System and method for measuring section shape and size of heavy caliber steel pipe

A cross-section shape and measurement system technology, applied in the field of geometric measurement, can solve the problems that the measuring tape is difficult to ensure that the measurement section is perpendicular to the steel pipe busbar, cannot fully reflect the size and shape of the entire section, and cannot reflect the roundness error or ellipticity of the section, etc. , to achieve stable and reliable measurement results, easy to record and save, and strong objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

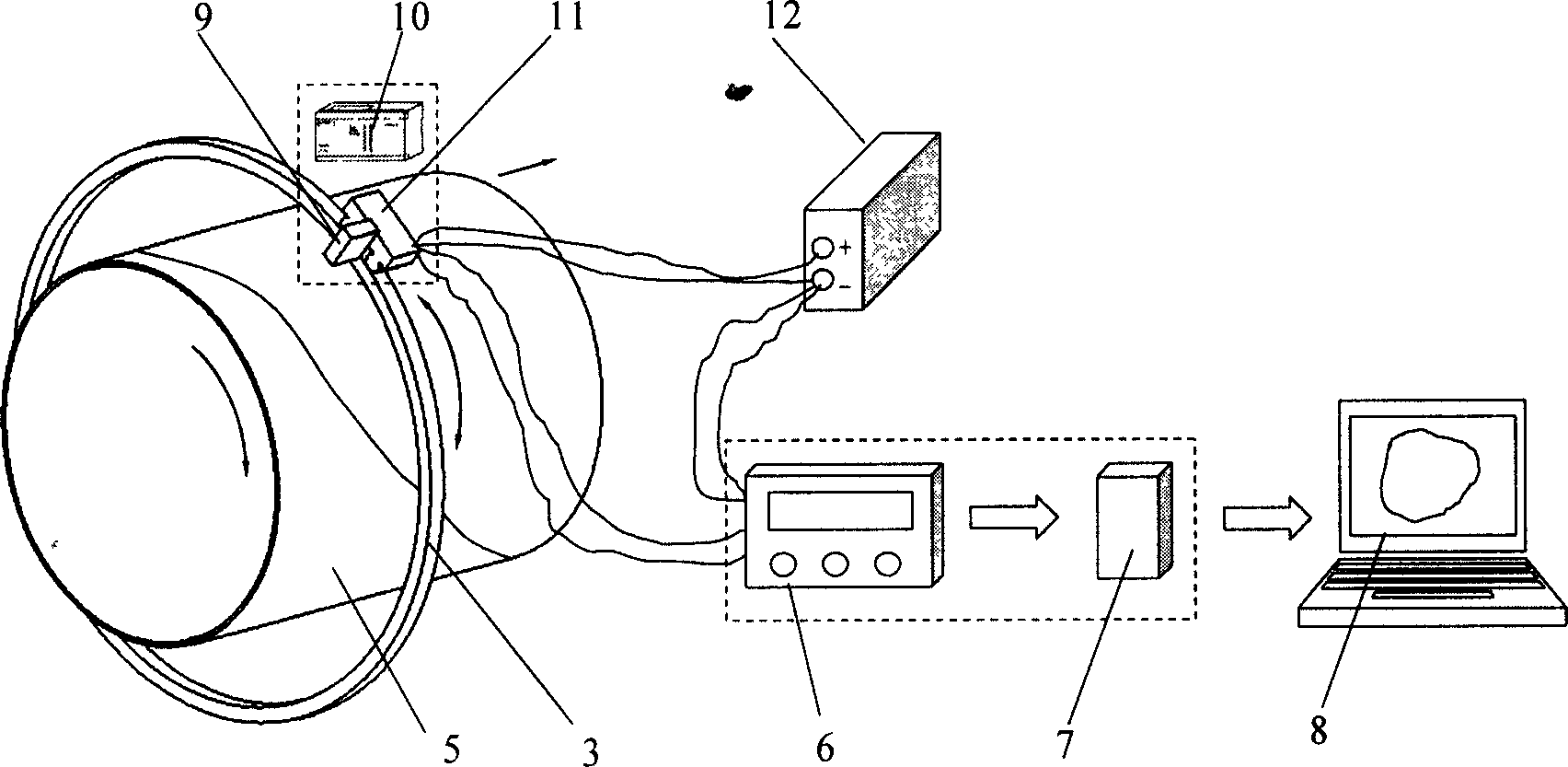

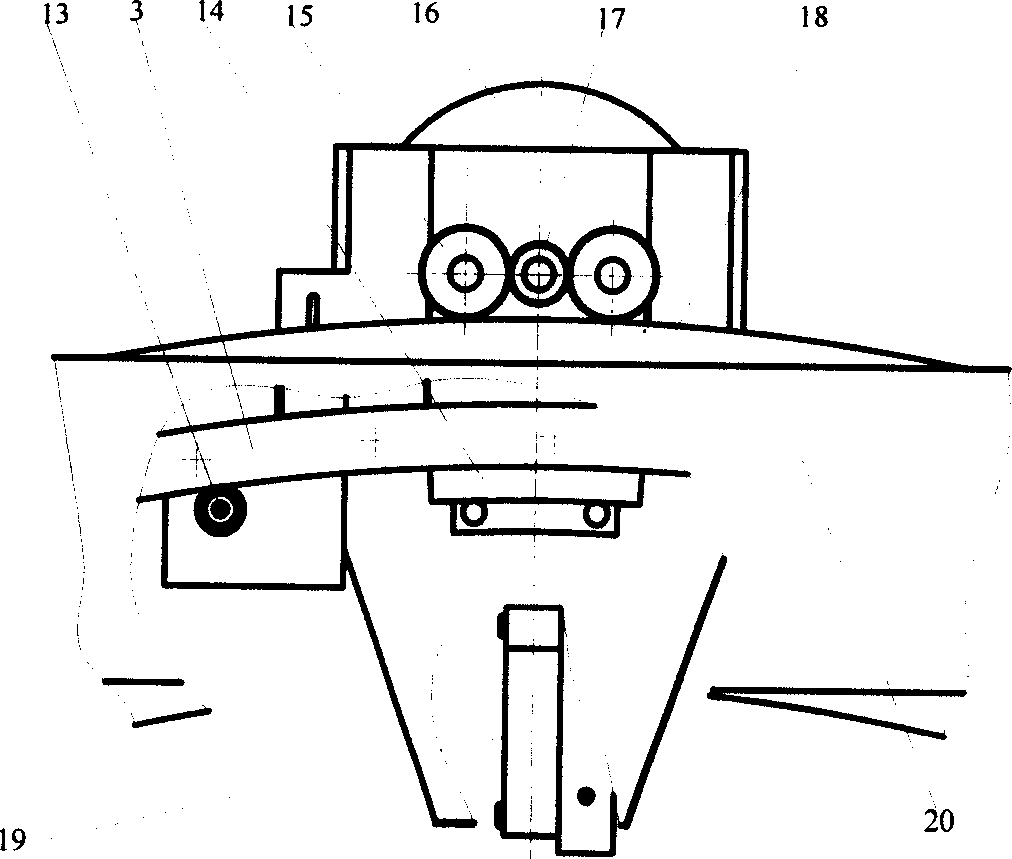

[0024] The invention provides a measuring system and a measuring method for the cross-sectional shape and dimension of a large-diameter steel pipe. The large-diameter steel pipe section shape and dimension measurement system includes a motion module, a measurement module, an information processing module, an input and output module, a data storage module and a data analysis module. The specific measurement principle, system composition and implementation, and measurement method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

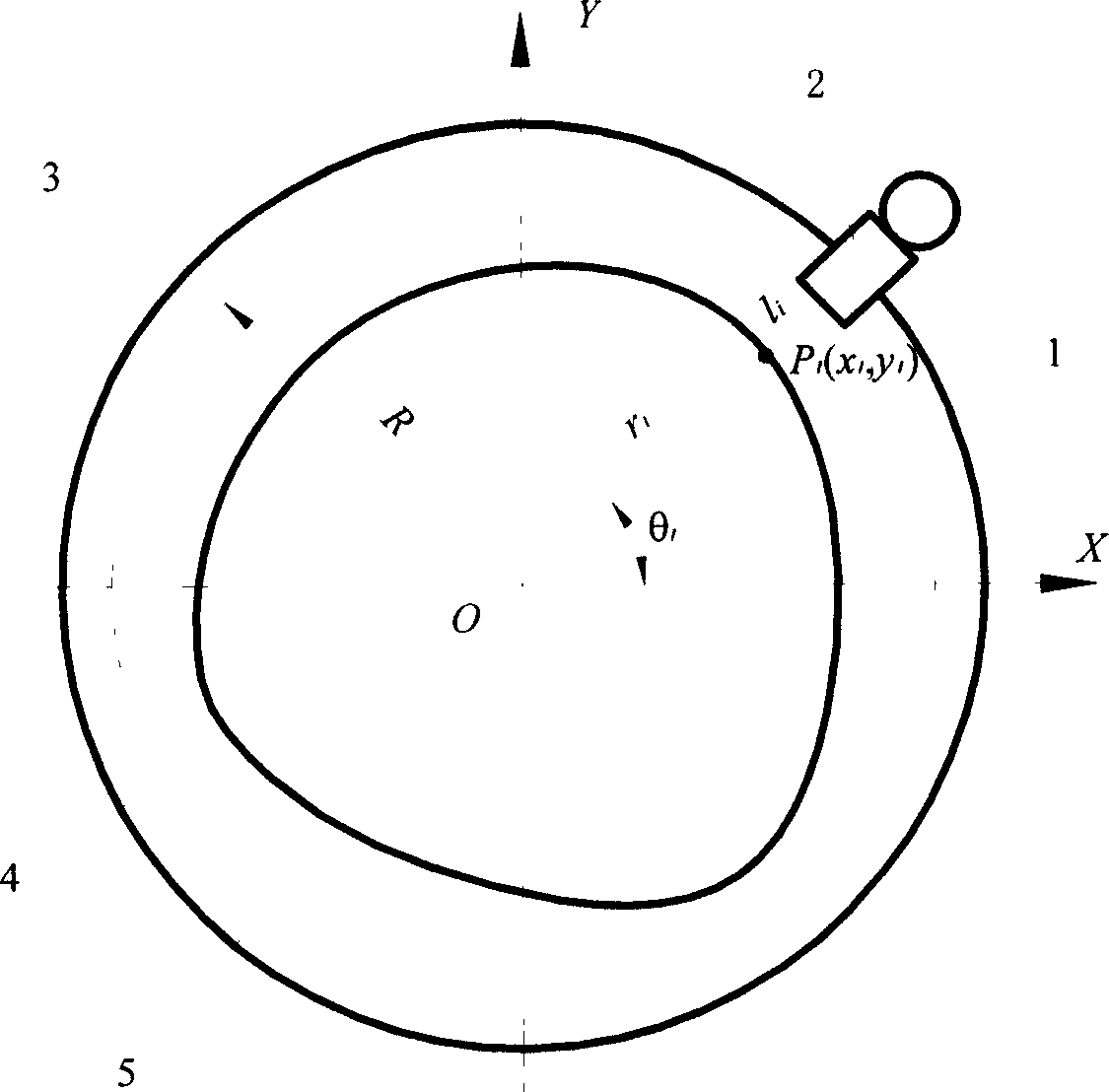

[0025] like figure 1 Shown is a measurement schematic diagram of an embodiment of a steel pipe cross-sectional shape and dimension measurement system of the present invention. The displacement sensor 2 and the angle sensor 1 move on a reference circular track 3 . Then, the movement trajectory 4 of the displacement zero point of the displacement sensor is also a standard ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com