Expanding type clamp used on lathe and machining method thereof

A processing method and expansion technology, which are used in the expansion fixture and processing field of lathes, can solve the problems such as can not meet the processing of special parts with small diameter and thin wall, poor control of coaxiality, and low clamping force of fixtures. , to achieve the effect of uniform and reliable clamping force, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] Option One:

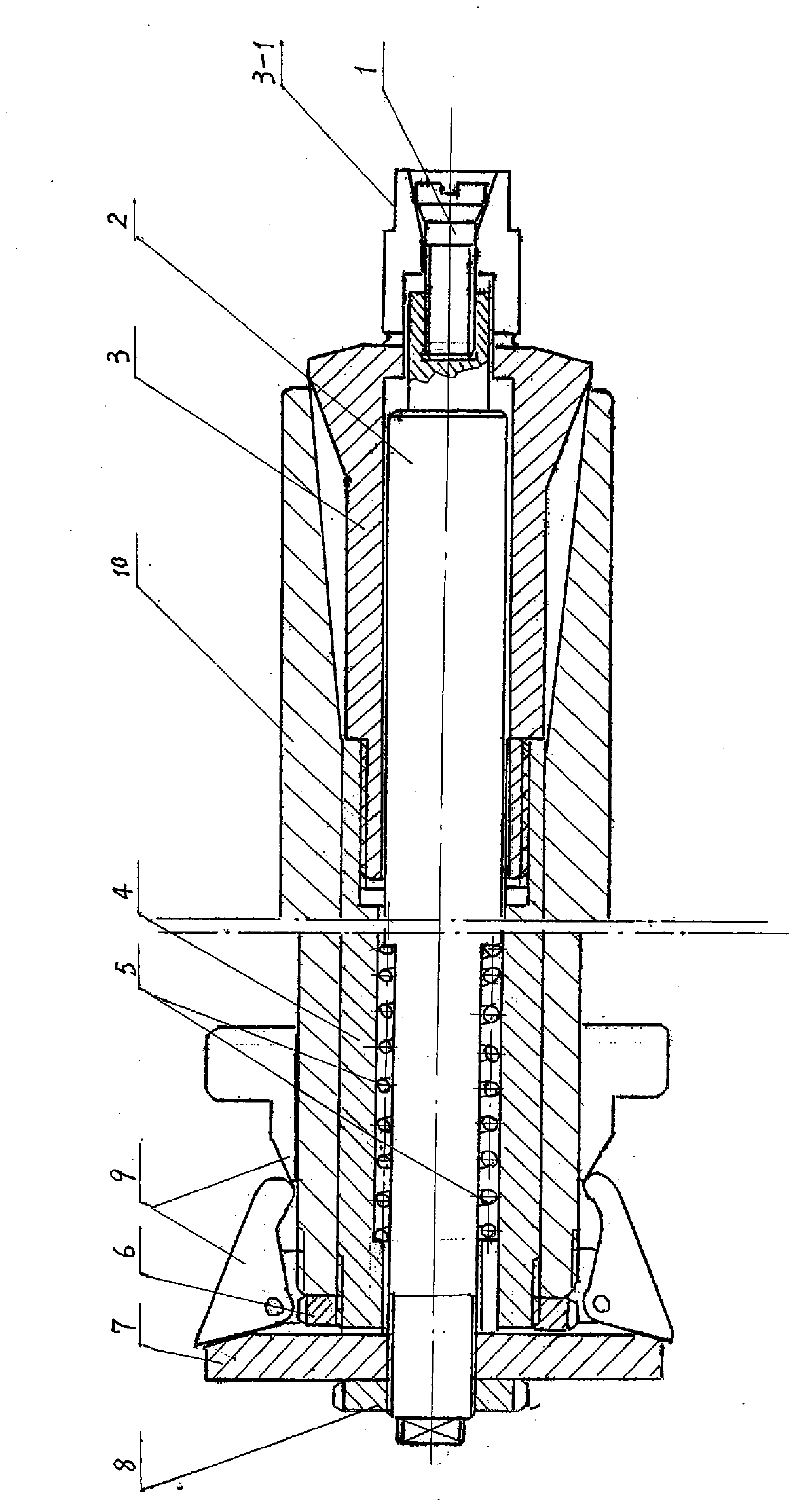

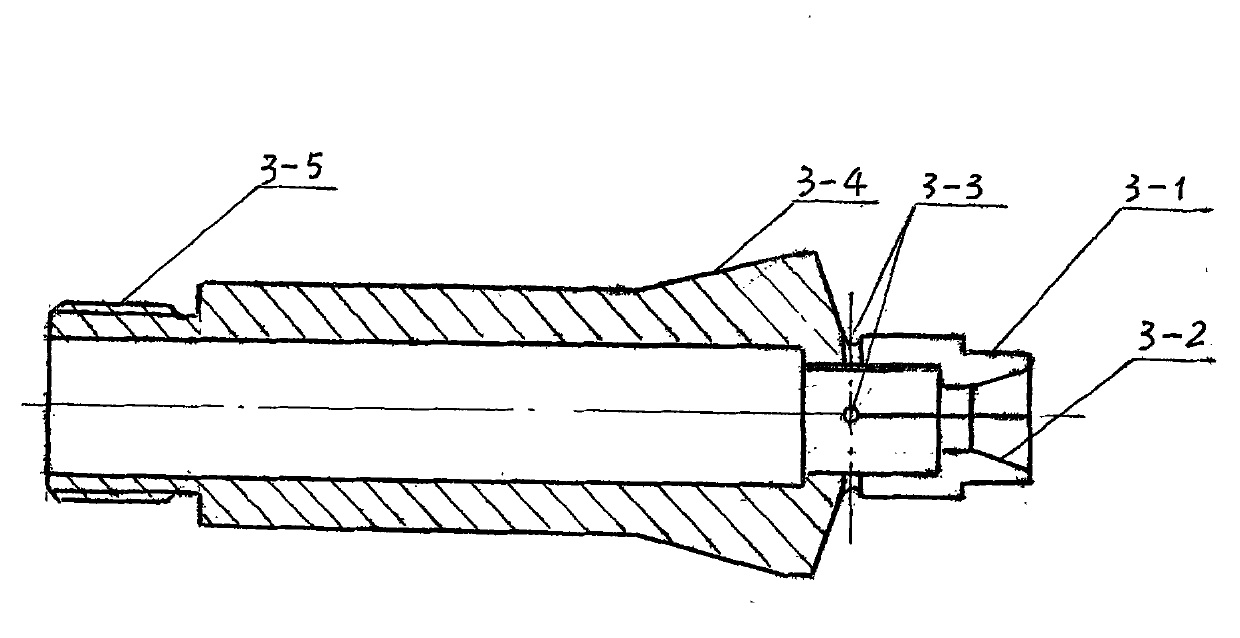

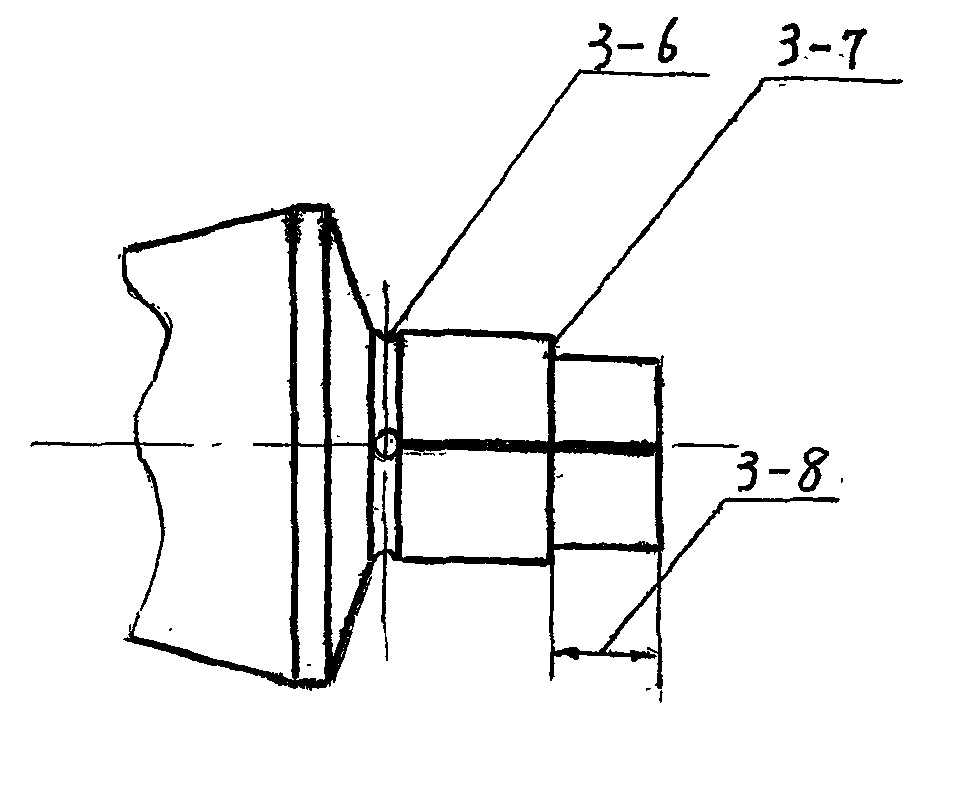

[0048] 1. An expansion fixture and a processing method on a lathe, in figure 1 Among them, it is composed of a shaft sleeve 4, a pull rod 2, a spring 5, an expansion chuck 3, an elastic screw 1, an adjusting nut 7, a nut 6, etc., and is characterized in that: the spring 5 and the pull rod 2 are respectively placed in the shaft sleeve 4, Thread the expansion chuck 3 into the shaft sleeve 4, and install the shaft sleeve 4 into the hole 10 of the lathe spindle, so that the expansion chuck neck 3-4 coincides with the inner taper hole end of the lathe spindle 10, and the other end of the shaft sleeve 4 is threaded Expose the tail end of the lathe spindle 10, screw in the nut 6 and tighten it. From the bell mouth 3-2 at the end of the expansion chuck 3, screw the elastic screw 1 into the internal thread at the end of the pull rod 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com