Non-contact measurement method for geometric parameters of optical part and measuring device thereof

A technology of non-contact measurement and optical parts, which is applied in the field of non-contact optical measurement of geometric quantities, and can solve problems such as slow speed, small dynamic range of measurement, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1, see figure 2 and image 3 .

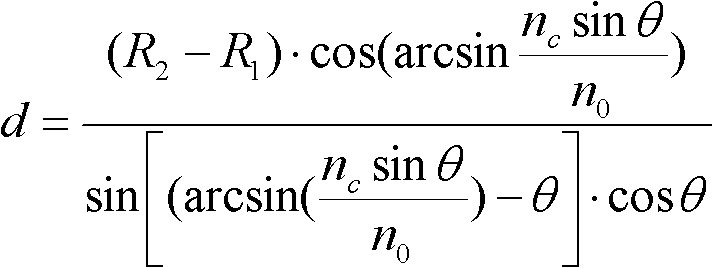

[0045] A non-contact measurement method for the thickness of an optical part. The optical switch drive 6 is controlled by the control and calculation unit 8 to drive the optical switch to form a transmission band 11 whose diameter decreases / increases successively, and the parallel light passing through the optical switch forms an annular band Parallel light, then the converging point after passing through the lens moves backward / forward sequentially along the optical axis direction, when the converging point is aimed at the upper and lower surfaces of the part, the optical path returns symmetrically to the original path, and energy peaks appear twice on the detector 9 , the two peaks appear one by one corresponding to the radius of different annular light bands, then the geometric thickness of the optical flat part to be tested is calculated according to the following formula:

[0046] d = ...

Embodiment 2

[0050] Example 2, see Figure 5 .

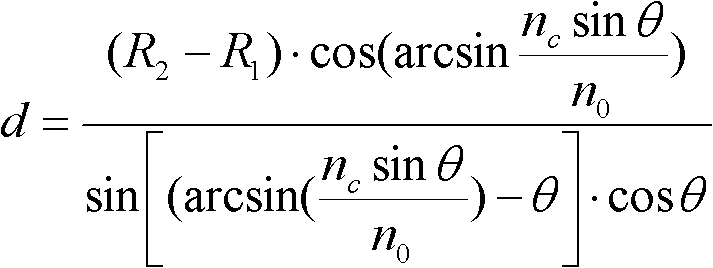

[0051] A non-contact measurement method for the moving distance of optical parts, through the control and calculation unit 8 to control the optical switch drive 6 to drive the optical switch to form a transmission zone 11 whose diameter is reduced / increased once, and the parallel light passing through the optical switch forms an annular zone shape parallel light, then the converging point after passing through the lens moves backward / forward in turn along the optical axis direction, aim at a surface of the part twice before and after the movement, record the energy change on the detector, and obtain the light band corresponding to the peak energy Radius, then the moving distance of the optical part 10 to be measured is:

[0052] d = ( R 2 - R 1 ) ...

Embodiment 3

[0054] Example 3, see Figure 6 .

[0055] A non-contact measurement method for the center height of an optical lens. The optical switch drive 6 is controlled by the control and calculation unit 8 to drive the optical switch to form a transmission band 11 whose diameter is reduced / increased once, and the parallel light passing through the optical switch forms a ring Strip parallel light, then the converging point after passing through the lens moves backward / forward in sequence along the optical axis. At a certain light band radius, after being focused by the axicon lens, the converging point is aimed at the front surface, the light path returns symmetrically, and an energy peak appears on the detector 9, record the radius R of the light band at this moment 1 , the radius of the light band continues to increase, and the converging point is far away from the optical system. When the light band passes through the front surface and just converges on the back surface, the light p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com