Garbage compression mechanism of garbage cleaning ship

A technology for compressing garbage and cleaning boats. It is used in presses, open-air water surface cleaning, water conservancy projects, etc. It can solve the problems of difficult transportation and large engineering volume, and achieve the effect of improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

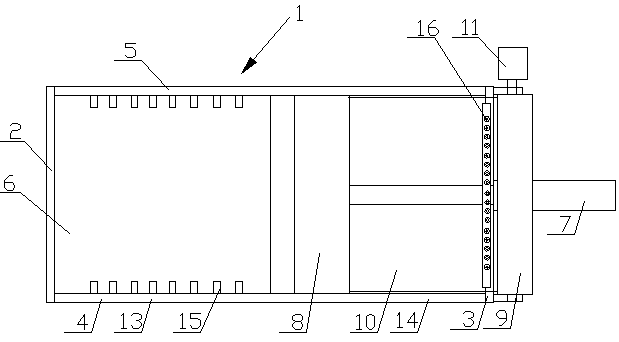

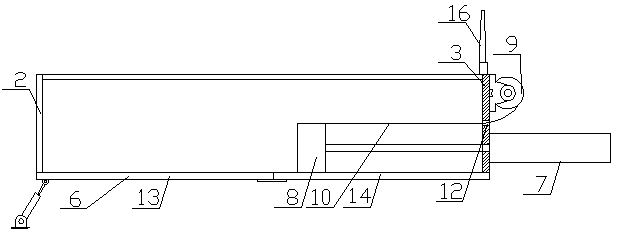

[0015] Such as figure 1 , 2 As shown, the present invention includes a garbage compression box 1, and the garbage compression box 1 is a casing surrounded by a front end plate 2, a rear end plate 3, a left side plate 4, a right side plate 5 and a bottom plate 6.

[0016] The central position of the bottom of the rear end plate 3 is equipped with a first hydraulic cylinder 7, and a compression head 8 is arranged in the garbage compression box 1. The piston rod end of the first hydraulic cylinder 7 is connected with the compression head 8. A reel 9 arranged horizontally is installed on the rear end plate 3, and a buffer retaining roll 10 is wound on the reel 9. The buffer retaining reel 10 is made of a flexible material, such as rubber, PVC, etc., and one end of the reel 9 is connected with a The driving motor 11 is provided with a transverse groove 12 in the middle of the rear end plate 3 , and the free end of the buffer blocking roll 10 passes through the transverse groove 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com