Method for making head of golf club showing various luster at the same time

A technology for golf club heads and manufacturing methods, which is applied to golf balls, golf clubs, rackets, etc., and can solve the problems of low yield rate, complicated manufacturing process, and high purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

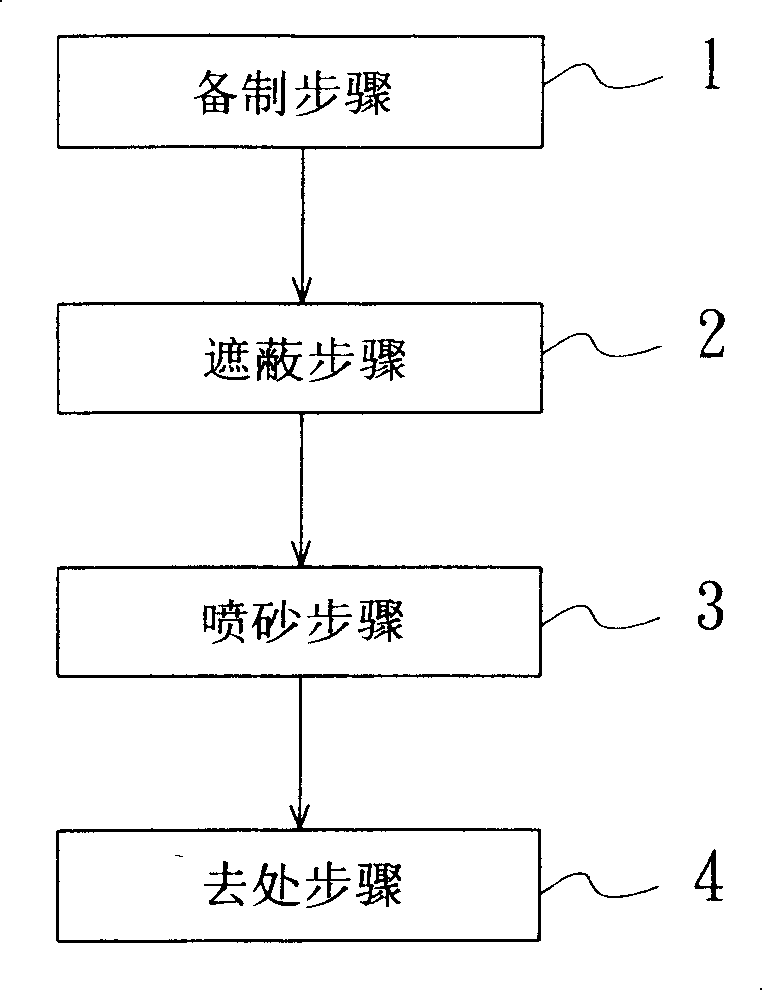

[0014] Such as figure 1 As shown, the preferred embodiment of the manufacturing method of the golf club head of the present invention that can simultaneously exhibit different gloss includes a preparation step 1 , a masking step 2 , a sandblasting step 3 , and a removal step 4 .

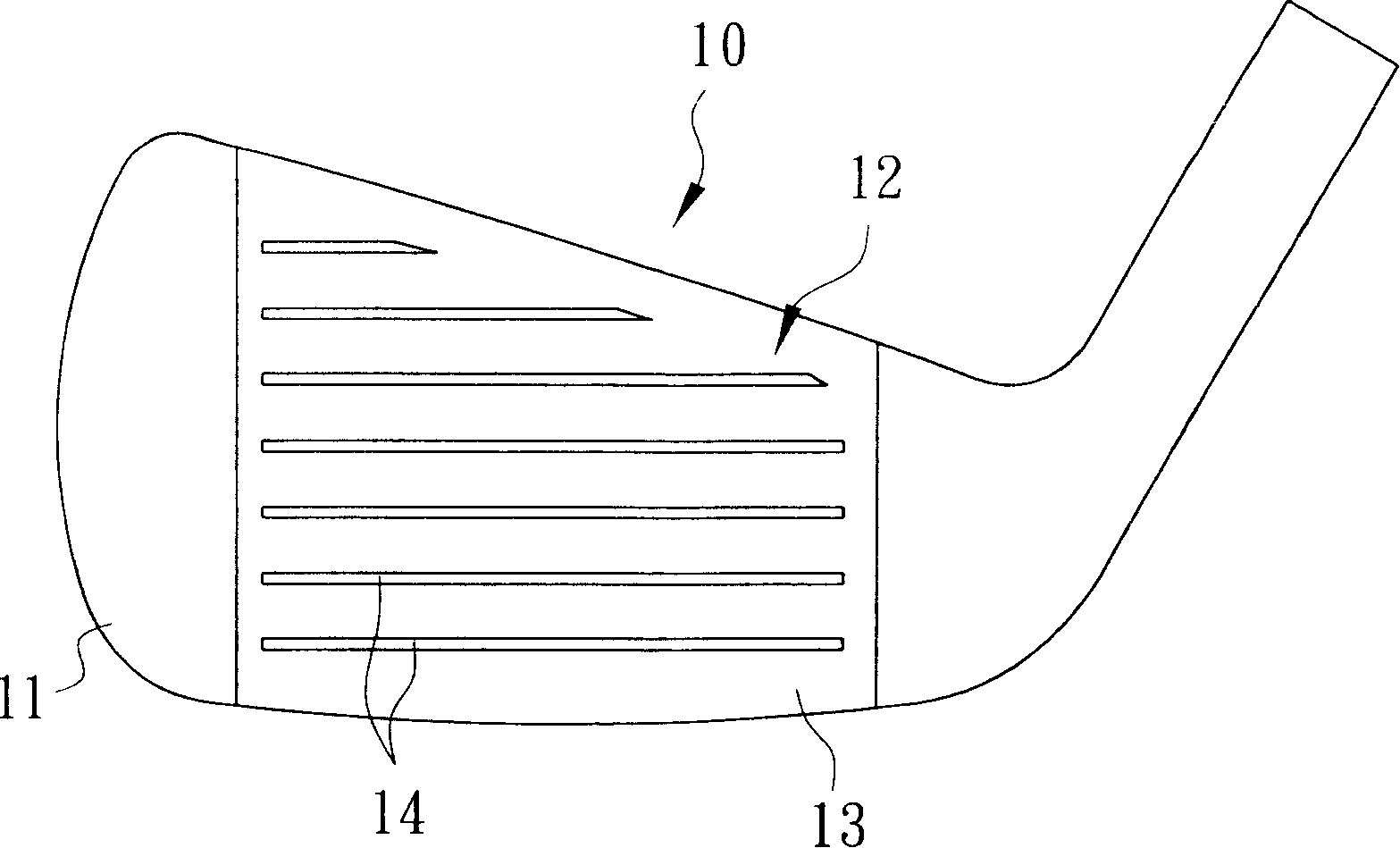

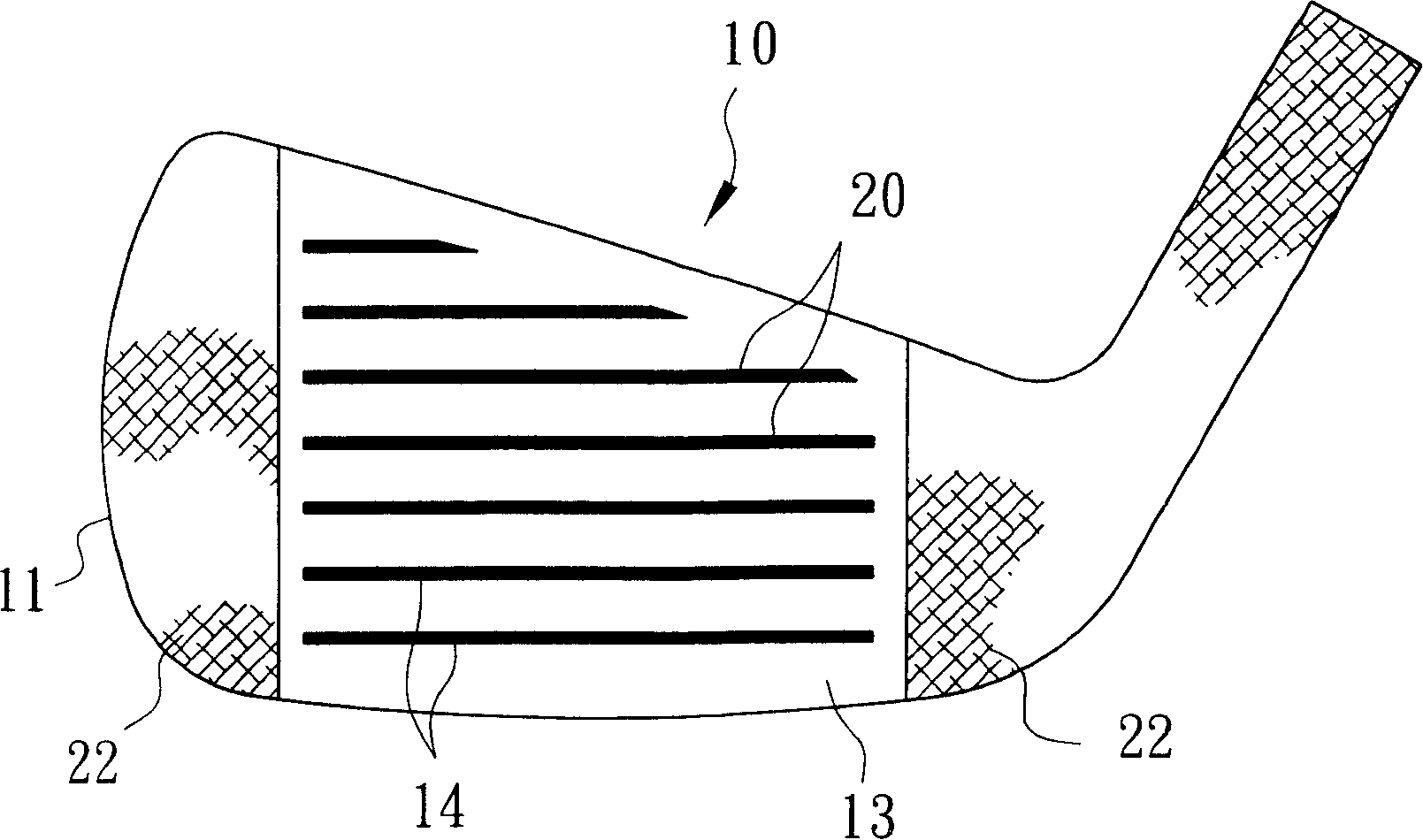

[0015] Please refer to figure 2 , the preparation step 1 is to prepare a club head 10 first, the club head 10 has a club head body 11, and a striking panel 13 arranged on the front side of the club head body 11, and then the club head The club head body 11 and the striking face plate 13 of the club head 10 are subjected to grinding, polishing, electroplating and anti-corrosion treatments, and a groove unit 12 is formed on the club head 10 .

[0016] In the preferred embodiment, the groove unit 12 is formed on the striking panel 13 , and the groove unit 12 has a plurality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com