Patents

Literature

143 results about "Geometric quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The geometrical Quantity also or whole increased Area consists of three Parts or Members, the first of which is the given Area, the second a Rectangle under the Ordinate and the Increment of the Absciss, and the third a curvilinear Space. And, comparing the homologous or correspondent Members on both Sides,...

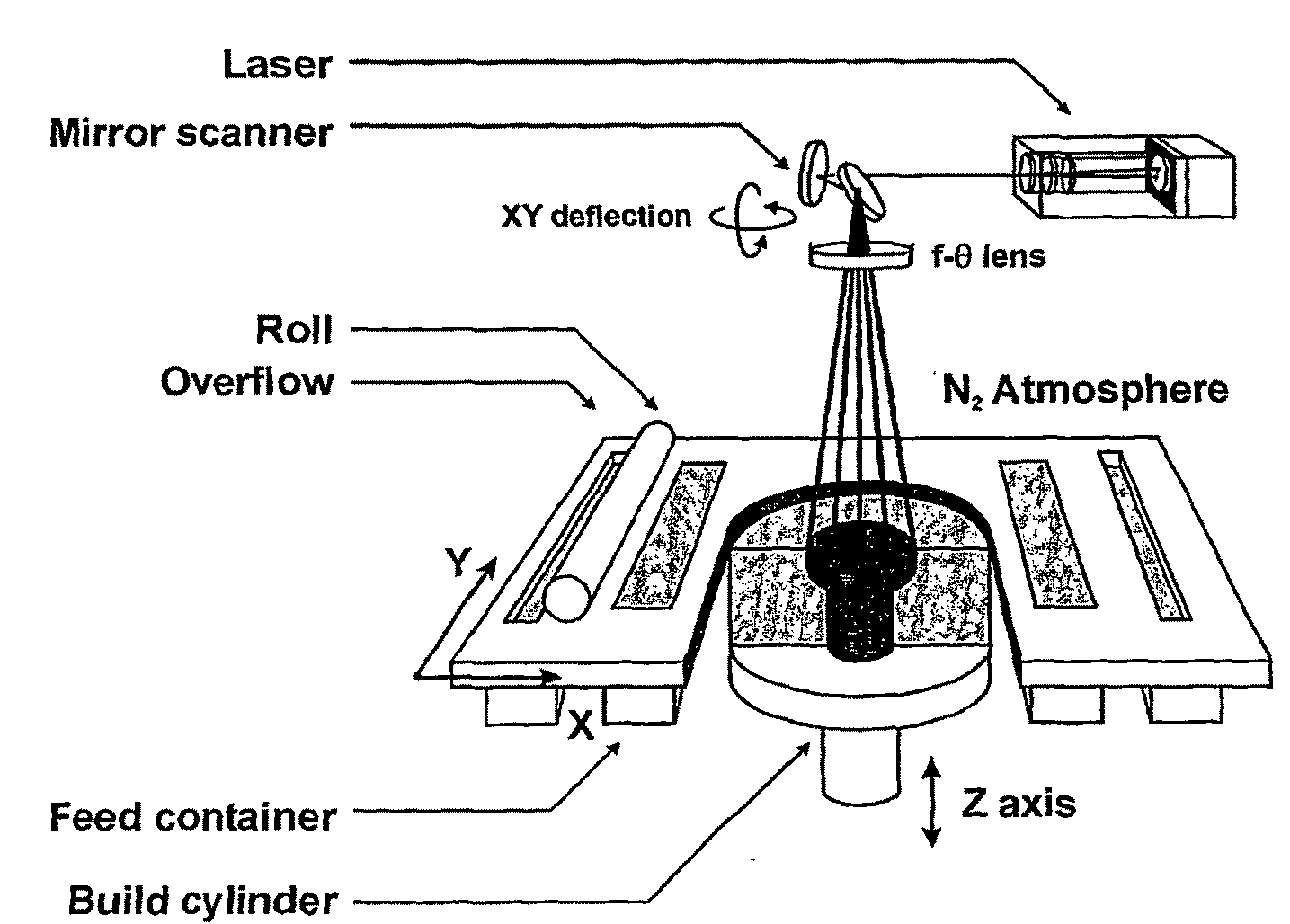

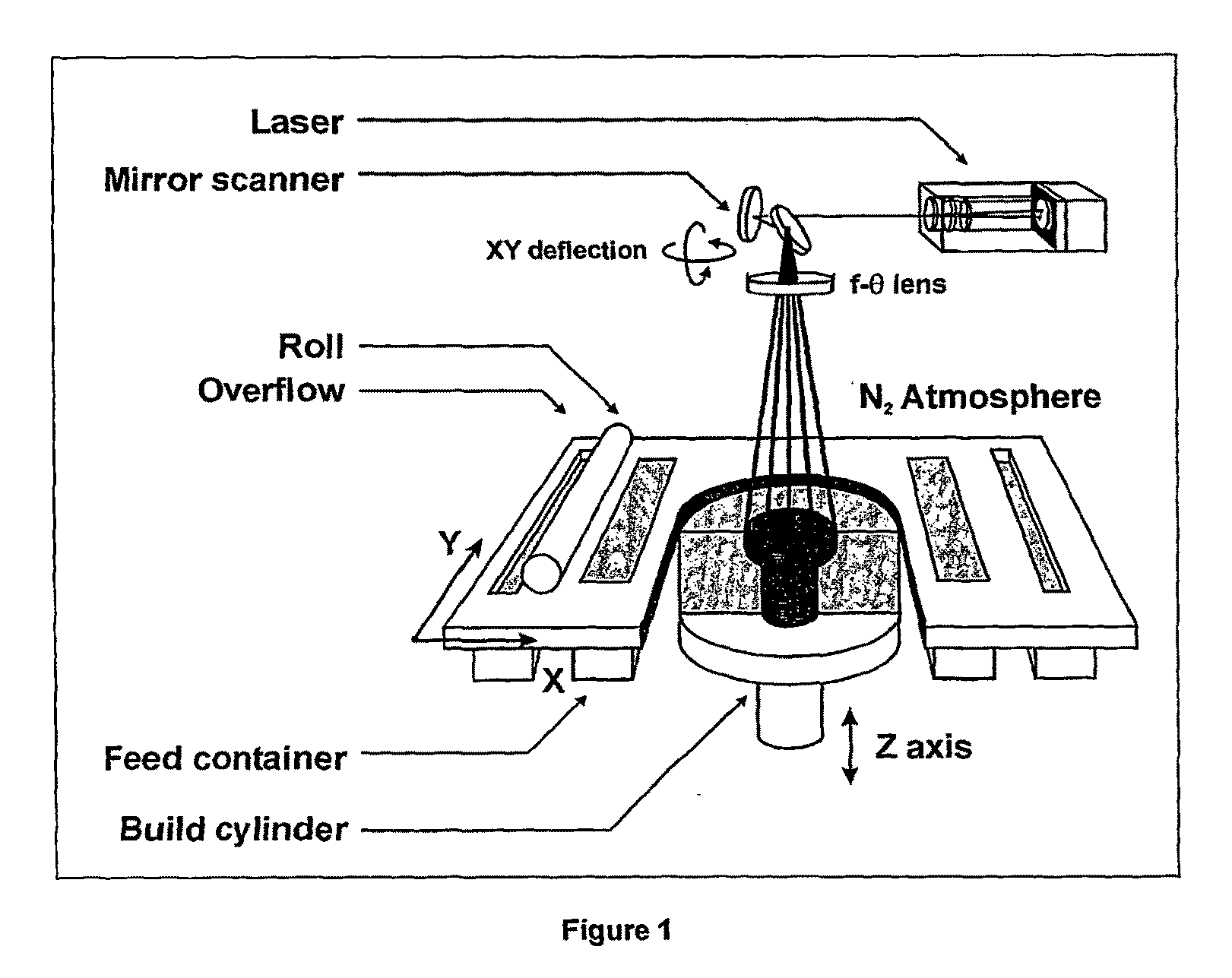

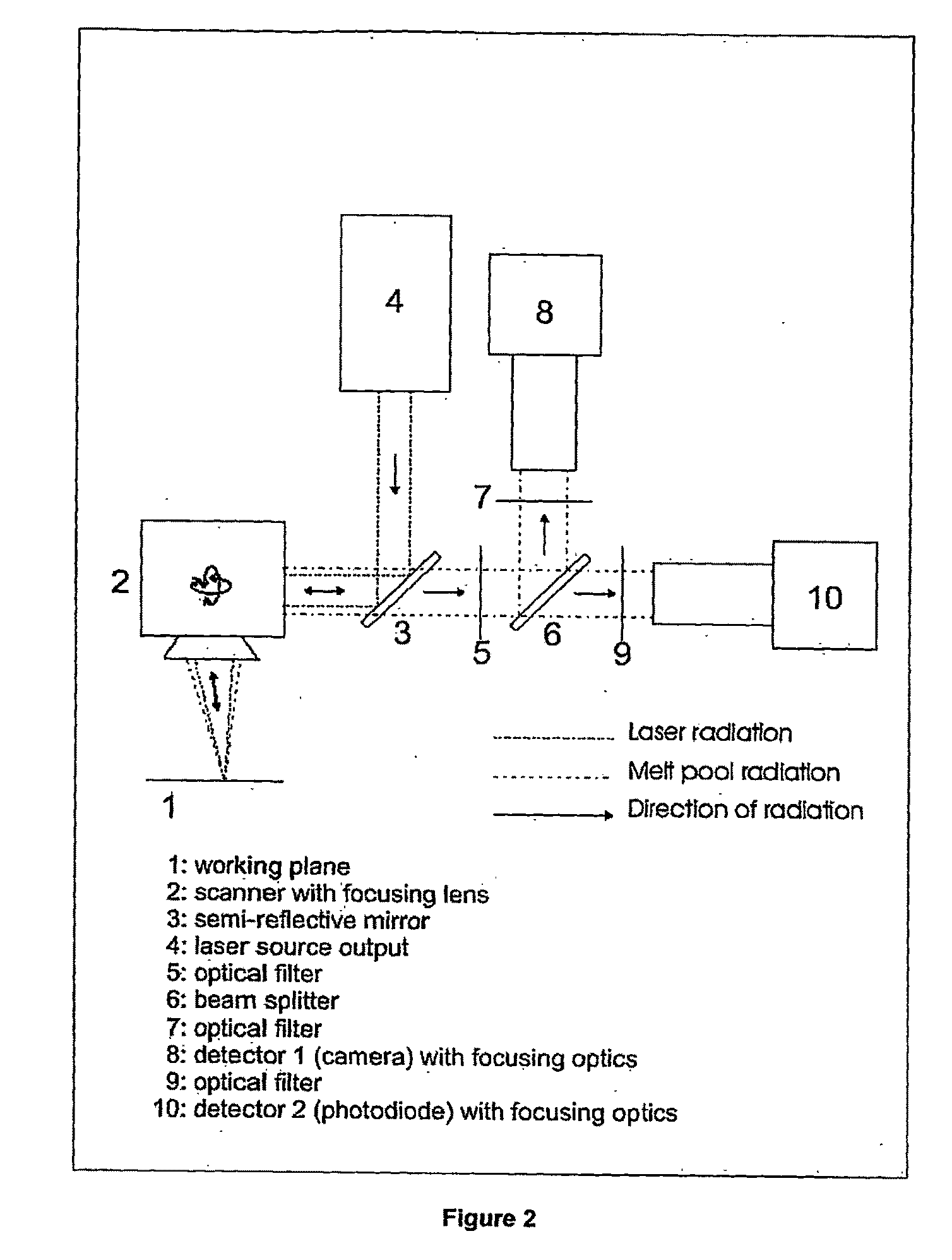

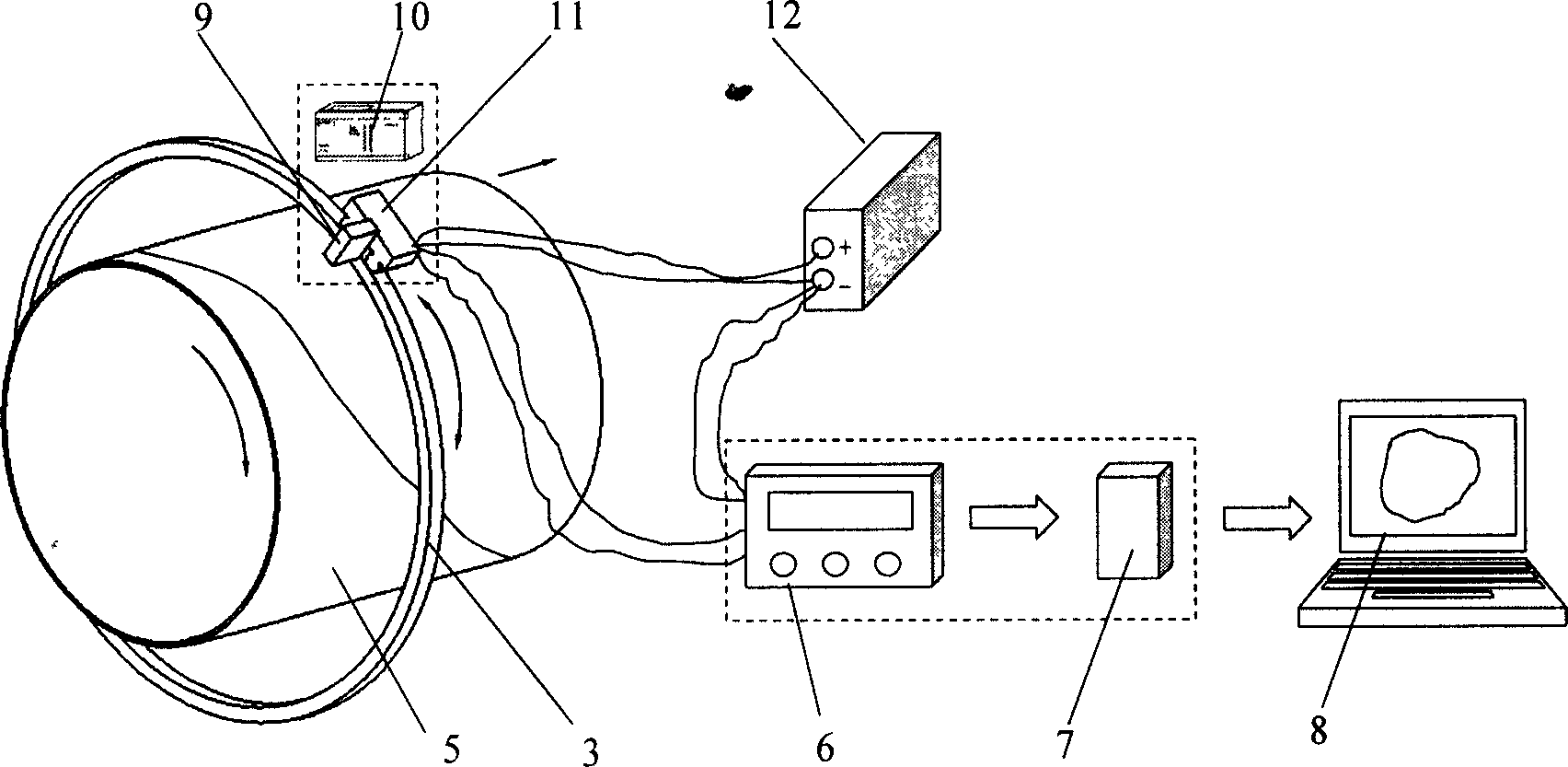

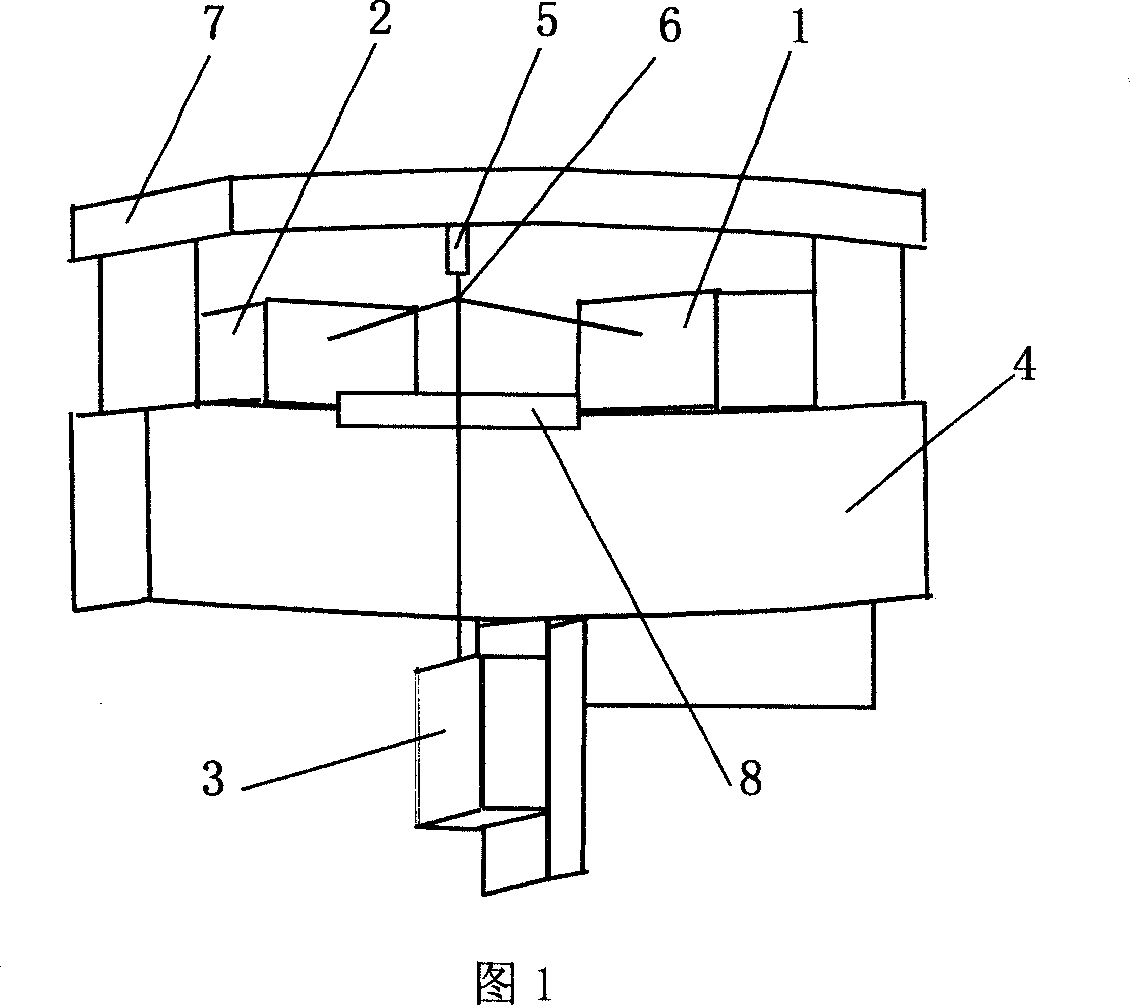

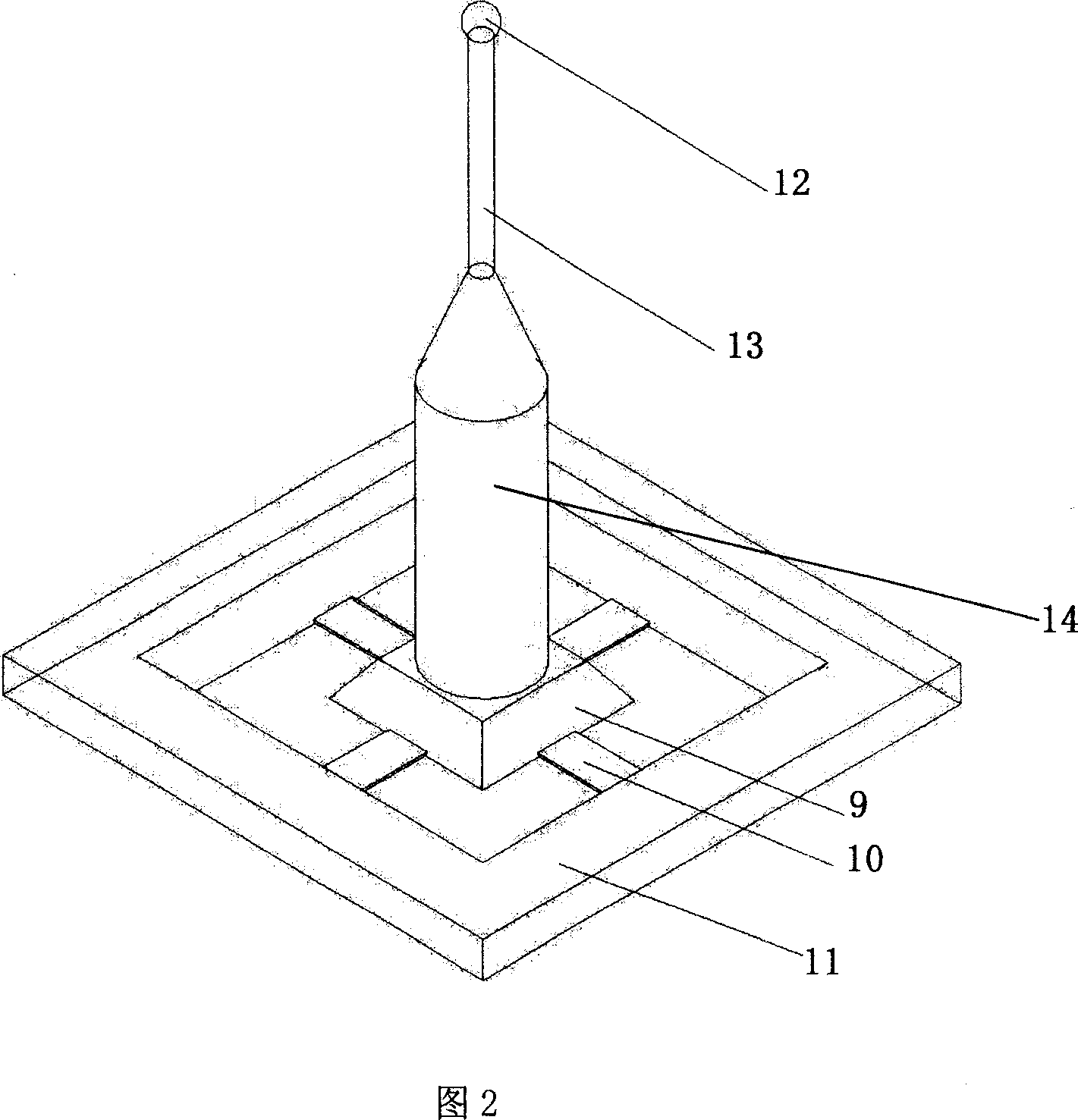

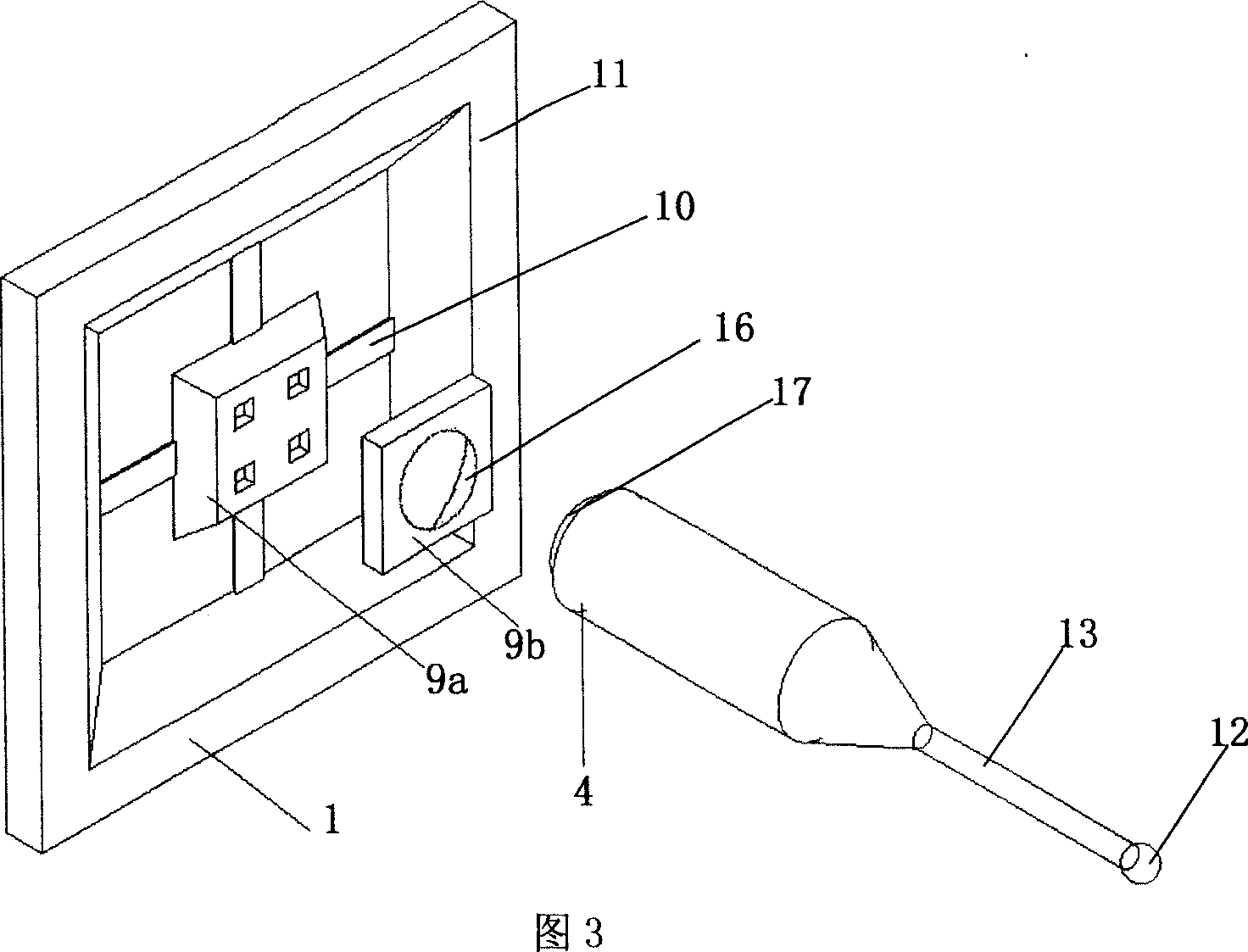

Procedure and apparatus for in-situ monitoring and feedback control of selective laser powder processing

InactiveUS20090206065A1Quality improvementReduce spectral distortionAdditive manufacturing apparatusIncreasing energy efficiencyControl systemFeedback controller

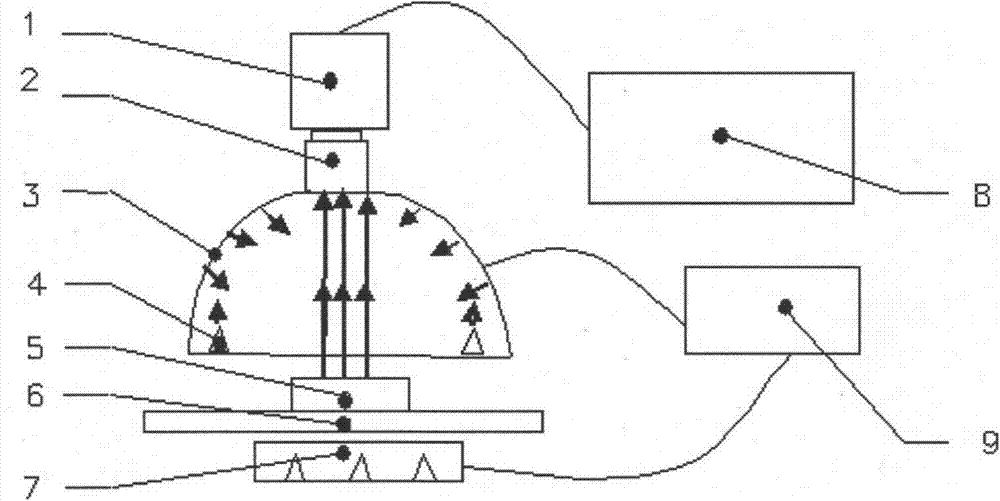

The present invention relates to a method and a device to monitor and control the Selective Laser Powder Processing. A Selective Laser Powder Processing device comprising a feedback controller to improve the stability of the Selective Laser Powder Processing process is presented. A signal reflecting a geometric quantity of the melt zone is used in the feedback controller to adjust the scanning parameters (e.g. laser power, laser spot size, scanning velocity, . . . ) of the laser beam (4) in order to maintain the geometric quantity of the melt zone at a constant level. The signal reflecting the geometric quantity of the melt zone can also be displayed in order to monitor the Selective Laser Powder Processing process. The present invention allows for the production of three-dimensional objects from powder material and improves the state of the art by compensating variations of the border conditions (e.g. local heat conduction rate) by a feedback control system based on a geometric quantity of the melt zone resulting in e.g. a lower amount of dross material when overhang planes are scanned.

Owner:KRUTH JEAN PIERRE +1

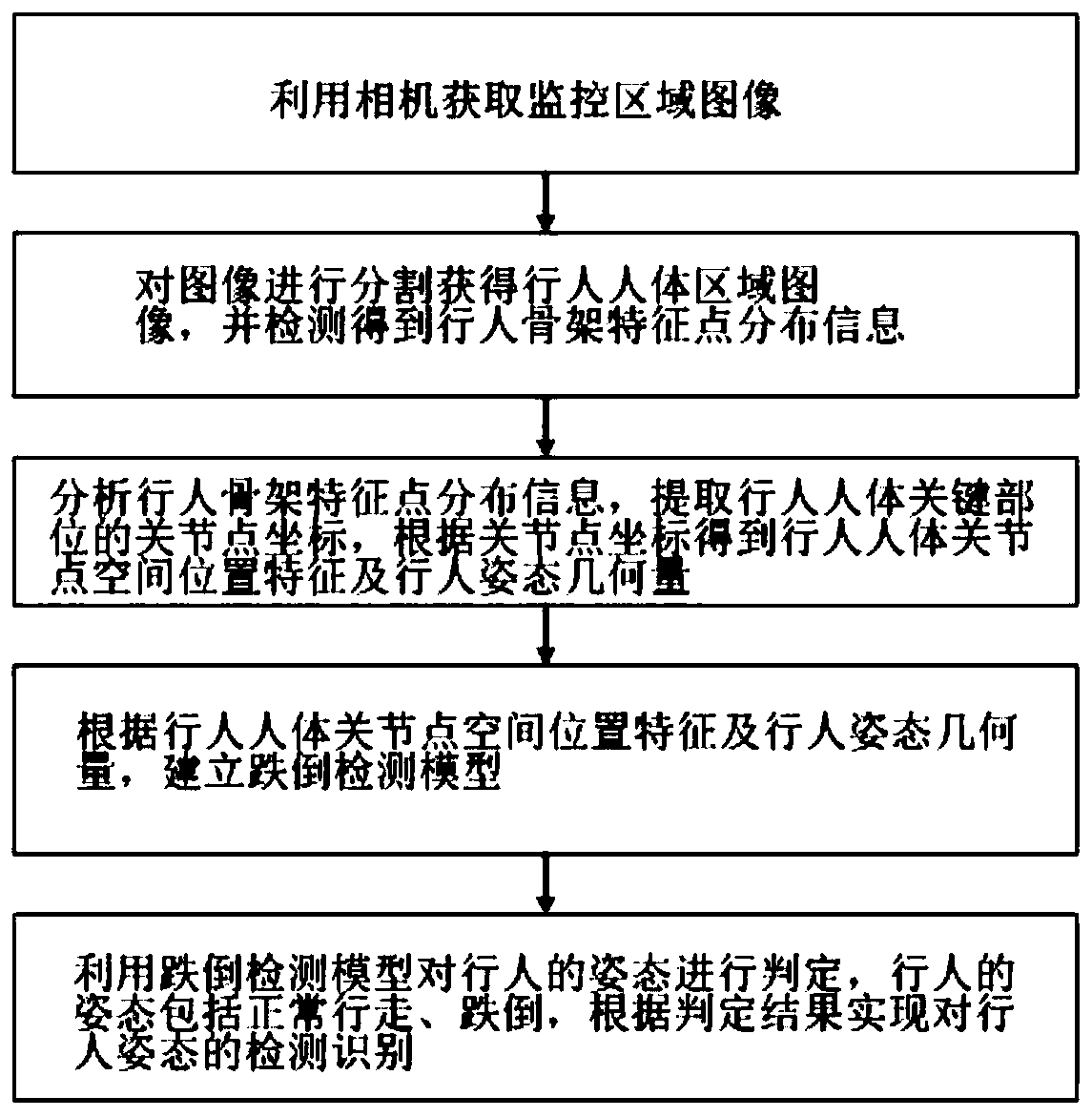

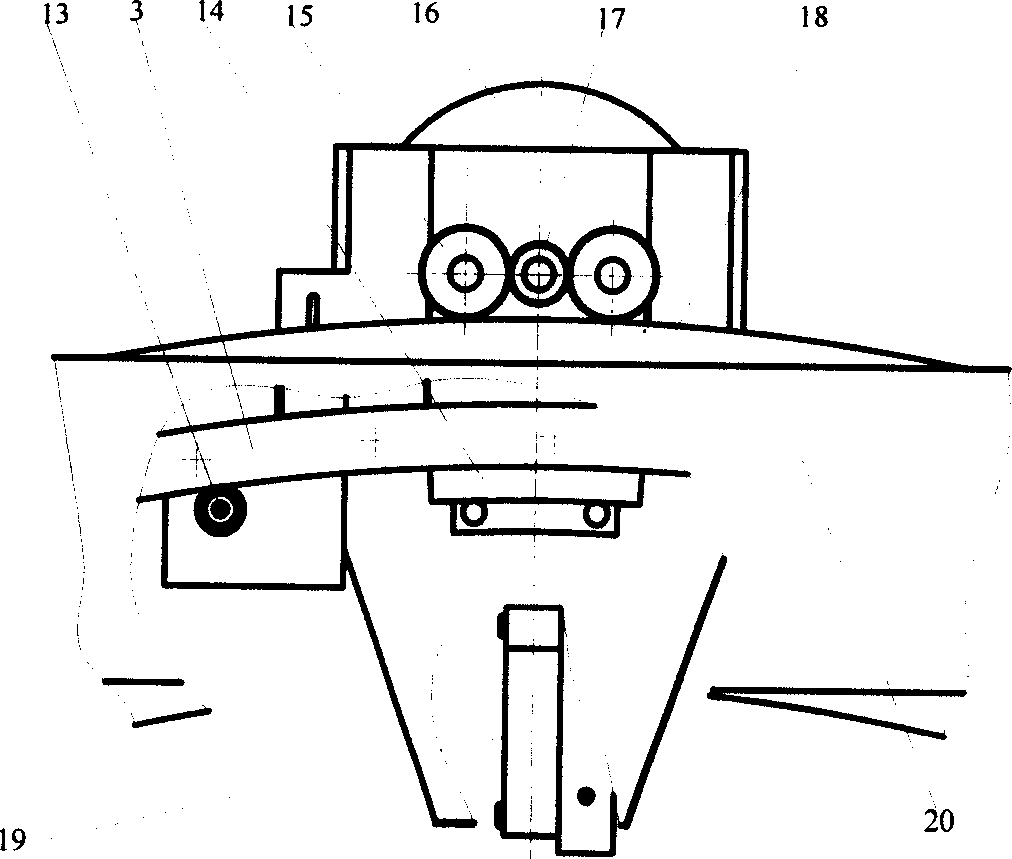

Pedestrian falling recognition method based on skeleton detection

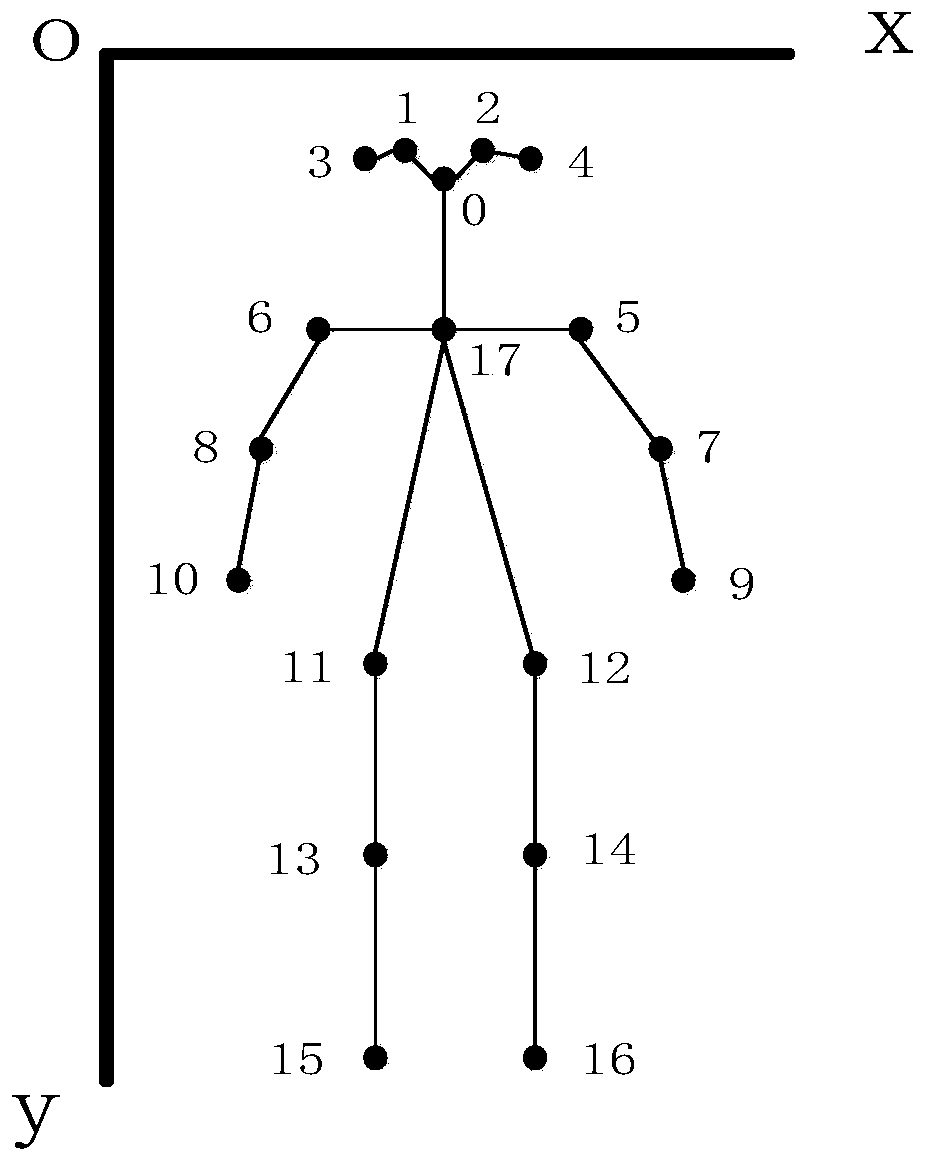

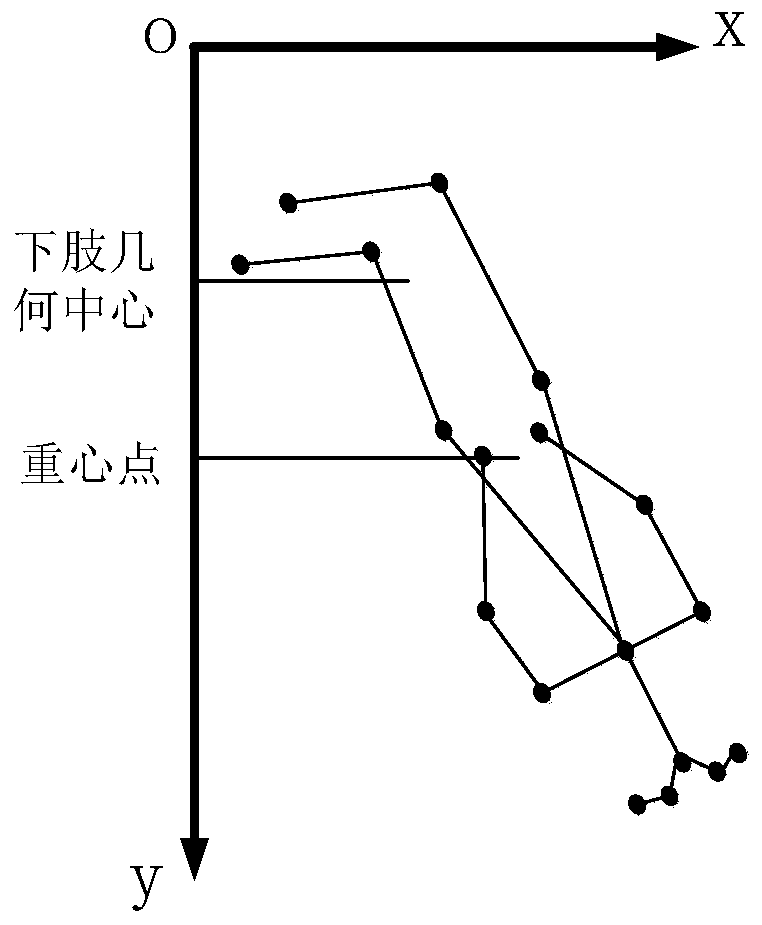

ActiveCN109919132AAccurate fall detectionGuarantee the safety of lifeCharacter and pattern recognitionEarly warning systemHuman body

The invention discloses a pedestrian falling recognition method based on skeleton detection. The method comprises the following steps: S1, acquiring a monitoring area image by using a camera; S2, segmenting the image to obtain a pedestrian body area image, and detecting to obtain pedestrian skeleton feature point distribution information; S3, analyzing pedestrian skeleton feature point distribution information, extracting articulation point coordinates of key parts of the human body of the pedestrian, acquiring pedestrian human body articulation point space position features and pedestrian posture geometrical quantities according to the articulation point coordinates, and the key parts are preset parts on the human body; S4, establishing a tumble detection model according to the spatial position characteristics of the joint points of the human body of the pedestrian and the pedestrian posture geometric quantity; and S5, judging the posture of the pedestrian by using the fall detectionmodel wherein the posture of the pedestrian comprises normal walking and fall, and the detection and recognition of the posture of the pedestrian are realized according to the judgment result. The method can actively detect abnormal conditions such as pedestrian falling in a monitoring video, and can improve the monitoring capability of pedestrian safety events by combining with an early warning system.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

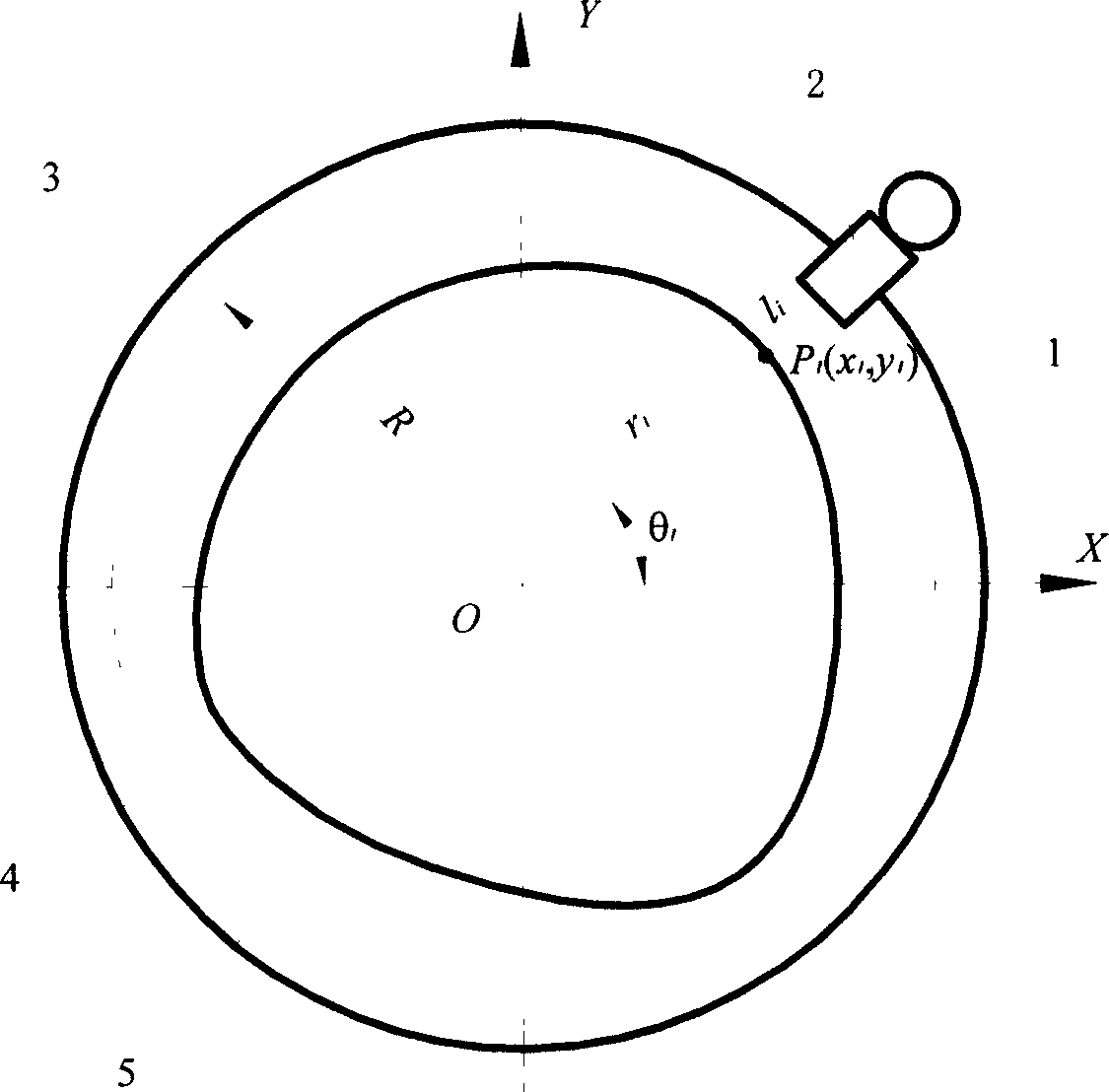

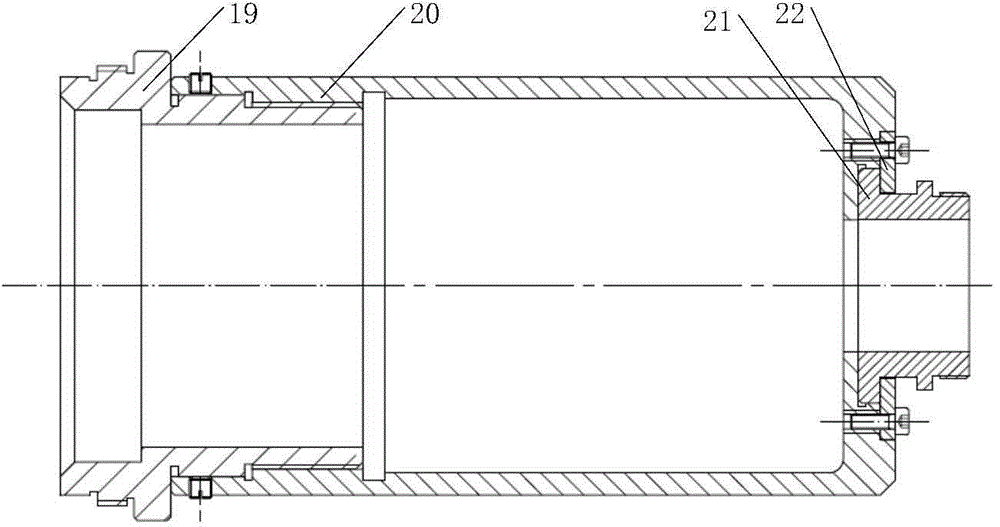

System and method for measuring section shape and size of heavy caliber steel pipe

InactiveCN1734233ATrue reflection of geometric featuresReflect geometric featuresMeasurement devicesInformation processingSize measurement

This invention discloses such a measurement and method of a large caliber steel tube cross-section shape, which belongs to the domain of geometric measurement technique. The measurement system of information processing mode and measurement mode is located in the small moving car, with the small car moving on the datum circular orbit. The input and output mode connect the information processing mode through the serial port. The measurement method is like this: testing a series of the steel tube surface and the radial distance of a certain known datum circular orbit radius in order to get a configuration point coordinates of the steel tube cross-section. When the amount of sampling points is abundant enough, we can get the accurate outline of steel tube. Then the information-processing mode counts the steel tube cross-section shape and dimension parameter.

Owner:TSINGHUA UNIV

Micro-geometric sense measuring device based on nano-measuring machine and micro-tactometering head

InactiveCN1975322AOvercome limitationsLarge measuring rangeSurface/boundary effectForce measurement by measuring optical property variationOptical measurementsMicroscopic scale

This invention disclosed a measuring equipment which consists of a nanometer measuring machine and a tiny feeling gauge head. The feeling gauge head was fixed on the machine by a plank. The measuring range of scanning probe micro-technique was improved by this equipment, the range of object by other measuring means was widened; it could manage to measure some micro-geometric senses including dimension, displacement, etc. The measuring precision was improved by this equipment.

Owner:TIANJIN UNIV

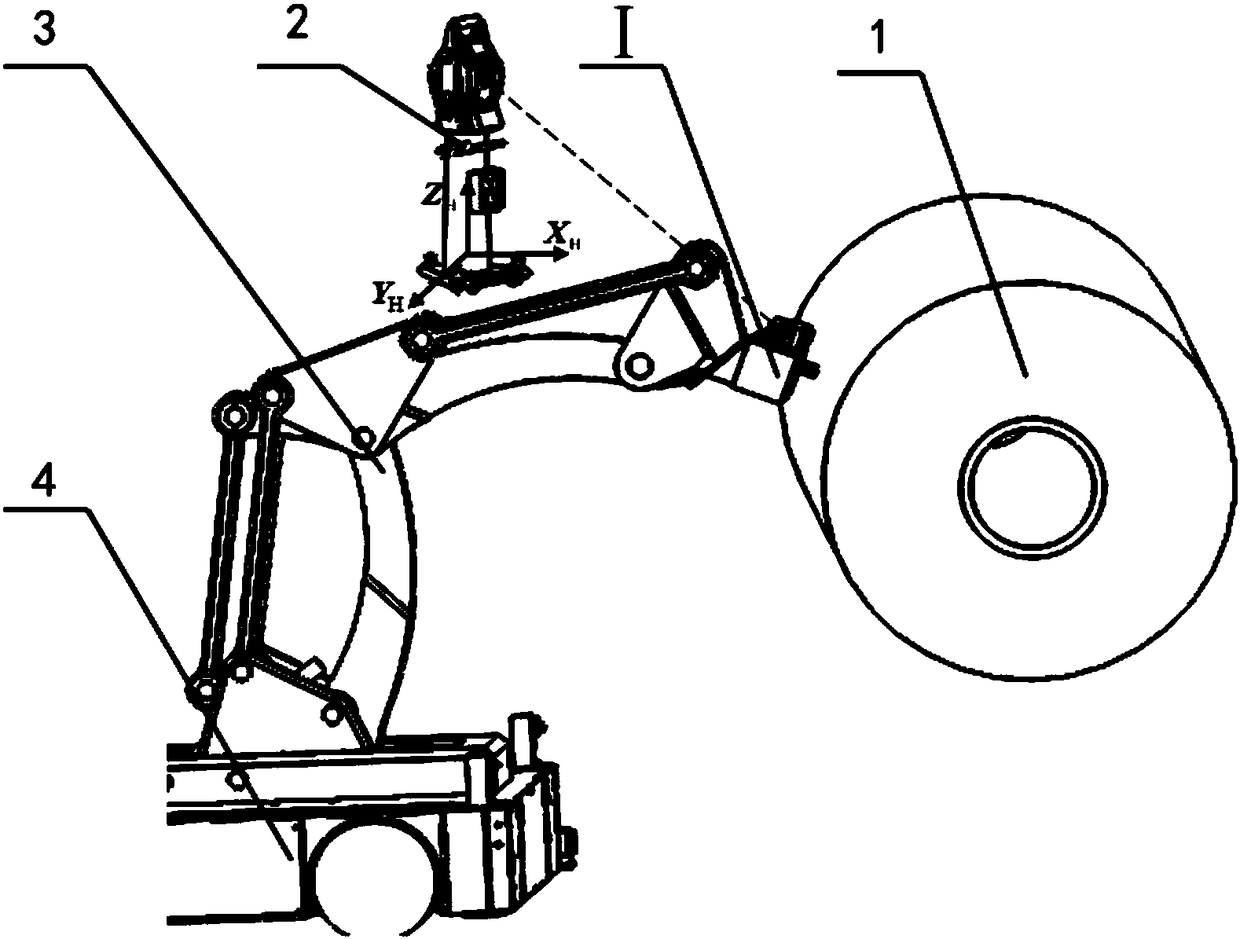

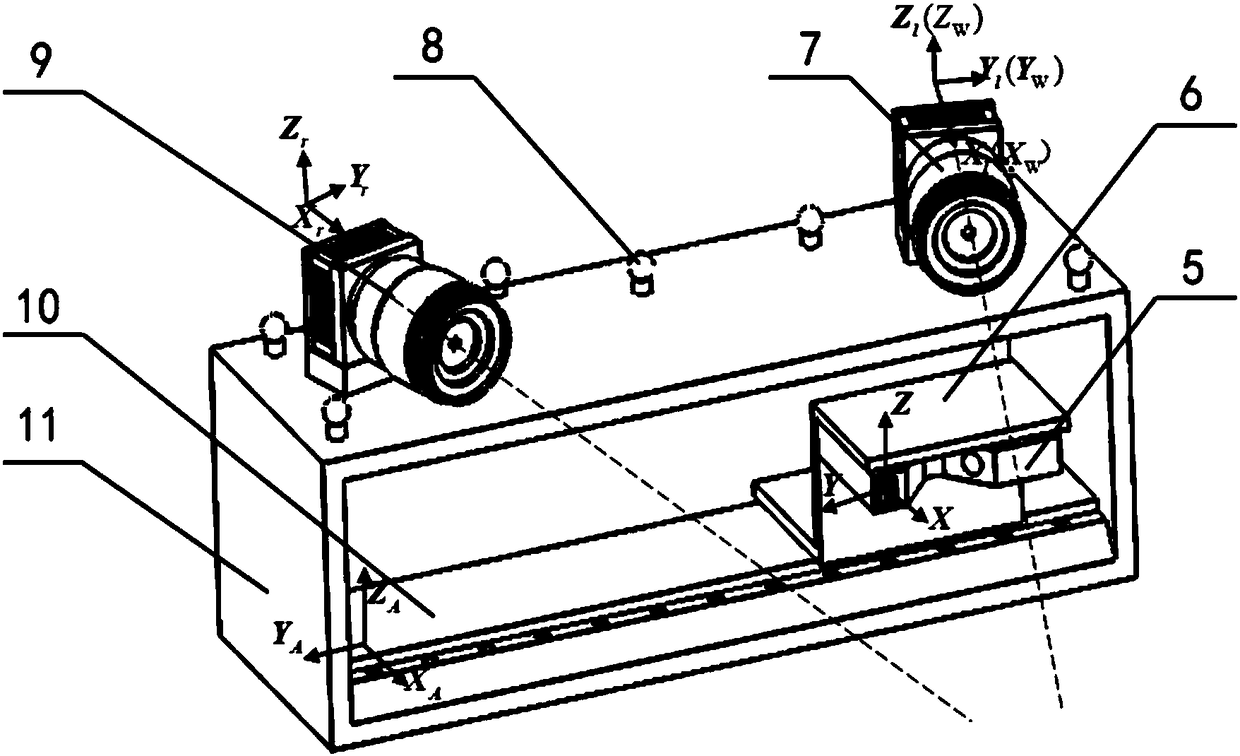

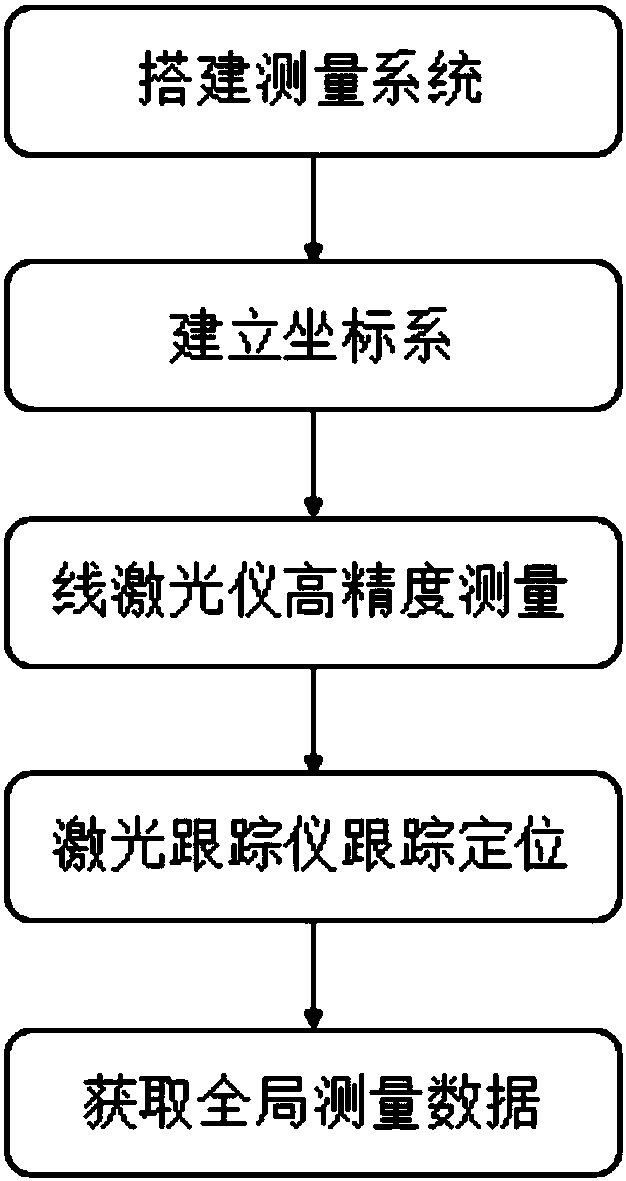

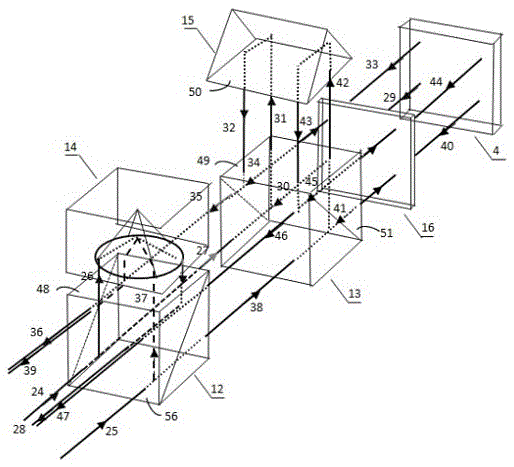

Combination type processing process integrated measurement method based on vision laser

ActiveCN108444383ASolve the problem of integrated measurement of high-precision machining processSolving all-in-one measurement problemsUsing optical meansMeasurement deviceLaser scanning

The invention relates to a combination type processing process integrated measurement method based on vision laser, and belongs to the field of geometric quantity measurement. The method adopts left and right cameras to realize online guidance of the pose of a tail end measurement device of a mechanical arm in a vision servo mode, so that local features of a part to be measured are in a measurement range of a laser scanner. The laser scanner is utilized to perform high-precision measurement on the local features, and a laser tracker is utilized to perform tracking positioning on the tail end measurement device; and the pose of the tail end measurement device is adjusted to perform multiple times of measurement on the part to be measured according to regions, and local laser scanning data of the multiple times of measurement are unified to a global coordinate system established based on the laser tracker. The method effectively solves the problem of high-precision processing process integrated measurement in a large space range, has the characteristics of high measurement precision, wide range and high robustness, and realizes large-space, cross-scale and high-precision processing process integrated measurement.

Owner:DALIAN UNIV OF TECH

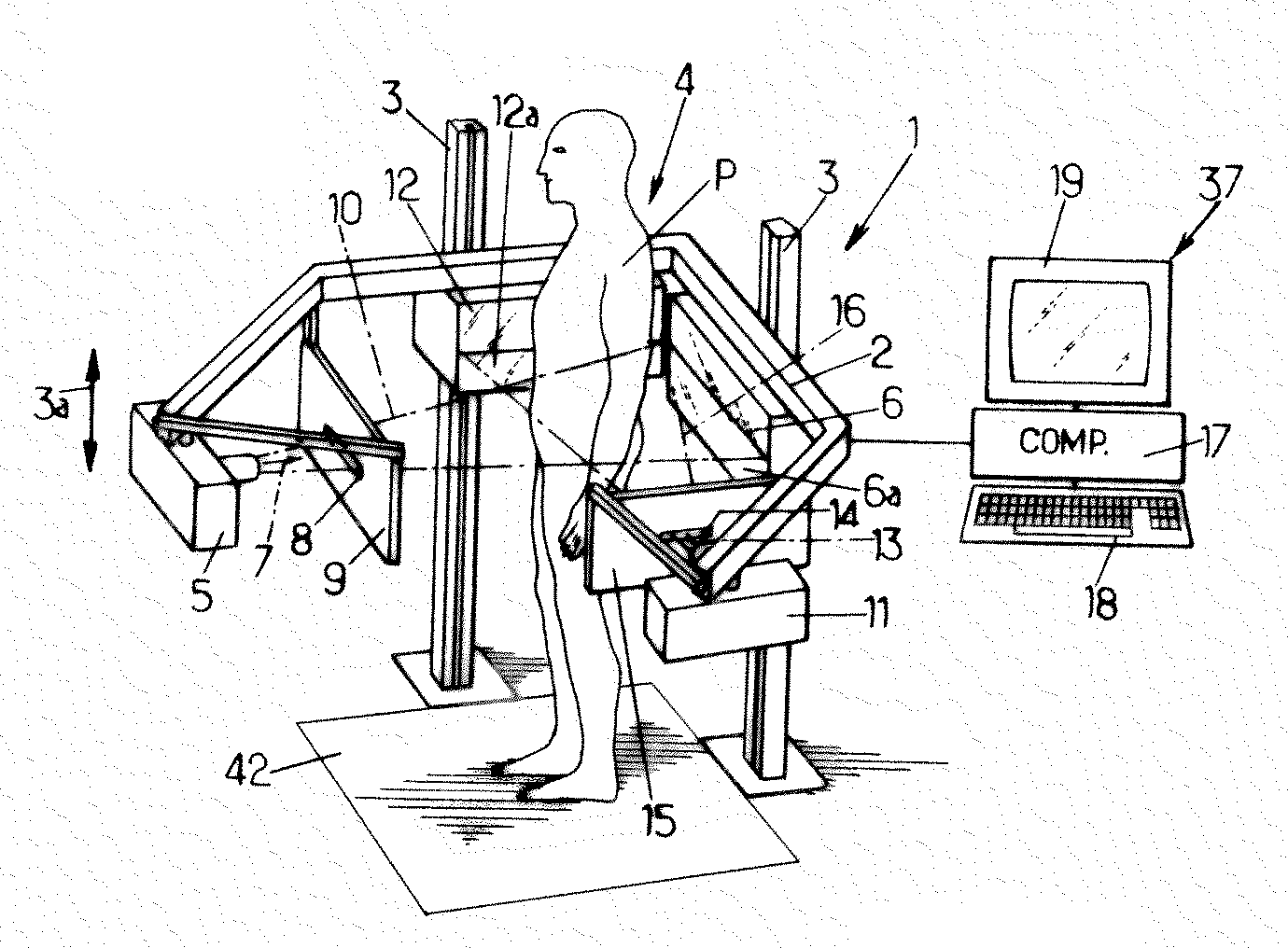

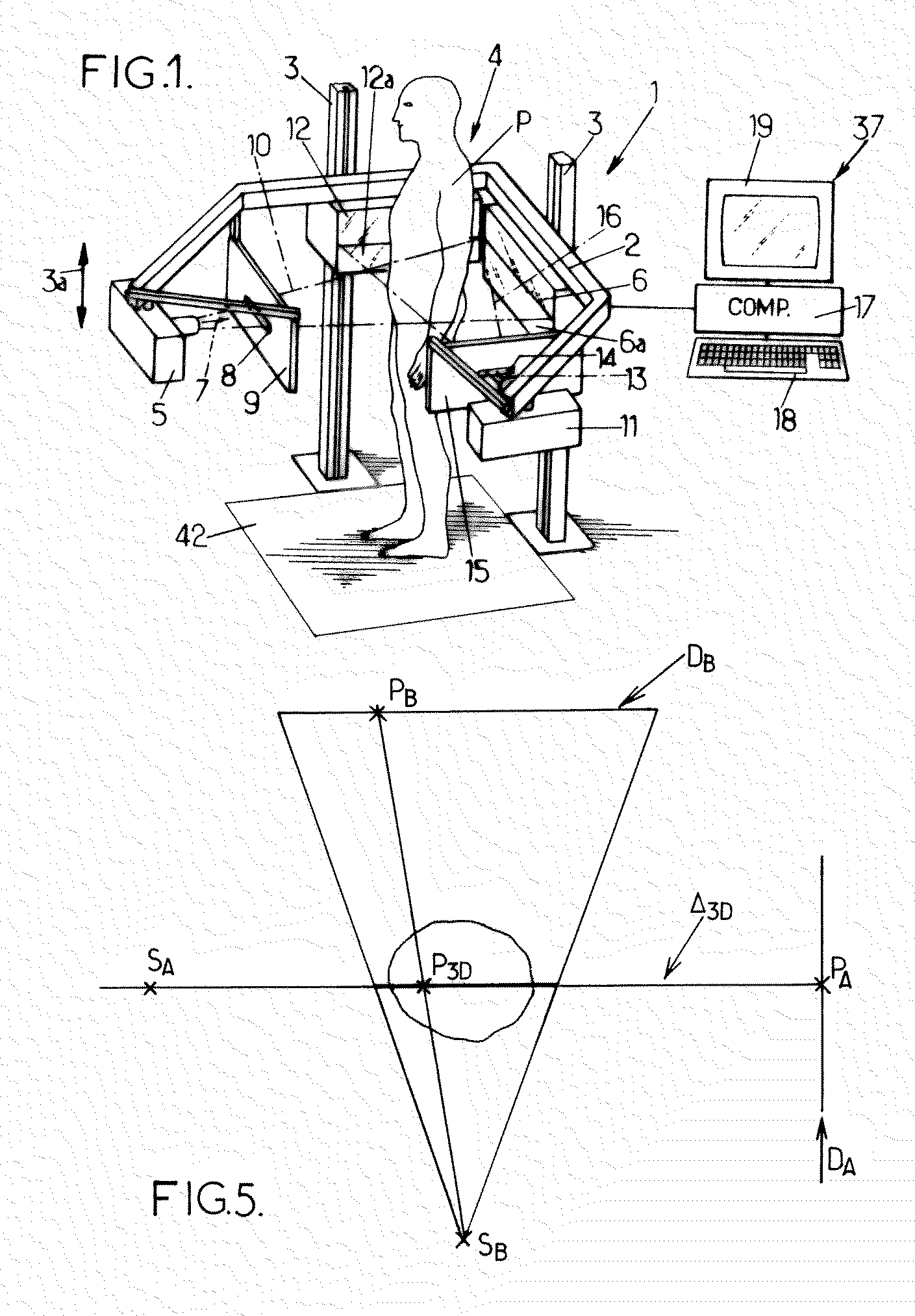

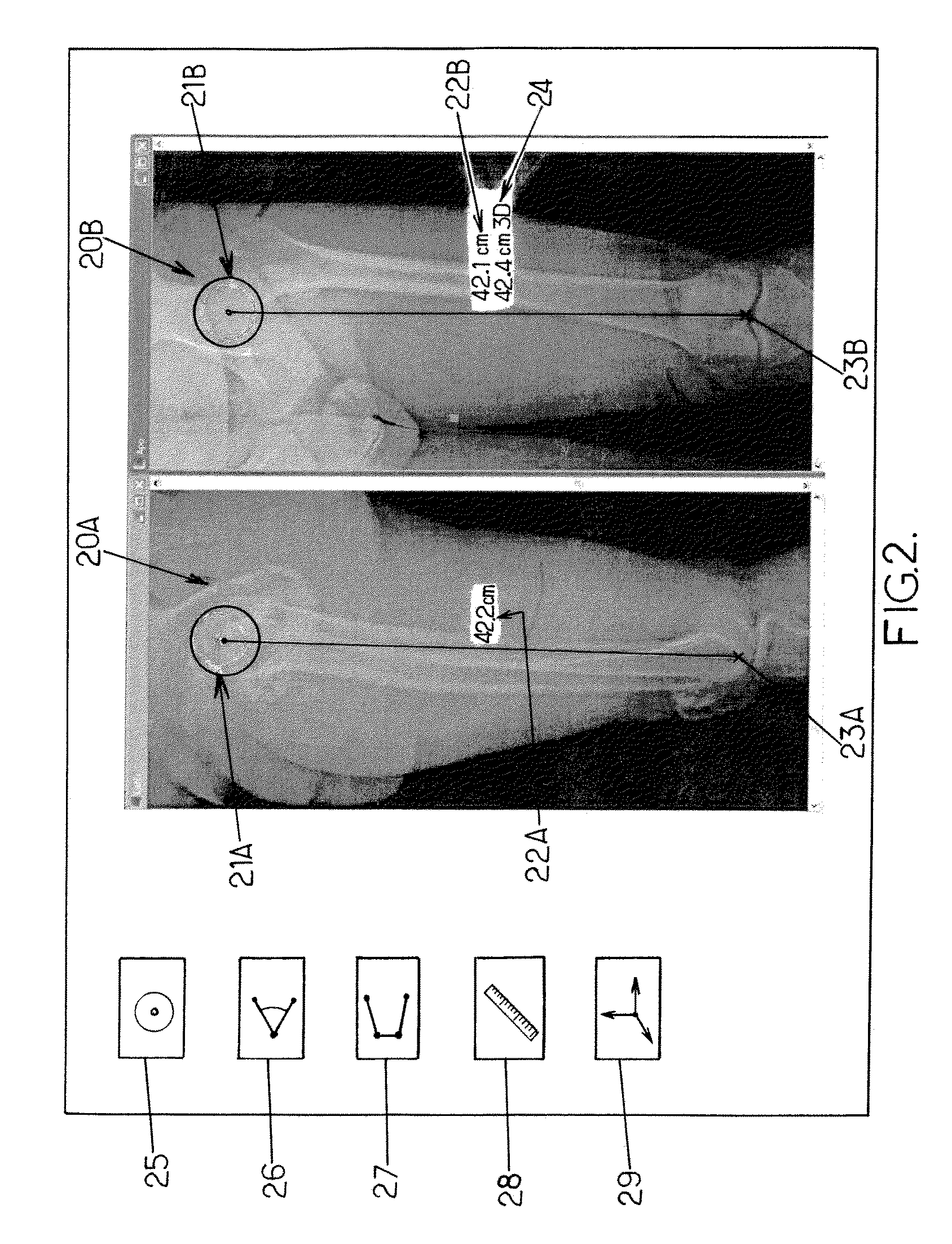

Measurement of geometric quantities intrinsic to an anatomical system

ActiveUS20100104150A1Simple for userPatient positioning for diagnosticsCharacter and pattern recognitionGeometric primitiveComputer science

A method for measuring geometric quantities intrinsic to an anatomical system of a patient, based on two stereoscopic images. Registration data are received on each of the two stereoscopic images. By using geometric calibration information, a three-dimensional geometric primitive is determined defined by at least a portion of the received registration data. Based on the three-dimensional geometric primitive, a value of geometric quantity intrinsic to the anatomical system is computed.

Owner:EOS IMAGING

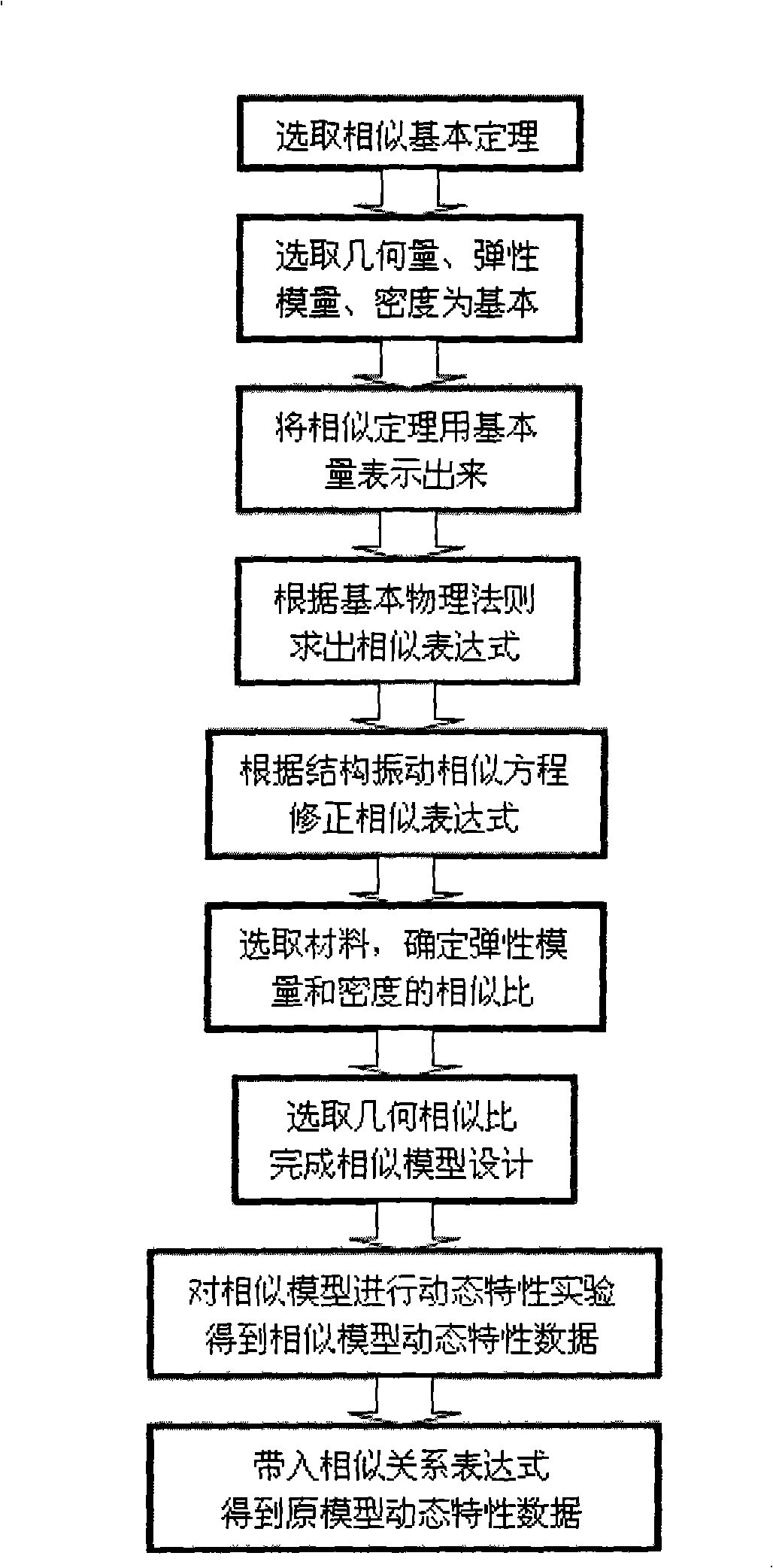

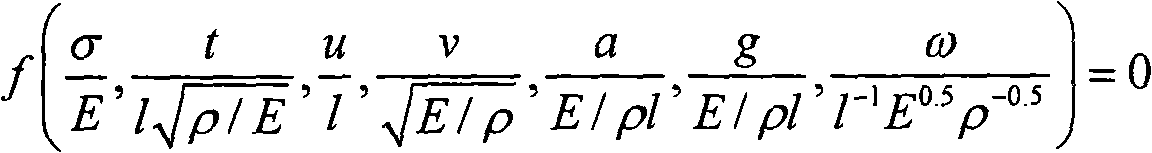

Large-sized mechanical equipment structure dynamic simulation test method

InactiveCN101261155ASmall scaleReduce testing costsSubsonic/sonic/ultrasonic wave measurementVibration testingElastic vibrationMechanical equipment

The invention provides a large mechanical equipment structure dynamic similarity test method, comprising the steps as follows: (1) a basic similarity theorem is adopted, all physical quantities are listed, geometrical quantity, density and elastic modulus are determined as basic physical quantities, and the similarity theorem is written into a dimensionless equation expressed by the basic physical quantity; (2) according to concerned basic physical principle, the similarity ratio of all physical quantities adopts similar relation expression, and the similar relation expression is modified according to a structure elastic vibration similarity equation; (3) similar model material is selected, density similarity ratio and elastic modulus similarity ratio are determined, geometrical quantity similarity ratio is determined, and the similar model design is then completed; (4) a structure dynamic test of the similar model is carried out so as to obtain the dynamic characteristic number which is substituted into the similarity relation expression so as to work out the dynamic characteristic data of the original model which is also the natural vibration frequency. The large mechanical equipment structure dynamic similarity test method realizes the conversion of ultra-large structure dynamic natural frequency with small model, effectively reduces the scales of dynamic test objects, simplifies the test instruments, and reduces the test cost.

Owner:BEIHANG UNIV

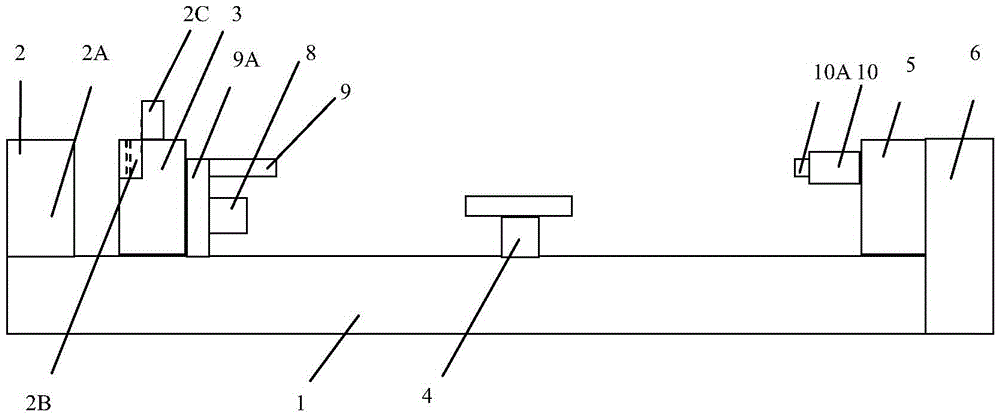

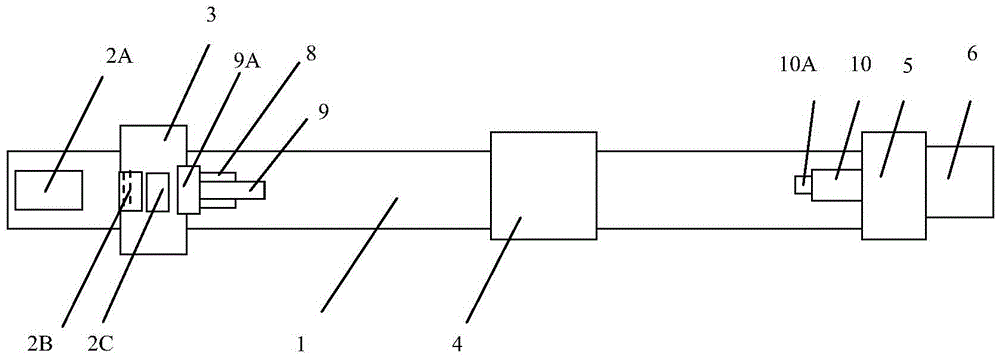

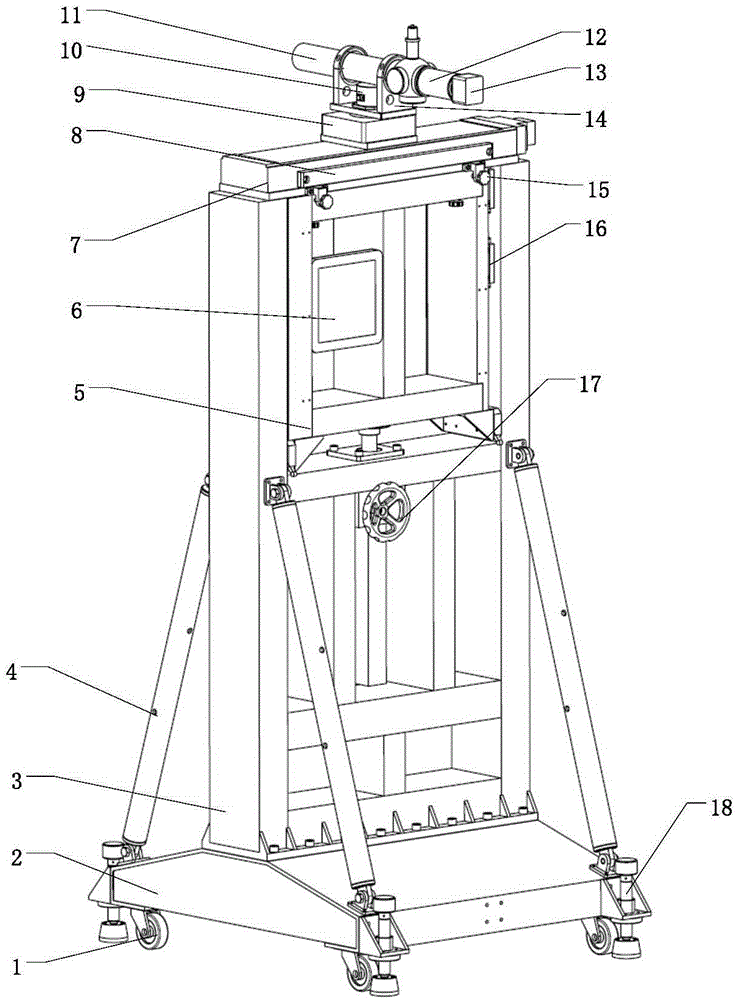

Test equipment calibration device and calibration method thereof

ActiveCN105547344ASolve the problem that the accuracy cannot be effectively controlledFast and accurate measurement guaranteeInstrumentsMeasurement testLength measurement

A test equipment calibration device and a calibration method thereof belong to geometric quantity measurement test equipment, are provided to solve the problem that the existing large-size test equipment calibration device needs large investment, has a single function and is hard to popularize and apply, and are used for geometric large-size equipment comprehensive calibration. The test equipment calibration device of the invention comprises a guide rail, a laser interferometer, a head base, a workbench, a tail base and a processor. According to the calibration method of the invention, through the precision length measurement, 2D angle measurement and 2D auto-collimation functions of the high-precision 5D laser interferometer, the accurate characteristic values of a physical standard (or target) installed on the guide rail in different attitudes in corresponding positions can be obtained. The problem that the technical state and test result accuracy of large special test equipment cannot be controlled effectively is solved, and quick and accurate measurement support is provided for product development and product quality improvement.

Owner:WUCHANG SHIPBUILDING IND

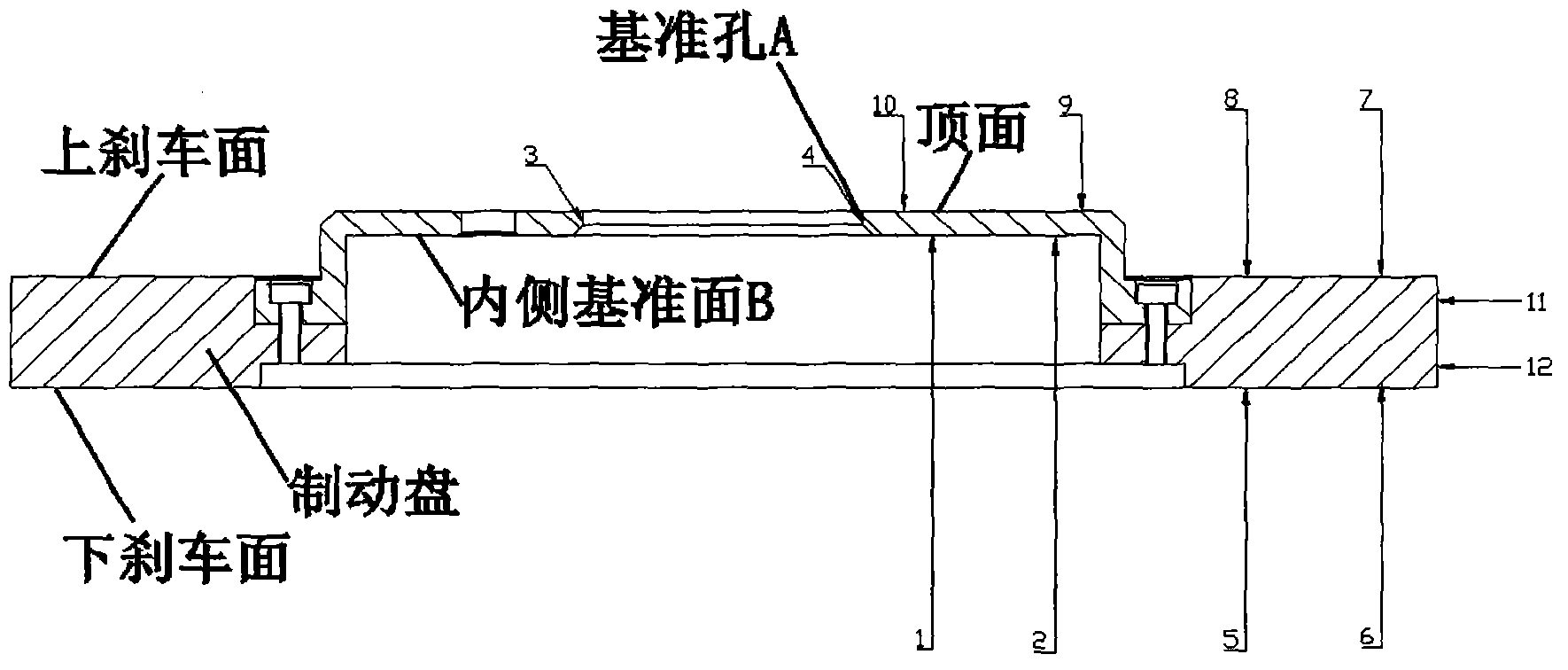

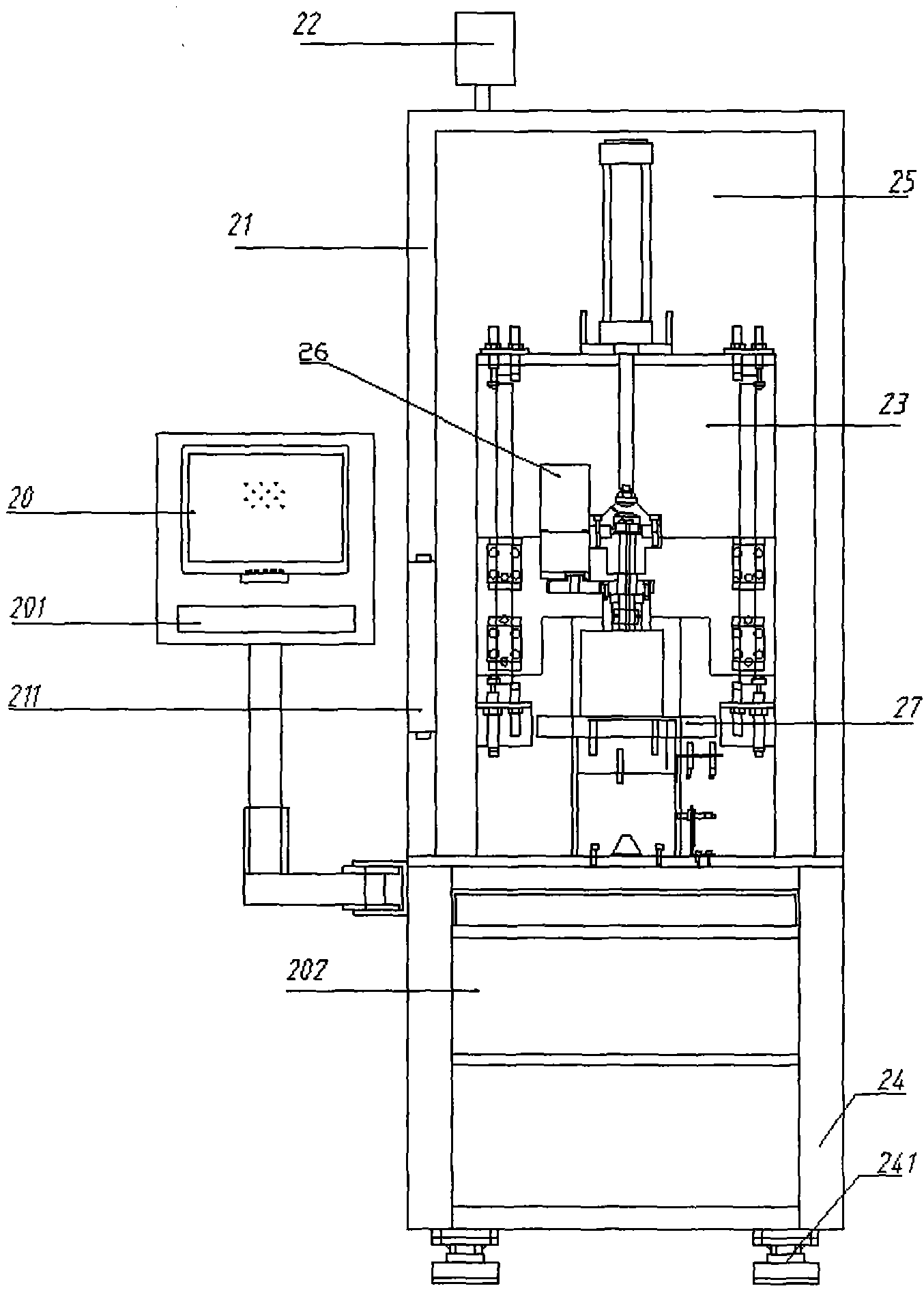

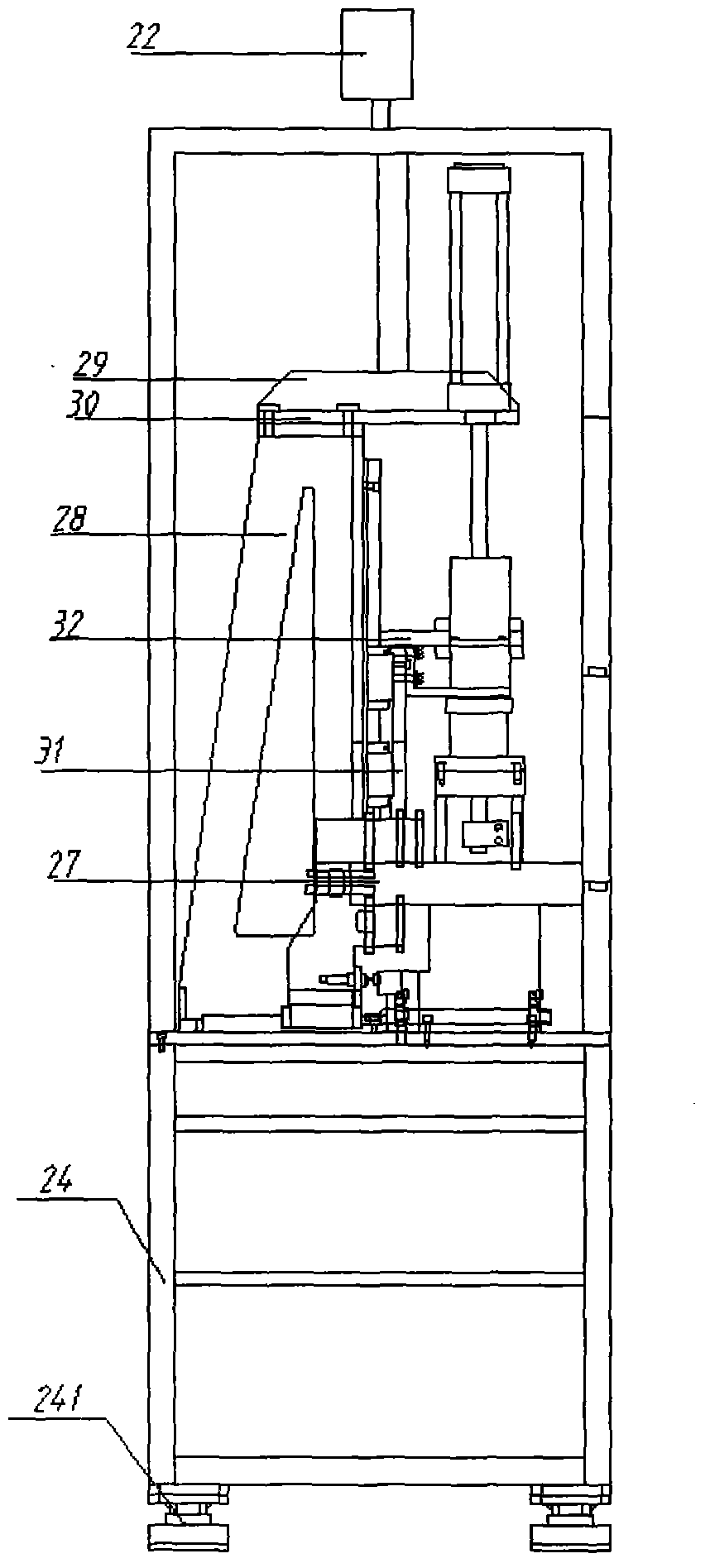

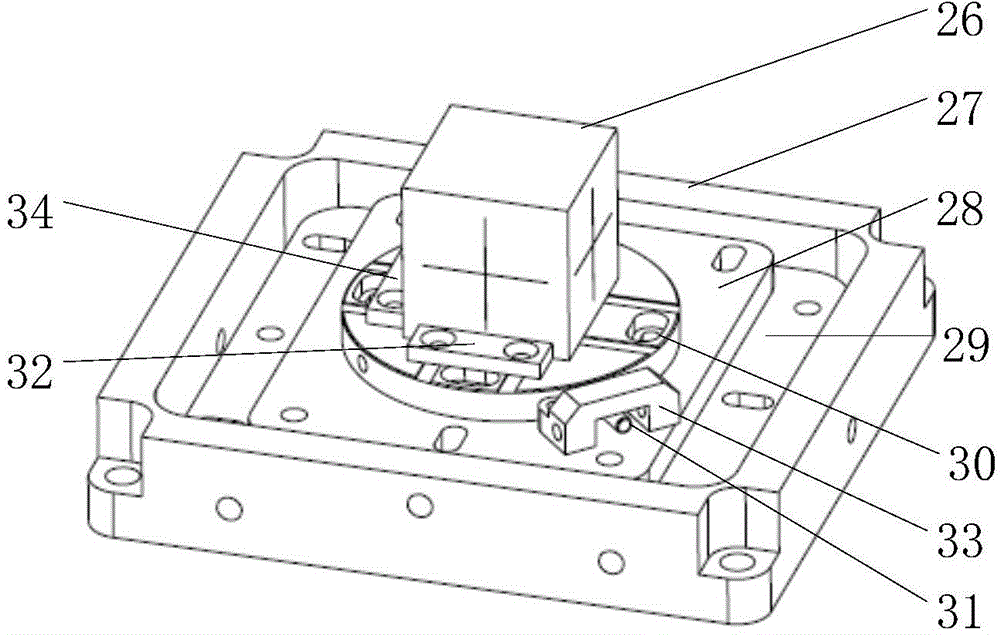

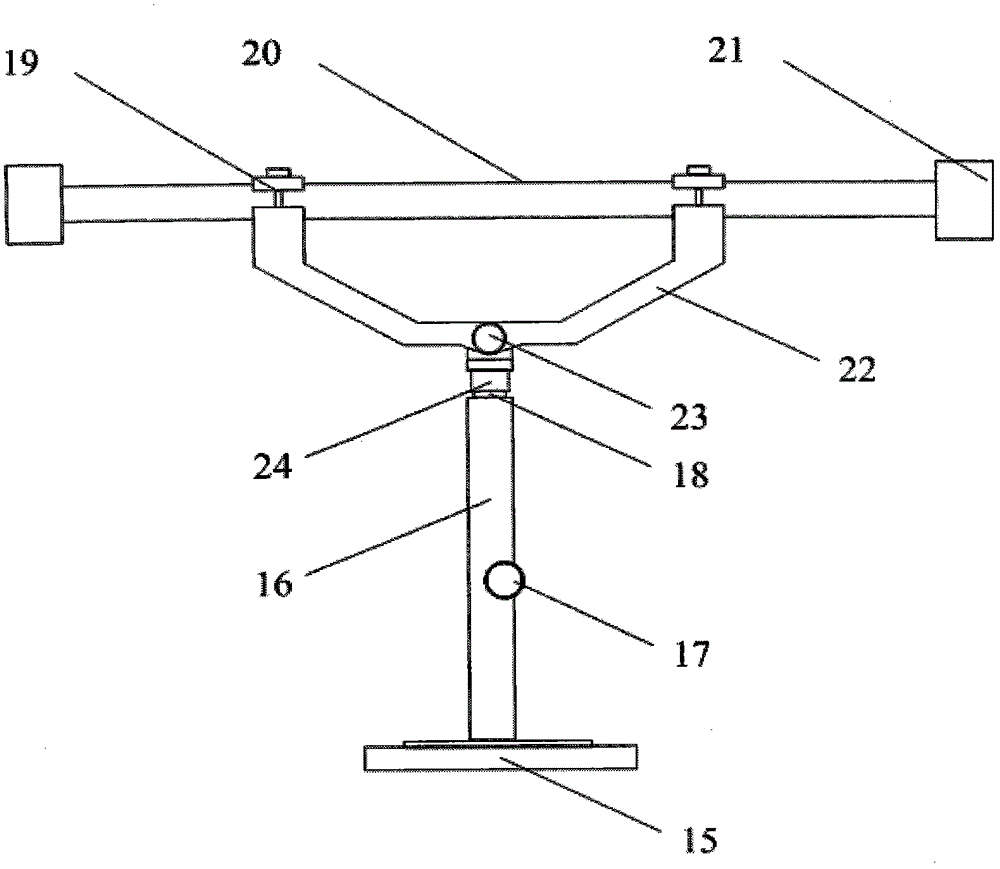

Brake disc form and location tolerance measuring method and measuring instrument for realizing same

The invention relates to a measuring method for measuring parameters such as jumpy geometric senses and planeness of upper and lower brake surfaces of a brake disc of a car and a measuring instrument for realizing the method. According to the measuring method and the measuring instrument for realizing the method, jumping amount and planeness of paired reference of the upper and lower brake surfaces, the jumping amount of the top surface and planeness of paired reference, the planeness of an inner reference surface, coaxiality of paired reference hole of the outer circle surface, and thickness difference of the brake disc on any circumference of the two brake surfaces can be measured. The measuring method comprises the steps of: calibrating, positioning and rotating the work-piece for a circle; sampling data from 12 displacement sensors and 12 sampling points during the rotating process; and performing comparison and analysis on sampled data and qualified data in a database by an IPC (Industrial Personal Computer). The measuring instrument for realizing the method comprises a display device, a device body, a bracket and the like, wherein the device body comprises a rotating mechanism, a measuring mechanism, a compressing mechanism, a locating mechanism, a driving mechanism, a three-color alarm and the like; and the measuring mechanism is internally provided with 12 displacement sensors.

Owner:ZHEJIANG JINDUN TECH CO LTD

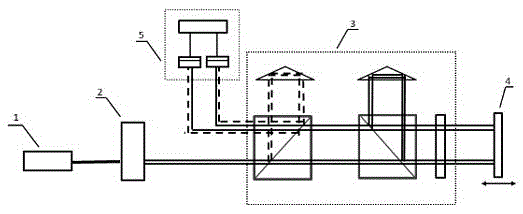

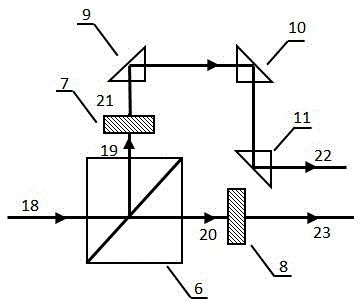

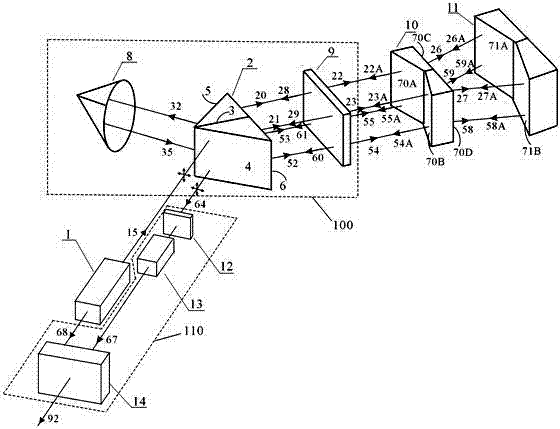

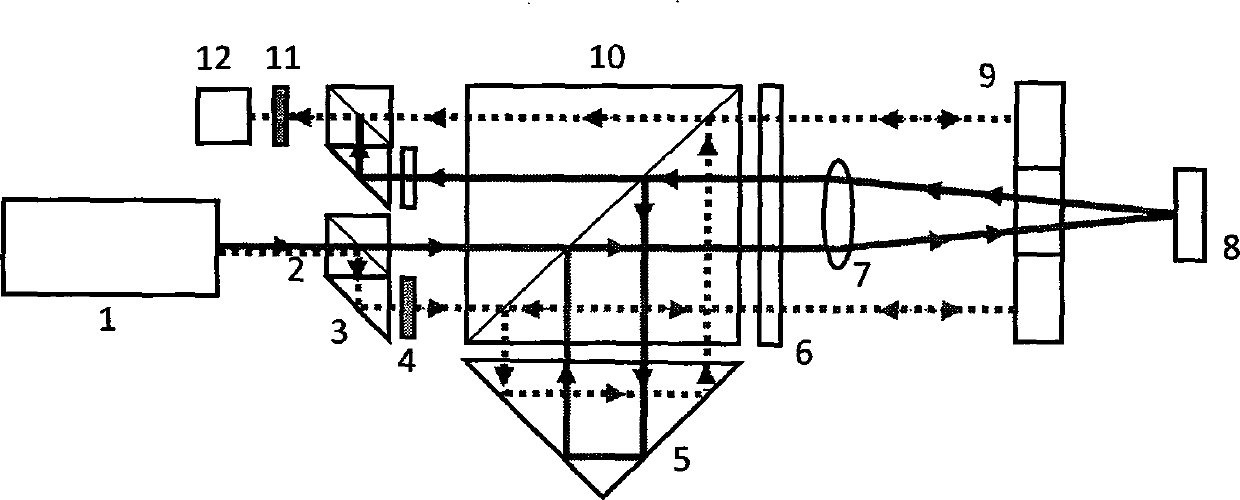

Nonlinear-error-free laser heterodyne interferometer system for angle measurement

InactiveCN105571529ASuitable for precision measurementAvoid Periodic Nonlinear ErrorsUsing optical meansNumerical controlPhase difference

The invention discloses a nonlinear-error-free laser heterodyne interferometer system for angle measurement, wherein the nonlinear-error-free laser heterodyne interferometer system comprises a single-frequency laser source, an acousto-optical frequency shift unit, an optical interference device, a planar mirror which moves along with the movement of a measured member, and a phase detecting device, wherein the single-frequency laser source and the acousto-optical frequency shift unit can operate for generating an incident light beam which has no frequency aliasing and has certain frequency difference and is spatially separated. Under the function of the optical interference device, the incident light beam is reflected twice by the planar mirror. Finally the reflected incident light beam is input to the phase detecting device. The yaw angle of the measured member is determined by means of change amount of the phase difference. Between generation of a measuring light beam with certain frequency difference from the acousto-optical frequency shift unit and interference, the transmission paths are separated and are spatially independent. The nonlinear-error-free laser heterodyne interferometer system prevents a periodical nonlinear error which is caused by polarized light with two frequencies in the interference optical path, thereby effectively improving measurement accuracy. The nonlinear-error-free laser heterodyne interferometer system can be widely used for geometric quantity precise measurement in the fields of numerical control machine tools, military industry, spaceflight, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

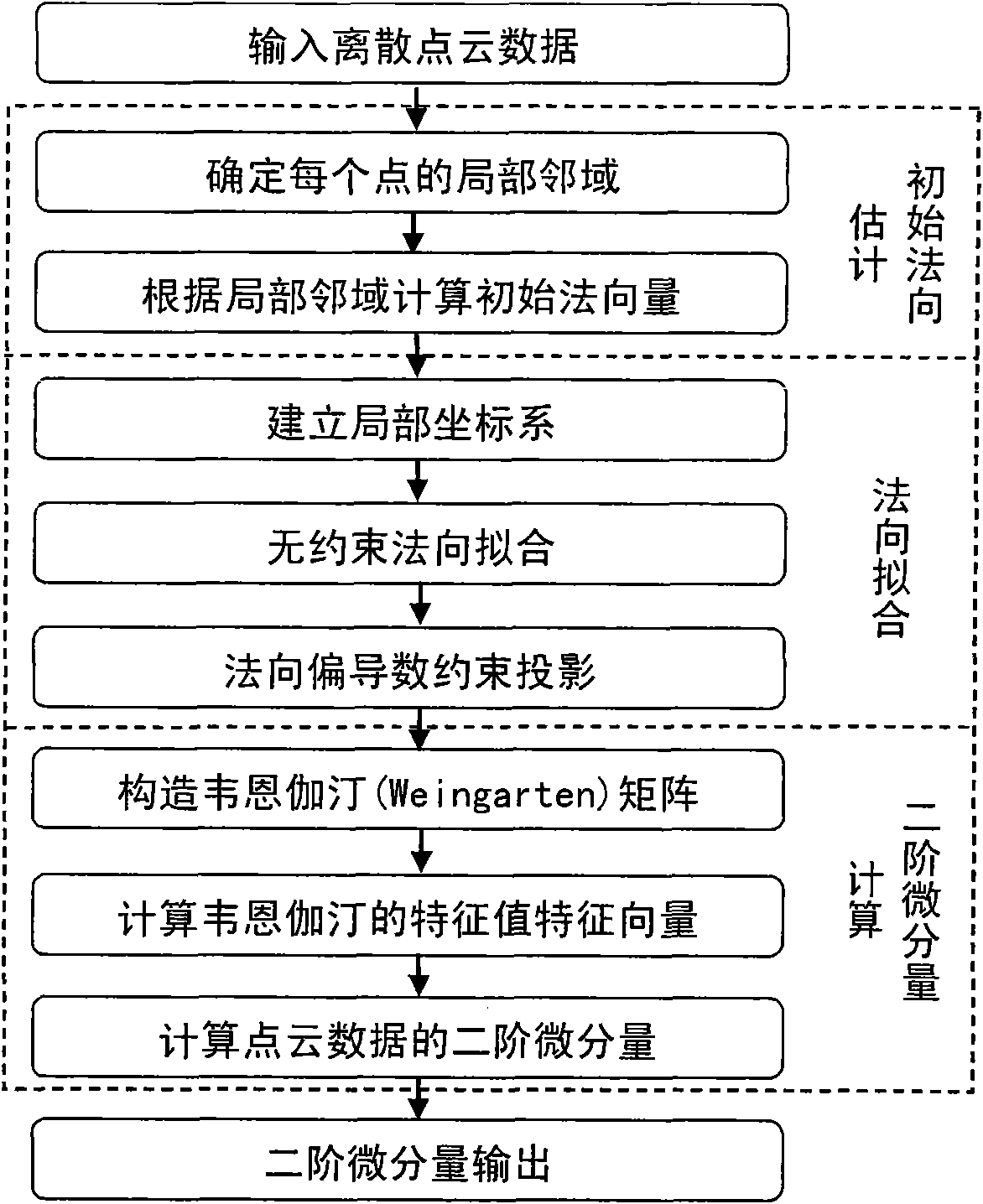

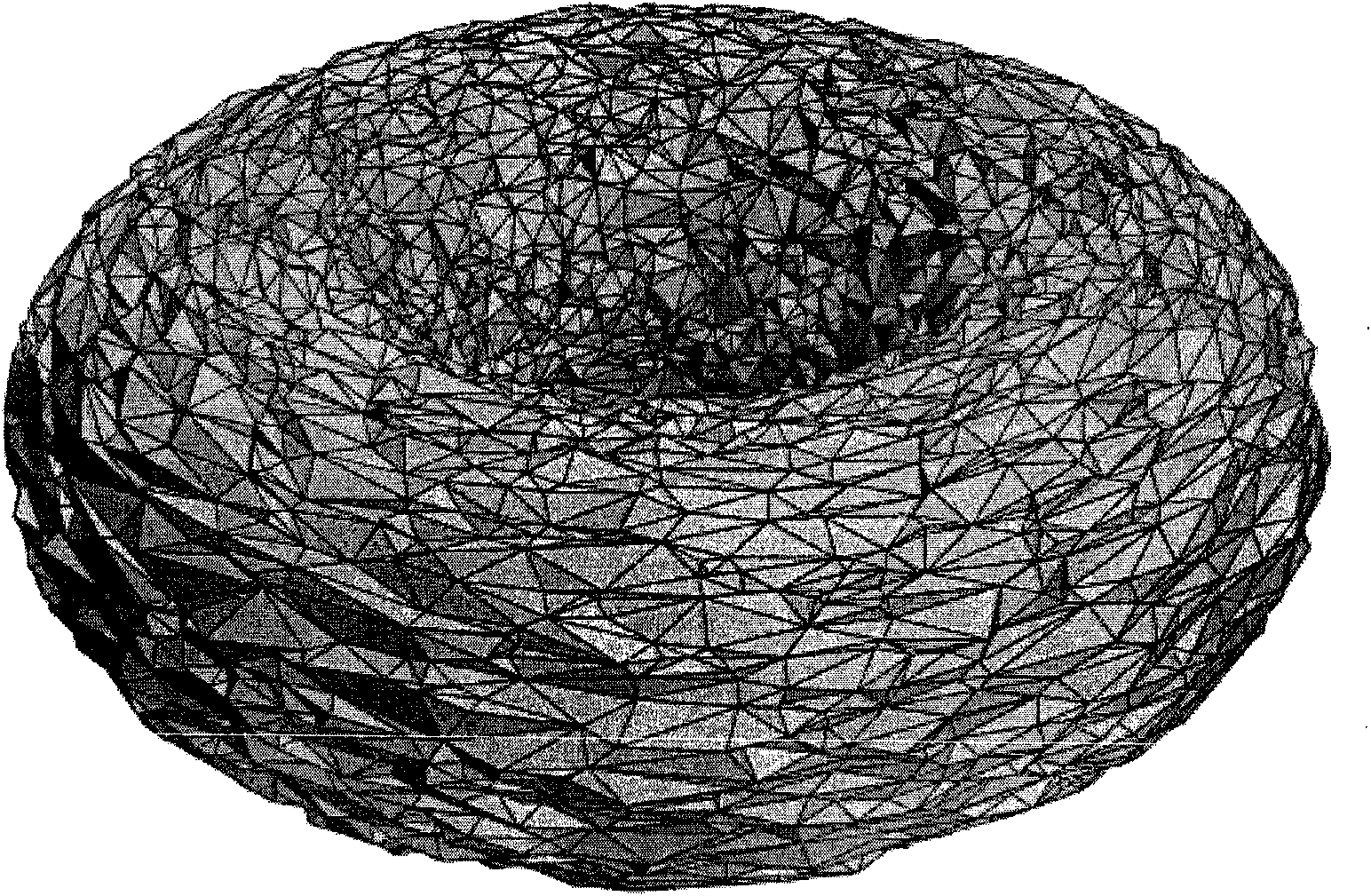

Estimation method of scattered point cloud data geometric senses

InactiveCN101833666AExact maximum principal curvatureIncrease credibilityCharacter and pattern recognitionPoint cloudEstimation methods

The invention relates to an estimation method of scattered point cloud data differential geometric senses, which comprises the following three parts of: estimating an initial normal vector for each point in point cloud data according to the position distributing situation of points in an adjacent field, and carrying out unitization on the initial normal vector of each point; carrying out normal fitting on the initial normal vectors, and computing the normal partial derivative of scattered point cloud at each point; and computing the second-order differential quantities such as the maximum principal curvature, the minimum principal curvature, the principal direction, the Gaussian curvature, the mean curvature and the like of the scattered point cloud at each point through the unitized initial normal vectors and the normal partial derivative. Aiming at the scattered point cloud data with strong noise, the invention can accurately estimate various differential geometric senses of each point and has important application value in computer graphics and computer visual adjacent fields.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

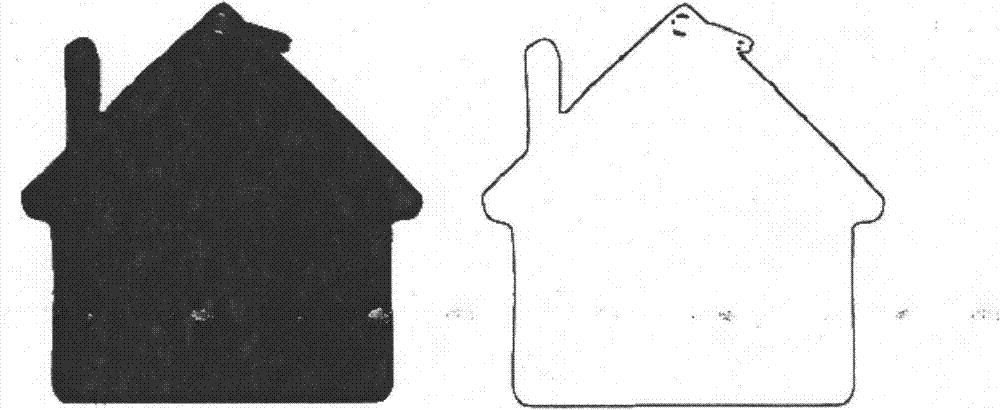

Batch part automatic detection system and method based on machine vision

The invention discloses a batch part automatic detection system and a batch part automatic detection method based on machine vision. The monitoring system comprises a transparent work table, wherein a lower light source is arranged under the transparent work table, an upper light source is arranged above the transparent work table, the upper light source and the lower light source are respectively connected with a light source illumination controller, an industrial camera is arranged above the upper light source, a lens is arranged at the lower side of the industrial camera, and the lens is aligned with the transparent work table through a hollow part of the upper light source. The method comprises the following steps that firstly, geometric quantity detection is carried out on workpeices; the collected image information is used as relevant measurement operation processing information of template part information to be stored into a system database so that the information can be automatically invoked during the subsequent part measurement; the workpiece is placed onto the transparent work table, the lens is aligned with the workpiece, and the similarity to the template part information is judged after the imaging of the workpiece; finally, the automatic detection is carried out, in addition, the qualification performance is judged, and a measurement report form is output. The technologies of machine vision relevant to image processing and databases and the like are utilized, and the fast and automatic detection on continuous large-batch parts is realized through adopting a machine demonstration mode.

Owner:DONGHUA UNIV

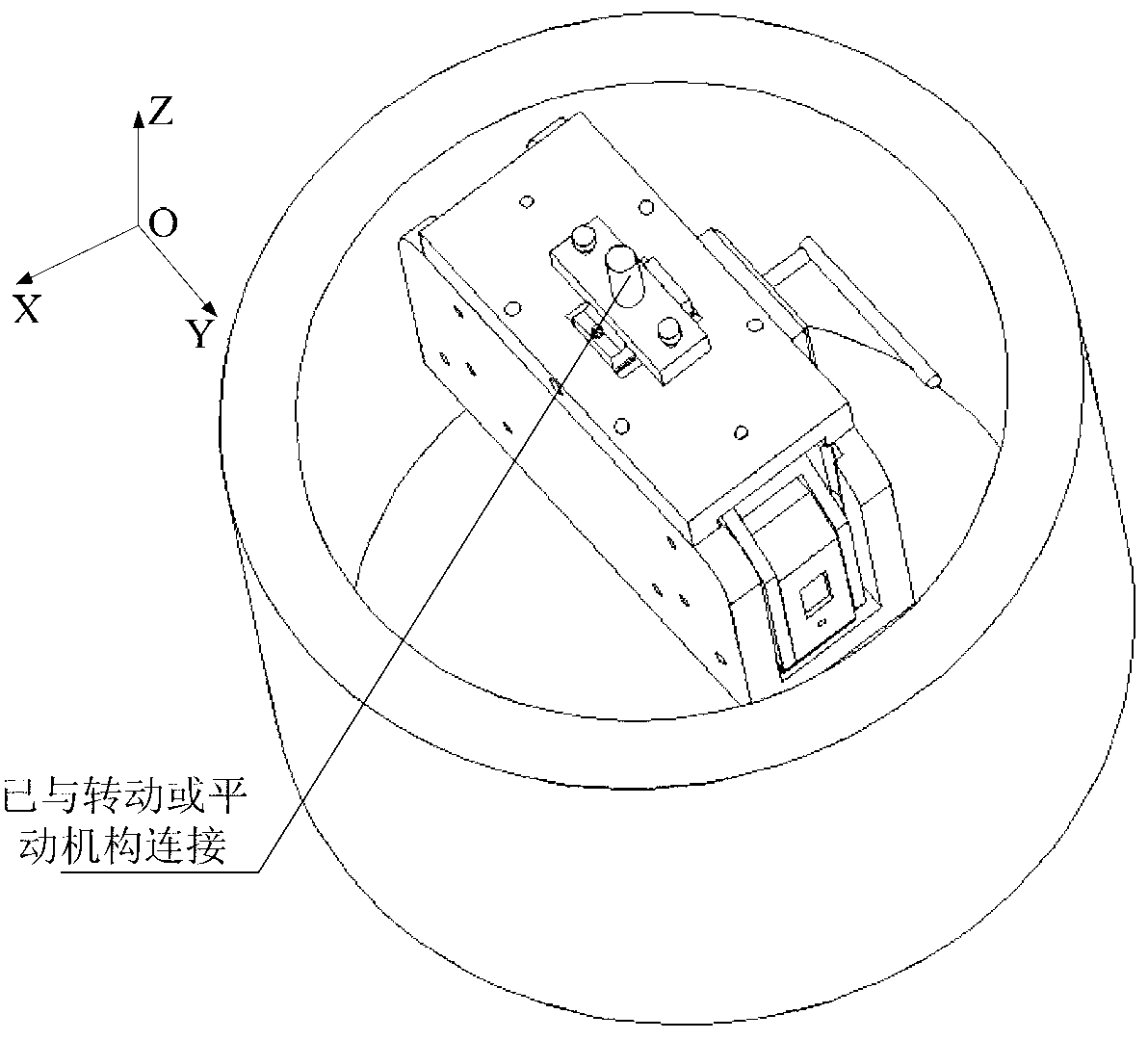

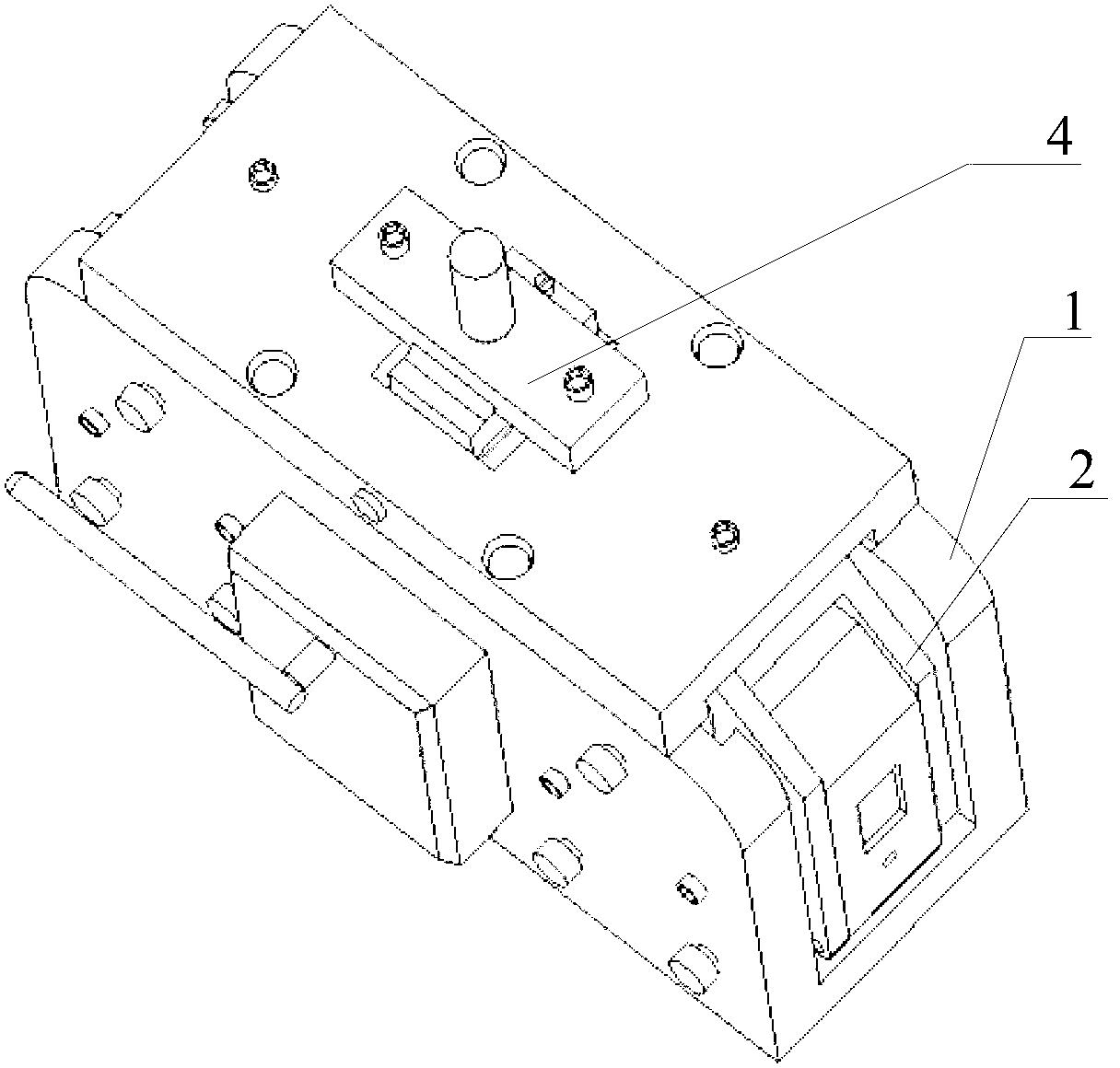

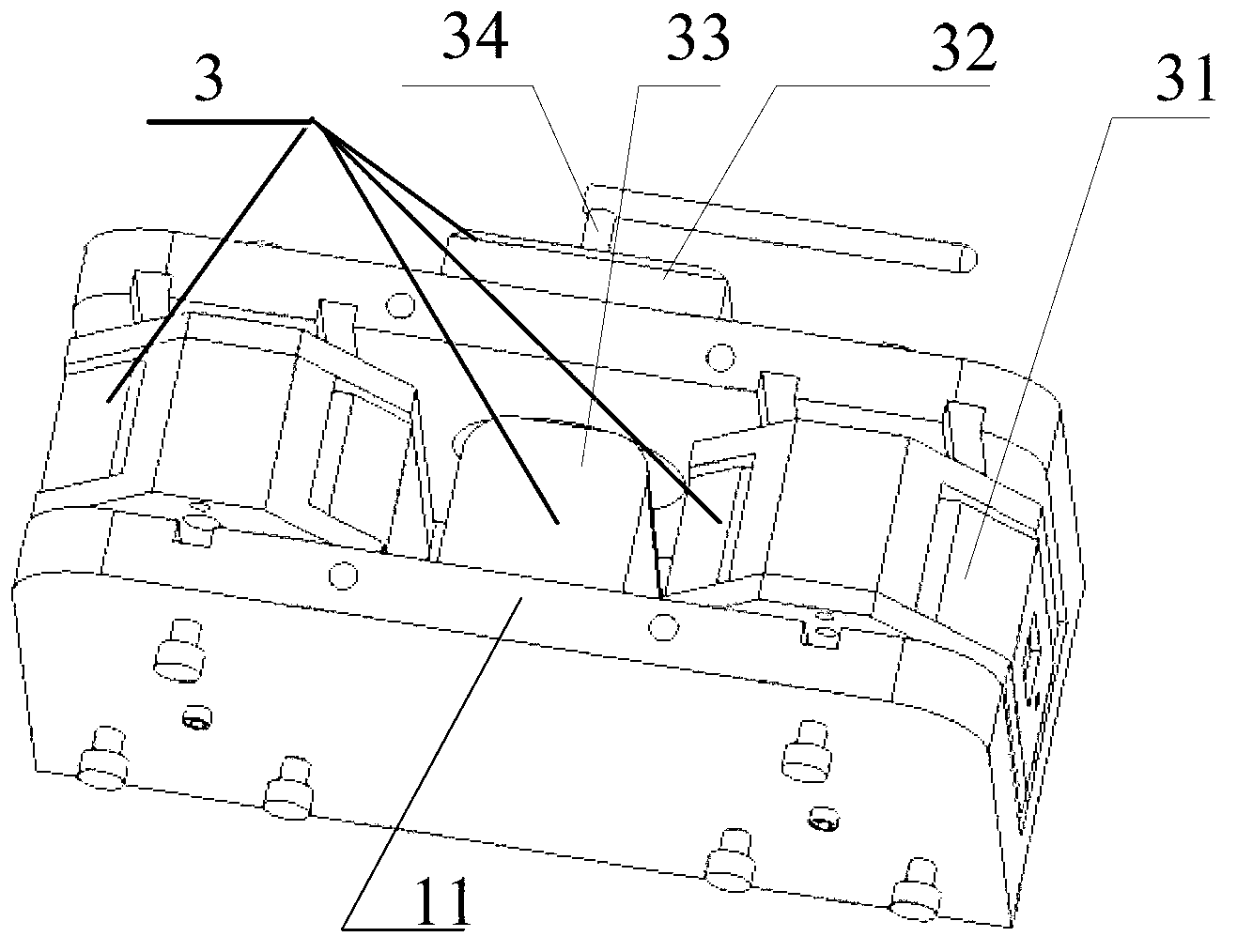

Aperture measuring method based on non-contacting type sensor combination

InactiveCN103278100AQuick and accurate measurementImprove detection accuracyUsing optical meansOptical axisDual sensor

The invention discloses an aperture measuring method based on non-contacting type sensor combination, is suitable for measuring the size of the inner diameter of a workpiece, and relates to the geometric sense measuring field. The method comprises the following steps: first, installing a main shaft of a double-sensor measuring head on a mechanism with the horizontal moving function so as to form a complete set of measuring system which is arranged in a workpiece to be measured; at measuring time, measuring optical axes of two sensors on the double-sensor measuring head being enabled to be on the same straight line; the double-sensor measuring head first rotating on a ZOY face, and then horizontally moving on an XOY face, finally the diameter of an inner hole of the workpiece to be measured is obtained; or, the double-sensor measuring head sequentially rotates on the ZOY face and the XOY face to obtain the diameter of the inner hole of the workpiece to be measured. When the method is used for measuring the diameter of the inner hole of the workpiece to be measured, only two procedures need operating theoretically, so that measuring efficiency is greatly improved, and a large number of measuring labor hours are saved. Moreover, the non-contacting measuring head is arranged on a lathe, a motion execution mechanism of the lathe is used for enabling the measuring head to rotate or move horizontally, so that on-machine accurate measuring can be achieved.

Owner:TIANJIN UNIV

Device for calibrating geometric quantity of static calibration table of wind tunnel balance

ActiveCN104568374AHigh measurement accuracyImprove measurement efficiencyAerodynamic testingGratingEngineering

The invention discloses a device for calibrating geometric quantity of a static calibration table of a wind tunnel balance, belongs to the field of geometric quantity, and is suitable for calibrating geometric parameters of a return mechanism of the static calibration table of the wind tunnel balance, a measurement system and a loading mechanism. According to the device, a loading coordinate system is reproduced by cooperation of a micro-alignment telescope and a reference cubic mirror mounted on a loading head; the micro-alignment telescope is rotated at an angle of 180 degrees by a precise rotary table; a linear guide rail equipped with a double-grating scale is driven to drive the micro-alignment telescope to move and be aligned to a reference line of the loading mechanism, and the geometric parameters of the loading mechanism are measured by data of the double-grating scale, so that the problems of low precision and low efficiency of an existing mounting measurement method are solved; in addition, a lifting mechanism is driven through a spiral lifting machine to adjust the height of the device, so that the calibration needs of geometric parameters of static calibration stables of wind tunnel balances different in type can be met.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

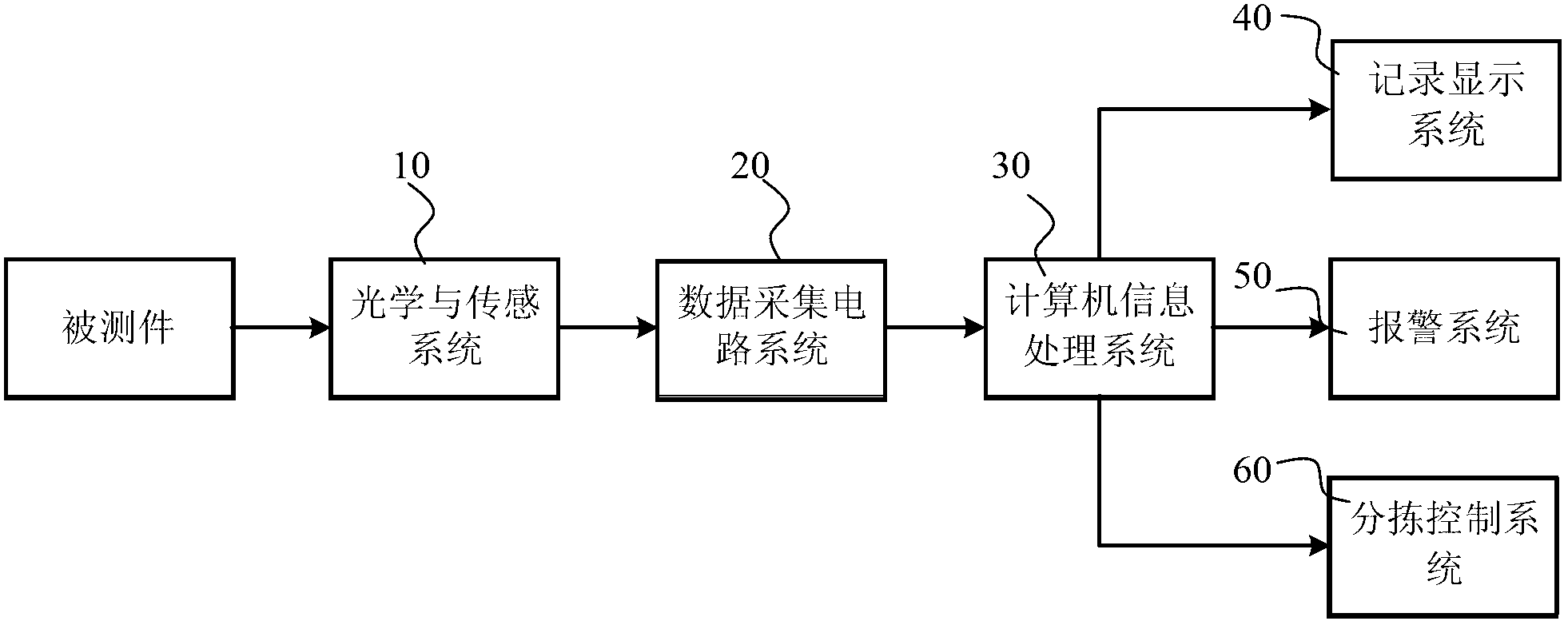

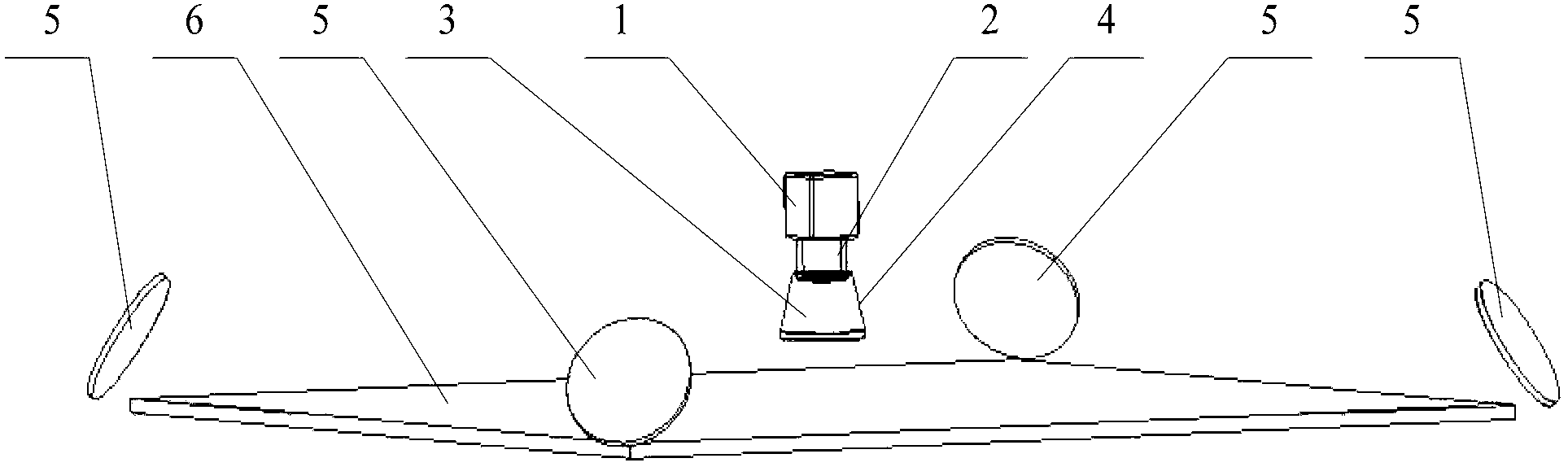

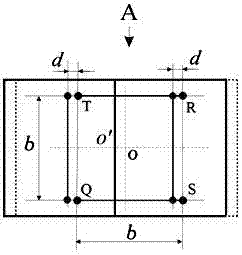

Device and method used for on-line optical measurement of two-dimensional large size of roof battenwall material

InactiveCN102798346ASolve the problem of reduced measurement accuracyHigh measurement accuracyUsing optical meansCamera lensInformation processing

The invention discloses a device and method used for on-line optical measurement of two-dimensional large size of roof battenwall materials, and belongs to the field of optical measurement on large-size geometric quantities. The measuring device comprises an optical sensing system, a data acquisition circuit system, a computer information processing system, a record display system, a warning system and a sorting control system, wherein the optical sensing system is composed of a high-resolution surface-array CCD (charge coupled device) camera, a low-distortion small-viewing-field standard lens matched with the camera, a quadrangular pyramid secondary reflection plane mirror, a high-transmittivity glass cover and four primary reflection plane mirrors, and is used for detecting the image information of four corners of a measured piece; and after calibration, the measuring device processes and computes the image information, so that the actual sizes of the measured piece are obtained and displayed. With the adoption of he device and the method provided by the invention, the problems of calibration and synchronous acquisition by a plurality of cameras are solved; and the device has high measurement speed and large-size measurement precision, and is widely applied for measuring sizes of ceramic piles, floor boards, marble tiles and the like.

Owner:TIANJIN UNIV

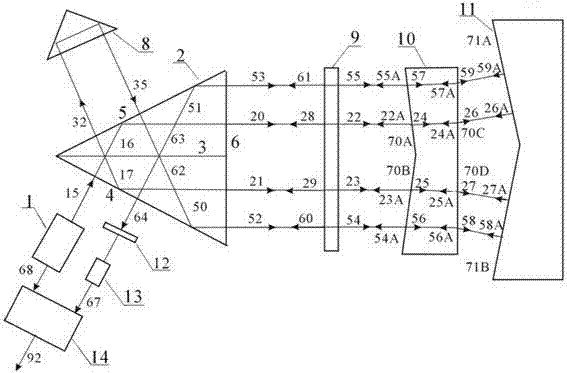

Laser interference system for displacement linearity measurement

The invention relates to a laser interference system for displacement linearity measurement, which comprises a laser source, a wedge angle prism moving with an object to be measured, a light reflection device arranged on one side of the wedge angle prism, a light interference device arranged between the other end of the wedge angle prism and the laser source, and a phase detecting device, wherein the laser source produces an incidence light beam with stable frequency, the incidence light beam passes the wedge angle prism for two times in the effect of the light interference device, and is correspondingly reflected for two times by the wedge angle prism and the light reflection device, and is finally inputted into the phase detecting device; and the linearity of the object to be measured is determined by a variable quantity of a phase difference. The laser interference system for the displacement linearity measurement has the advantages of simple structure and high measurement accuracy, and can be widely applied to geometric sense precision measurement of fields such as war industry, aerospace and numerical control machines and the like, and establishment of a measurement reference.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

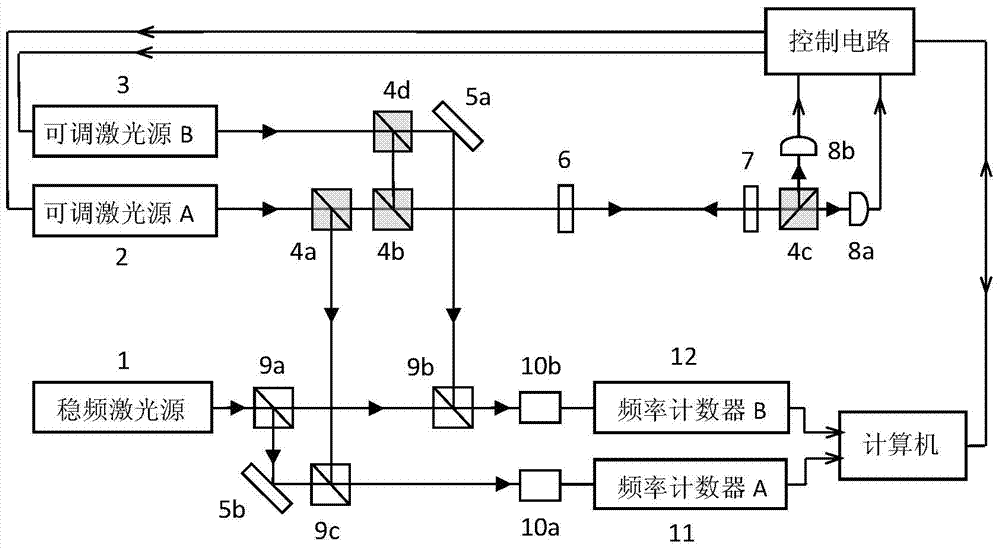

Micro displacement measuring system with double light-source-adjustable Fabry-Perot interferometers

ActiveCN104266593AHigh measurement resolutionSolve measurement resolutionUsing optical meansClassical mechanicsLength wave

The invention relates to a micro displacement measuring system with double laser-source-adjustable Fabry-Perot interferometers, and belongs to the technical field of geometrical product measurement. According to the measuring system, two Fabry-Perot interferometers with wavelength-adjustable lasers as light sources are used for measuring the displacement of a measured target, the two adjustable light sources are used for alternately tracking the frequencies of different resonant modes of Fabry-Perot cavities, and the range of displacement measurement is broadened while it is guaranteed that the Fabry-Perot interferometers have the high measurement resolving ability. The micro displacement measuring system effectively solves the conflict between the improvement of the interferometer measurement resolving ability and the broadening of the measurement range, and can be applied to micro displacement measurement with nanometer-level accuracy.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

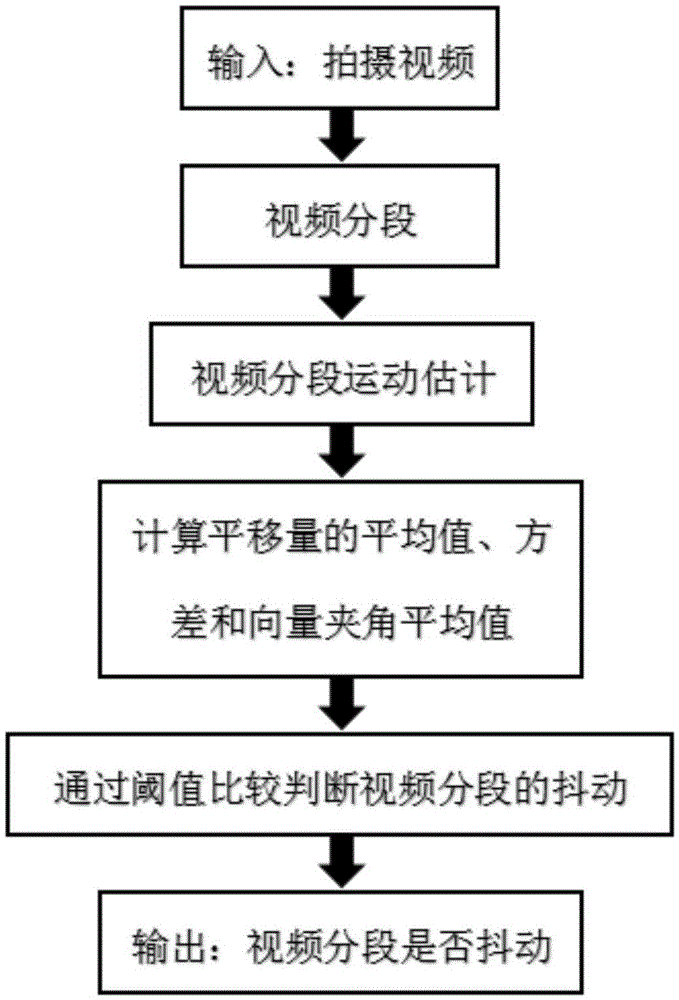

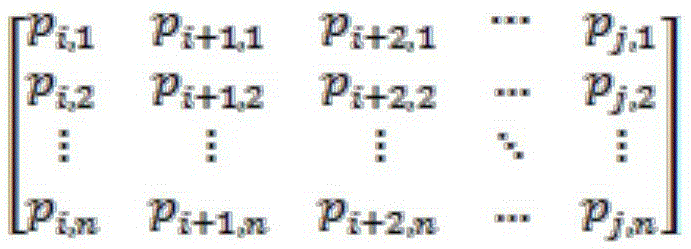

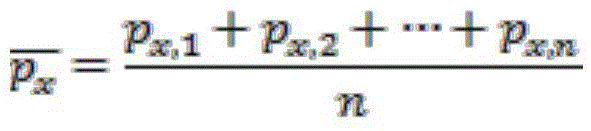

Video jitter detection method based on inter-frame motion geometric smoothness

ActiveCN105681663AImprove computing efficiencyImprove accuracyImage enhancementTelevision system detailsVideo processingEuclidean vector

The invention relates to a video jitter detection method based on inter-frame motion geometric smoothness, and belongs to the technical field of video processing. The method comprises the following steps: step 1, segmenting according to an inter-frame similarity degree; step 2, performing motion estimation on every segment by using characteristic point detection and matching; step 3, after that, calculating an average value and a variance of a translation of adjacent frames within the segments and an average value of a translation vector angle, and measuring the motion geometric smoothness through the three geometric quantities; and step 4, comparing the three geometric quantities with a preset threshold, and judging whether the segments jitter. Compared with an existing method, the video jitter detection method based on the inter-frame motion geometric smoothness provided by the invention uses the three geometric quantities relevant to the inter-frame translation vector to measure a jitter degree of one segment, and the calculation efficiency is fast and the accuracy is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

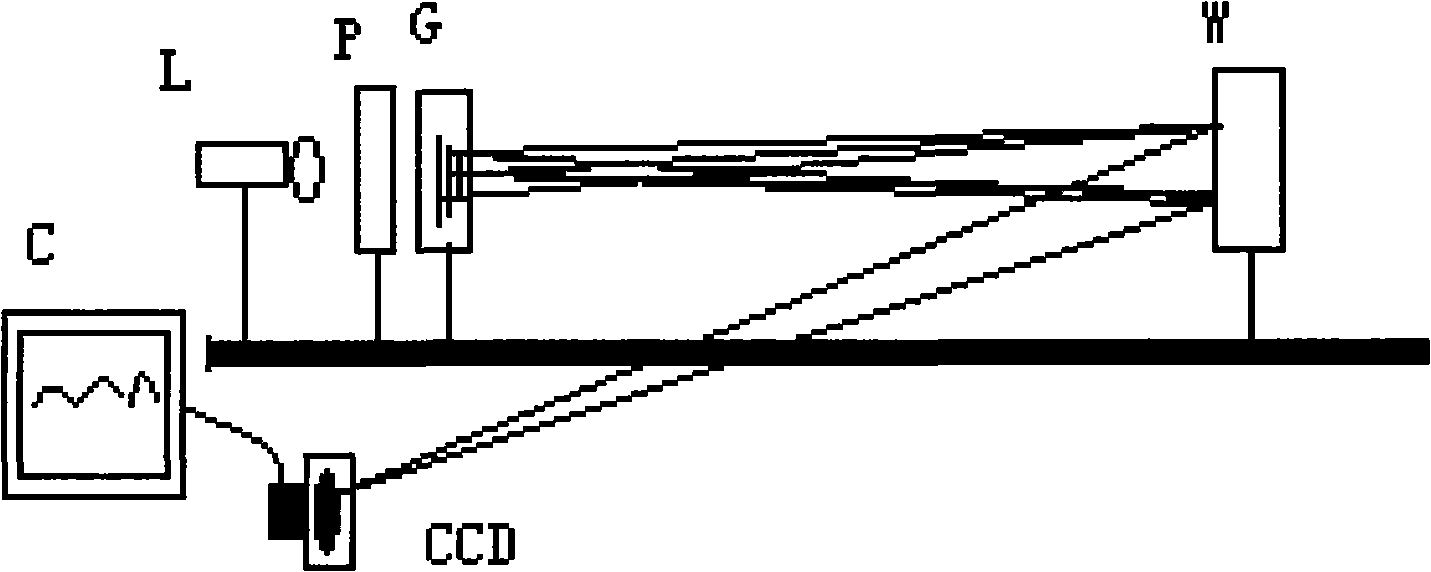

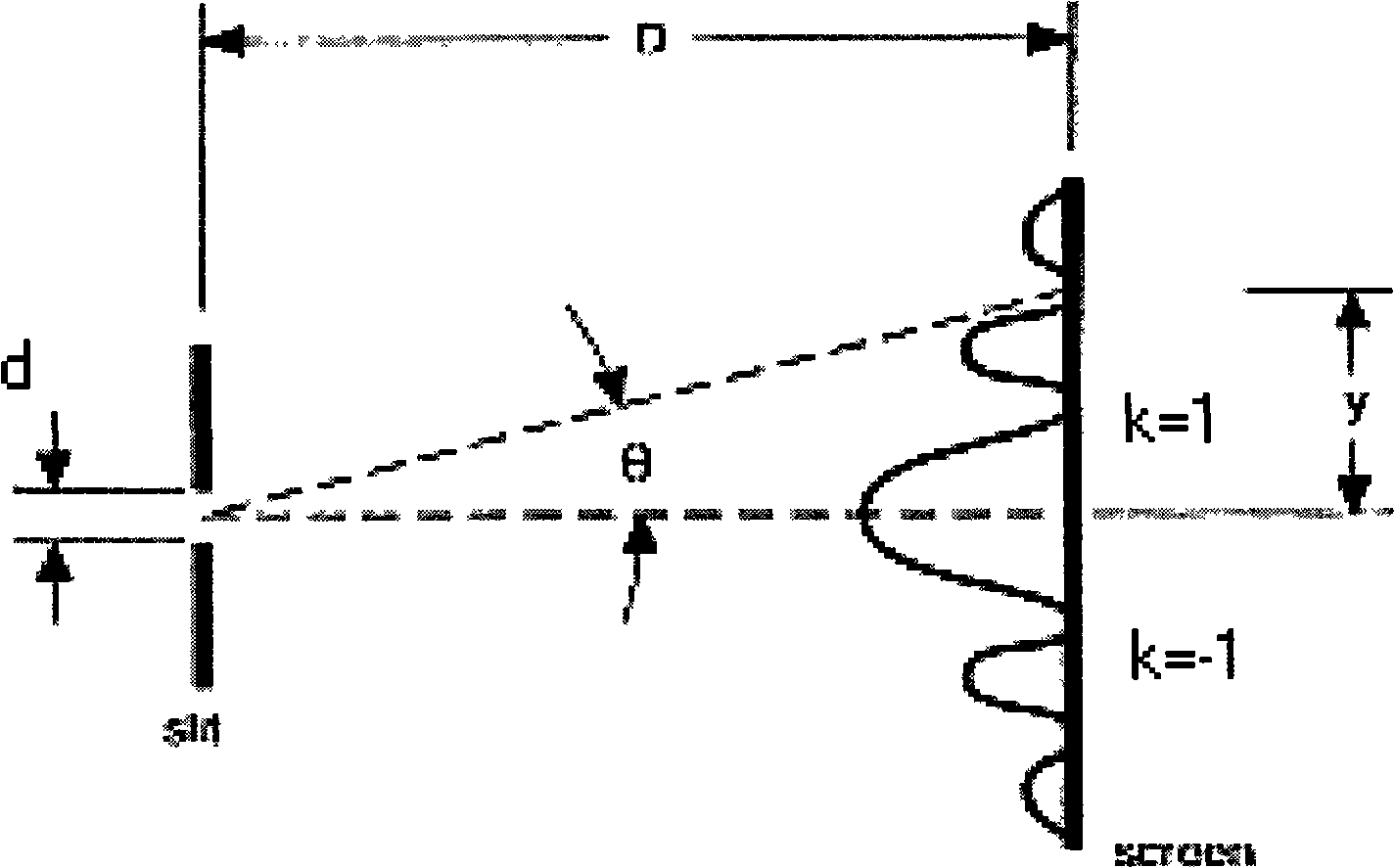

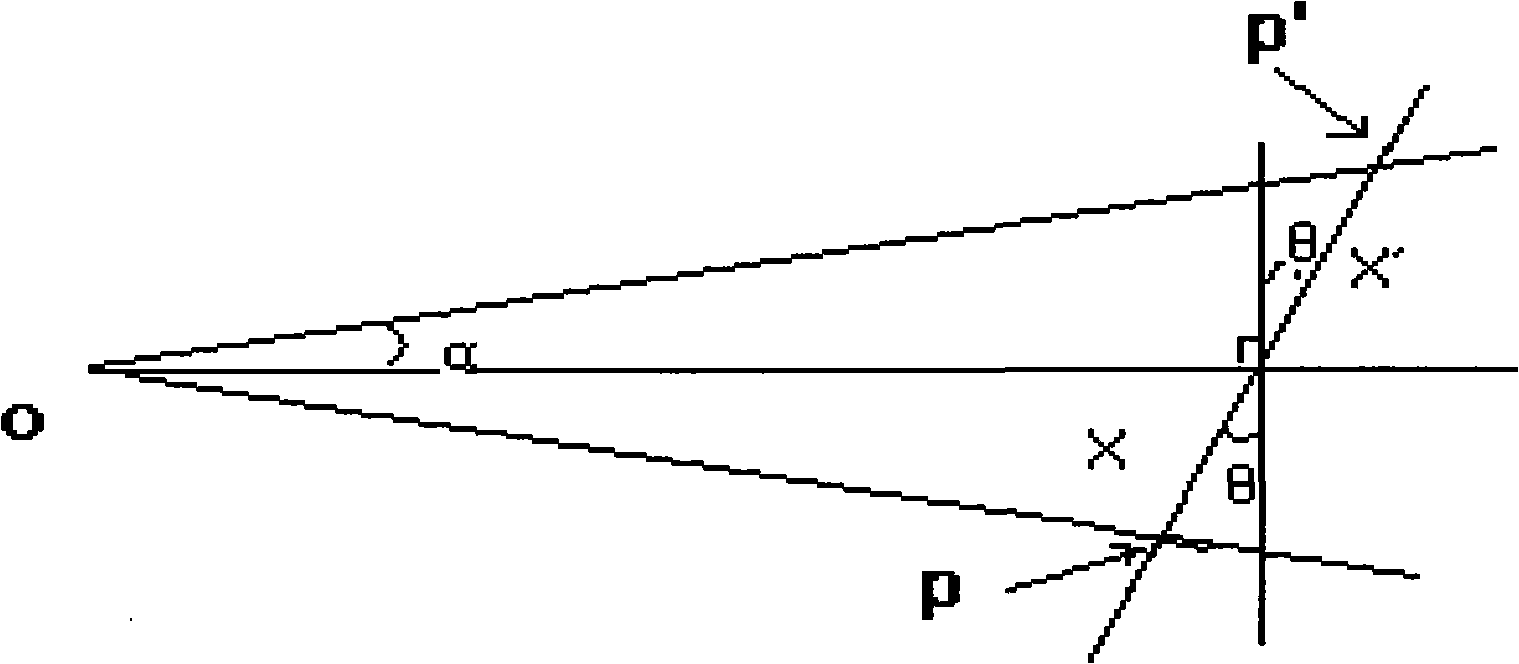

Method for measuring flat inclination grating diffraction fringe

InactiveCN101298981AEasy to operateFast measurementUsing optical meansMeasurement deviceThree dimensional measurement

A grate diffract stripe measurement method of the plane elevation angle is provided. The measurement device includes a laser, a polaroid sheet, a grate, a CCD, a measured object, a computer. The invention uses the laser to generate the interference light source, which generates the diffract stripe image after passing through the diffract stripe, adjusts the position of the light source and the grate to generate the clear diffract stripe image on the object. The CCD is used to collect the diffract stripe image on the surface of the object, and transmit the collected image data to the computer, obtain the quantitative relation between the stripe mode change and the plane elevation angle theta through the corresponding computer software. The measurement device of the invention has convenient device, easy operation, fast measurement speed, non-contact measurement, which satisfies the presition requirement of the general geometric measurement. The measurement technology has practicality and high cost performance, higher practicality which can be widely used in the surface measurement of the industrial instrument, meanwhile is suitable is the three-dimensional measurement of the small scene and large scene.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Interferometry measurement system of micro-displacement based on cat eye reflecting principle

ActiveCN103105134AImprove measurement accuracyRealize non-contact measurementUsing optical meansObservational errorMathematical model

The invention relates to an interferometry measurement system of micro-displacement based on cat eye reflecting principle, and belongs to the technical field of geometric measurement. The interferometry measurement system is characterized by applying cat eye reflecting principle into interferometry measurement of micro-displacement, providing a displacement measuring error correcting mathematical model introduced by cat eye reflector, and adopting a balanced double-optical-path optical system structure to improve disturbance-resisting capacity of the system. The error correction method is capable of reducing measuring error made by the cat eye reflector to manometer level. Hardware of the interferometry measurement system is composed of a stable frequency laser light source, a polarizing beamsplitting mirror, a lens-reflector cat eye reflector, a cube-corner prism, a wave plate, a polarizing film, necessary reflector and rectangular prism and photoelectric receiver. The system has the advantages of high measuring resolving power, strong disturbance-resisting capacity, non-contact measurement and the like, is used for solving the problem that interferometry measurement of micro-displacement cannot be conducted when the cube-corner prism is not used, and has significant popularization and application values in the measurement fields of micro-displacement, micro-vibration, thermal expansion parameter and the like.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

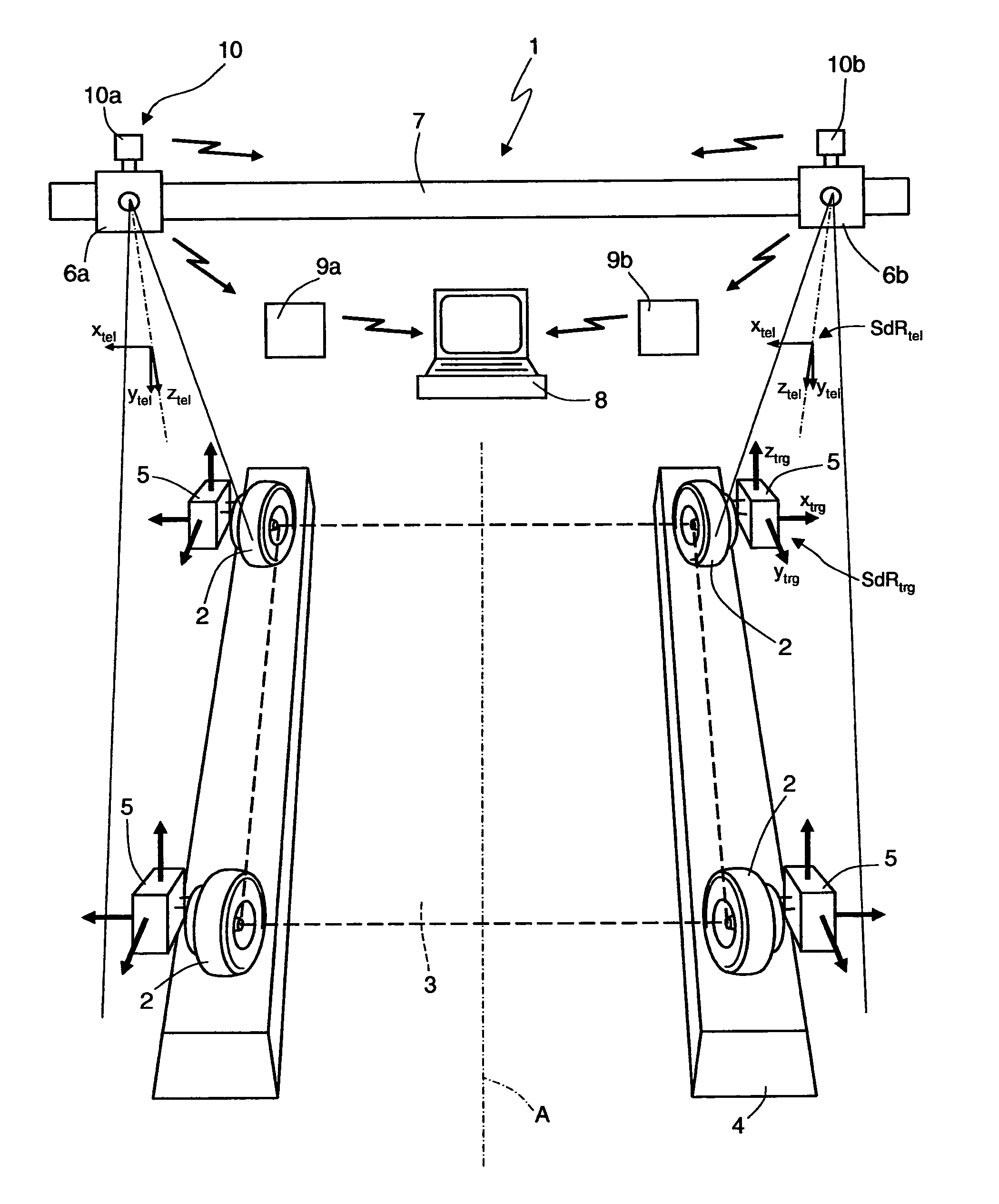

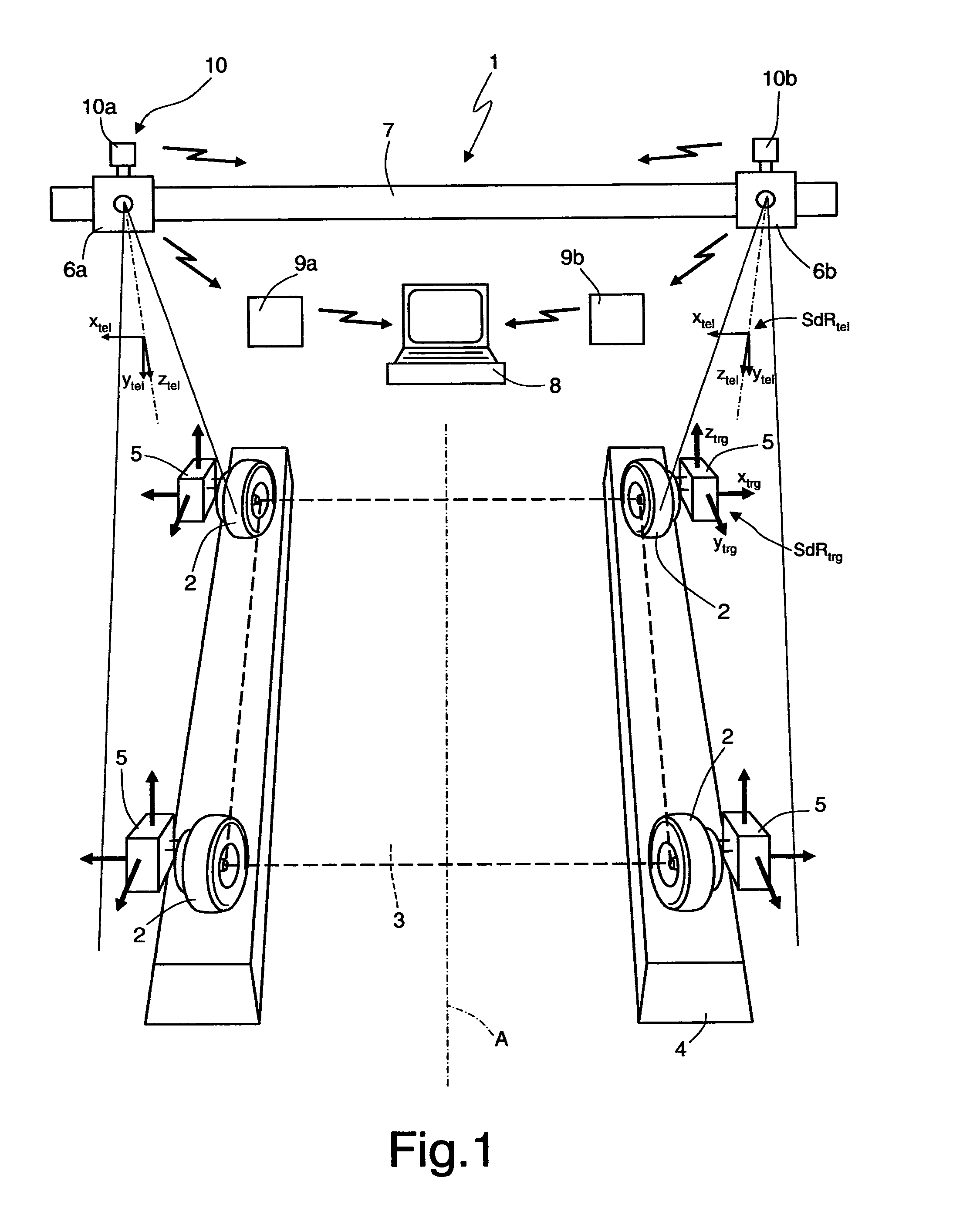

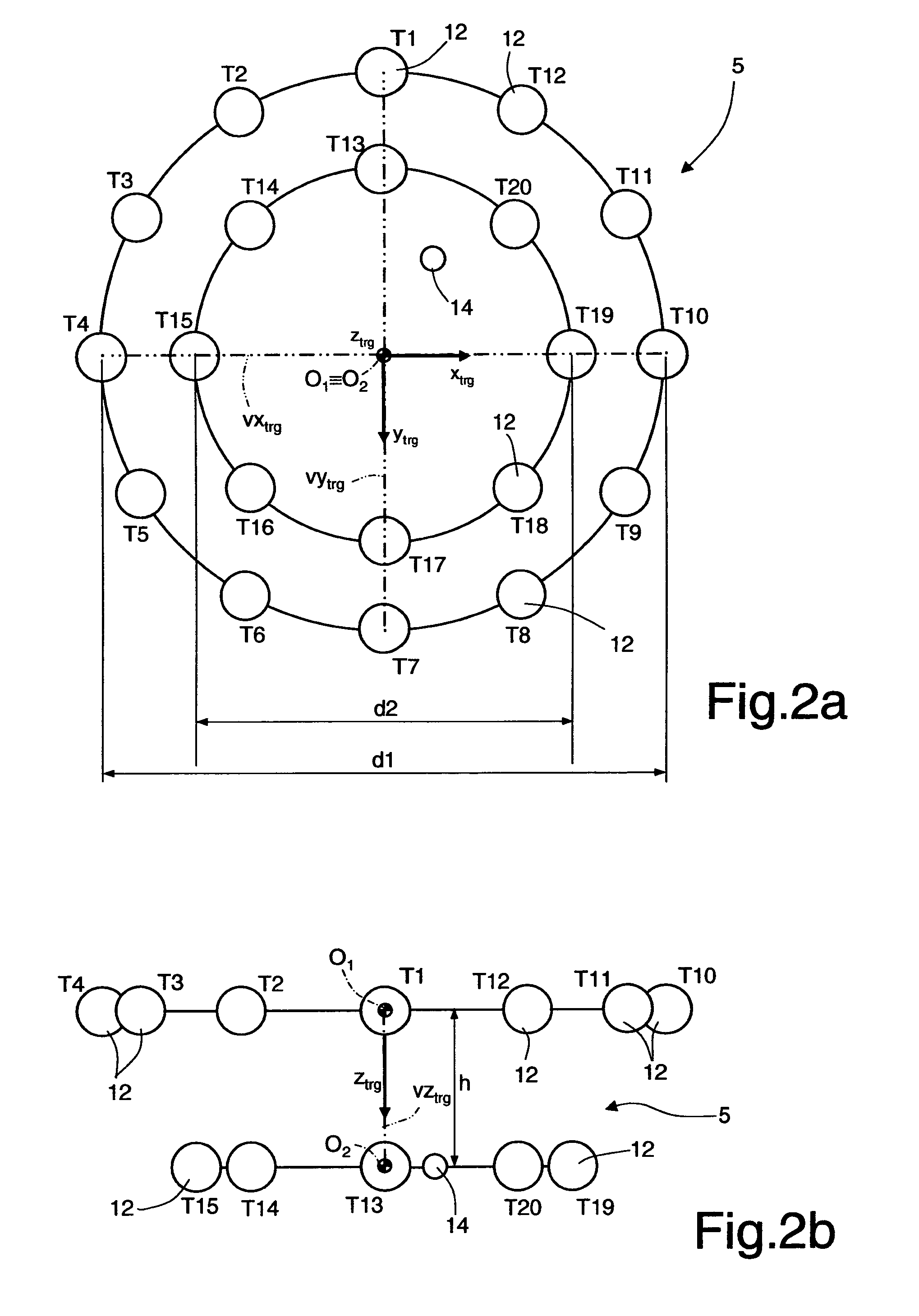

System and related method for determining vehicle wheel alignment

Owner:SPACE S R L CON UNICO SOCIO

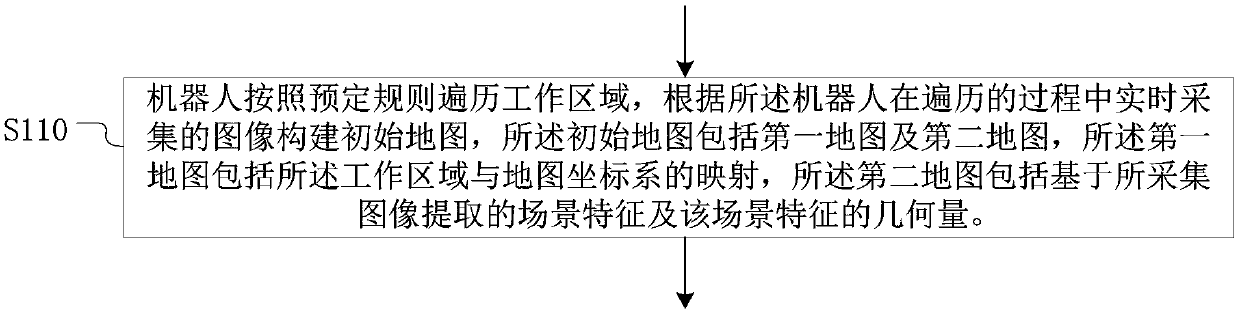

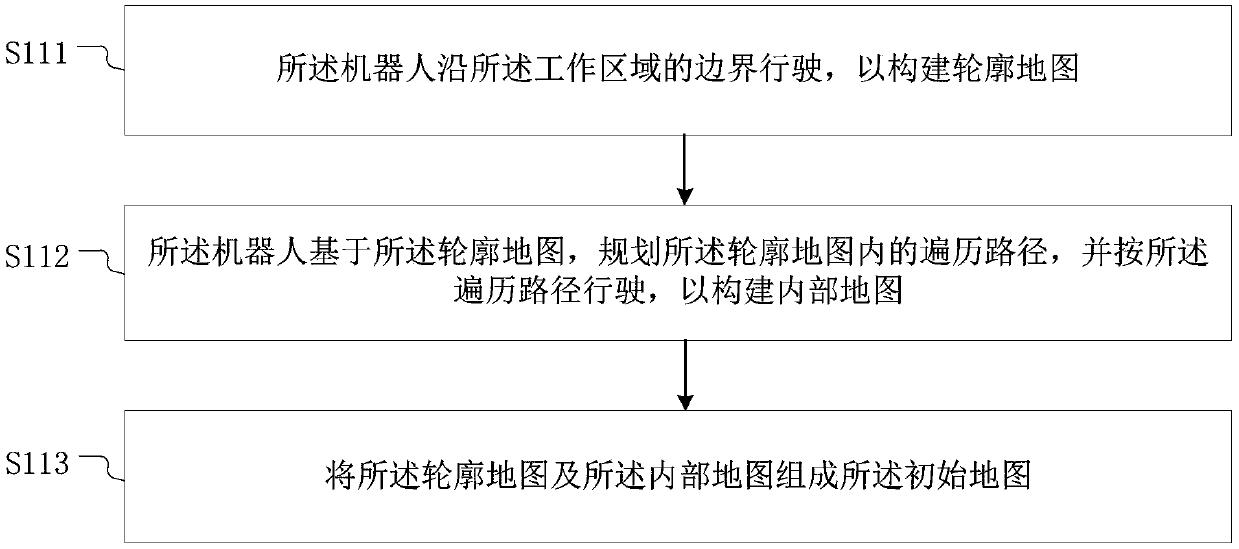

Robot, map construction method, positioning method, electronic equipment and storage medium

ActiveCN109682368AReduce power consumptionLow costNavigation instrumentsVehicle position/course/altitude controlImage extractionVision sensor

The invention provides a robot, a map construction method, a positioning method, electronic equipment and a storage medium. The map construction method of the robot includes the steps that the robot traverses a working region according to a preset rule, and an initial map is constructed according to images which are collected in real time when the robot traverses the working region, and comprisesa first map body and a second map body, wherein the first map body includes mapping of the working region and a map coordinate system, and the second map body includes extracted scene features based on the collected images and a geometric quantity of the scene features. The map is constructed without active signals by the adoption of a passive vision sensor, the vision sensor is low in power consumption and cost, the quantity of obtained signals is large, and the map construction of the intelligent robot is optimized.

Owner:NEXTVPU SHANGHAI CO LTD

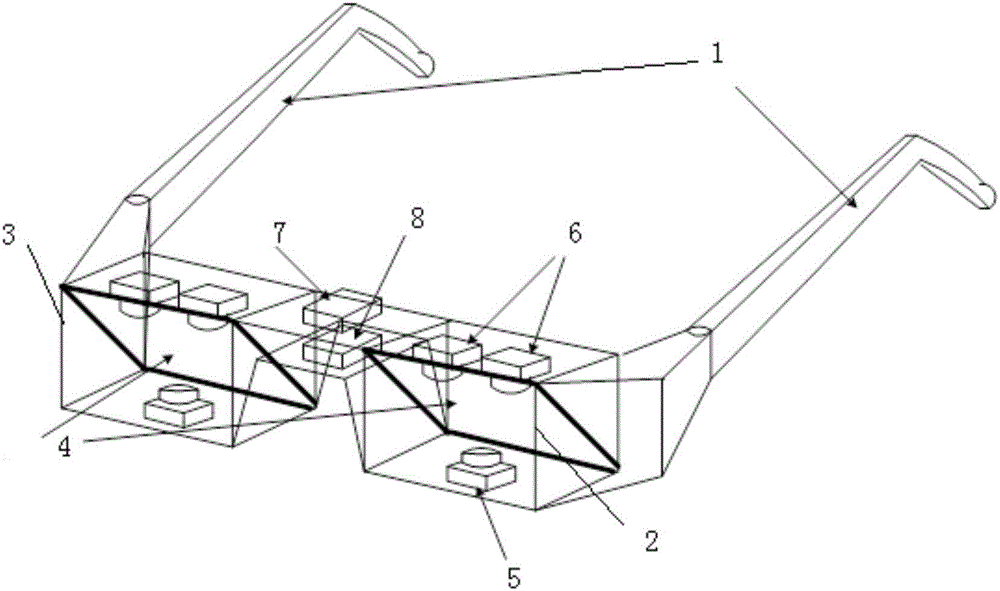

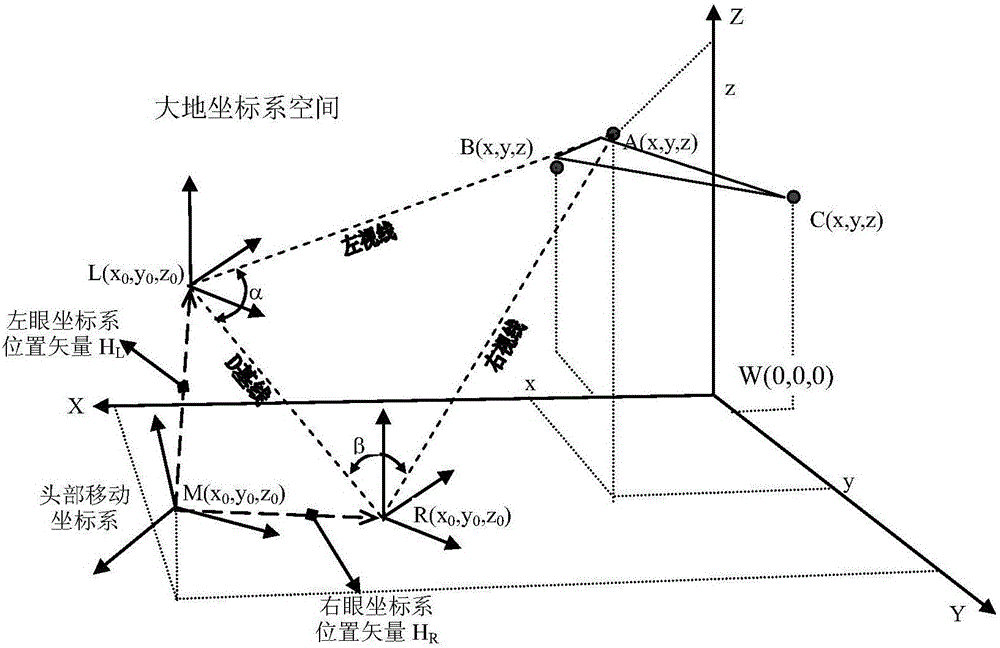

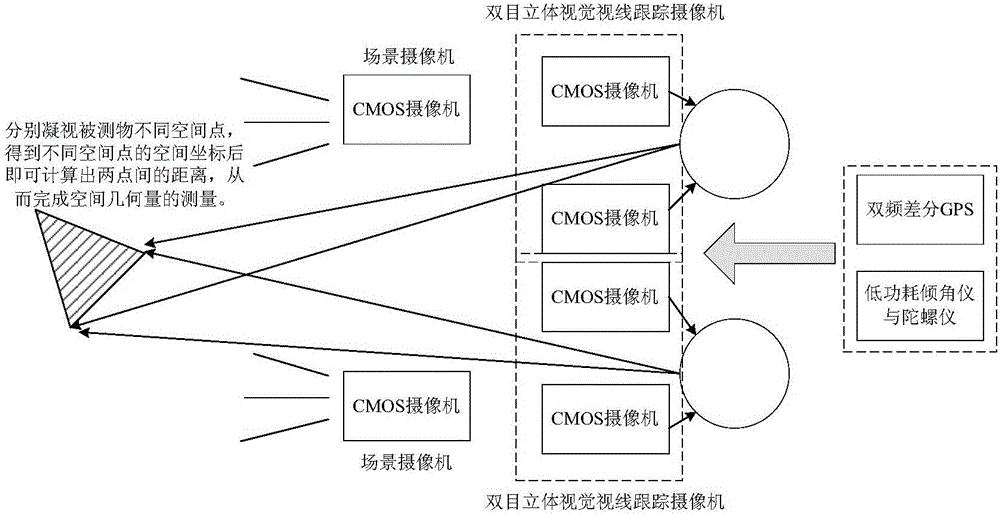

Space geometrical quantity measurement method of using sight fixation points of free space

InactiveCN106840112ARealize non-contact measurementEffective combinationNavigation instrumentsSatellite radio beaconingFixation pointPupil

The invention relates to a space geometrical quantity measurement method of using sight fixation points of a free space. The method comprises the steps of obtaining an image of a measured object by using a scene camera; determining space coordinates of a pupil center for each group of sight tracking binocular cameras; defining a normal direction of a plane in which pupils through the pupil center are located as the sight direction, and determining sight direction expressions for a left eye and a right eye separately; obtaining coordinates of fixation points; obtaining invariable geodetic coordinates of the fixation points through real-time pose transformation of a pose measurement assembly according to the characteristics that the coordinates of the fixation points in a geodetic coordinate system of the measured space are invariable; and after carrying out sight operation on the measured object for multiple times, obtaining space coordinates of multiple points of a body surface, calculating the distances among the points separately, and completing space geometrical quantity measurement of the measured object by combining an image of a scene camera.

Owner:TIANJIN UNIV

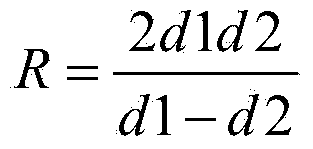

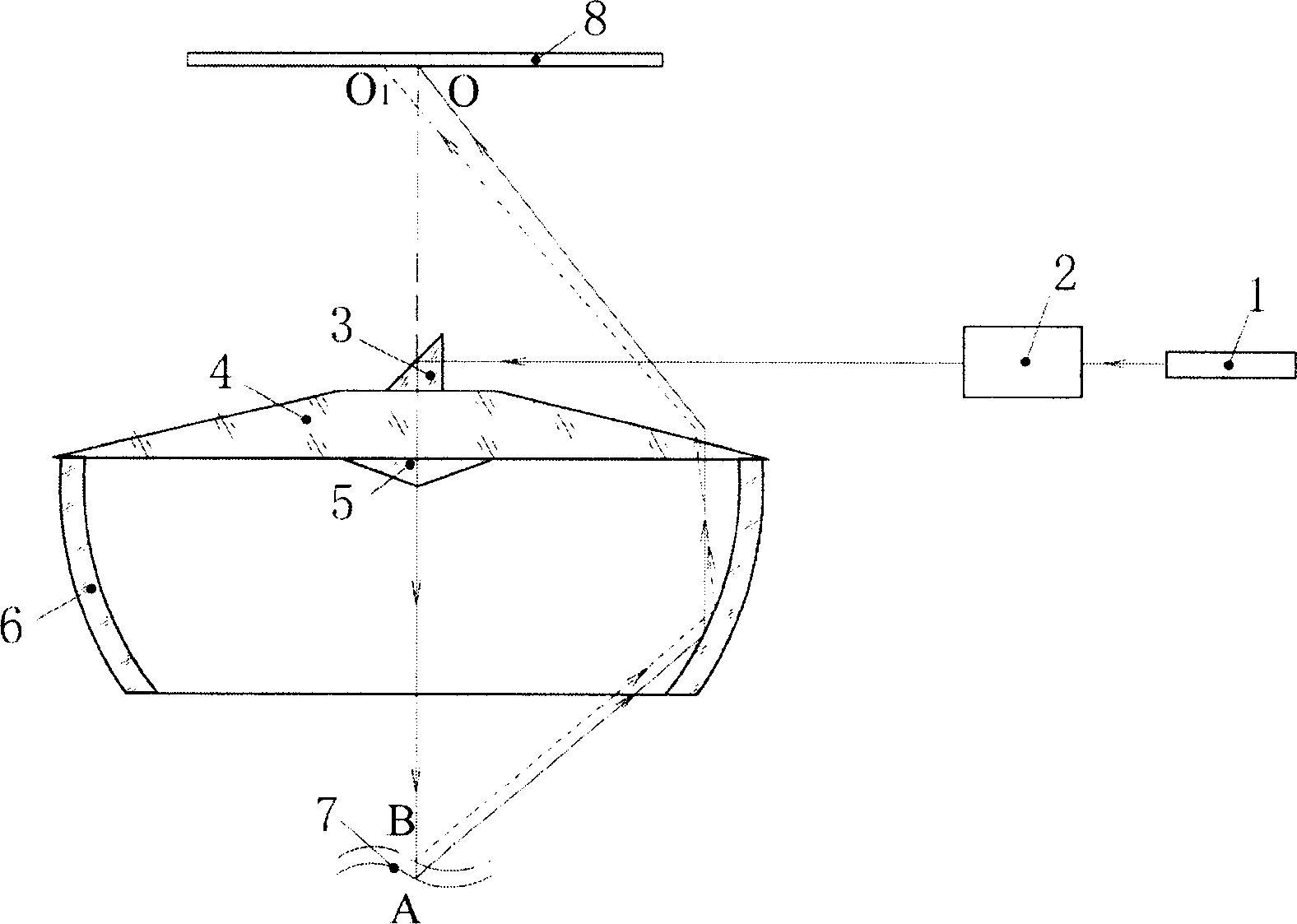

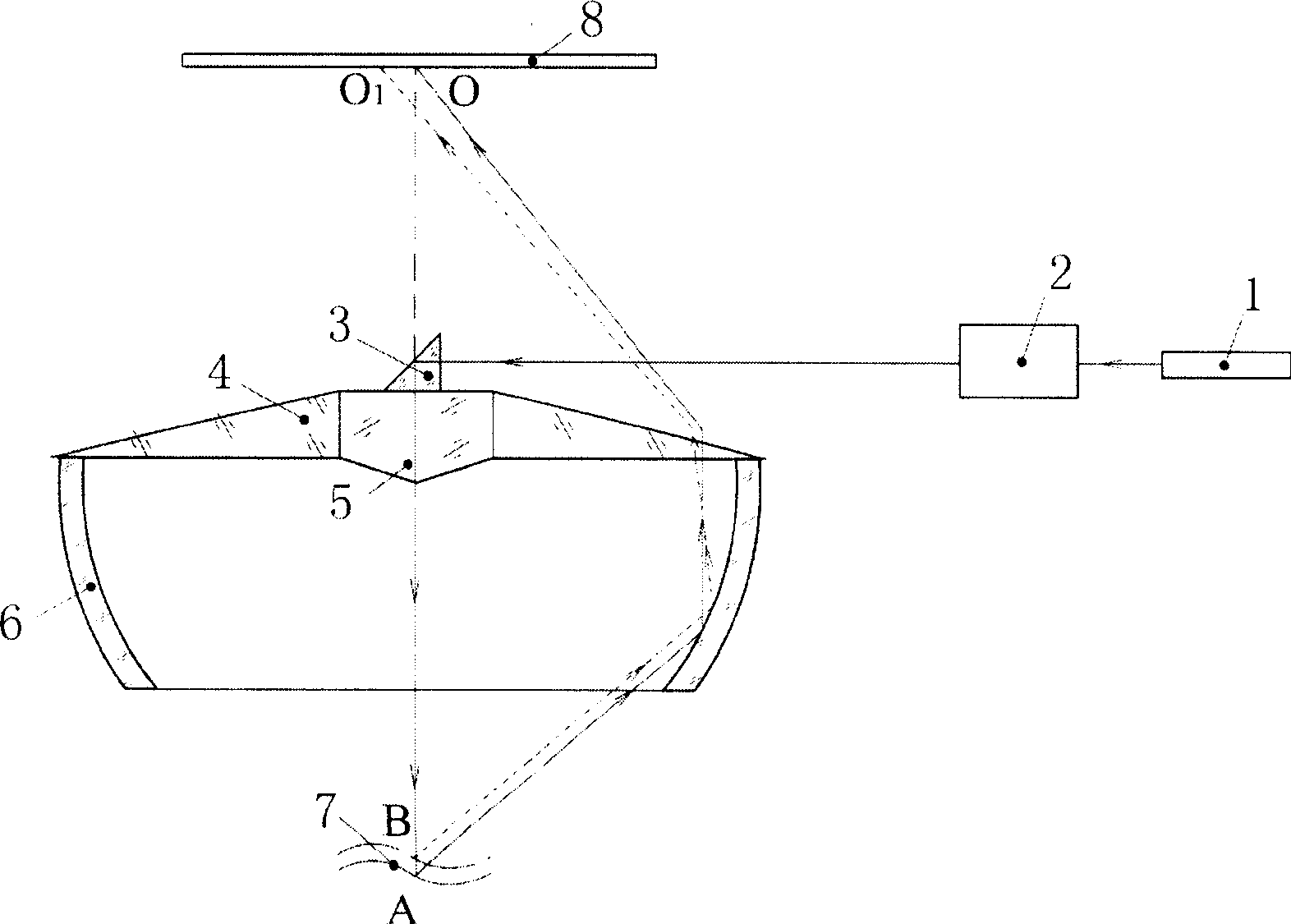

High-accuracy geographic sense measuring method in convex hyperboloid Hindle detection

ActiveCN104075668ASolve complexitySolve the accuracy problemUsing optical meansHyperboloidOptical axis

A high-accuracy geographic sense measuring method in convex hyperboloid Hindle detection relates to the field of aspherical surface detection and solves the problems of an existing method is low in accuracy, poor in repeatability and inaccurate in detection. The method comprises the steps of adjusting an interferometer, a Hindle ball mirror and a convex hyperboloid to carry out inference detection on the convex hyperboloid to enable a surface shape error root mean square value to be the minimum, placing a target ball of a laser tracker at the outer focal point of the convex hyperboloid, carrying out interference detection on the surface of the convex hyperboloid, adjusting the inclination and the defocus to the minimum, measuring space coordinates of the convex hyperboloid, using the laser tracker to measure the surface characteristics of the convex hyperboloid, moving the convex hyperboloid away, carrying out interference detection on the Hindle ball mirror, adjusting the inclination and the defocus to the minimum, placing the target ball of the laser tracker at the inner focal point of the convex hyperboloid, carrying out interference detection on the surface of the convex hyperboloid, adjusting the inclination and the defocus to the minimum, measuring space coordinates of the convex hyperboloid, and constructing and detecting an optical axis line and an interval to calculate out the geometric senses. The measuring accuracy of the high-accuracy geographic sense measuring method is about 0.05mm. Furthermore, the high-accuracy geographic sense measuring method is high in accuracy and good in repeatability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

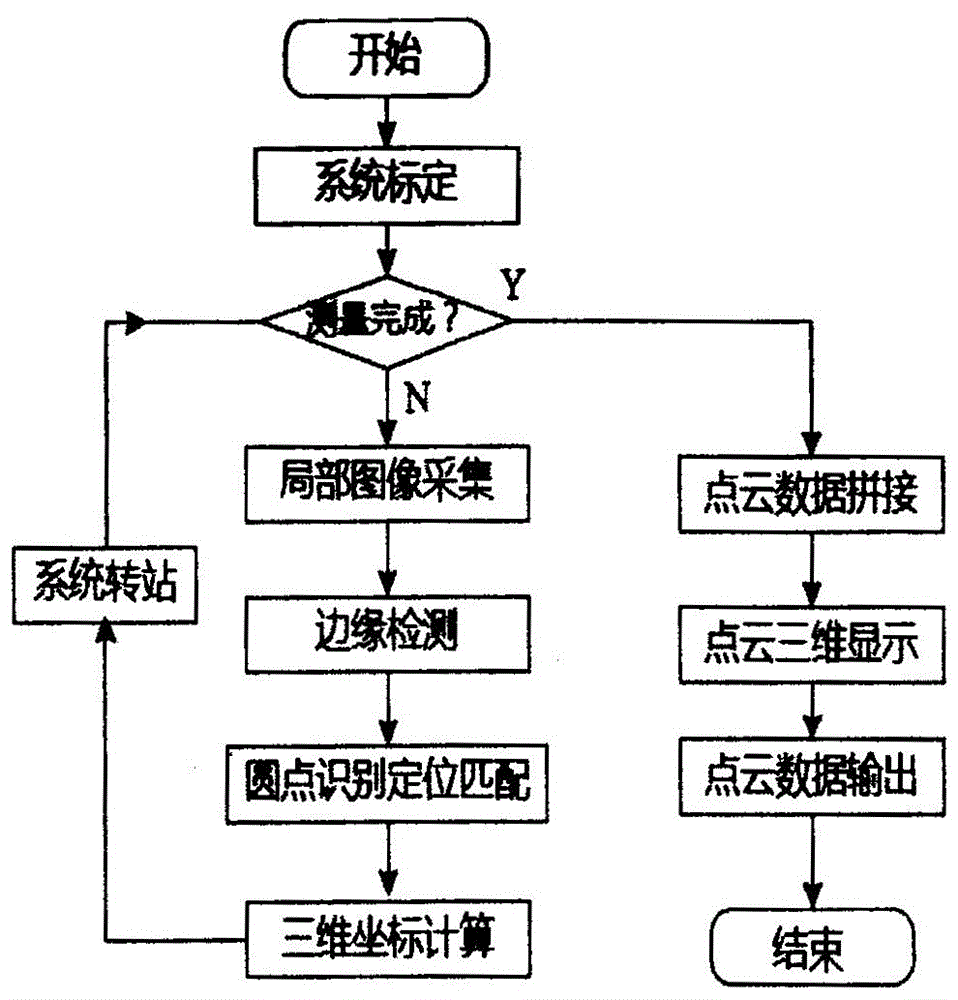

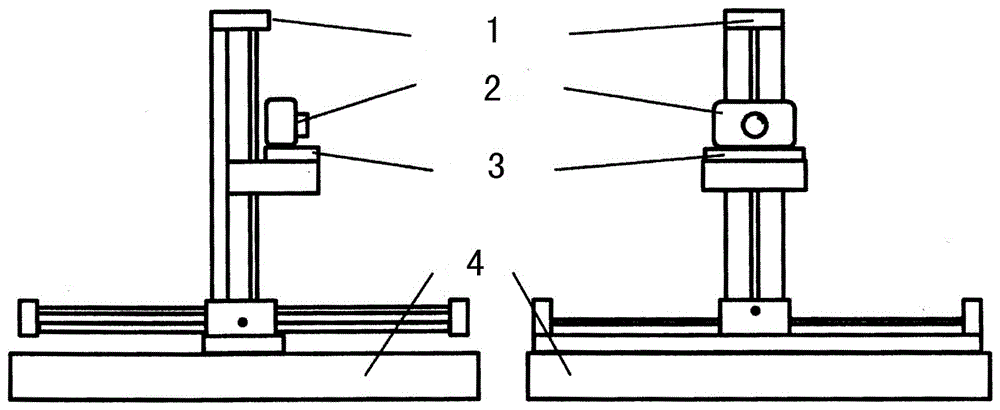

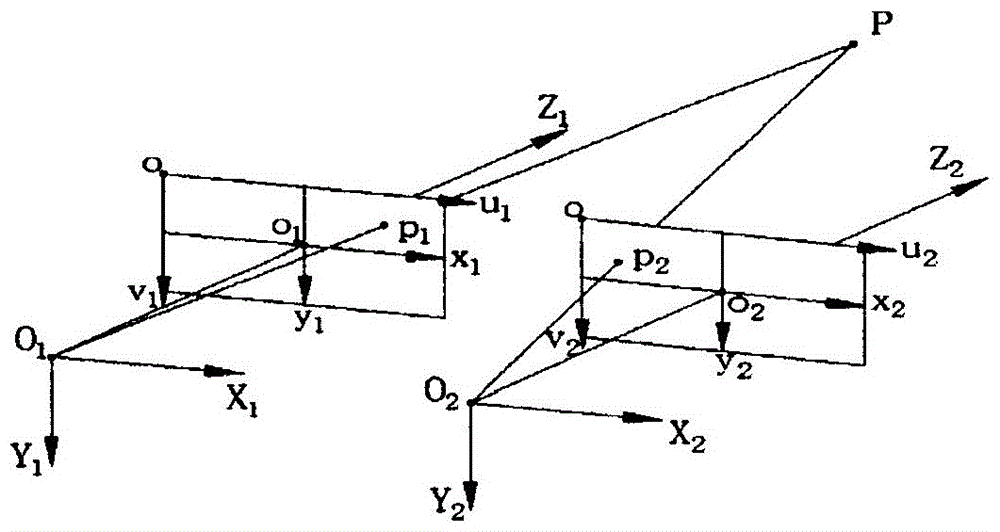

Binocular vision-based large-dimensional geometric quantity measurement method

InactiveCN106017321AAccurate CalibrationThe recognition effect is accurateUsing optical meansJet aeroplaneMeasurement point

The invention provides a binocular stereoscopic vision station-transfer measurement-based large-dimensional geometric quantity measurement method. The objective of the invention is to solve problems in large-dimensional geometric quantity measurement in the manufacture field of large equipment such as airplanes and ships. The method includes the following steps that: a plane target and active vision combined calibration method is adopted to obtain visual system parameters through precise calibration, and therefore, the defect of the poor stability of the principal point of a camera caused by inaccurate positioning of an angular point can be elinminated; with a non-coding origin adopted as a measuring point, a circularity method and a fitting method are adopted to realize the identification and circular positioning of the origin, and an epipolar constraint method and a crossratio constraint method are combined to match high-density similar dots; and an SVD method is used to solve a splicing matrix between adjacent stations, and data splicing can be completed. As indicated by a test result, the relative error of the measurement result of the method and a numerical value measured by a coordinate measurement machine is smaller than 0.1%.

Owner:SHENYANG AIRCRAFT CORP

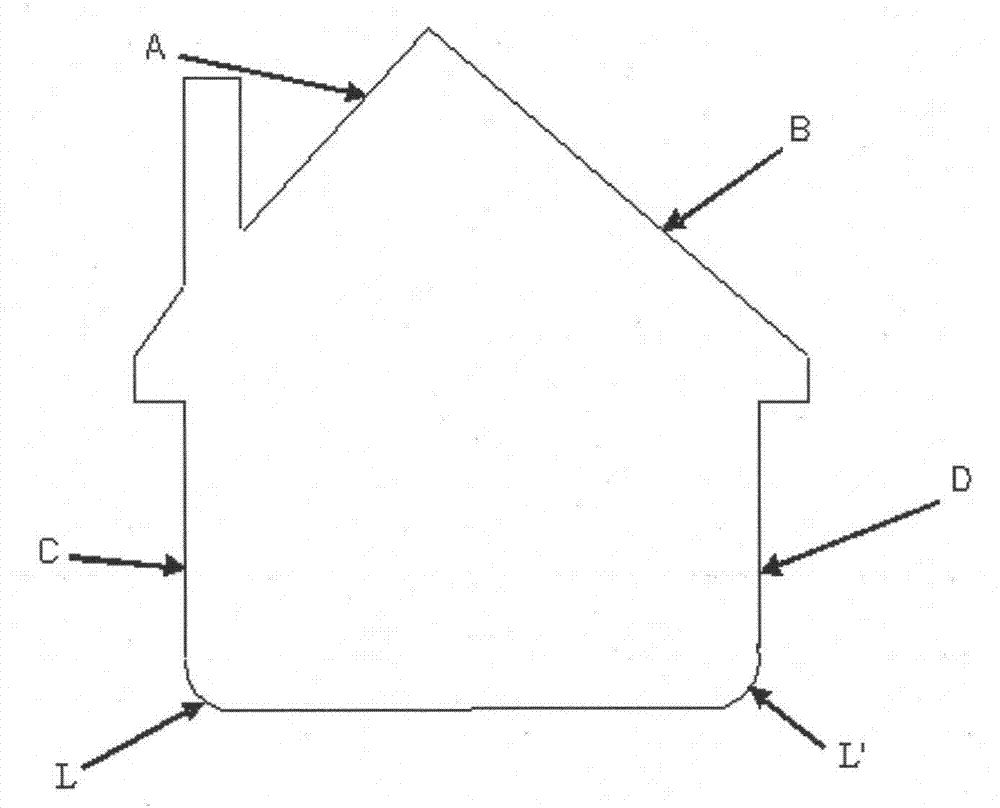

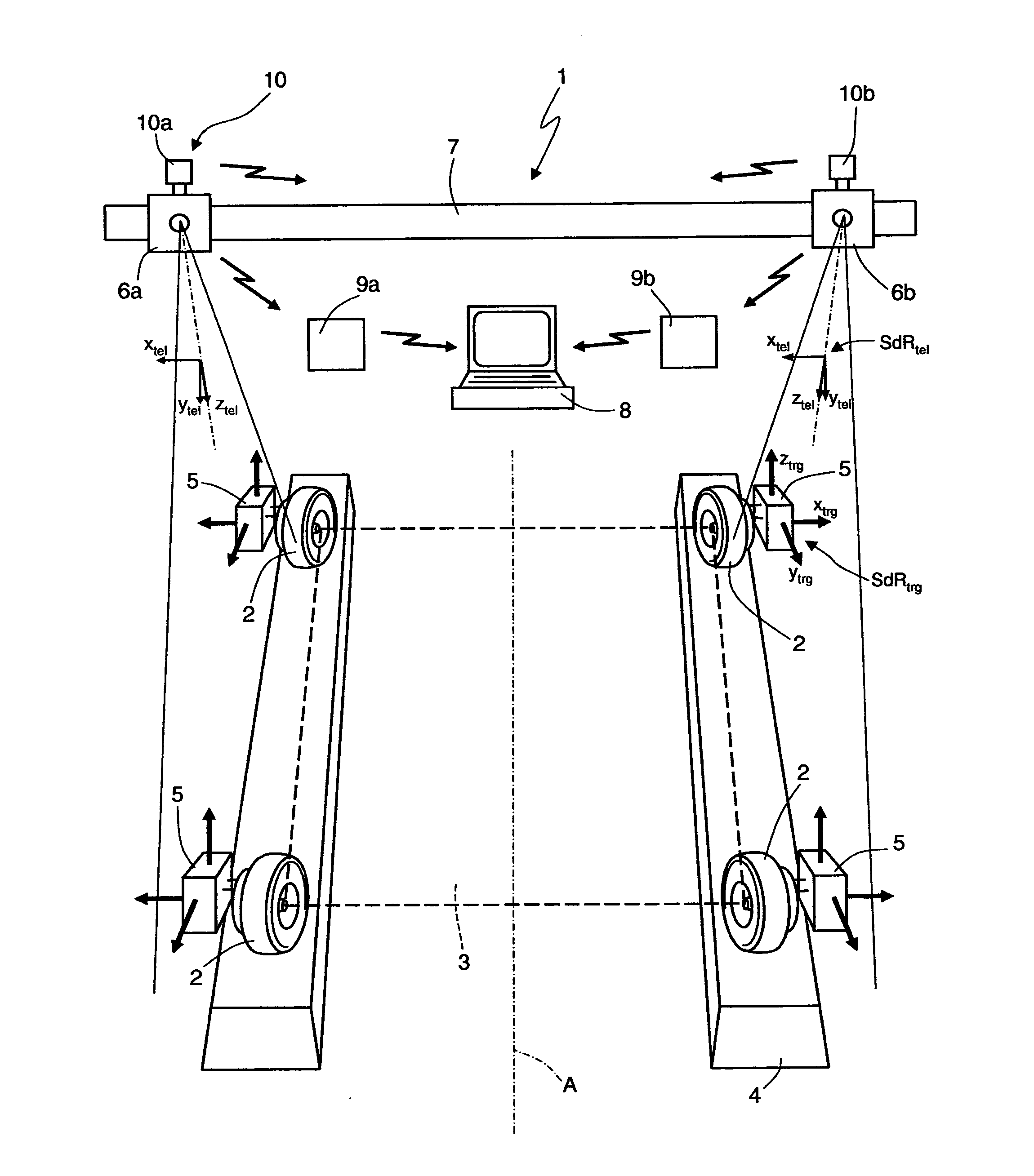

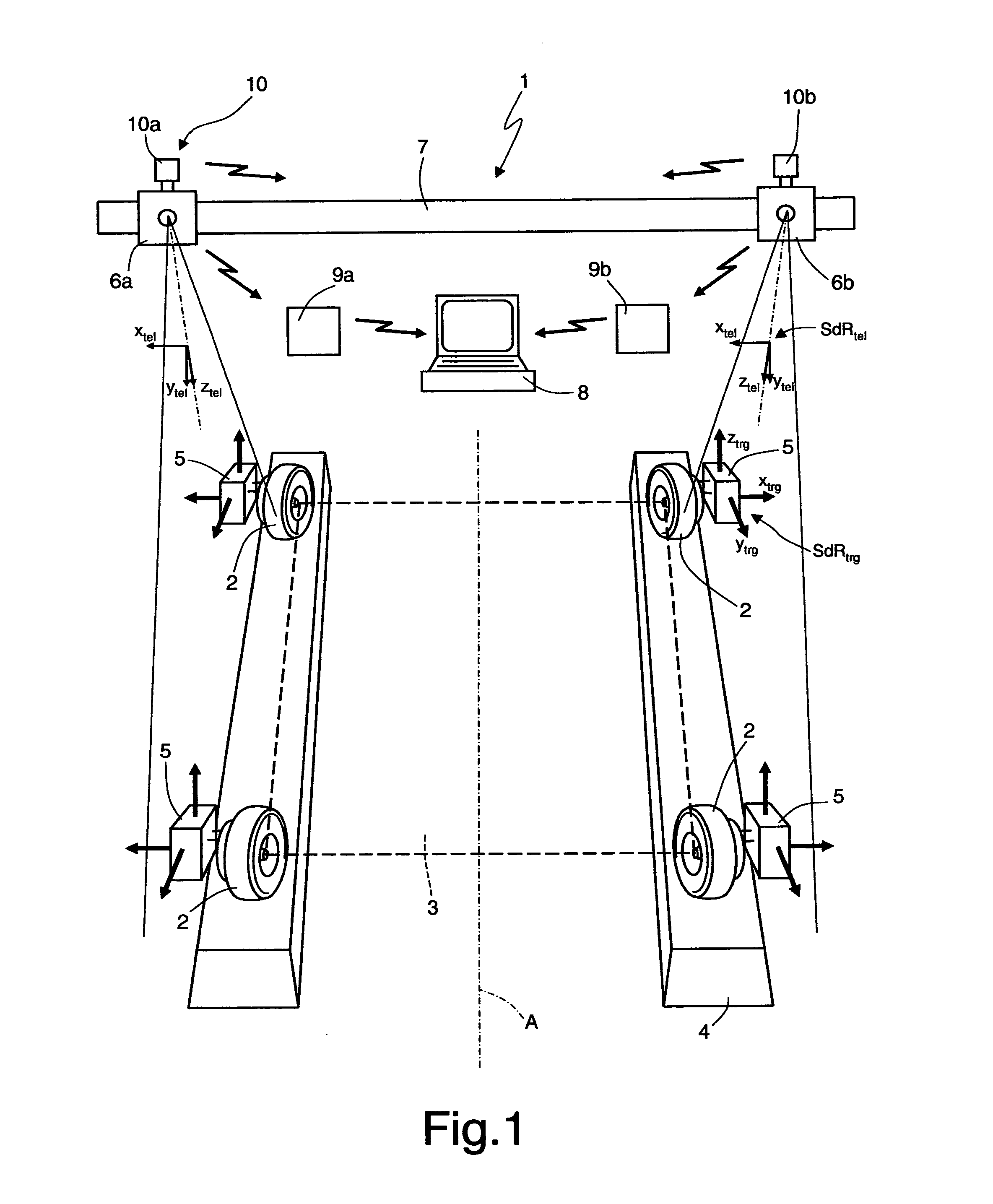

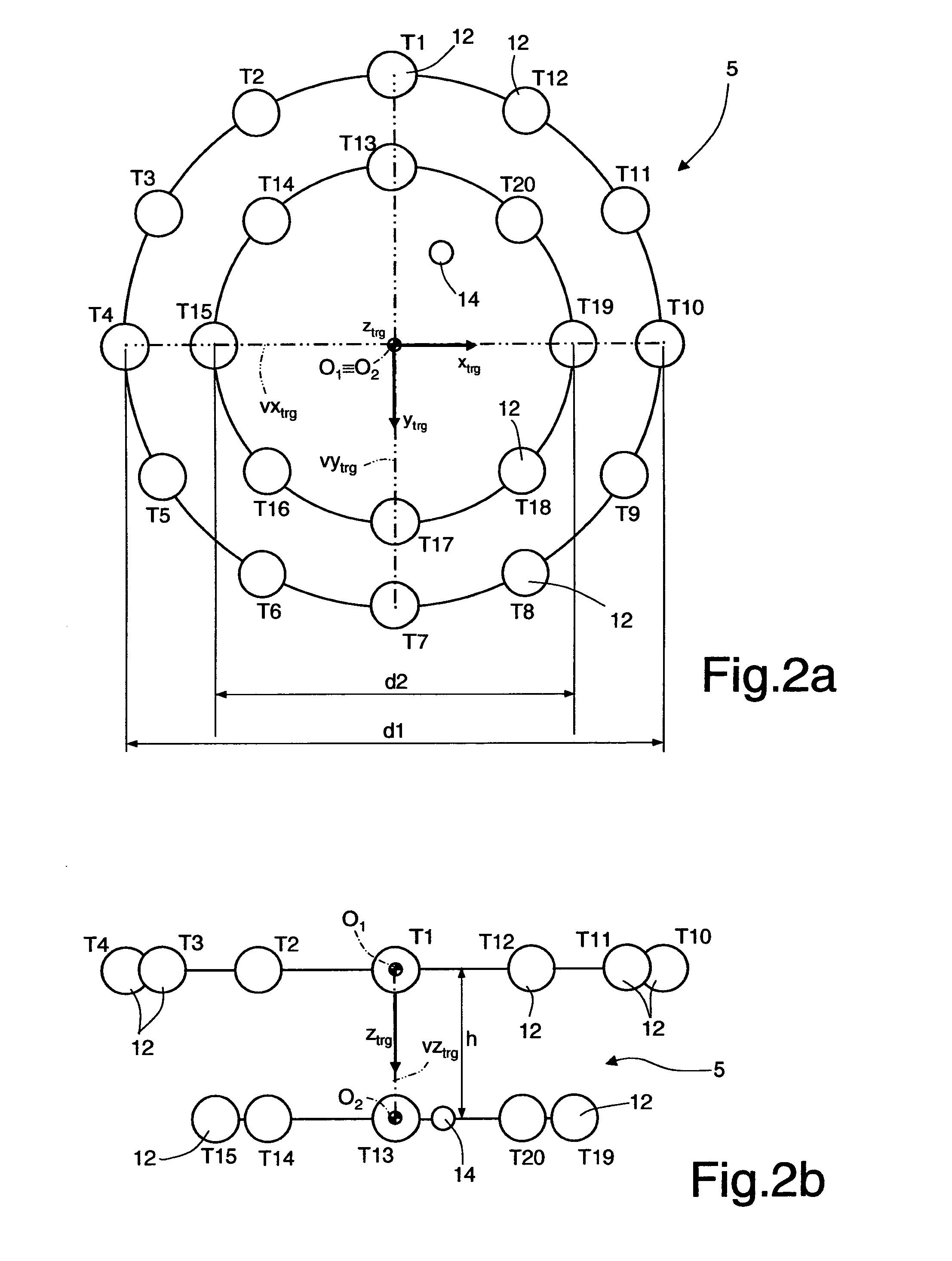

System and related method for determining vehicle wheel alignment

A system for determining the orientation of at least one first wheel of a vehicle and provided with: at least one first target integrally coupled to the first wheel, an image capturing device that acquires a first two-dimensional image of the first target and a processing device, operatively connected to the image-capturing device and processing the first two-dimensional image. The first target has a three-dimensional shape suitable for defining geometric quantities arranged according to a known three-dimensional arrangement; the processing device processes the first two-dimensional image to identify the projections of the geometric quantities and determine a spatial arrangement of the first target with respect to a reference system based on the geometrical characteristics of the projections, to determine the orientation characteristics of the first wheel.

Owner:SPACE S R L CON UNICO SOCIO

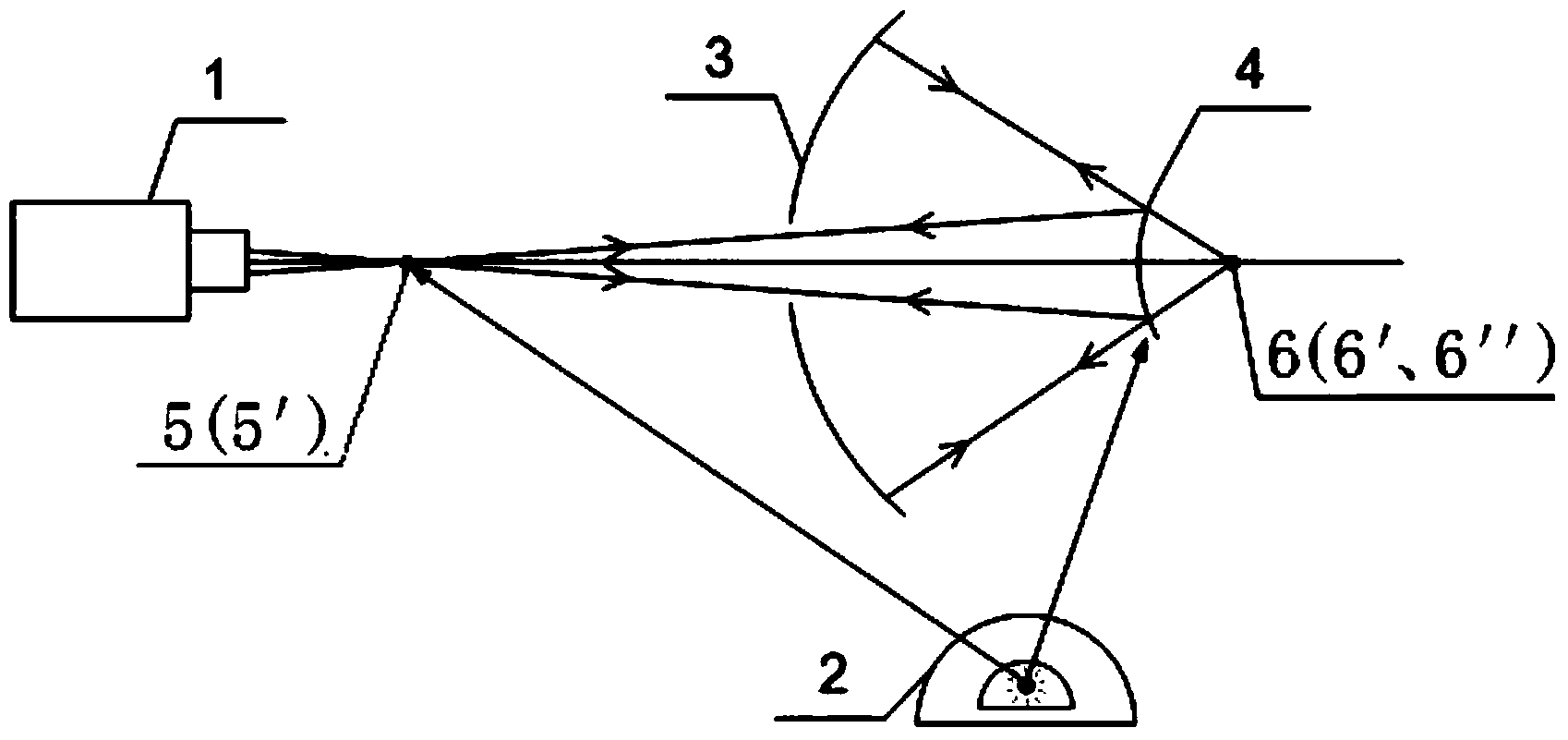

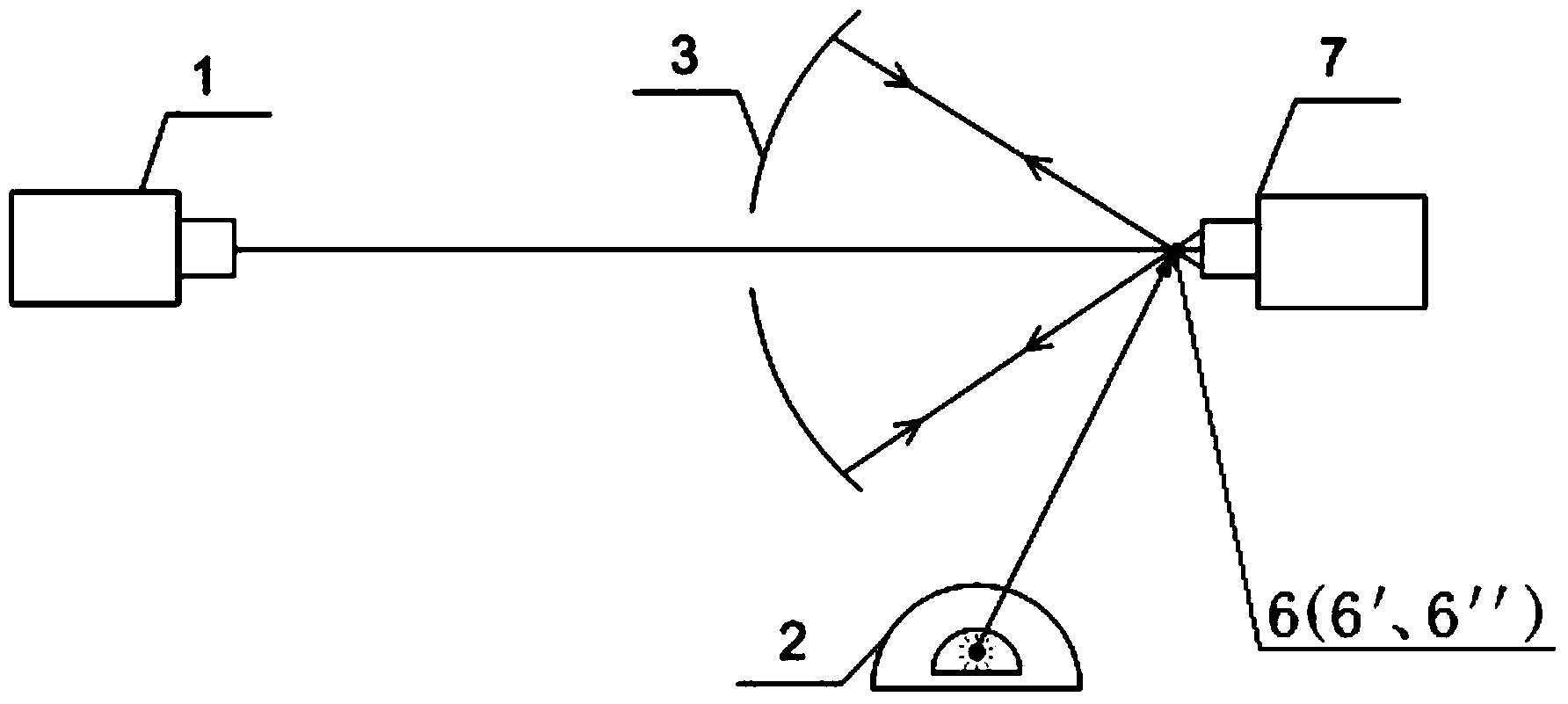

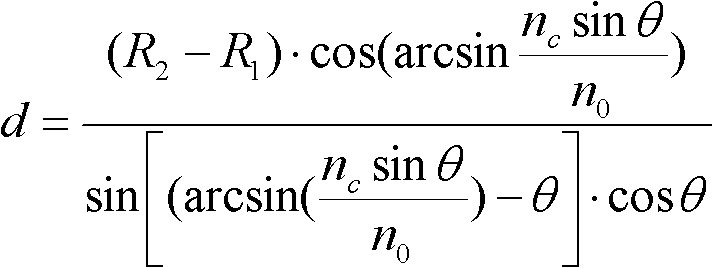

Non-contact measurement method for geometric parameters of optical part and measuring device thereof

The invention belongs to the field of non-contact optical measurement of geometrical quantities, and particularly relates to a non-contact measurement method for geometric parameters of an optical part and a measuring device thereof. The invention aims to overcome the defects of low speed, small dynamic range for measurement, high cost and inapplicability to on-line quick measurement in the priorart. In order to overcome the defects, the technical scheme provided by the invention is a non-contact measurement method for geometric parameters of an optical part, which comprises the following steps: modulating the collimated light by using an electric scanning optical switch to form annular collimated light, converging the collimated light through an axicon lens (Fresnel lens) to realize convergent points at different distances, collimating by utilizing the convergent points and identifying the surface of the optical part, thereby measuring the geometrical thickness and motion distance of the optical part and the center height of the optical lens. The invention has the advantages of low cost, high stability, simple instrument structure and easy processing, is suitable for quick on-line measurement, and can realize wider dynamic measurement range compared with spectral scanning instruments.

Owner:西安波谱致航光电科技有限公司

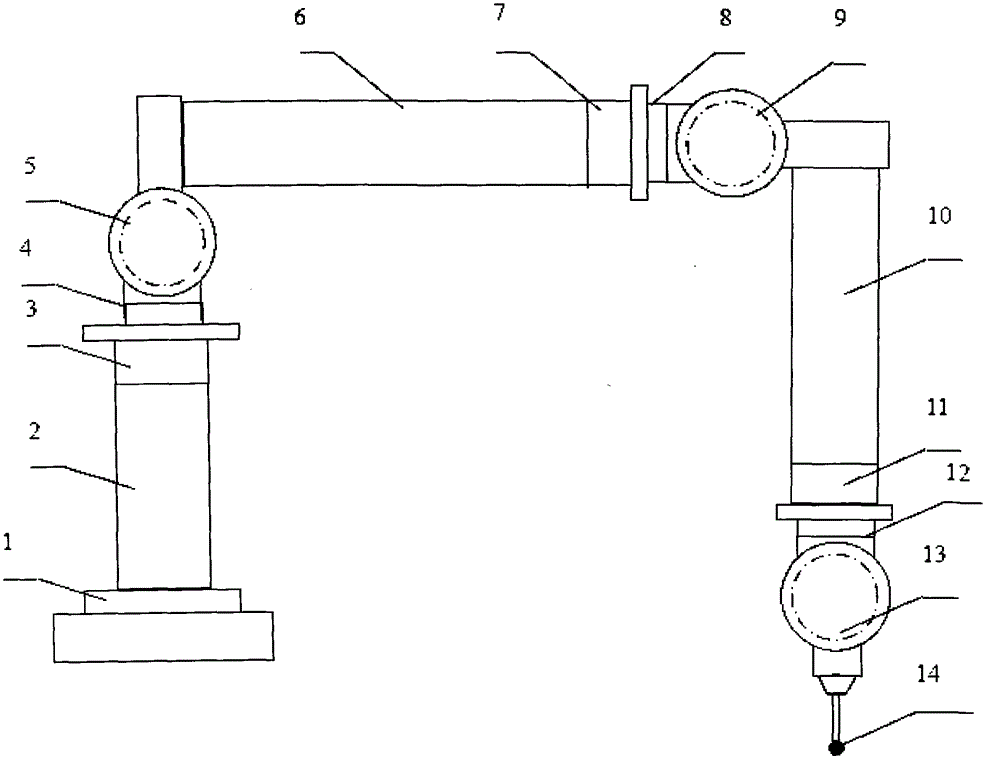

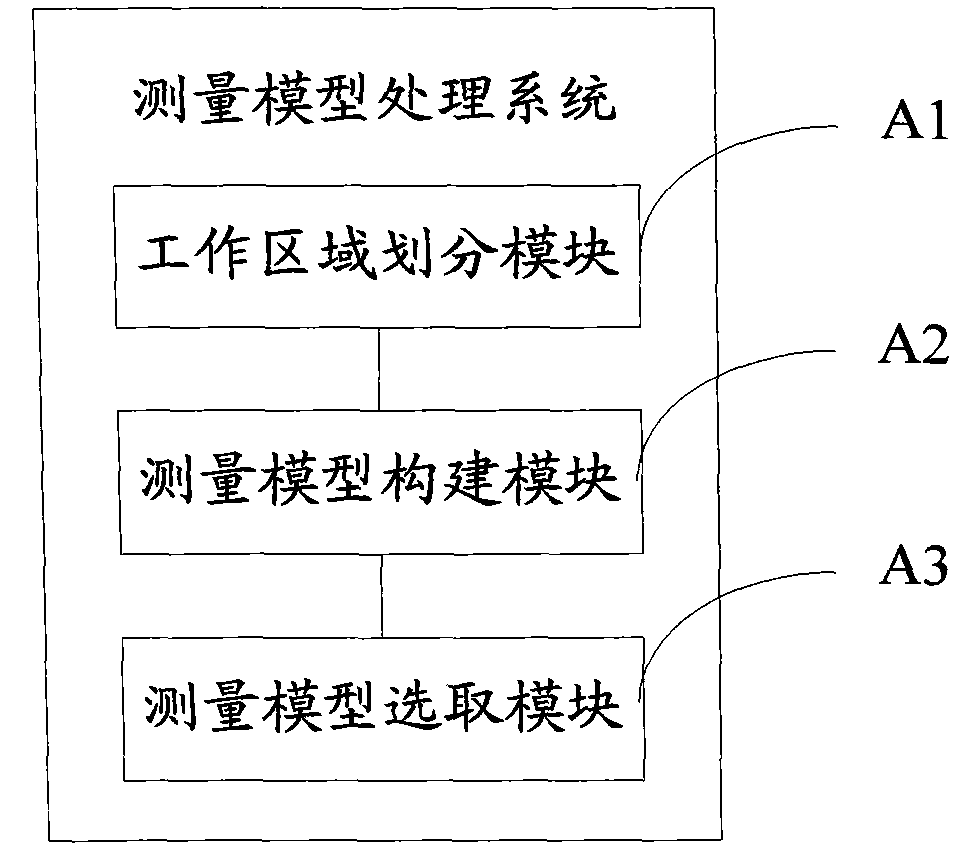

Articulated-arm three-coordinate measuring machine, multi-measuring model system and workpiece measuring method

InactiveCN104359436AHigh measurement accuracyReal-time automatic selection switchingMeasurement devicesModel systemCoordinate-measuring machine

The invention provides an articulated-arm three-coordinate measuring machine, a multi-measuring model system and a workpiece measuring method. The workpiece measuring method includes the steps: N subareas in measuring machine operating space are planned; a measuring model is built in each subarea, namely N measuring models are built in the operating space; a measurement step includes determining the subarea where a workpiece locates and automatically switching the measuring models corresponding to the subareas in real time; the measuring models are used to calculate geometric coordinates of the workpiece. The articulated-arm three-coordinate measuring machine, the multi-measuring model system and the workpiece measuring method have the advantage that measuring precision of the articulated-arm three-coordinate measuring machine can be improved with no hardware manufacturing cost increased.

Owner:JINGGANGSHAN UNIVERSITY

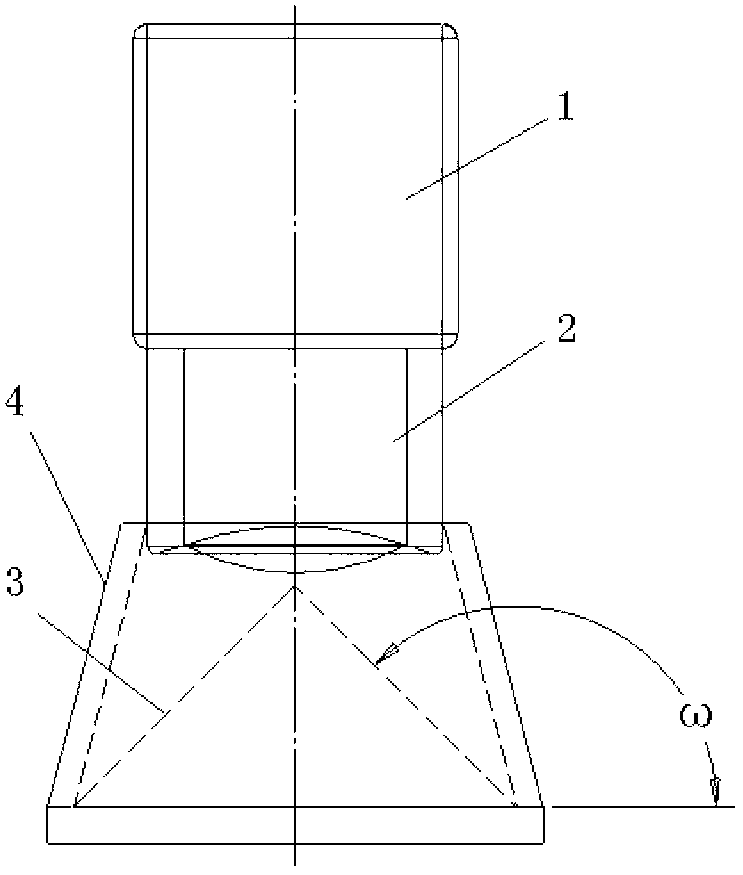

Body surface three-dimensional topographic information measuring device

InactiveCN1888817ACompact structureReduce adjustment and positioning workUsing optical meansMeasurement deviceDetector array

Object surface three-dimensional morphology communication measuring equipment relates to a kind of geometry value equipment, especially to a kind of equipment to measure the three-dimensional morphology communication to object surface. It adopts single beam of light, single photoelectric measuring parts of an apparatus to solve the measuring problem about the slope of the object surface, offering one concept based on non-diffract light and using one new laser triangular surveying method. It relates to laser, collimating optics system, constant waist right-angle prism, two eddy prisms, circularity inner-reflector and photoelectric detector array. The collimating optics system sets in front of the single beam of light coming from the laser. The right-angle part of the constant waist right-angle prism aims at the incidence aspect of the collimated single beam of light. The center axes of the two eddy prisms are the same axes. The center of ball and symmetry axes to the circularity inner-reflector is on the center axes of the eddy taper prisms. The photoelectric detector array sets on the imaging base point of the eddy taper prisms.

Owner:XIAMEN UNIV

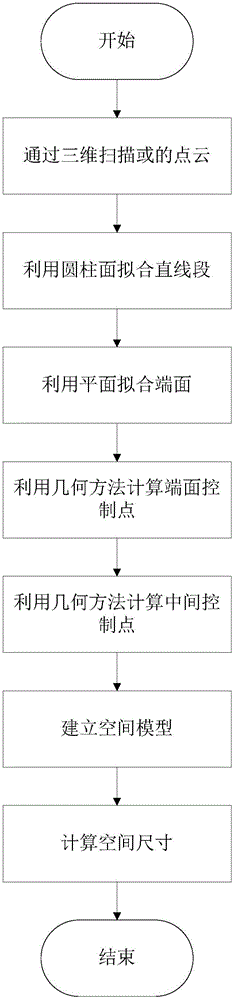

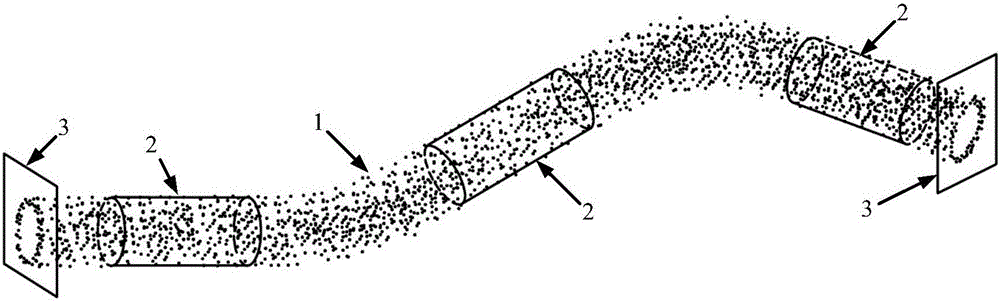

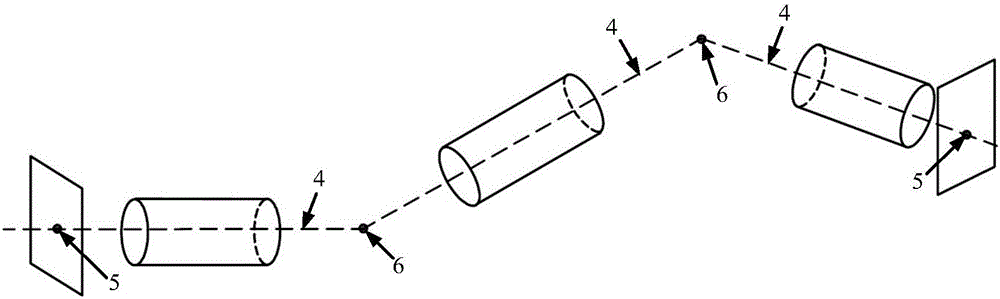

Method for measuring space size of hydraulic pipeline

ActiveCN105973149AImprove measurement efficiencyReliable means of measurementUsing optical meansPoint cloudEngineering

The invention relates to a method for measuring the space size of a hydraulic pipeline. According to the method, the actual surface of the measured hydraulic pipeline is converted into a point cloud by utilizing a photographing type three-dimensional scanner, then a hydraulic pipeline space model is constructed based on the point cloud, and finally geometric measurement is performed on the hydraulic pipeline space model so that the space size of the measured hydraulic pipeline is obtained. A new reliable measurement means is provided for controlling the geometric forming quality of the hydraulic pipeline so that the measurement accuracy of the space size of the hydraulic pipeline can be guaranteed, and the measurement efficiency of the hydraulic pipeline can also be enhanced. Meanwhile, the provided method for measuring the space size of the hydraulic pipeline based on three-dimensional scanning is a flexible method, and arrangement of multiple measuring tools is not required so that measurement for the size of the hydraulic pipelines of various pipe diameters can be supported.

Owner:BEIJING MECHANICAL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com