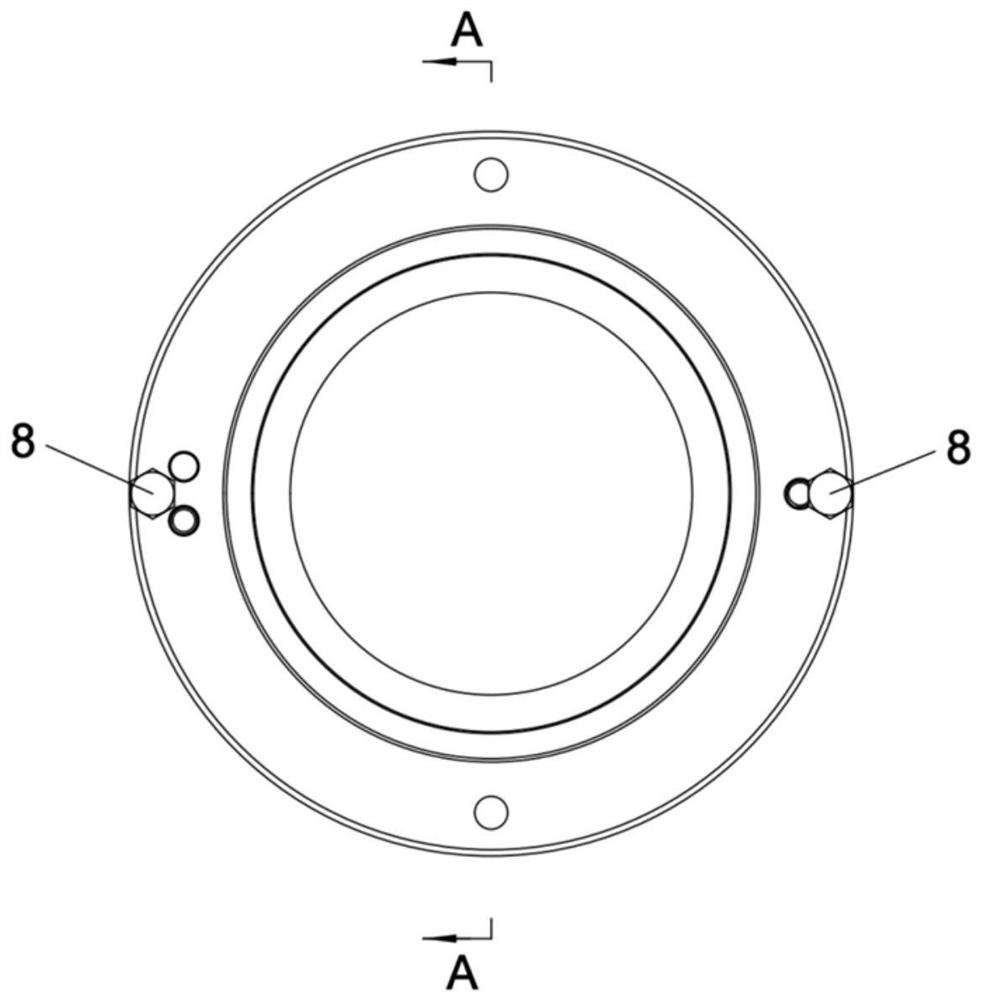

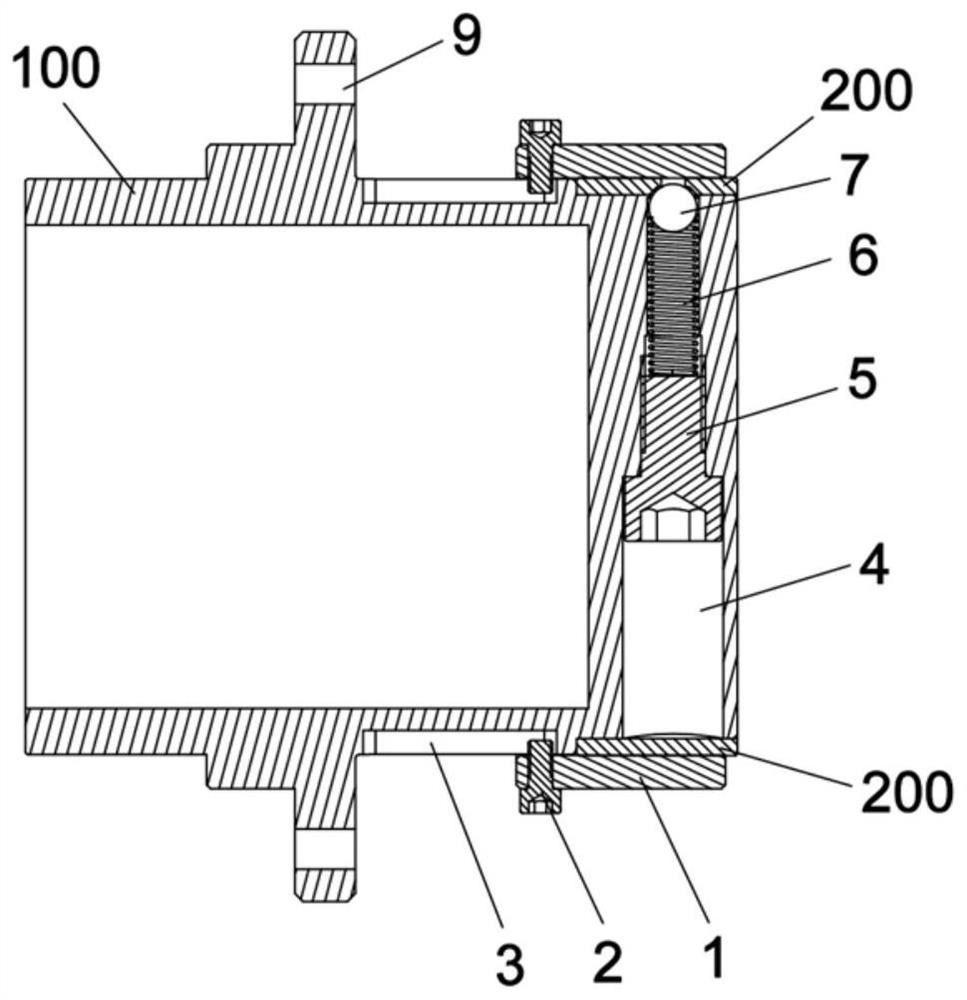

Rolling Bearing

ActiveUS20210156422A1Prevent overloadLow costRolling contact bearingsWaterborne vesselsRolling-element bearingClassical mechanics

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Novel oil-well pump

InactiveCN103452822AStrong bending resistancePrevent radial deformationPositive displacement pump componentsFlexible member pumpsEngineeringPressure difference

The invention discloses a novel oil-well pump, which comprises a pump barrel assembly, a plunger assembly and a fixed valve assembly. When an ordinary oil-well pump is used for sucking gas-mixed crude oil, the pumping efficiency is low since the submergence depth is difficult to determine. A complex stress environment causes radial deformation and bending of a pump barrel during working, so that leakage is increased, the pumping efficiency is influenced, descending resistance of a plunger is increased, and the phenomena of eccentric wear and pump blocking are caused. In the novel oil-well pump, a pressure-bearing outer pump barrel is added outside an ordinary oil-well pump, and only one end of an inner pump barrel is fixed, so that radial deformation caused by stress of the inner pump barrel is avoided, additional leakage caused by the change of the gap between the pump barrel and the plunger is eliminated completely, and the pump has higher bending resistance and eccentric wear resistance. A traveling valve of the novel oil-well pump is formed by connecting a traveling valve carrier rod and a traveling valve ball in series, and the area of the lower end of the carrier rod is larger than the area of the inner hole of a traveling valve base, so that the opening pressure difference of the traveling valve of the pump is smaller than that of the traveling valve of an ordinary pump, negative influences of gas in the pump on the pumping efficiency can be reduced, and the phenomenon of ''airlock'' is avoided.

Owner:CHANGZHOU UNIV

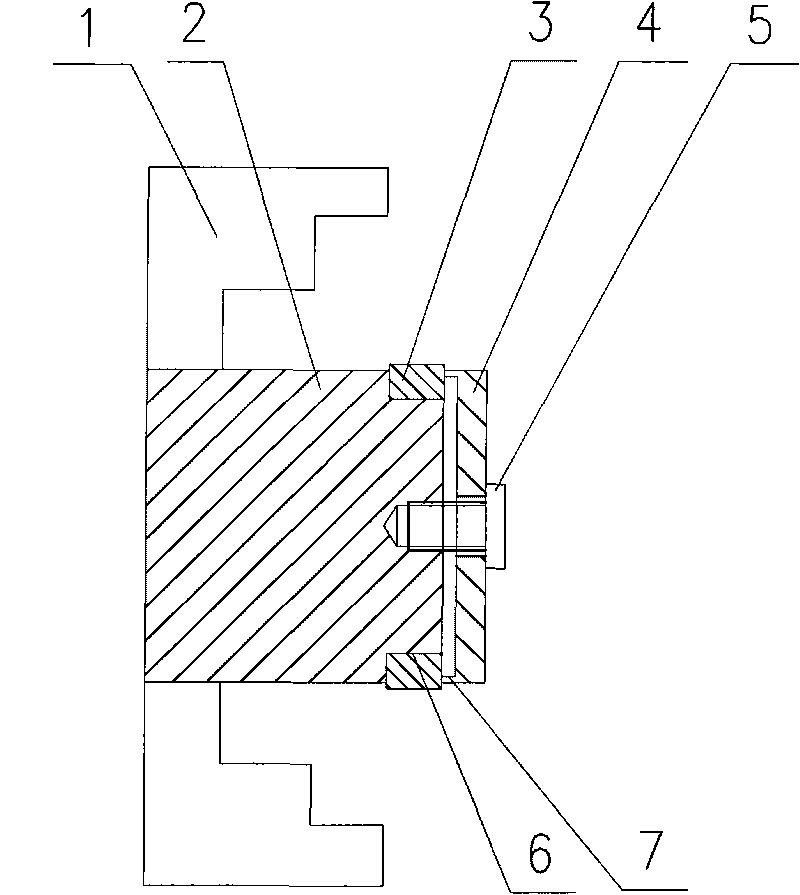

Engine bearing bush mounting and dismounting tool

ActiveCN112975338APrevent radial deformationPrevent radial displacementMetal working apparatusEngineeringMechanical engineering

The invention discloses an engine bearing bush mounting and dismounting tool, and belongs to the field of engine assembly. The engine bearing bush mounting and dismounting tool comprises a tool body. The two ends of the tool body are a dismounting end and a mounting end respectively, and the mounting end sequentially comprises a guide journal and a bearing bush matching journal in the direction away from the dismounting end. The diameter of the guide journal is larger than that of the bearing bush matching journal, the bearing bush matching journal is used for sleeving two half bushes of a bearing bush, and a step surface between the guide journal and the bearing bush matching journal is a bearing bush thrust surface. A guide ring can be hooped on the peripheries of the two half bushes and can provide radial limiting for the bearing bush in the mounting process, so that the two half bushes are prevented from radial deformation or radial displacement. In addition, the guide ring can axially move along the guide journal in the press-fitting process so as to play an axial limiting role in mounting of the bearing bush and determine the press-in amount of the bearing bush pressed into a bearing seat. The engine bearing bush mounting and dismounting tool is simple in structure and low in manufacturing cost, and the assembly precision is easy to guarantee.

Owner:FAW JIEFANG AUTOMOTIVE CO

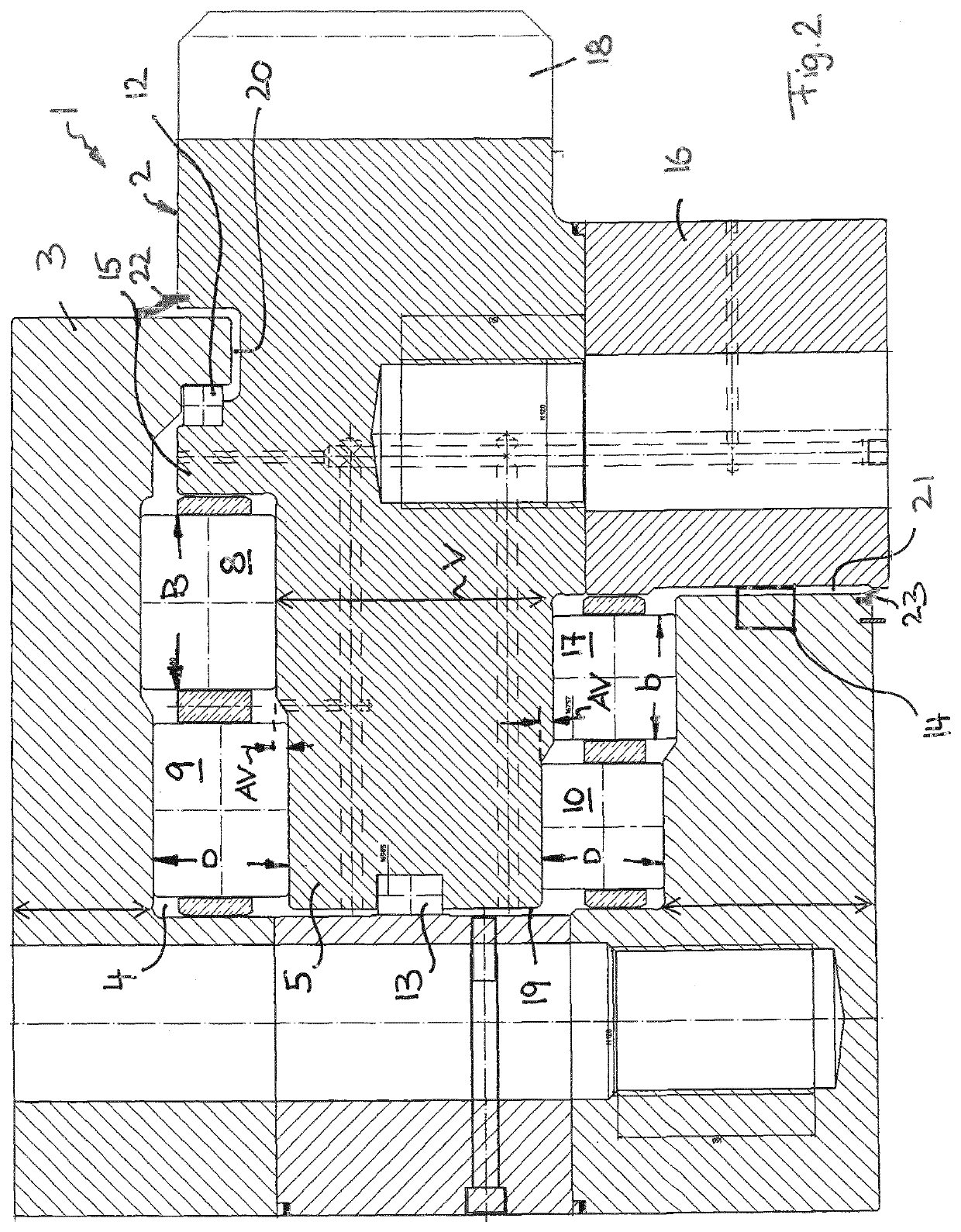

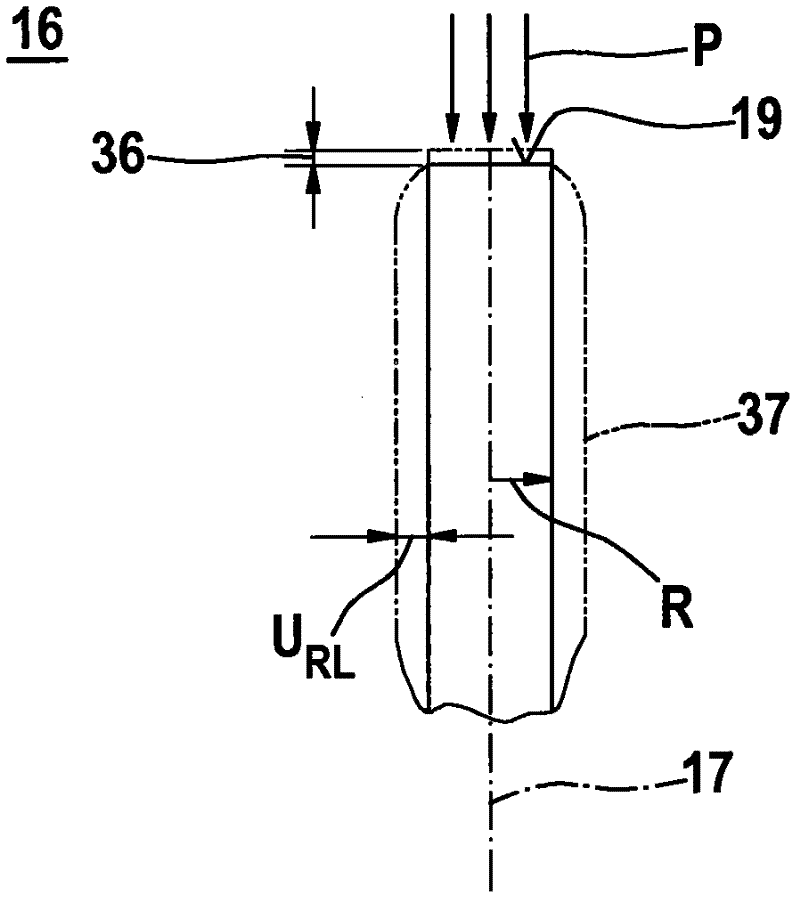

High-pressure pump

InactiveCN102414434APrevent radial deformationPrevent leakagePositive displacement pump componentsFuel injecting pumpsRadial piston pumpDrive shaft

A high-pressure pump (1), in particular serving as a radial piston pump or in-line piston pump for fuel injection systems of air-compressing auto-ignition internal combustion engines, has a pump assembly (13) and a driving shaft (6). The pump assembly (13) comprises a pump piston (16) guided in a cylinder bore (15) along an axis (17) of the cylinder bore (15), which can be driven by the driving shaft (6). Furthermore, a front surface (19) of the pump piston (16) in the cylinder bore (15) defines a pump working chamber (20). The pump piston (16) is made of a material which has an anisotropic elastic modulus. Thus having a high-pressure in the pump working chamber (20) causing the expansion of the cylinder bore (15), a radial deformation of the pump piston (16) can be reached, compensating the expansion of the cylinder bore (15).

Owner:ROBERT BOSCH GMBH

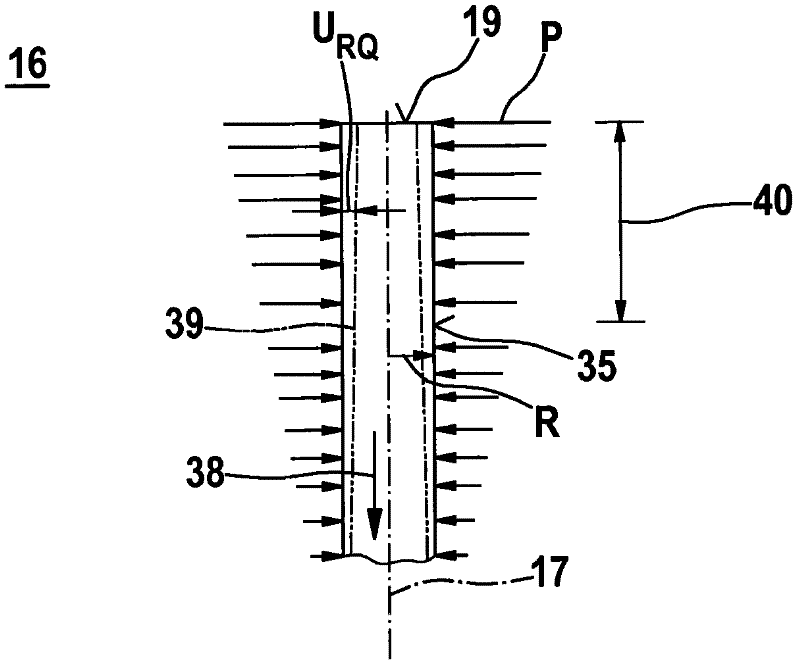

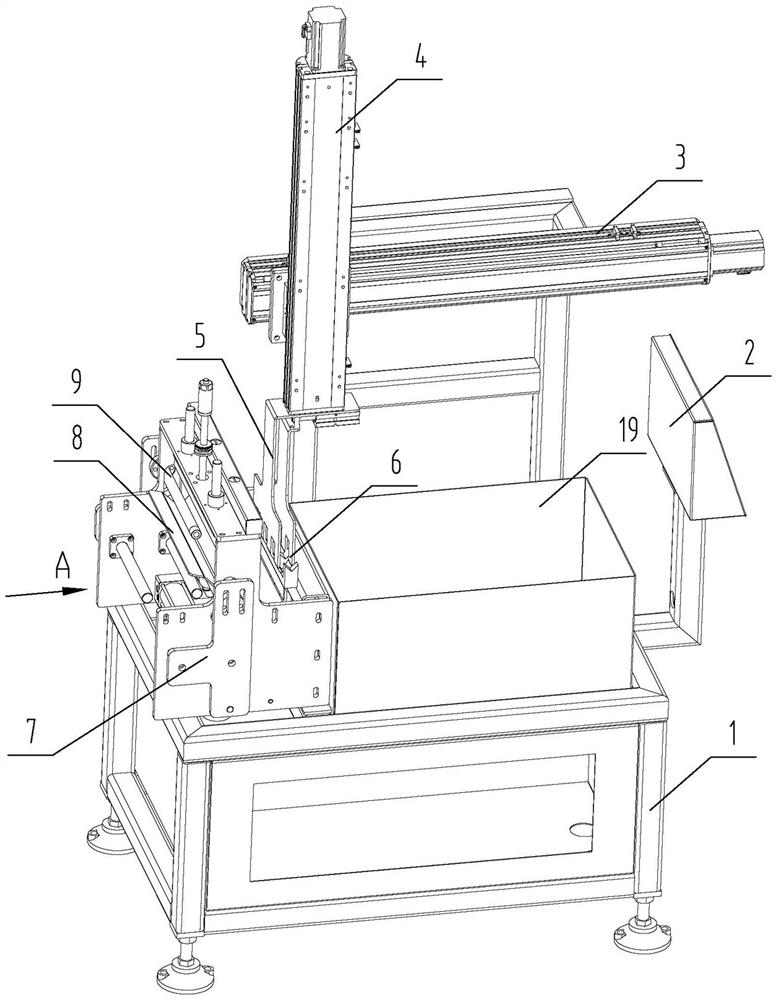

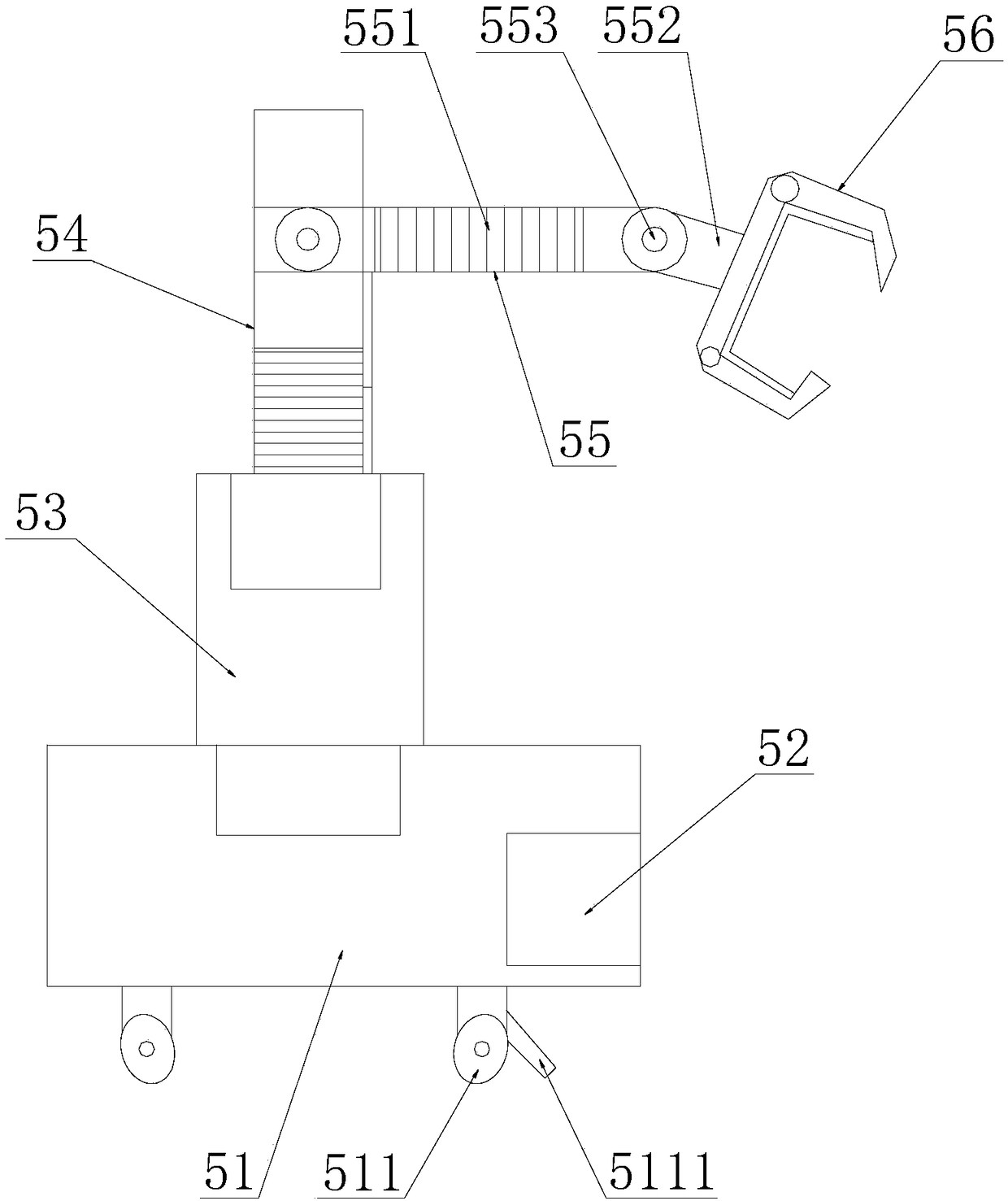

Automatic basketing method and equipment for sleeving-shrinkage casings

ActiveCN112109942AIncrease effective storage spaceSimple structureGripping headsLifting devicesRobot handEngineering

The invention discloses an automatic basketing method and equipment for sleeving-shrinkage casings, and belongs to the technical field of packaging and storage. The automatic basketing equipment comprise a machine frame, and is characterized in that a material guide table is arranged on the machine frame, the rear end of the material guide table is connected with a lifting table, a clamping grooveis formed in the top wall of the lifting table, when the lifting table descends, the top end of the front wall of the clamping groove is not higher than the top wall of the rear end of the material guide table, when the lifting table ascends, the top end of the front wall of the clamping groove is higher than the top wall of the rear end of the material guide table, a basket placing platform anda movable support are arranged on the machine frame, the movable support can ascend, descend and horizontally move, and a mechanical arm is arranged on the movable support and can horizontally move within the range of the basket placing platform. On one hand, the equipment structure is simplified, the process is controllable, and therefore reliable basketing is achieved; and on the other hand, thedefect that in the prior art, a supporting frame is needed to be used for cooperating basketing is overcome, the effective storage space of a material basket is increased, and the storage amount canbe increased.

Owner:青岛齐林智信自控技术有限公司

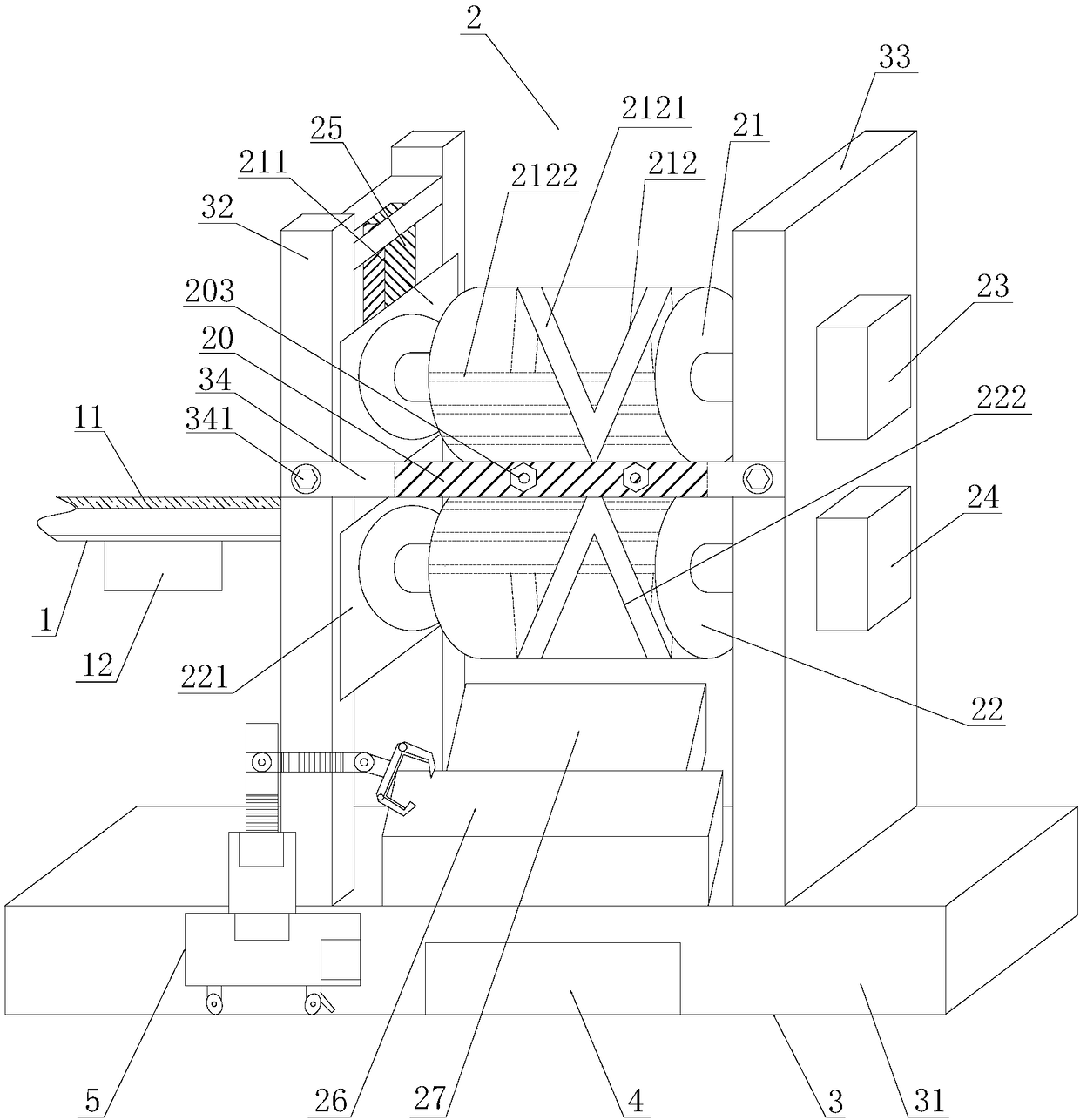

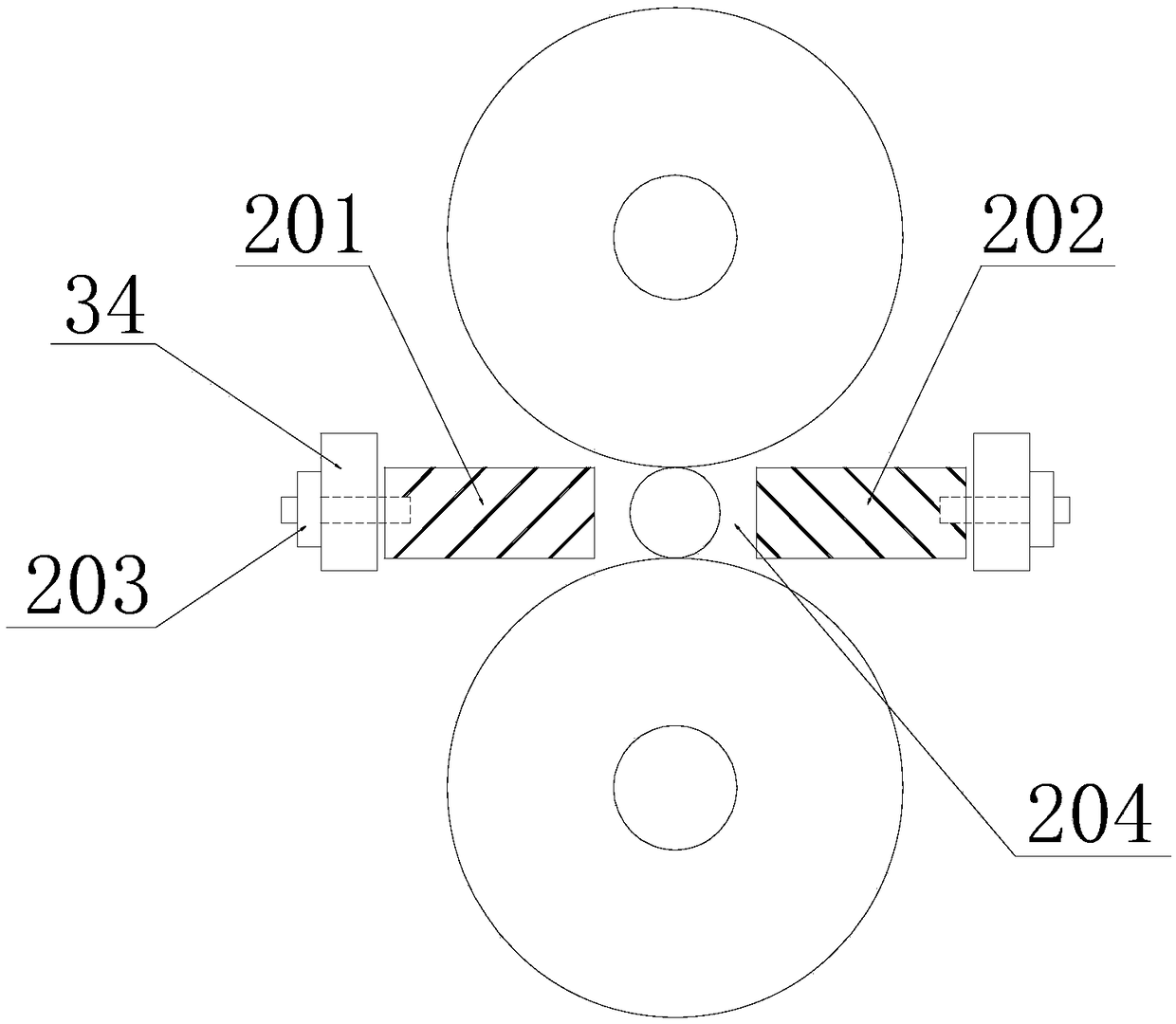

Cross rolling device for wrench processing

The invention discloses a cross rolling device for wrench processing. The cross rolling device for wrench processing comprises a feeding and conveying mechanism, a cross rolling mechanism, a base, a control mechanism and a mobile manipulator mechanism. The base comprises a base chassis, a left side foundation pillar and a right side foundation pillar; the cross rolling mechanism comprises a positioning assembly, an upper roller, a lower roller, an upper roller drive motor, a lower roller drive motor, and a power transmission system for driving the upper roller and the lower roller to co-rotateat the same speed; the upper roller is connected with the upper roller drive motor; the lower roller is connected with the lower roller drive motor; the upper roller drive motor, the lower roller drive motor, the power transmission system and the control mechanism are connected; the mobile manipulator mechanism is matched with the control mechanism; and the mobile manipulator mechanism is matchedwith the cross rolling mechanism. According to the cross rolling device for wrench processing provided by the invention, the automation degree is high, one initial rod material enters the cross rolling device, two rod materials can be processed at one time, the production efficiency is high, and the raw materials are saved by 10 percent to 20 percent.

Owner:HAIYAN XINGCHEN HANDTOOLS

Electromechanical actuator limiting stroke circumferential anti-blocking structure

InactiveCN109695683ASimplify the supporting relationship of parts and componentsMeet the requirements of anti-jamming at extreme positionsGearingBall screwEngineering

The invention discloses an electromechanical actuator limiting stroke circumferential anti-blocking structure. The structure is used for providing full-stroke and high-reliability transmission for anelectromechanical actuator controlled by air power; a clamping buckle structure and a clamping groove structure are correspondingly added between a ball screw rod and a ball nut, so that axial brokenend face rigid contact between the ball screw rod and the ball nut at the limit position is prevented; by means of cooperation with a ball, transmission is stable, the requirement of anti-blocking ofthe electromechanical actuator at the limit position is skillfully realized, the transmission reliability and the position control precision of a ball screw rod pair are improved.

Owner:随州职业技术学院

High-voltage circuit breaker and nozzle thereof

ActiveCN105355507AKeep shapePrevent axial movementHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention relates to the field of high-voltage power supply and distribution, particularly to a high-voltage circuit breaker and a nozzle thereof, so as to solve the problems of inconvenient processing and installation of the nozzle since the existing nozzle is connected with a flange through threads. In order to solve the technical problem, one end of the nozzle used for the high-voltage circuit breaker is processed with notches extending along the axial direction, wherein the notches allow the tail end of the nozzle to form elastic contact fingers which can deform in a stretchable manner along the radial direction, the elastic contact fingers are processed with convex edges, and grooves which can be clamped with the convex edges in a matched manner are processed in a flange. The axial fixation of a workblank is achieved by utilizing the notches in the nozzle when using a tooling for fixing the workblank in a radial manner, the axial movement of the workblank during the processing process is prevented, and the processing precision is guaranteed; and the convex edges on the nozzle can be clamped and matched with the grooves in the flange by inserting the nozzle into the flange through pressing the elastic contact fingers in assembly without using a tool for auxiliary fastening, thereby avoiding the resulting secondary deformation and processing design of the tool and operation tooling.

Owner:PINGGAO GRP +1

Self-clamping structure for solving short-circuit resistance problem of amorphous alloy transformers

ActiveUS10902996B2Cumbersome operationStructure cumbersomeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringMechanical engineering

A self-clamping structure for solving a short-circuit resistance problem of amorphous alloy transformers comprises an A-phase coil, a B-phase coil and a C-phase coil which are horizontally arranged, the A-phase coil being in close contact with the B-phase coil, and the B-phase coil being in close contact with the C-phase coil. By using a solidified low-voltage coil as a fastening splint and binding with a high-strength binding strap, the low-voltage coils of the A-phase and the B-phase clamp and fix a weak portion between the A and B phases; and the low-voltage coil of the B-phase and the C-phase clamp and fix a weak portion between the B and C phases. Outer sides of the A- and C-phase coils are each provided with a high-strength insulation splint, so that the splint and the low-voltage coil of corresponding phase constitute the splint pair to clamp and fix the corresponding weak portion.

Owner:JIANGSU HUAPENG TRANSFORMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com