Elastomeric guide-sleeve

A technology of guiding device and punch, applied in the direction of light impact tools, manufacturing tools, striking tools, etc., can solve problems such as poor integrity of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

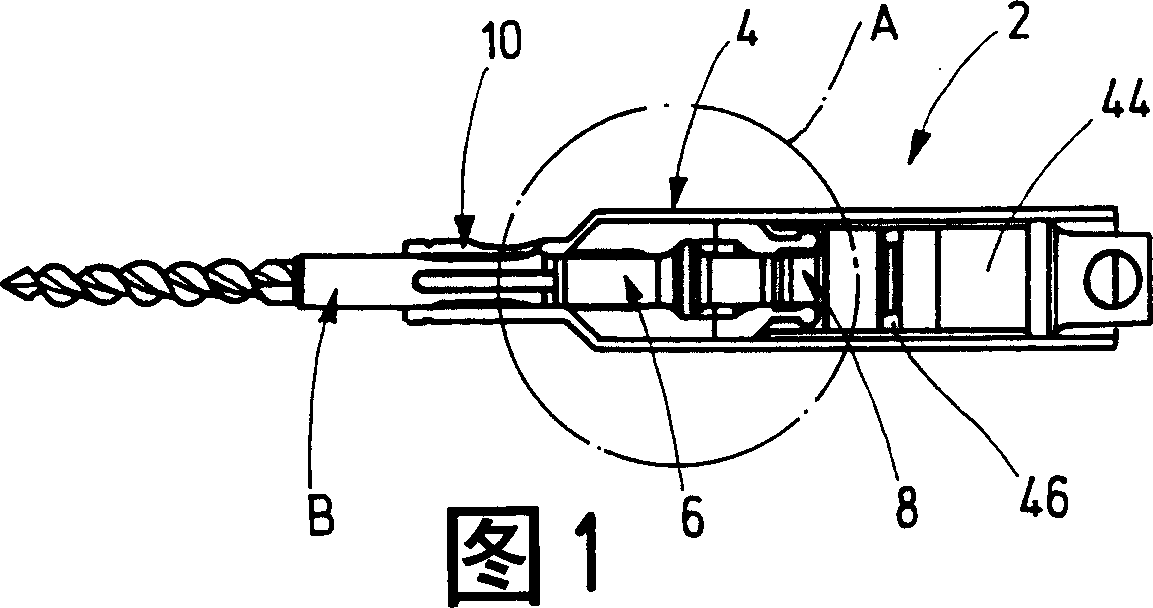

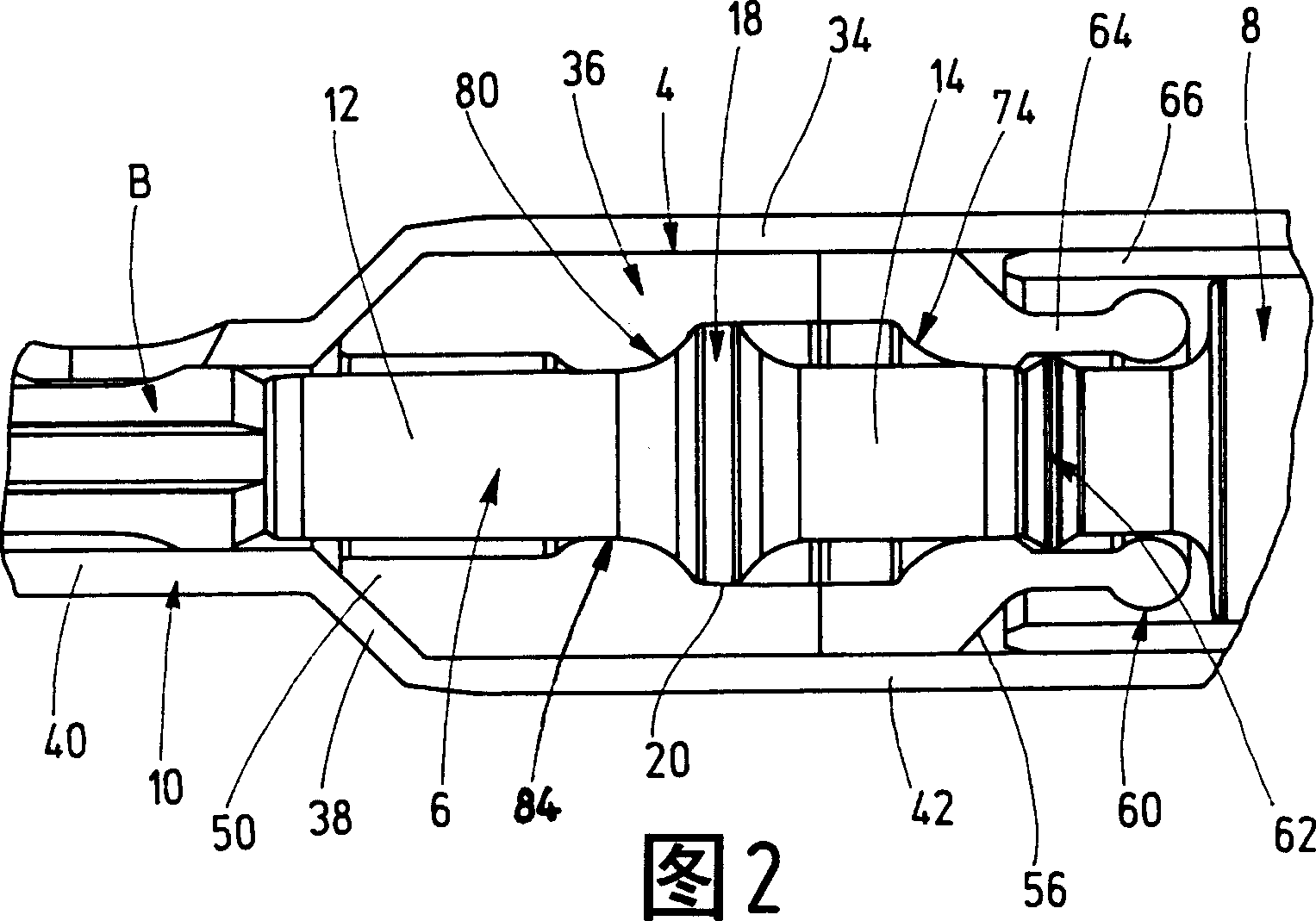

[0020] Shown in Figure 1 of the accompanying drawings, the punch assembly 2 of the impact mechanism of a portable electric impact drill or impact hammer machine (not shown) basically consists of a punch guide 4 and a Consists of an axially movable punch 6 which transmits the impact pulses of a hammer 8 of a percussion mechanism driven by the drive motor of a portable percussion drill or percussion hammer machine to a drill bit inserted in a tool holder 10 of the machine tool Or impact on tool B.

[0021] As shown most clearly in Fig. 4, the punch 6 made of solid steel consists of two elongated cylindrical end portions 12, 14 with chamfered flat end faces 16 and with these two end portions 12, 14 The thickened middle part 18 is connected and arranged between them. The central part 18 has a narrow, preferably but not necessarily cylindrical peripheral surface 20 in its center and is bounded on both sides by an oblique front side 22 and an oblique rear side 24 . The two side fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com