Method for manufacturing ultra-large reinforced concrete cooling tower reduced scale test model

A technology of reinforced concrete and test models, applied in teaching models, educational tools, instruments, etc., can solve the problems of difficulty in ensuring accuracy, cracking of cylinder walls, and high production costs, and achieve the effects of easy control of accuracy, smooth surface, and easy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] In order to make reinforced concrete cooling tower scale test model, the present invention can complete model making according to the following steps:

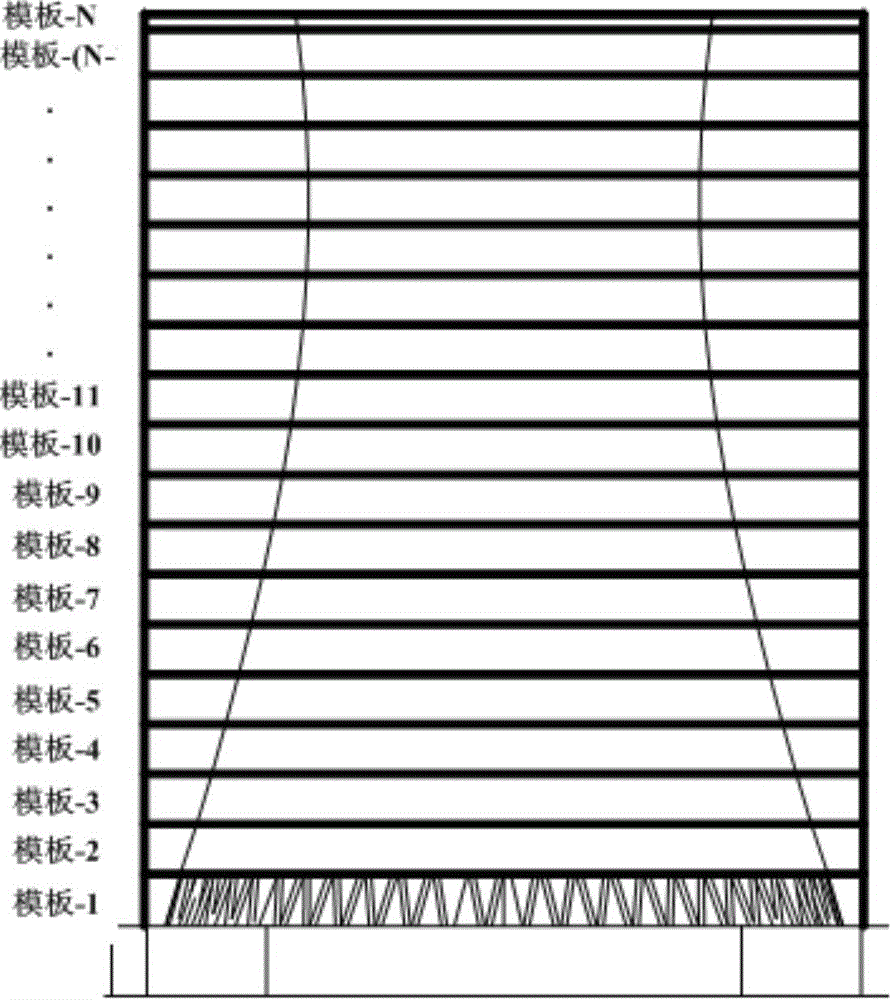

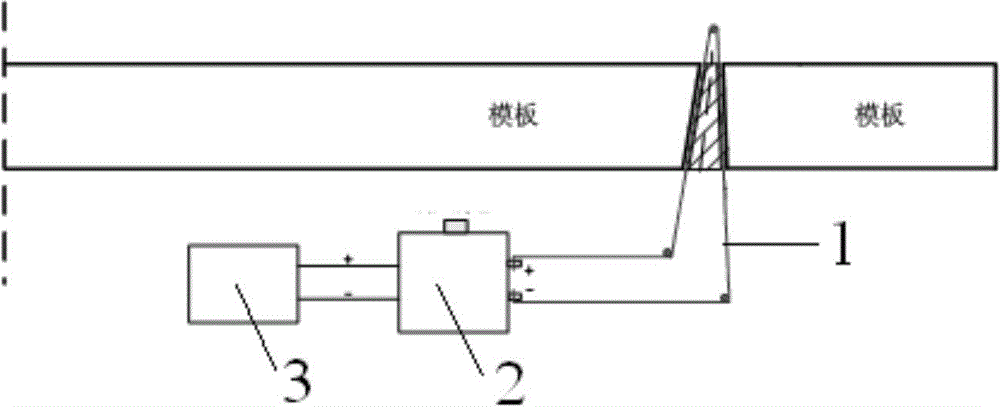

[0030] (1) Design of model template. ① According to the space size of the cooling tower model, the cooling tower formwork is divided into N layers along the height direction of the model, and the height of each layer of formwork is determined respectively. Among them, the first layer of formwork is the formwork layer of the cooling tower model pillar, and the height of the formwork is the same as the height of the model pillar. The second to (N-1) layers are the tower model formwork layer, and the height of each layer of formwork is 100-250mm. The upper layer (that is, the Nth floor) is the top formwork layer of the tower model, and its height is the sum of the height of the cooling tower model minus the height of the former (N-1) layer formwork, such as figure 1 shown; ②According to the maximum plane size of the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com