Test equipment calibration device and calibration method thereof

A technology of testing equipment and calibration devices, applied in the direction of instruments, etc., can solve the problems of single function, unfavorable popularization and application, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

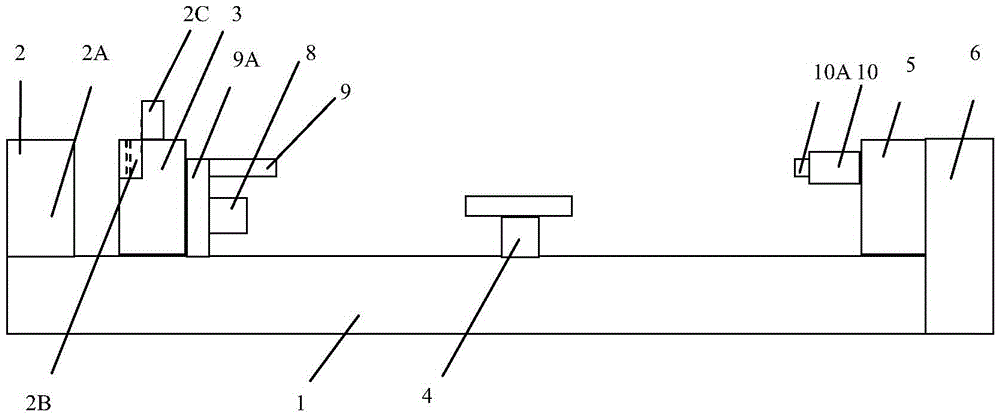

[0053] Embodiment 1, the calibration of the large-scale test equipment of the length measurement class (the initial value of 7000mm of the telescoping ruler whose measurement range is 70000mm~12000mm) includes the following steps:

[0054] 1. Adjust the laser head 2A so that its optical axis is parallel to the axis of the guide rail, and the optical axis of the laser head is used as the reference axis, and record the distance H between the axis of the equipment being calibrated and the reference axis 1 =100mm, the axis of the equipment to be calibrated is the axis of the movable measuring head 9 and the measuring head 10A;

[0055] 2. Drive the headstock 3 along the X axis, so that the movable measuring head 9 contacts the measuring head 10A of the fixed measuring rod 10 on the tailstock 5, and the measuring axis of the measuring head 10A is adjusted to the measuring axis of the movable measuring head 9 After being coaxial, it is set to the initial zero position by the process...

Embodiment 2

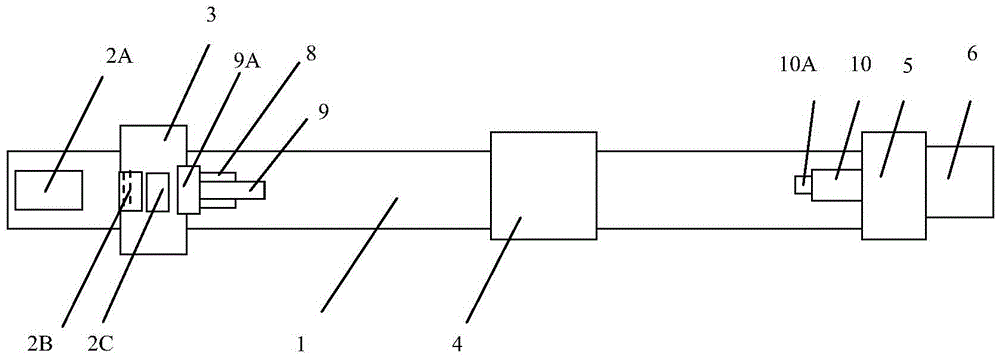

[0061] Embodiment 2, to the calibration of line pattern class large-scale test equipment (inductive synchronizer ruler 0~5000mm pitch size), comprises the following steps:

[0062] 1. Adjust the laser head 2A so that its optical axis is parallel to the axis of the guide rail, and the optical axis of the laser head is used as the reference axis;

[0063] 2. Drive the head seat 3 to the limit position to the left, place the equipment to be calibrated on the working table of the guide rail 1, adjust the measurement axis of the equipment to be calibrated along the Y direction so that it is coaxial or parallel to the reference axis, and record the measurement of the equipment to be calibrated The distance H between the axis and the reference axis 2 = 400mm, the measuring axis of the equipment to be calibrated is the axis of large-scale testing equipment such as lines;

[0064] 3. Drive the head seat 3 along the X direction and adjust the industrial COMS camera 8 along the Z direct...

Embodiment 3

[0069] Embodiment 3, to the calibration method of large-scale three-dimensional test equipment (laser radar measuring system 0~18000mm measuring range), comprises the following steps:

[0070] 1. Adjust the laser head 2A so that its optical axis is parallel to the axis of the guide rail, and the optical axis of the laser head is used as the reference axis;

[0071] 2. Place the equipment to be calibrated on the left or right end of the guide rail of the calibration device, and adjust the position of the equipment to be calibrated so that its axis is coaxial or parallel to the reference axis; at the same time, fix the target ball or target of the equipment to be calibrated on the head seat 3, make the equipment to be calibrated in working condition and record the projection H of the distance between the axis of the equipment to be calibrated and the reference axis on the XOY plane 3 =100mm, the projection H on the XOZ plane 4 = 100mm;

[0072] 3. According to the working stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com