Patents

Literature

62 results about "Head First" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A direction of movement in which a person's head leads the way.

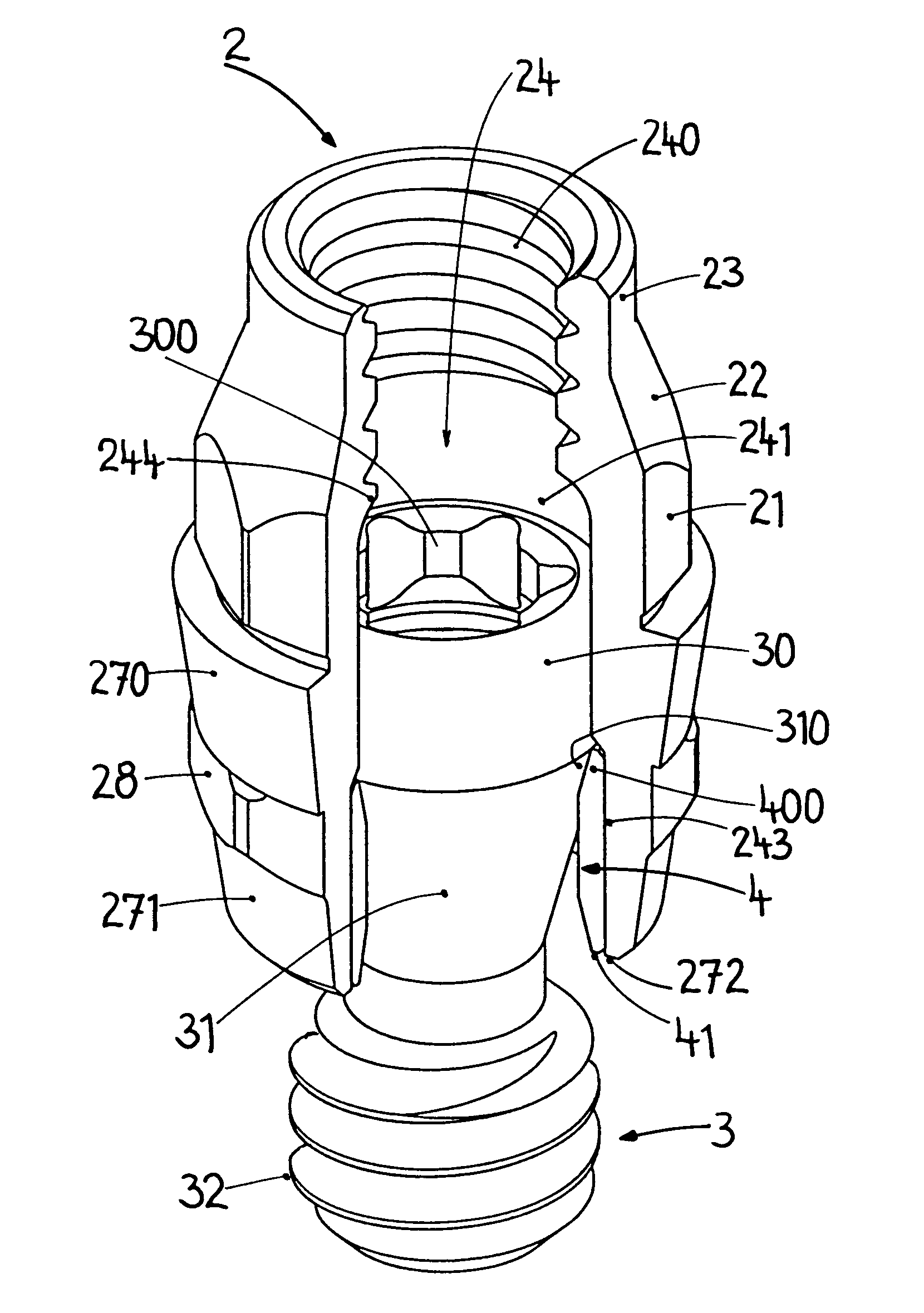

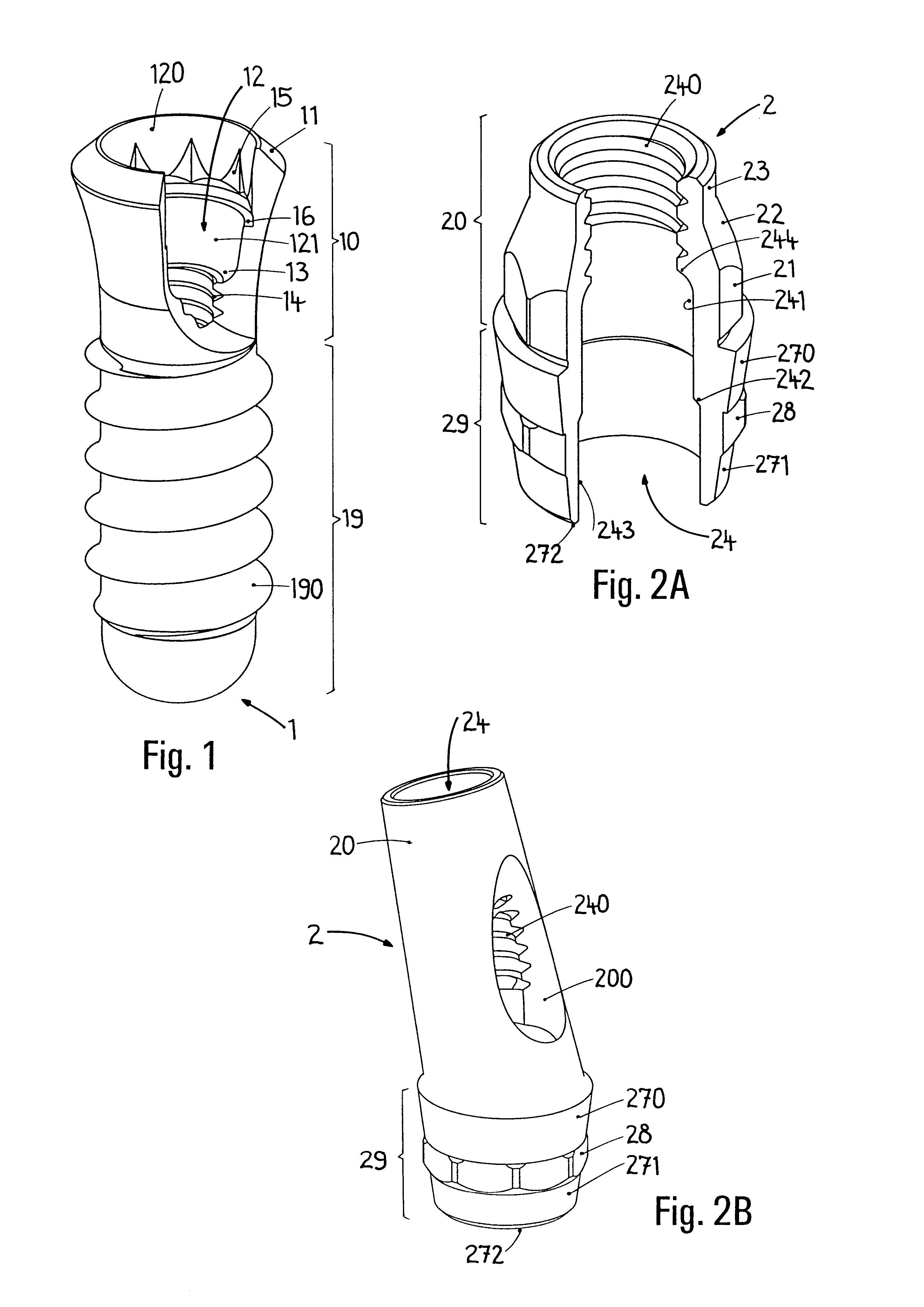

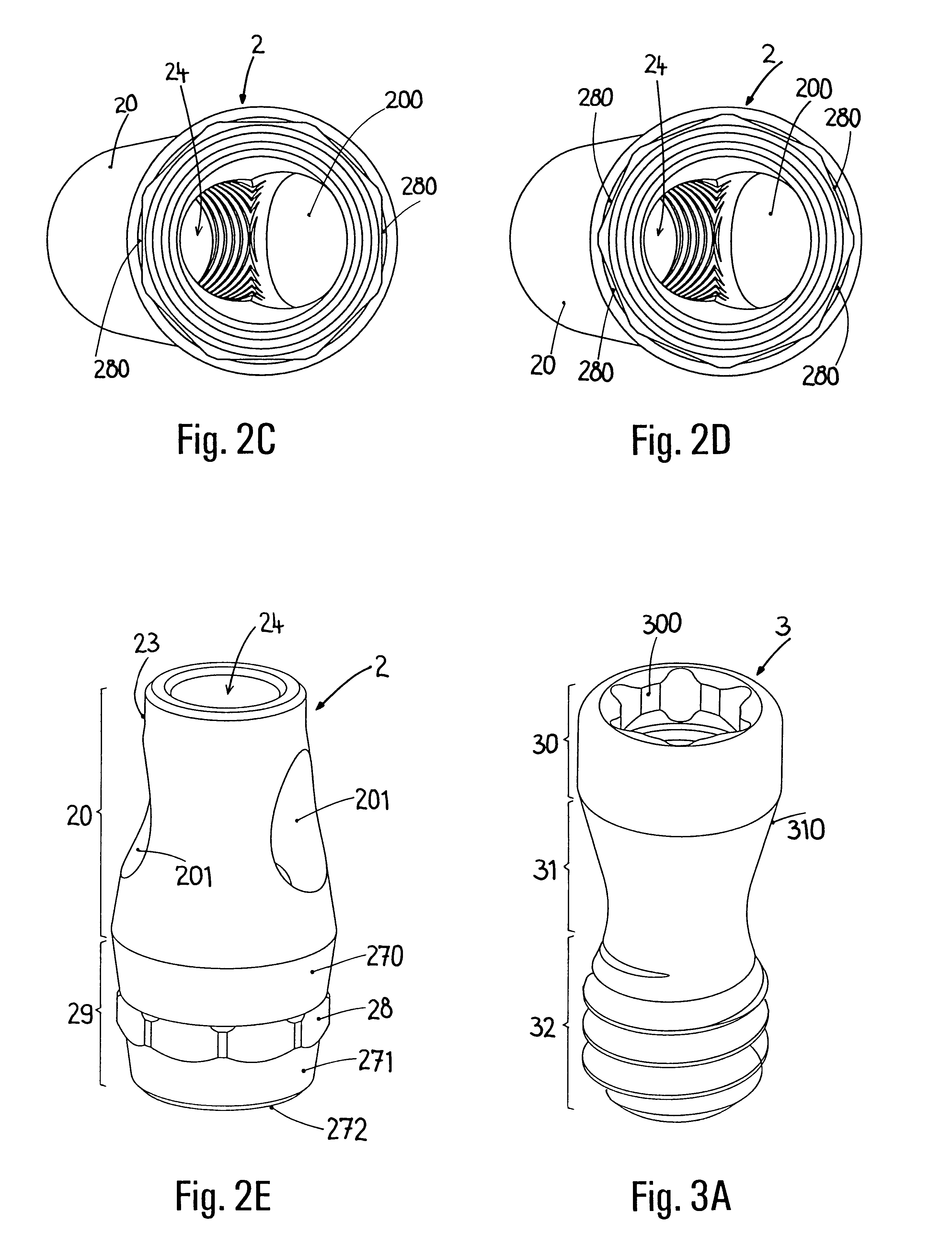

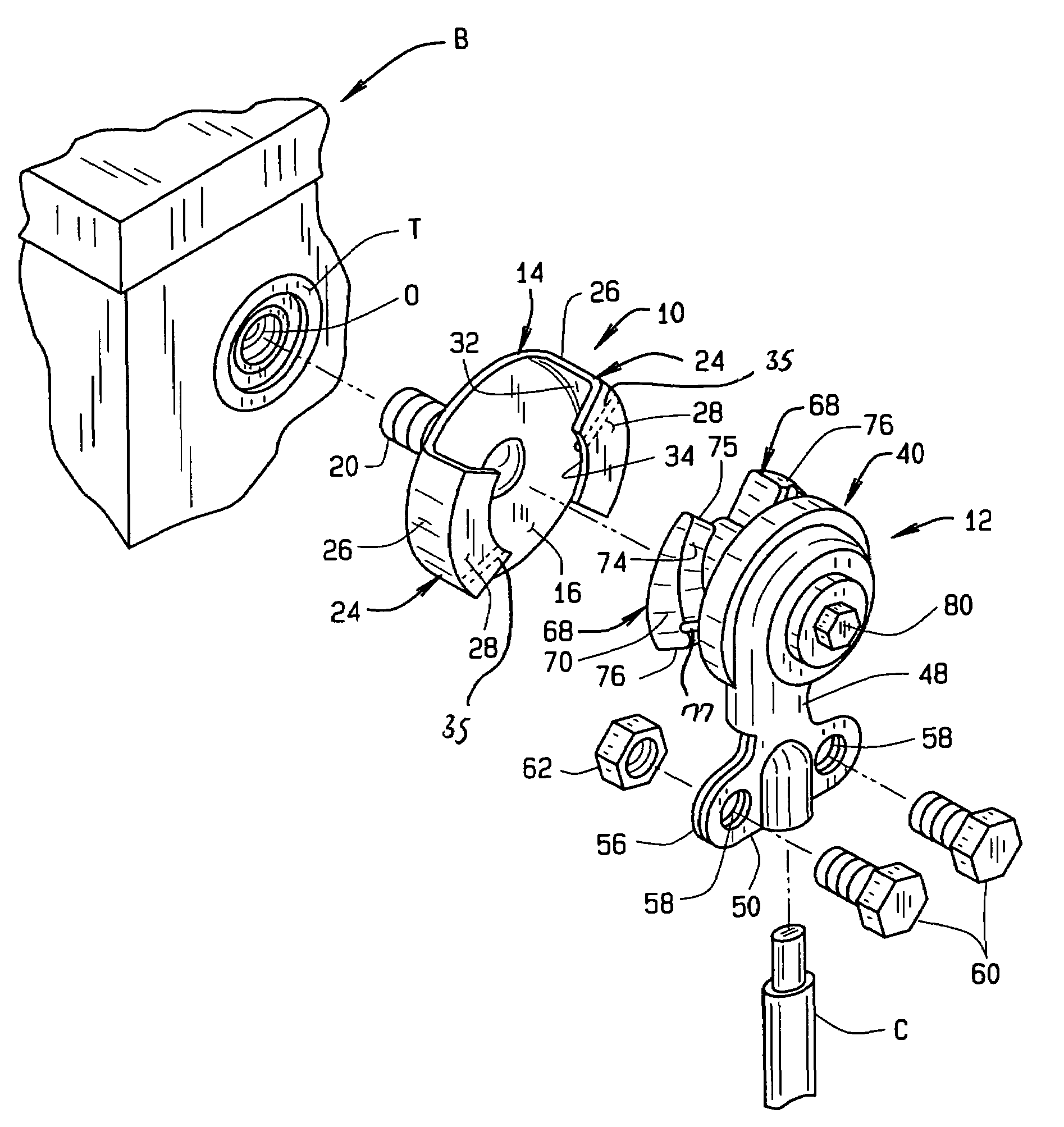

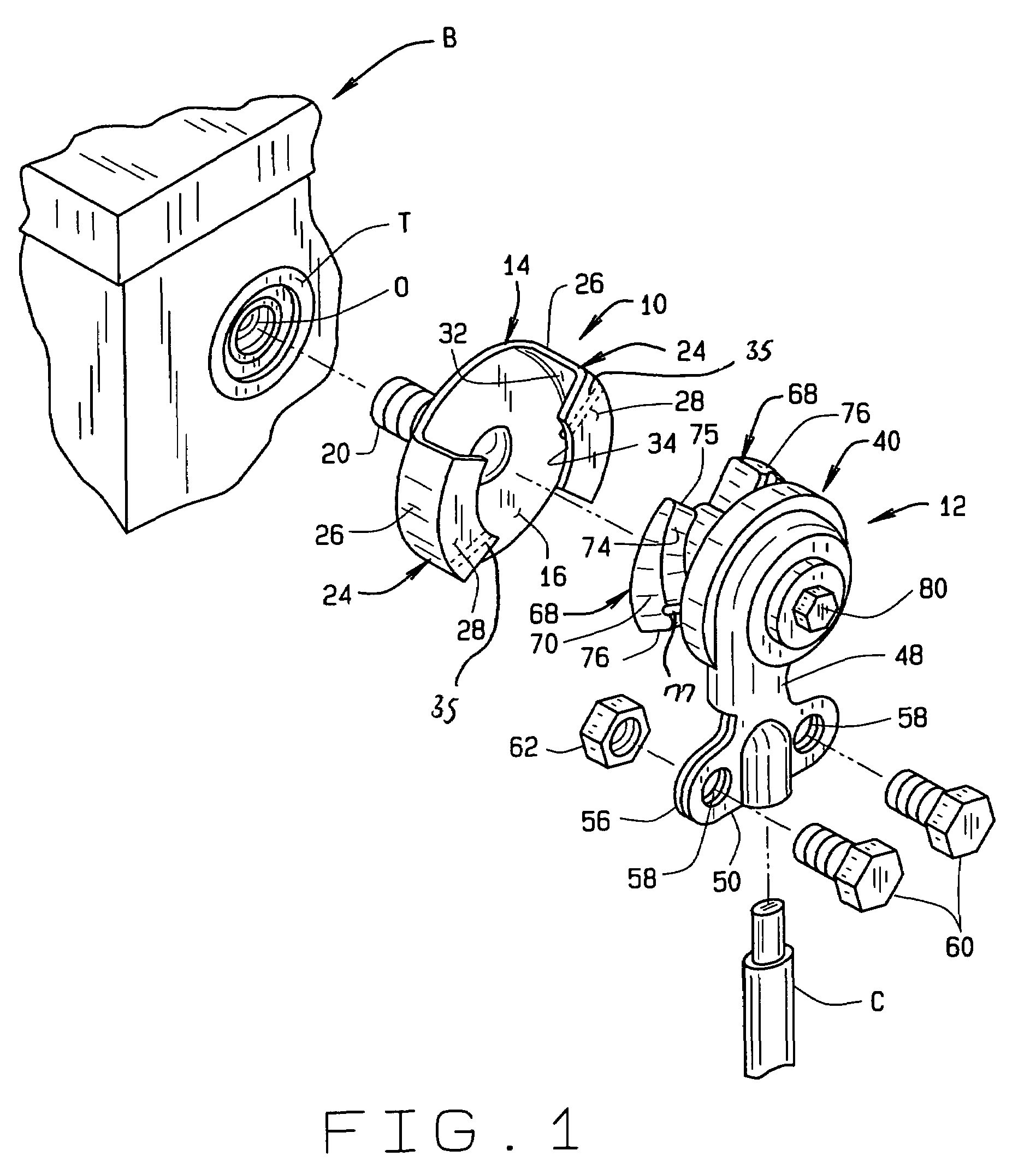

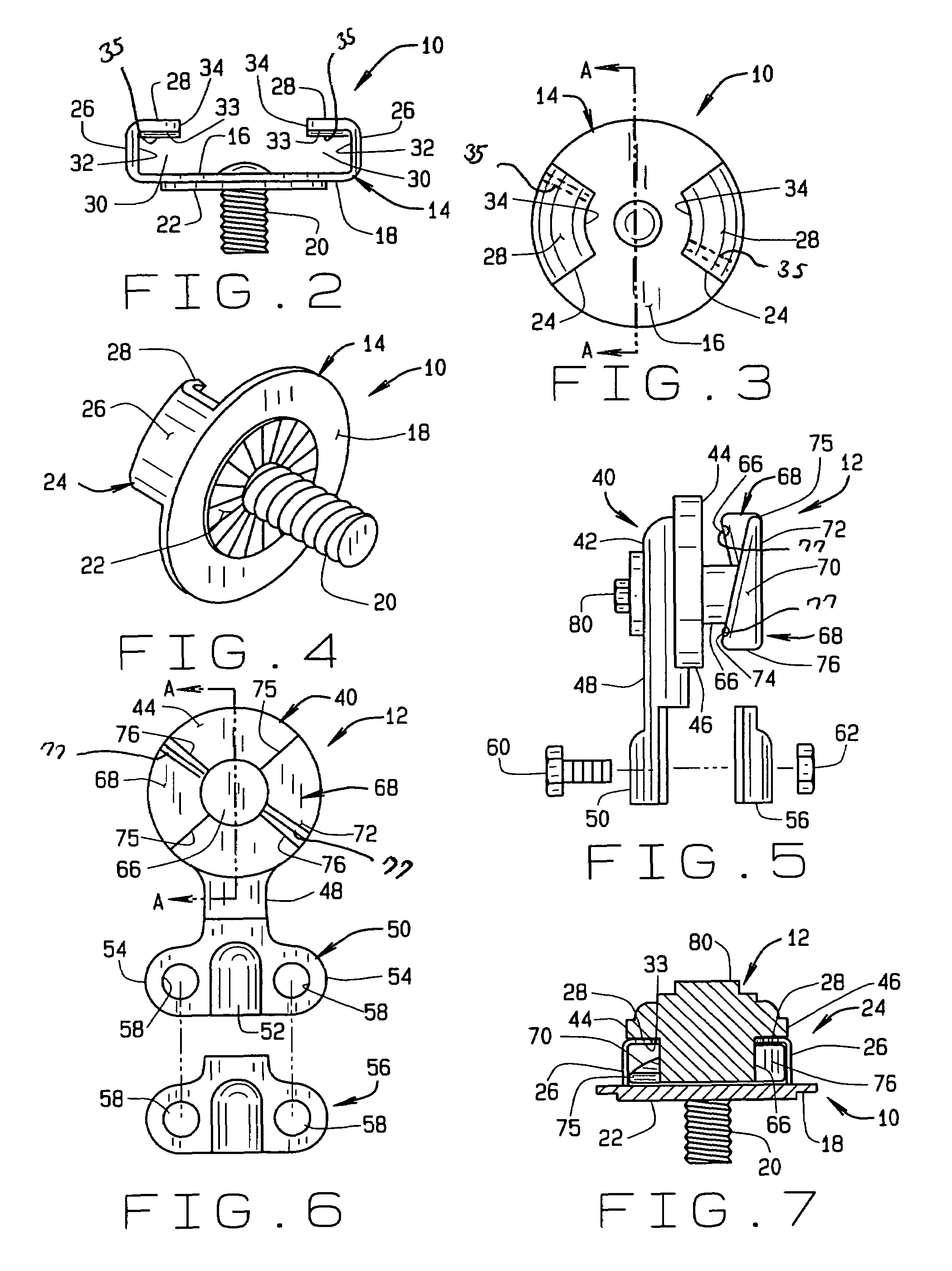

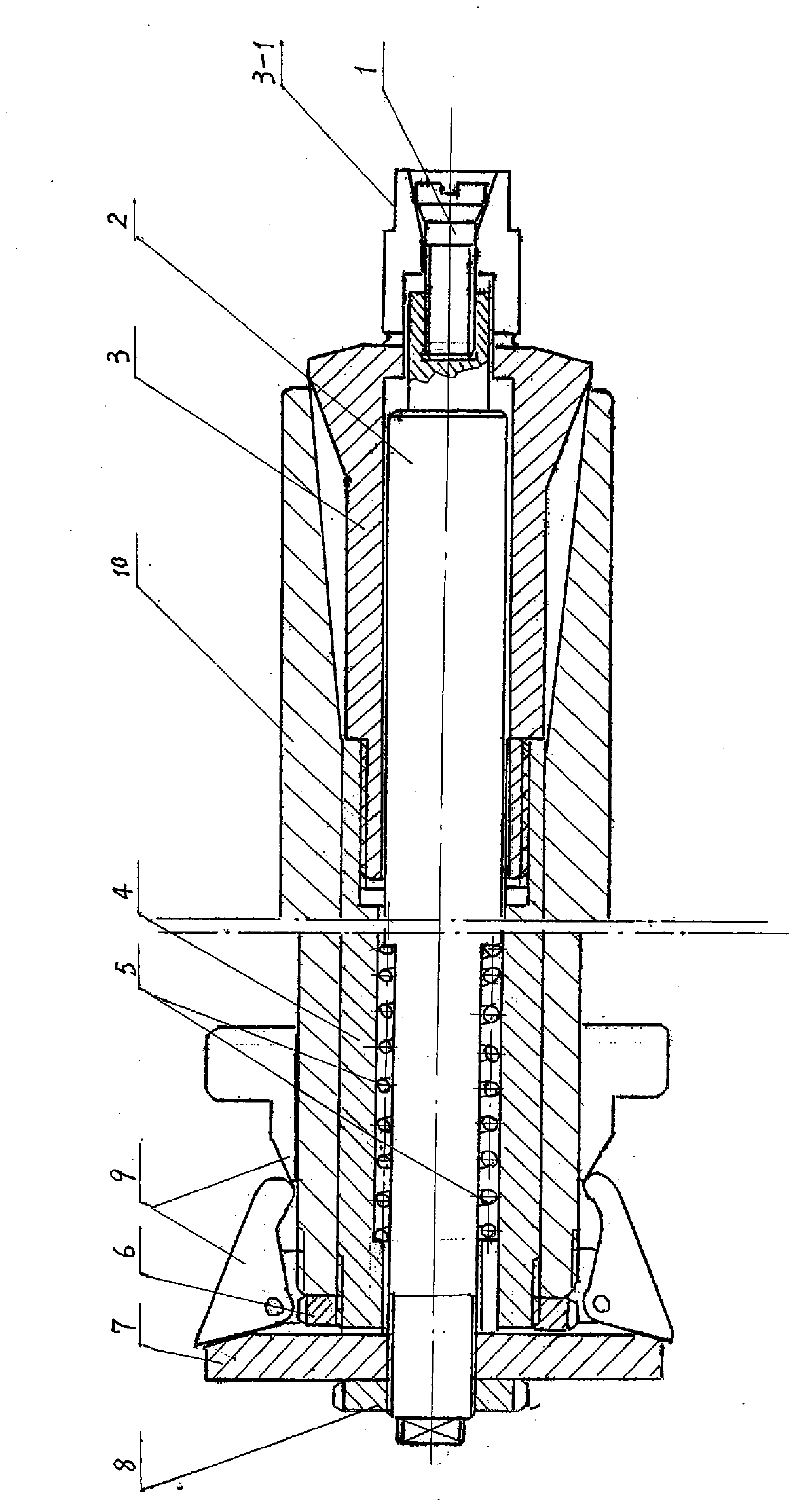

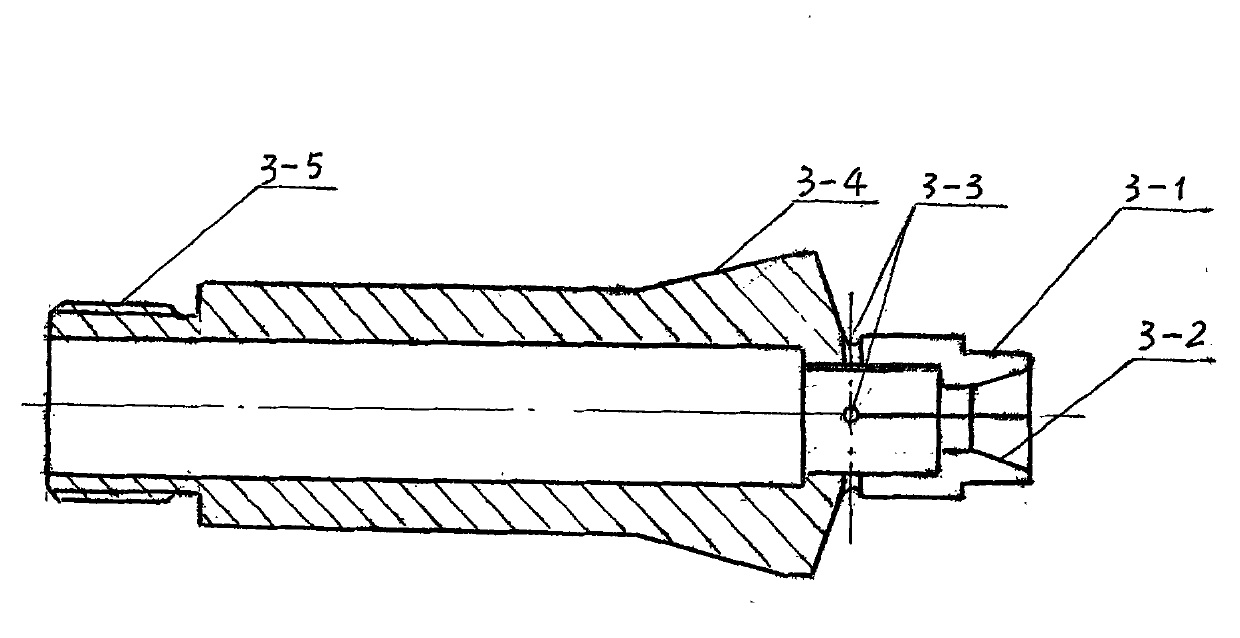

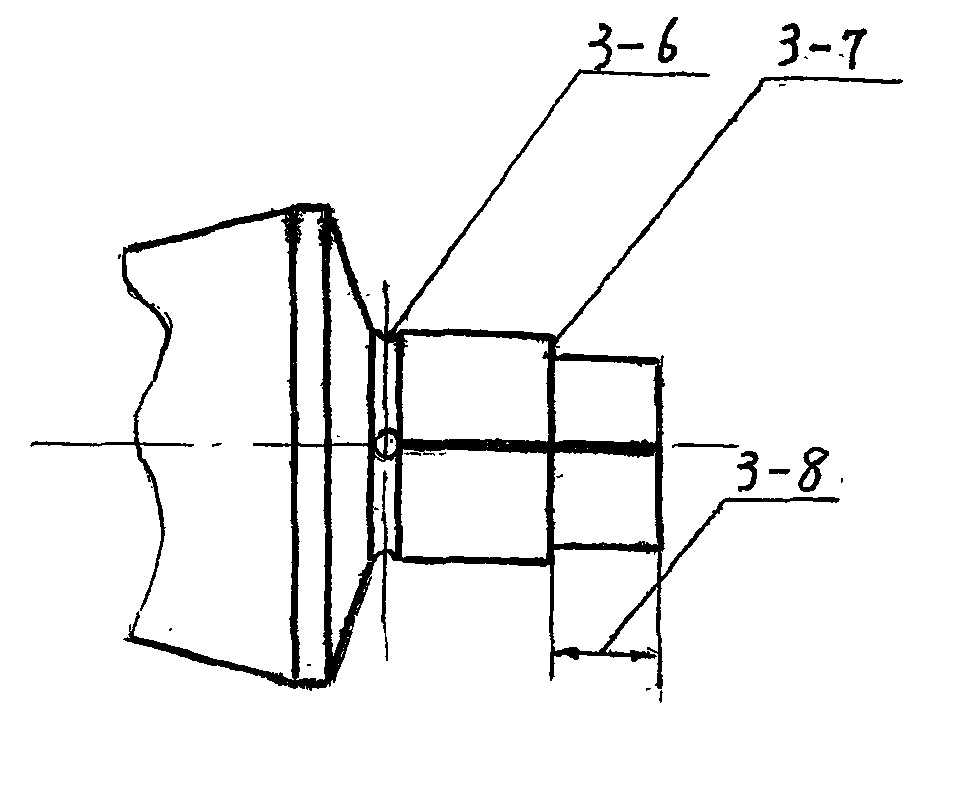

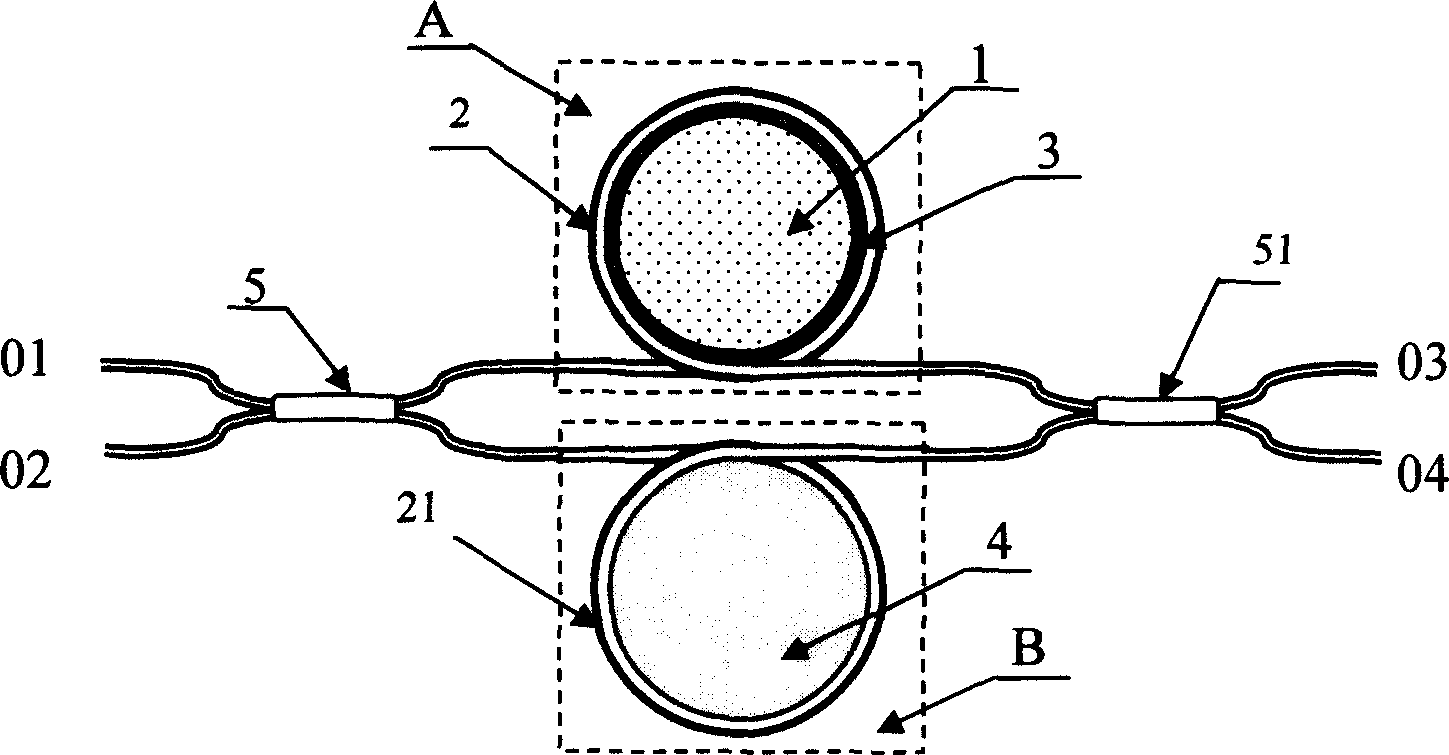

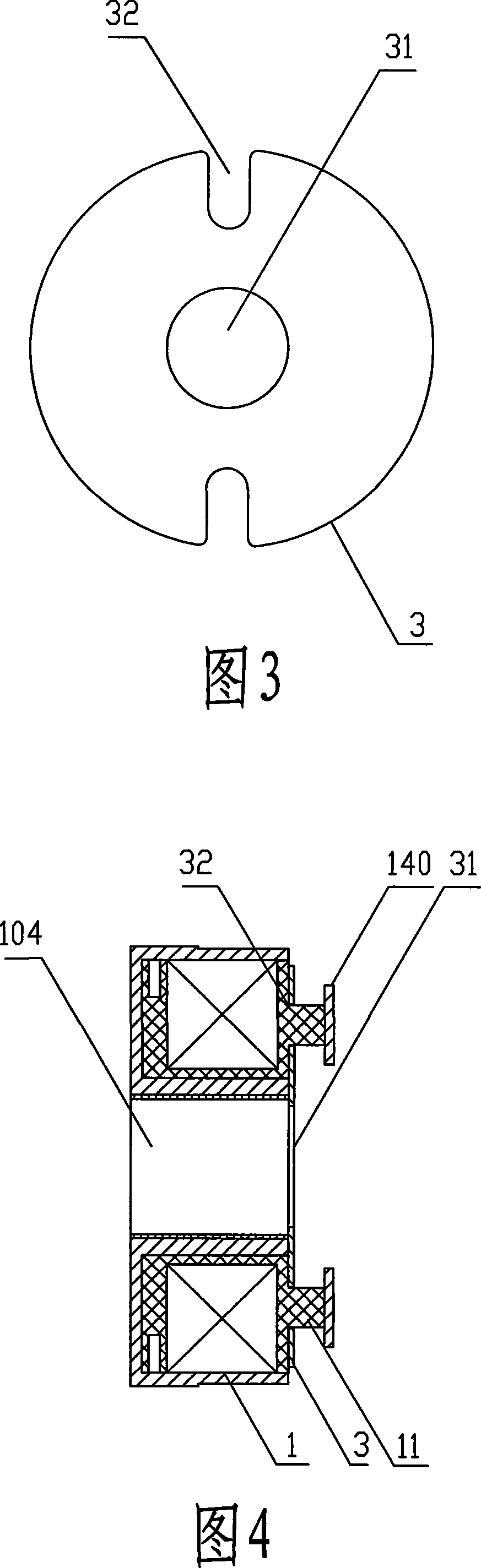

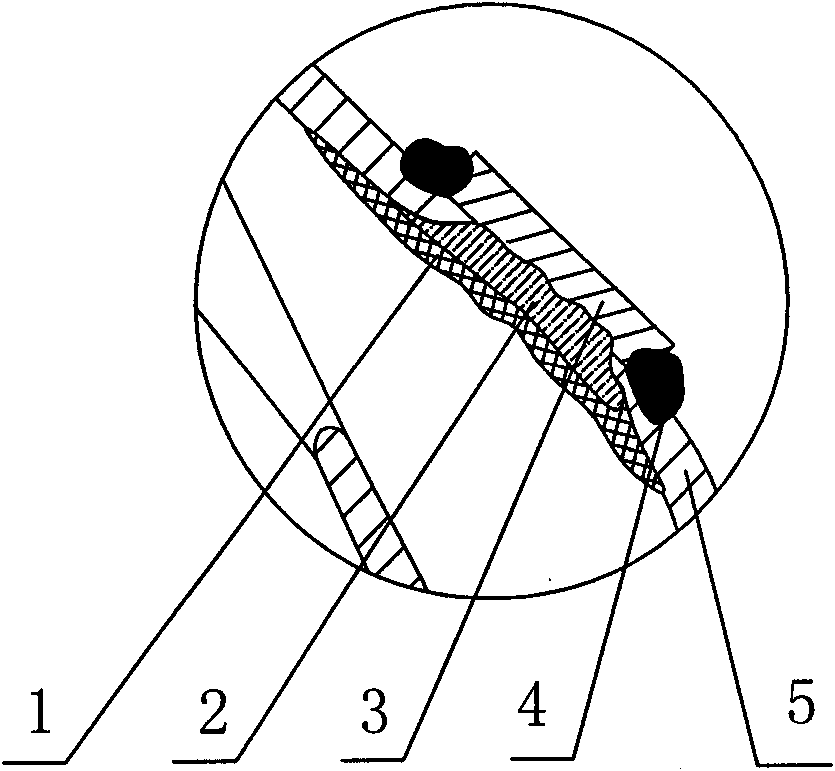

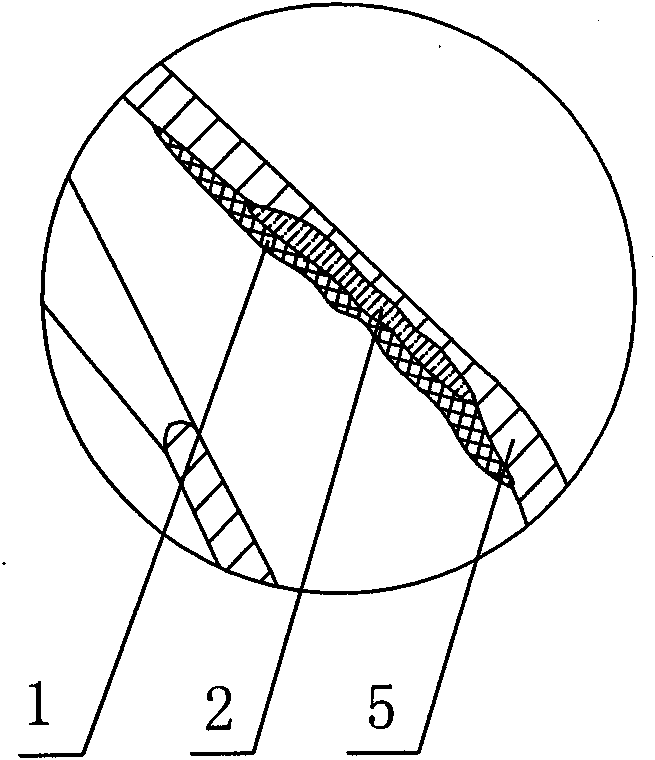

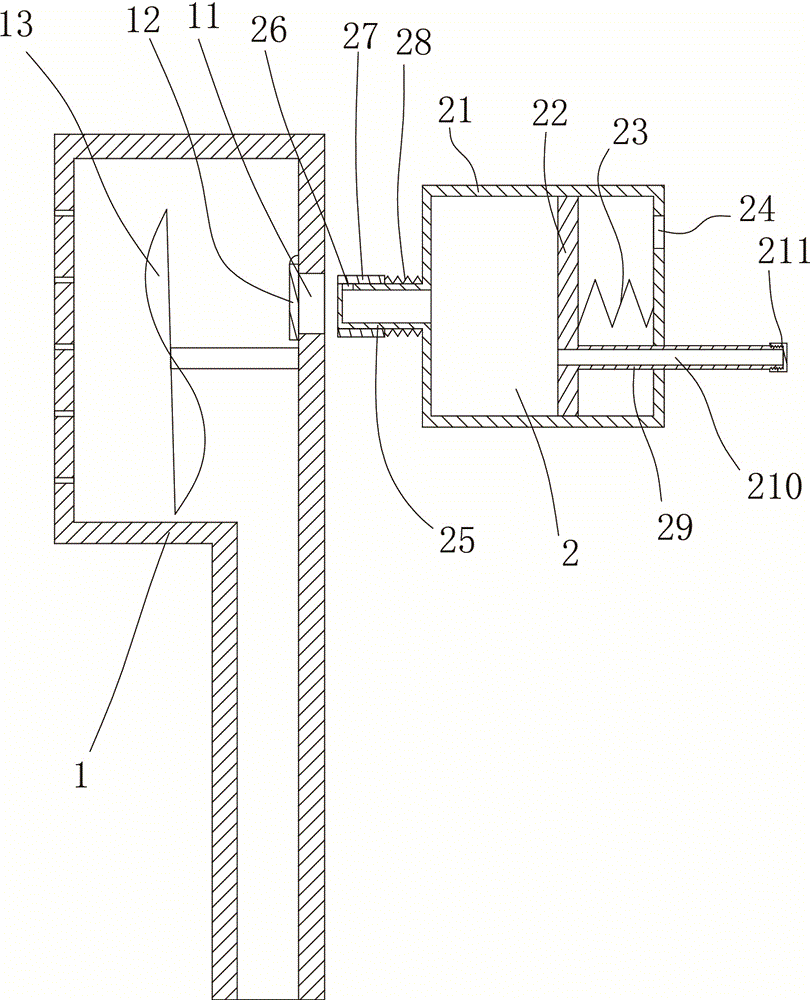

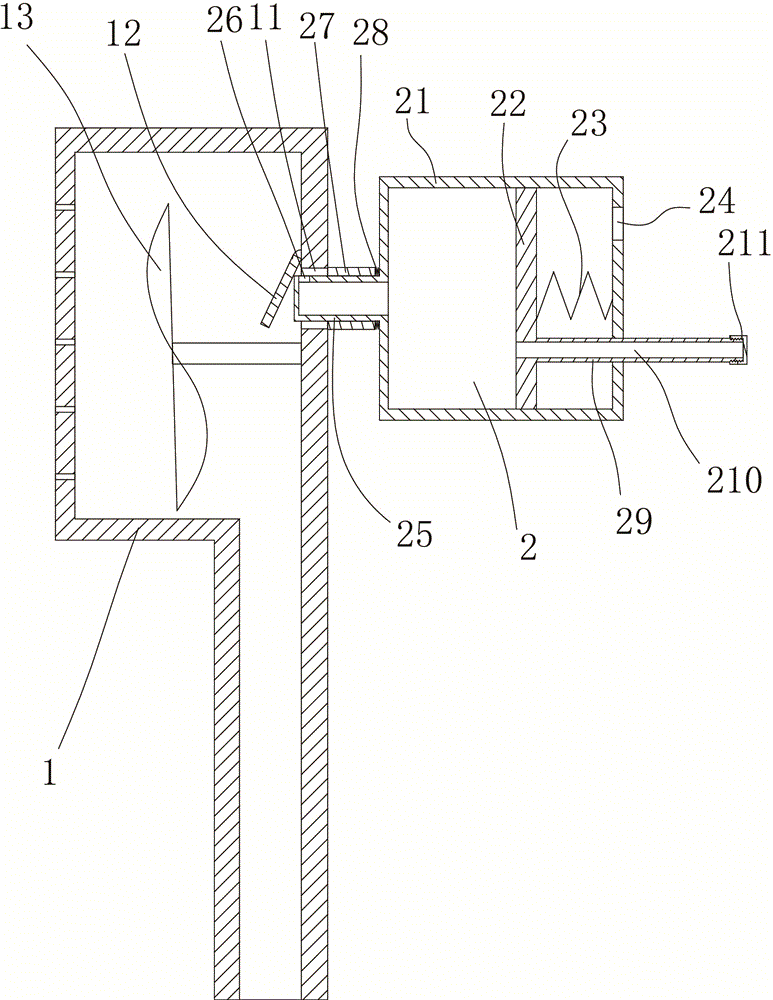

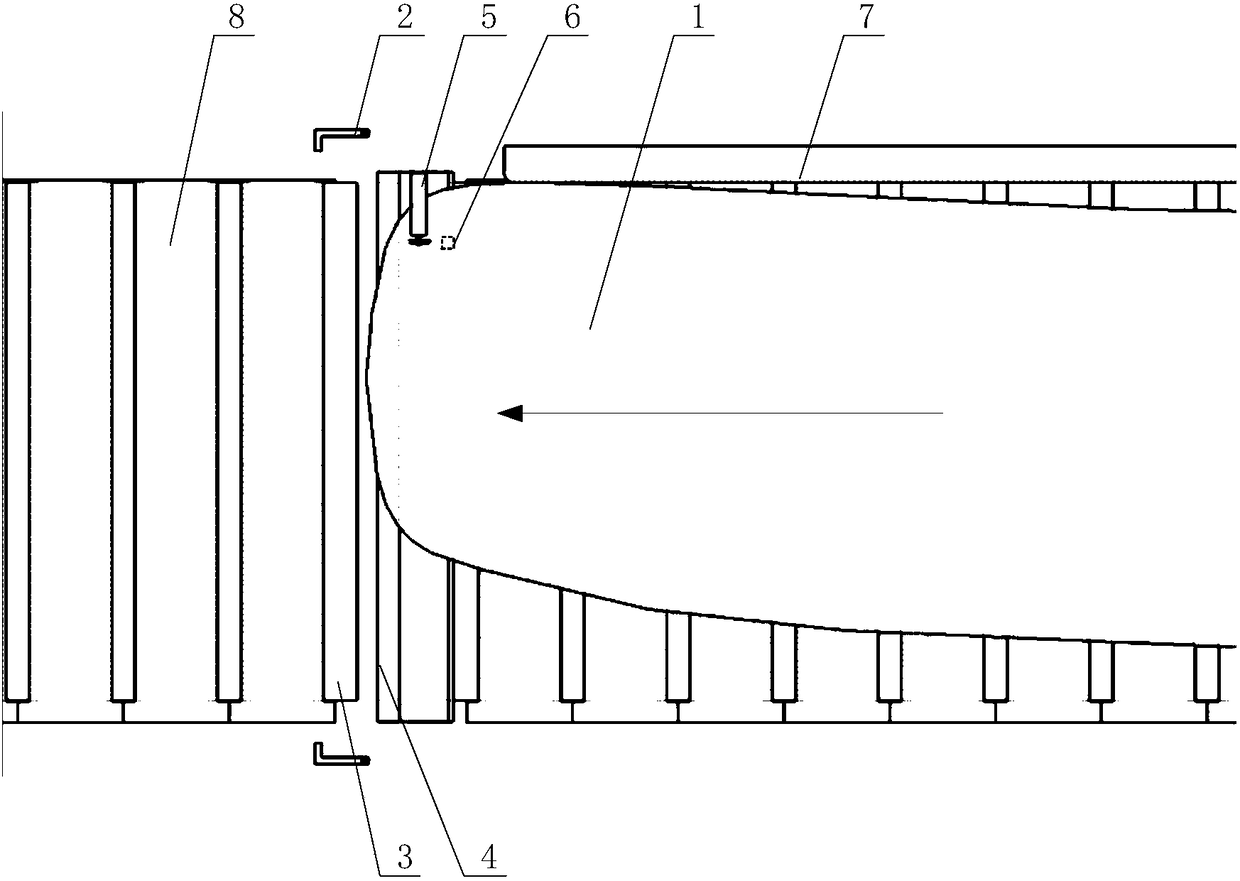

Connection between a dental implant and an abutment

InactiveUS6663388B1Increased functional reliabilityImprove reliabilityDental implantsAbutmentWeld seam

The invention relates to a connection between a known dental implant (1) and a straight or angular abutment (2) which can be established by means of a base screw (3) and a support ring (4). The support ring (4) is fixedly introduced into the inlet of the abutment (2) near the lower edge of same, preferably by welding or by bending over of the lower edge of the abutment (2). Before insertion of the support ring (4) the base screw (3) is introduced head first into the inlet (24) from the side of the root part of the abutment. The base screw is held in the abutment (2) by the support ring (4) on which the base screw (3) rests. The threaded shank (32) of the base screw (3) engages the inner thread (14) provided for in the implant (1) and draws the abutment (2) into the receiving hole (12) of the implant (1). An angled surface of the base screw (3) and a beveled surface of the support ring (4) contact each other so that the welding seam or bent over lower edge of the abutment (2) are relieved of axial stress. The above connection system is designed especially for implants (1) with a conical receiving hole (12) and internal polygon as well as abutments (2) having a complementary external conical shape and external polygon.

Owner:STRAUMANN HLDG AG

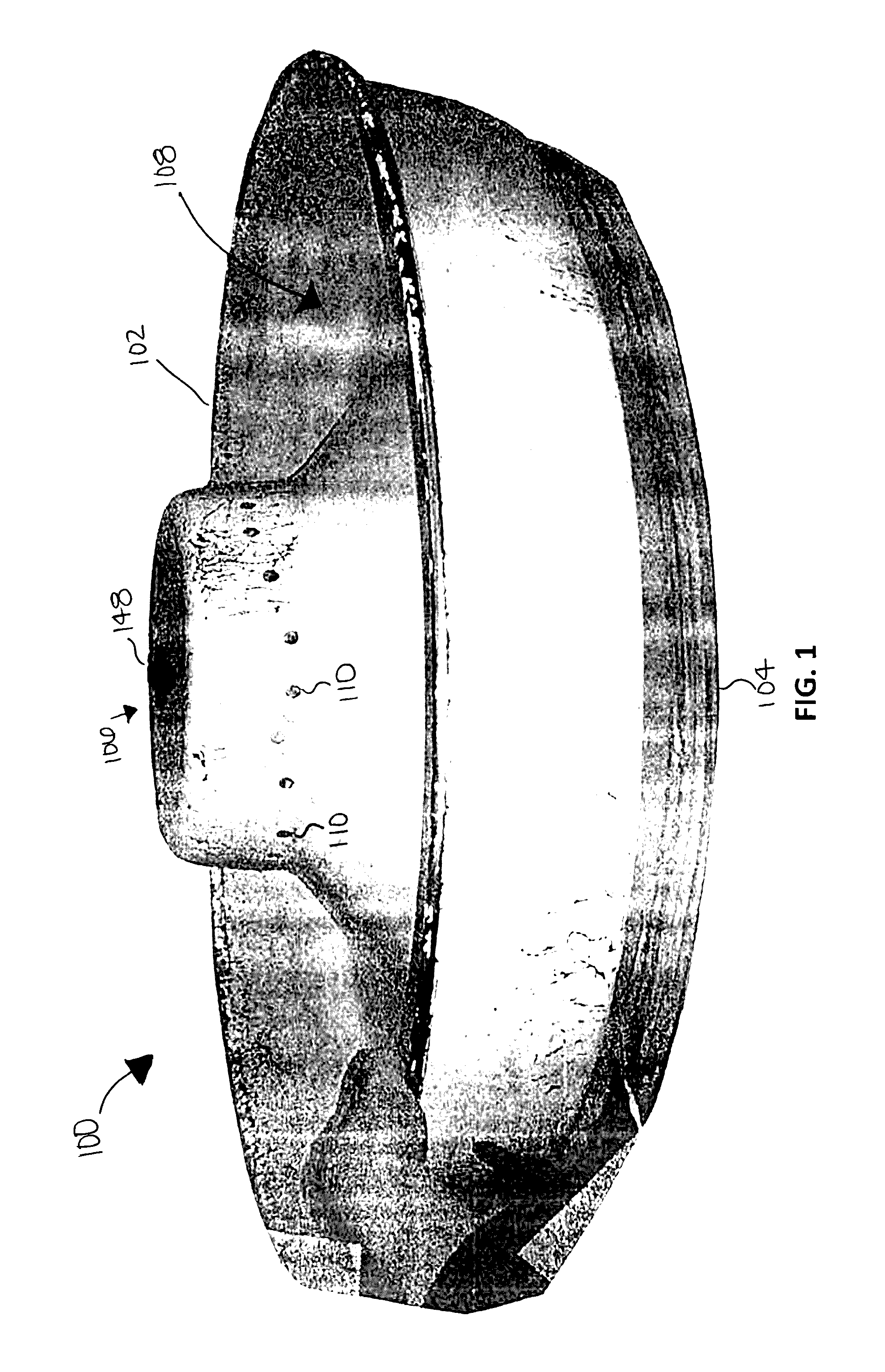

Scent training device

A device for training animals such as rats, dogs, etc. to recognize and associate target odors / scents with food. The training device, sometimes referred to herein as an odor or scent training device, includes a feeding dish / pan that is configured to have food positioned therein. The scent training device creates a scent curtain of a target scent above the food so that the animal's nose and head first penetrate the scent curtain before the animal can eat the food. As such, each time the animal reaches for more food in the feeding dish, an association between the reward of food and the target scent is strengthened.

Owner:NOLAN PATRICK L

Quick release battery cable connector

InactiveUS7344421B1Easy and quick connectionCoupling contact membersElectric connection structural associationsFast releaseHead First

A bracket and quick connect / disconnect battery cable connector are disclosed to facilitate connection of a battery cable to a vehicle batter. The bracket is adapted to be connected to a battery to be in electrical communication with a terminal of the battery. The bracket comprises a head having a first surface, a second surface opposite the first surface, and two or more spaced apart lock members extending from the bracket head first surface. The lock members are generally C-shaped forming channels defined by a curved side surface and an upper surface. The connector comprises a body having a surface, a stem extending from the body surface and two or more flanges extending radially from the stem. The flanges have an upper surface spaced from the connector body surface. One of the flange upper surface and the channel upper surface is sloped such that, as the connector is rotated relative to the channel, the locking member radially extending surface will be sandwiched between the flange upper surface and the connector body surface. In a preferred embodiment, the flange upper surface is sloped, such that the flange defines a wedge.

Owner:SPENCER TROY L

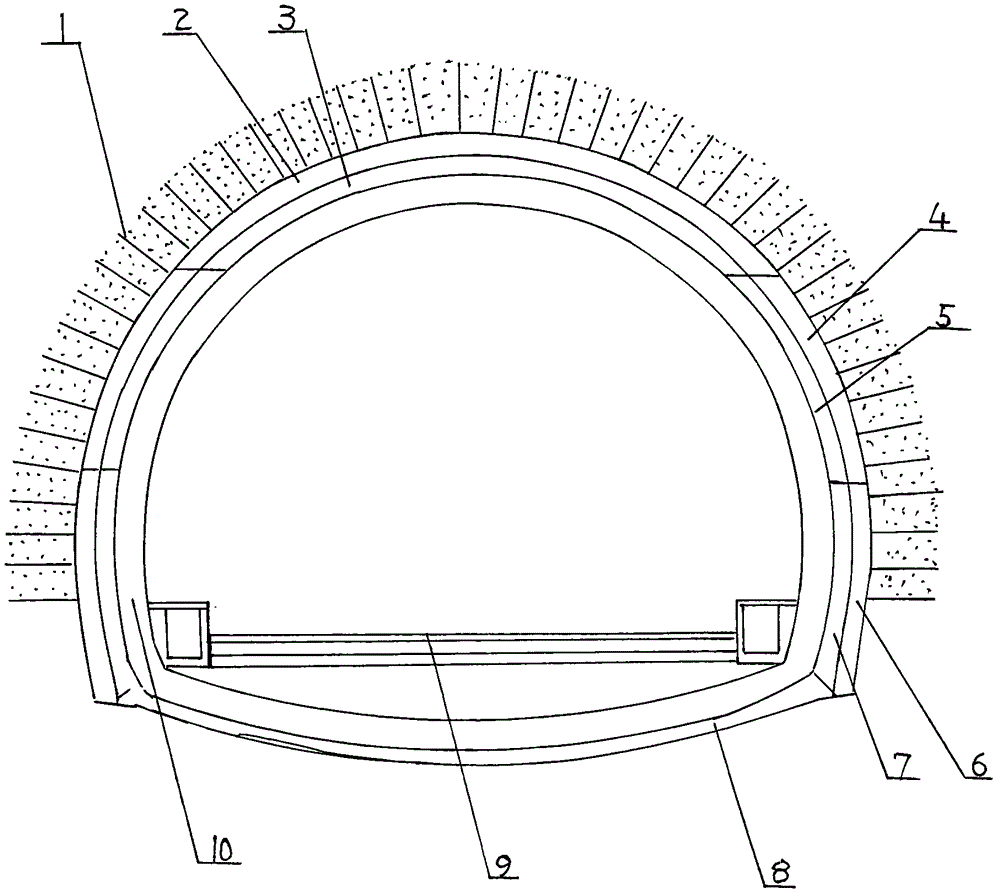

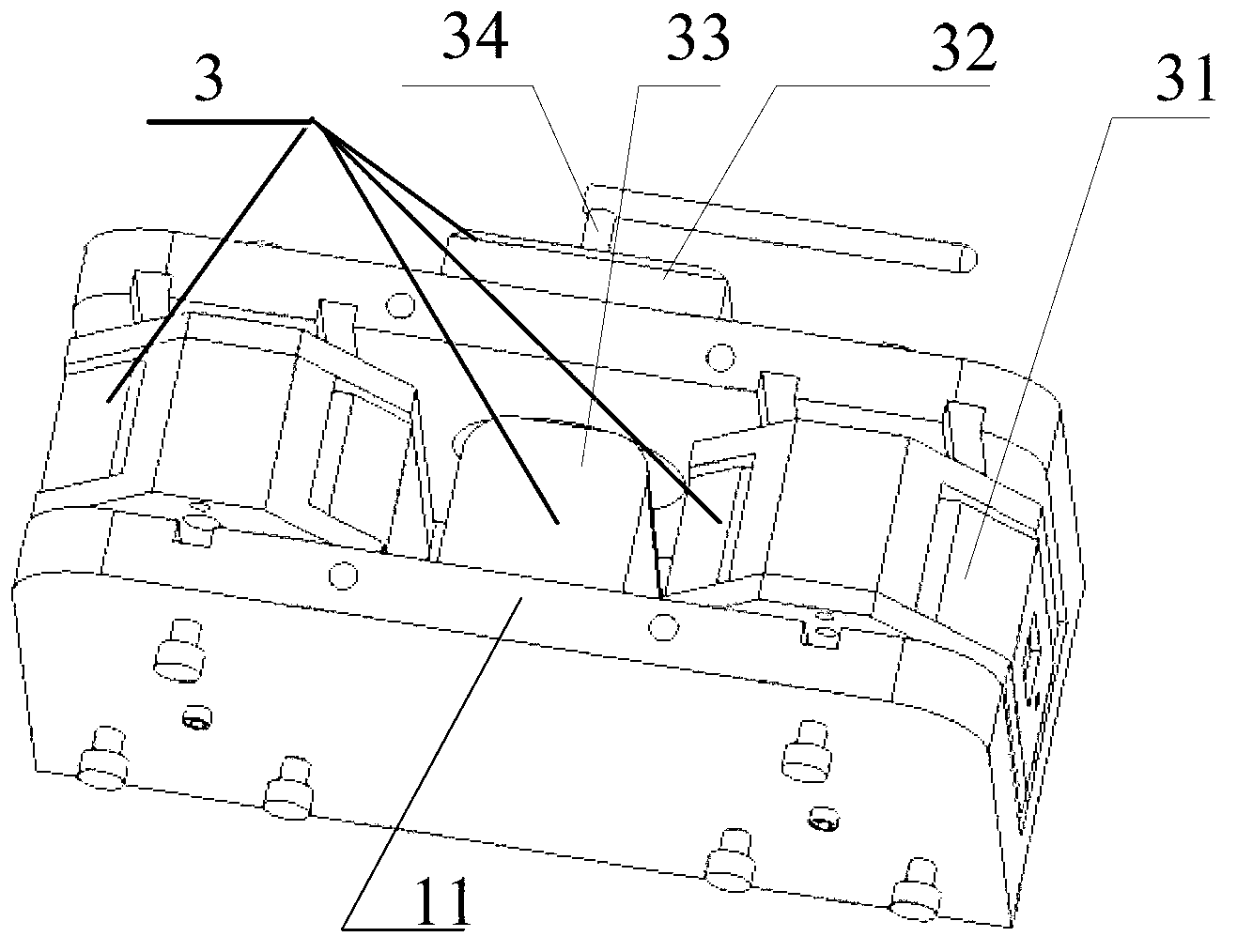

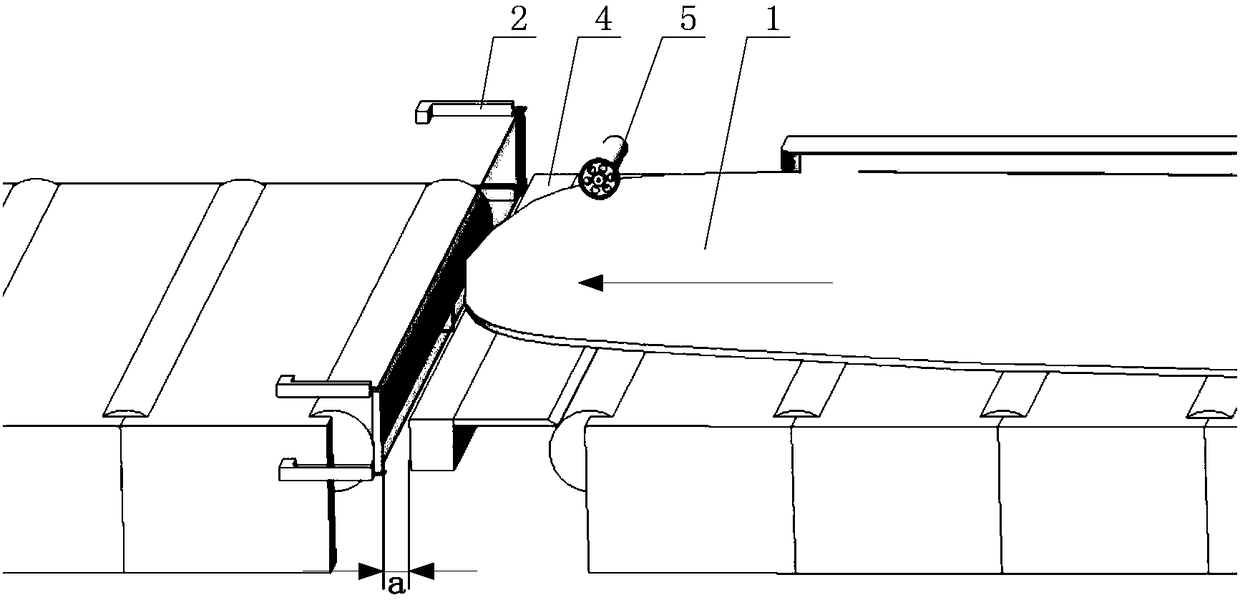

Construction method and structure of two-layer preliminary support for preventing geological disaster of large-section weak surrounding rock tunnel

ActiveCN104533446AEnsure construction safetyGuaranteed operational safetyUnderground chambersTunnel liningRock tunnelHead First

The invention belongs to the construction method and structure of two-layer preliminary supports for preventing a geological disaster of a large-section weak surrounding rock tunnel. The construction method based on a three-step tunnel construction method comprises the first step of constructing advance supports of the tunnel, the second step of constructing top-heading first-layer preliminary supports of top headings, the third step of constructing center-heading first-layer supports and center-heading second-layer preliminary supports of center headings, the fourth step of constructing top-heading second-layer preliminary supports of the top headings, the fifth step of constructing bottom-heading first-layer preliminary supports and bottom-heading second-layer preliminary supports of bottom headings and the sixth step of constructing inverted arches, so supporting structures of closed rings of steel arches in the preliminary supports on all layers are formed. According to the construction method and structure, the geological disaster of the large-section weak surrounding rock tunnel can be effectively prevented, the safety of tunnel construction and operation is guaranteed, and economic loss caused by the geological disaster is reduced; besides, the construction method and structure have the advantages of being low in construction resource amount and cost, construction is easy, the construction speed is high, safety risks are small, and construction quality is high.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

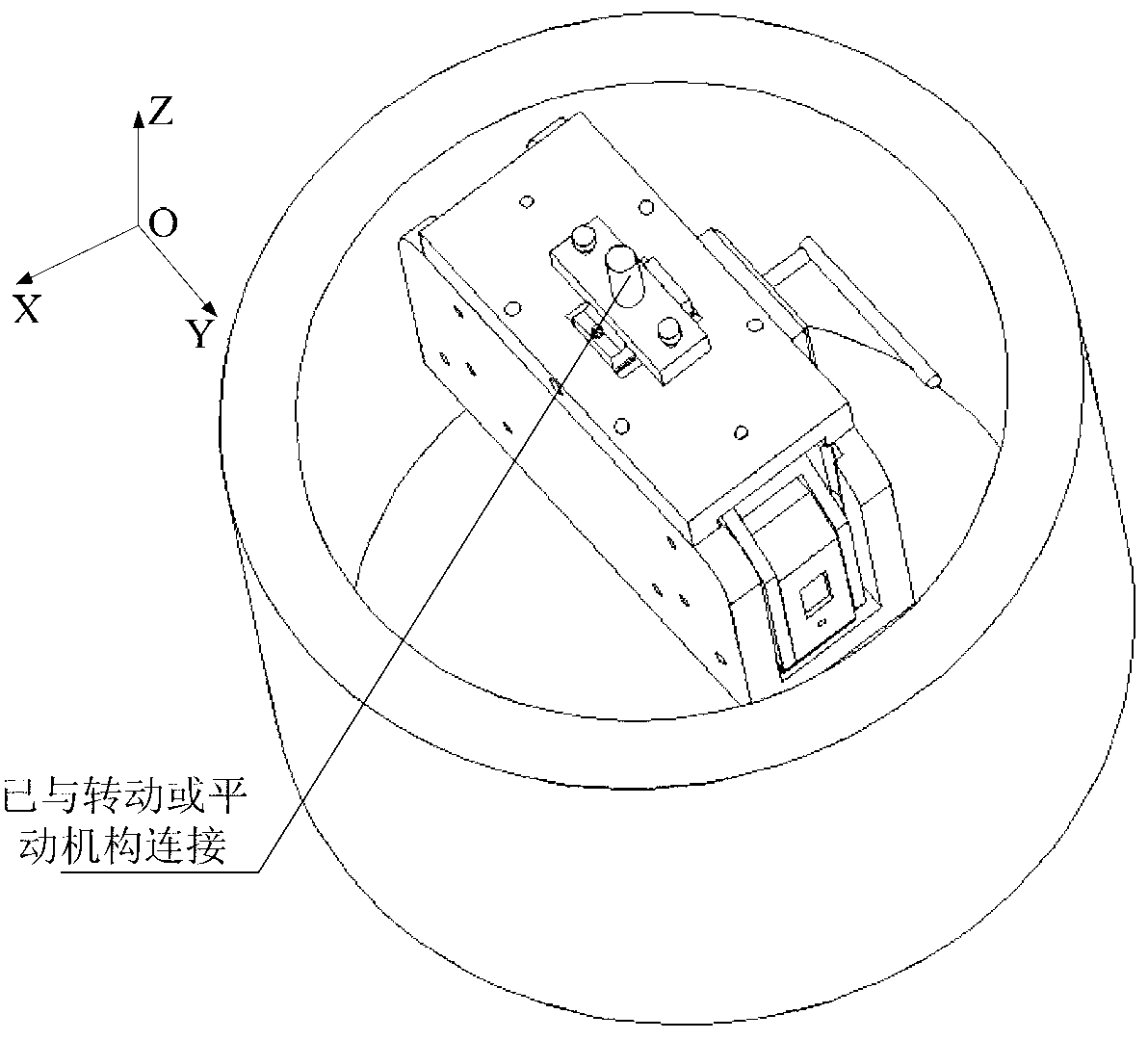

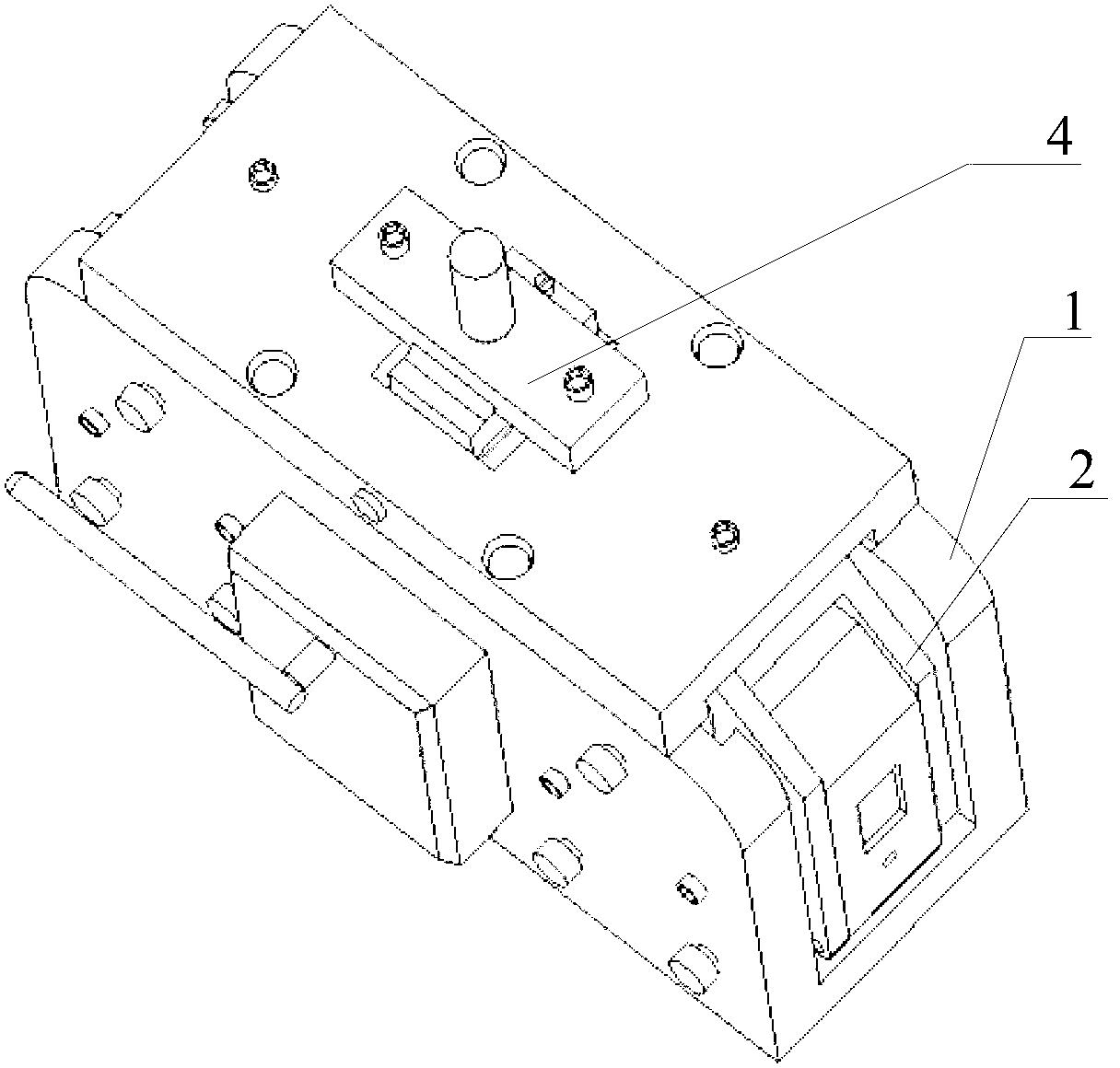

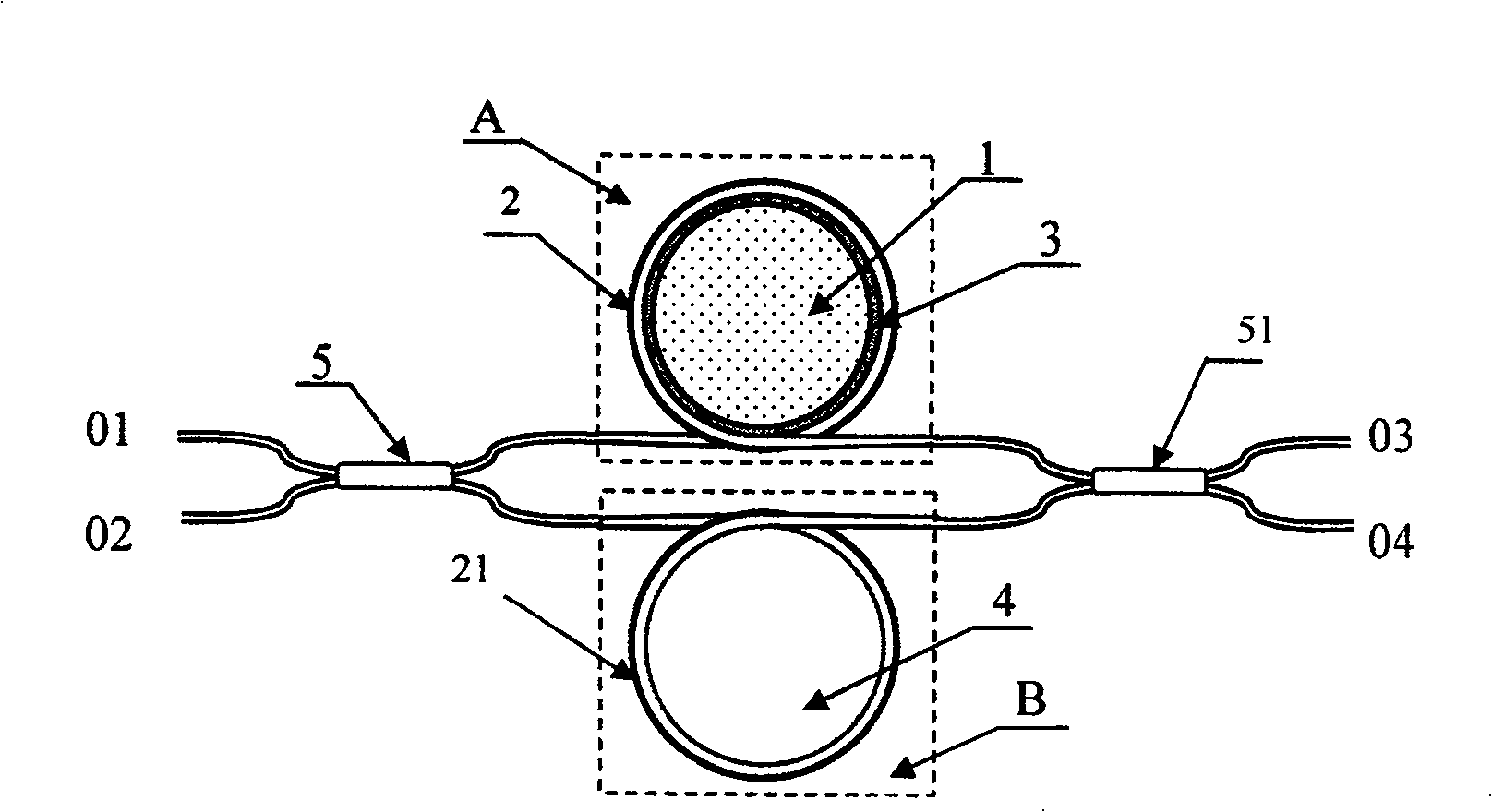

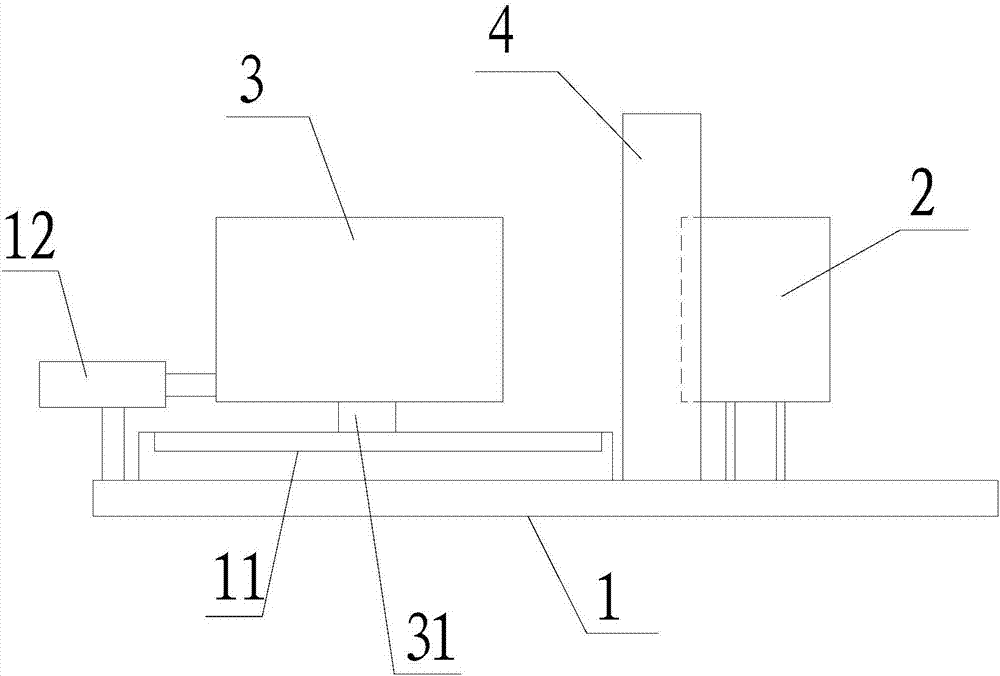

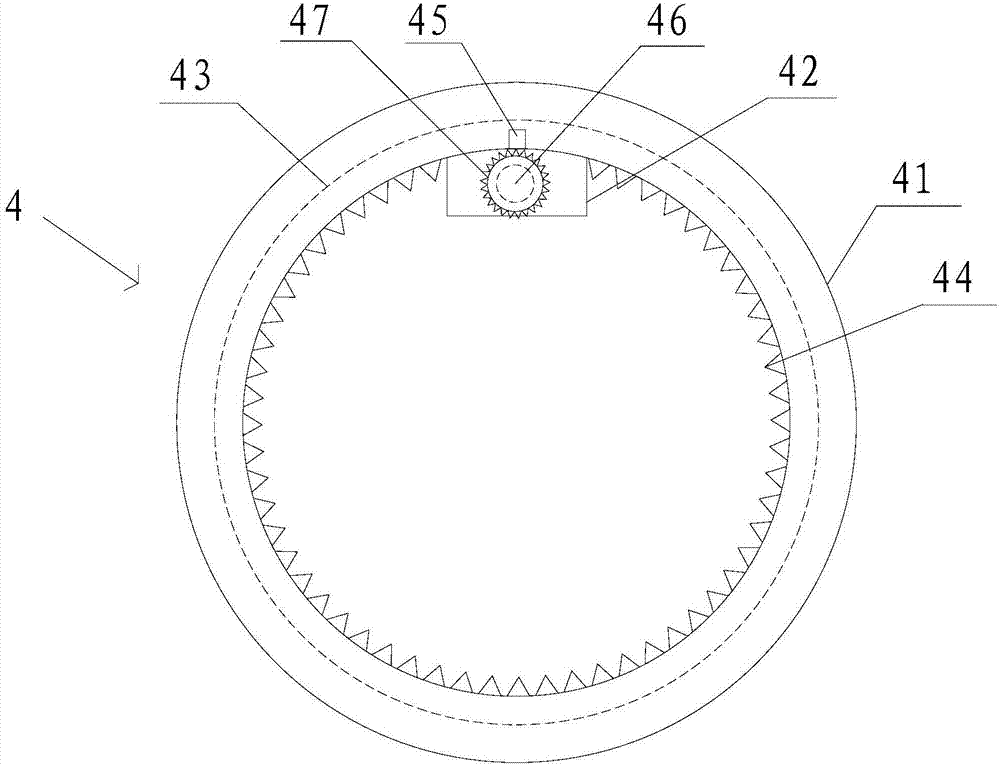

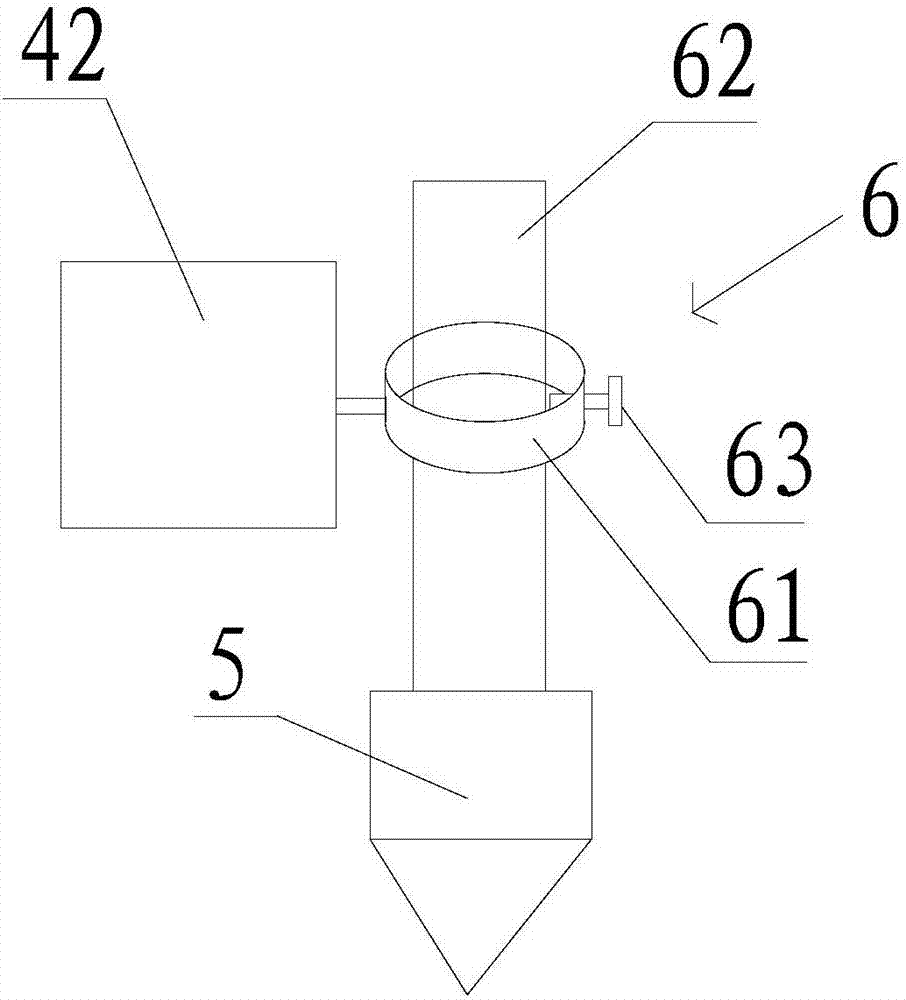

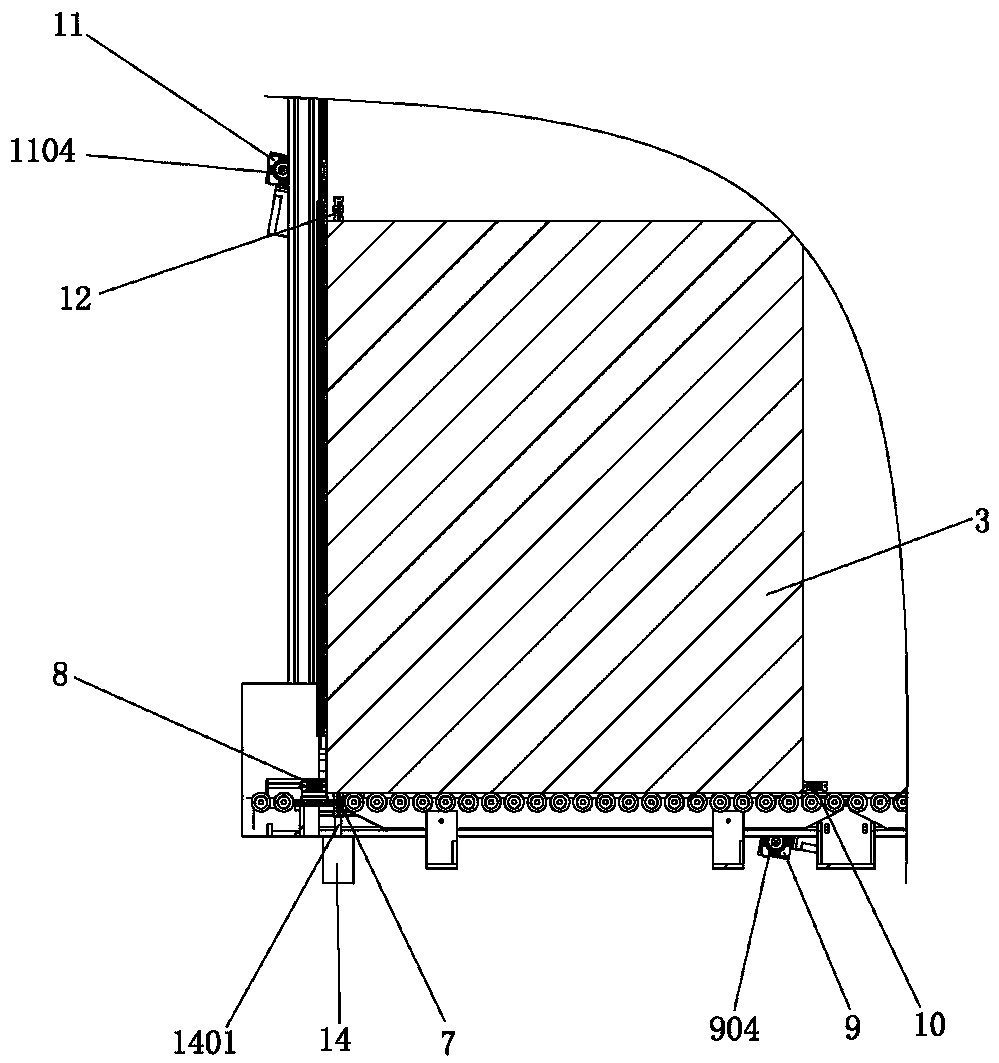

Aperture measuring method based on non-contacting type sensor combination

InactiveCN103278100AQuick and accurate measurementImprove detection accuracyUsing optical meansOptical axisDual sensor

The invention discloses an aperture measuring method based on non-contacting type sensor combination, is suitable for measuring the size of the inner diameter of a workpiece, and relates to the geometric sense measuring field. The method comprises the following steps: first, installing a main shaft of a double-sensor measuring head on a mechanism with the horizontal moving function so as to form a complete set of measuring system which is arranged in a workpiece to be measured; at measuring time, measuring optical axes of two sensors on the double-sensor measuring head being enabled to be on the same straight line; the double-sensor measuring head first rotating on a ZOY face, and then horizontally moving on an XOY face, finally the diameter of an inner hole of the workpiece to be measured is obtained; or, the double-sensor measuring head sequentially rotates on the ZOY face and the XOY face to obtain the diameter of the inner hole of the workpiece to be measured. When the method is used for measuring the diameter of the inner hole of the workpiece to be measured, only two procedures need operating theoretically, so that measuring efficiency is greatly improved, and a large number of measuring labor hours are saved. Moreover, the non-contacting measuring head is arranged on a lathe, a motion execution mechanism of the lathe is used for enabling the measuring head to rotate or move horizontally, so that on-machine accurate measuring can be achieved.

Owner:TIANJIN UNIV

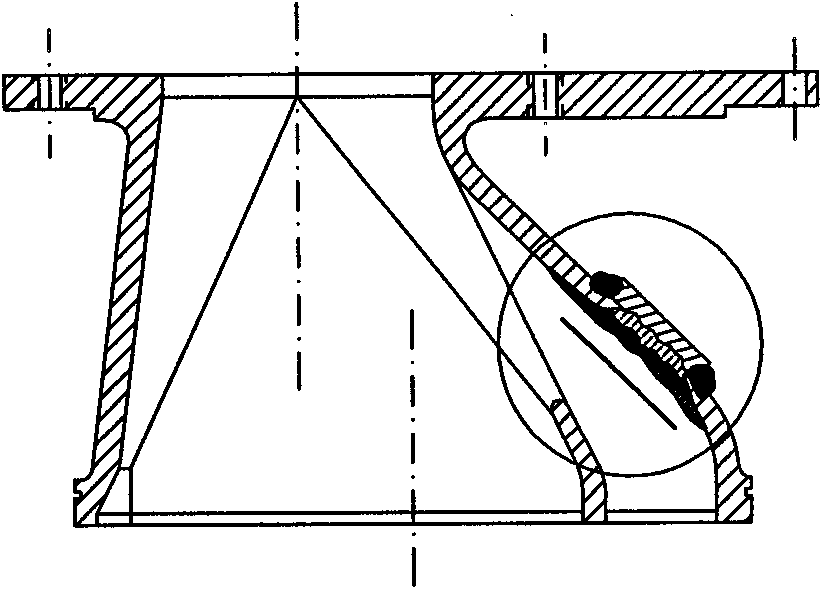

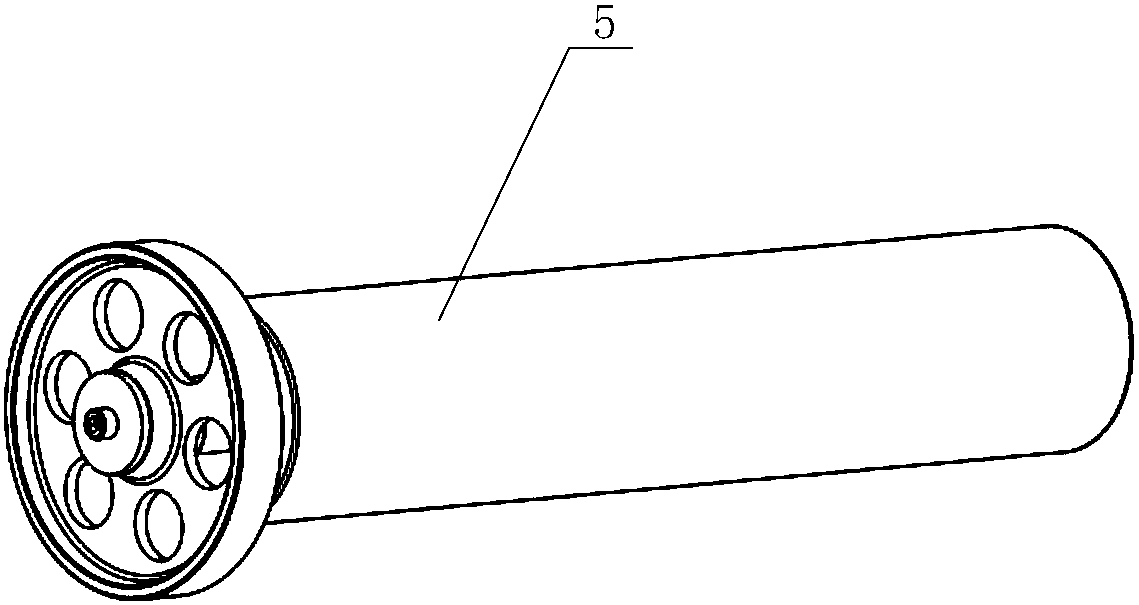

Expanding type clamp used on lathe and machining method thereof

The invention discloses an expanding type clamp used on a lathe and a machining method thereof. A workpiece is usually clamped from outside to inside when being machined on the lathe. However, for a short thin-wall workpiece which has a cone-shaped outer surface, does not have a cylindrical surface and has high requirements for machining accuracy and coaxiality, when machining of one end of the workpiece is finished and the other end needs to be machined, a universal clamp can not meet the requirements due to the fact that the universal clamp is low in clamping force and prone to deformation. The expanding type clamp used on the lathe and the machining method thereof are suitable for being used in the situation that machining of one end of a short thin-wall workpiece, with a small inner diameter and a cone-shaped or angular outer surface and having high requirements for machining accuracy and coaxiality and free of a cylindrical surface, is finished and the other end needs to be machined. A hole of the machined workpiece is sleeved on an expanding type clamping head first, and then the circumference of the clamp expands outwards evenly in a clamping process to stretch the inner diameter of the workpiece to be machined to carry out lathe work. The clamp is loosened after the machining is finished, the expanding type clamping head contracts elastically, and then the machined workpiece is taken down easily.

Owner:JIANGSU XINGHE VALVE +1

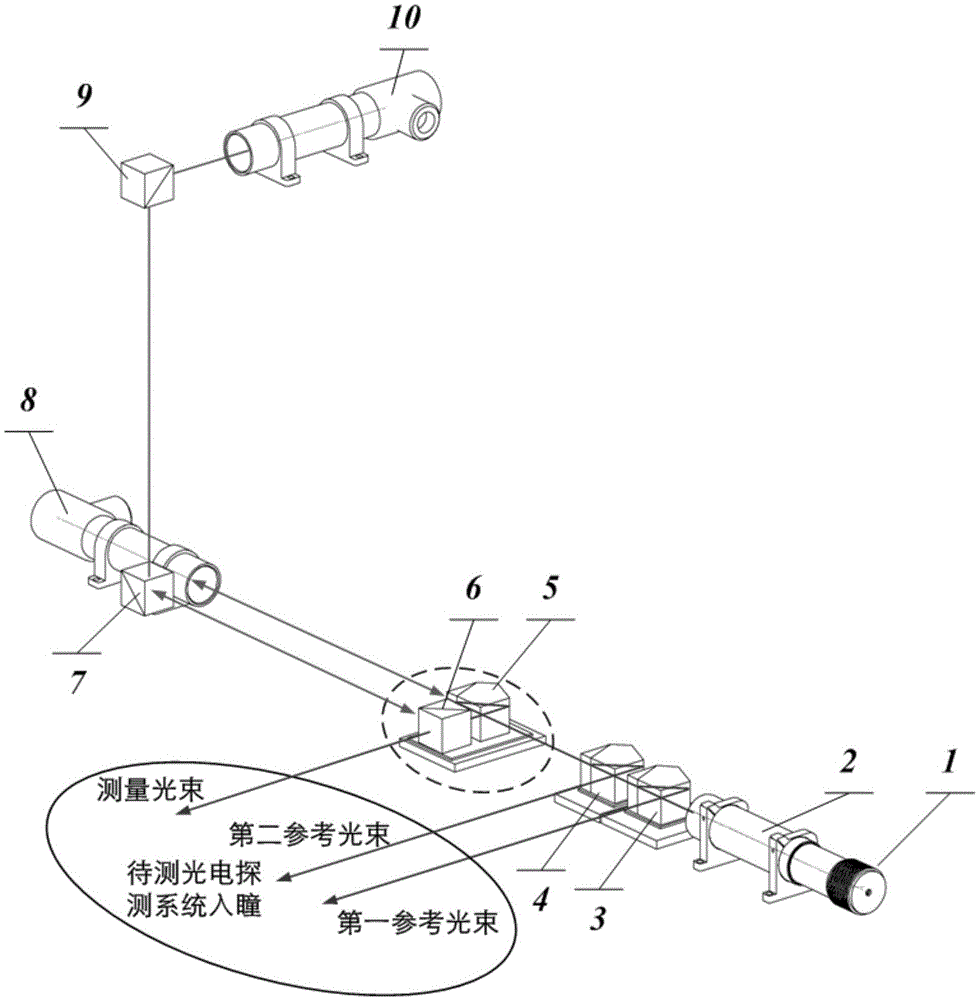

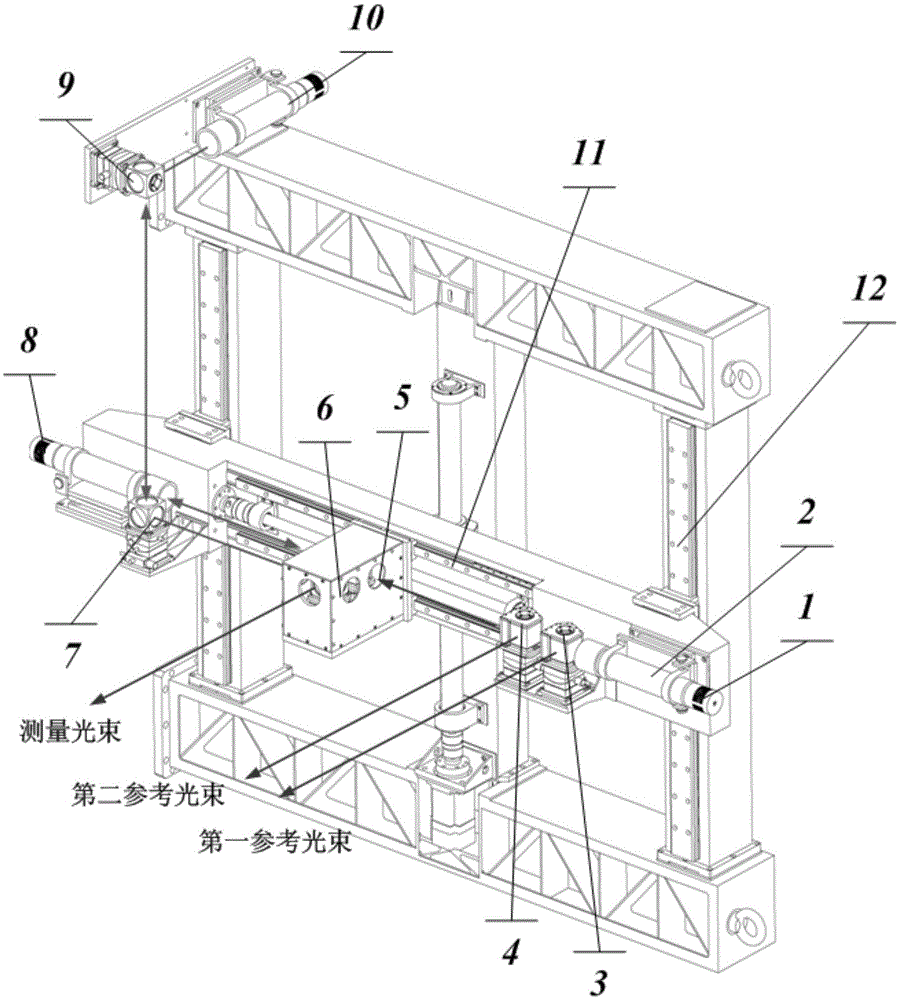

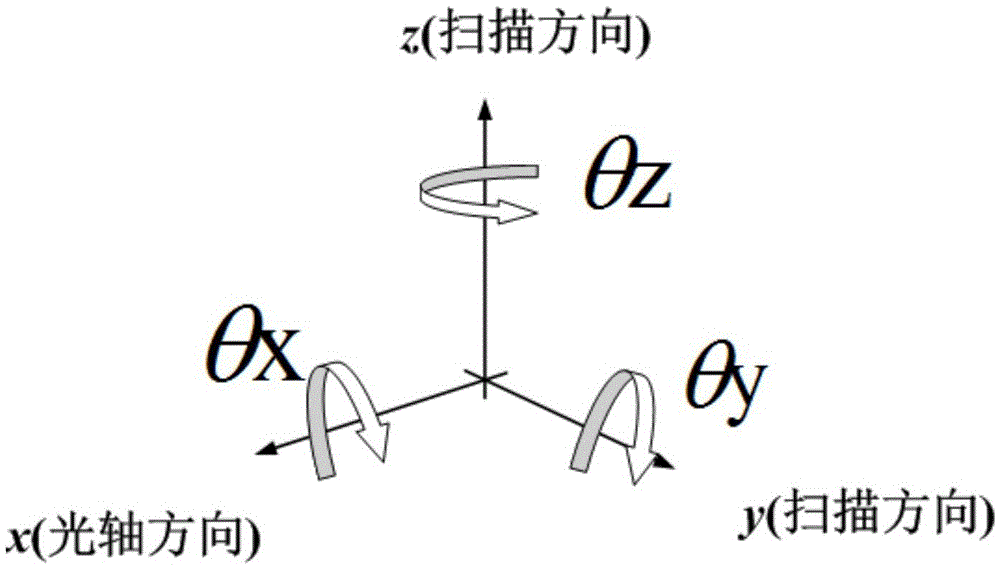

Wave-aberration indoor detection method of large-caliber photoelectric detection system at different elevations

ActiveCN105571833AAccurate and stable measurement resultsTarget characteristics are controllableTesting optical propertiesImaging qualityBeam splitting

The invention relates to a wave-aberration indoor detection method of a large-caliber photoelectric detection system at different elevations. An objective target plate and illumination system, a small-caliber collimating optical system with a variable diaphragm, a first turning beam-splitting prism, a second turning beam-splitting prism, a measuring head third turning beam-splitting prism, a measuring head first beam-splitting prism, a second beam-splitting prism, a first photoelectric auto-collimator, a third beam-splitting prism and a second photoelectric auto-collimator are successively arranged on a detection optical path. According to the technical scheme of the invention, the wave-aberration indoor detection method of the large-caliber photoelectric detection system at different elevations is mainly used for detecting the wave aberration of the large-caliber photoelectric detection system at different elevations. In this way, the imaging quality at different elevations and the stability quantitative assessment thereof are realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

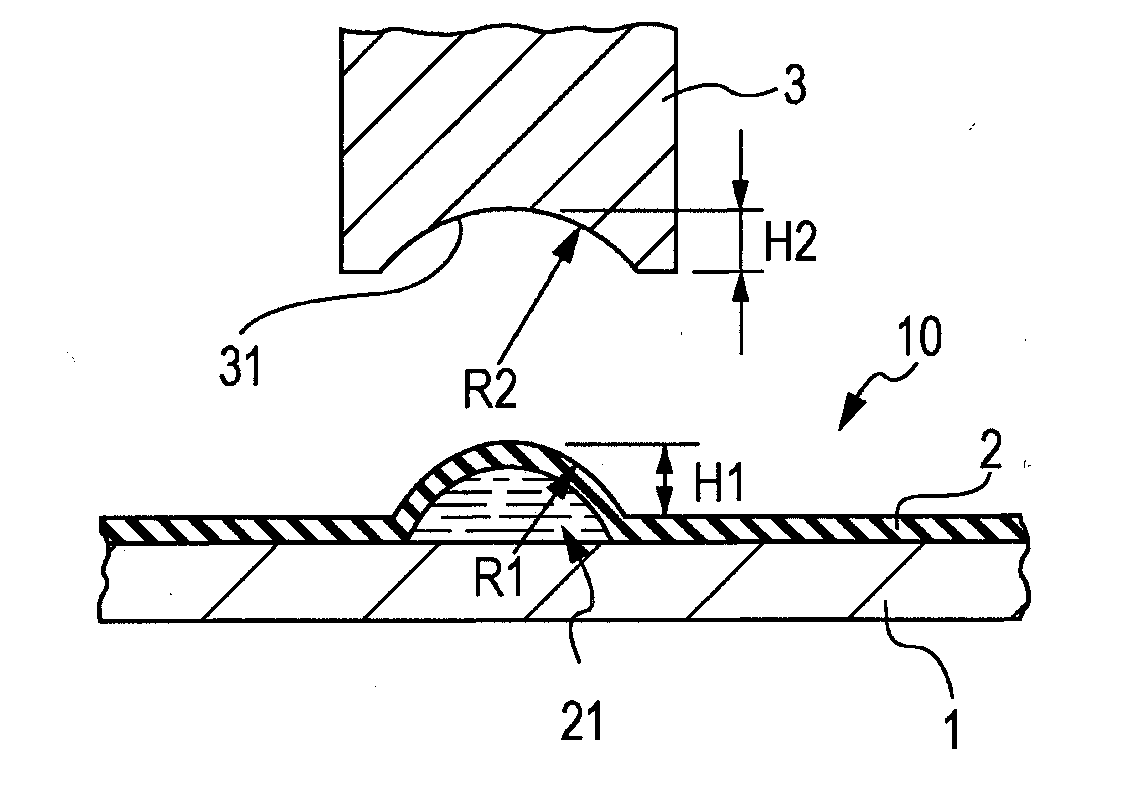

Cartridge system for chemical processing

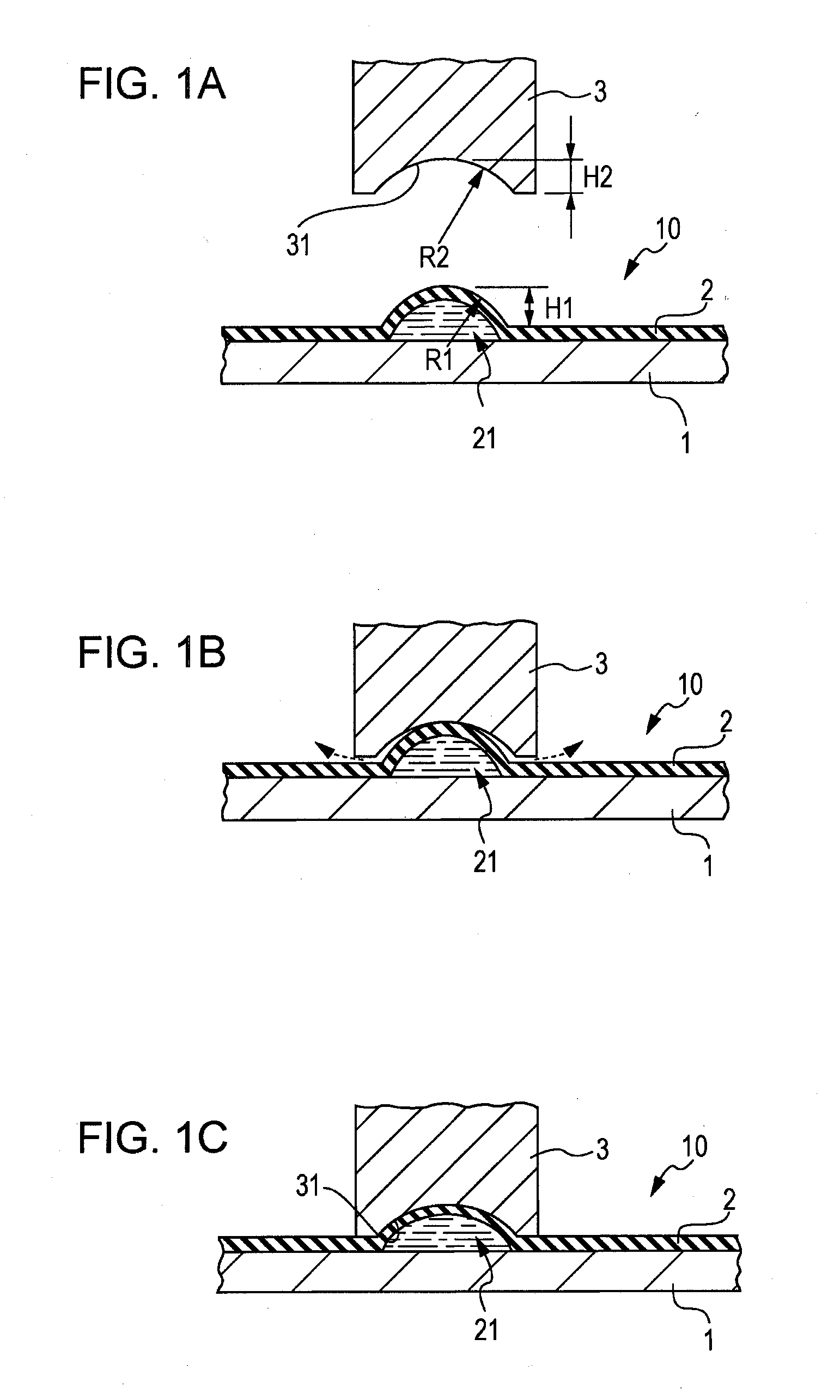

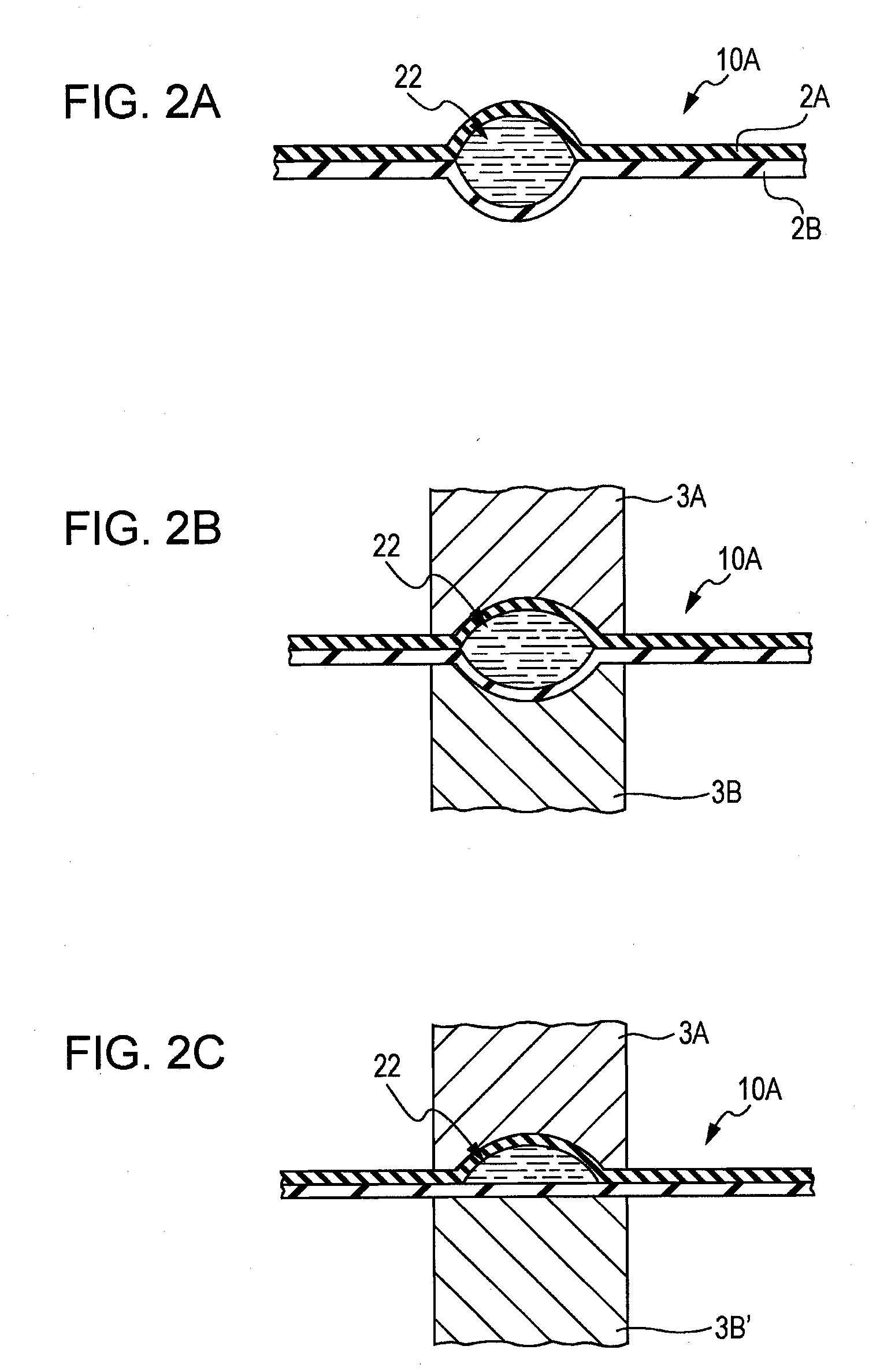

InactiveUS20110318824A1Controlled rapidly and stablyQuick controlBioreactor/fermenter combinationsHeating or cooling apparatusCompound (substance)Head First

An end portion of a head has a recess having an inner shape corresponding to a dome shape of a well when the well is in an expanded state. The radius of curvature of the recess is larger than the radius of curvature of the dome shape of the well. Moreover, the depth of the recess is smaller than the height of the dome shape of the well. Therefore, the head first contacts the apex of the well, and the contact area gradually expands toward the outer periphery. At this time, a gap is generated between the head and the cartridge around the well. Thus, the air between the head and the well is expelled from around the well as the head is pressed against the well.

Owner:YOKOGAWA ELECTRIC CORP

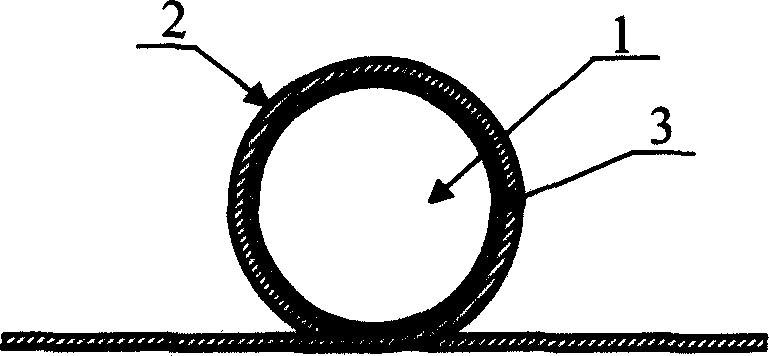

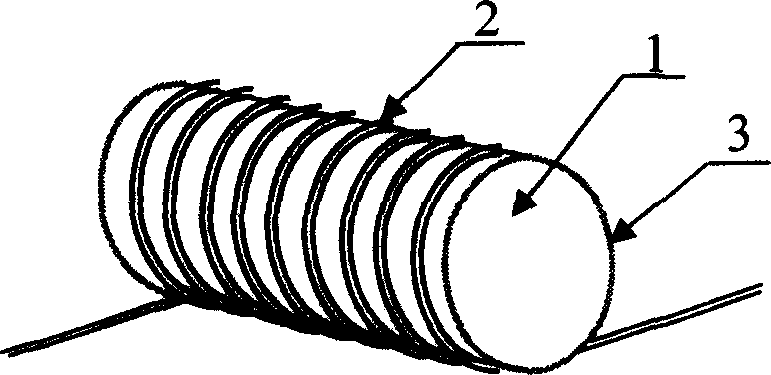

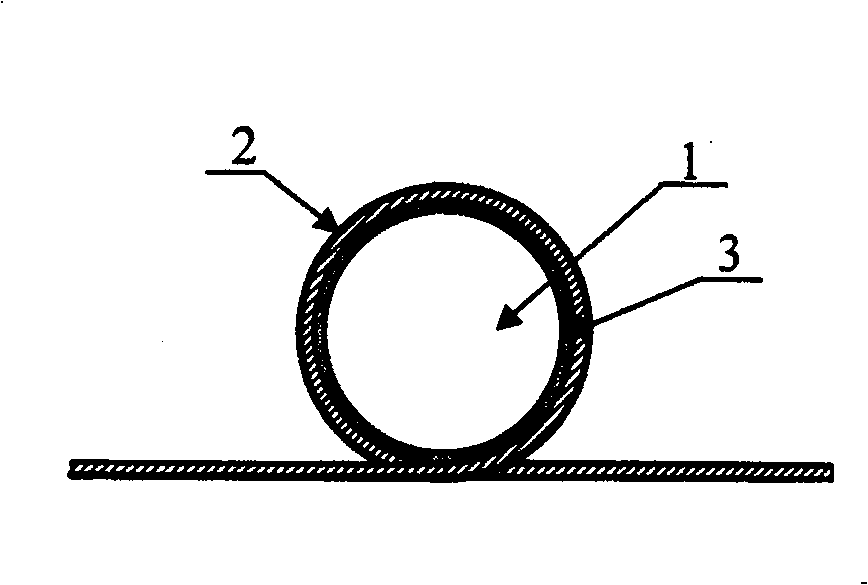

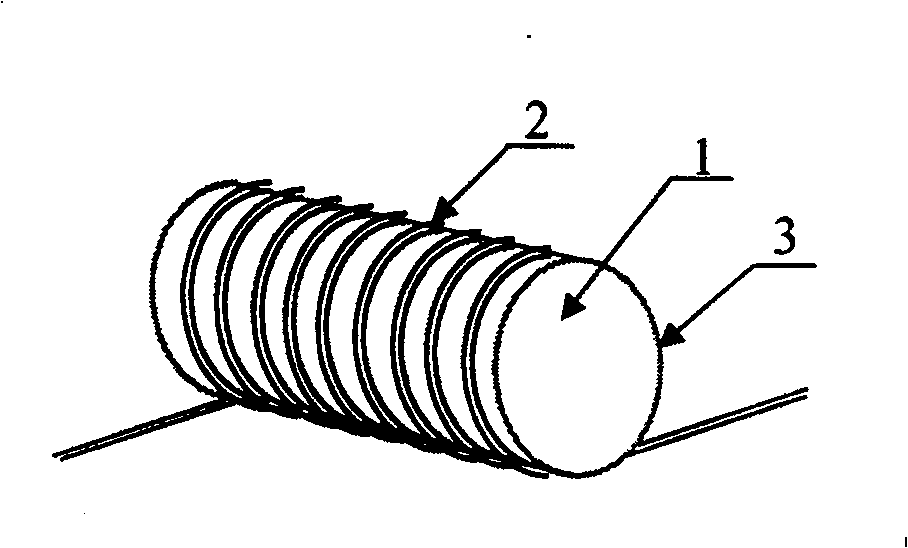

Fibre-optical sensing device for monitoring metal rust

InactiveCN1657908ASimple structureEasy to manufacturePhase-affecting property measurementsCouplingOptical fiber coupler

A monitor metal rusts away the optical fiber transmitter, its constitution includes: The detecting head is in waits on the monitor metal material by the first optical fiber to twine the N circle constitution; Reference is in one with treats on the monitor metal structure material configuration and the radius same anti-corrosive material by the second optical fiber twines the N circle constitution; States a detecting head first optical fiber end and refers to the head a second optical fiber end to tie the ratio after the minute is 1: 1 first optical fiber coupler coupling and forms the first port and the second port, states the first optical fiber and the second optical fiber another end ties the ratio after the minute is 1: 1 second optical fiber coupler coupling and forms the third port and the fourth port. This invention has the structure simply, the manufacture is easy, may obtain the high sensitivity survey; May use certain optical fiber paths of rays to constitute the multi- viewpoints the distributional supervisory system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

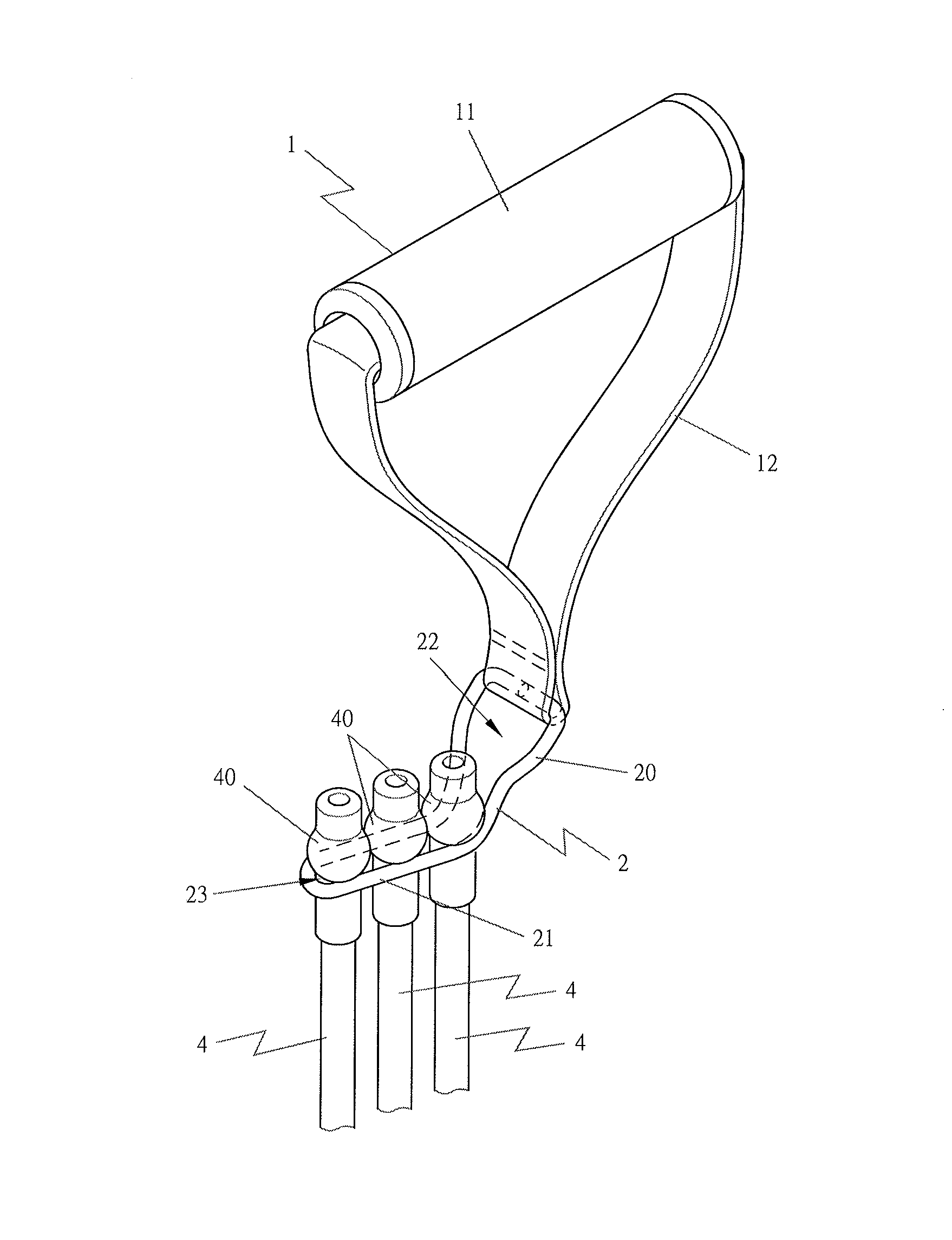

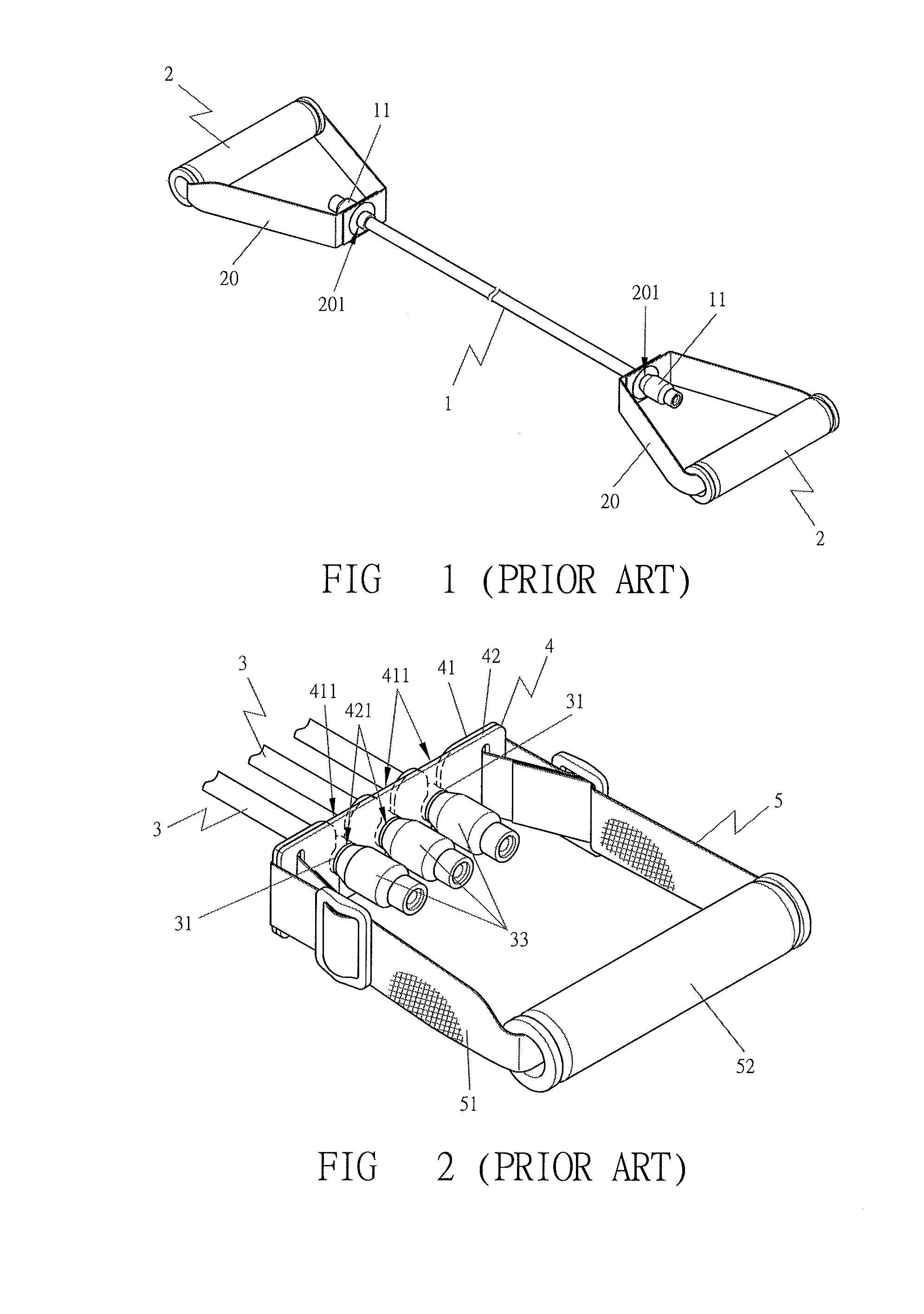

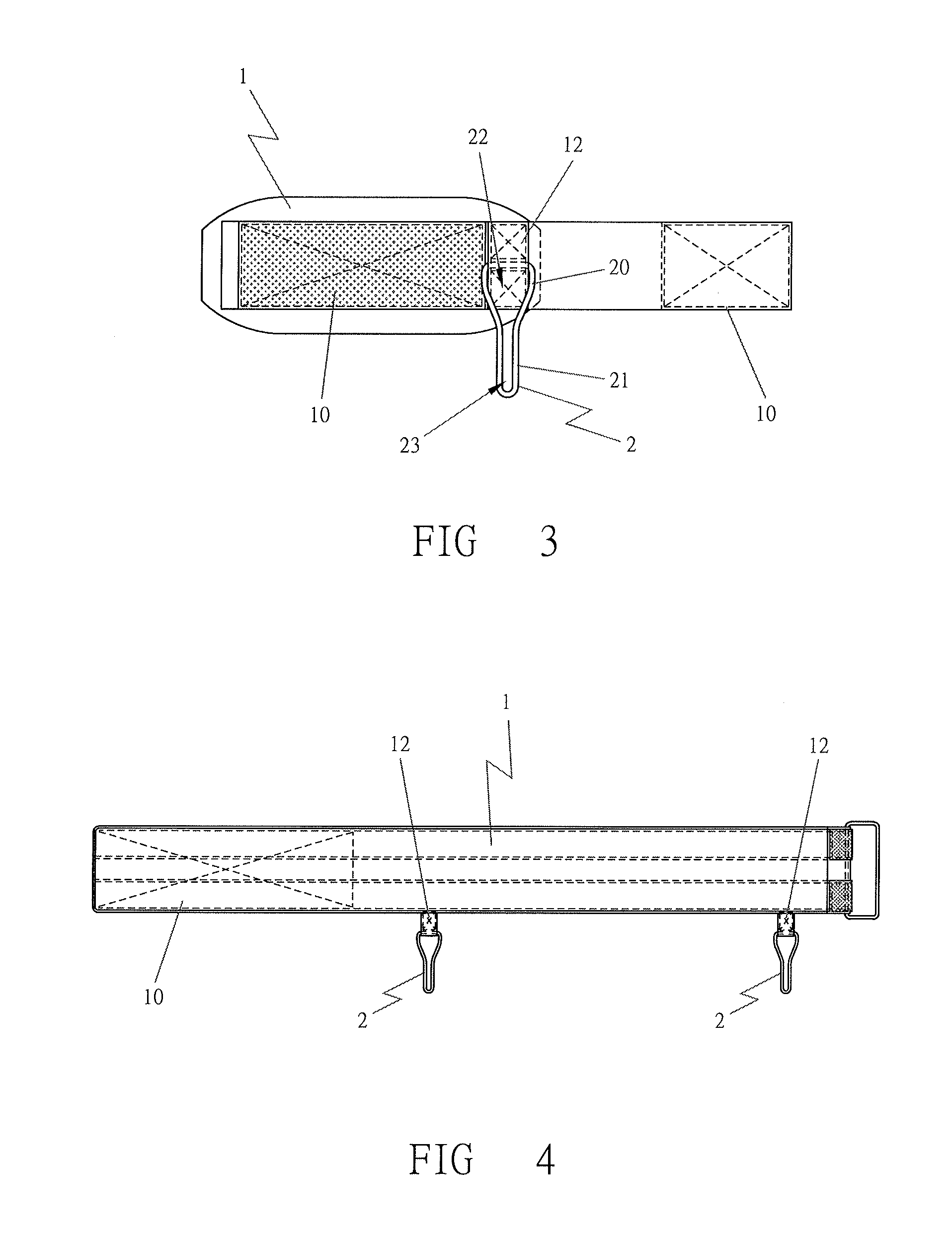

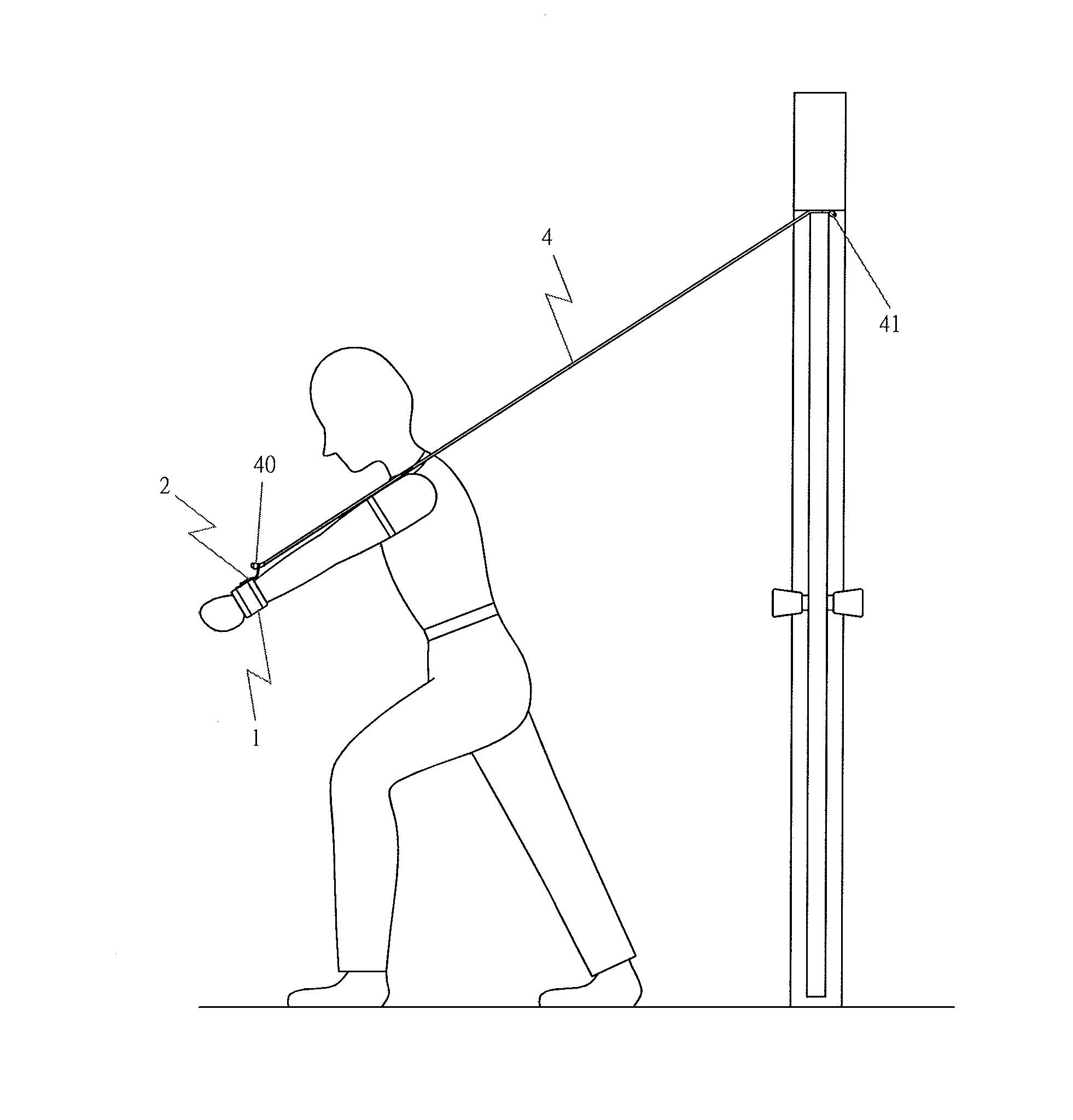

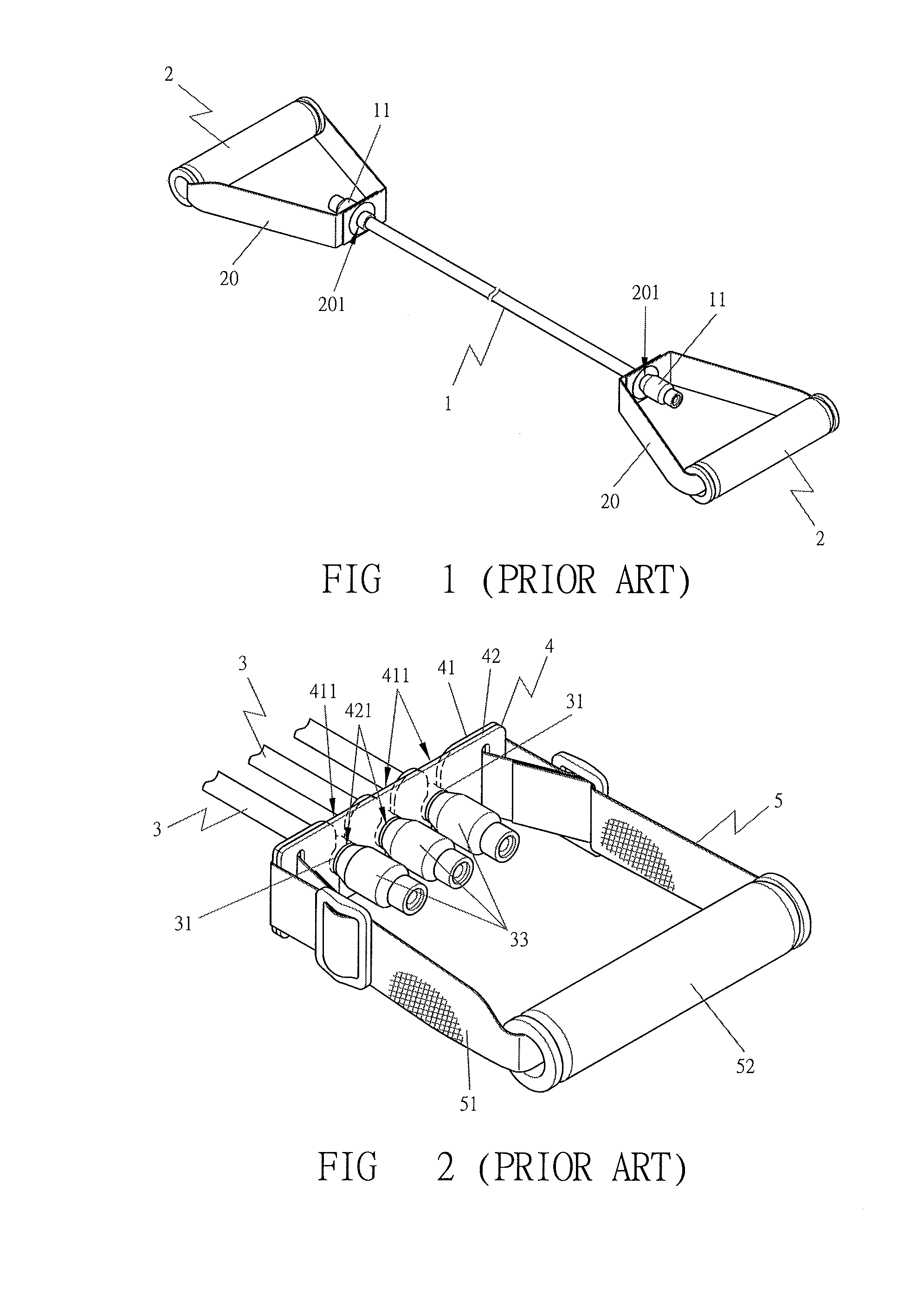

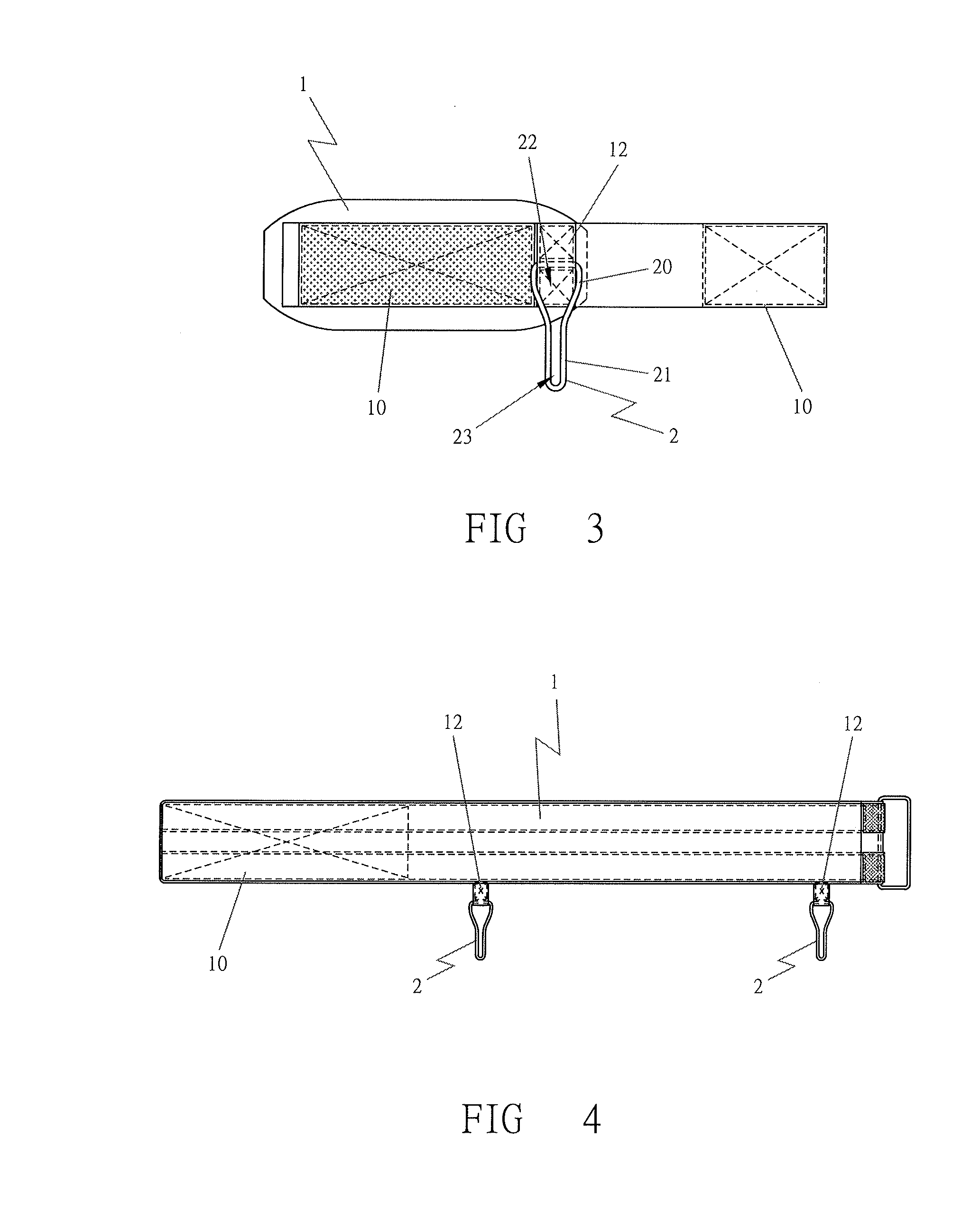

Apparatus for exercise, body building and rehabiliation

An apparatus for exercise, body building and rehabilitation includes a main body to be grasped by a user or bound around a proper part of a user's body. A fixing member is secured with the main body for fixing one end of an elastic rope, loop-shaped and provided with a first and a second end portion in proper proportion. The first end portion is formed with an open hole extending downward and contracting gradually to form a longer open hole at the second end portion. The elastic rope has one end head first put in the larger open hole of the first end portion and then the elastic rope is moved downward to force its end head to be stuck in the narrower open hole of the second end portion of the fixing member not to slip off, facilitating a user to carry out exercise, body building or rehabilitation.

Owner:LIU LI HSIA

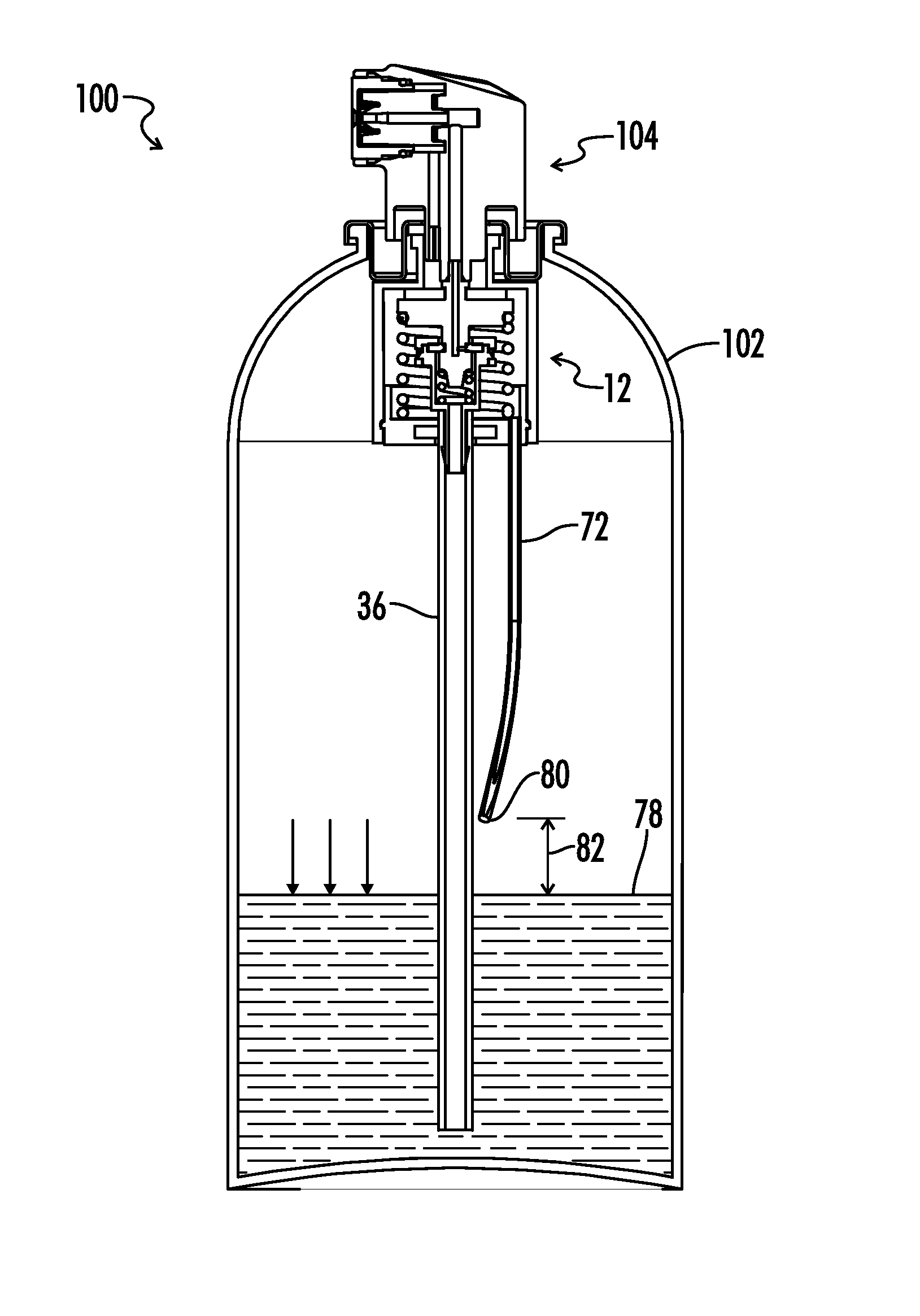

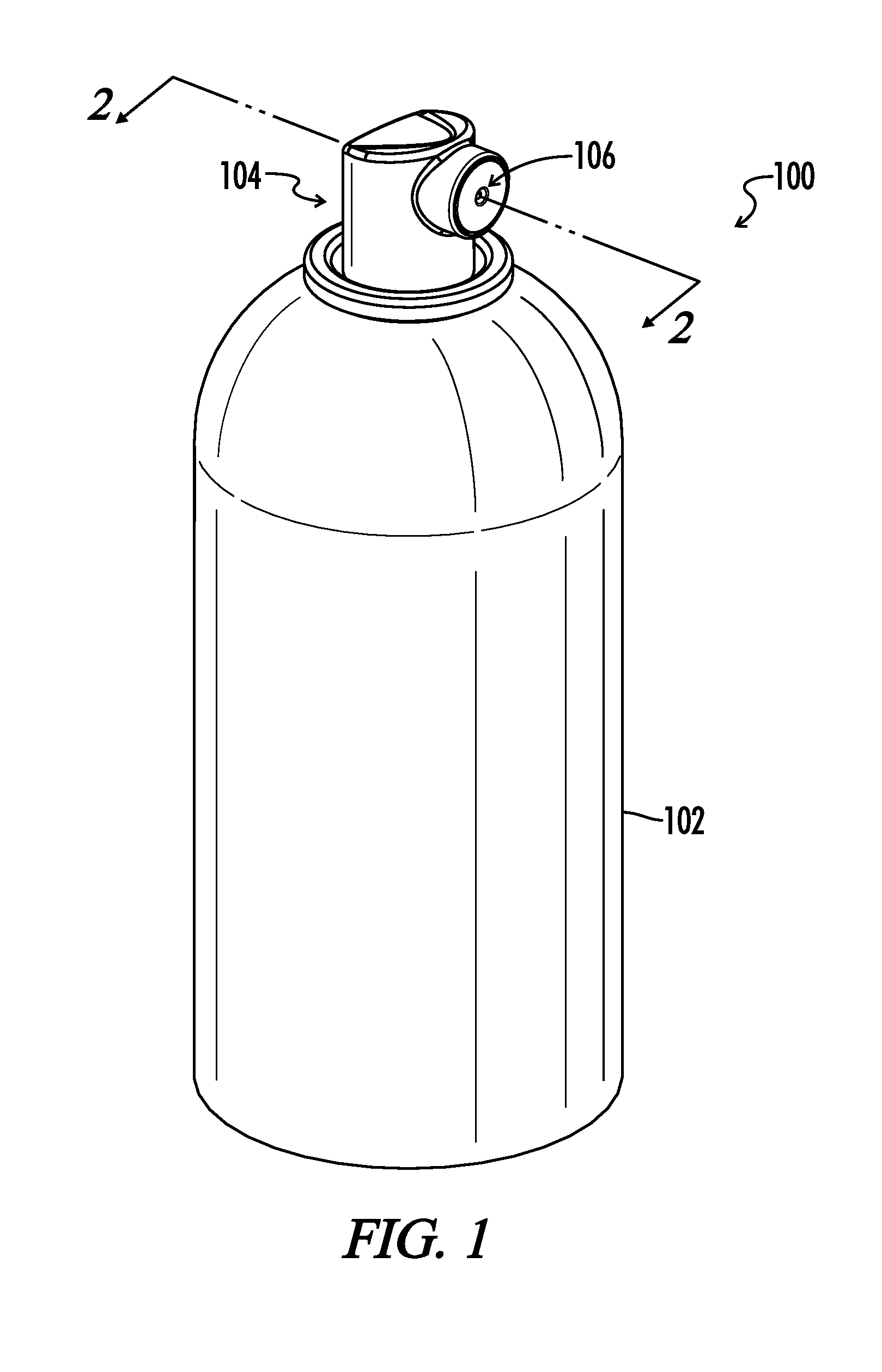

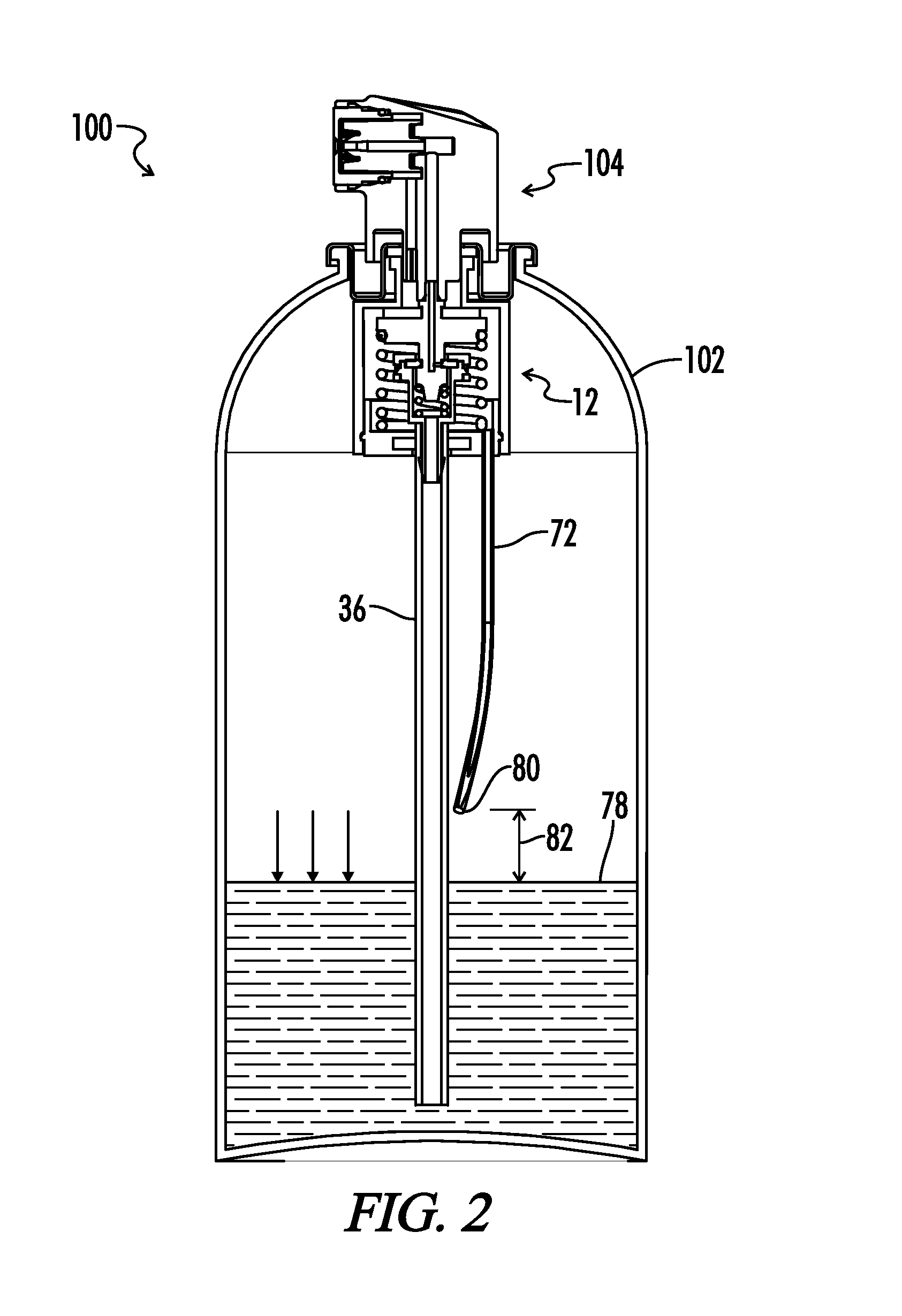

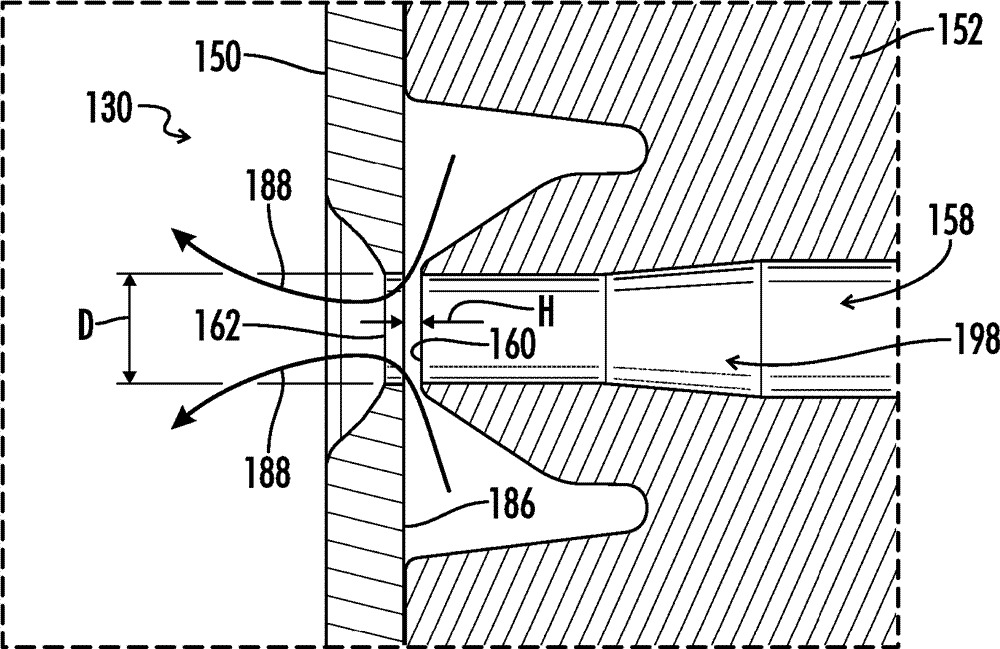

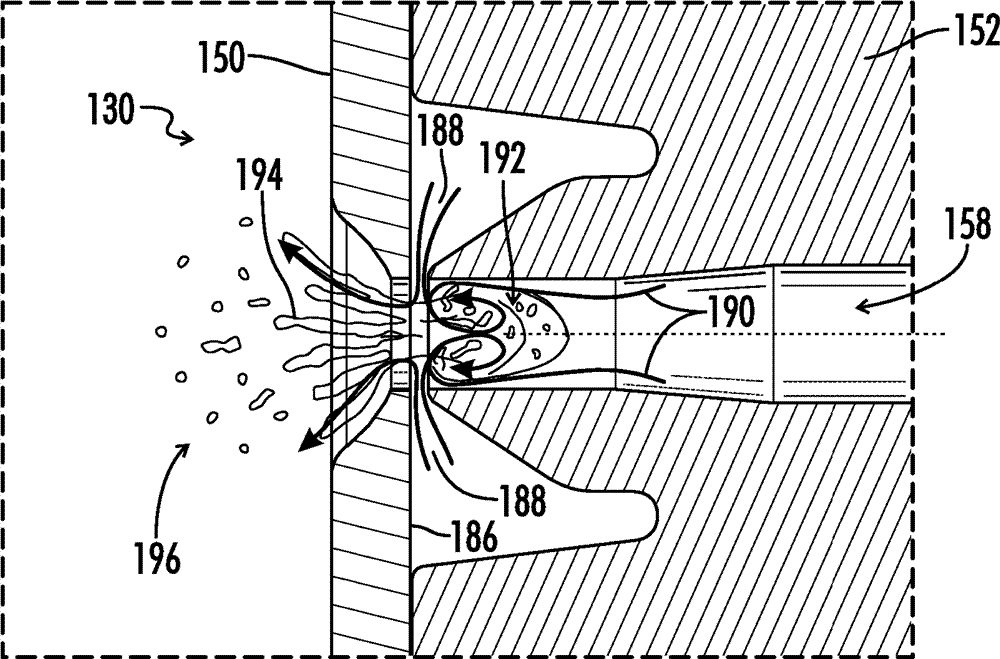

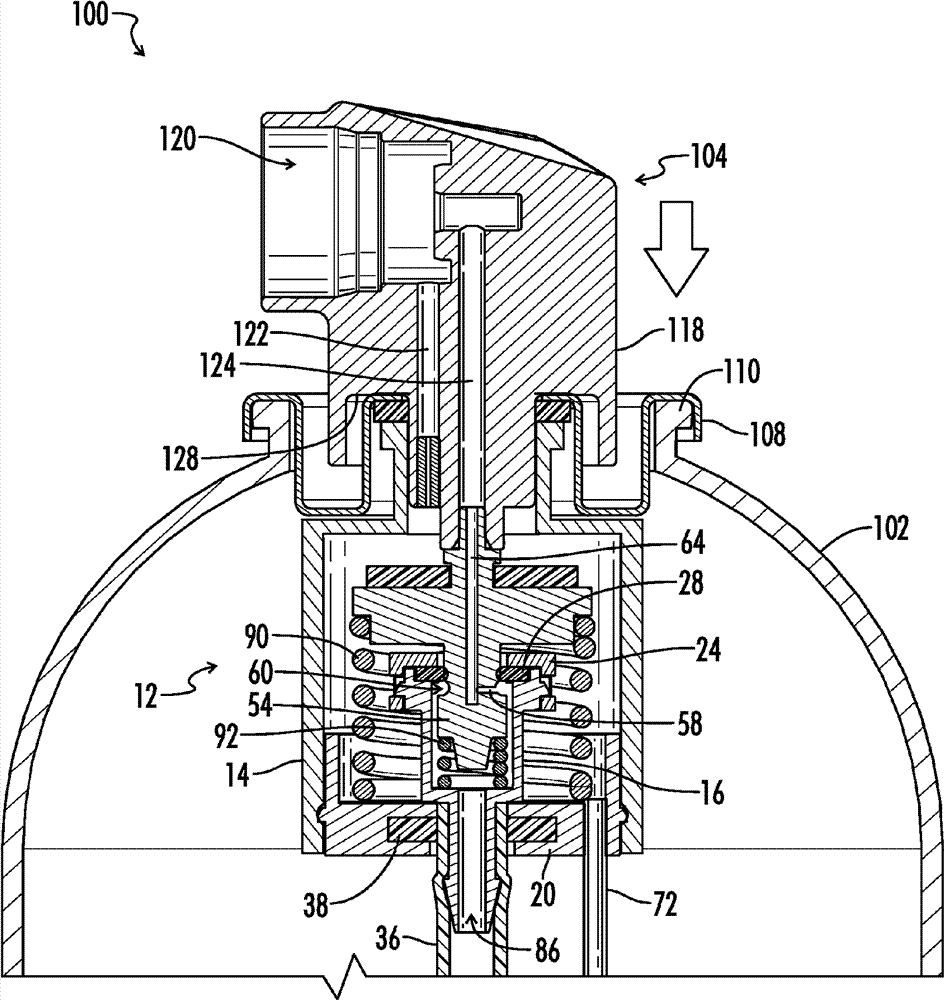

Dispensing device and methods for emitting atomized spray

A device for dispensing a liquid product as an atomized spray includes a container, a depressible dispensing head for initiating emission of the spray from the device and for terminating emission of the spray from the device, and a sequential delivery valve attached to the dispensing head. The dispensing device is configured to initiate flow of gas only into the dispensing head first when the dispensing head is depressed from a first axial position to a second axial position. When the dispensing head is depressed further toward the container to a third axial position, the dispensing device allows both liquid and gas to travel from the container into the dispensing head. When the dispensing head is released from the third axial position back to the first axial position, the dispensing device first stops flow of liquid into the dispensing head before stopping flow of gas into the dispensing head.

Owner:UNIV DE SEVILLA

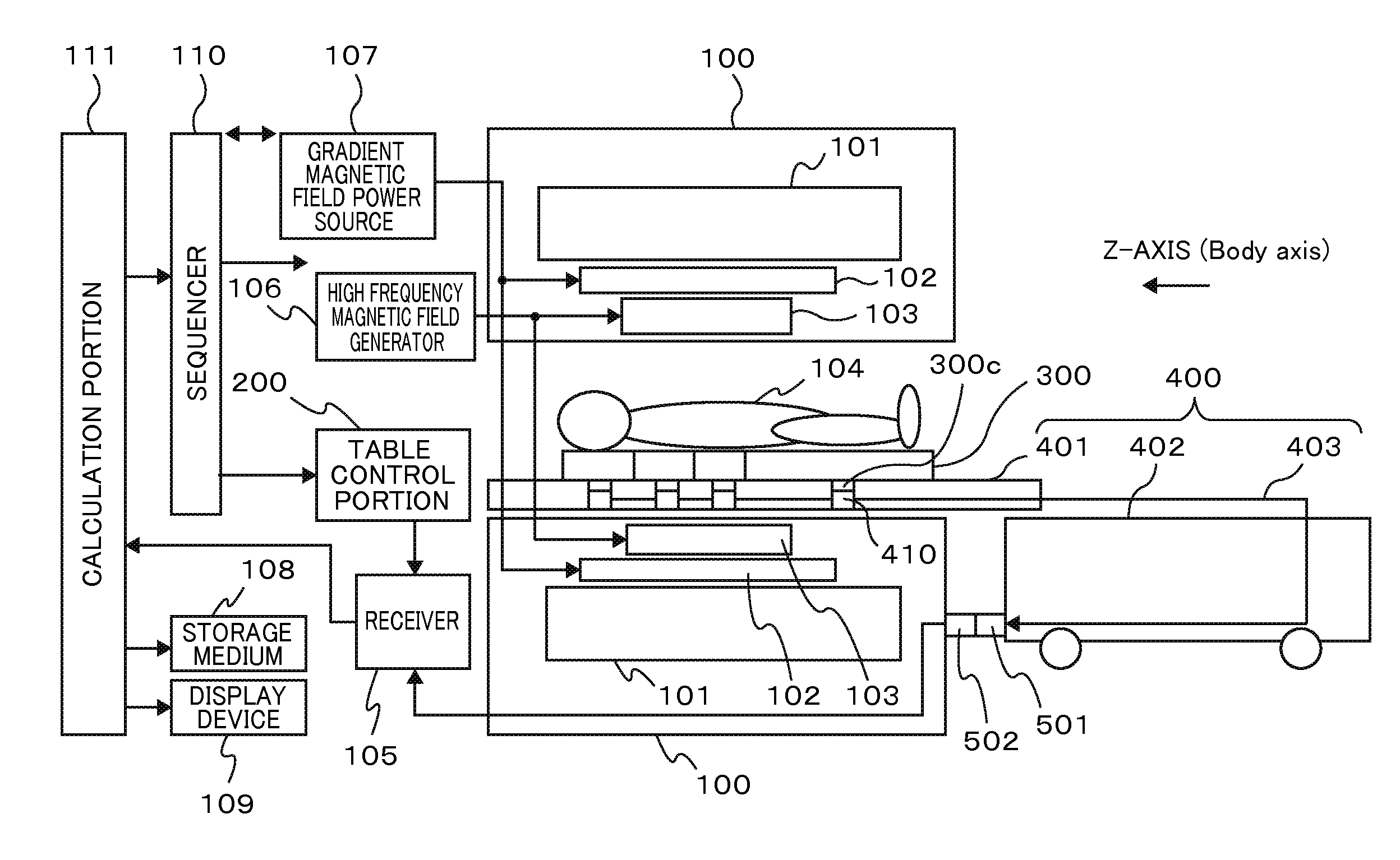

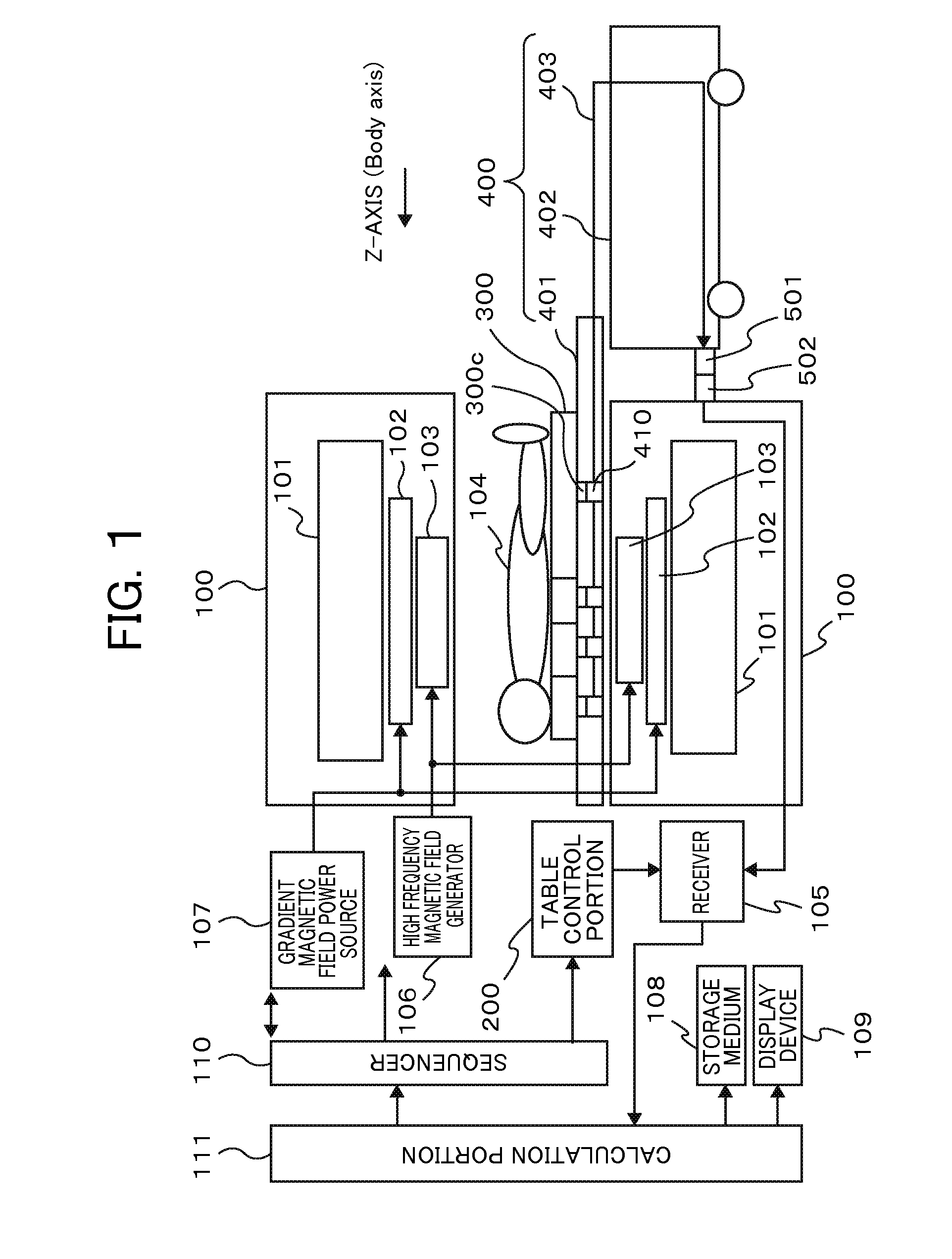

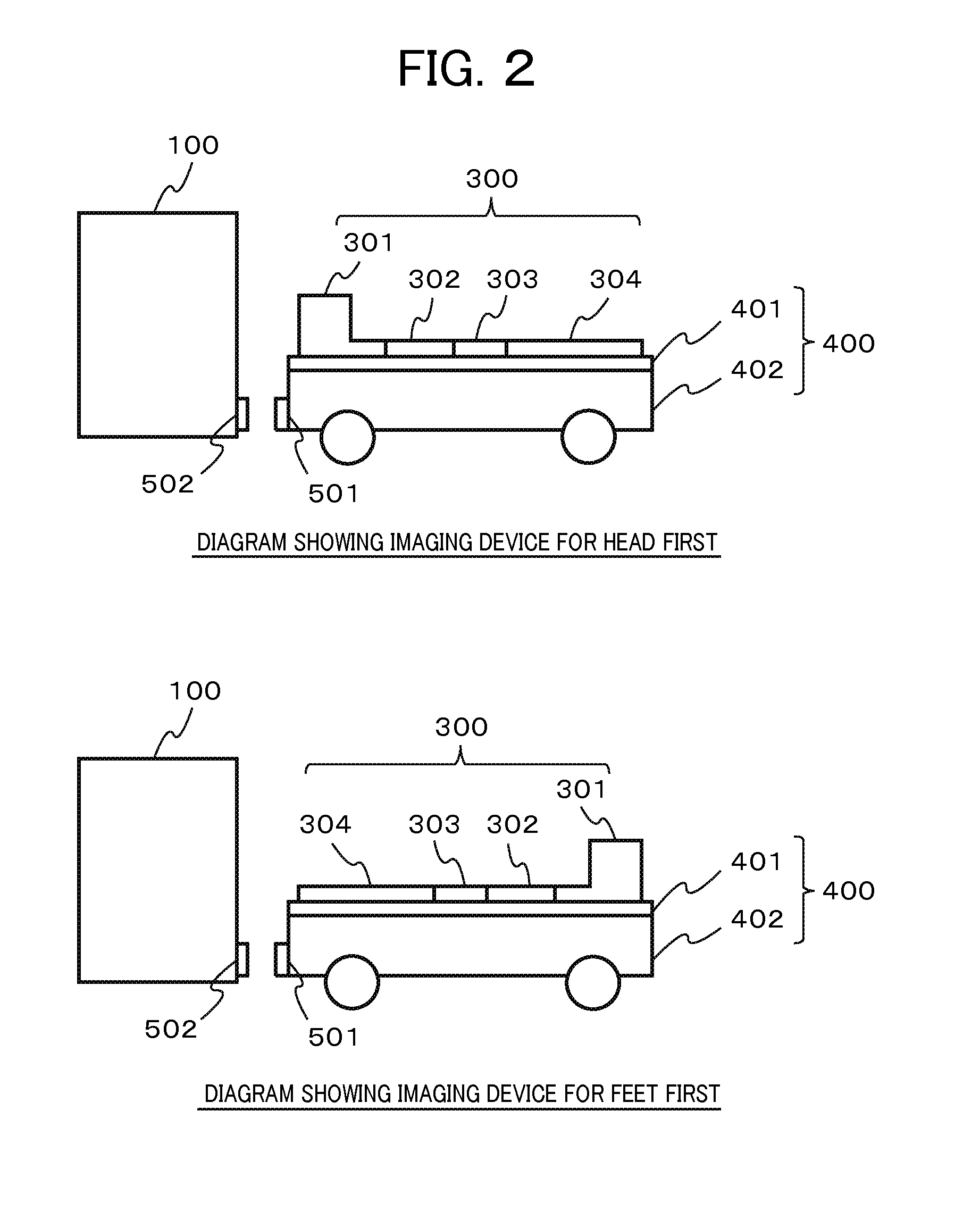

Magnetic resonance imaging device and RF coil

ActiveUS20150028873A1Improve installabilityEasy to operateMeasurements using NMR imaging systemsElectric/magnetic detectionElectrical connectionEngineering

A lower cost MRI device with a portable table detachable from the gantry is provided along with a lower cost table equipped with an easy-to-use and easy-to-install RF coil system able to perform high-resolution head and neck imaging and high-speed whole body imaging in both head-first and feet-first modes. This magnetic resonance imaging device has a portable table detachable from the gantry, and the portable table has a docking connector that can be connected to the gantry and a ceiling panel on which an RF coil can be installed to receive nuclear magnetic resonance signals generated by the examinee and to irradiate the examinee with a high-frequency magnetic field. The RF coil is divided into two or more RF coil units, the ceiling panel has a plurality of ceiling panel connectors enabling each RF coil unit to be connected, and each RF coil unit has a connector. Each RF coil unit is arranged in overlapping fashion on the ceiling plate and the ceiling panel connectors and coil connectors are connected without having to establish an electrical connection between RF coil units.

Owner:FUJIFILM HEALTHCARE CORP

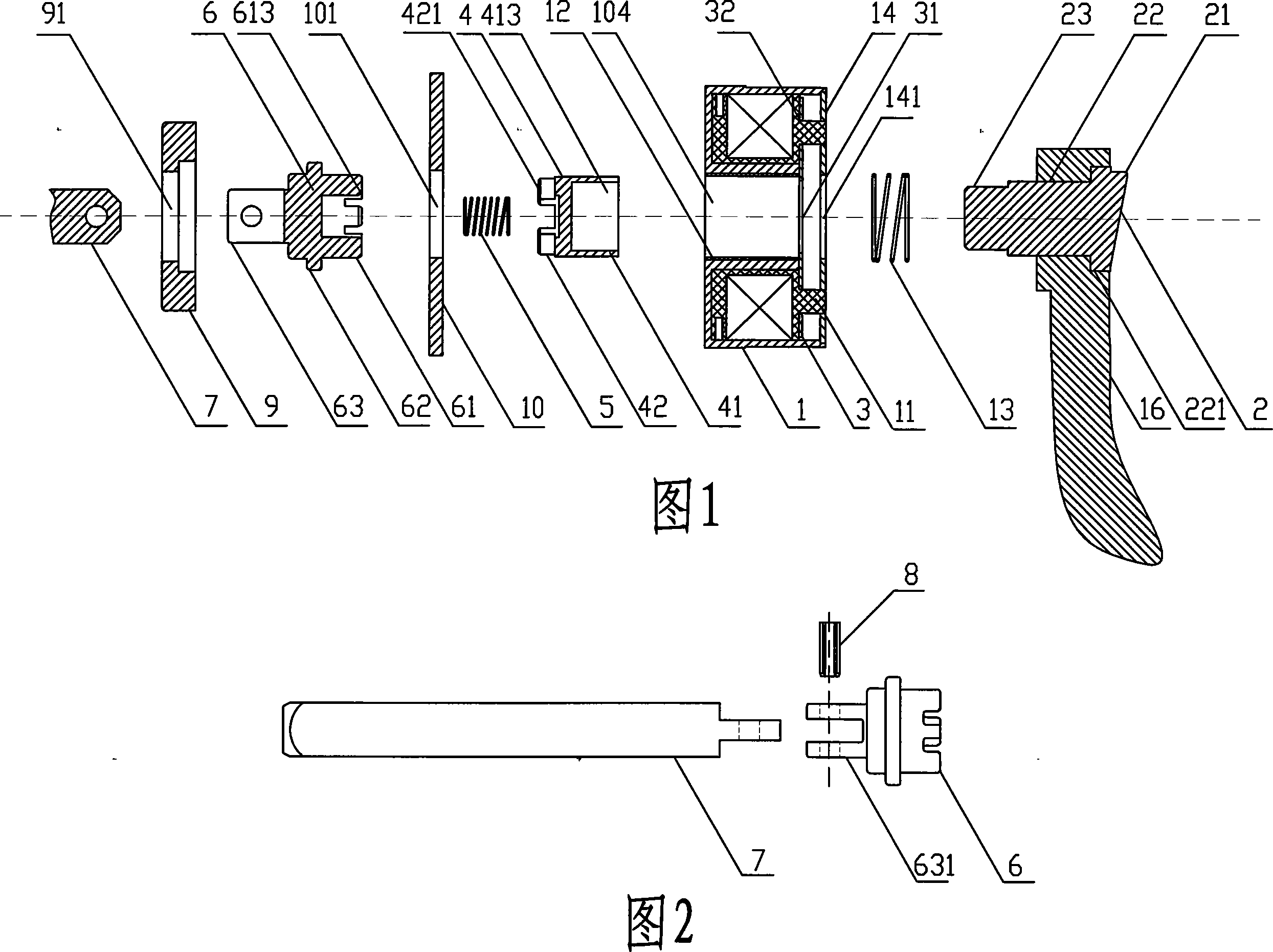

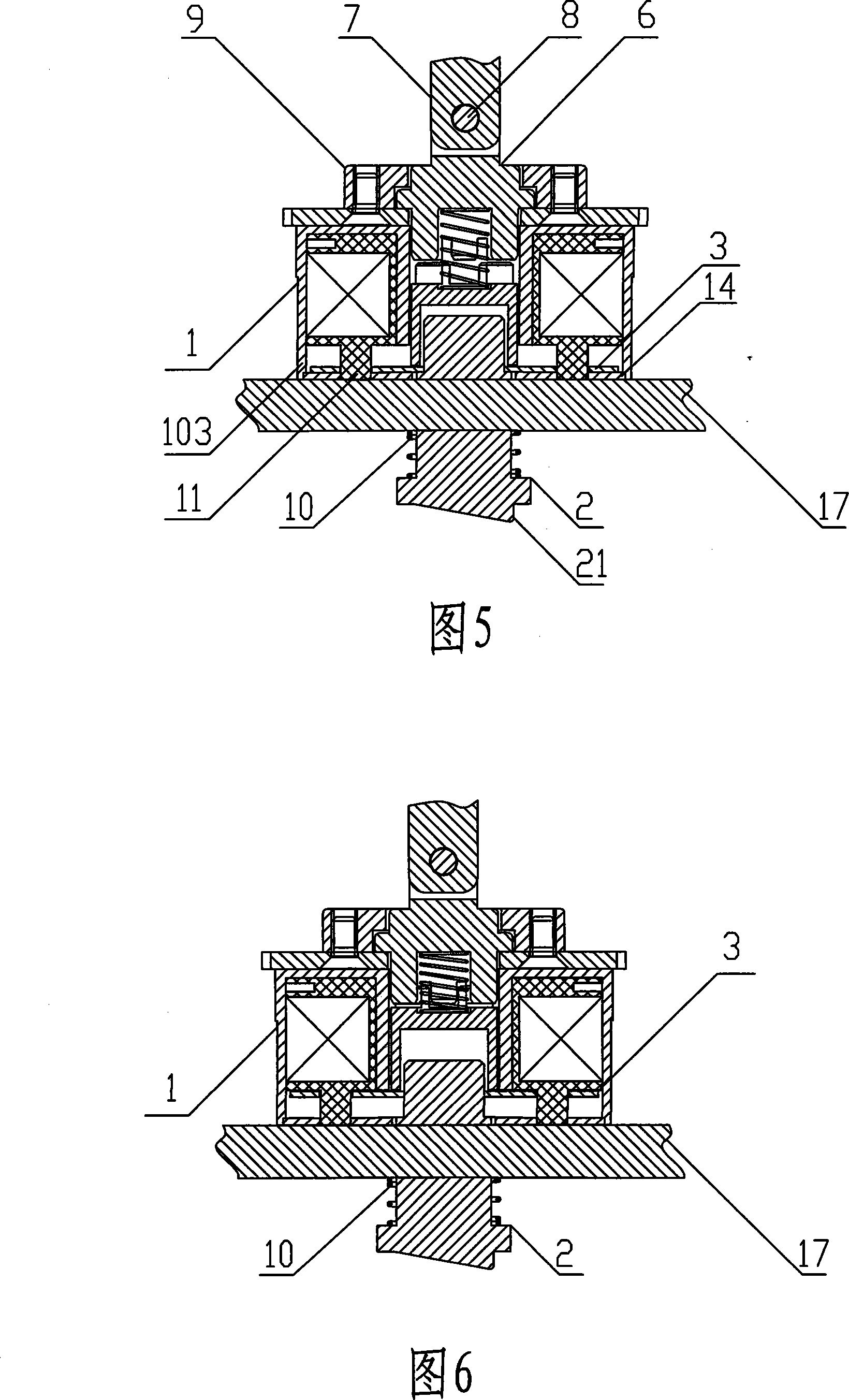

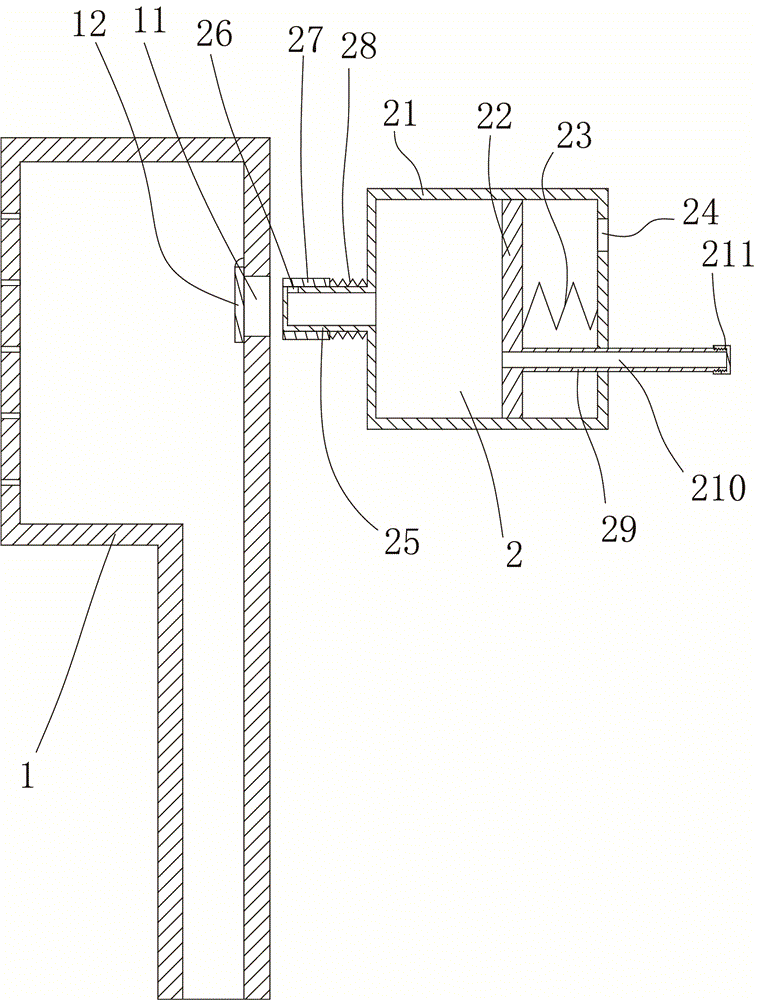

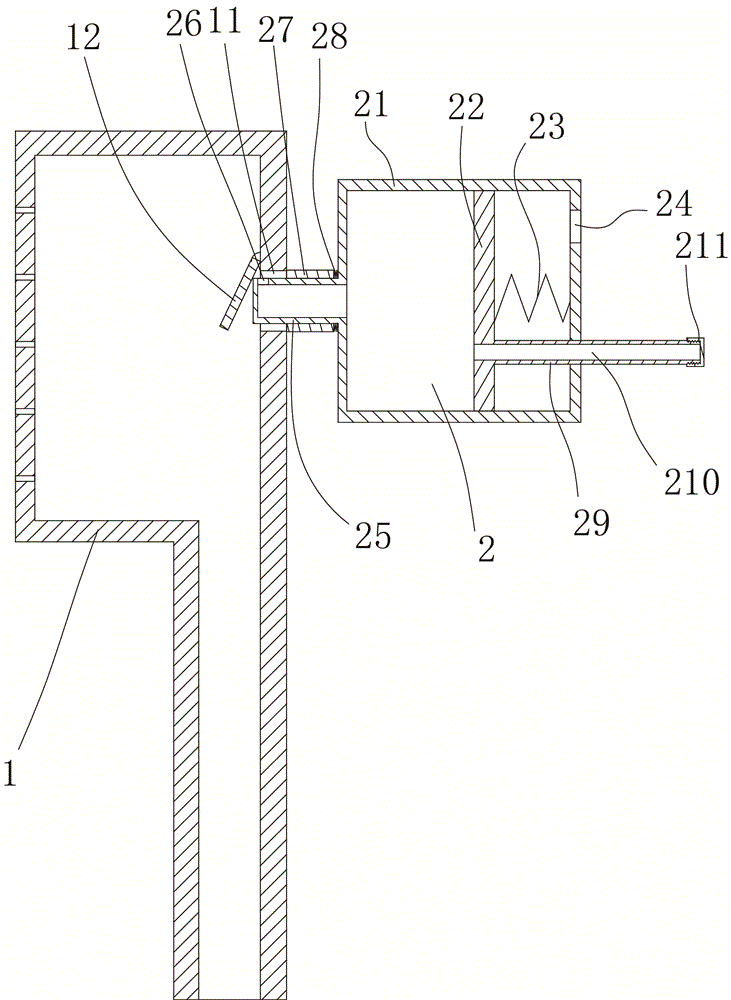

Clutch mechanism of electromagnetic lock

InactiveCN101182741AHave a positive effectHigh concentricityNon-mechanical controlsMagnetically actuated clutchesLocking mechanismElectromagnetic lock

The clutch mechanism of the electromagnetic lock consists of an electromagnet assembly, a push piece connected in sequence, a push piece return spring, a movable piece, a transmission piece, a transmission piece return spring, a square bar linkage block, and a square bar. A sliding shaft and a stopper are arranged on the top end surface of the electromagnet assembly, and the stopper is fixedly connected with the sliding shaft; the movable piece is slidably sleeved on the sliding shaft; the head of the transmission part is provided with a first blind hole cavity; the pushing part The protruding part of the main body passes through the central hole of the movable piece and fits into the first blind hole cavity of the transmission part, and the square rod linkage block is movably connected with the square rod, which facilitates the replacement and folding of the square rod. The clutch mechanism is mainly used in a dual-purpose electromagnetic lock that can be opened and closed mechanically and controlled by an electric circuit.

Owner:GUANGDONG ARCHIE HARDWARE

Apparatus for exercise, body building and rehabiliation

An apparatus for exercise, body building and rehabilitation includes a main body to be grasped by a user or bound around a proper part of a user's body. A fixing member is secured with the main body for fixing one end of an elastic rope, loop-shaped and provided with a first and a second end portion in proper proportion. The first end portion is formed with an open hole extending downward and contracting gradually to form a longer open hole at the second end portion. The elastic rope has one end head first put in the larger open hole of the first end portion and then the elastic rope is moved downward to force its end head to be stuck in the narrower open hole of the second end portion of the fixing member not to slip off, facilitating a user to carry out exercise, body building or rehabilitation.

Owner:LIU LI HSIA

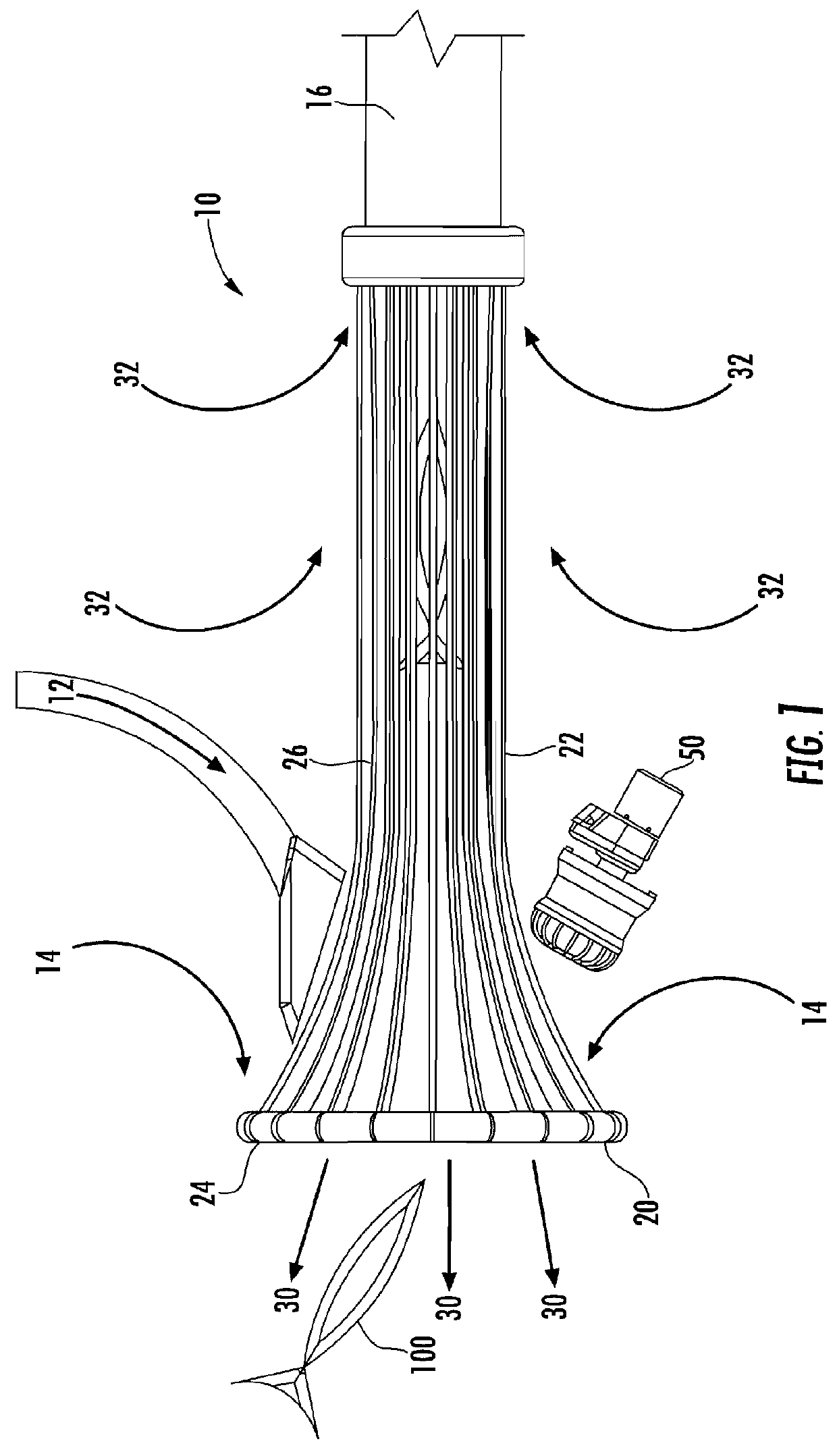

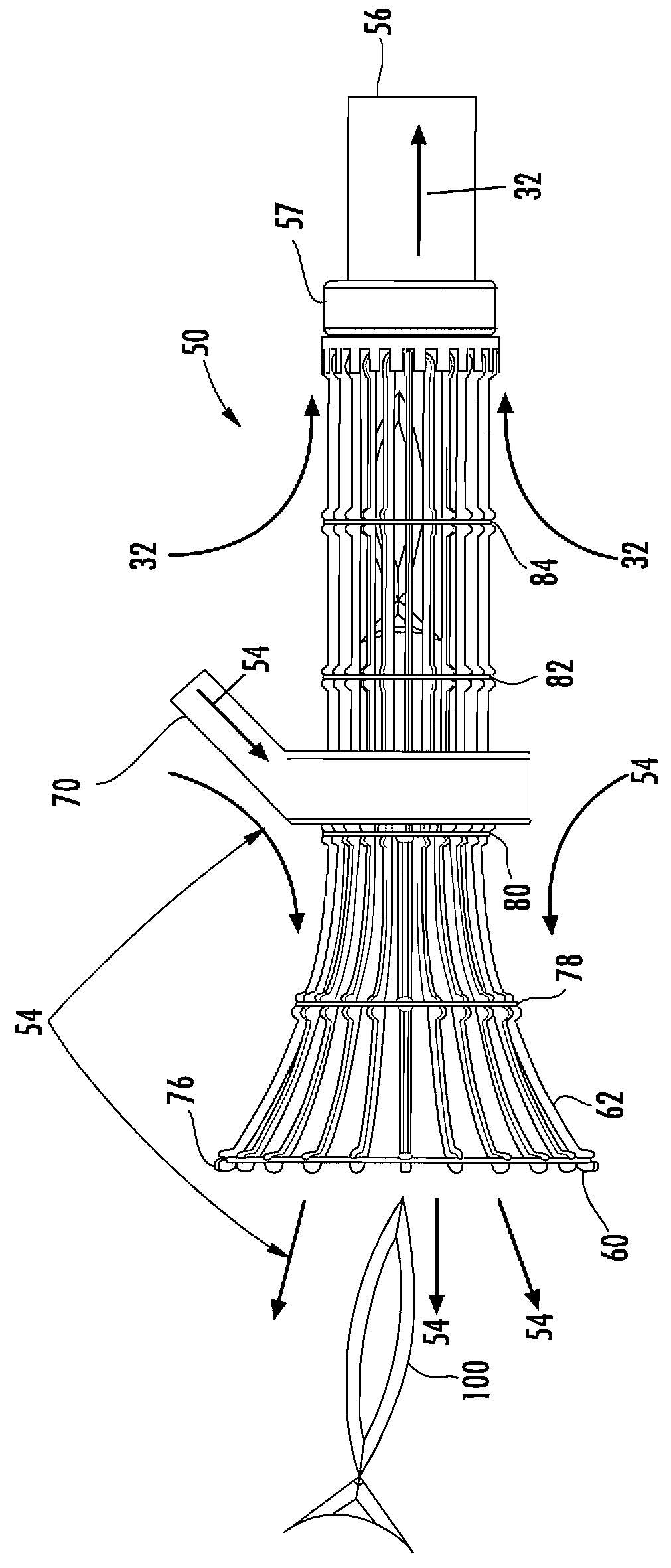

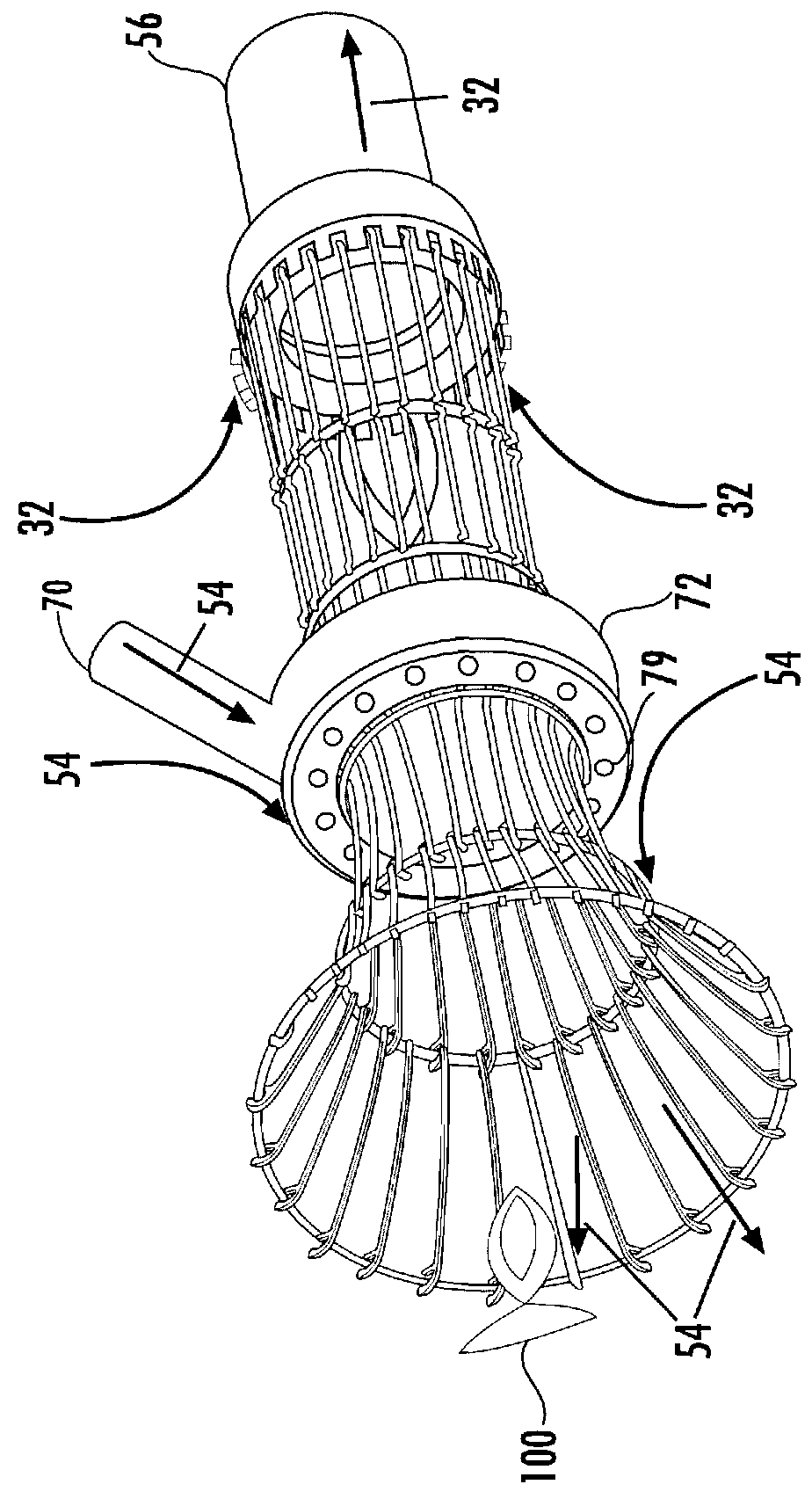

Sea lice fish pump

InactiveUS20180160657A1Avoid turningPump componentsClimate change adaptationPower flowDistribution system

An assembly designed to encourage fish to enter a Coanda effect fish pumping system head first to allow delicing through the pump. The assembly includes a funnel shaped tube made of spaced bars and a water distribution system that provides a current that fish will swim toward. Once within the funnel shaped tube, wall spacing allows the current to dissipate where a suction current of the pump further transfers the fish. The current changes within the Coanda effect pump provide delicing of the fish by orientating the fish in a forward direction as the fish pass through the pump.

Owner:LINDGREN PETER B

Dispensing device and methods for emitting atomized spray

A device for dispensing a liquid product as an atomized spray includes a container, a depressible dispensing head for initiating emission of the spray from the device and for terminating emission of the spray from the device, and a sequential delivery valve attached to the dispensing head. The dispensing device is configured to initiate flow of gas only into the dispensing head first when the dispensing head is depressed from a first axial position to a second axial position. When the dispensing head is depressed further toward the container to a third axial position, the dispensing device allows both liquid and gas to travel from the container into the dispensing head. When the dispensing head is released from the third axial position back to the first axial position, the dispensing device first stops flow of liquid into the dispensing head before stopping flow of gas into the dispensing head.

Owner:UNIV DE SEVILLA

Fibre-optical sensing device for monitoring metal rust

InactiveCN100424497CSimple structureEasy to manufacturePhase-affecting property measurementsCouplingEngineering

A monitor metal rusts away the optical fiber transmitter, its constitution includes: The detecting head is in waits on the monitor metal material by the first optical fiber to twine the N circle constitution; Reference is in one with treats on the monitor metal structure material configuration and the radius same anti-corrosive material by the second optical fiber twines the N circle constitution; States a detecting head first optical fiber end and refers to the head a second optical fiber end to tie the ratio after the minute is 1: 1 first optical fiber coupler coupling and forms the first port and the second port, states the first optical fiber and the second optical fiber another end ties the ratio after the minute is 1: 1 second optical fiber coupler coupling and forms the third port and the fourth port. This invention has the structure simply, the manufacture is easy, may obtain the high sensitivity survey; May use certain optical fiber paths of rays to constitute the multi- viewpoints the distributional supervisory system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

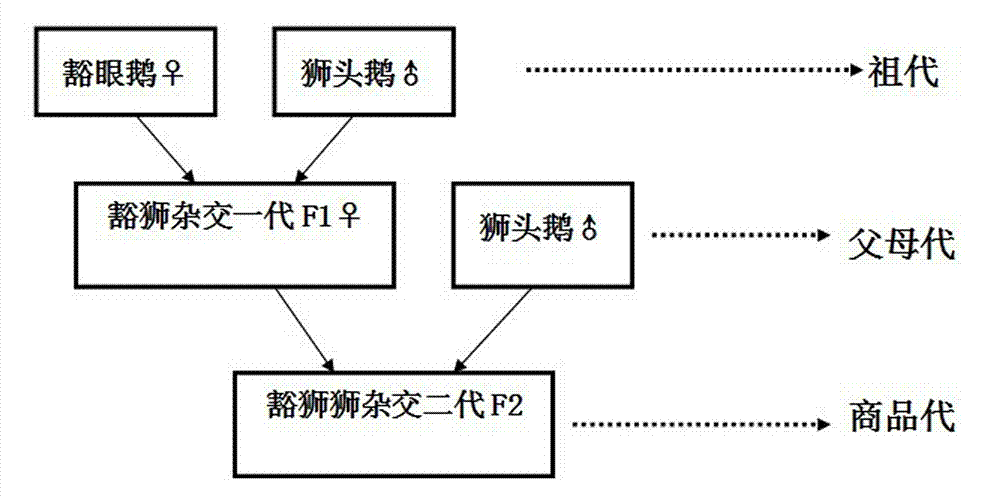

Cultivating method for meat type hybridized goose capable of laying more eggs and being large in size

InactiveCN103004694AImprove growth performanceIncrease egg productionAnimal husbandryHead FirstBiology

The invention discloses a cultivating method for a meat type hybridized goose capable of laying more eggs and being large in size. The cultivating method comprises the steps: firstly conducting hybridization by taking a Huoyan goose as a female parent and a lion-head goose as a male parent to obtain Huoyan-lion-head first-filial generation F1; and then conducting hybridization by taking the Huoyan-lion-head first-filial generation F1 a female parent and a lion-head goose as a male parent to obtain Huoyan-lion-head second-filial generation F2 which is large in size. The Huoyan-lion-head first-filial generation F1 which is good in growth property and higher in egg laying rate is obtained by enabling the Huoyan goose capable of laying more eggs and the lion-head goose which is large in individual to be hybridized, and then the meat type Huoyan-lion-head second-filial generation F2 is obtained by taking the Huoyan-lion-head first-filial generation F1 as a female parent to be hybridized with the lion-head goose, so that the Huoyan-lion-head second-filial generation F2 not only inherits the high egg laying rate characteristic of the Huoyan goose, but also inherits the large individual characteristic of the lion-head goose, thereby laying a foundation for the development of meat geese.

Owner:兴安县嘉鑫养殖农民专业合作社

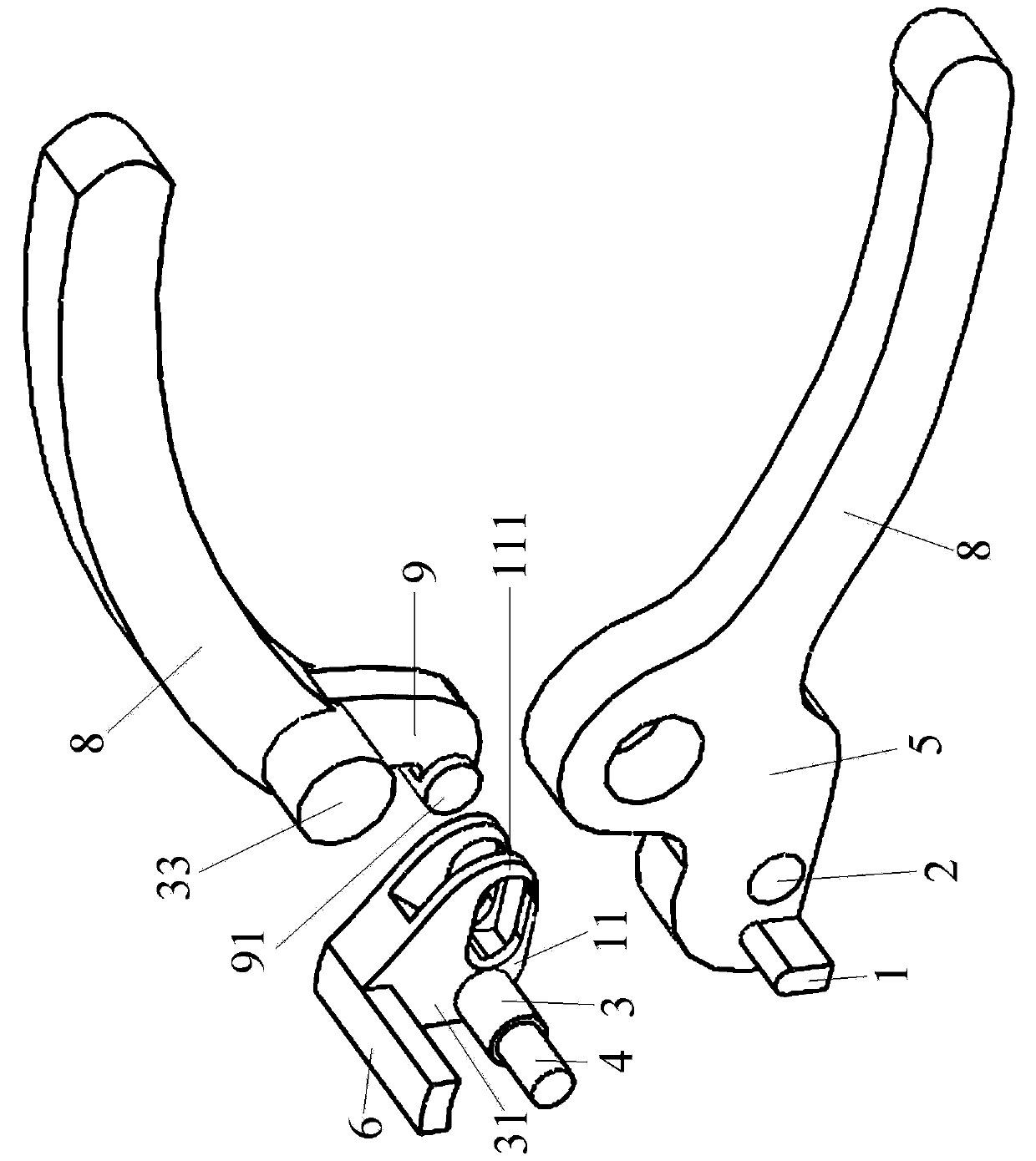

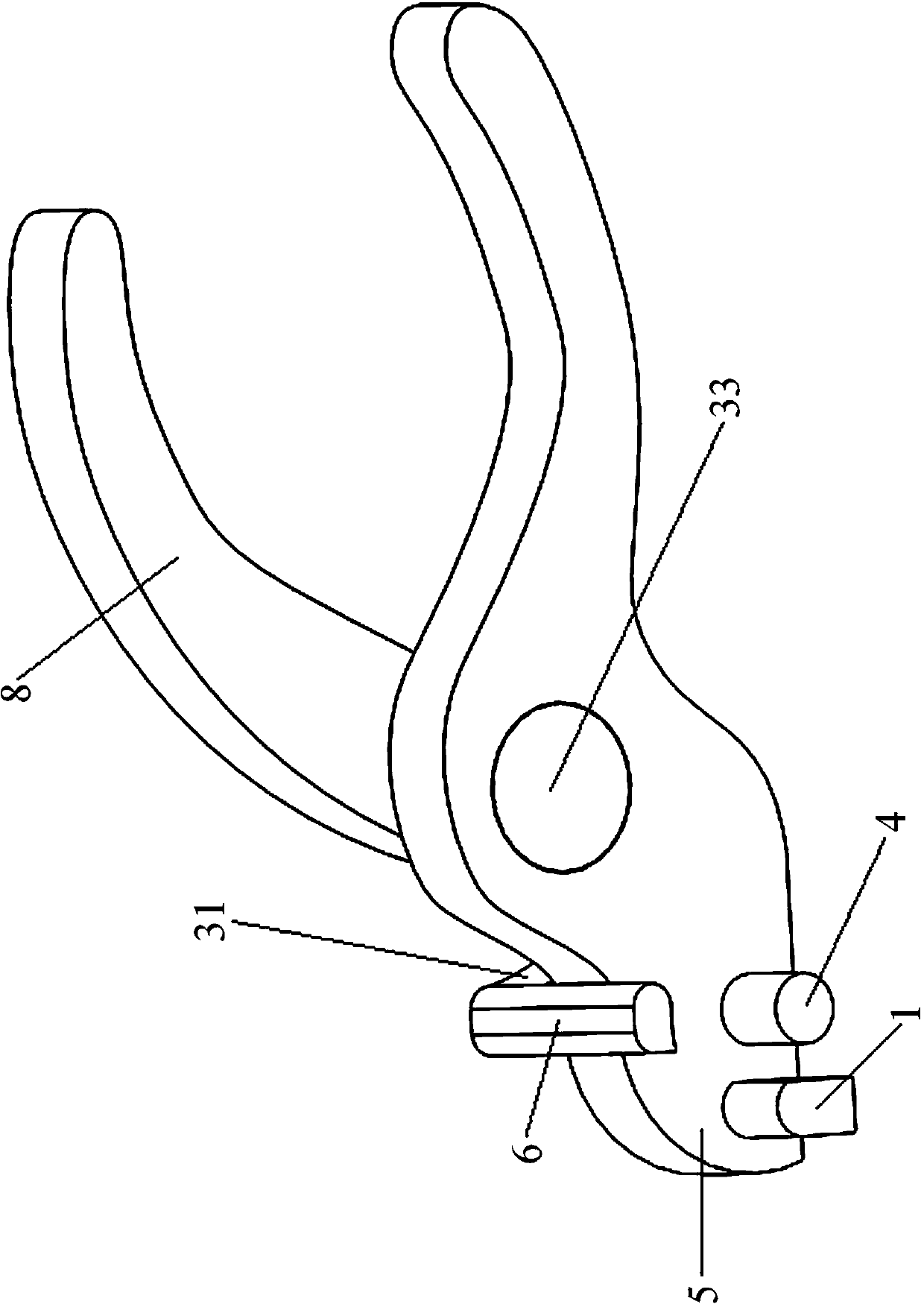

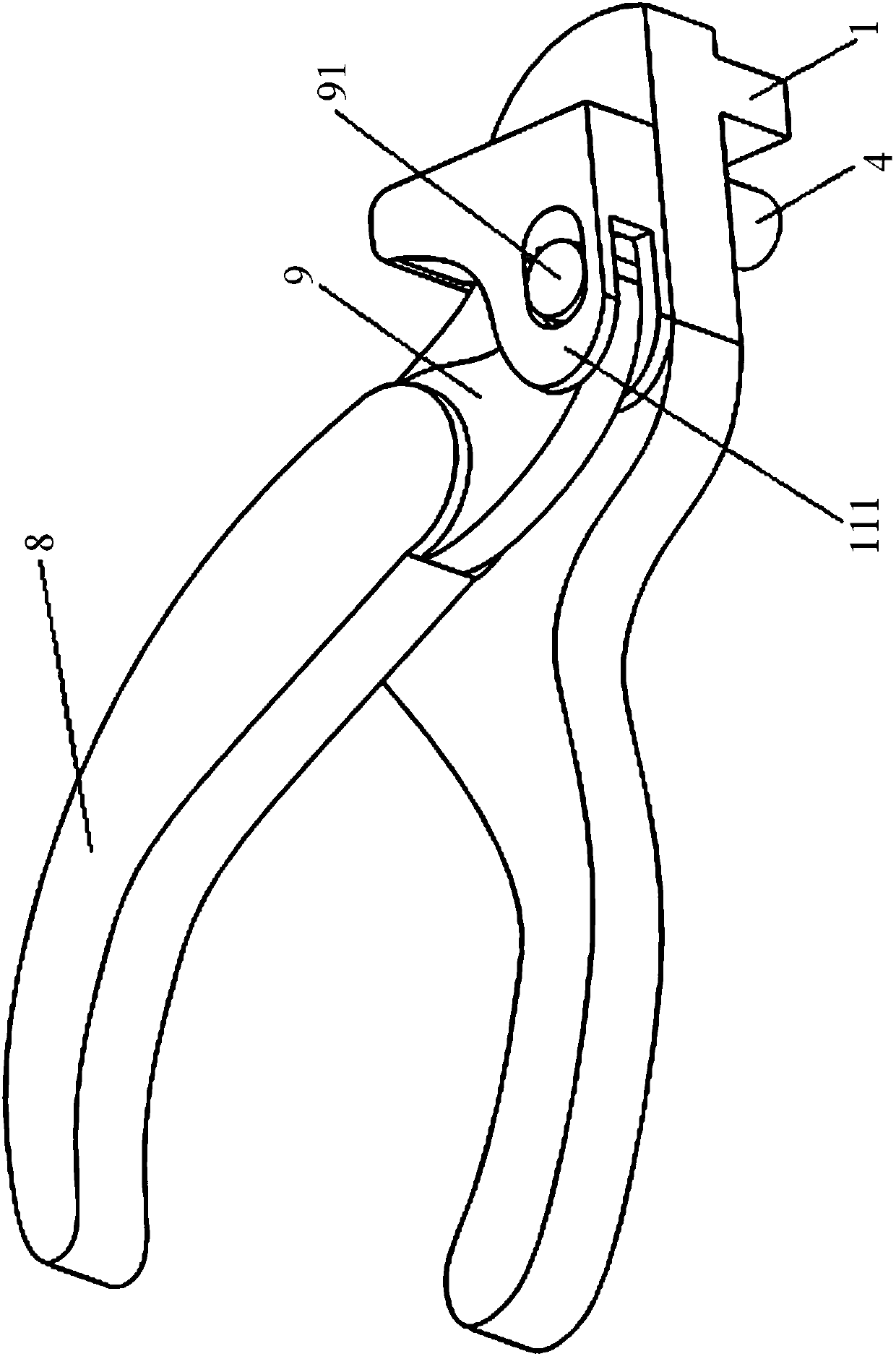

Orthopedic kirschner pin bending device

InactiveCN104414727ATime-consuming and laborious to solveOsteosynthesis devicesHead FirstMechanical engineering

The invention discloses an orthopedic kirschner pin bending device. A formed core block is fixed on a base which is provided with a shaft hole; a rotating shaft is arranged in the shaft hole; the rotating shaft extends out of the shaft hole to form a limiting column; a kirschner pin is positioned through the limiting column and the formed core block together; a shifting block is fixed through a connecting part due to the rotating shaft. According to the orthopedic kirschner pin bending device, the kirschner pin is often clamped through a tong head first in the prior art and is forcibly to be bent under the clamped state, the time and the labor are consumed, and the shifting block which rotates around the rotating shaft shifts the kirschner pin to be bent around the formed core block to form a standard hooked elbow.

Owner:ZHENGZHOU ZEZHENG TECHN SERVICES

Process for repairing worn discharging head of rotor scale

InactiveCN101850477AImprove wear resistanceSolve the problem of short service lifeWelding apparatusWear resistantManganese

The invention discloses a process for repairing a worn discharging head of a rotor scale, belongs to the technical field of maintenance of cement production equipment, and in particular relates to a process for repairing worn parts of coal feeding wearing parts in the discharging head of the German Pfister rotor scale. The process is characterized by comprising the following steps of: performing a first layer of repair welding on the inner side of the worn part of the discharging head by using a J422 welding rod; after the first layer of welding is finished, cooling the welding layer until the welding layer is not dark red, cleaning off coatings and performing repair welding on another layer; and performing repair welding layer by layer and overlaying a high-manganese-alloy wear-resistant overlaying layer (1) on the repair welding layer (2) by using a D256 welding rod. The process for overlaying a wear-resistant layer for a new discharging head and repairing the seriously worn discharging head first and then overlaying the wear-resistant layer effectively improves the wear resistance of the discharging head, makes the overlaying wear-resistant layer have the service life of 7 to 8 months, solves the problem of short service life of the discharging head, and can repeatedly repair the worn discharging head for use so as to save the purchase cost of the imported parts.

Owner:SHANDONG DONGHUA TECH CO LTD

Corrugated pipe welding device

InactiveCN107009066AImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHead First

The application discloses a bellows welding device, which includes a base, a first clamp, a second clamp, a welding torch bracket and a welding torch. The first clamp is fixedly installed on the base, and the second clamp is movably arranged on the base. The second clamp can be The first clamp moves back and forth; the welding torch support is arranged on the base, and is located between the first clamp and the second clamp. The welding torch support includes an annular support and a welding torch seat that can move circumferentially on the inner wall of the annular support; the welding torch seat is provided with a telescopic mechanism, and the welding torch Set in telescopic mechanism. Therefore, by first aligning and fixing the corrugated pipe and the connecting head, and then performing circumferential welding on the corrugated pipe and the connecting head through a welding torch capable of moving in the circumferential direction, there is no need to rotate the corrugated pipe and the connecting head, and the welding quality is improved.

Owner:NANTONG SHIFA SHIP MACHINERY

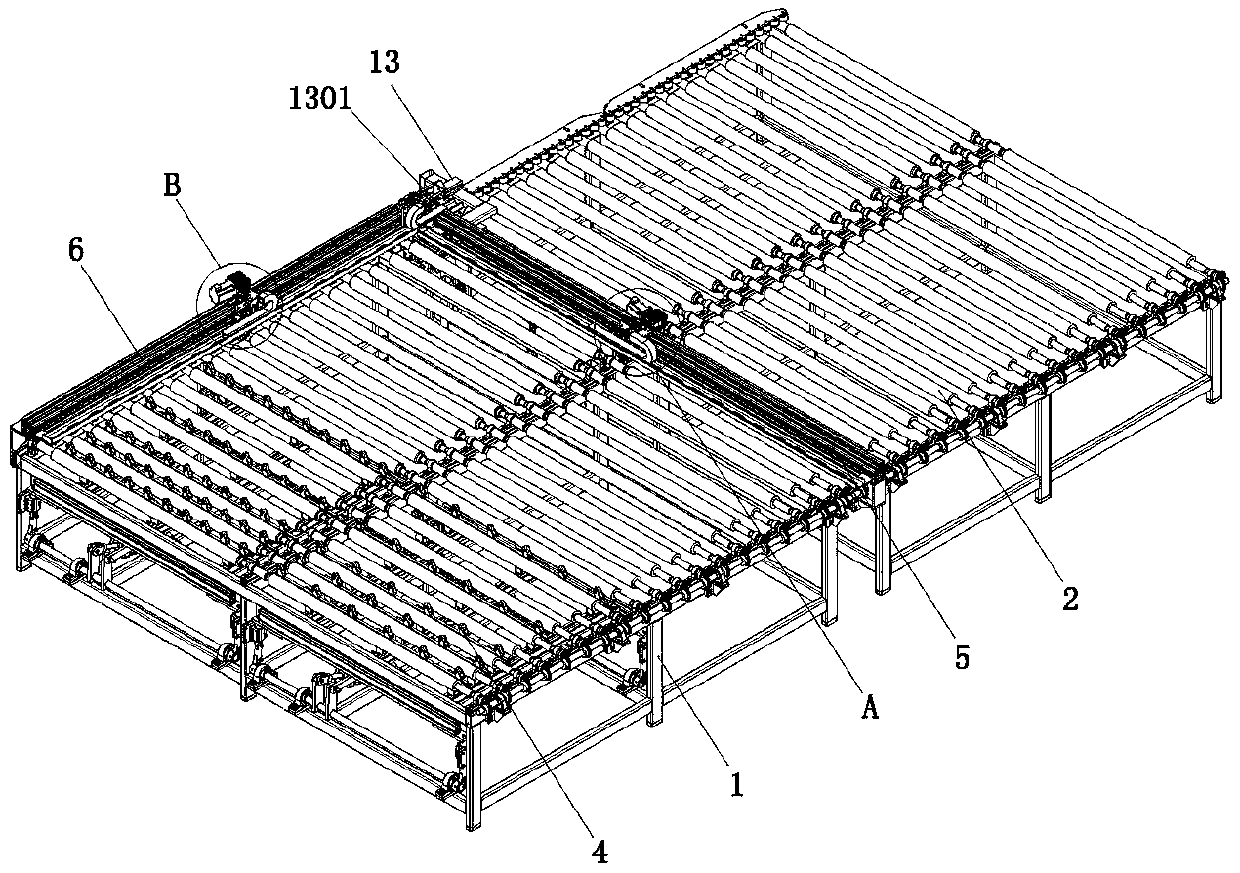

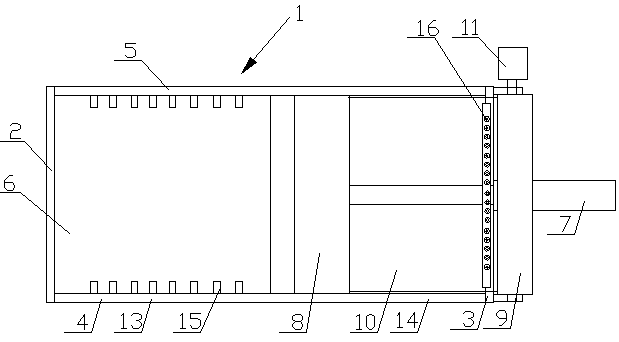

Fast glass detection table with transversely and vertically arranged double-detection head

A fast glass detection table with transversely and vertically arranged double-detection head comprises a frame; a detection mechanism is arranged on the frame; a conveying mechanism used for conveyingglass is arranged below the detection mechanism; the detection mechanism is provided with detection mechanism crossbeams and detection mechanism side beams; the detection mechanism is movably provided with a first transverse detection head and a first vertical detection head; the detection mechanism crossbeams are provided with a second transverse detection head in a slide manner through a transverse slide device; the glass transverse dimension can be calculated through measuring the distance between the first and second transverse detection heads; the detection mechanism side beams are provided with a second vertical detection head through a vertical slide device in a slide manner; the glass vertical dimension can be calculated through measuring the distance between the first and secondvertical detection heads. The glass cannot closely abut against side wheels in the prior art, so the glass cannot be accurately measured if the glass is not in position or tilted; the fast glass detection table can solve said problems, is accurate in data, and stable in measuring precision.

Owner:广东盈贯新机械有限公司

Low-overflow dam equal-water head step-by-step energy dissipation structure

The invention discloses a low-overflow dam equal-water head step-by-step energy dissipation structure. The structure comprises an overflow dam; the overflow dam is provided with a first-grade overflow dam absorption basin, a second-grade overflow dam absorption basin and a third-grade overflow dam absorption basin; the first-grade overflow dam absorption basin is connected with the dam top of the overflow dam through an equal-water head first-grade overflow dam vertical wall surface; the bottom of the first-grade overflow dam absorption basin is connected with an equal-water head first-grade drainage energy dissipation pipe; the second-grade overflow dam absorption basin is connected with a first-grade overflow dam absorption basin streamline sill through an equal-water head second-grade overflow dam vertical wall surface; and the bottom of the first-grade overflow dam absorption basin and the bottom of the second-grade overflow dam absorption basin are connected with an equal-water head second-grade drainage energy dissipation pipe. Compared with the prior art, the structure adopts such designs as equal-water head energy dissipation pipe graded drainage energy dissipation, equal-water head graded vertical overflow, flooding jet absorption basin energy dissipation, advanced overflow and reservoir capacity increment, and is prominent in cavitation resisting effect of overflow surfaces, better in energy dissipation effect, simple in structure, lower in maintenance cost and larger in popularization space.

Owner:HOHAI UNIV

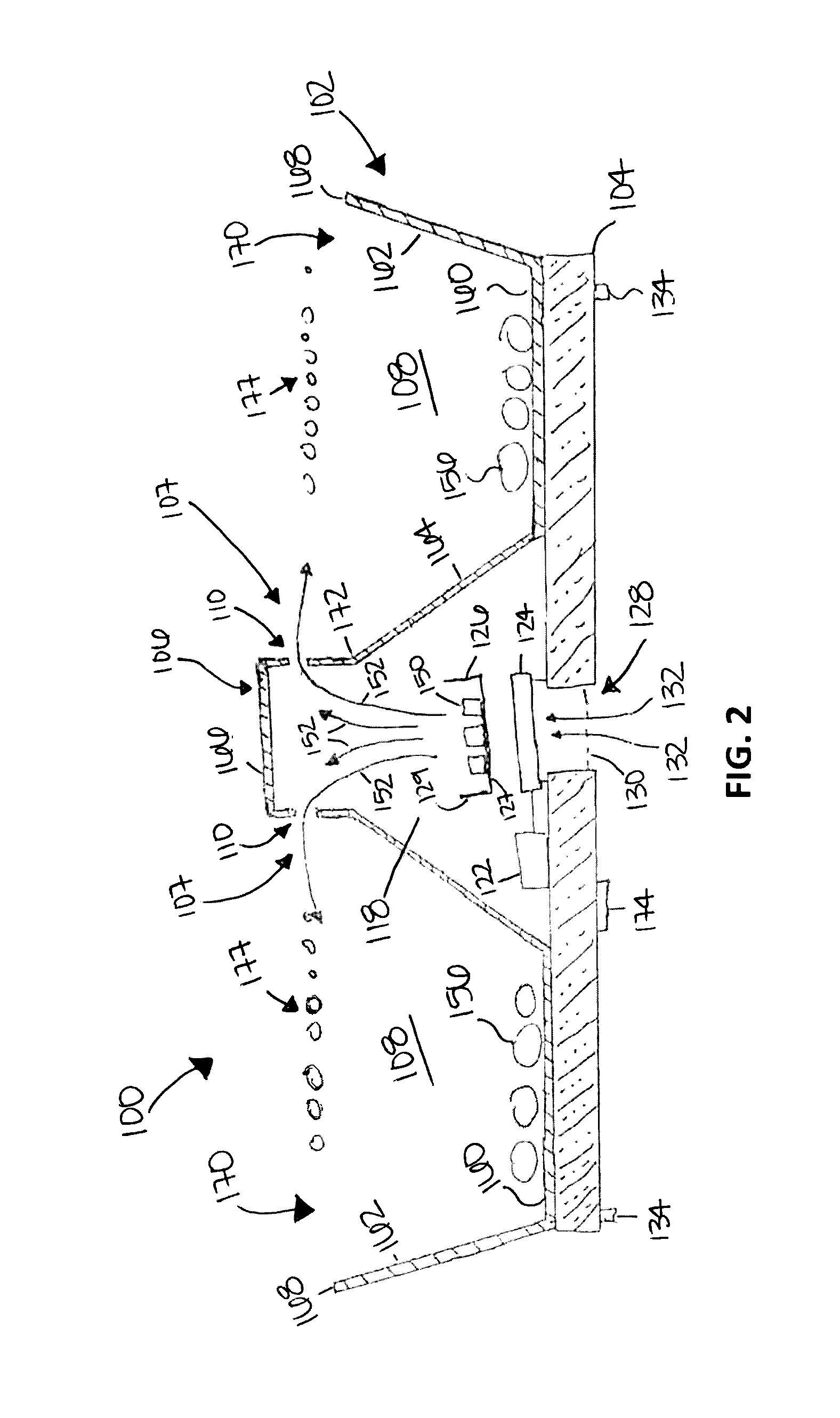

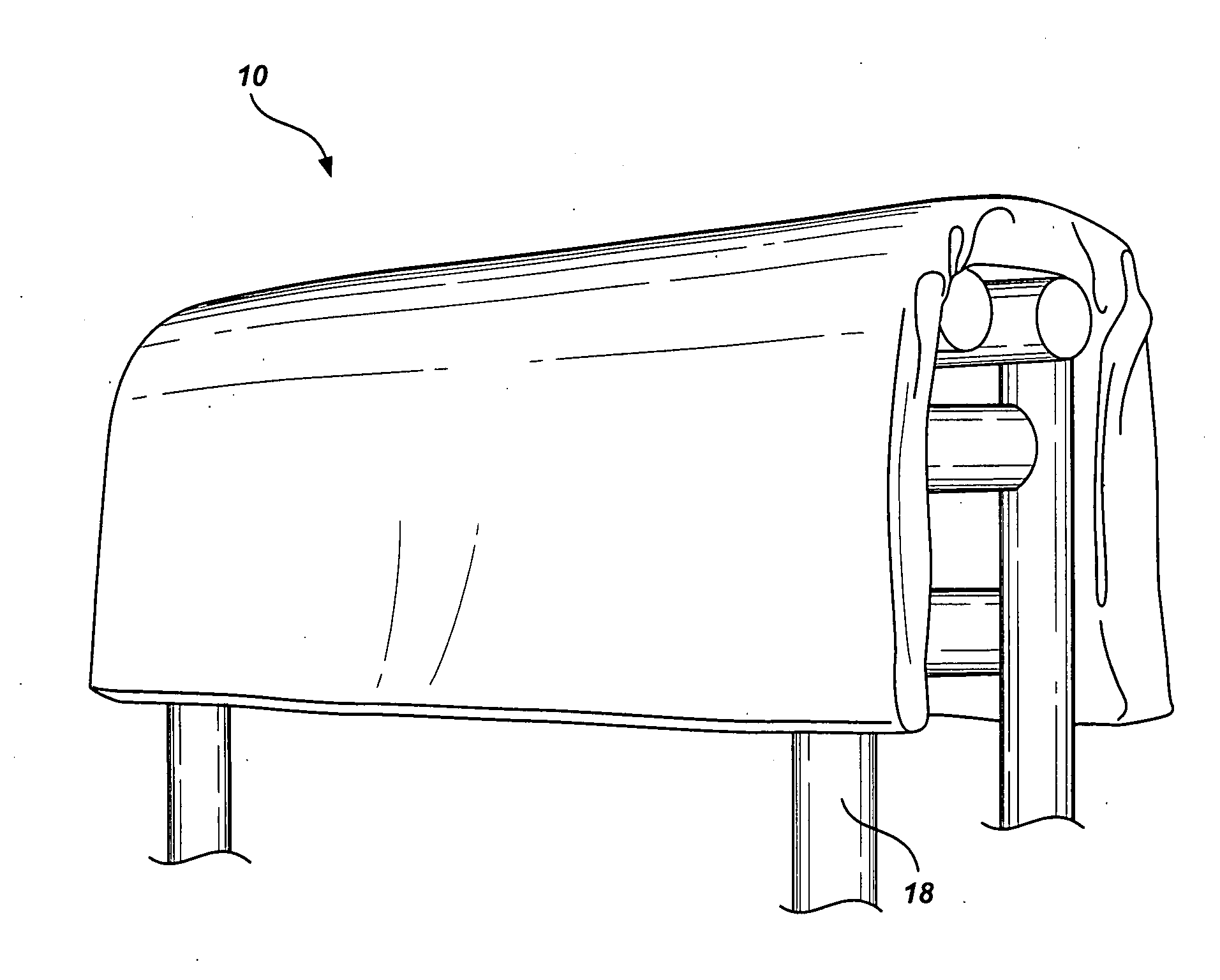

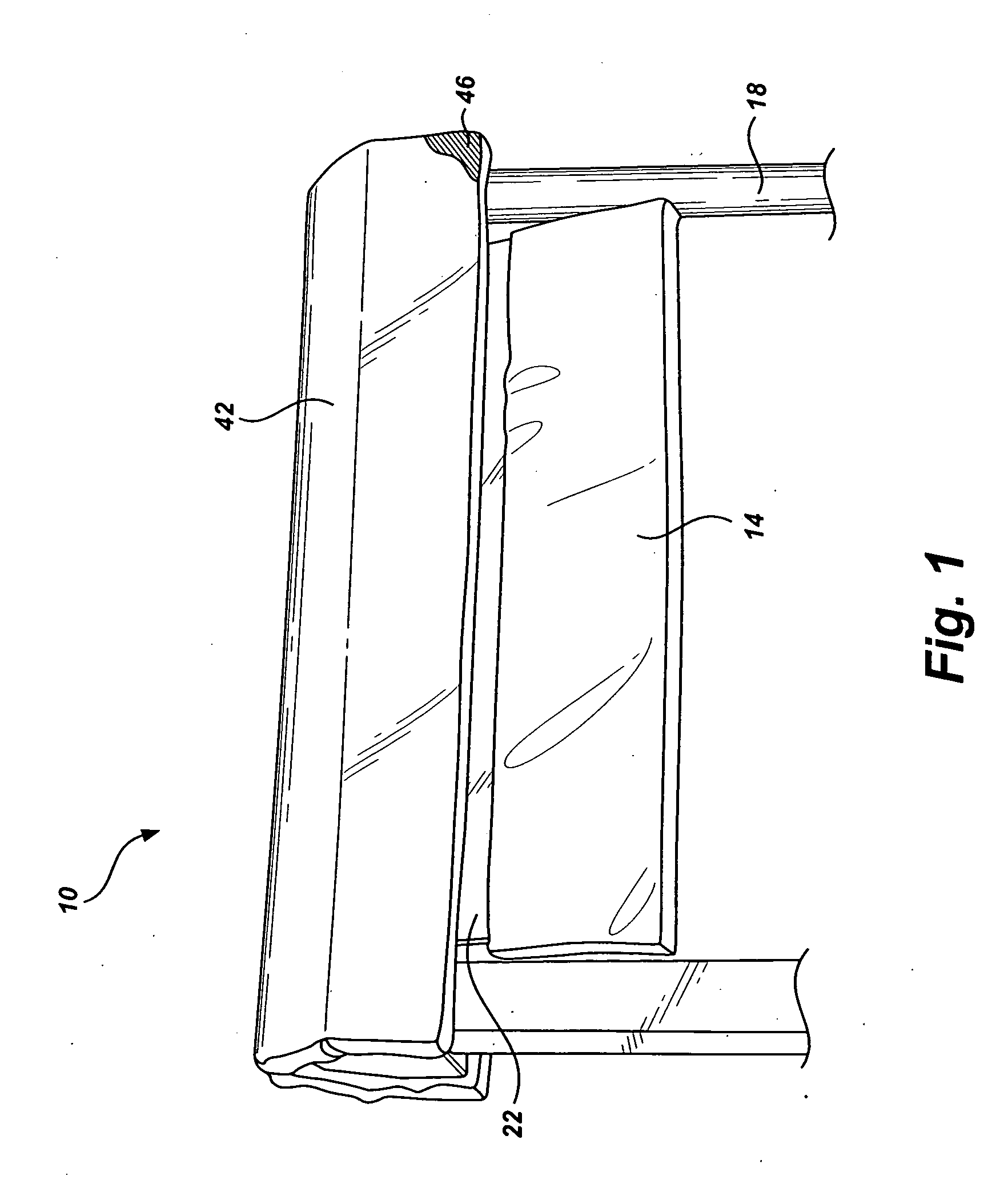

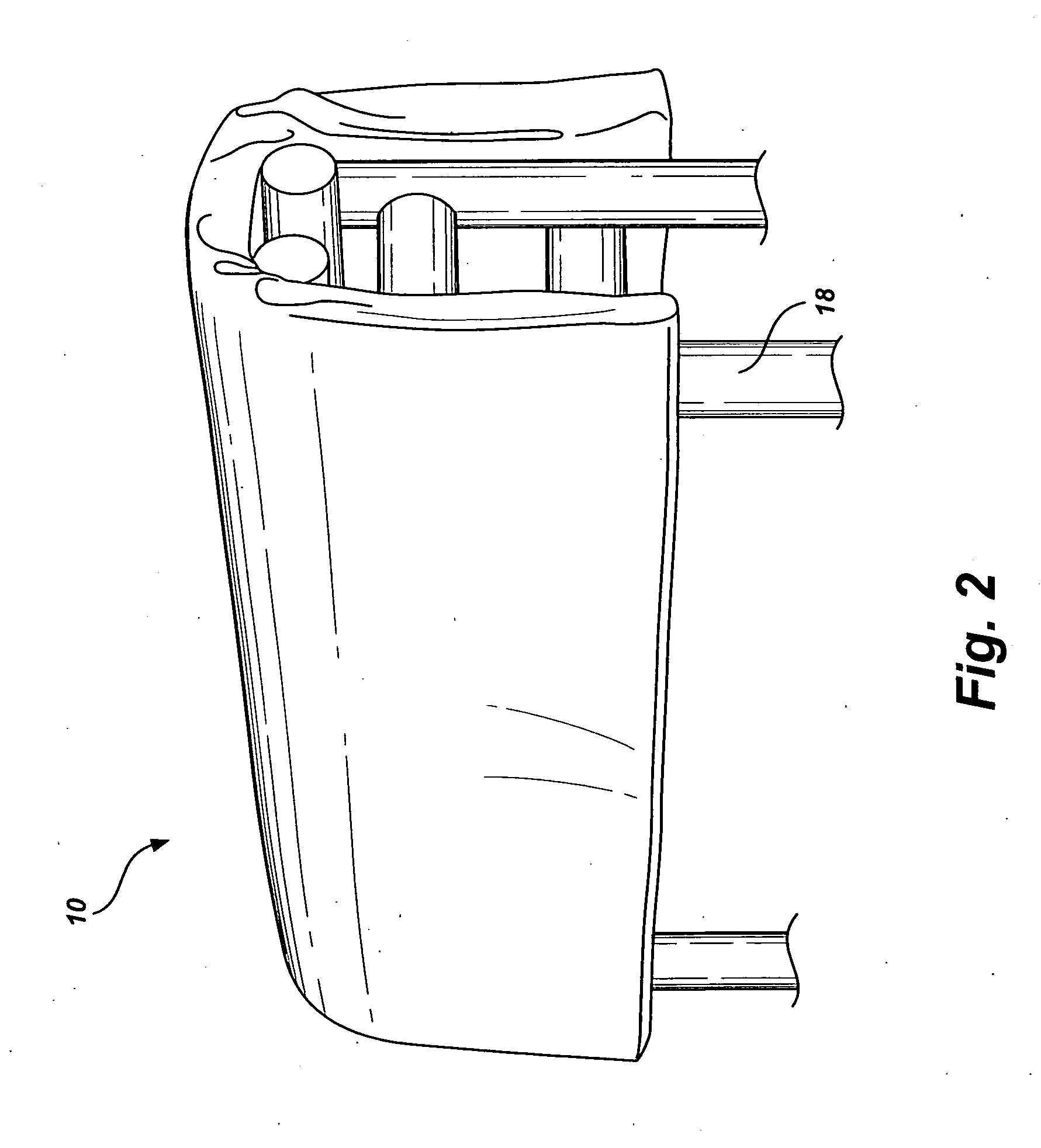

Bucking chute safety pad

The present embodiment 10 provides a safety device for use with rodeo type bucking chutes as a means of reducing serious injuries to the participant, (which are common to the sport of bull riding and bronc riding) while preparing to mount livestock during exhibitions and competitions. The device comprises of a pad 42 filled with shock absorbing material 46 and covered with an encasement 42 made of vinyl, leather or other material strong enough to withstand substantial impact by individuals and / or livestock. The embodiment 10 is designed to fit over the top of the chute gate slider frame 18, extending slightly below the attachment area and attached at both ends of the chute frame 18. Attachment is accomplished with the use of nylon straps 30 (or other suitable material) to hold the embodiment 10 in place. Velcro strips 38 may also be used to attach the embodiment 10 to the chute frame 18. The embodiment 10 as shown 10 FIGS. 1,2 and 3 when properly mounted to the bucking chute frame 18 front and back, will greatly reduce the possibility of injury caused by the animal lunging forward and throwing the participant head first into the steel bars on the chute gate frame. It will also prevent injury when animals rare over backwards, pining the participant between the animal and the top of the chute gate.

Owner:LILES JAMES P

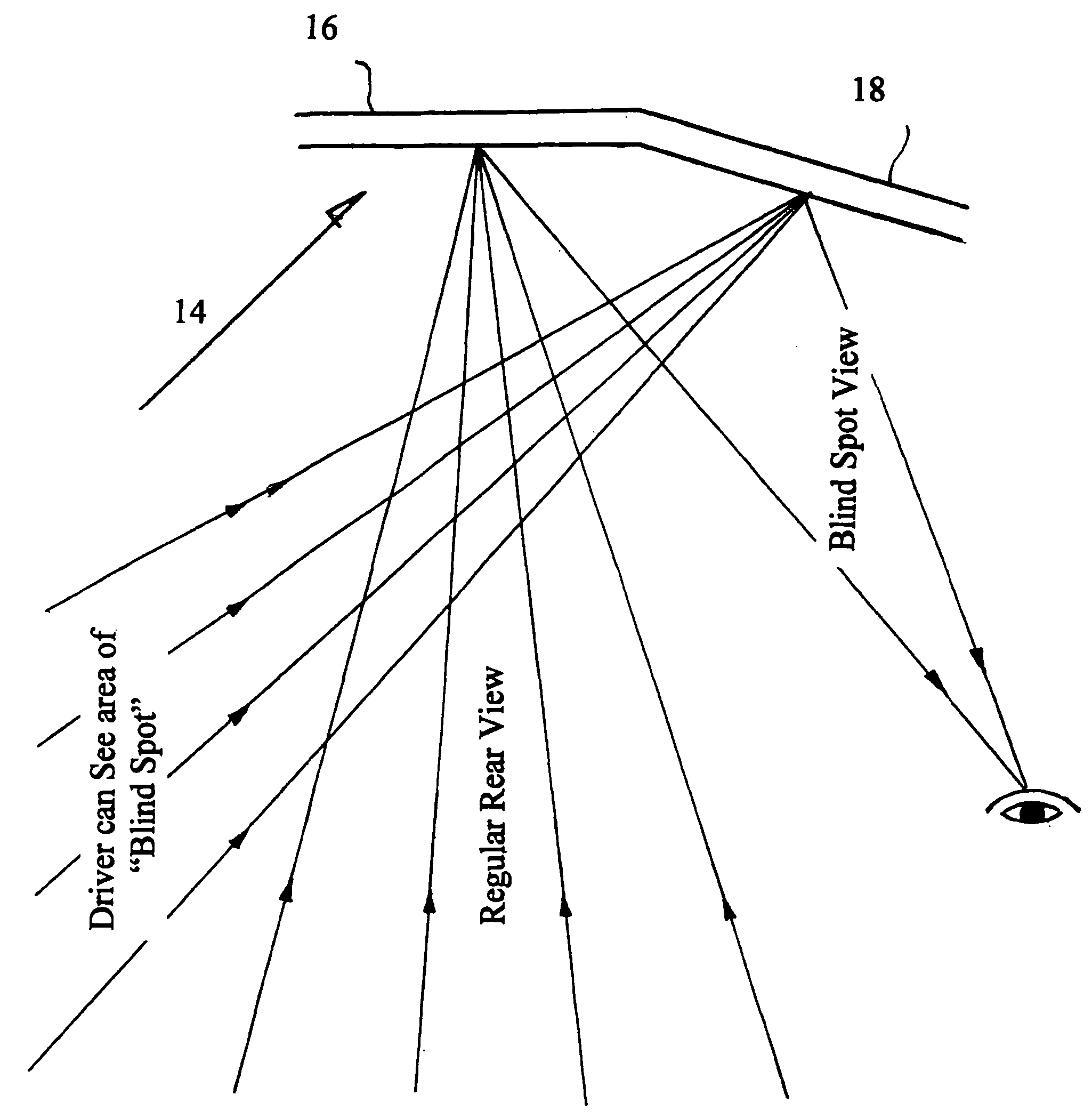

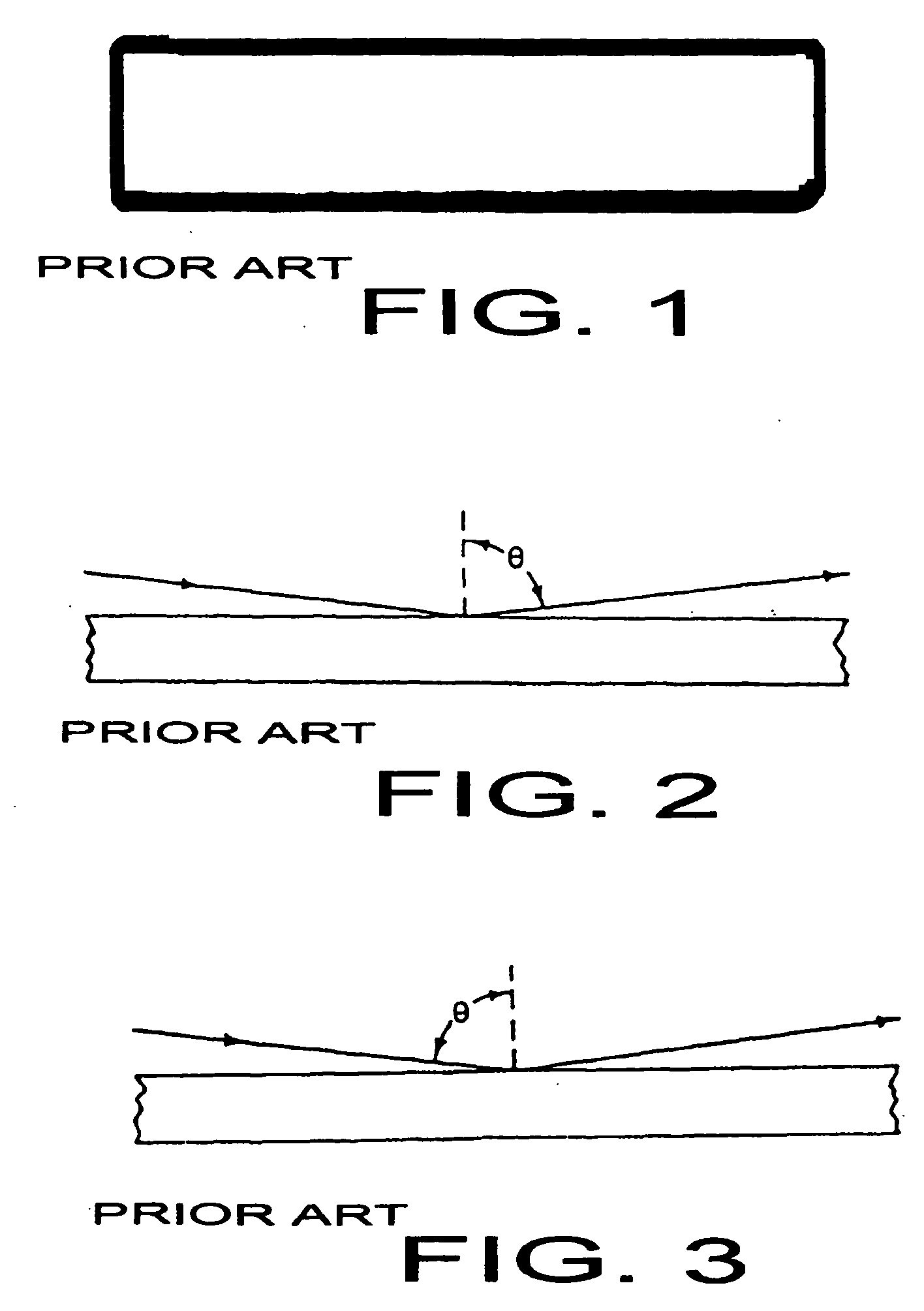

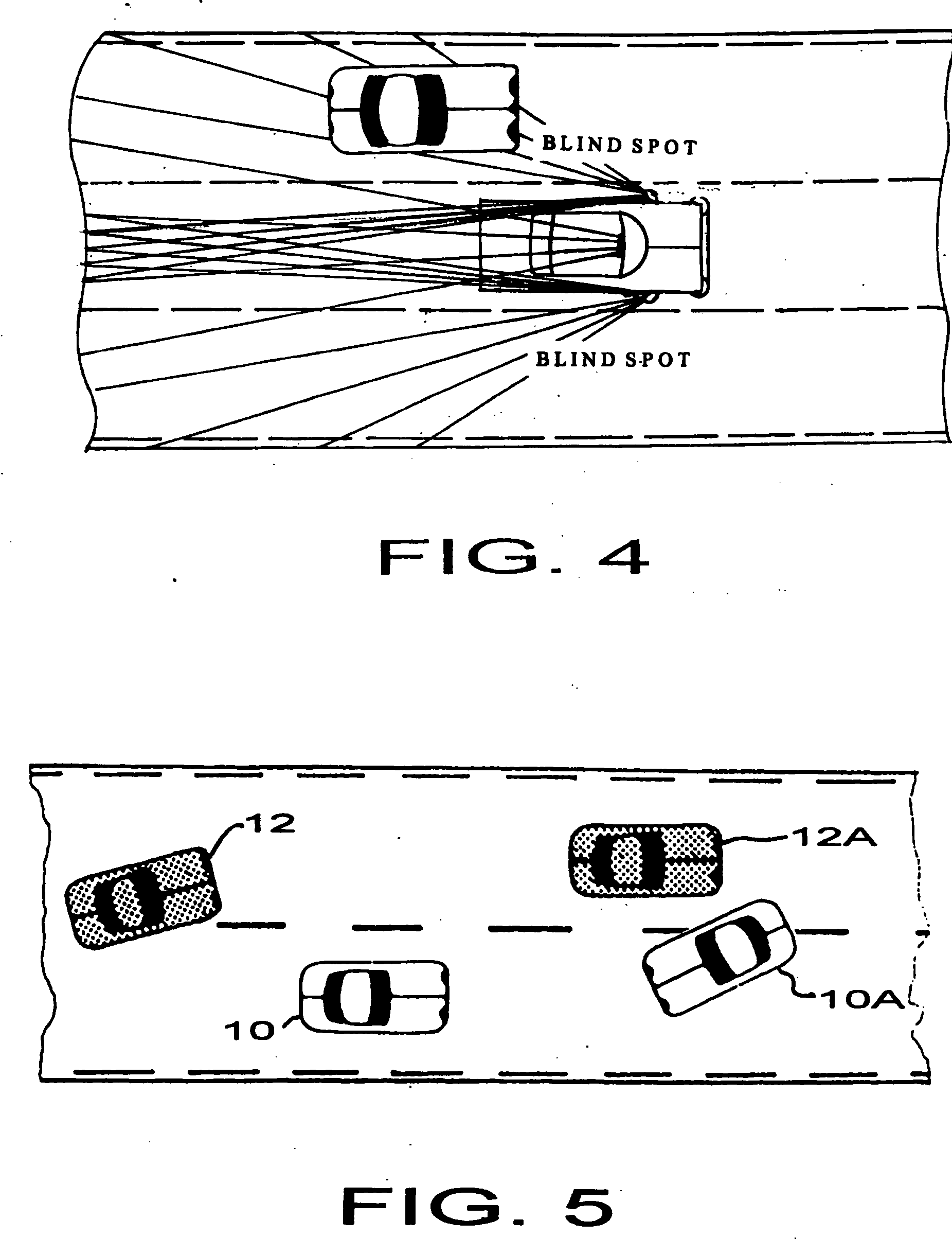

Rear view mirror

InactiveUS20060256458A1Fast perceptionSimple and inexpensiveMirrorsOptical viewingEngineeringWing mirror

A rear view mirror has a single mirror surface. The single mirror surface heads first and second planar reflective portions having an included angle therebetween that is less than 180°. In some cases the mirror is elongated in a direction that is normally horizontal when the mirror is mounted for use and the first and second portions many intersect to define a line that is vertical when the mirror is mounted for use. For some applications an included angle of approximately 160° is preferred. In some cases the first portion is mounted during normal use with the plane thereof substantially normal to the major axis of the vehicle on which the mirror is mounted. For some embodiments, the second portion is to the right of the first portion during normal use. The first portion may be elongated and many more specifically be elongated in a direction that is horizontal during normal use. Similarly, the second portion may be elongated and this elongation may be in a direction that is horizontal during normal use.

Owner:ZMARLICKI HIERONIM

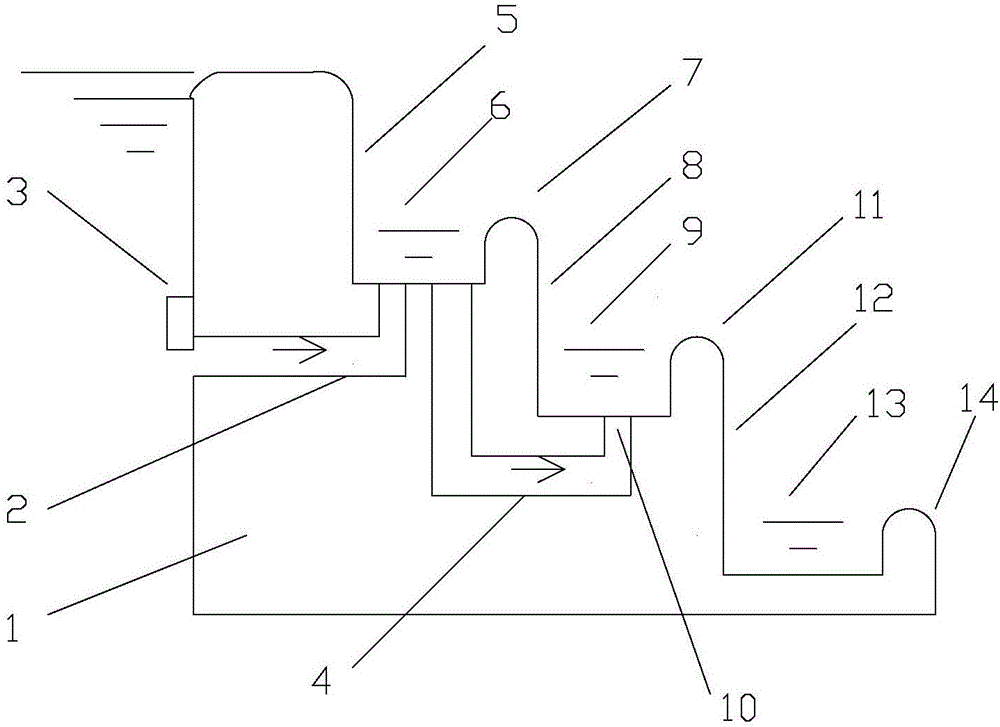

Shower head with shower wash heating function

ActiveCN103949358AImprove liquidityHeating up fastMovable spraying apparatusSpray nozzlesImpellerWater flow

The invention discloses a shower head with a shower wash heating function, which comprises a shower head body, the body is provided with an injection hole for injecting shower wash, a sealing cover which is rotatably connected with the body is arranged in the injection hole, a torsional spring is arranged between the sealing cover and the body and tightly presses the sealing cover on the body, and an impeller is arranged in the body. When in use, the shower head first discharges hot water for shower, shower wash is injected into the injection hole when needed, consequently, the shower wash can rush out along with water flow, and cold cannot be felt during the bath; because the shower wash is low in temperature and poor in fluidity when just injected into the shower head, when water flows, the impeller can rotate to agitate the shower wash in the shower head, so that the temperature rise of the shower wash becomes quicker and the fluidity of the shower wash becomes better, and thereby the shower wash can be more quickly ejected out from the shower head.

Owner:安徽格太信控科技有限公司

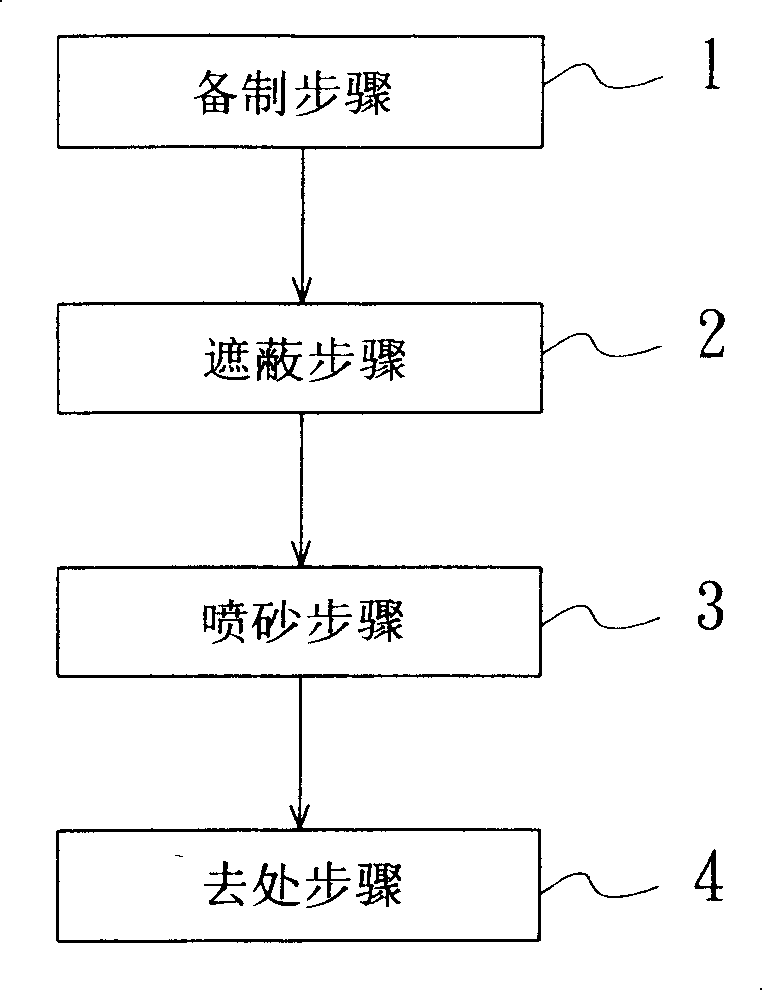

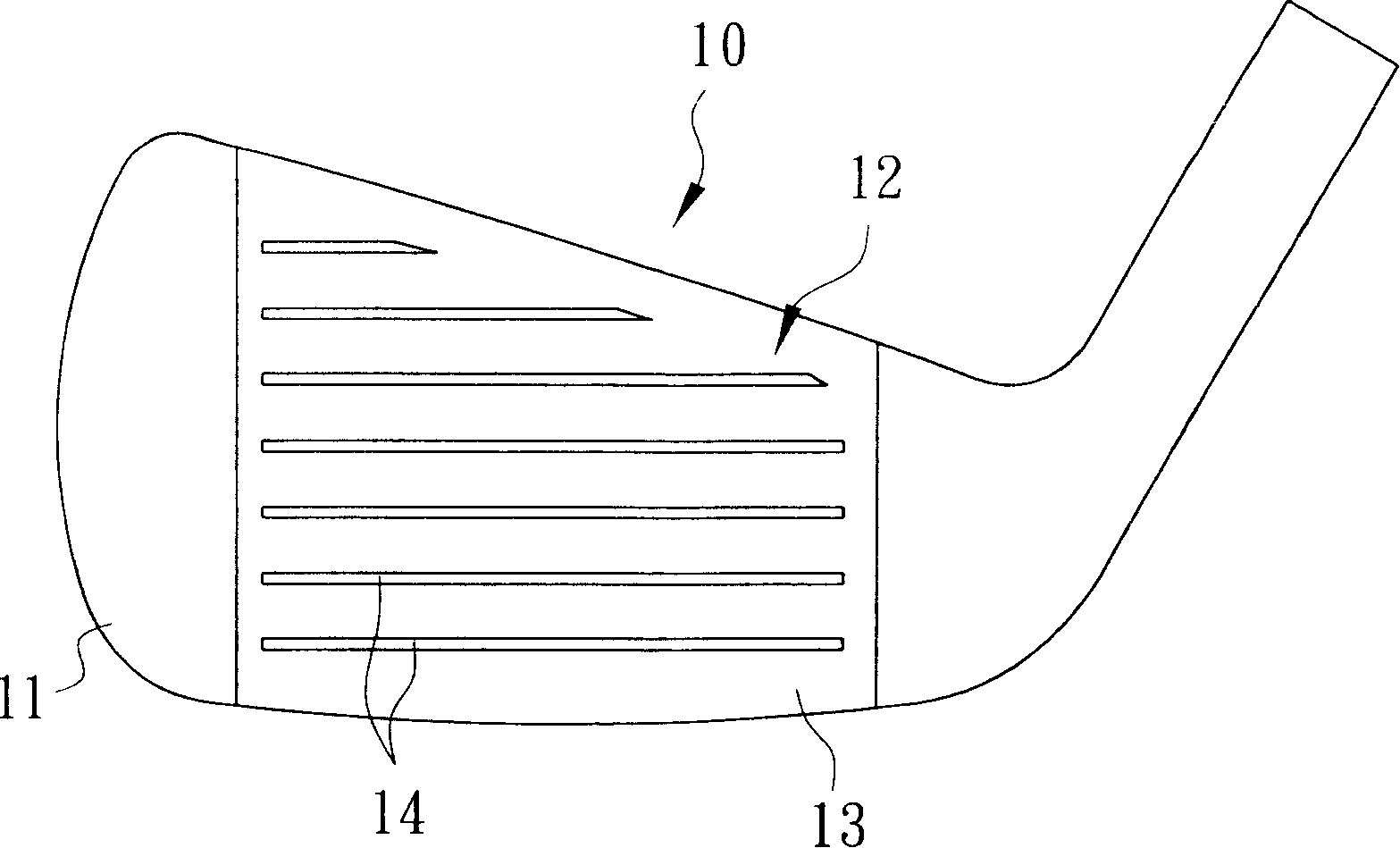

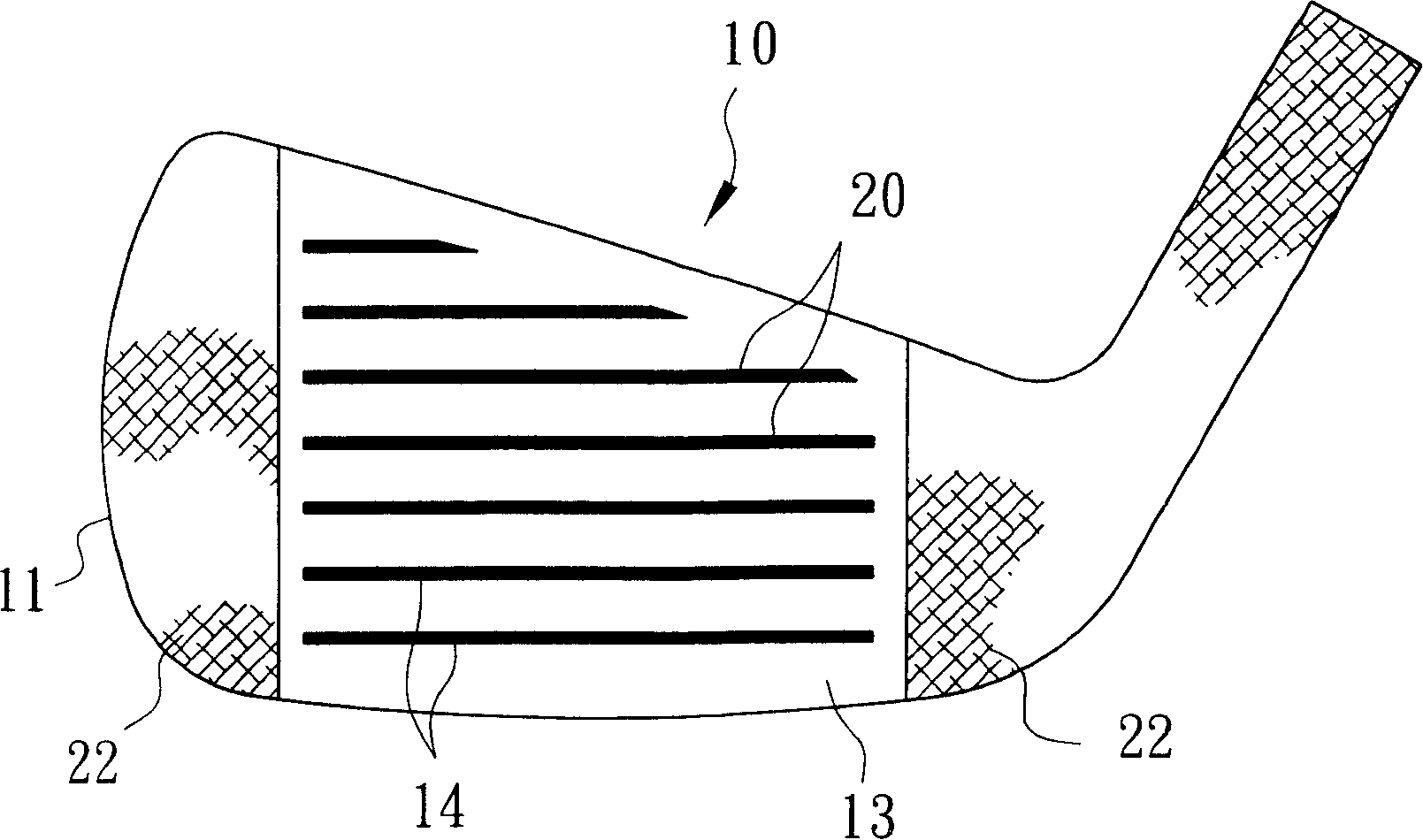

Method for making head of golf club showing various luster at the same time

ActiveCN101161313AImprove aestheticsImprove textureGolf clubsRacket sportsTactile sensationEngineering

The present invention discloses a method for making the golf club head which simultaneously present different lusters, and the method comprises a preparing procedure, a shielding procedure, a sand spraying procedure and an eliminating procedure, etc., the shielding material is filled in the groove unit of the club head first, the preparing procedure is preparing a club head and molding one groove unit at the club head, the shielding procedure is filling the shielding material in the groove unit, the sand spraying procedure is processing sand spraying to the club head to cause that the surface is different from the original luster, the eliminating procedure is eliminating the shielding material in the groove unit of the club head to cause that the luster at the groove unit of the club head is different from the surface of other positions, the method can also increase the appearance and tactile sensation of the golf club head and effectively compact the manufacturing process, to reduce the time of manufacturing process and save manufacturing cost and can effectively increase the good rate.

Owner:DUNLOP SPORTS CO LTD

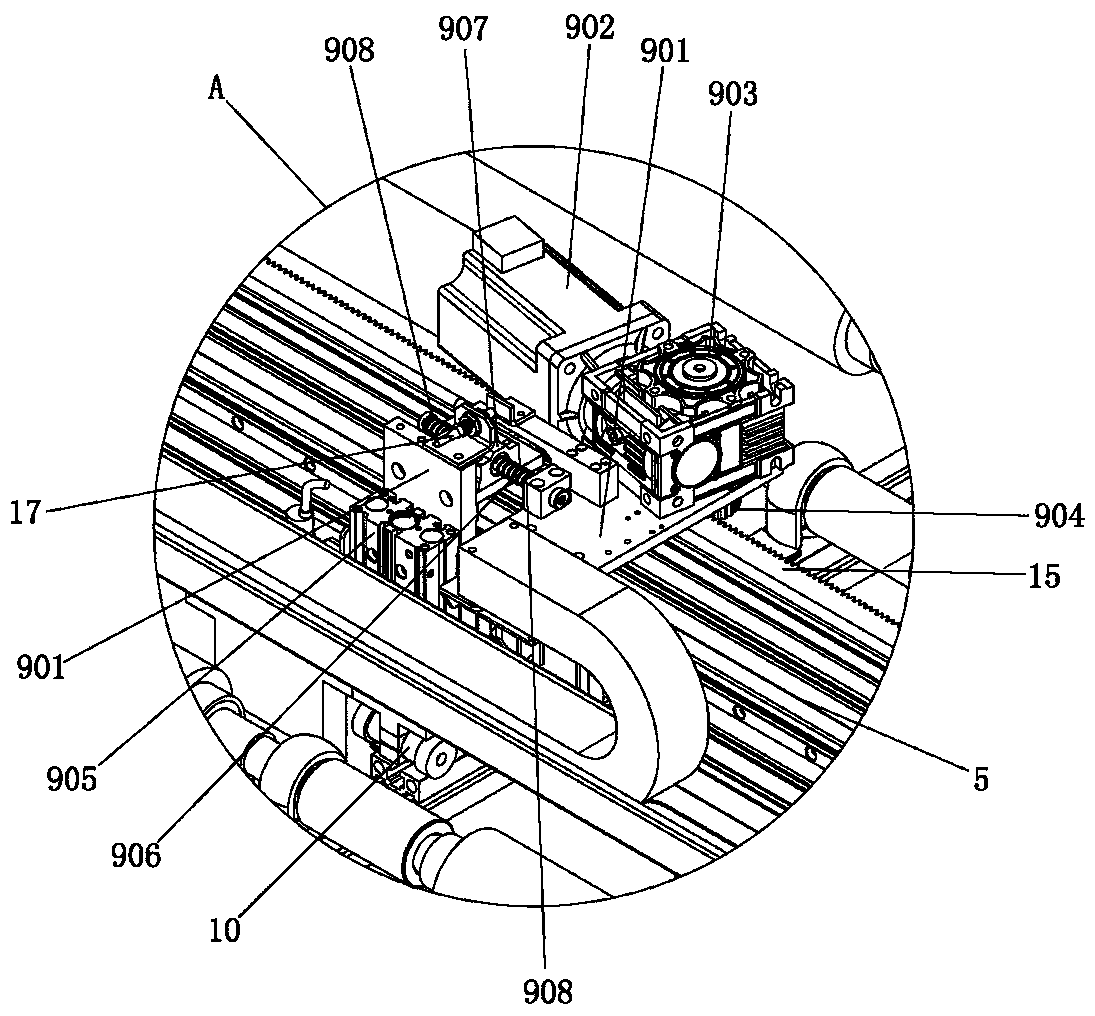

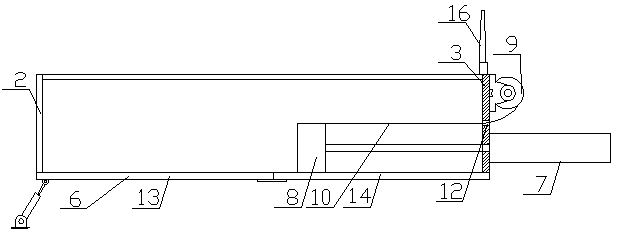

Thick plate head first-shearing positioning device and control method

ActiveCN109420795AAutomate cuttingHigh positioning accuracyShearing control devicesShearing machine accessoriesHysteresisThick plate

The invention provides a thick plate head first-shearing positioning device and control method, and relates to the technical field of automatic shearing control on thick plates. The device comprises head cutting shears, an output roller bed, a length measuring roller, an input roller bed, light curtains and a to-be-sheared steel plate; the to-be-sheared steel plate is placed on the input roller bed; the head cutting shears are mounted at the headmost end of the input roller bed; the length measuring roller is mounted on the head cutting shears; and the light curtains are mounted on a head cutting shear rack, are used in pairs and are arranged in a face-to-face manner. According to the device and the control method, through combined control by the aid of the light curtains and the originallength measuring roller of the head cutting shears, high-precision positioning of first shearing of the head of the thick plate is realized, the serious defects that the hysteresis exists during length measurement by the aid of the single length measuring roller of the head cutting shears and positioning control and the headmost end of the steel plate cannot be positioned effectively are overcomeeffectively, and the positioning precision of the head of the thick plate is improved remarkably.

Owner:BAOSHAN IRON & STEEL CO LTD

Shower head

The invention discloses a shower head, which comprises a shower head body, the body is provided with an injection hole for injecting shower wash, a sealing cover which is rotatably connected with the body is arranged in the injection hole, and a torsional spring is arranged between the sealing cover and the body and tightly presses the sealing cover on the body. When in use, the shower head first discharges hot water for shower, shower wash is injected into the injection hole when needed, consequently, the shower wash can rush out along with water flow, and cold cannot be felt during the bath.

Owner:山东凡小果智能制造产业园有限公司

Garbage compression mechanism of garbage cleaning ship

InactiveCN107932956AReduce volumeReduce moisture contentWater cleaningWaterborne vesselsHydraulic cylinderTransverse groove

The invention discloses a garbage compression mechanism of a garbage cleaning ship, and belongs to the field of garbage cleaning equipment. The garbage compression mechanism of the garbage cleaning ship comprises a garbage compression box; the garbage compression box is a box body defined by a front end plate, a back end plate, a left side plate, a right side plate and a baseplate; a first hydraulic cylinder is mounted in the center position of the lower part of the back end plate; a compression head is arranged in the garbage compression box in a cooperation manner; a piston rod end of the first hydraulic cylinder is connected with the compression head; a winding drum, horizontally arranged, is mounted on the back end plate and above the first hydraulic cylinder; a caching stop coil is wound on the winding drum; one end of the winding drum is connected with a driving motor; a transverse groove is formed in the middle part of the back end plate; and a free end of the caching stop coilpenetrates through the transverse groove to be connected with the compression head. Garbage is conveyed into the garbage compression box through a conveying device; the first hydraulic cylinder is started to drive the compression head to forwards compress the garbage; and water in the garbage flows outside the garbage compression box by compression water outlets on the two sides of the front baseplate, so that the purposes of compressing the garbage size and reducing the garbage water content are achieved.

Owner:张建宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com