Patents

Literature

969 results about "Size parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parameter Size property provides the size of parameters that have variable length, such as strings and binary fields. This setting ensures that the provider allocates sufficient space for variable-length parameter values. The default is -1, which lets SQL Server determine the correct size.

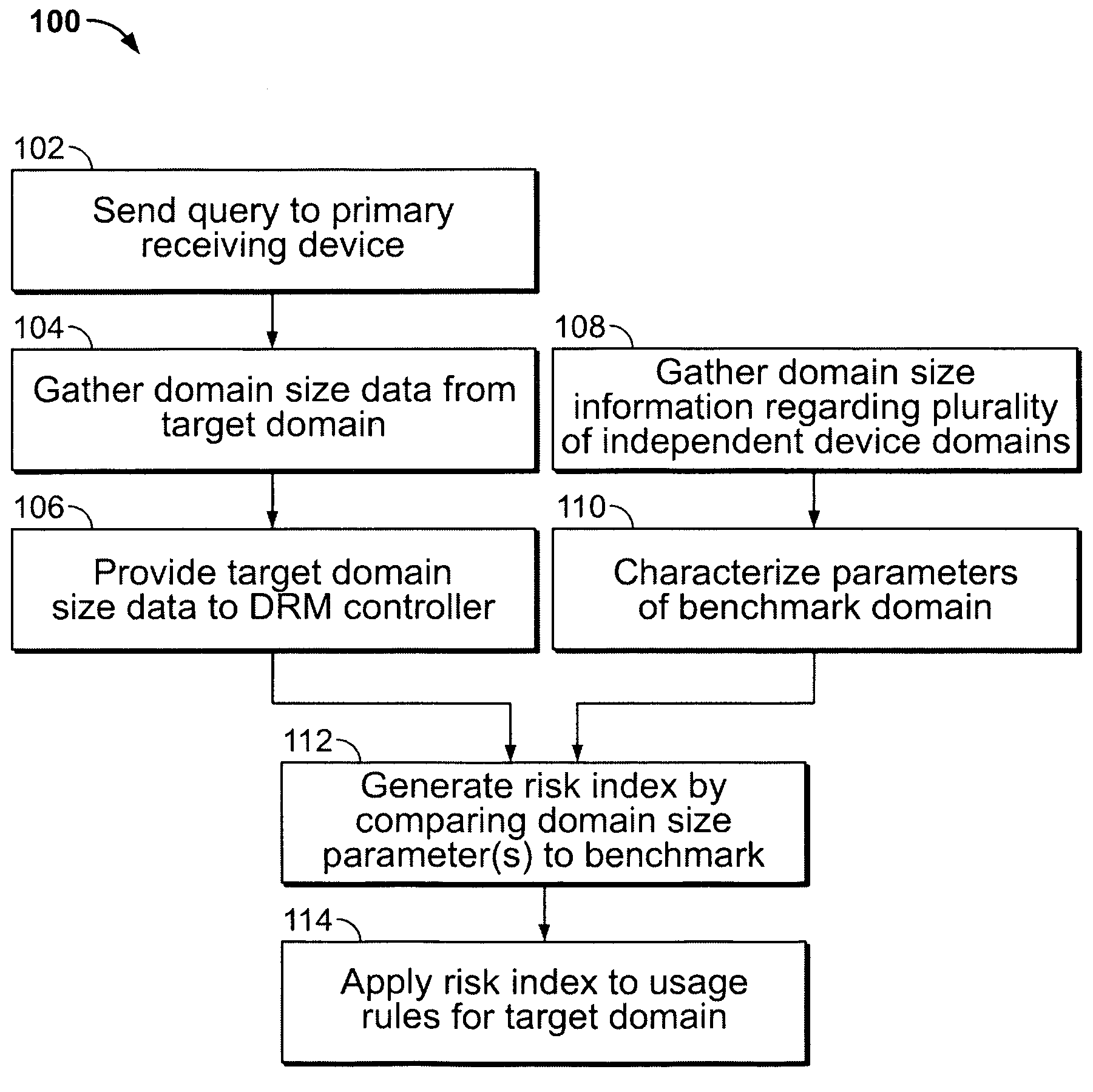

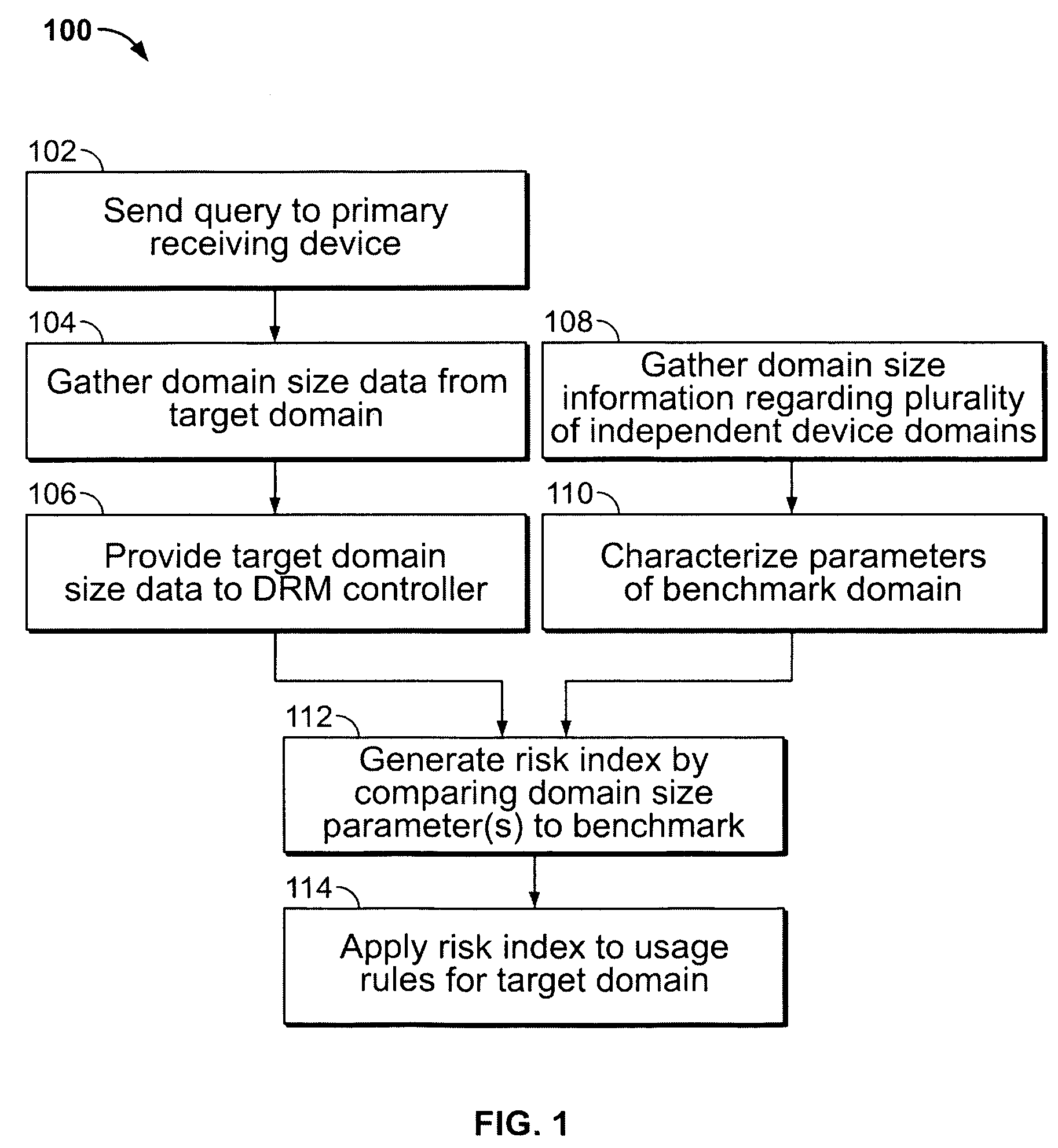

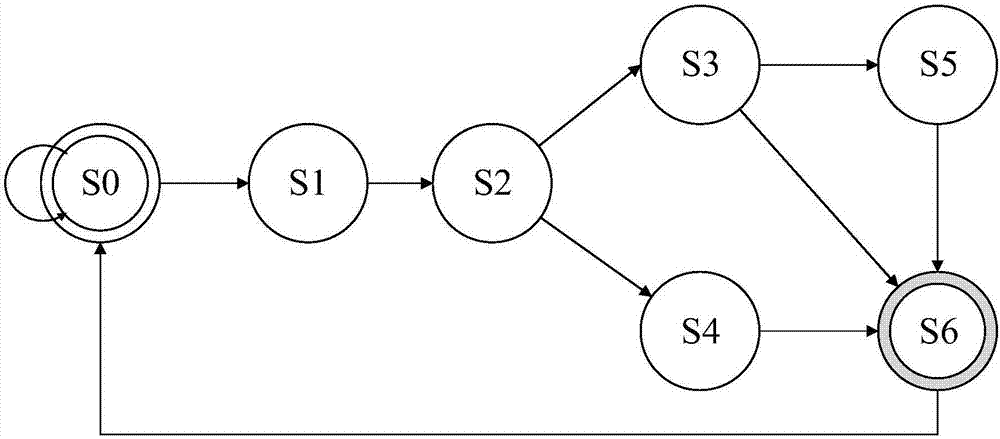

Adaptive digital rights management system for plural device domains

InactiveUS7512987B2Digital data processing detailsUser identity/authority verificationInternet privacyDigital rights management system

A system and methods of digital rights management for plural device domains that adapts in response to external use data. Domain size parameters of a target domain that includes multiple receiving devices are determined. The domain parameters are compared to a domain benchmark developed from external data. A risk index for the target domain is then generated and used to create content usage rights for controlling access and usage of digital content by the collection of devices within that domain. The system may include a plurality of information-gathering tools for collecting the domain parameters from a plurality of independent domains as well as from the target domain.

Owner:MOTION PICTURE ASSOC OF AMERICA

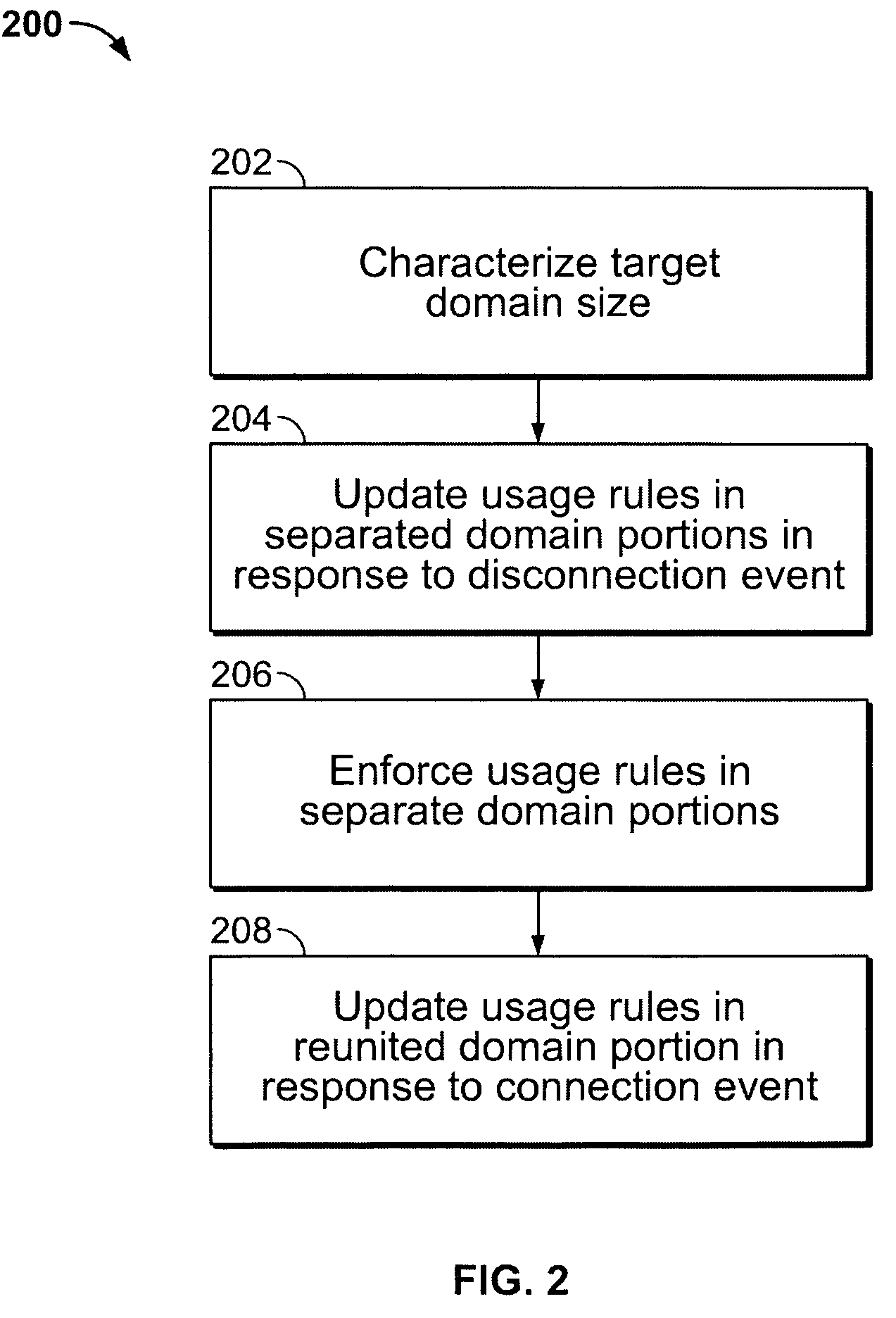

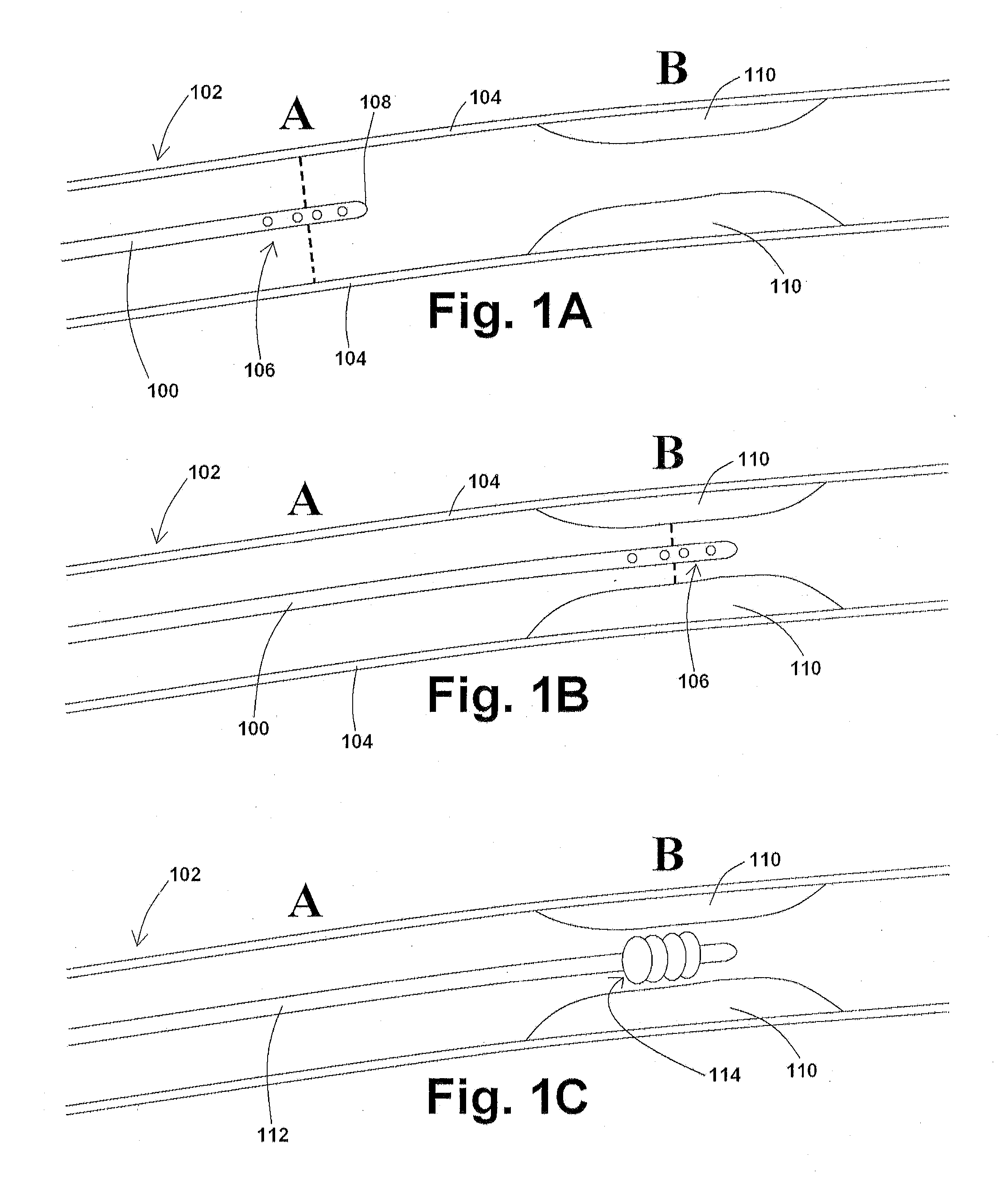

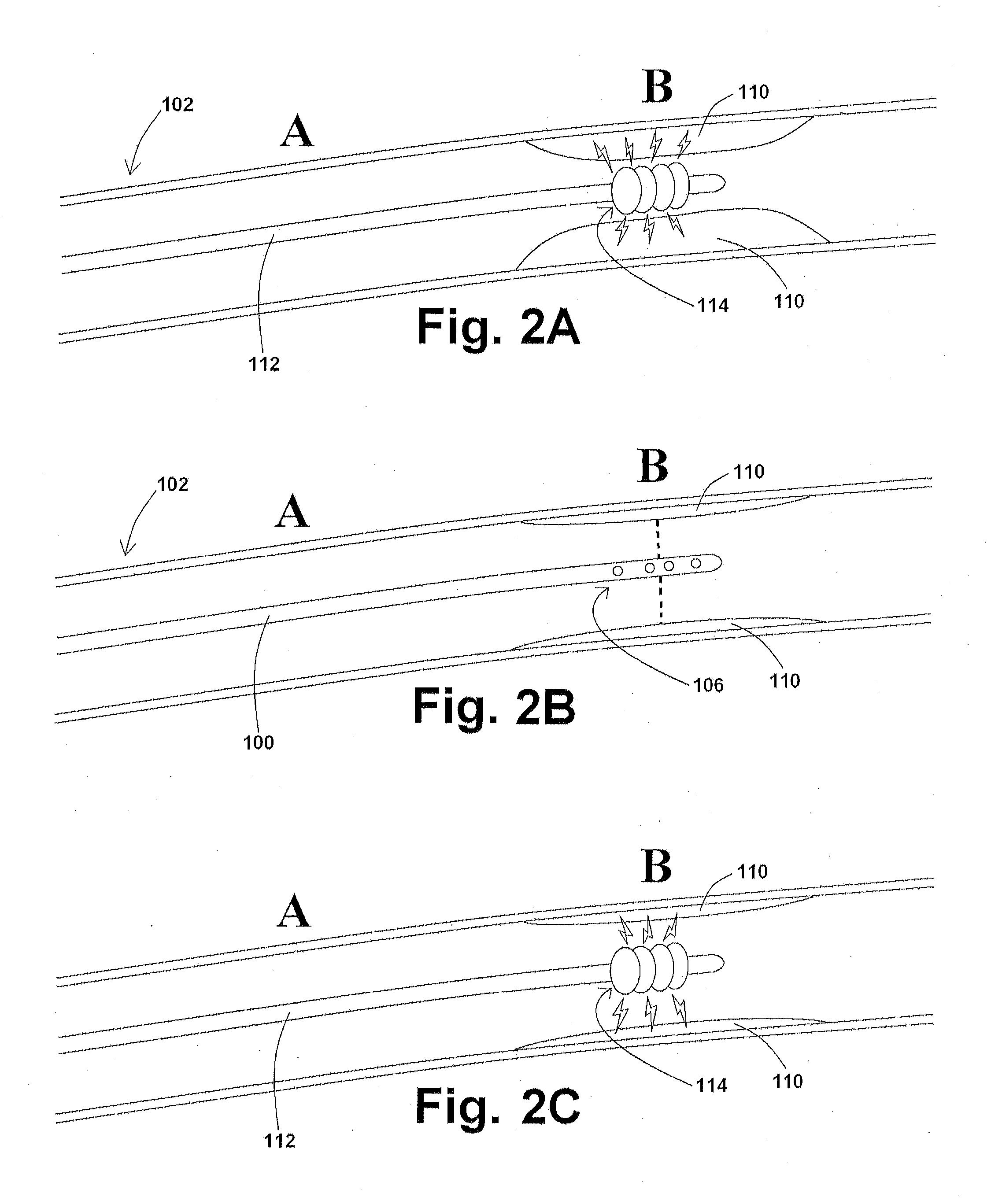

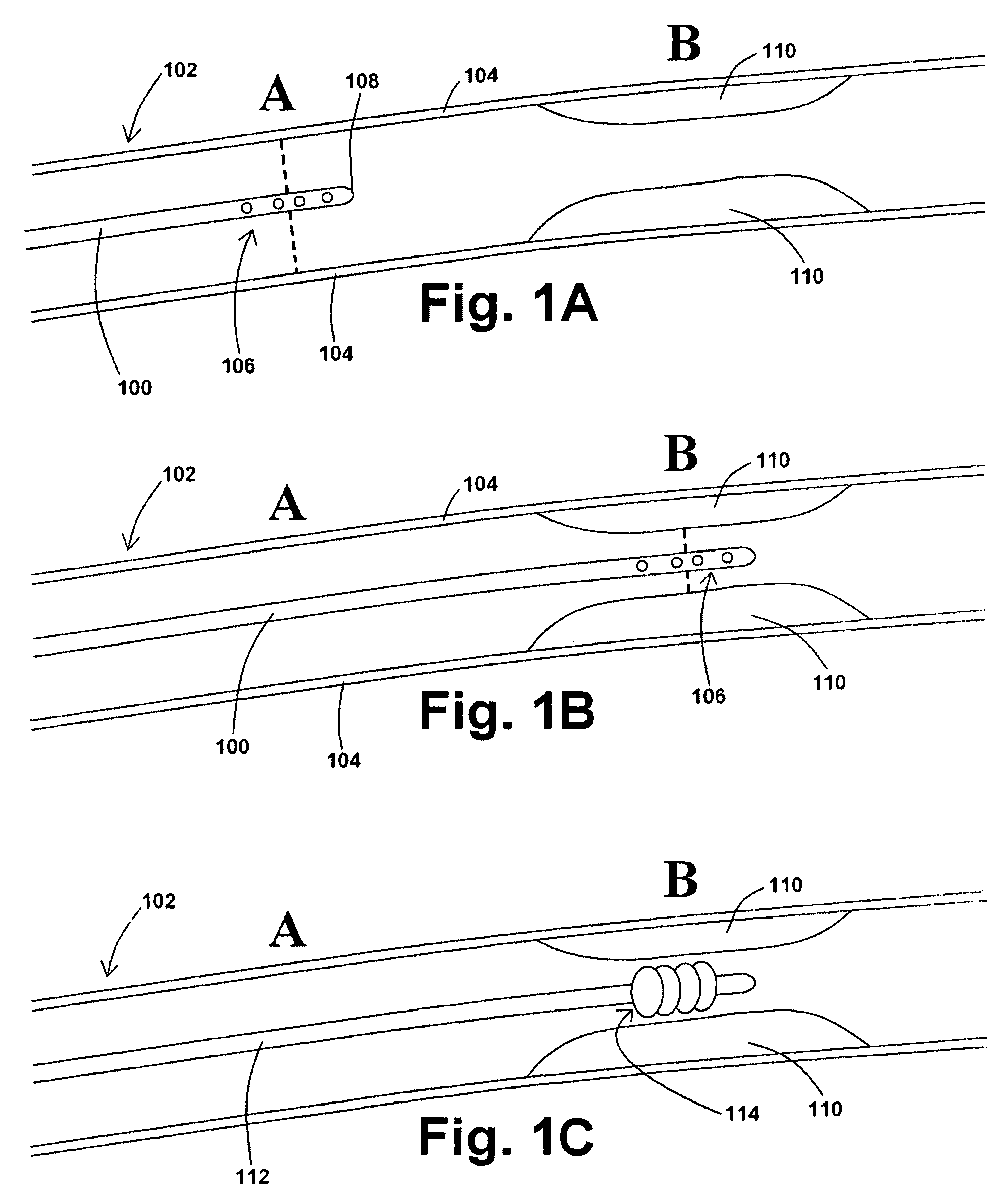

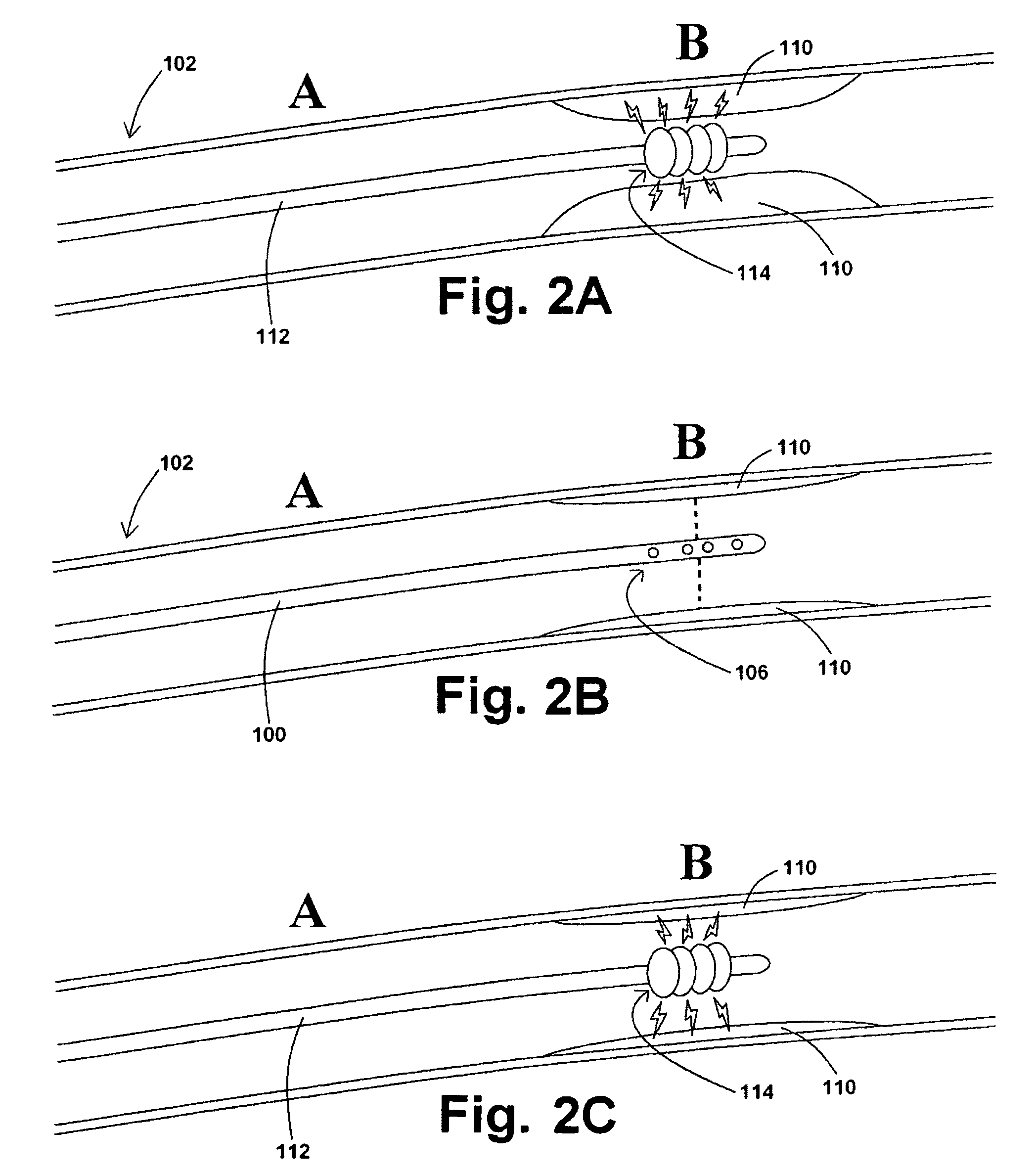

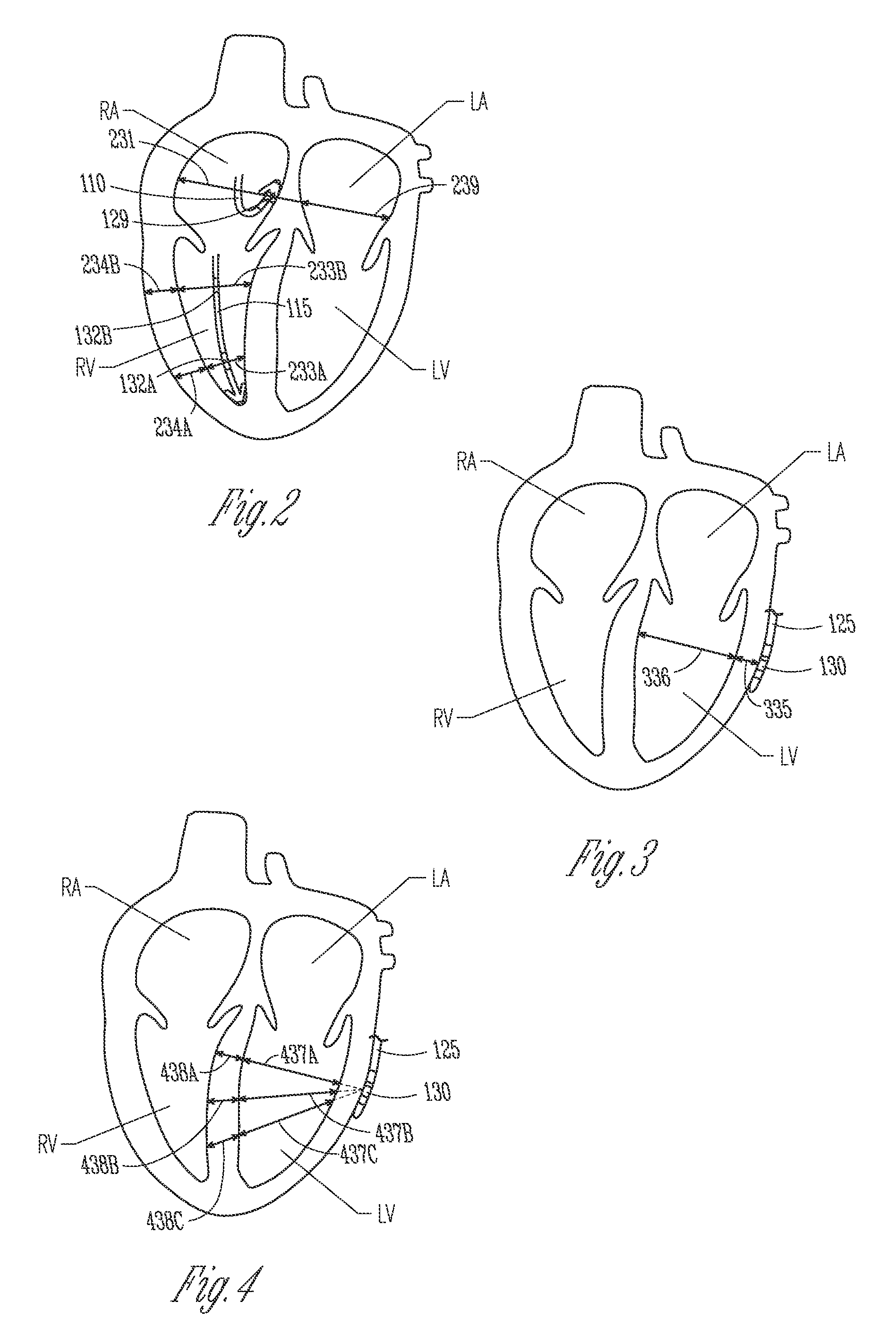

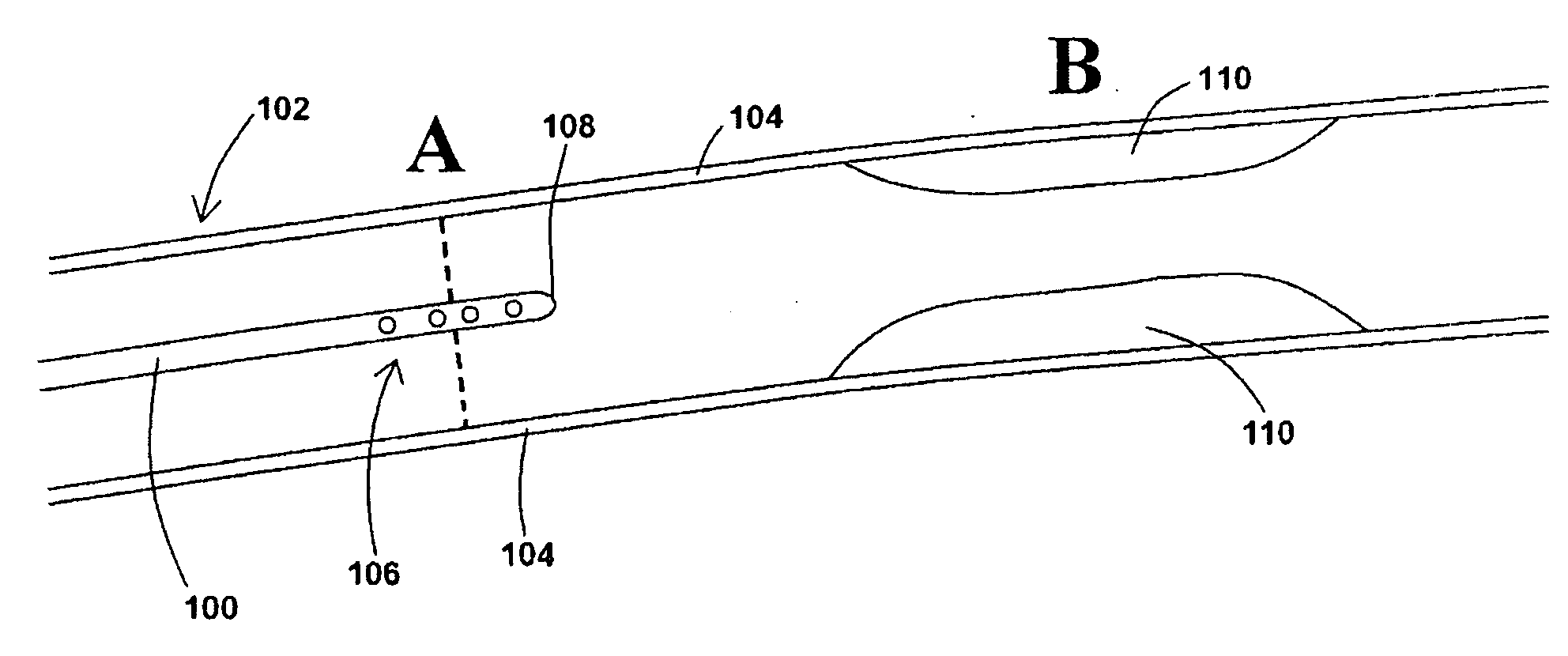

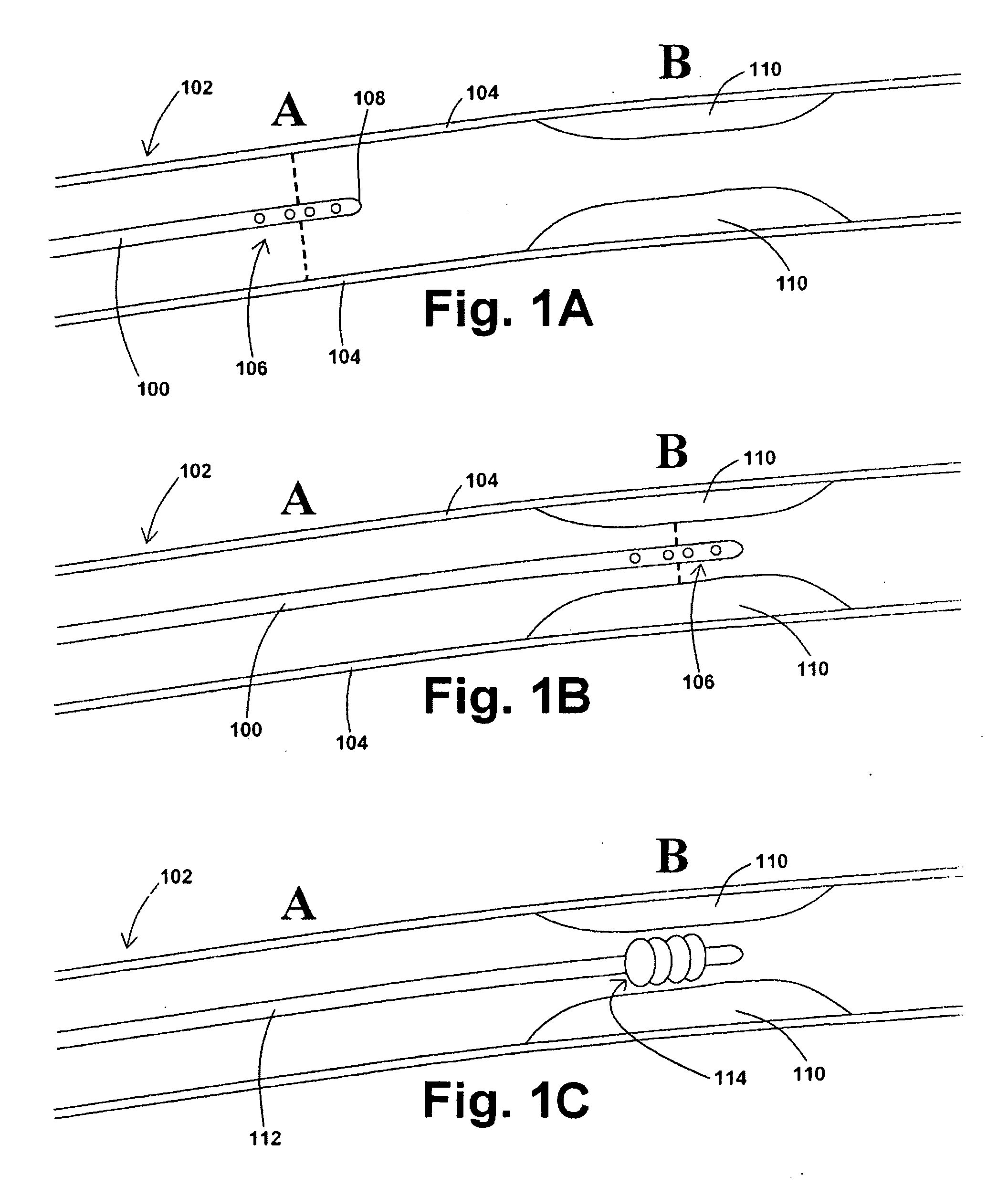

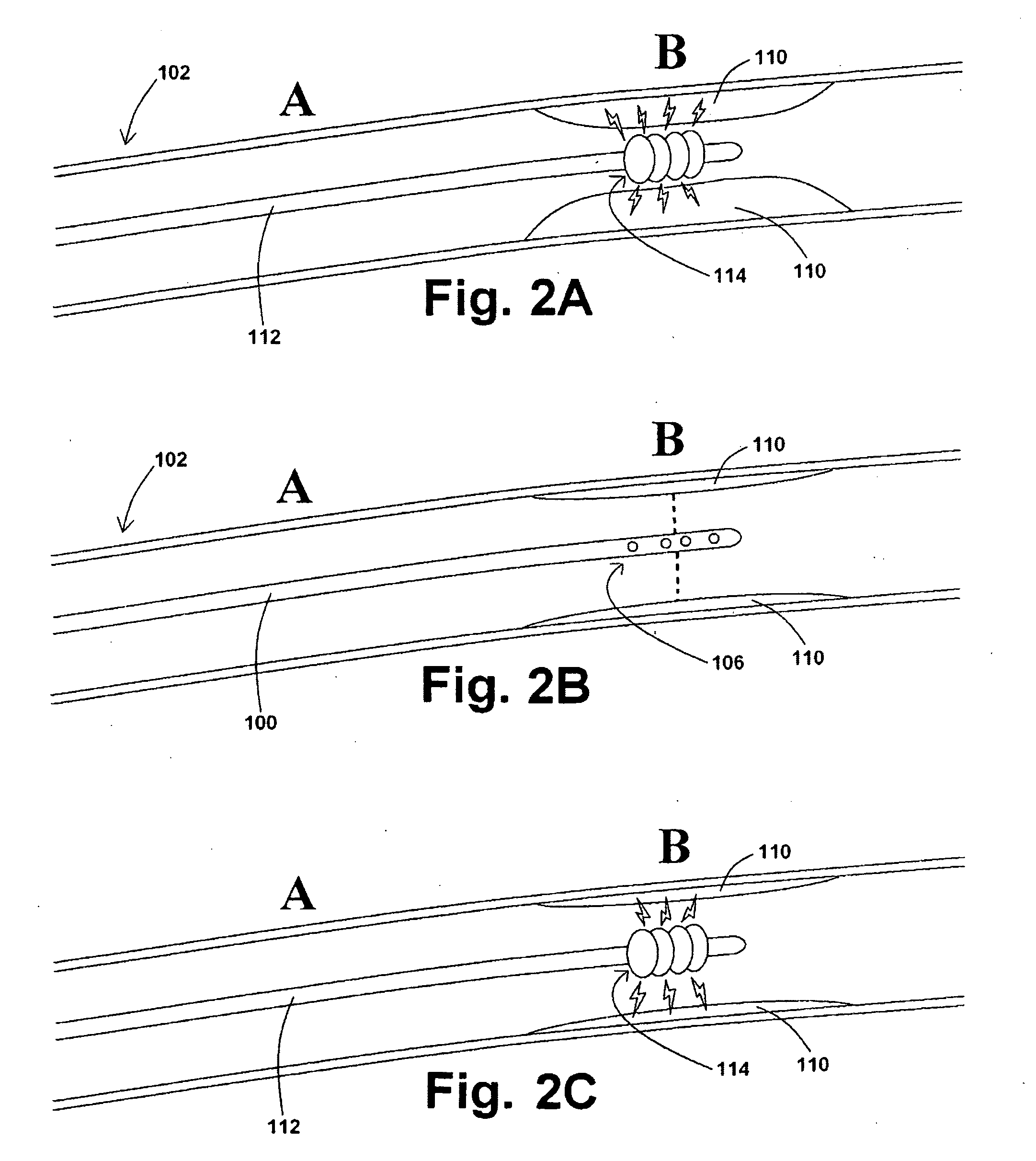

Devices, systems, and methods for removing targeted lesions from vessels

ActiveUS20100222786A1Easy to operate and controlFacilitate one or more fluid injectionsStentsCannulasStenotic lesionTyping

Devices, systems, and methods for removing targeted lesions from vessels. In at least one embodiment of a device for removing a stenotic lesion from a vessel, the device comprises a sizing portion capable of measuring a luminal size parameter when at least part of the device is positioned within a lumen of a luminal organ, a typing portion, wherein at least part of the at least one typing portion is capable of physically touching a portion of the luminal organ or a structure therein, and a treatment portion capable of removing at least part of a stenotic lesion from the luminal organ.

Owner:3DT HLDG

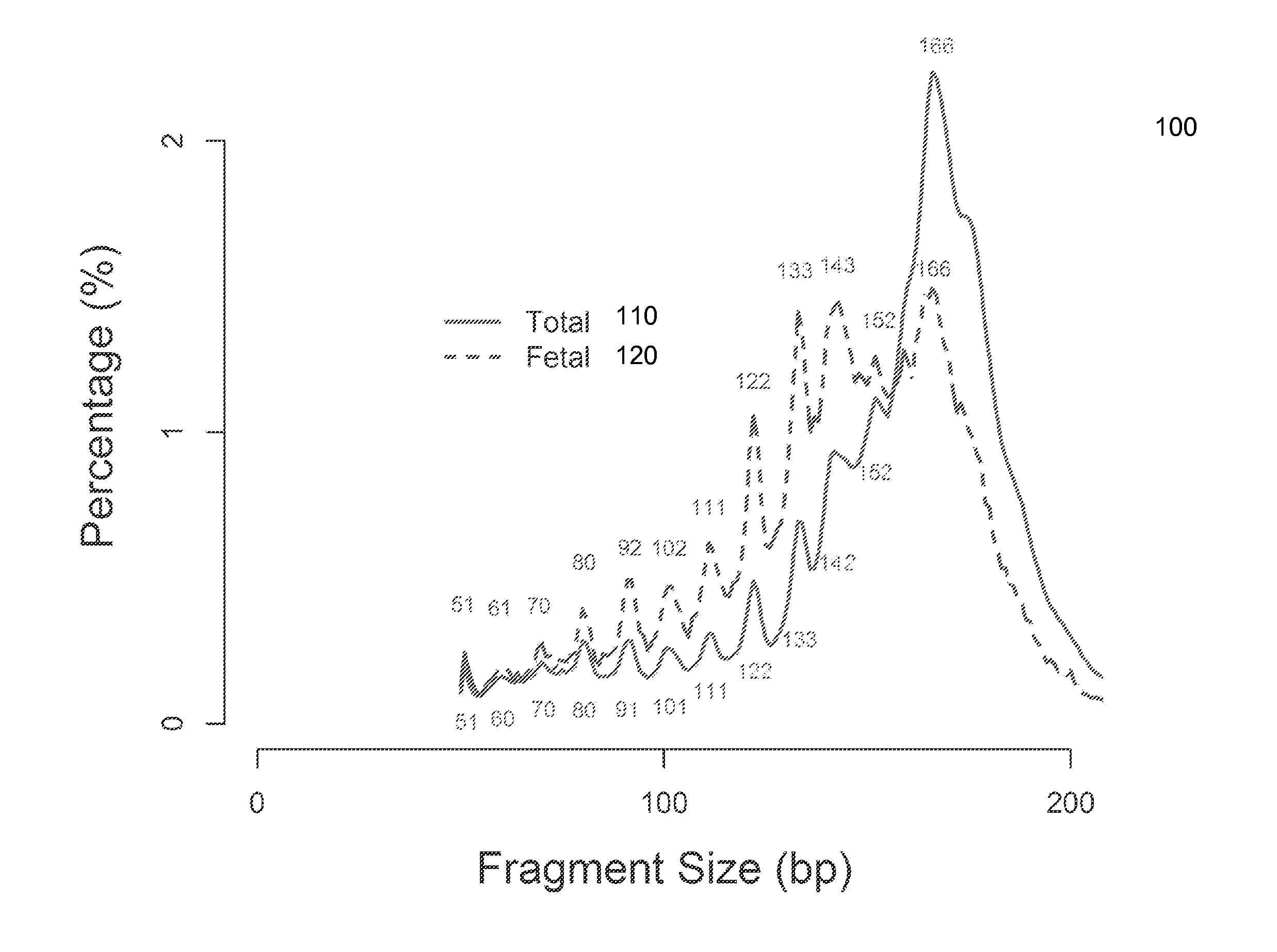

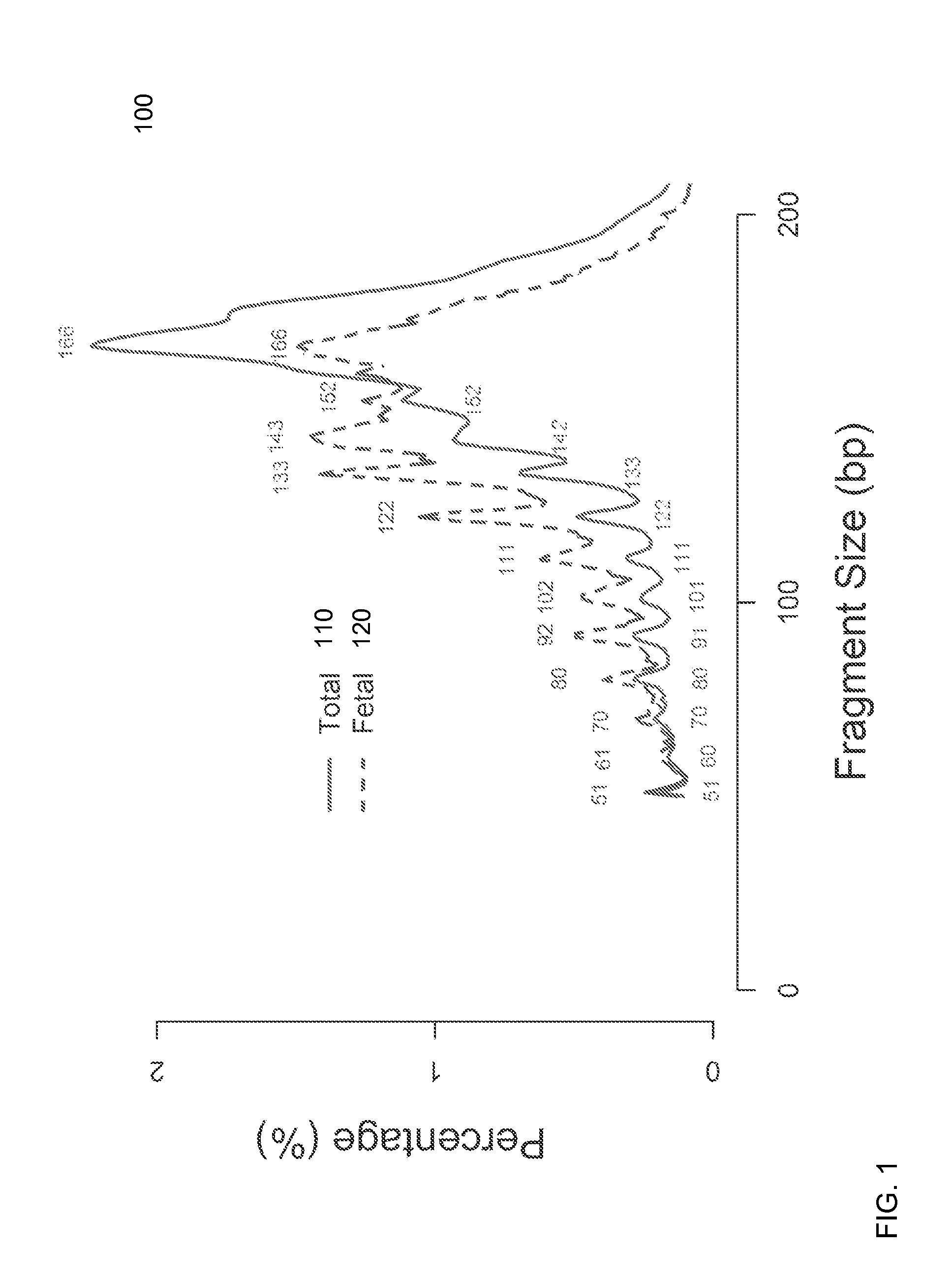

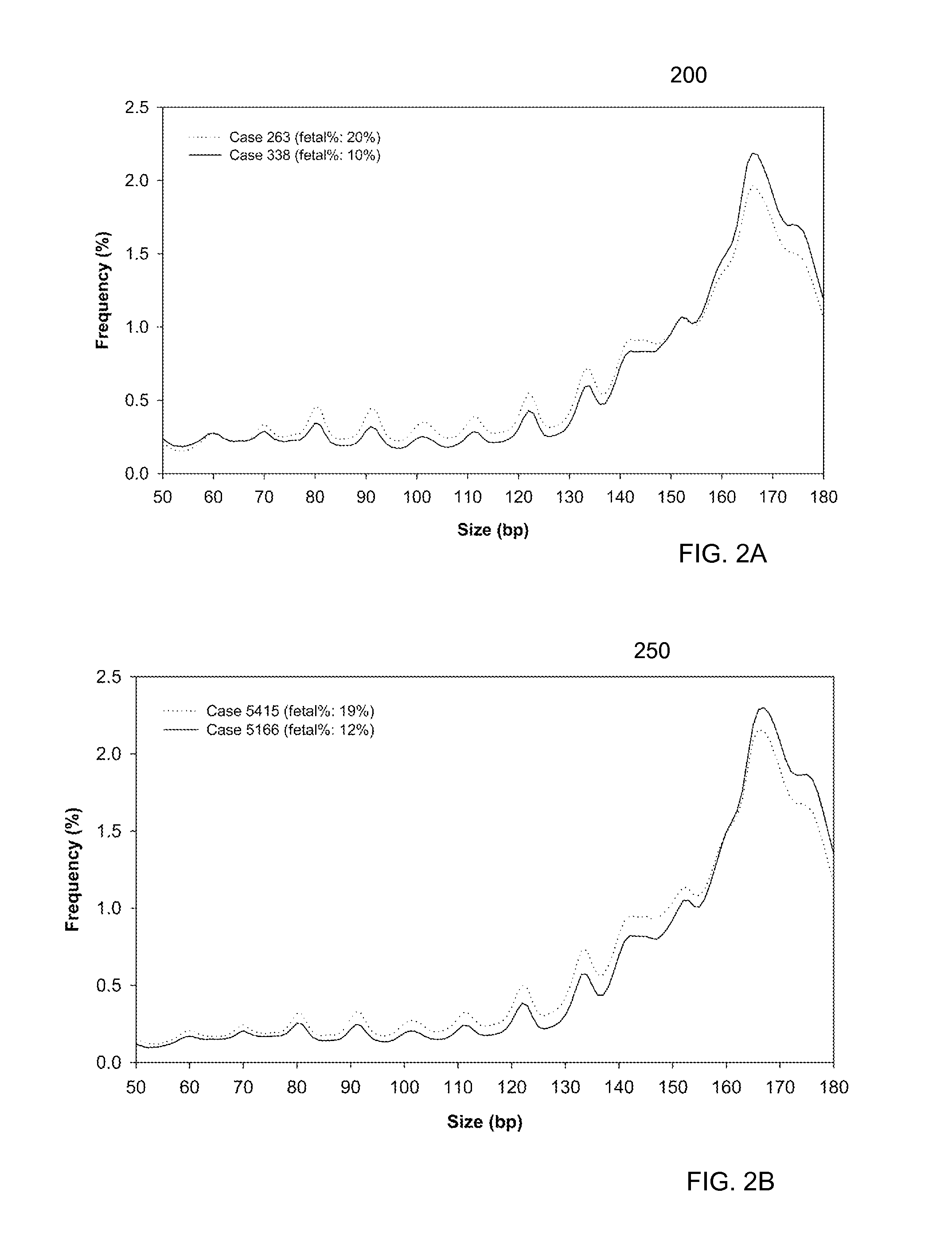

Size-based analysis of fetal DNA fraction in maternal plasma

ActiveUS20130237431A1Health-index calculationMicrobiological testing/measurementAbnormal tissue growthBlood plasma

A fractional concentration of clinically-relevant DNA in a mixture of DNA from a biological sample is determined based on amounts of DNA fragments at multiple sizes. For example, the fractional concentration of fetal DNA in maternal plasma or tumor DNA in a patient's plasma can be determined. The size of DNA fragments in a sample is shown to be correlated with a proportion of fetal DNA and a proportion of tumor DNA, respectively. Calibration data points (e.g., as a calibration function) indicate a correspondence between values of a size parameter and the fractional concentration of the clinically-relevant DNA. For a given sample, a first value of a size parameter can be determined from the sizes of DNA fragments in a sample. A comparison of the first value to the calibration data points can provide the estimate of the fractional concentration of the clinically-relevant DNA.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

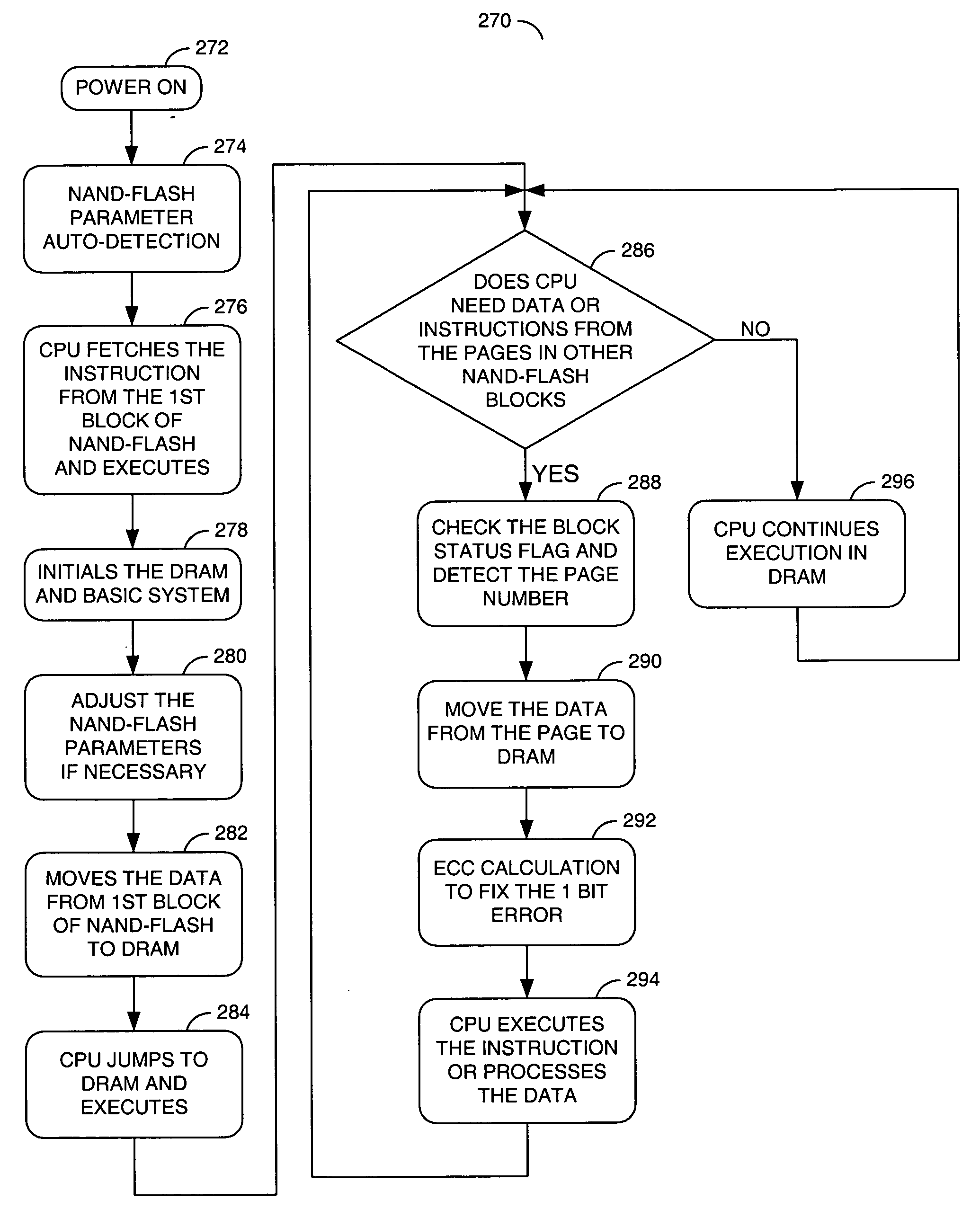

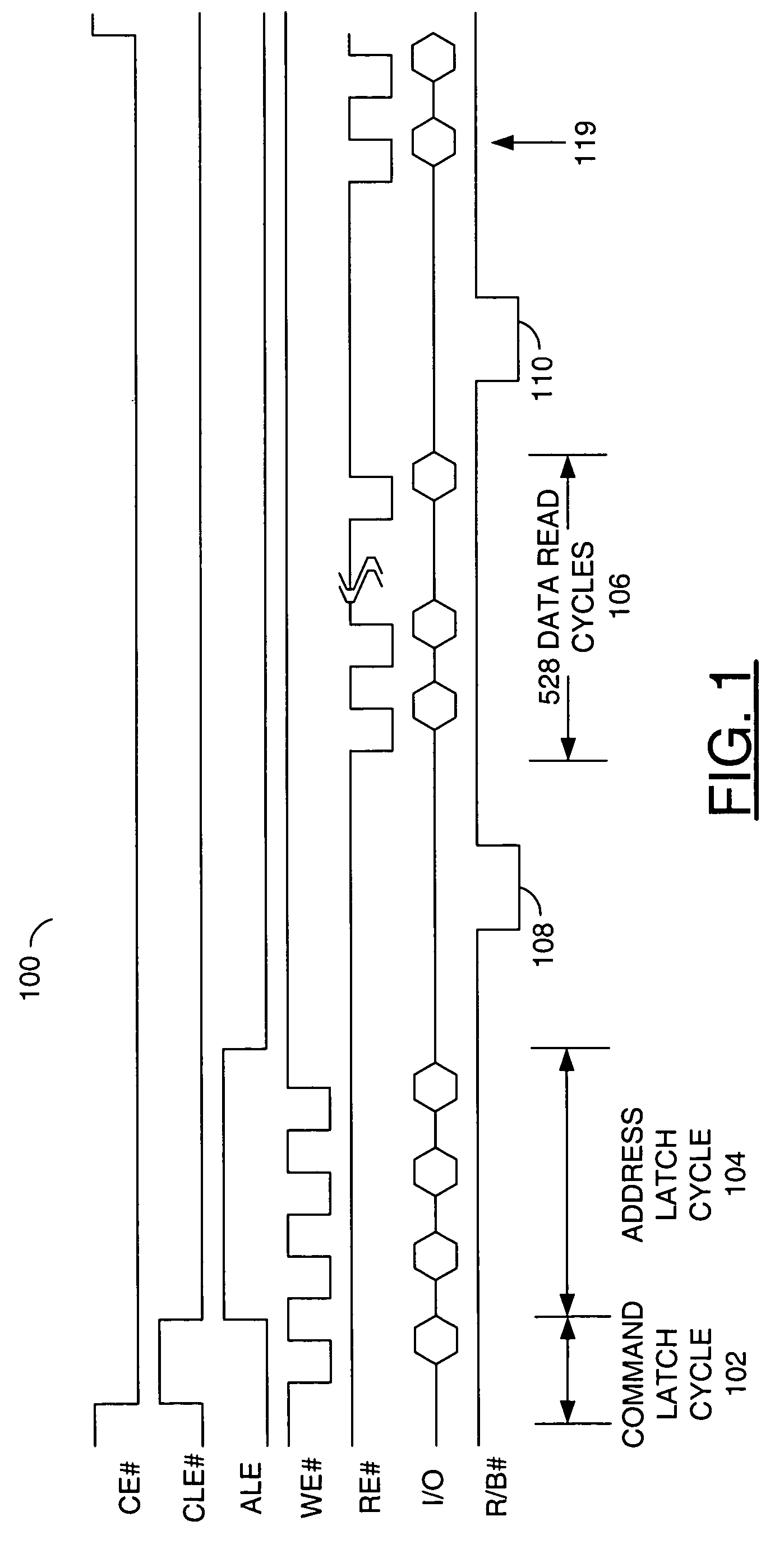

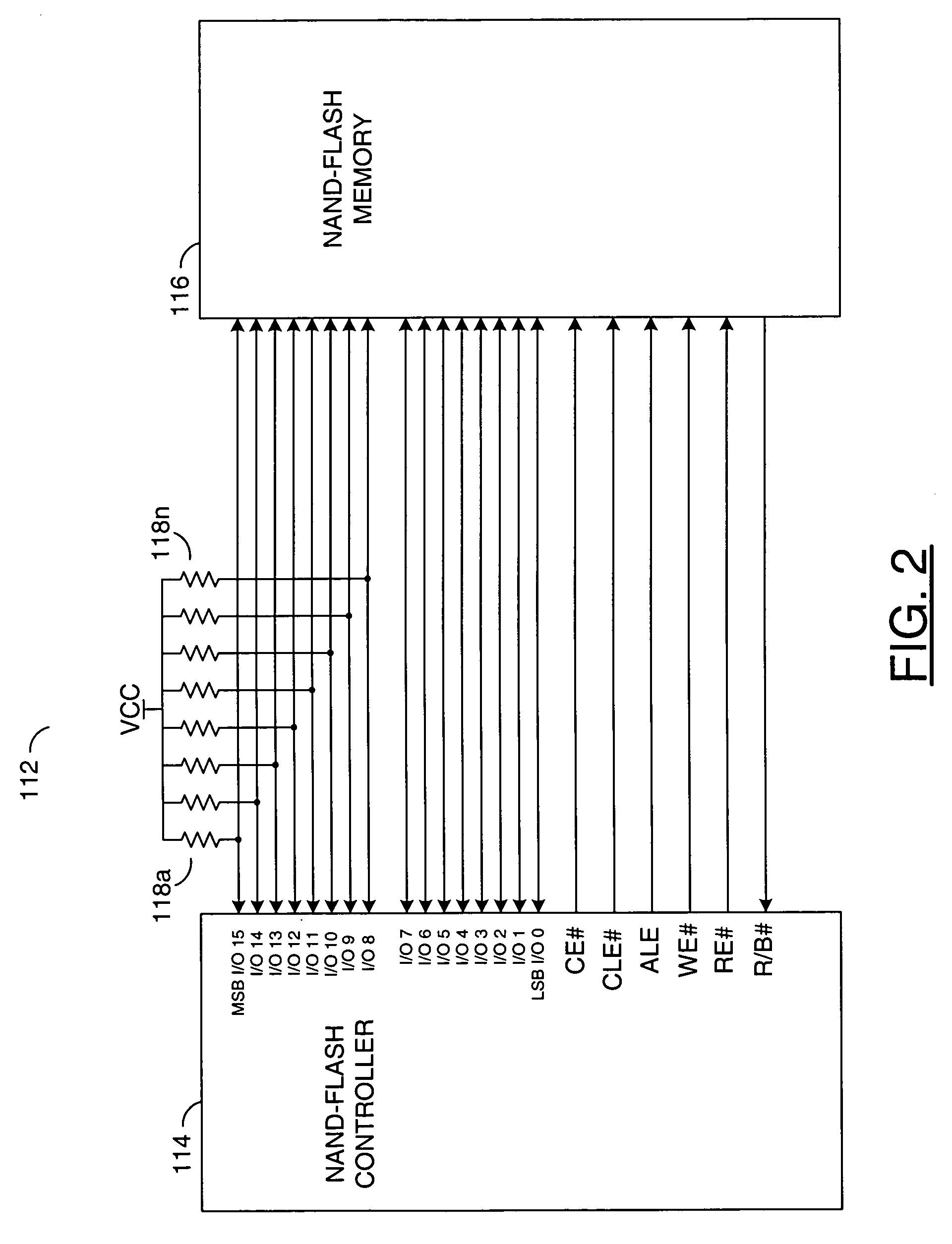

Method to detect NAND-flash parameters by hardware automatically

InactiveUS20060195650A1Reduce areaLow costRead-only memoriesDigital computer detailsSize parameterReal-time computing

Owner:AVAGO TECH INT SALES PTE LTD

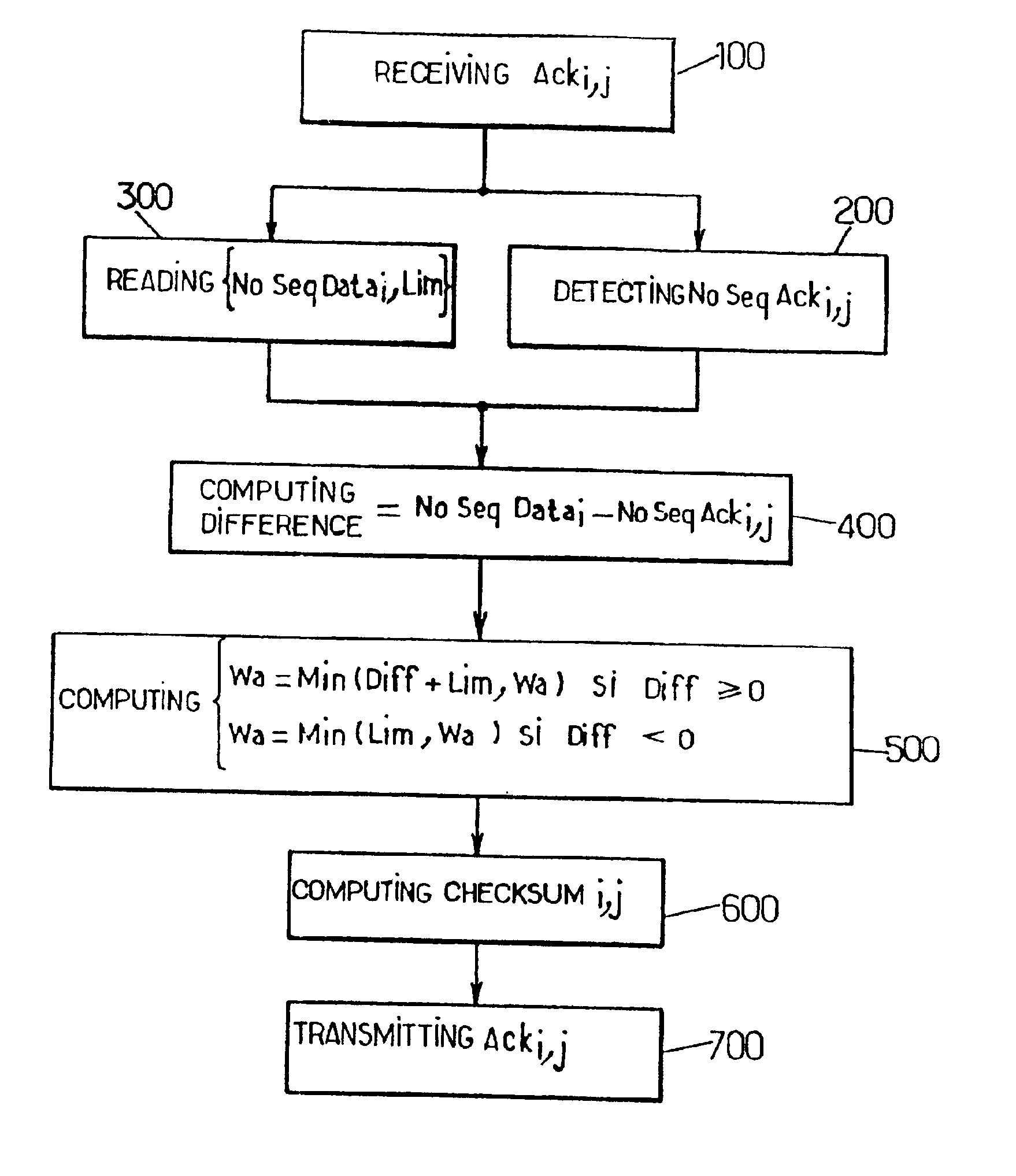

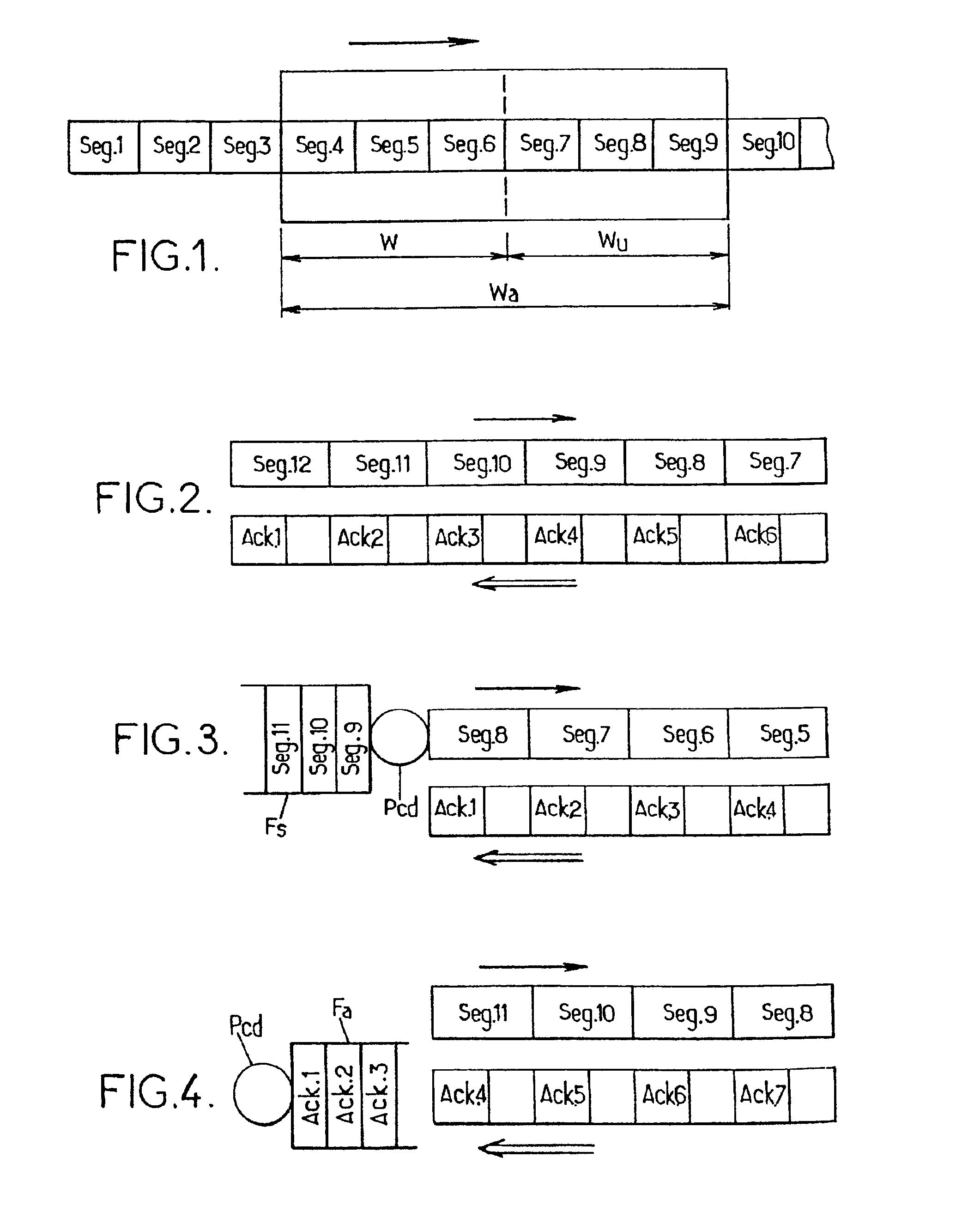

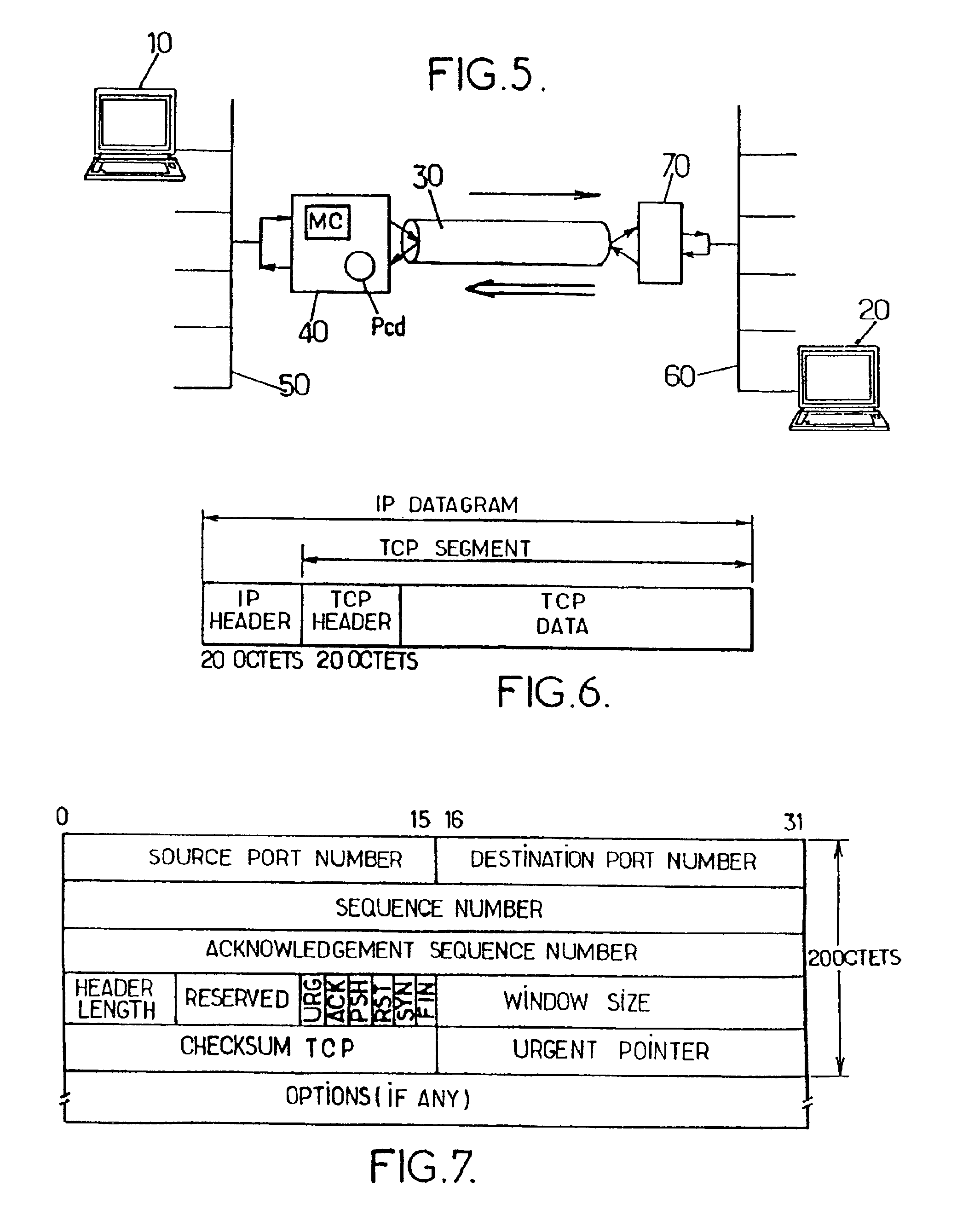

Method and unit for controlling the flow of a TCP connection on a flow controlled network

InactiveUS6925060B2Easy to implementAvoid congestionError prevention/detection by using return channelTransmission systemsMultiplexingComputer science

The invention proposes a method and a unit for controlling the flow of at least one TCP connection between a sender and a receiver. The method is of the type which consists in controlling, at the level of a given multiplexing node through which TCP segments relevant to the connection pass, a window size parameter contained in acknowledgement segments sent back by the receiver. The method comprises the steps of:a) receiving an acknowledgement from the receiver on the up link (receiver to sender) of the connection at the level of said given multiplexing node;b) controlling a window size parameter contained in, said acknowledgement segment on the basis of the difference between, firstly, a first context value associated with the TCP connection, defined as being the sequence number of the last segment that was transmitted from said given multiplexing node on the down link (sender to receiver) of the connection, to which the length of said segment is added, and, secondly, the sequence number indicated in said acknowledgement segment;c) transmitting the acknowledgement segment to the sender the up link of the connection from said multiplexing node with the window size parameter thus controlled.

Owner:MITSUBISHI ELECTRIC CORP

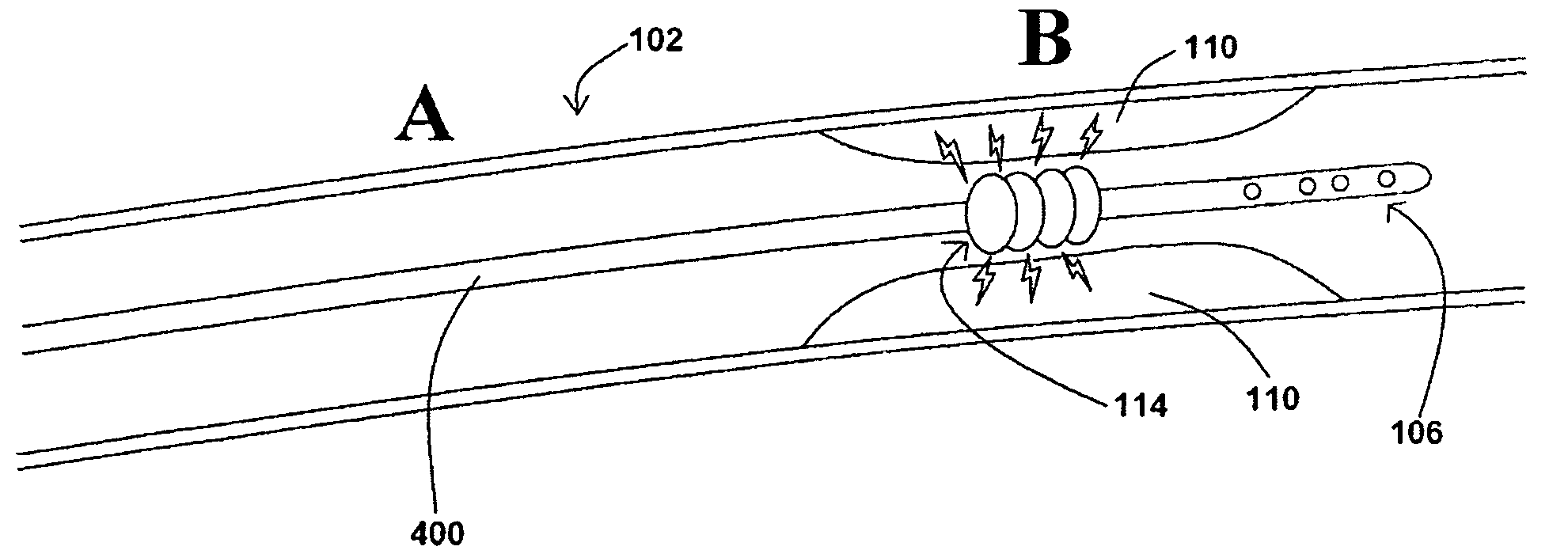

Devices, systems, and methods for removing stenotic lesions from vessels

The present application provides various devices, systems, and methods for removing stenotic lesions from vessels. In at least one embodiment of an exemplary device, the device comprises at least one sizing portion and at least one treatment portion. Such a device may be useful to, for example, remove a stenotic lesion from a vessel by positioning the device within a vessel lumen, operating the sizing portion to obtain luminal size parameter data, operating the treatment portion at a location within the vessel lumen at or near a stenotic lesion, and ceasing operation of the treatment portion when the luminal size parameter data indicates a preferred luminal size parameter.

Owner:3DT HLDG

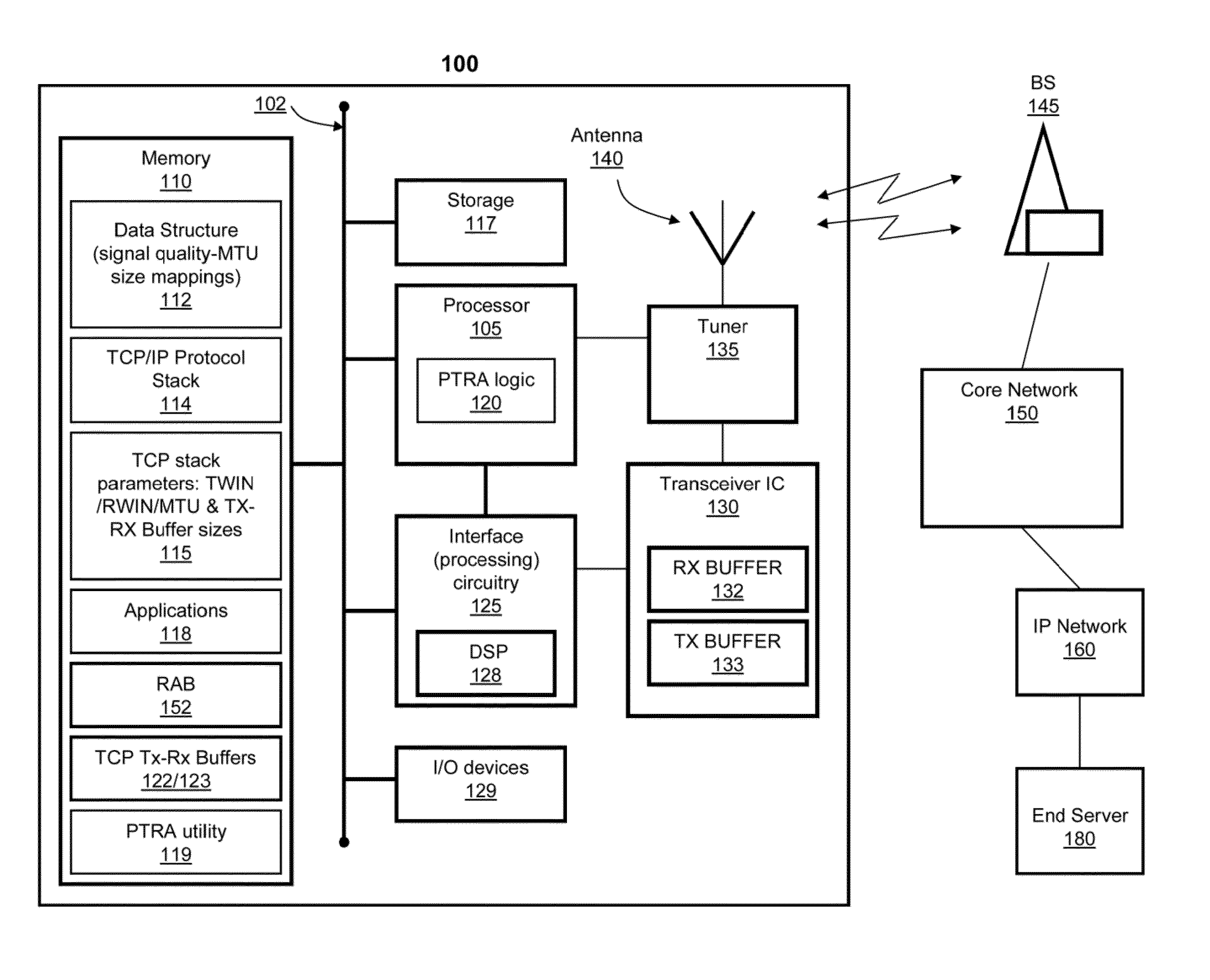

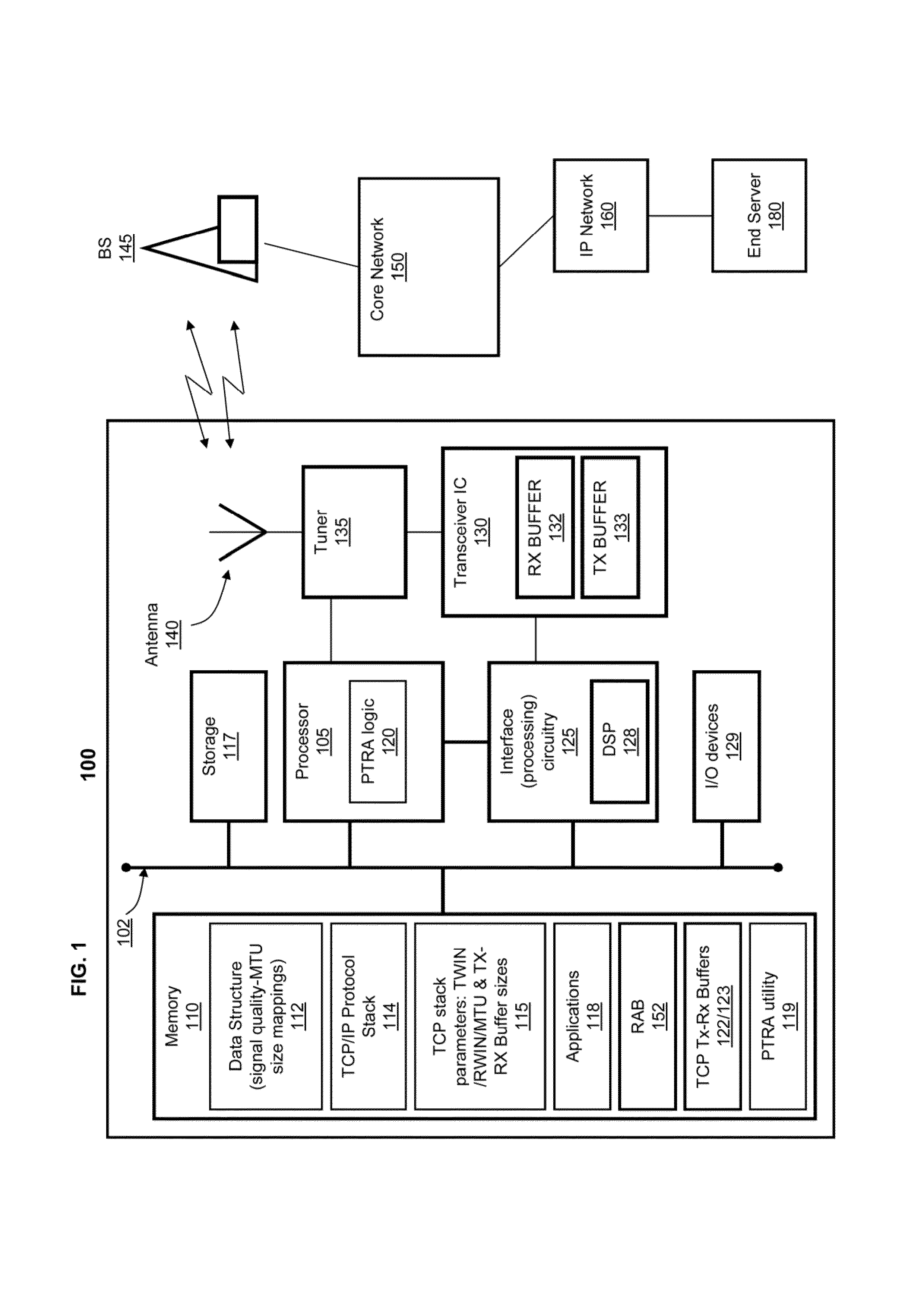

Dynamic TCP layer optimization for real-time field performance

ActiveUS20130176854A1Error preventionFrequency-division multiplex detailsTerminal serverTelecommunications link

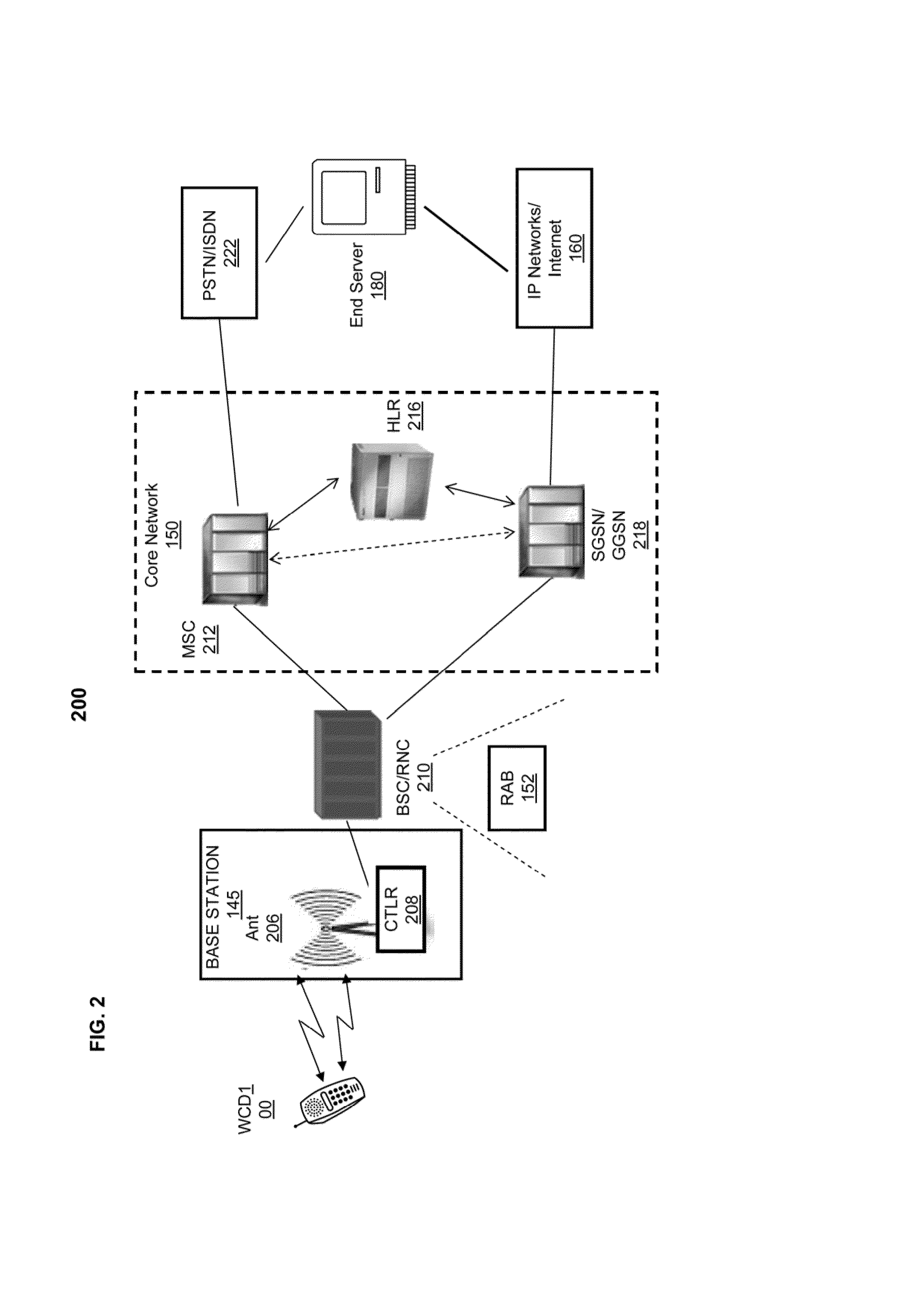

A method and system that mitigates data session degradation over a radio link connection with an end server by allocating resources at a wireless communication device based on real-time radio frequency (RF) channel conditions. A performance tracking and resource allocation (PTRA) logic monitors radio access bearer (RAB) configuration and radio link quality for communication links between the WCD and the end server. The PTRA logic sets a maximum transmission unit (MTU) size parameter to a pre-established size associated with the measured radio link quality. In response to detecting a change in the RAB configuration, the PTRA logic performs a real-time round trip time (RTT) measurement utilizing individual RTTs associated with packet segments transmitted at a lower protocol layer. In addition, the PTRA logic modifies at least one of a transmission control protocol (TCP) receive window (RWIN) and a TCP transmit window (TWIN) using the real-time RTT measurements and RAB configuration.

Owner:GOOGLE TECH HLDG LLC

Robust static and moving object detection system via attentional mechanisms

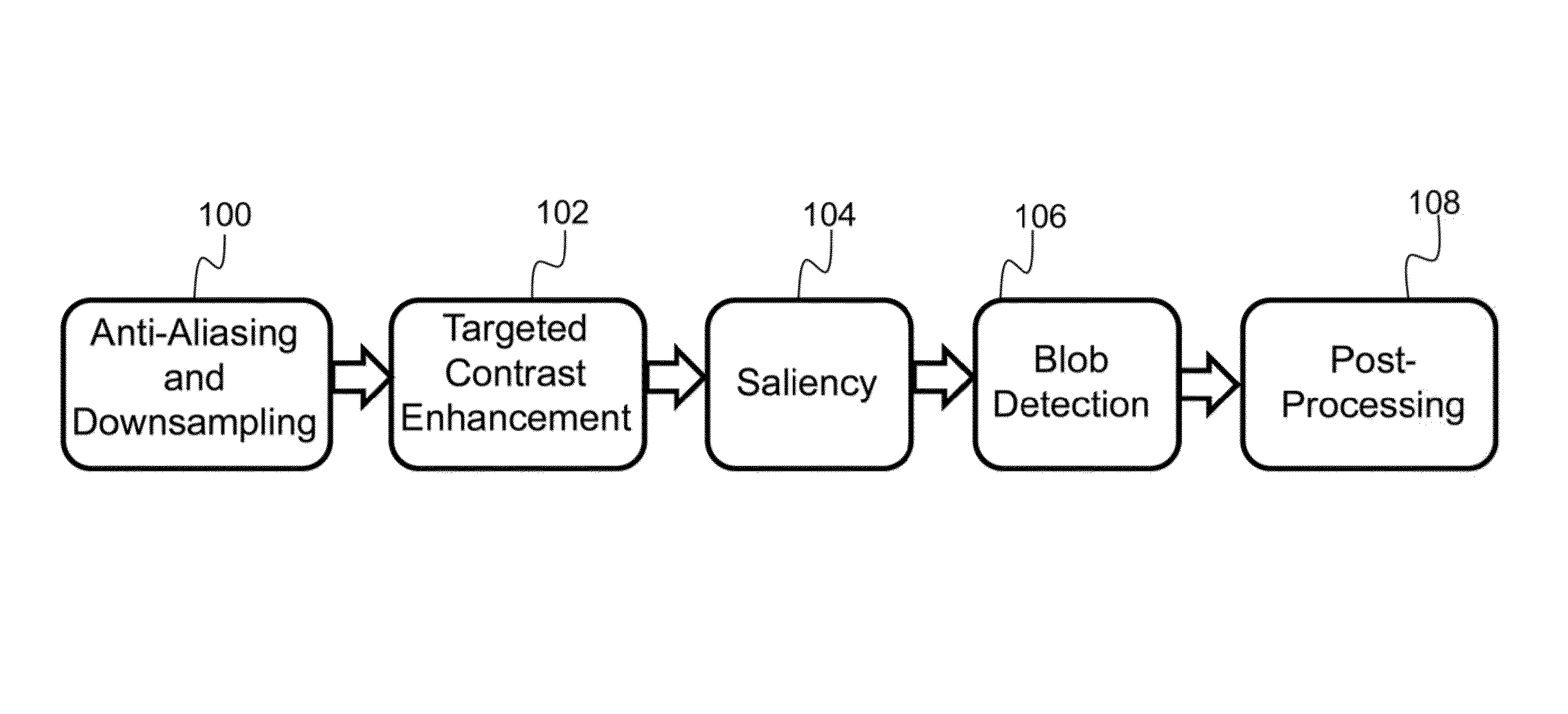

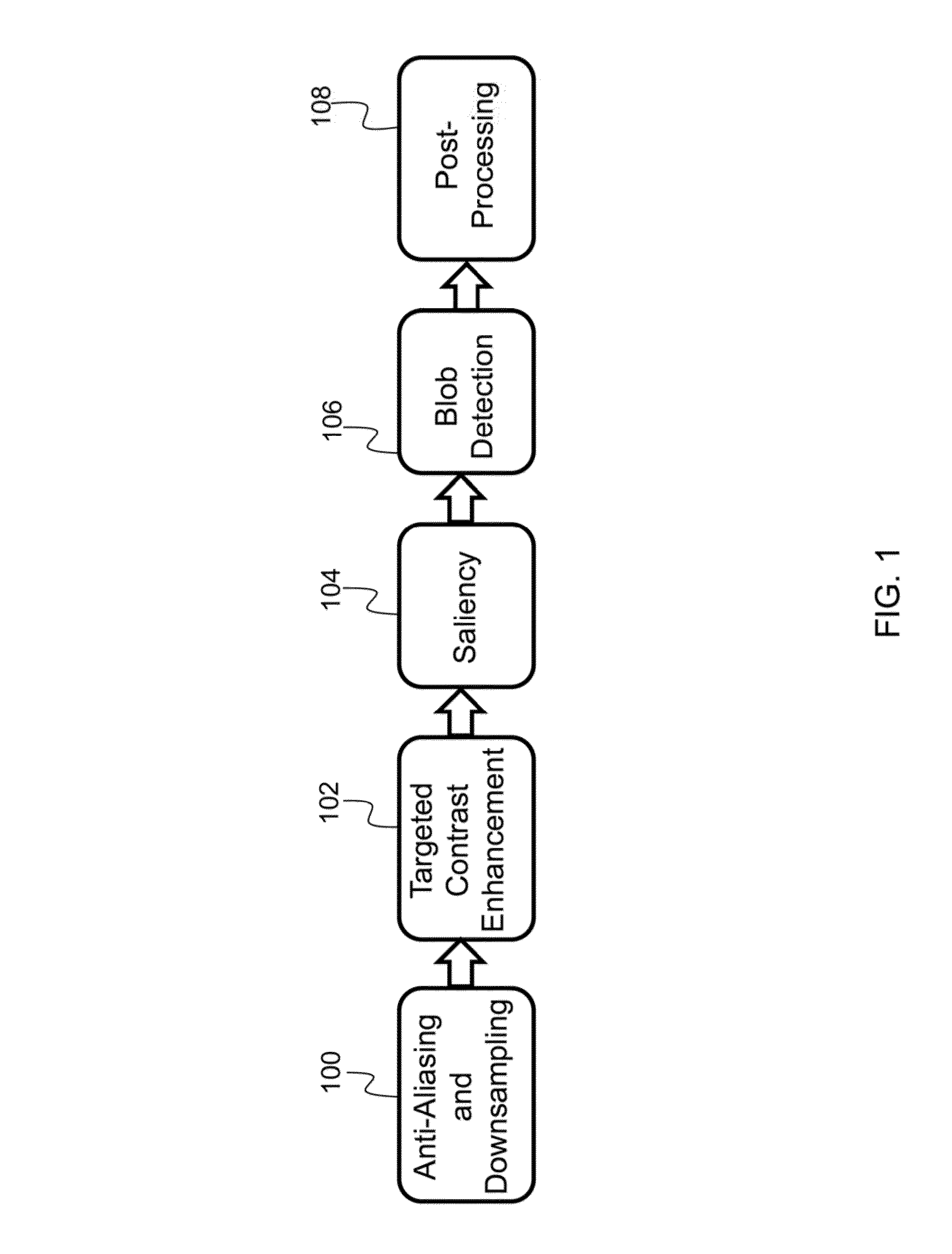

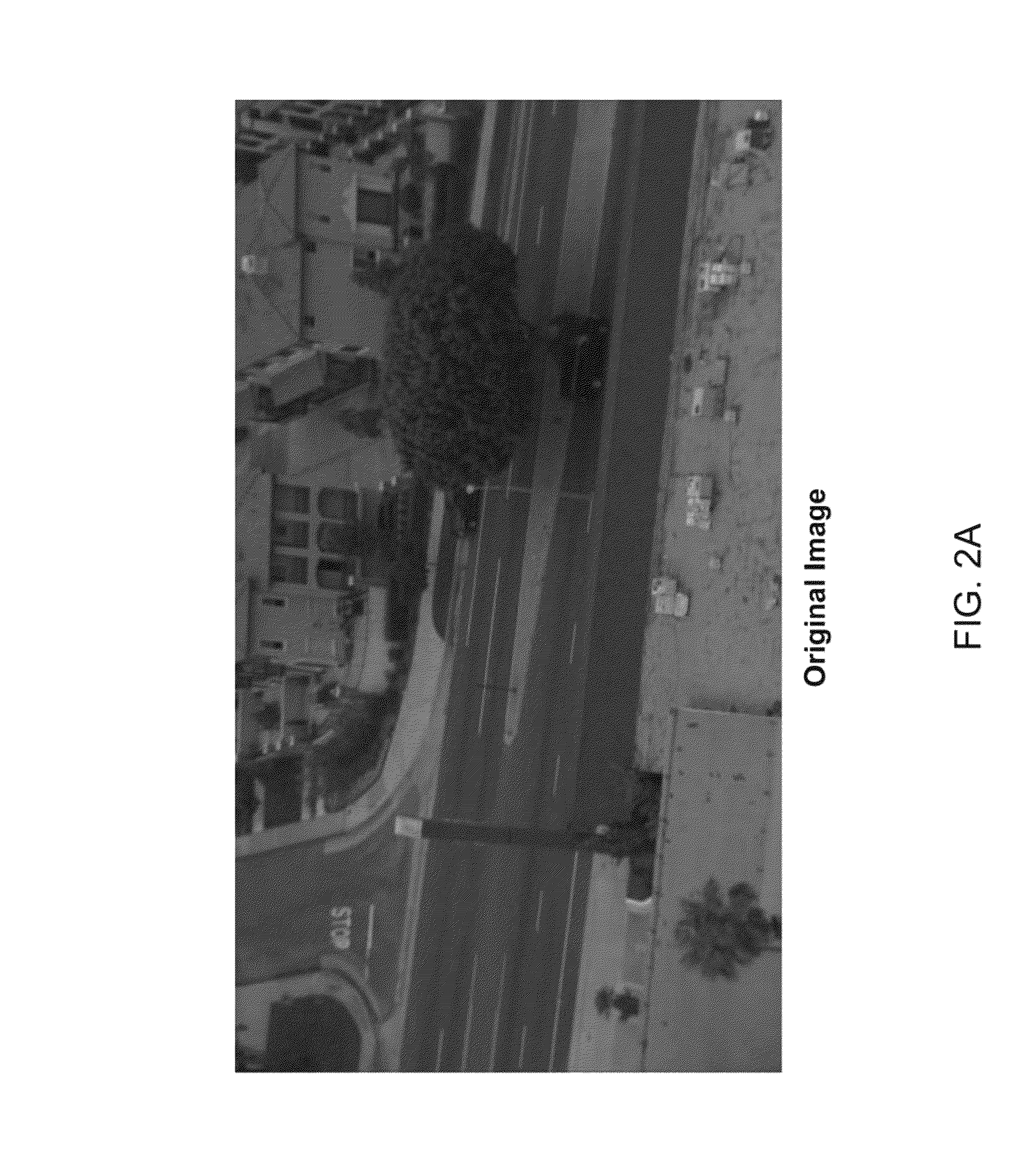

Described, is a system for object detection via multi-scale attentional mechanisms. The system receives a multi-band image as input. Anti-aliasing and downsampling processes are performed to reduce the size of the multi-band image. Targeted contrast enhancement is performed on the multi-band image to enhance a target color of interest. A response map for each target color of interest is generated, and each response map is independently processed to generate a saliency map. The saliency map is converted into a set of detections representing potential objects of interest, wherein each detection is associated with parameters, such as position parameters, size parameters, an orientation parameter, and a score parameter. A post-processing step is applied to filter out false alarm detections in the set of detections, resulting in a final set of detections. Finally, the final set of detections and their associated parameters representing objects of interest is output.

Owner:HRL LAB

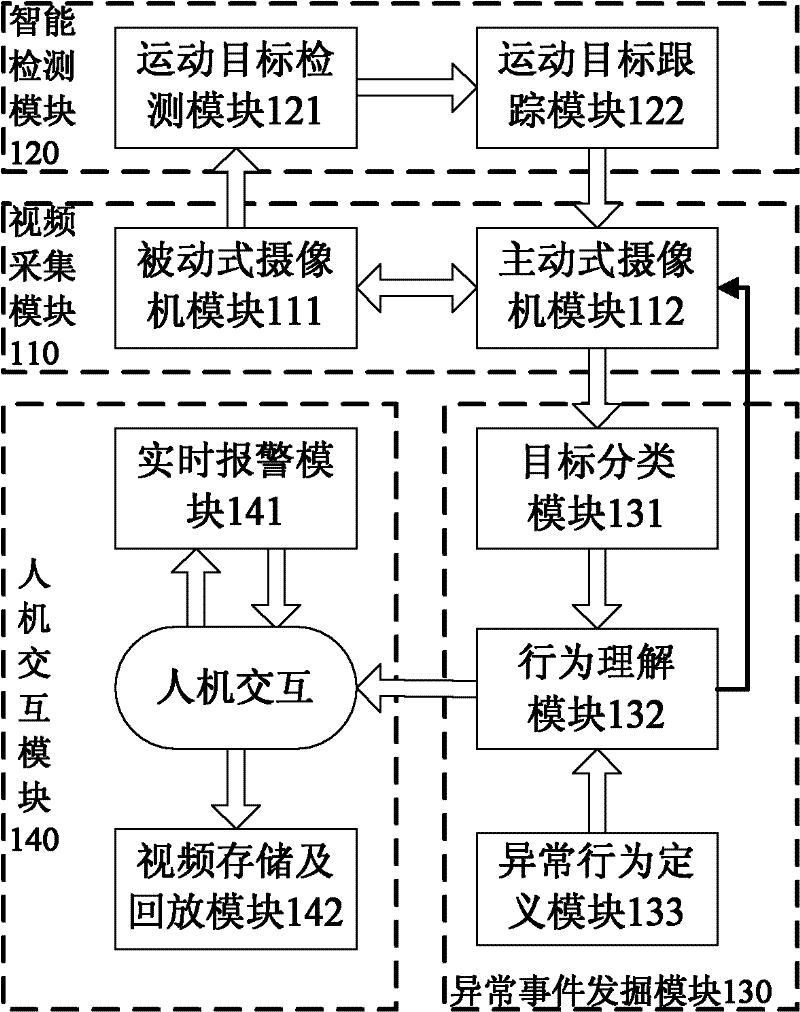

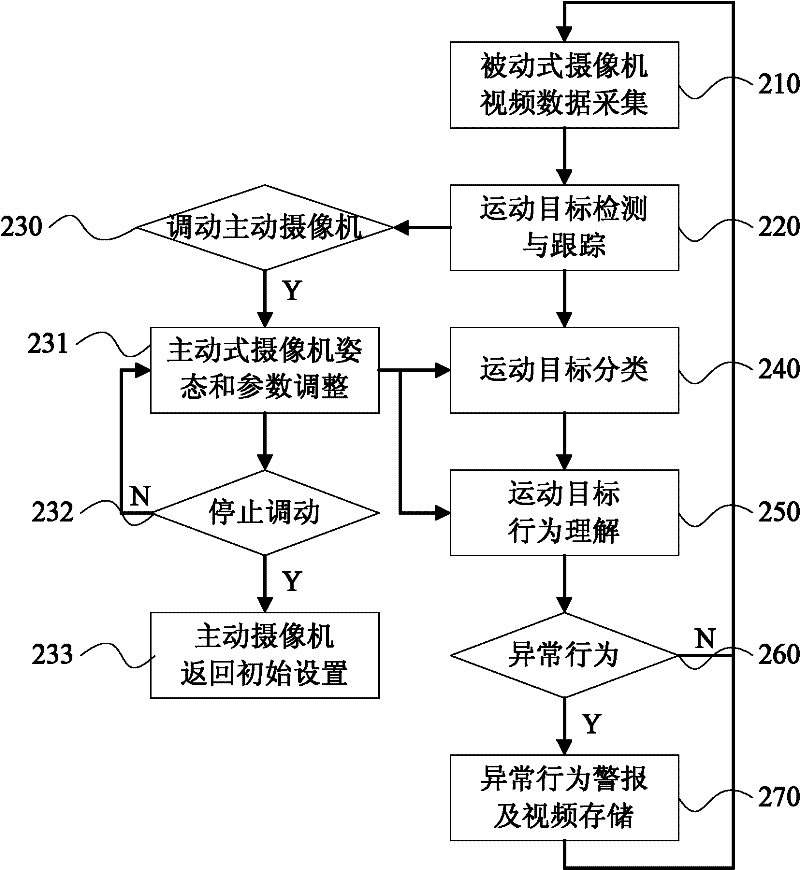

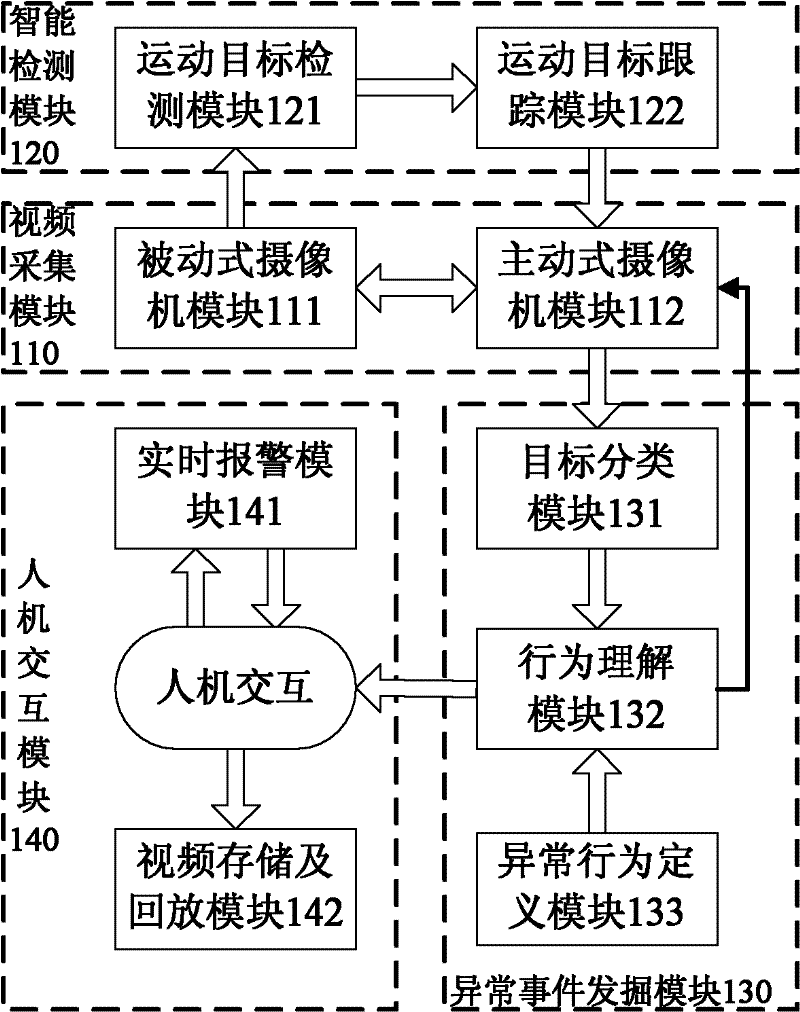

Intelligent video monitoring method and system capable of exploring abnormal events

InactiveCN102164270AObserve local close-upsImage analysisCharacter and pattern recognitionVideo monitoringComputer vision

The invention relates to an intelligent video monitoring method capable of exploring abnormal events, and the method comprises the following steps: 1) using a driven type camera to monitor the abnormal conditions around the camera and collect video data in a monitored scene; 2) detecting and tracking a motion target occurred in the monitored scene, marking the motion target and transmitting the position and size parameters of the motion target to a driving camera; 3) self-adaptively giving a close shot for the motion target by the driving type camera according to the acquired parameters; 4) correctly classifying the detected motion target; 5) performing behavior understanding on the classified motion target; and 6) judging whether an abnormal event occurs according to the preset standard, and triggering the alarm if the abnormal event occurs. The invention also relates to a system for realizing the method. The system provided by the invention has the function of automatically finding and analyzing the abnormal events, and has the advantages that the intelligent degree is high, and the operations of alarming and information treatment can be performed timely.

Owner:ZHEJIANG UNIV OF TECH

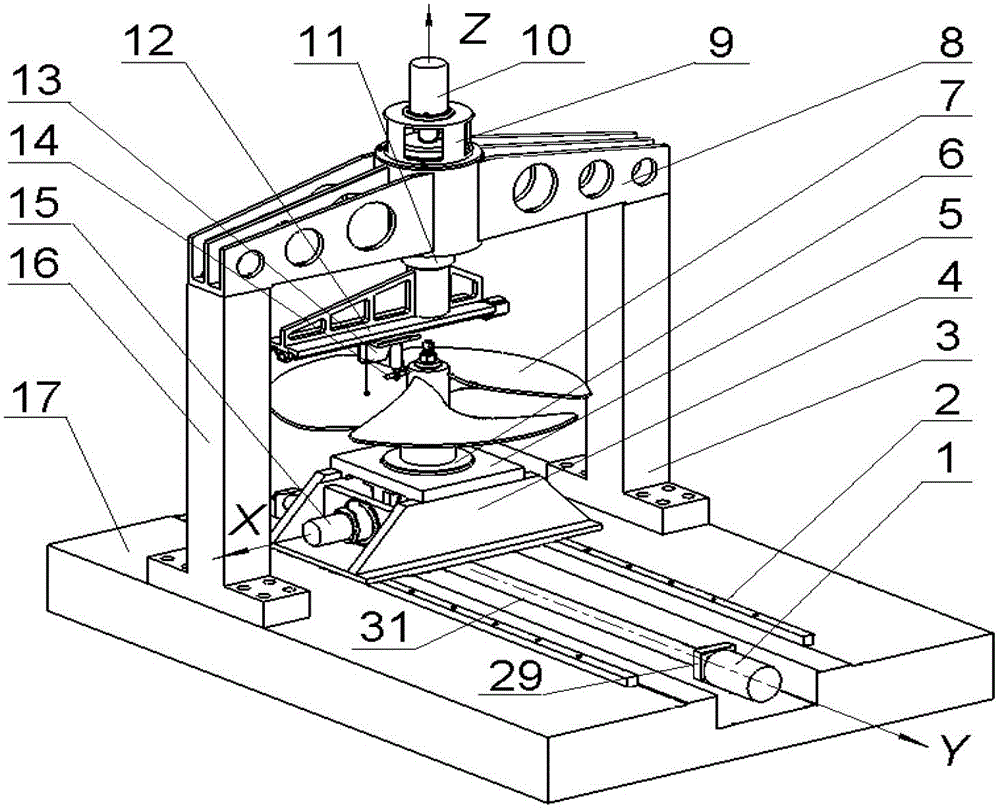

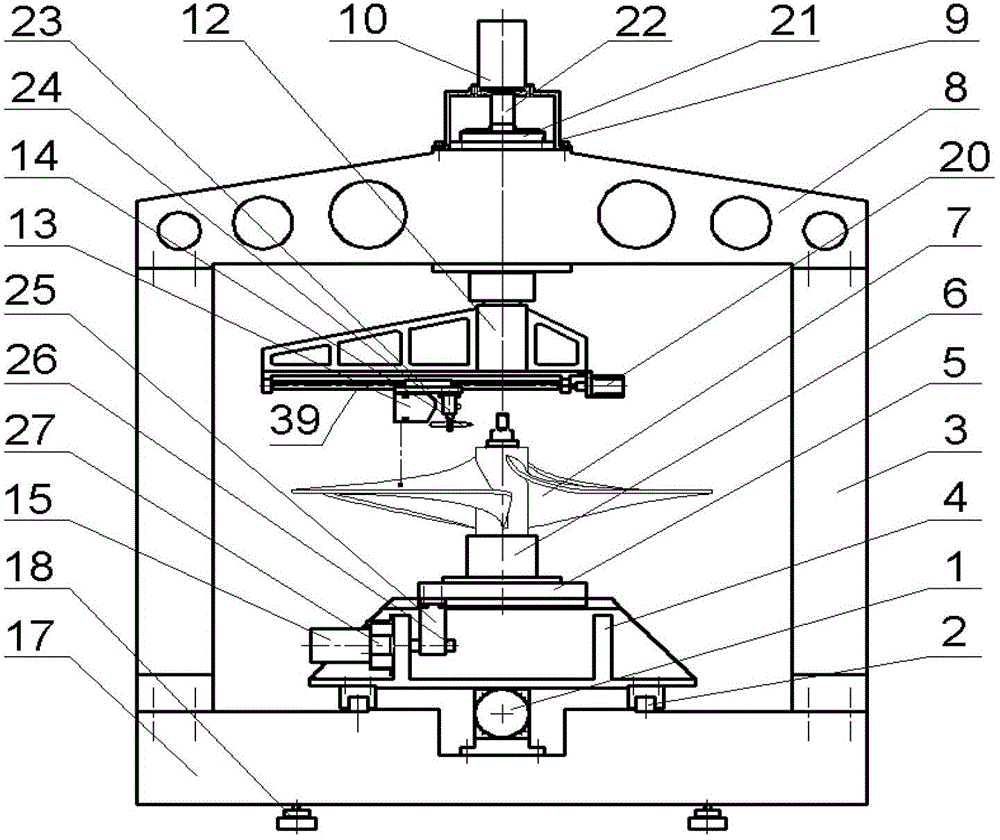

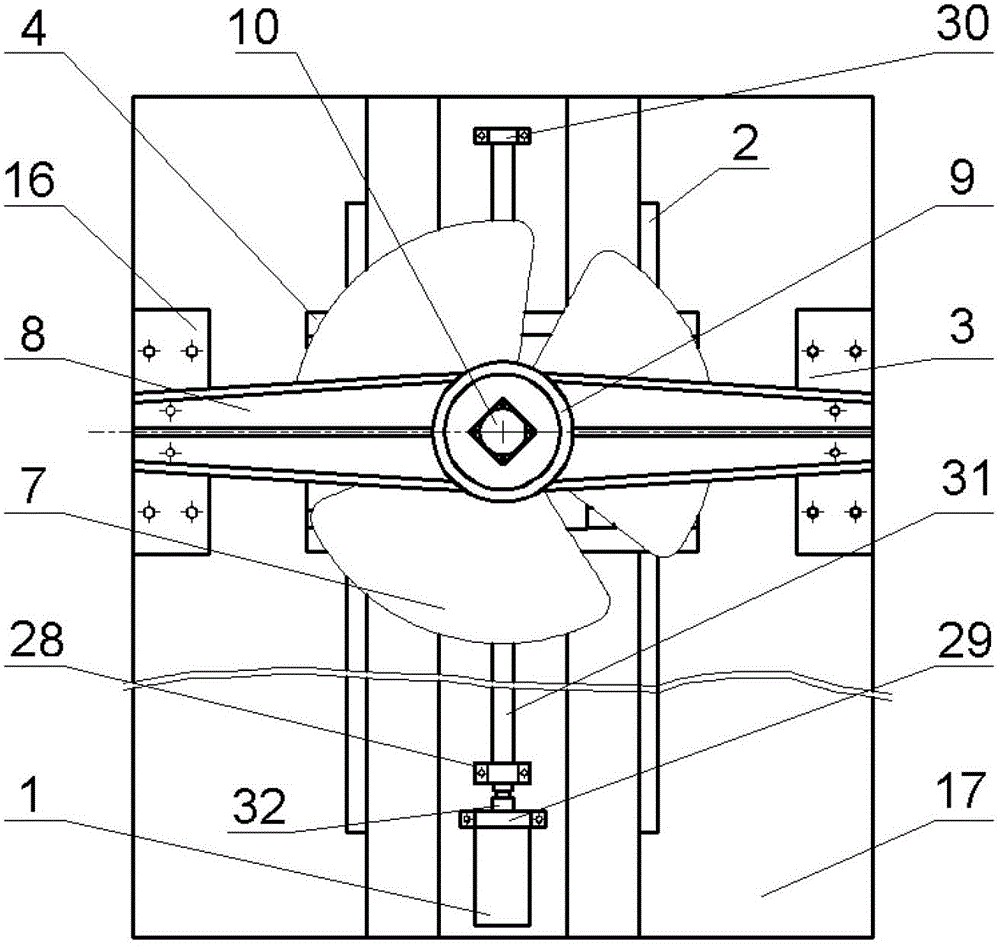

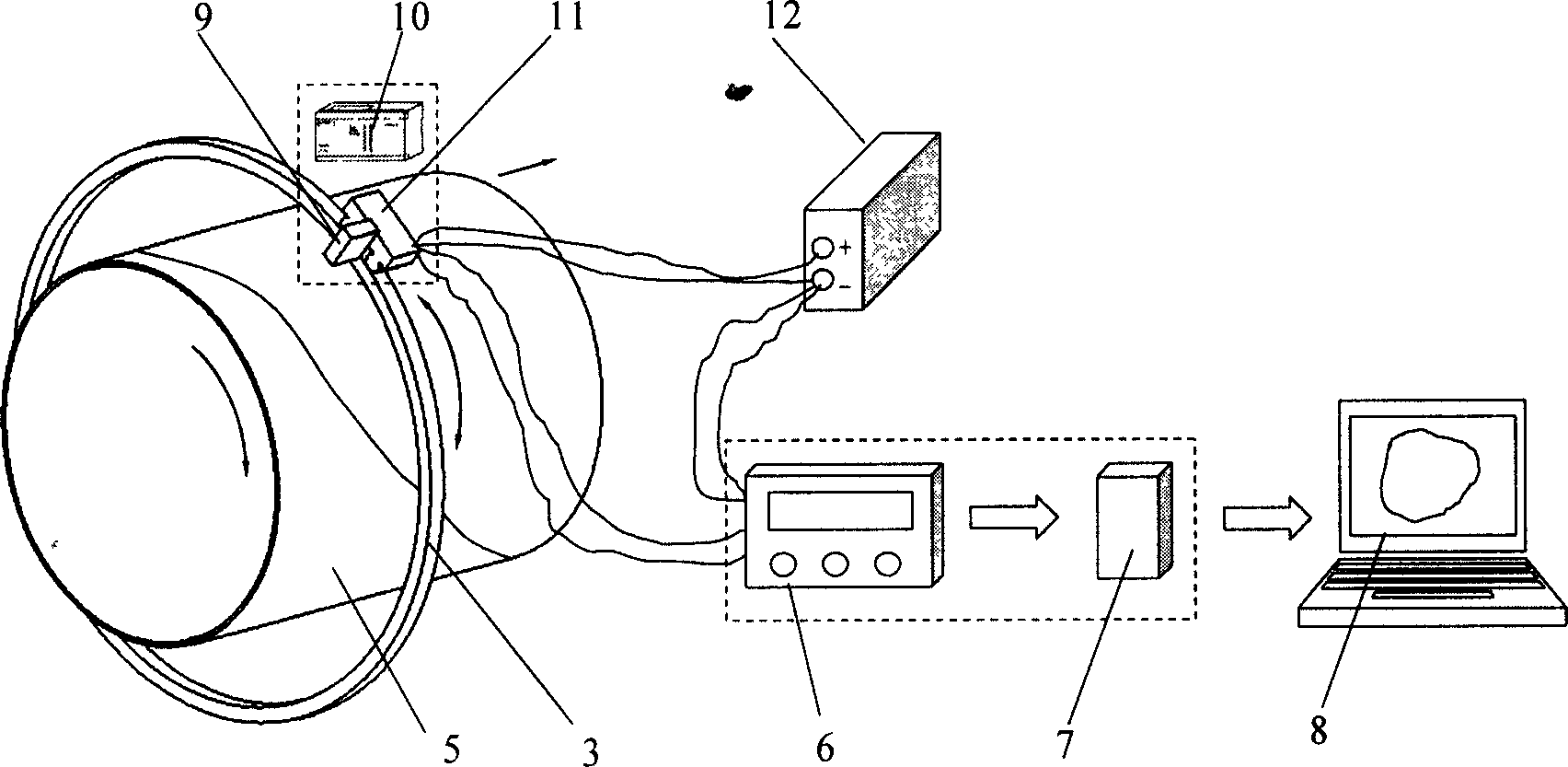

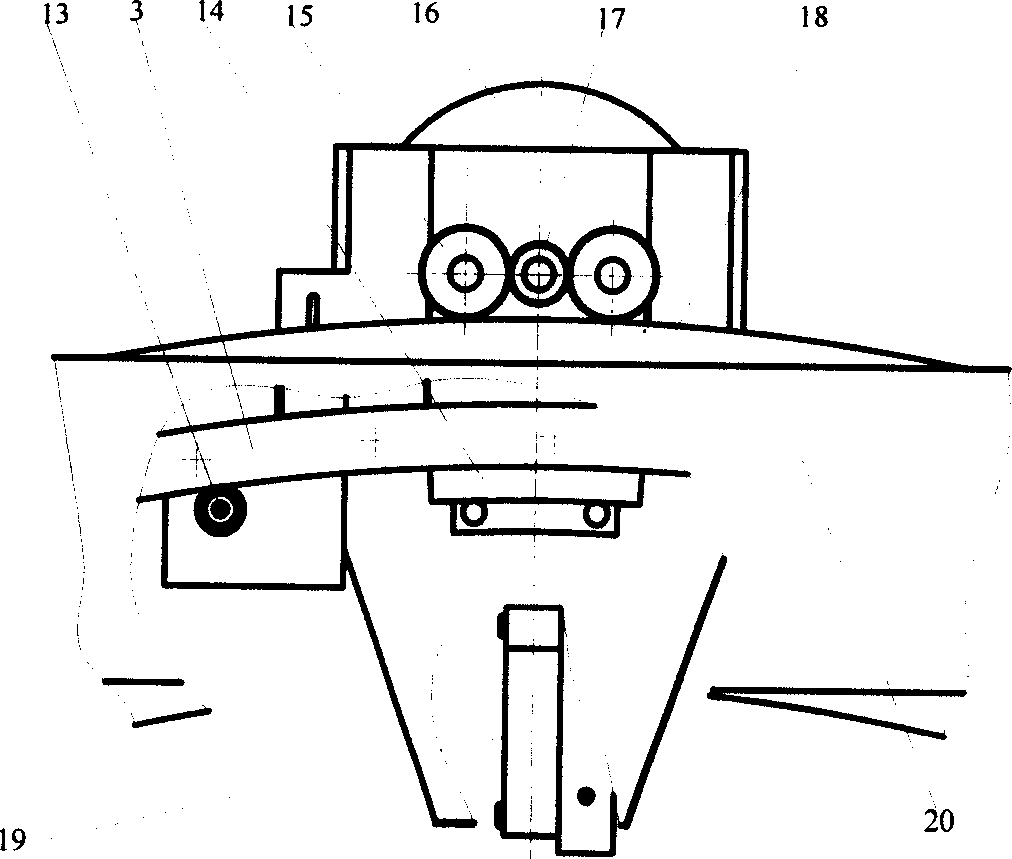

Propeller type surface contour error measurement instrument and method

ActiveCN102749041AEasy to achieve 3D reconstructionAvoiding Probe Radius Compensation ProblemsElectric/magnetic contours/curvatures measurementsUsing optical meansGeometric errorMeasurement device

The invention discloses propeller type surface contour error measurement instrument and method. The propeller type surface contour error measurement instrument is characterized in that a gantry structure is adopted, a left upright, a right upright and a top cross beam are arranged on a base, and a revolving spindle is arranged on a cross beam; the lower end of the revolving spindle is horizontally and fixedly connected with a measuring arm; a linear guiderail is arranged on the bottom surface of the measuring arm along the radial direction of the revolving plane of the measuring arm, a working platform capable of doing linear movement along the linear guiderail is arranged on the linear guiderail, and a displacement sensor is arranged on the working platform; and a Y-direction working platform and an X-direction working platform are arranged on the base in an overlapping, and the blade of a detected propeller is arranged in a positioning groove at the top surface of the X-direction working platform. The measuring device and the measuring method are established by adopting a cylindrical coordinate system according to the axial symmetry structure characteristics of the propeller blade. The measuring device and the measuring method are fast in data acquisition, have no objective errors of an operator, and are simple in follow-up error processing and analysis, and can be used for precision measurement on size parameters and geometric error parameters of large revolving parts.

Owner:HEFEI UNIV OF TECH

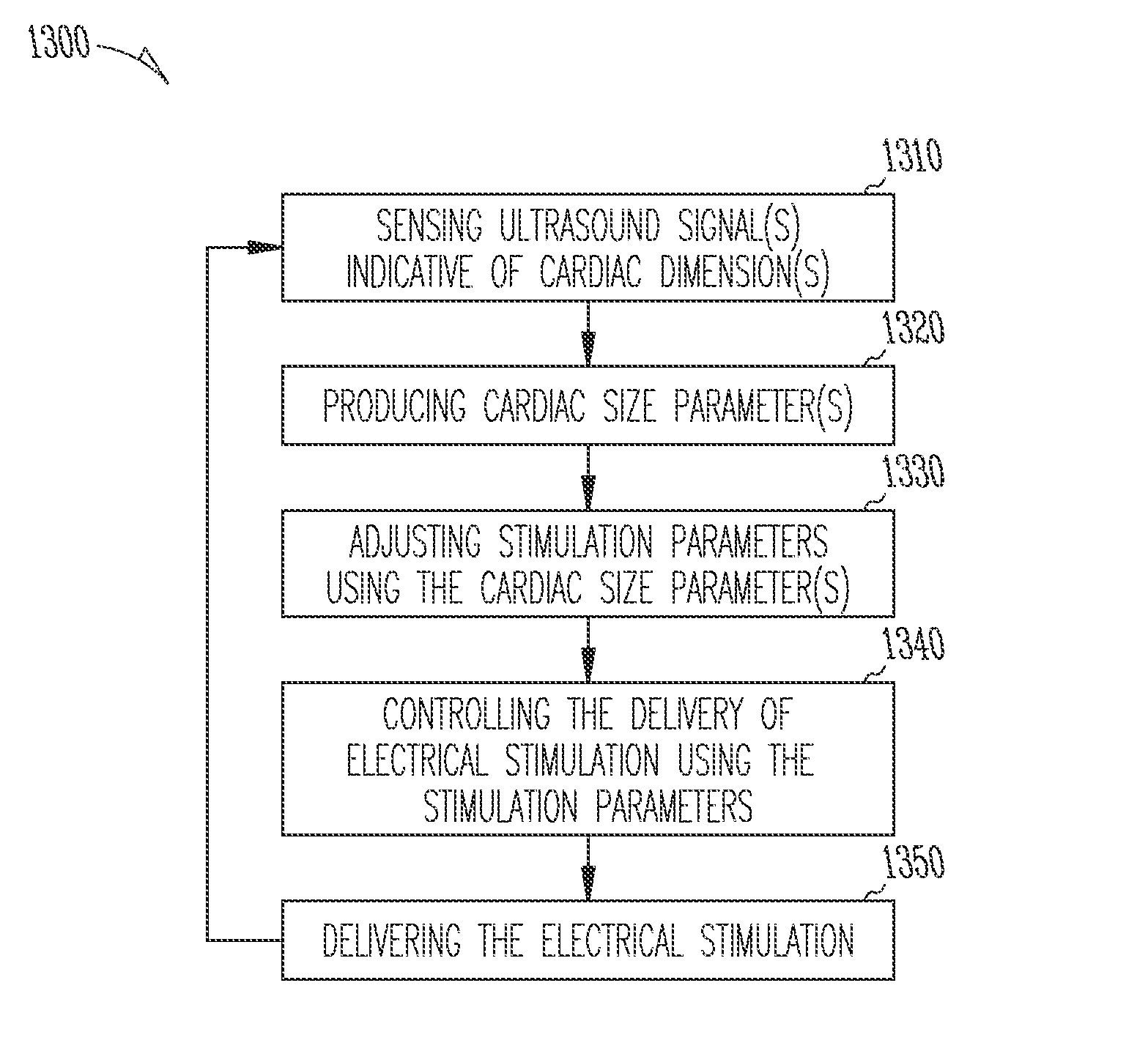

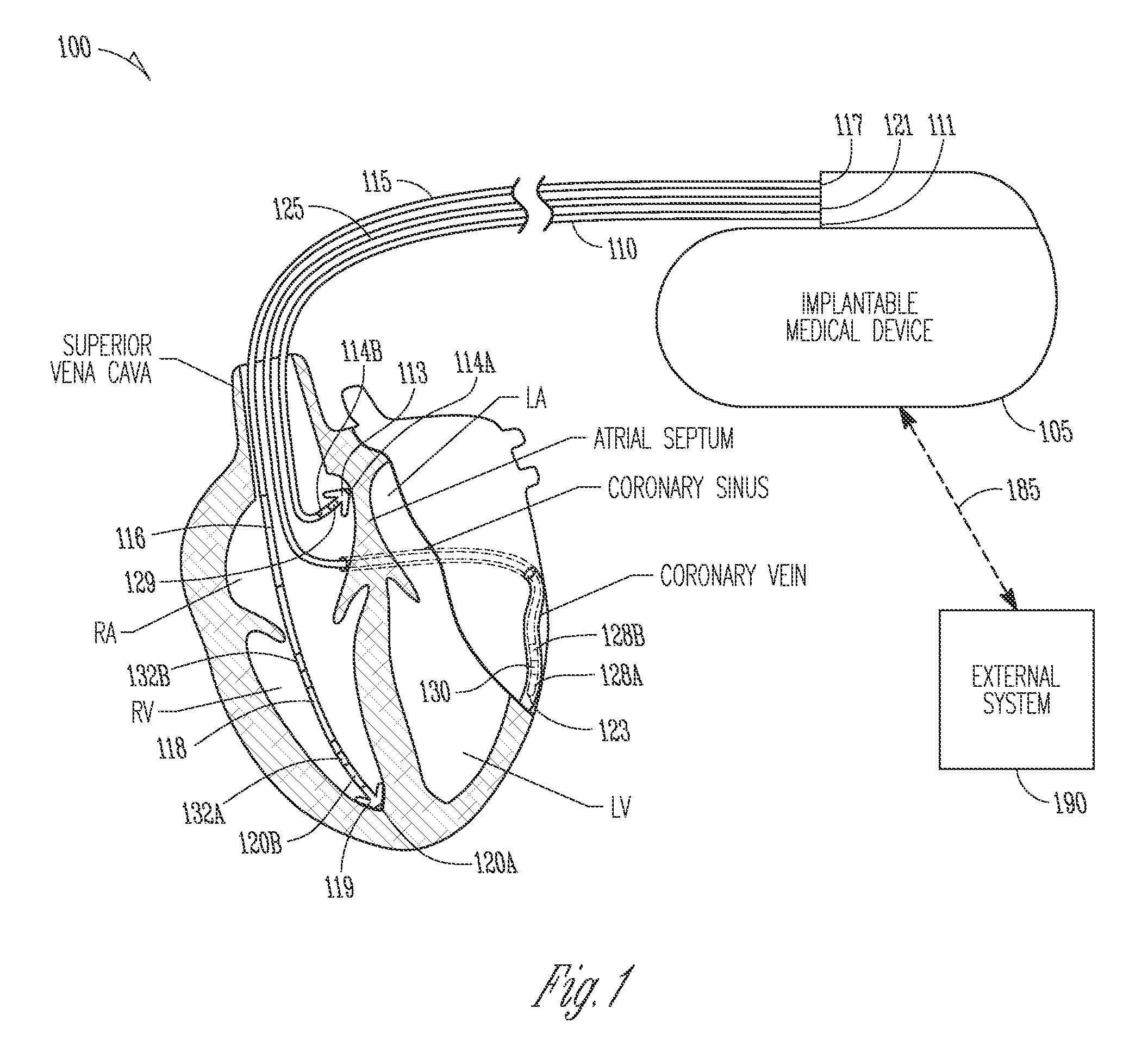

Method and apparatus for controlling cardiac therapy using ultrasound transducer

ActiveUS7914452B2Good effectUltrasonic/sonic/infrasonic diagnosticsElectrotherapySonificationUltrasonic sensor

A cardiac rhythm management (CRM) system provides for post-myocardial infarction (MI) therapy with closed-loop control using one or more ultrasound transducers sensing one or more ultrasound signals indicative of cardiac dimensions. Cardiac size parameters are produced using the one or more ultrasound signals to represent, for example, cardiac chamber diameter, cardiac chamber volume, cardiac wall thickness, infarct size, and degree of change in any of these parameters over time or between measurements. In various embodiments, such cardiac size parameters provide for titration, safety check, and acute optimization of the post-MI therapy.

Owner:CARDIAC PACEMAKERS INC

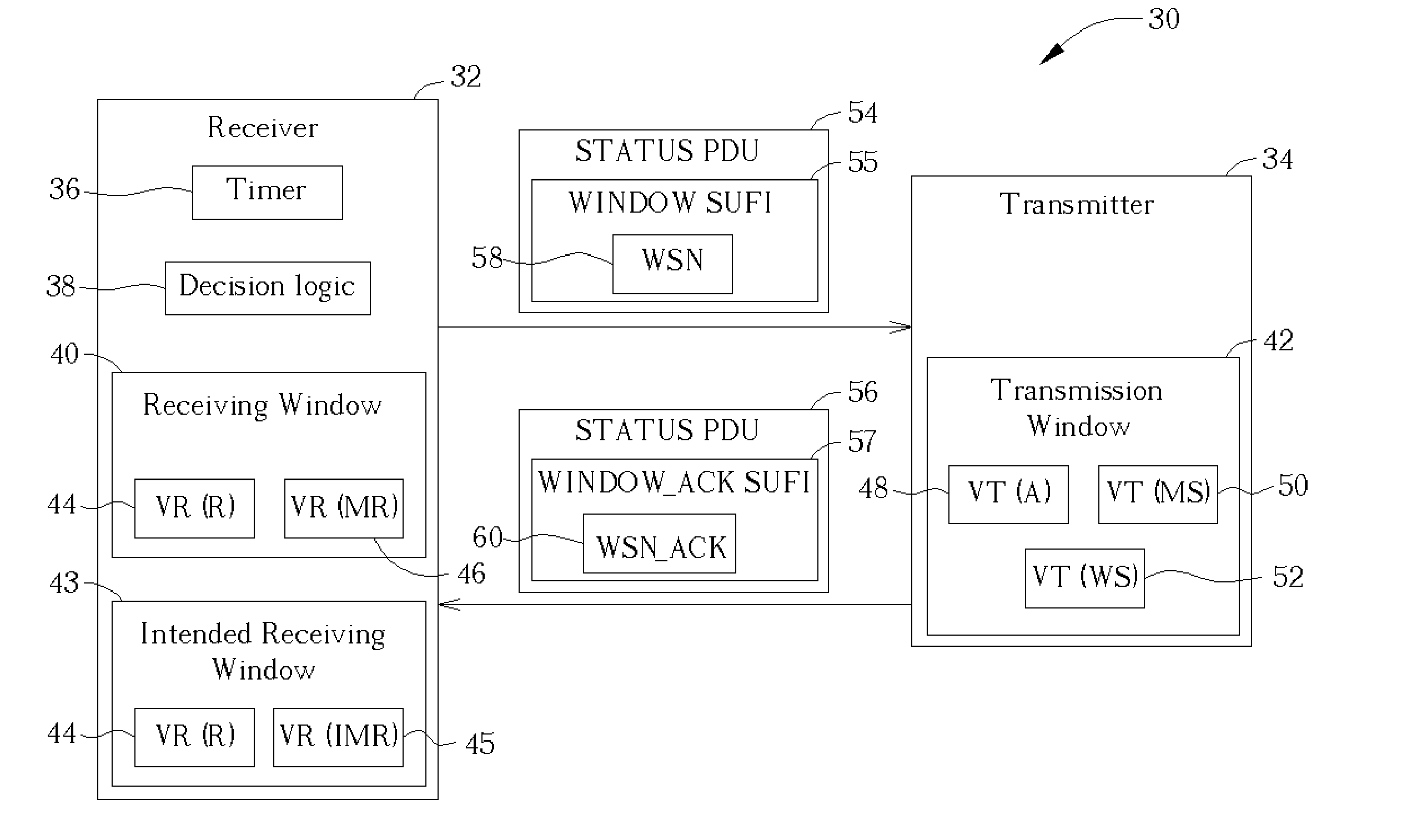

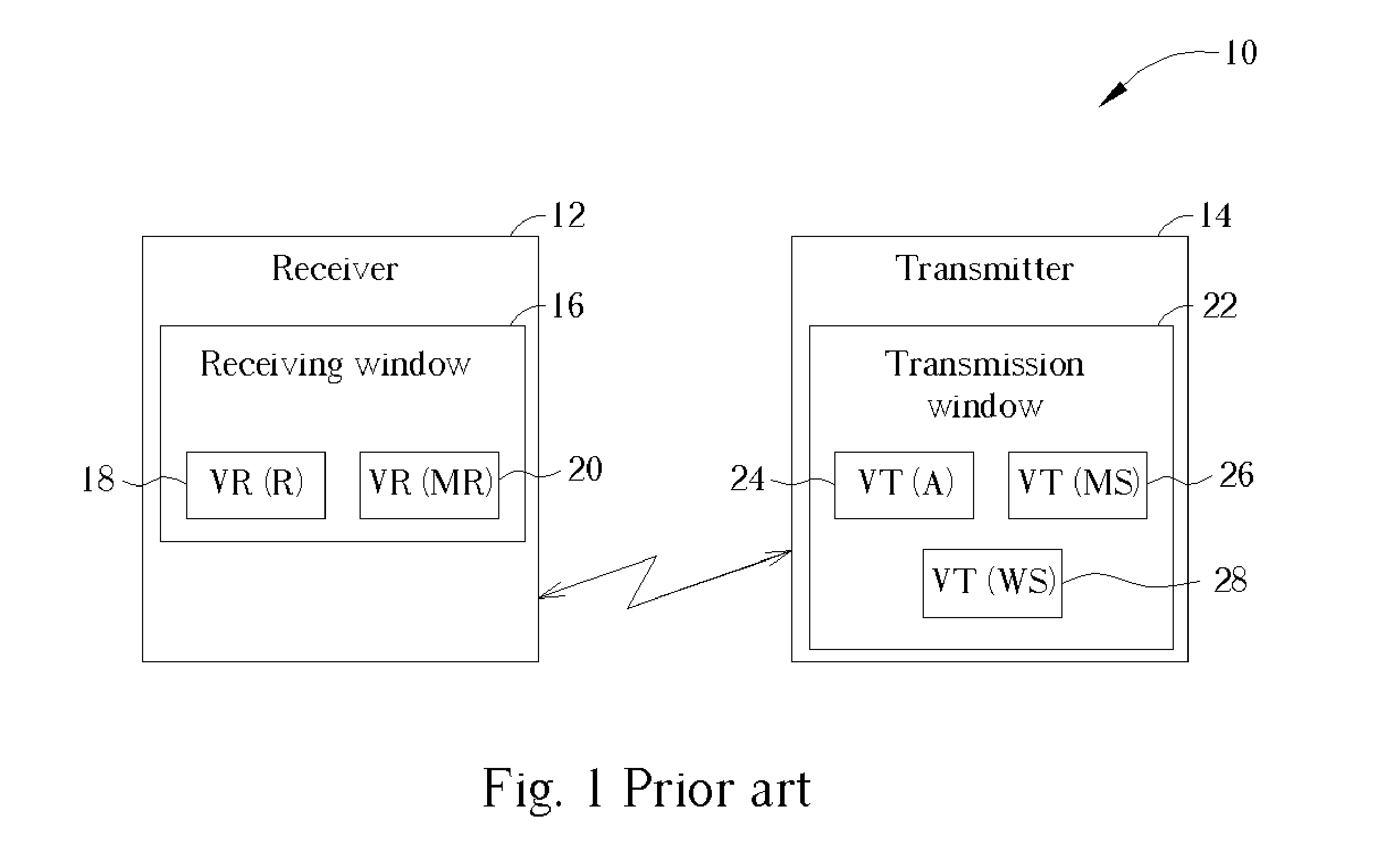

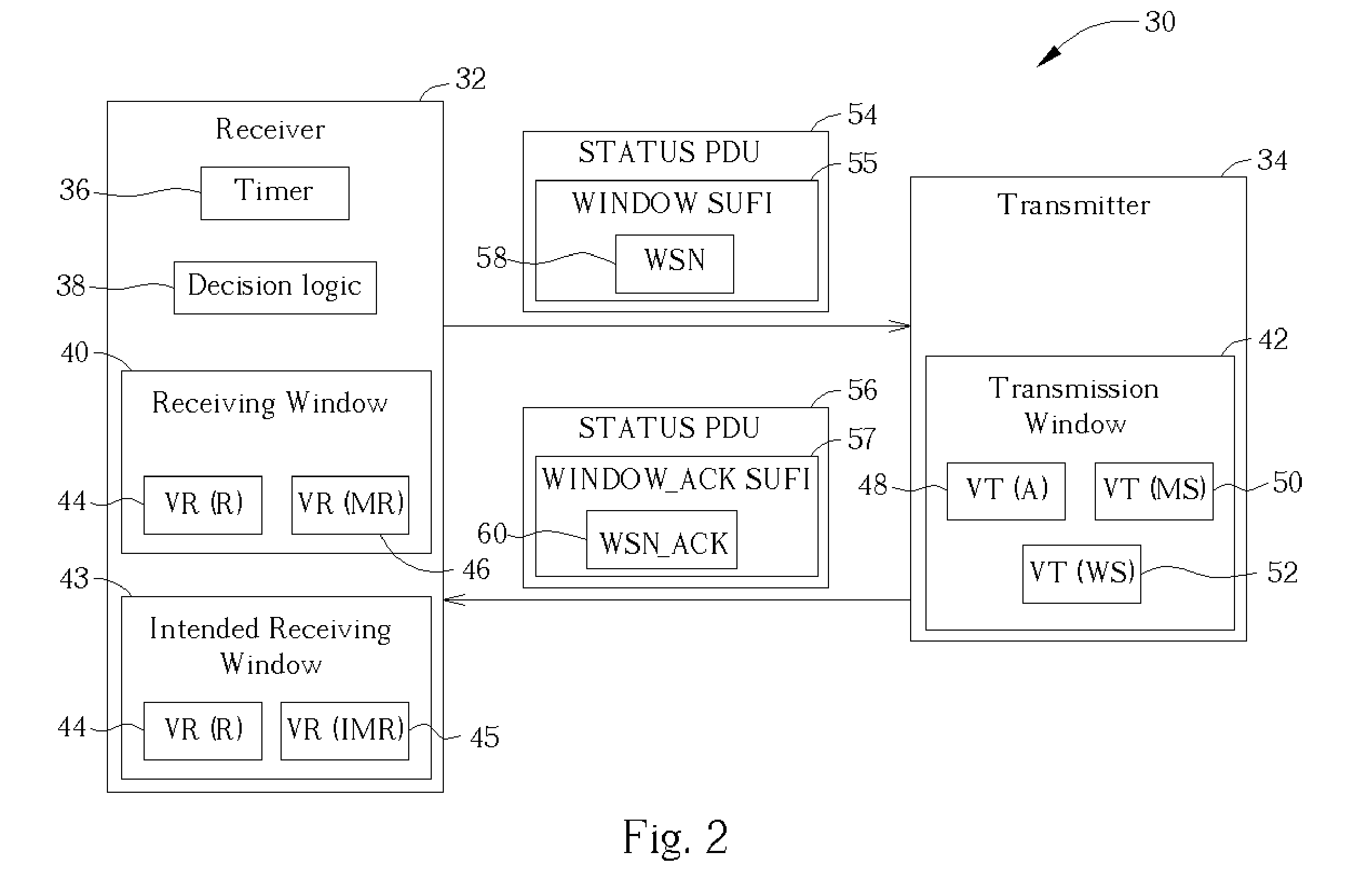

Method of controlling a receiver and a transmitter in a wireless communication system to handle a transmission window size change procedure

InactiveUS20050041586A1Decrease size of transmission windowImproves radio transmission efficiencyError prevention/detection by using return channelFrequency-division multiplex detailsCommunications systemSize change

A method of controlling a receiver and a transmitter to handle a transmission window size change procedure is disclosed. The method includes driving the receiver to deliver a control message having a window size parameter to the transmitter for adjusting a transmission window size of the transmitter, and driving the transmitter to output an acknowledgement message to the re- ceiver and adjust the transmission window size according to the window size parameter when the transmitter receives the control message.

Owner:INNOVATIVE SONIC

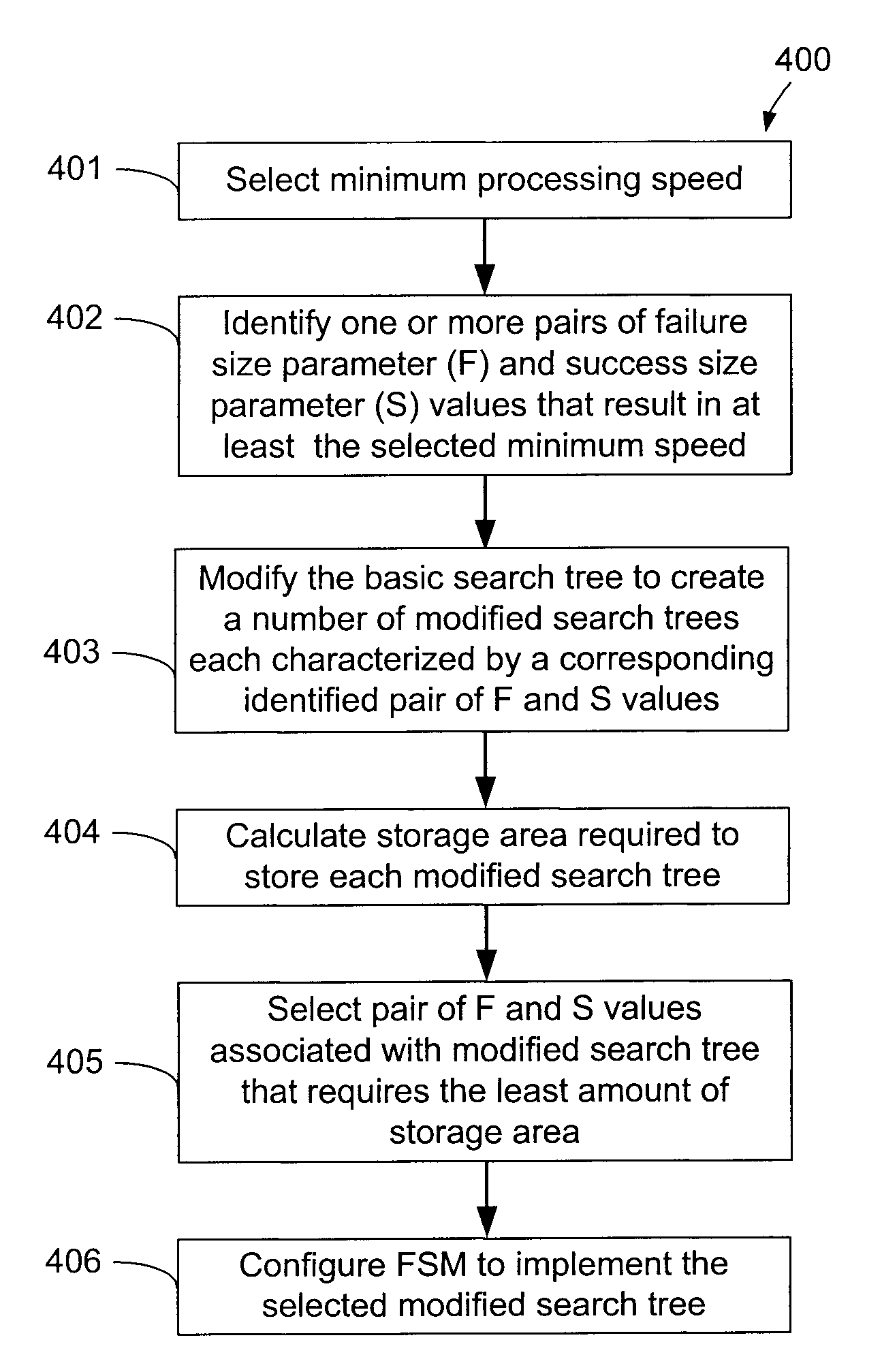

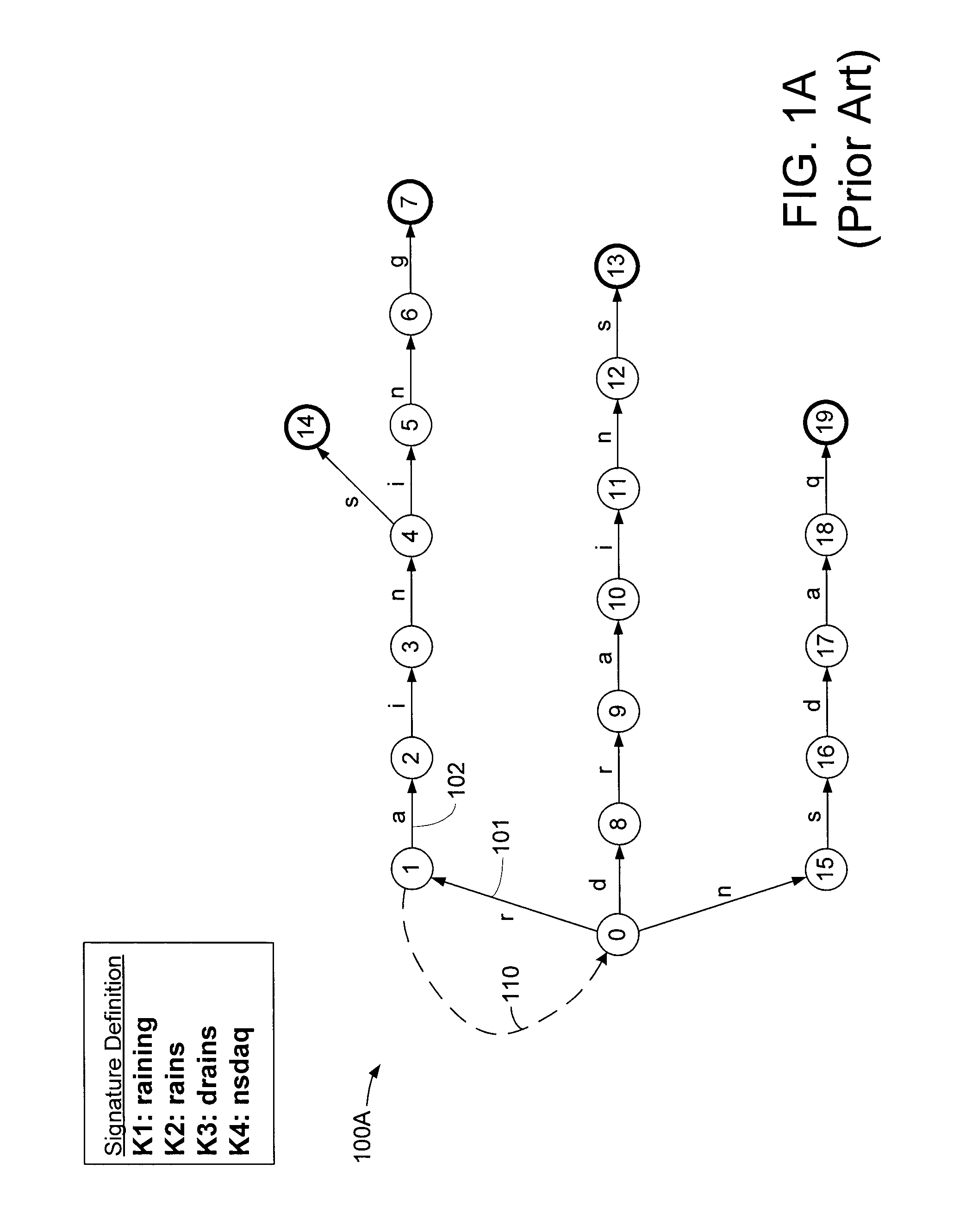

Method and apparatus for optimizing string search operations

InactiveUS7636717B1Digital data information retrievalData processing applicationsFailoverTheoretical computer science

A search tree embodying a plurality of signatures to be compared with an input string of characters and including a number of success transitions characterized by a success size parameter and including a number of failure transitions characterized by a failure size parameter is selectively modified to achieve a desired balance between processing speed and memory area requirements.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

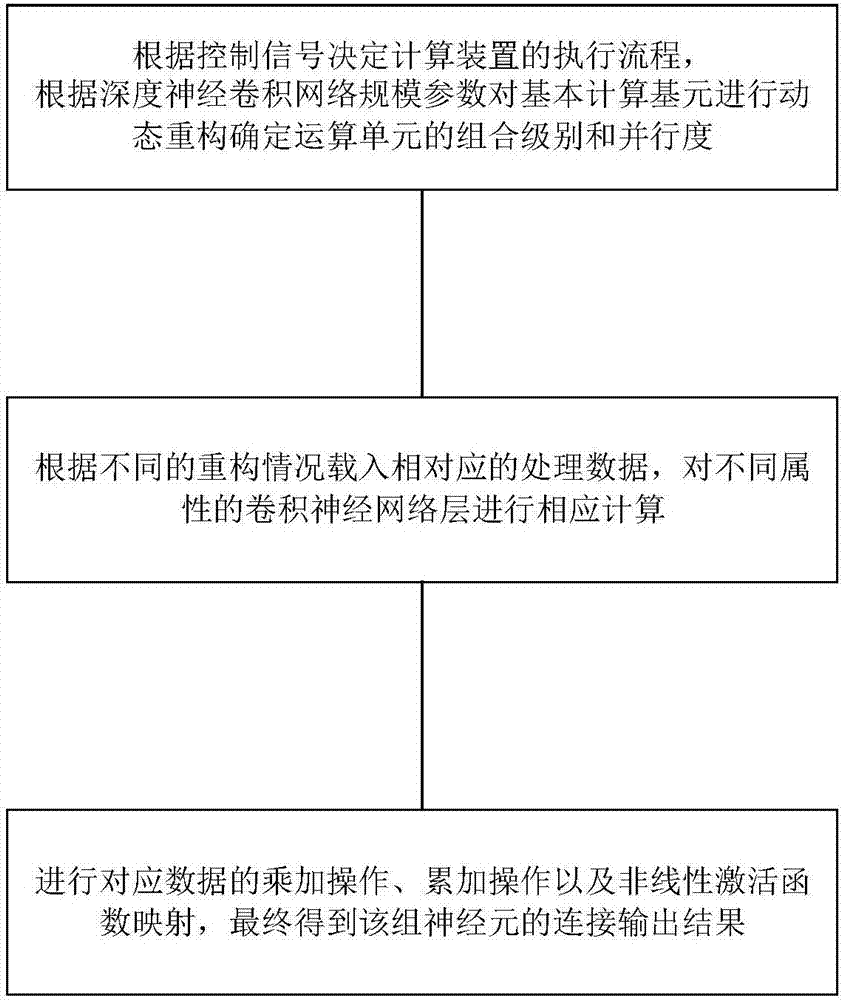

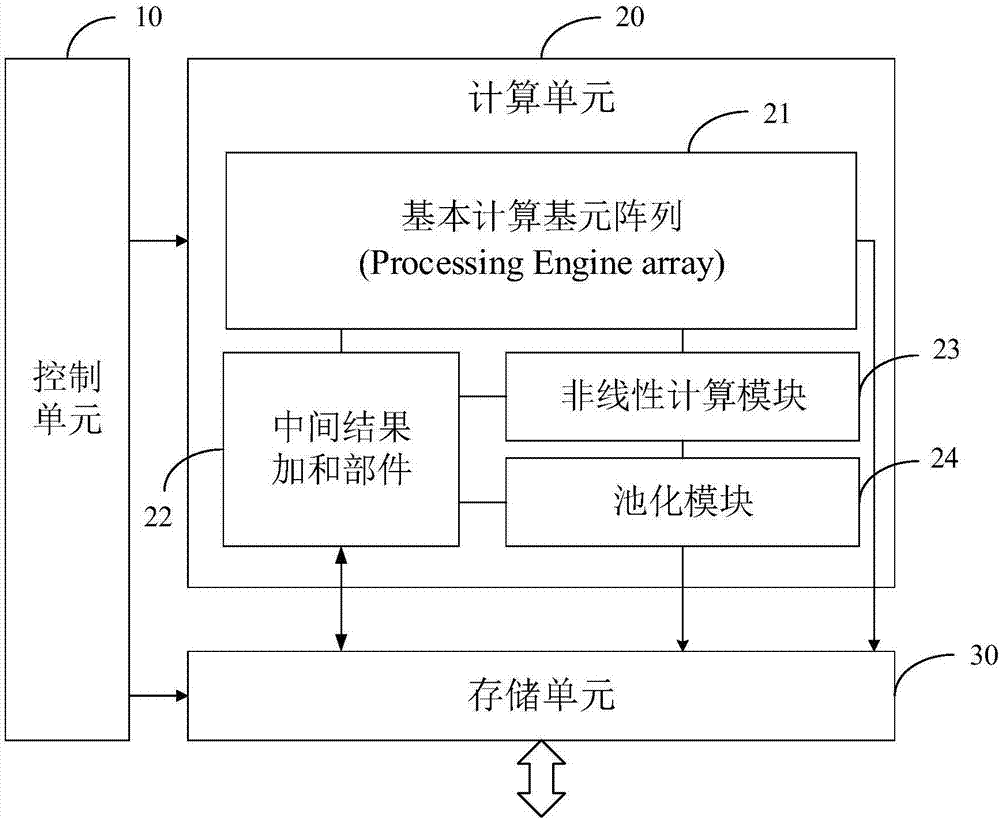

Adaptive and reconfigurable deep convolutional neural network computing method and device

ActiveCN107169560ASolve the shortcomings of low flexibilityAvoid wastingNeural architecturesNerve networkAlgorithm

The invention relates to an adaptive and reconfigurable deep convolutional neural network computing method and device. The method comprises the steps that a program execution process of the computing device is decided according to a control signal; dynamic reconfiguration is performed on basic computing elements according to deep convolutional neural network size parameters to determine a combination level and a parallelism degree of arithmetic units; and corresponding processed data is loaded according to different reconfiguration conditions, corresponding computing is performed on convolutional neural network layers of different properties, and finally a connection output result of a group of neurons is obtained. Through the computing method and device, the defect of low flexibility of special hardware is overcome, and design parameters of the arithmetic units can be reconfigured to achieve the purpose of supporting deep convolutional neural networks of different sizes; parallel operation of convolution kernels of the same size can be realized, parallel operation of convolution kernels of different sizes can also be realized, the parallelism degree of deep convolutional neural network operation is greatly improved through the arithmetic units which can be dynamically reconfigured, and computing performance is improved.

Owner:TSINGHUA UNIV

Devices, systems, and methods for removing stenotic lesions from vessels

The present application provides various devices, systems, and methods for removing stenotic lesions from vessels. In at least one embodiment of an exemplary device, the device comprises at least one sizing portion and at least one treatment portion. Such a device may be useful to, for example, remove a stenotic lesion from a vessel by positioning the device within a vessel lumen, operating the sizing portion to obtain luminal size parameter data, operating the treatment portion at a location within the vessel lumen at or near a stenotic lesion, and ceasing operation of the treatment portion when the luminal size parameter data indicates a preferred luminal size parameter.

Owner:3DT HLDG

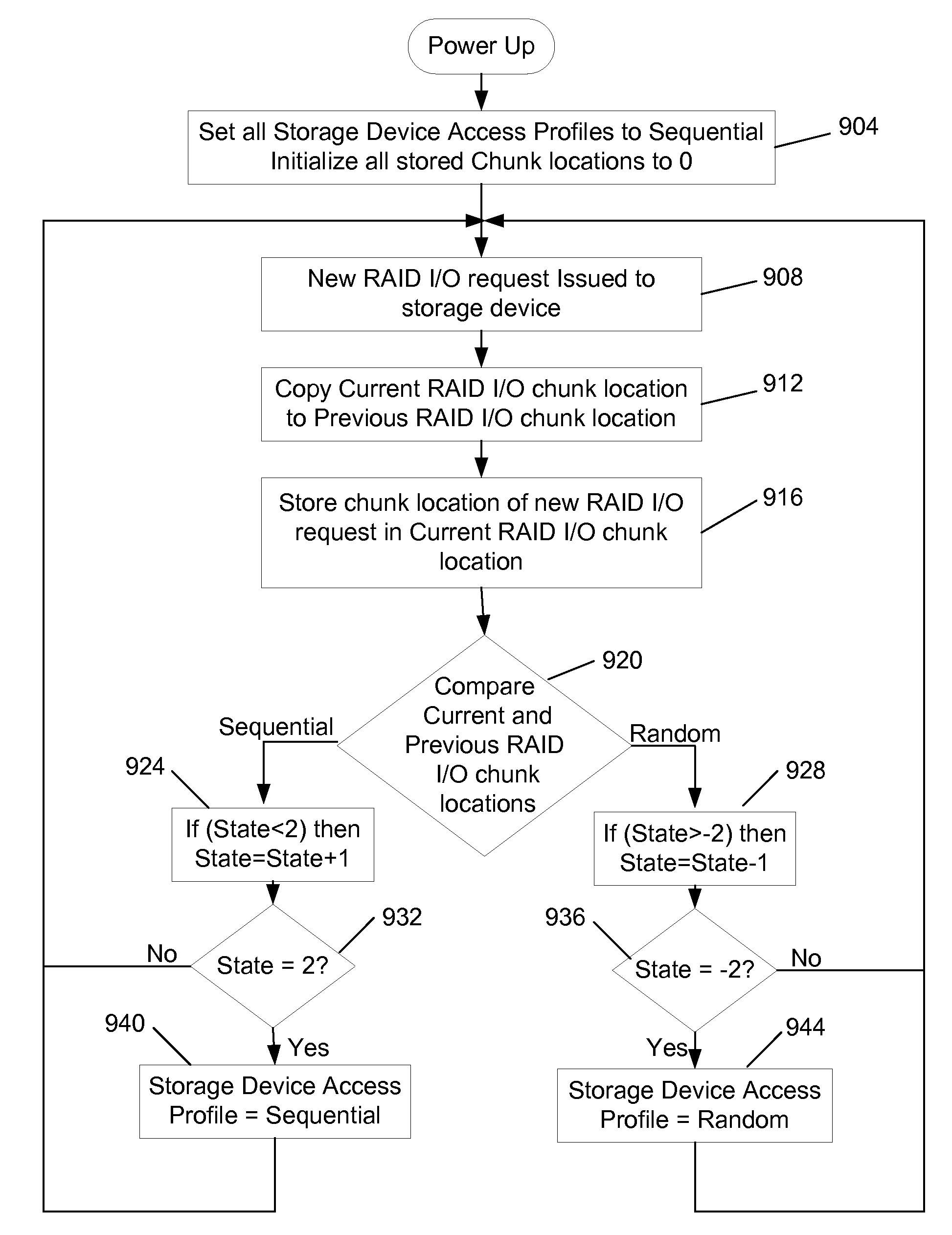

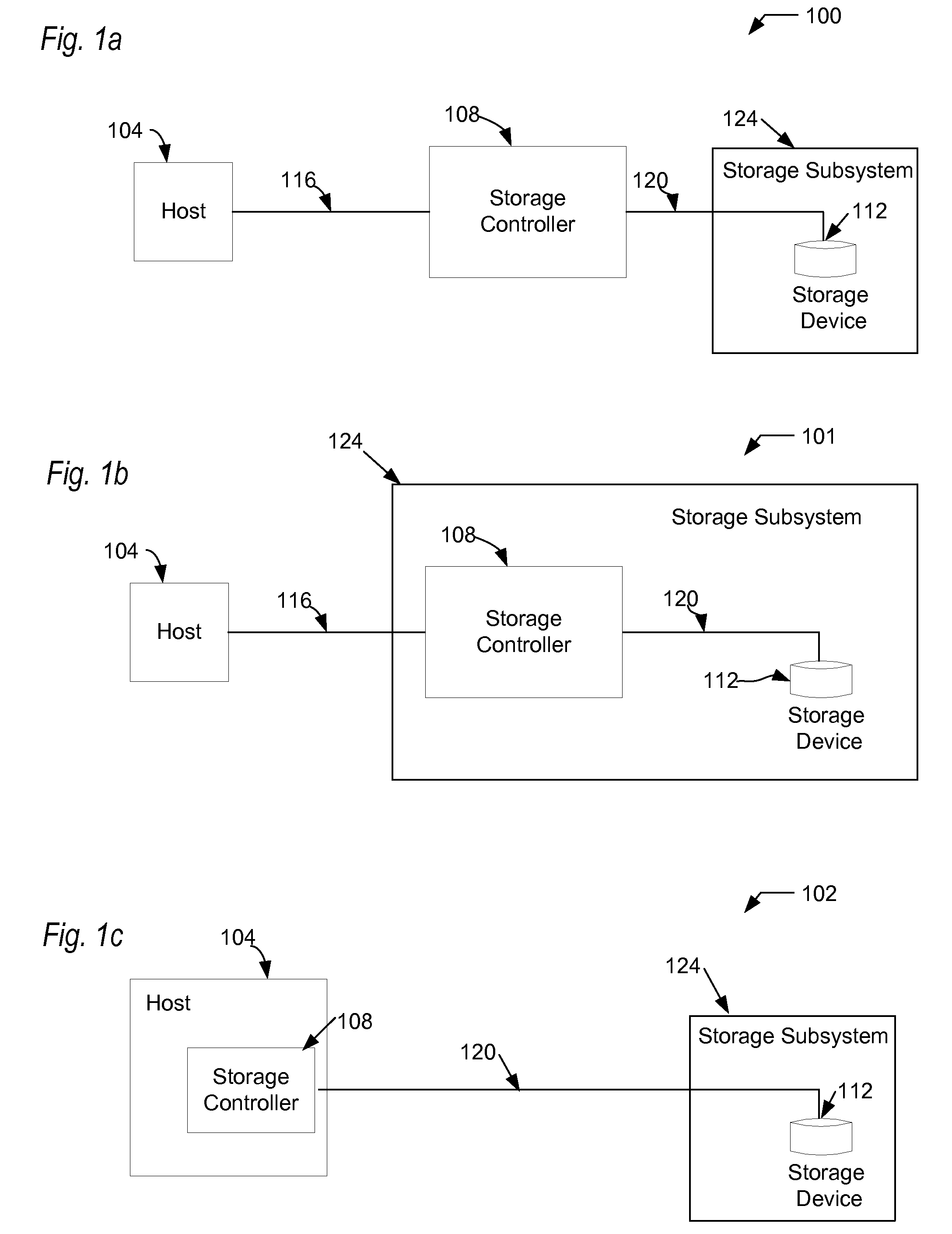

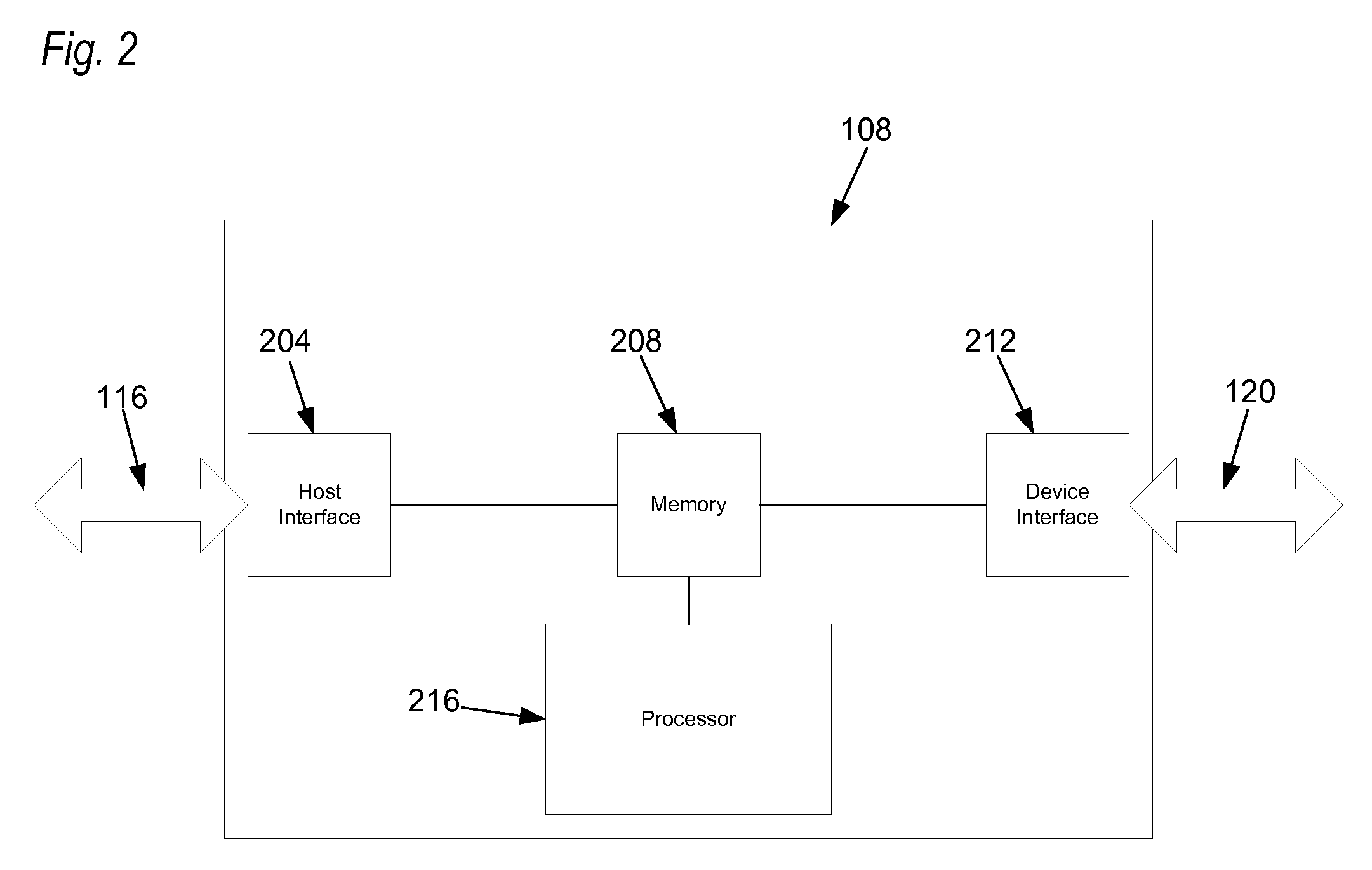

Dynamic input/output optimization within a storage controller

InactiveUS20080282030A1Efficient processingMemory systemsInput/output processes for data processingRAIDConfigfs

A system and method for optimizing accesses to storage devices based on RAID I / O request characteristics is disclosed. A current I / O request processed by a storage controller is analyzed for relative locality to a previous I / O request, and adjusted over time such that storage device accesses will be efficiently conducted with respect to sequential or random workloads. A storage device access profile is maintained for each storage device based on sequential or random locality characteristics of previous RAID I / O requests. The chunk locations of the two most recent accesses are sampled according to predetermined criteria in order to create a storage device access profile, which governs queue depth and I / O size parameters used to communicate with storage devices. By managing I / O requests to storage devices using this invention, performance of such a storage controller will be optimized for changing random and sequential workloads.

Owner:DOT HILL SYST

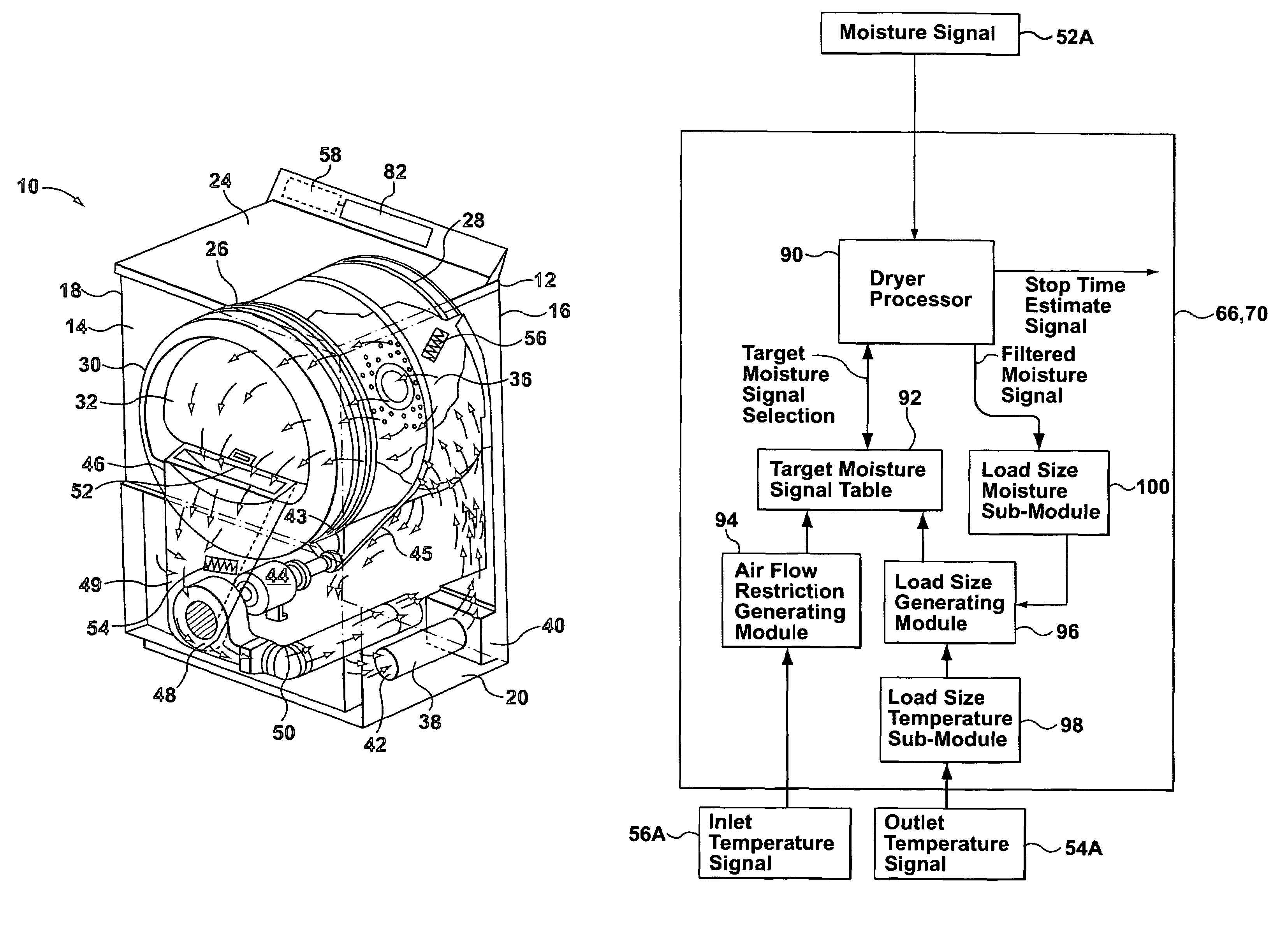

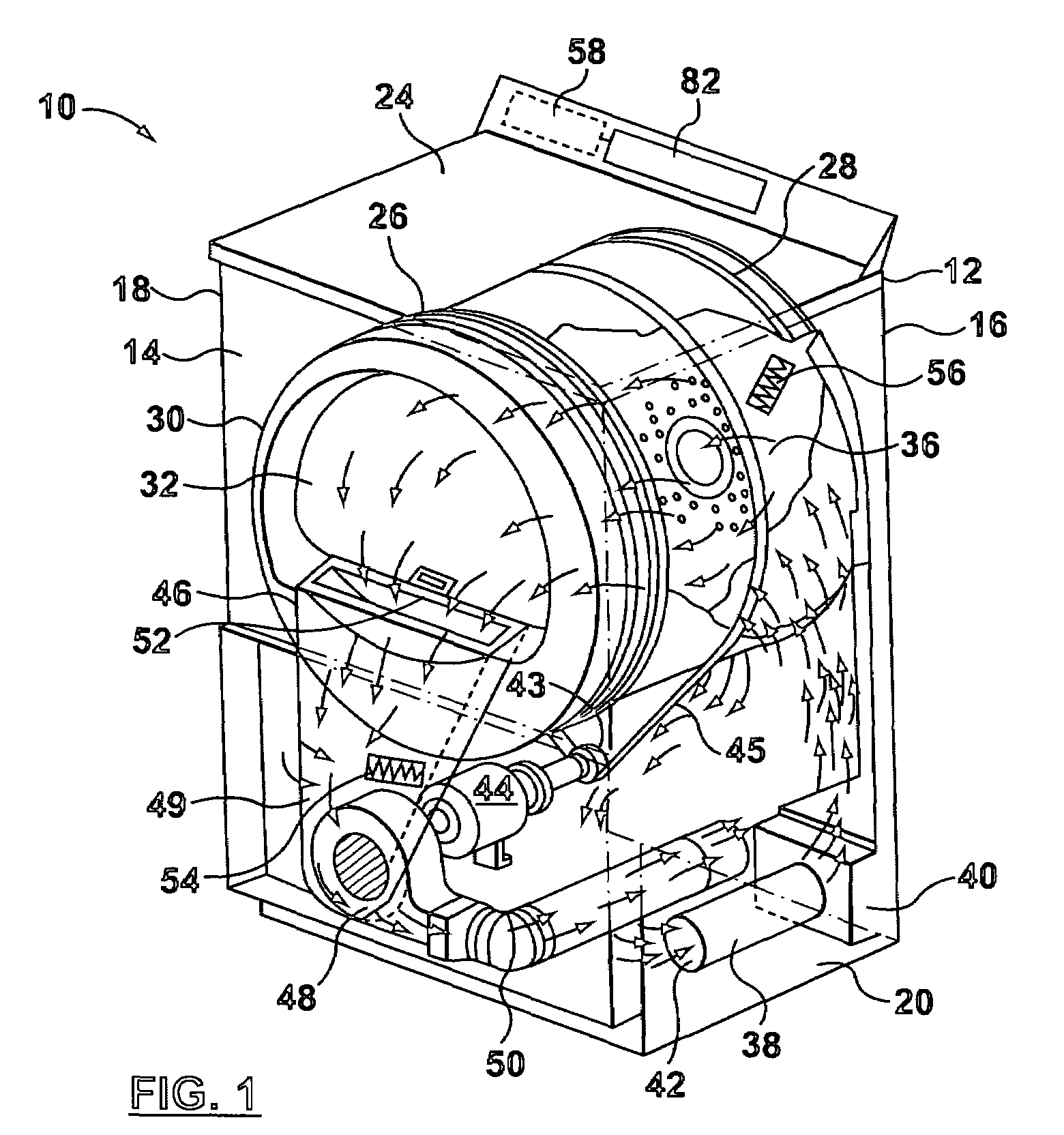

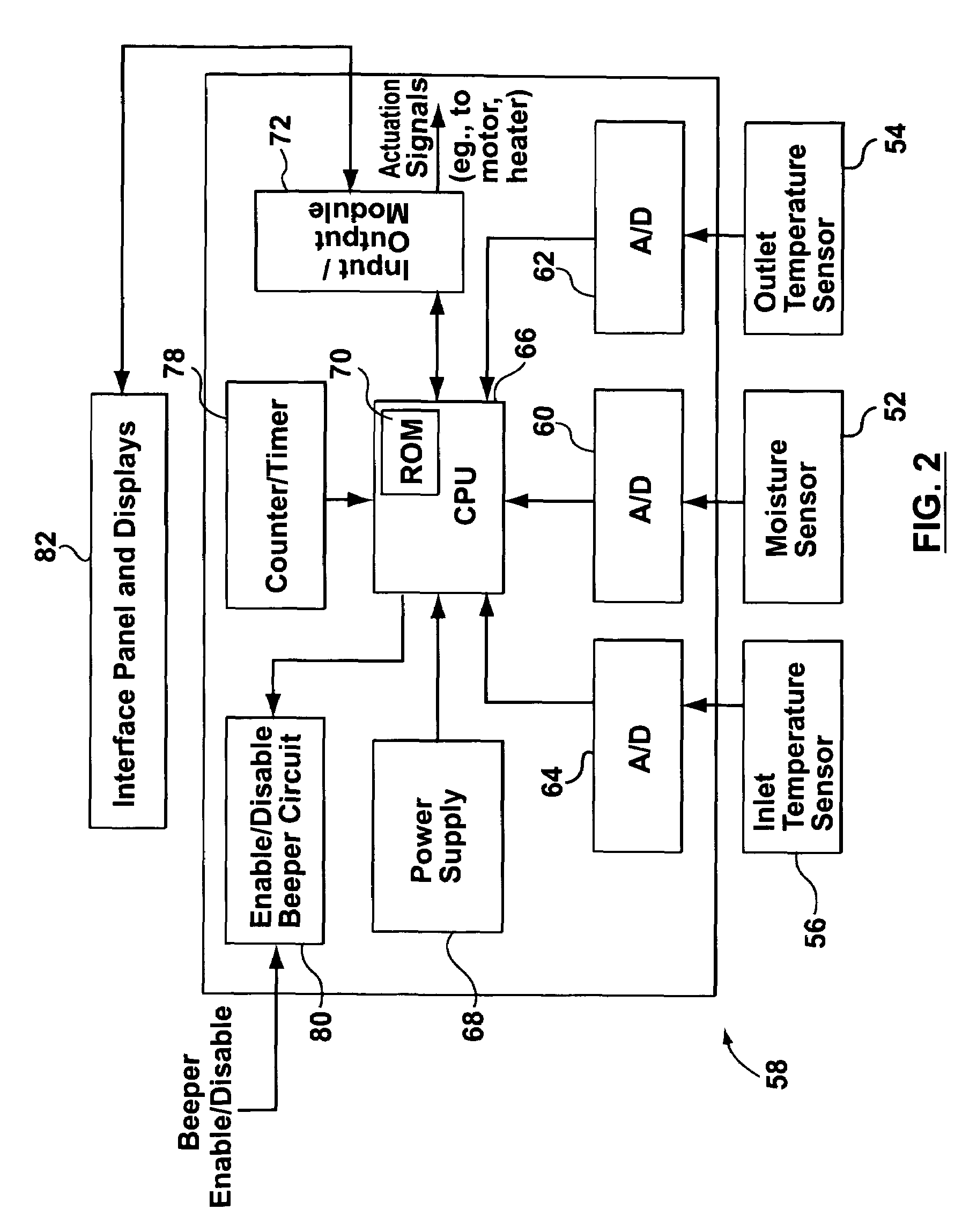

Apparatus and method for controlling a clothes dryer

ActiveUS7322126B2Drying solid materials with heatDrying machines with non-progressive movementsControl systemEngineering

A clothes dryer has a degree of dryness control system that is responsive to moisture level of clothing articles tumbling in a drum and a target moisture value to control the drying cycle of the clothes dryer. The clothes dryer has a load size parameter producing module and an air flow detection parameter module. These modules generate one of two parameter conditions used by the processor to modify or select an appropriate moisture target value. The load size producing parameter module generates one of a small load input parameter and a large load input parameter. The air flow detection module produces one of a first and second air flow parameter to be utilized by the degree of dryness processor. As a result, the processor selects one of four target moisture values from these conditions.

Owner:MABE CANADA

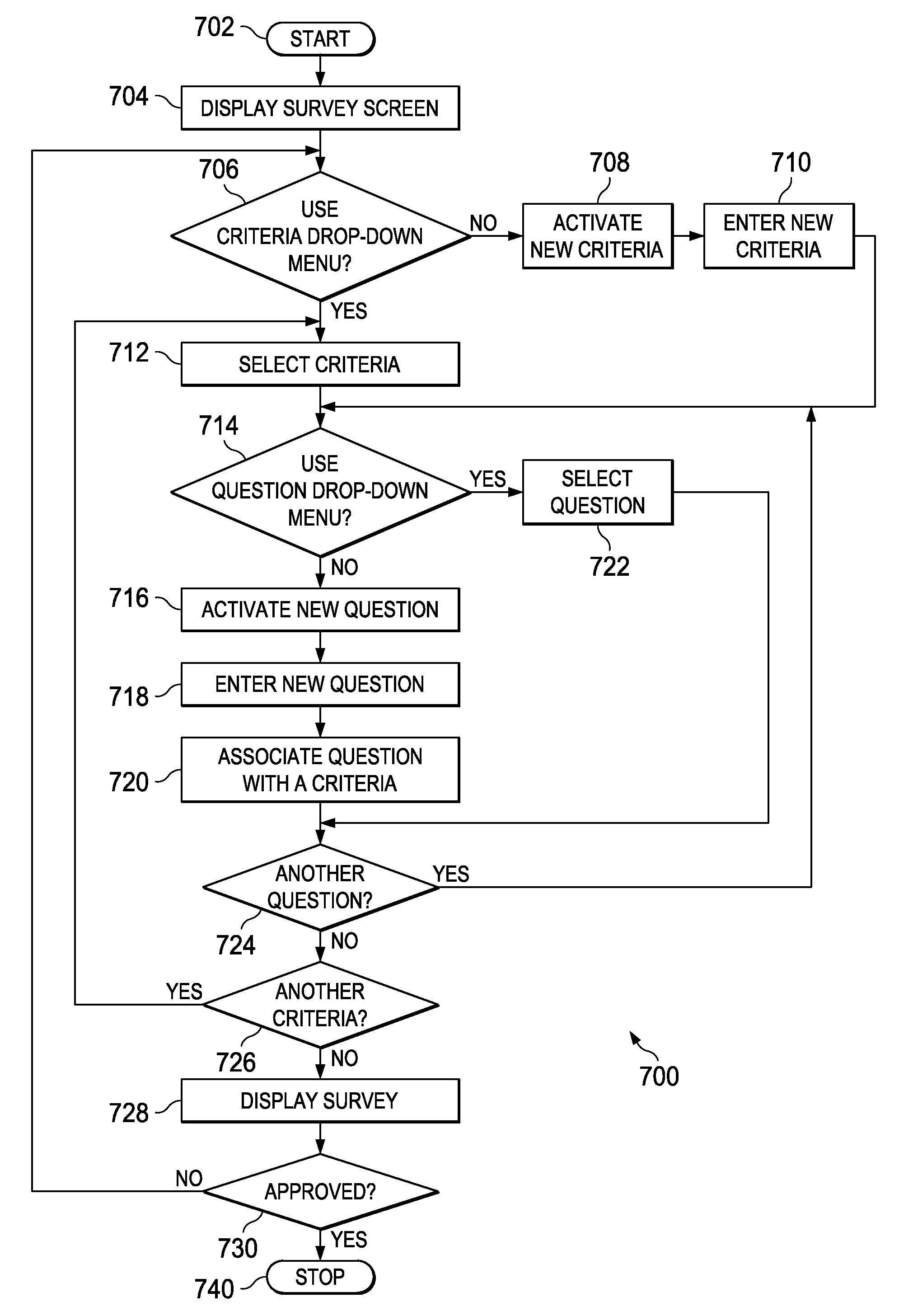

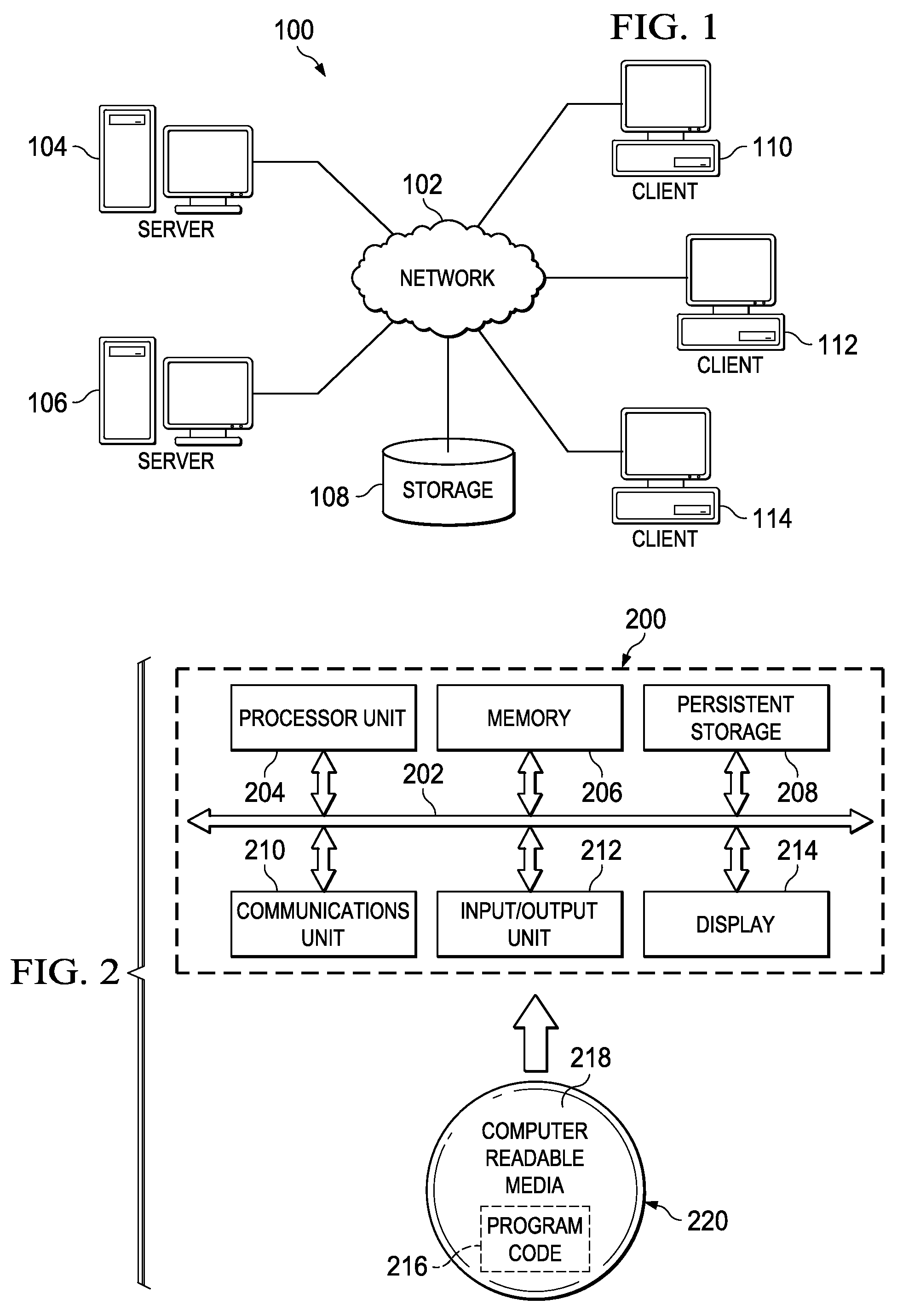

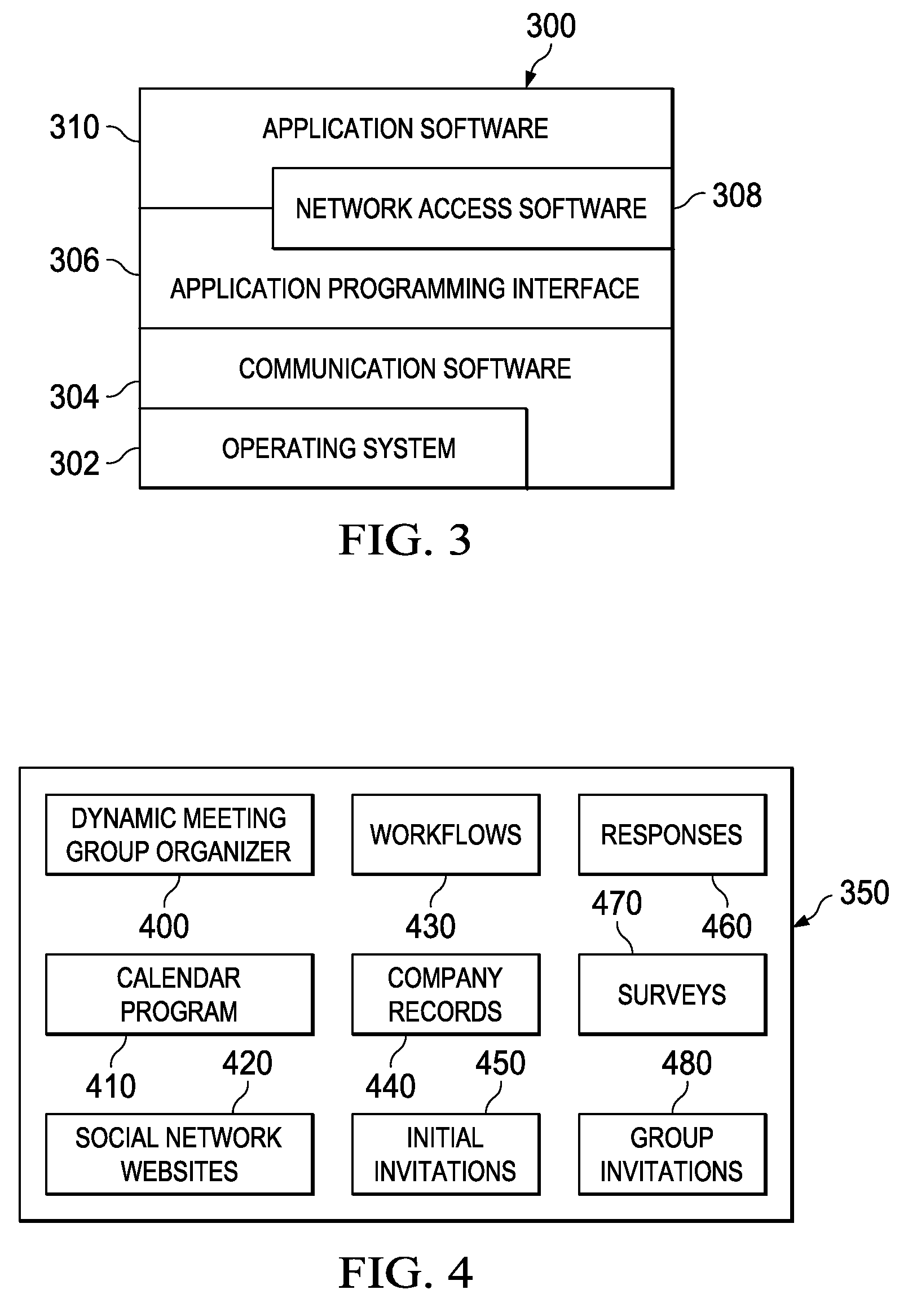

Dynamic meeting group organizer

InactiveUS20100198648A1Multiple digital computer combinationsOffice automationWorld Wide WebElectronic mail

A Dynamic Meeting Group Organizer automatically creates sub-groups from a group of responders to a meeting invitation sent by email by determining a number of subgroups and a subgroup size parameter; determining a question and a criteria associated with the question to create a survey; determining a list of invitees and a response date by which an invitee is to return a completed survey; sending a plurality of invitations with the survey attached to each invitee on the list; accumulating a plurality of responses to the questionnaire in a response file; and accessing the response file and automatically processing the plurality of responses by organizing the list of invitees into a plurality of subgroups according to each invitee's response to the question and the subgroup size parameter.

Owner:IBM CORP

Symmetrical liquid drop injecting three-dimensional fast shaping method and apparatus thereof

The present invention belongs to rapid molding field of technology, which especially relates to a rapid shaping method and a device of metal. Inert gas used by the present invention is bled into a crucible and a vacuum tight chamber that can obtain steady differential pressure by means of pressure control system, which makes mental fusant ejected in the form of laminar jet from a micro-nozzle that is positioned on a bottom of the crucible. Vibration disturbance mental shooting flow produced by a piezoelectric oscillator turns metal shooting flow into uniform droplets. And real-time size parameters of the droplets mentioned-above can be obtained by monitoring system and computer analysis system. Subject to the size parameters of part that are input in advance, micro-computer control system has the real-time control for electrical field parameters of a deflexion polar plate, thus, controlling flight profile of the metal droplets and manufacturing metal parts with good quality in cooperation with a three-dimensional control station. The present invention is able to directly turn liquid metal into close-finished metal parts that are provided with rapid coagulation and delicate structure. The present invention has short technological process and products have good quality, which greatly reduces equipment investments.

Owner:TIANJIN UNIV

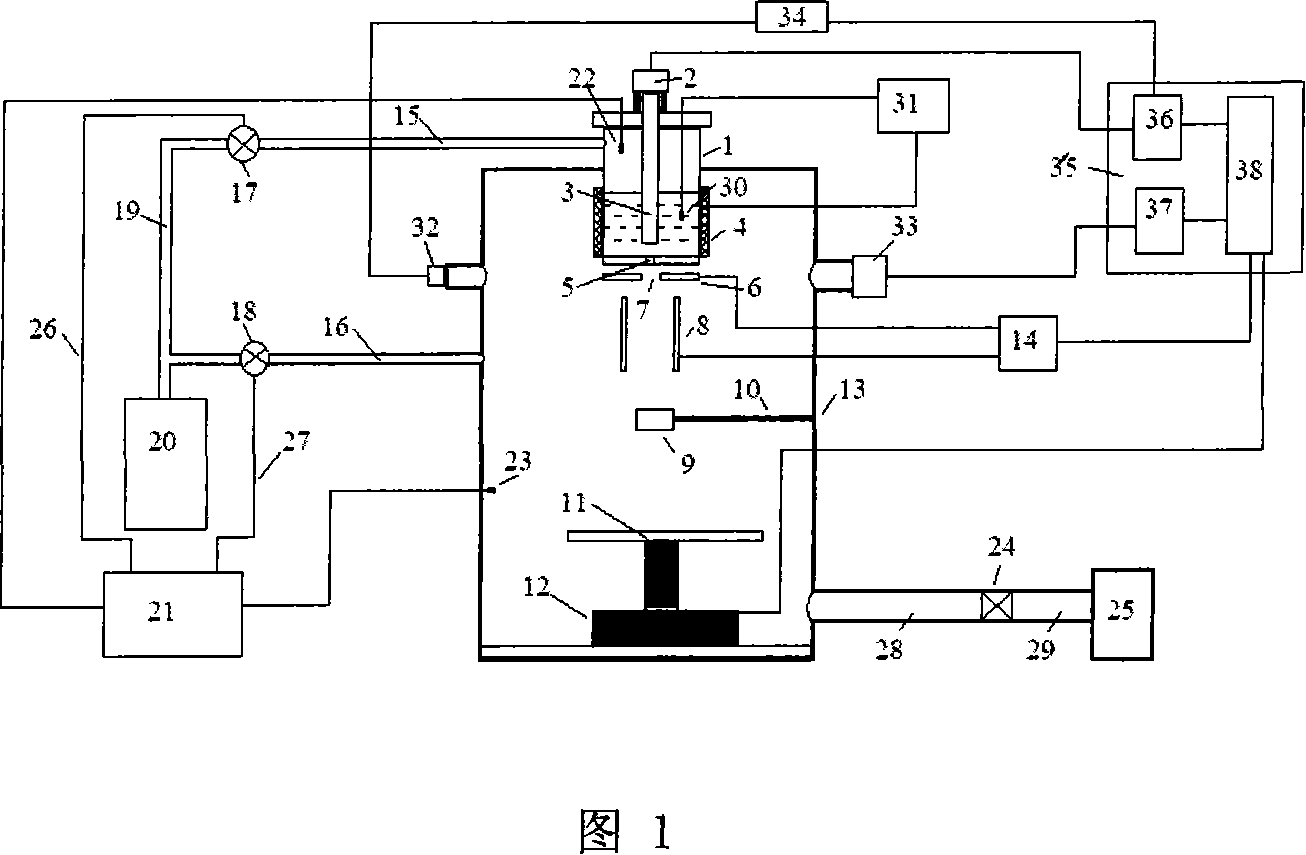

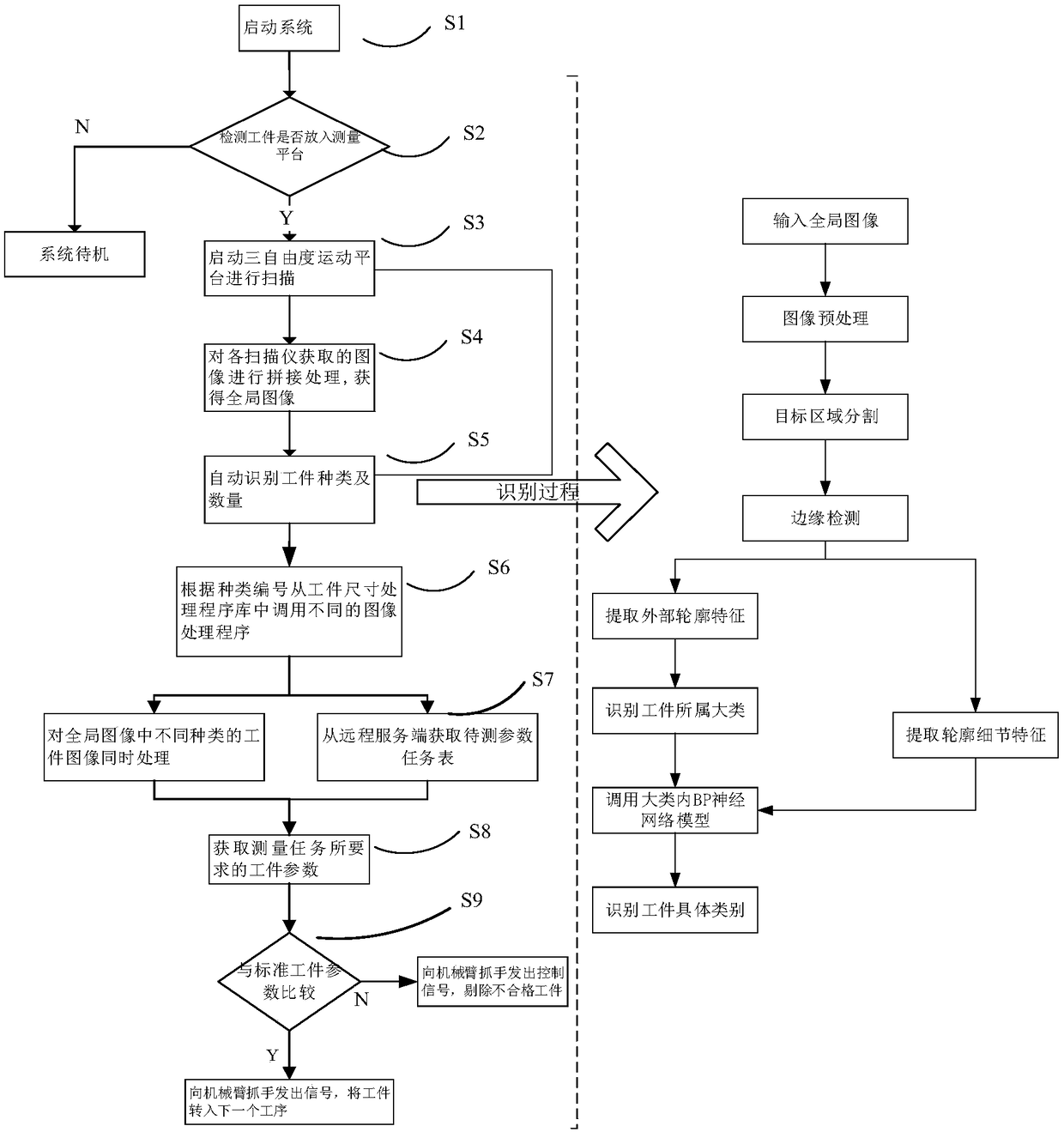

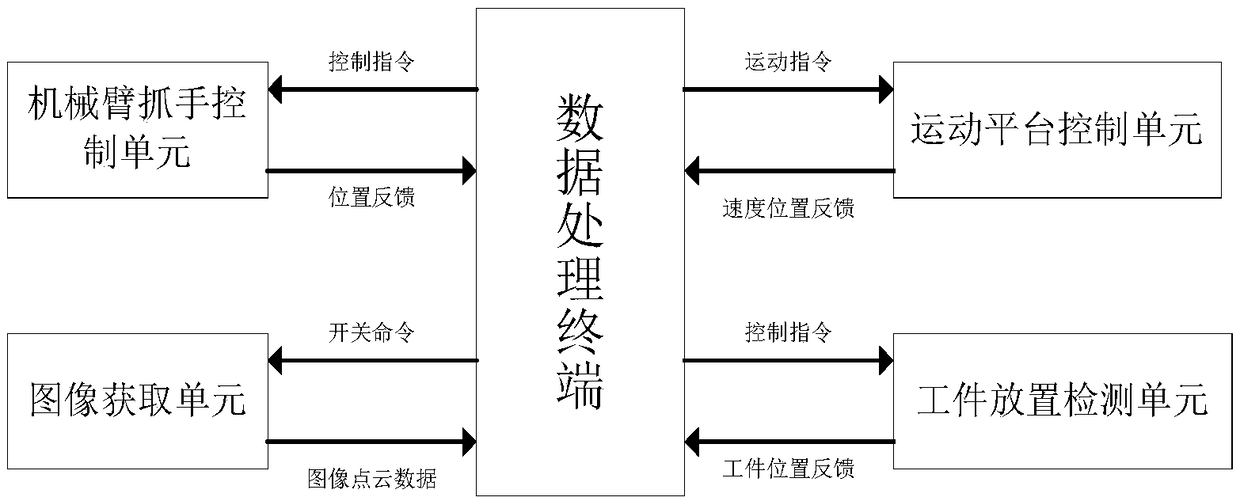

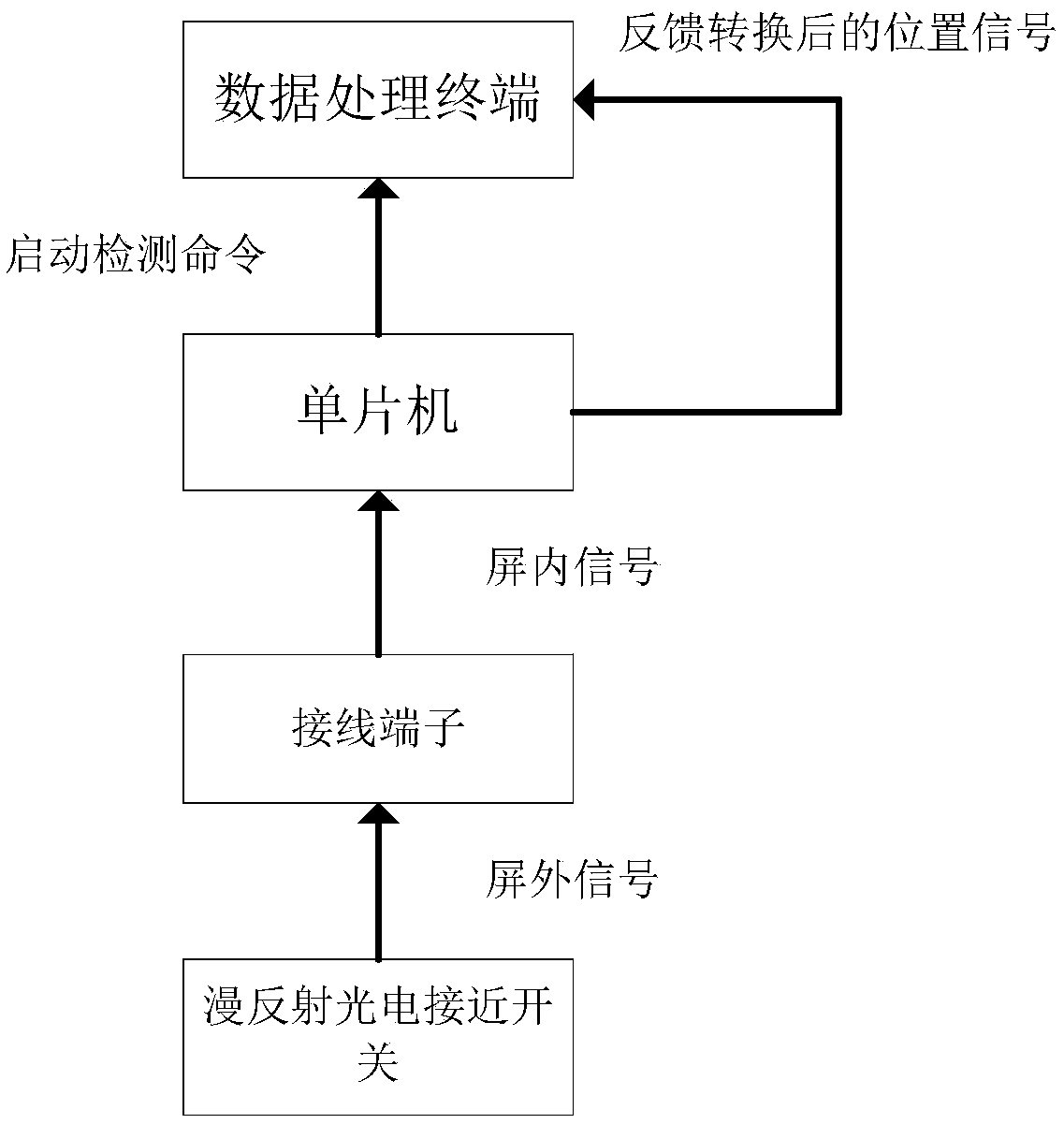

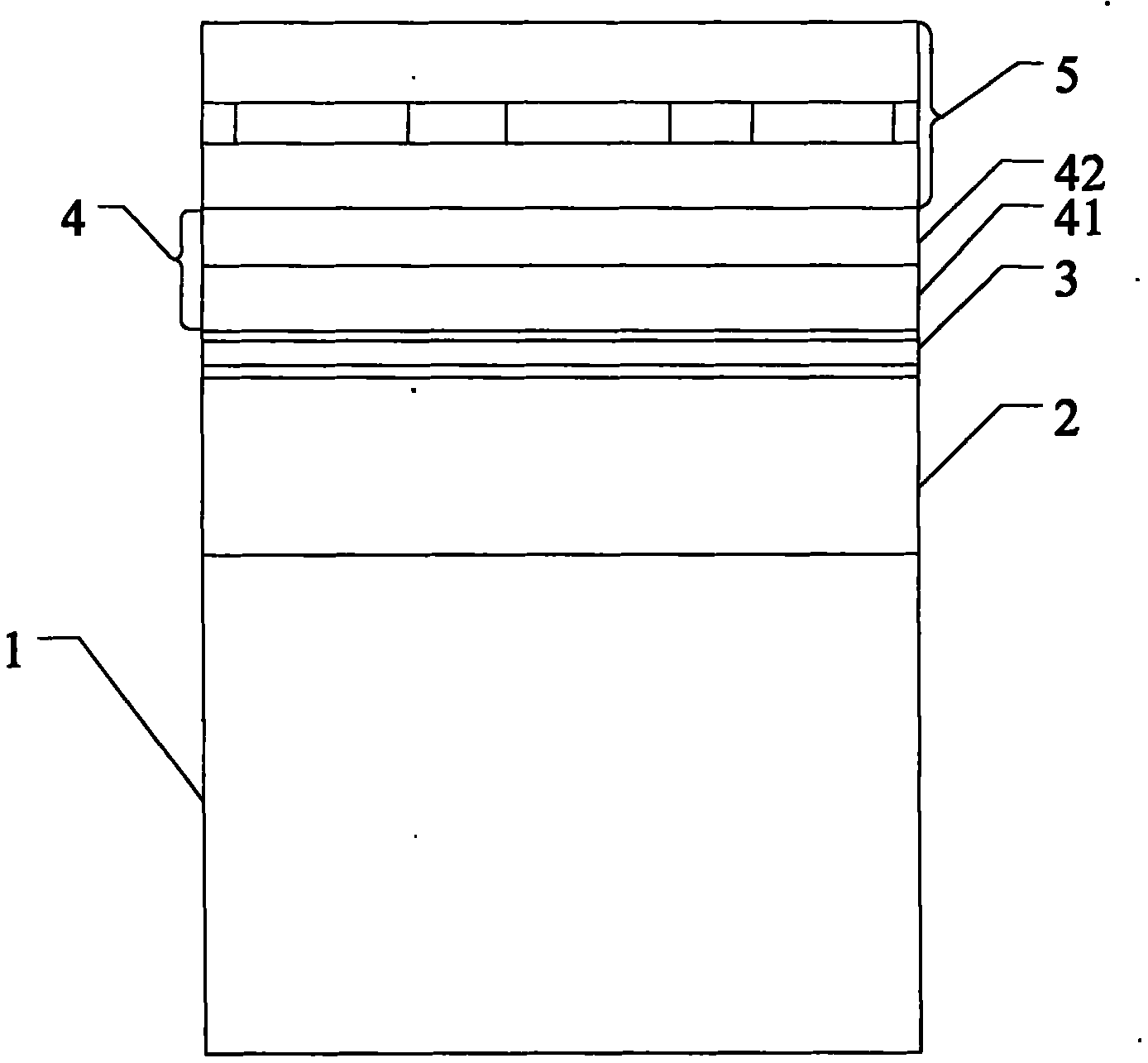

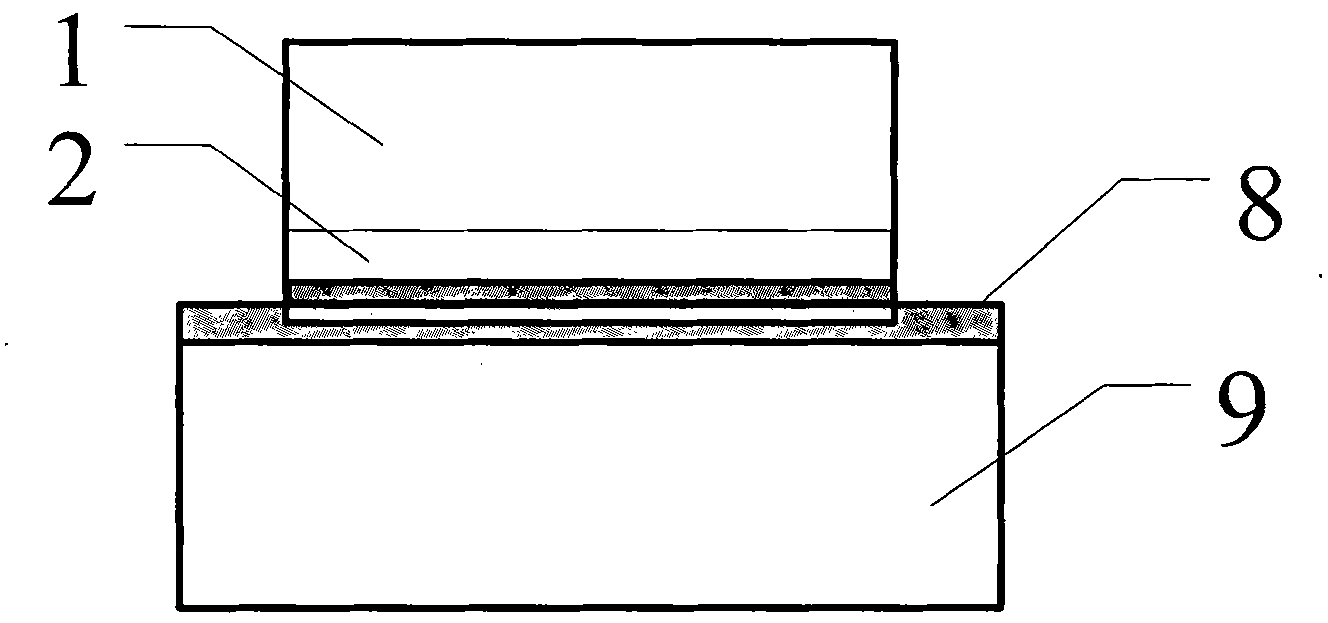

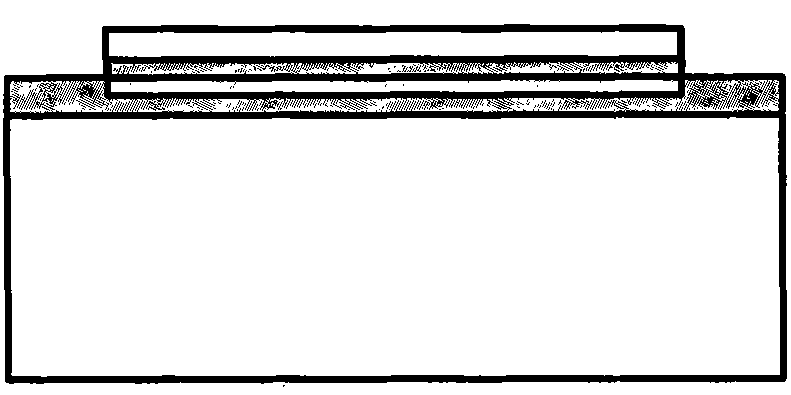

Multi-type workpieces batch visual measuring system and method

ActiveCN109357630AReduce manual intervention in the measurement processReduce labor costsUsing optical meansComputer scienceSize parameter

The invention provides a multi-type workpieces batch visual measuring system and a method, and belongs to the field of industrial detection automation. The measuring system comprises a data processingterminal, a workpieces detecting unit, an image acquiring unit, a control unit and the like. The measuring method comprises the following steps of: judging whether the to-be-detected workpieces are put into a detecting platform or not; obtaining a local depth image; obtaining a global image; identifying the type and number of the workpieces; and completing the size parameter measurement requiredby the measurement task. According to the multi-type workpieces batch visual measuring system and method, multiple kinds and multiple workpieces can be simultaneously detected at the same time; compared with traditional measurement means, the type and quantity of the workpieces, speed and accuracy and the like in measuring are significantly improved.

Owner:NANJING UNIV OF TECH

Method for analyzing chip failure

ActiveCN102253325AImprove work efficiencySave time and costOptically investigating flaws/contaminationContactless circuit testingEngineeringFailure analysis

The invention provides a method for analyzing chip failure, which is used for detecting defect characteristics of a chip grid and comprises the following steps: removing most of a substrate and an active region of a chip to be subjected to failure analysis through mechanical grinding; removing the remained substrate and active region of the chip through wet etching; removing most of a gate oxide layer of the chip through dry etching, wherein the remained gate oxide layer is used for protecting a first polysilicon layer of the grid; and detecting whether the defect characteristics exist on thefirst polysilicon layer or not. By utilizing the method provided by the invention, the chip can be accurately stripped to the bottom of the first polysilicon layer of the grid, the accurate size parameters of the bottom of the first polysilicon layer can be measured, the working efficiency can be greatly improved, and the time can be saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

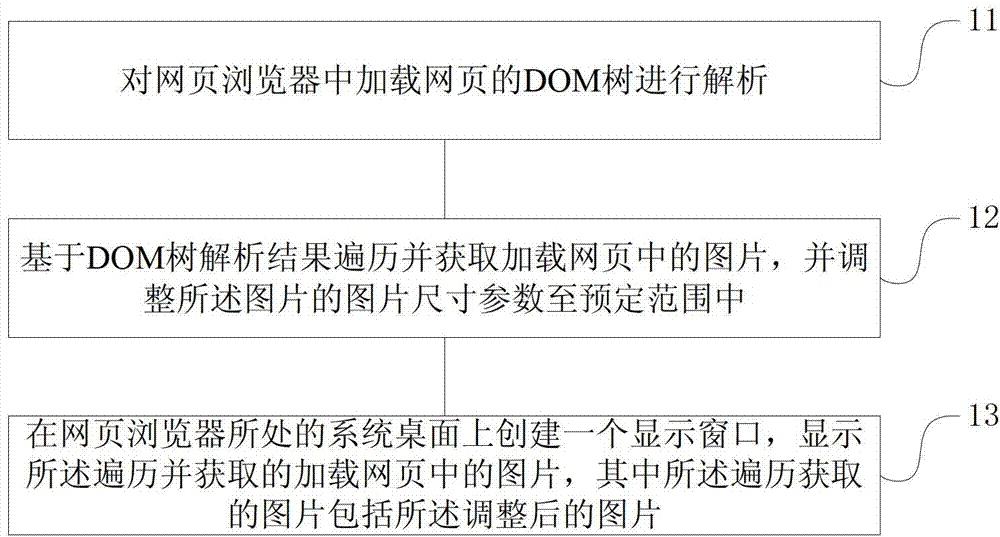

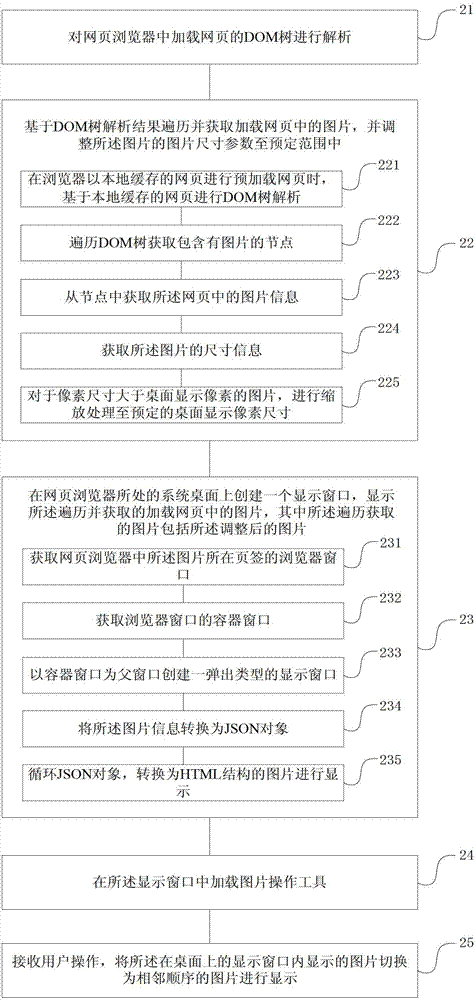

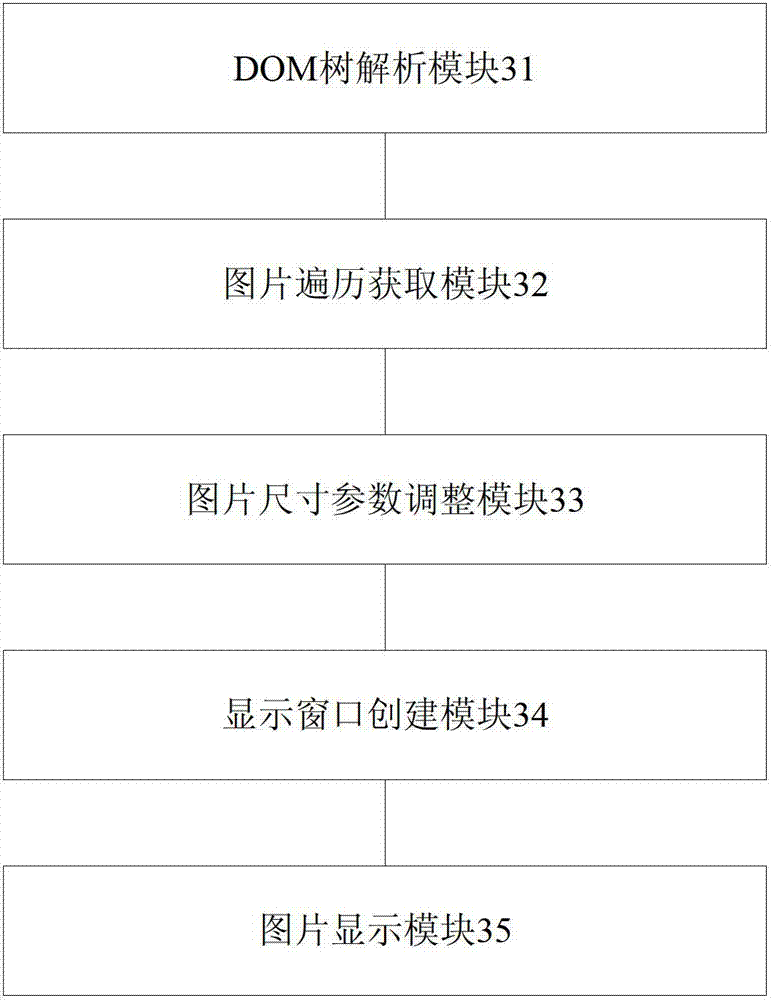

Display method and device of picture in webpage

ActiveCN102819560ASimple and fast operationEasy to browseSpecial data processing applicationsWeb browserComputer graphics (images)

The invention provides a display method and device of a picture in a webpage, which solve the problem in the prior art that a user can browse the whole picture with a larger size by drawing a scroll bar. The method comprises the following steps: analyzing a DOM (Document Object Model) tree of a loaded webpage in a webpage browser; going through based on an analyzed result of the DOM tree and obtaining the picture in the loaded webpage; adjusting a picture size parameter of the picture to a pre-set range; establishing a display window on a system desktop of the webpage browser and displaying the picture in the loaded webpage, which is obtained by going through, wherein the picture obtained by going through comprises the adjusted picture. Based on the analyzed result of the DOM tree, the picture in the loaded webpage is obtained by going through and the picture size parameter of the picture is adjusted to a pre-set range; and a picture book obtained by gonging through is displayed and operated in the window established on the desktop. According to the display method and device of the picture in the webpage, the picture with the larger size in the webpage can be conveniently browsed and a user can conveniently operate the picture in the webpage.

Owner:北京鸿享技术服务有限公司

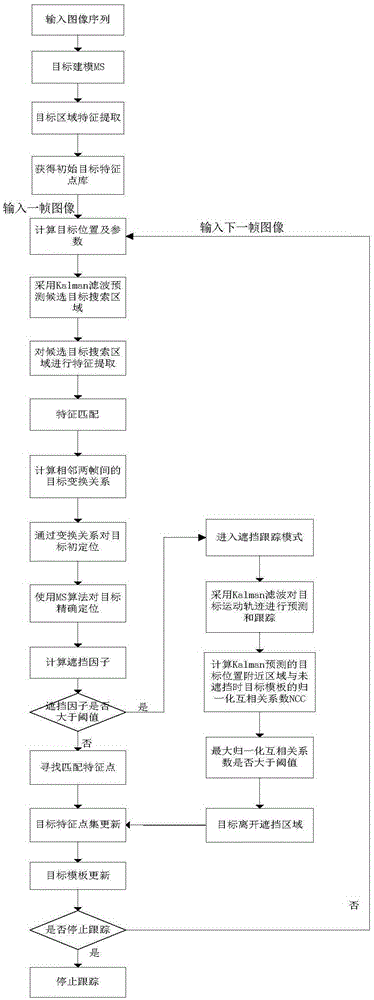

Characteristic matching and MeanShift algorithm-based target tracking method

The invention discloses a characteristic matching and MeanShift algorithm-based target tracking method. The method comprises the following steps: inputting an image sequence, carrying out background reconstruction on the image sequence, obtaining a target area of an initial moment and modelling by adopting a MeanShift algorithm; carrying out SIFT characteristic extraction on a target area model of the initial moment and taking the SIFT characteristic point of the target area model of the initial moment as an initial characteristic point of a characteristic library; calculating the initial position, size parameter and rotation parameters of the current frame of target through SIFT characteristic matching; accurately positioning the target by adopting the MeanShift algorithm; calculating a shielding factor of the target, judging the shielding degree of the target and determining the tracking mode of the target; and ending the target tracking after all the images in the image sequence are tracked. According to the method, the MeanShift algorithm and the SIFT characteristic matching algorithm are combined and the advantages of the two algorithms are exploited so that the stable tracking the target is realized.

Owner:XIDIAN UNIV

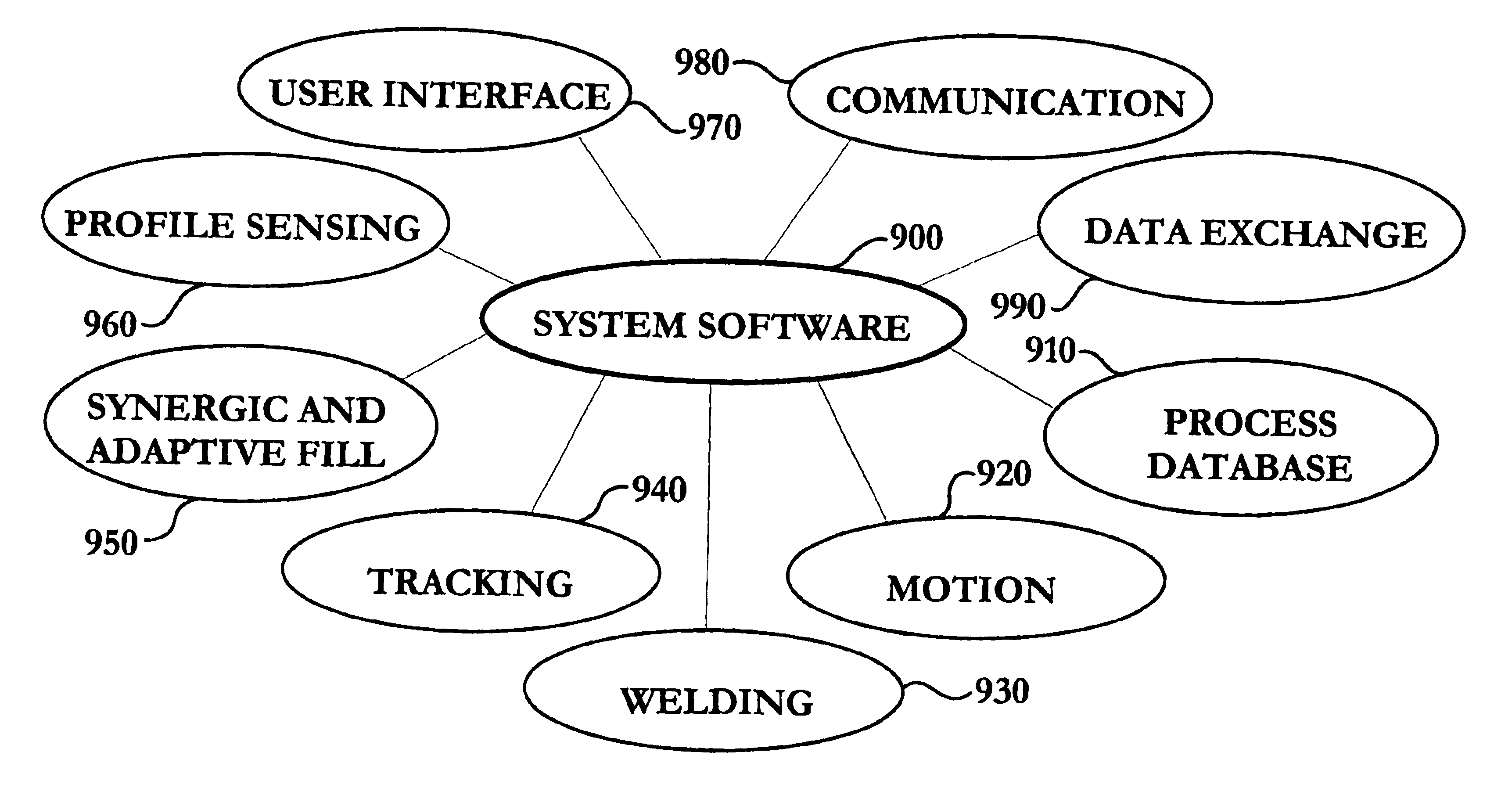

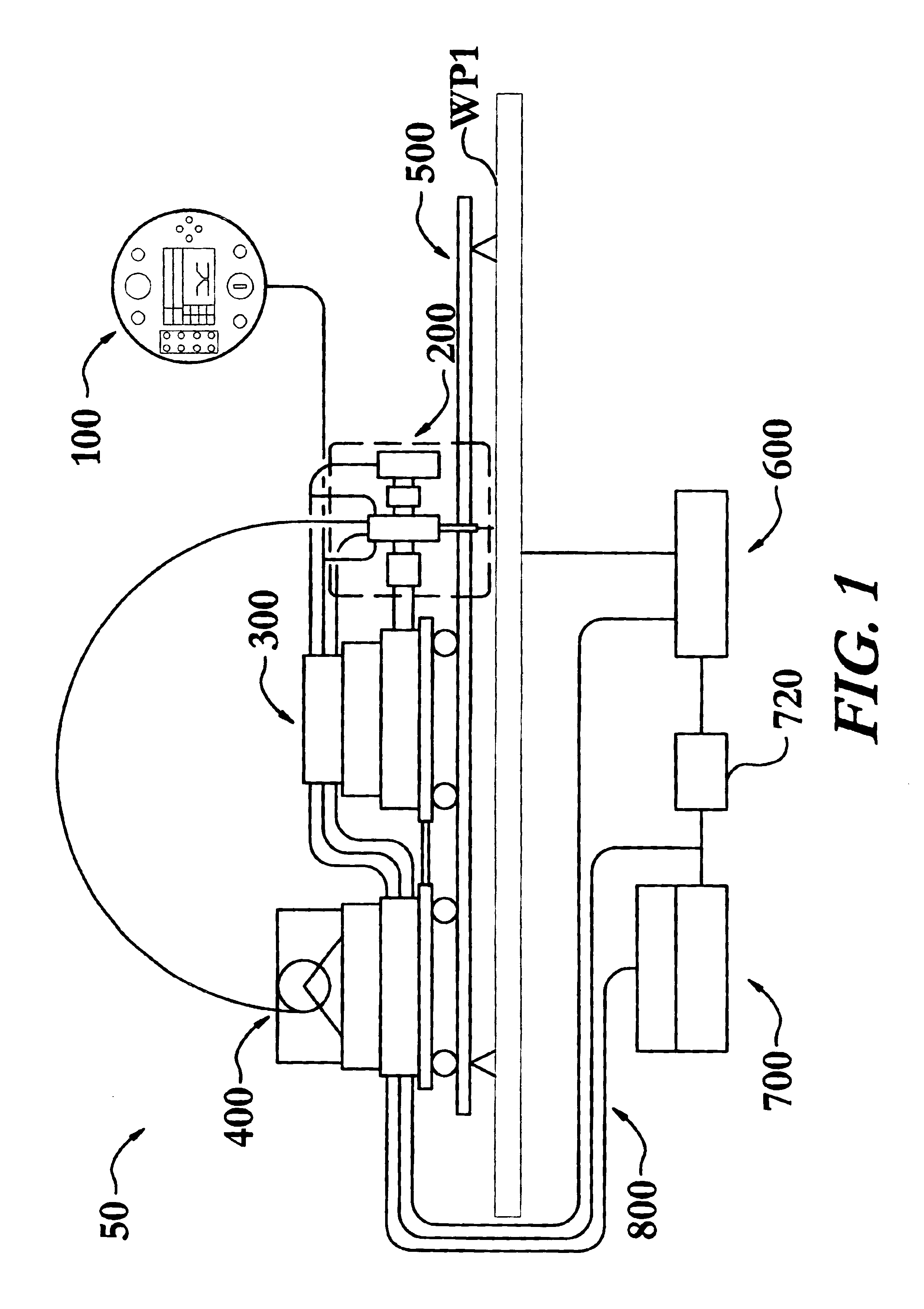

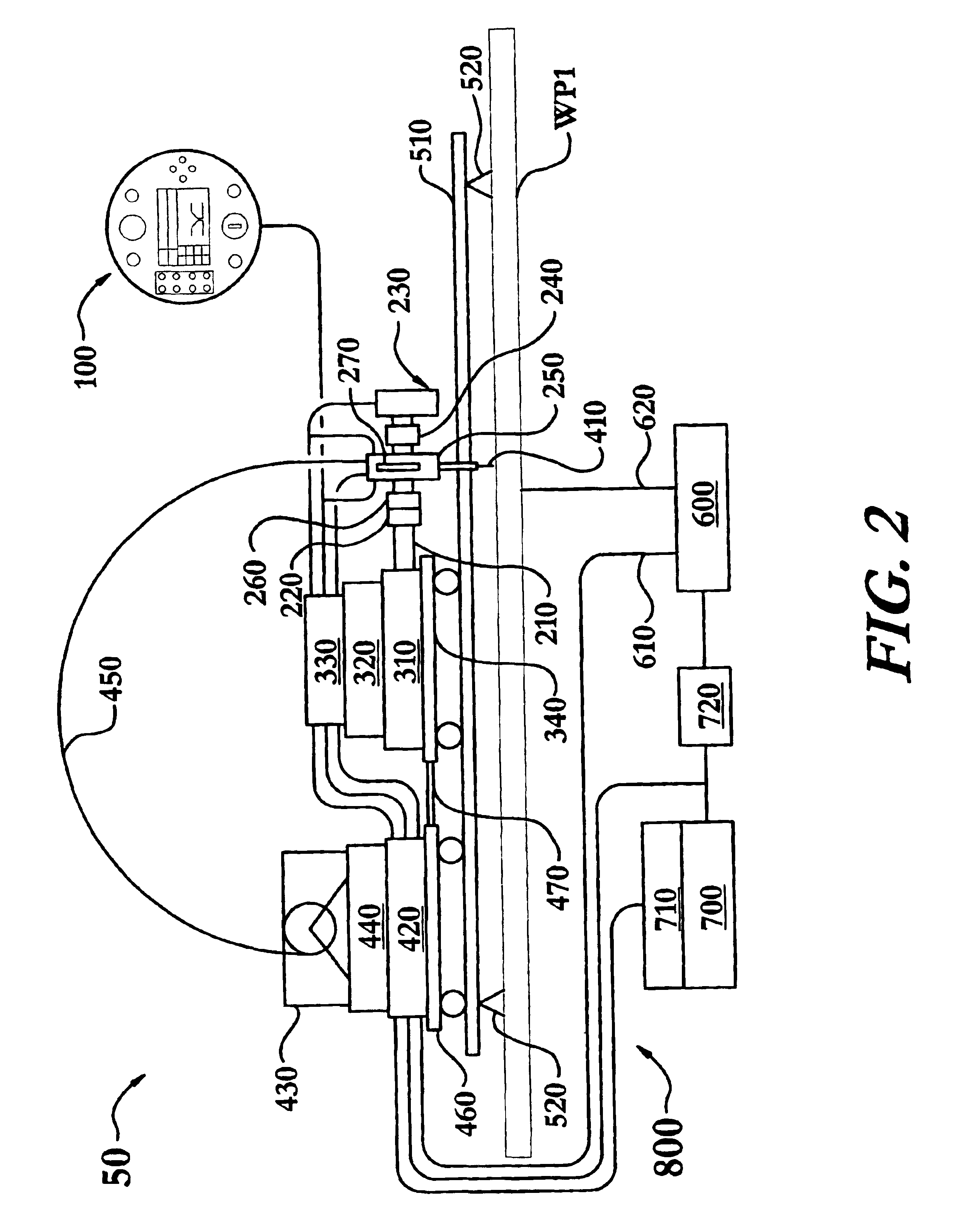

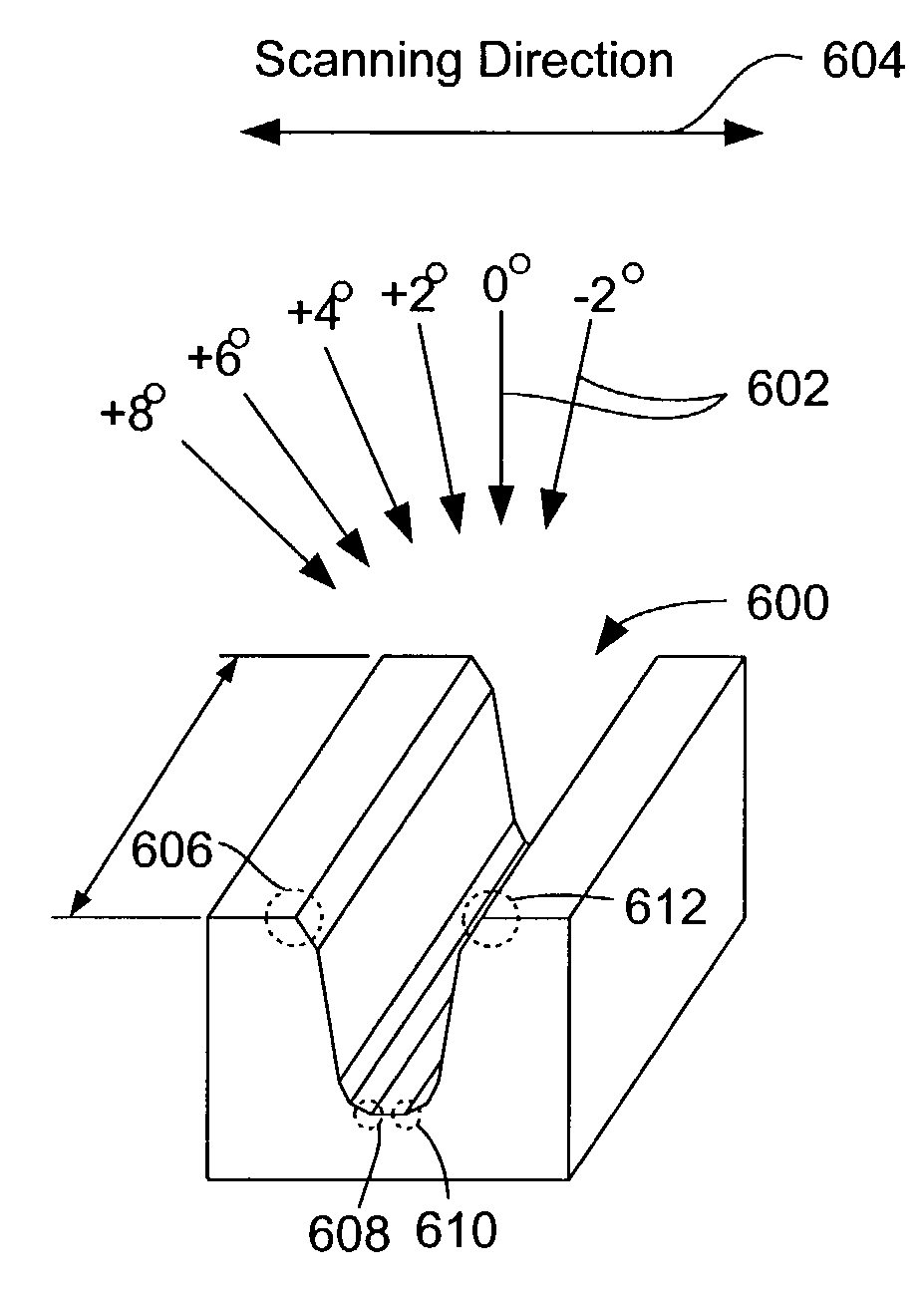

Adaptive and synergic fill welding method and apparatus

Owner:EDISON WELDING INSTITUTE INC

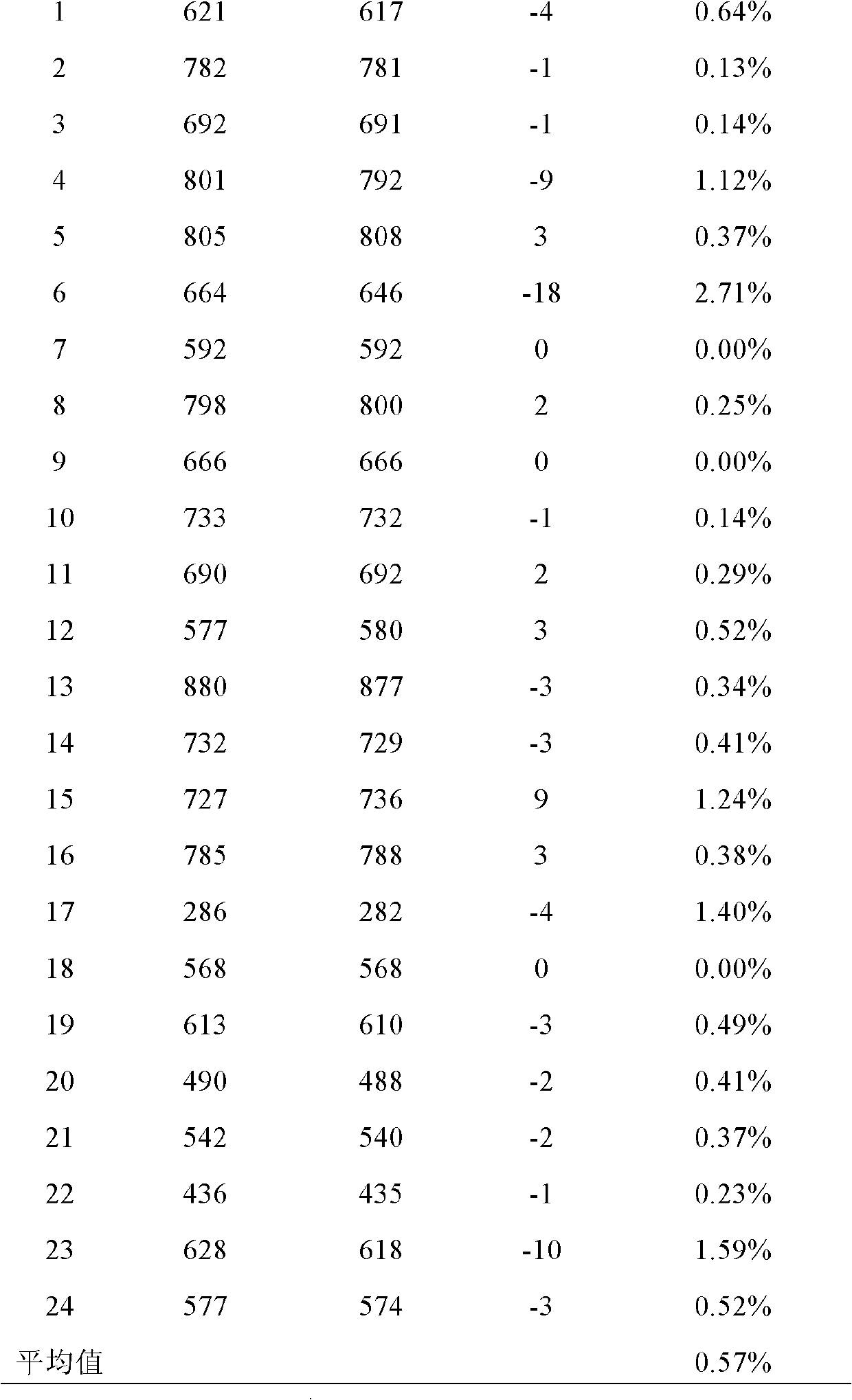

Digitalized paddy rice seed testing machine

ActiveCN101905215AEvenly dispersedSolve adhesionGas current separationIndividual particle analysisAgricultural scienceRice grain

The invention relates to an online non-destructive testing method which is suitable for automatically measuring and recording the total grain number, the filled grain number, the maturing rate, the grain lengths, the grain widths and the length-width ratio of a single plant or single-batch paddy rice in the paddy rice seed testing process for agricultural scientific research personnel. The digitalized paddy rice seed testing machine mainly comprises six functional modules of a bar code recognizer, a grain transfer device, an air separation device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. The digitalized paddy rice seed testing machine can be used for separating filled grains and empty and shriveled grains by utilizing the air separation device, dynamically acquiring grain parameters by utilizing a machine vision technology and simultaneously measuring the total grain number and the filled grain number of the paddy rice, thereby overcoming a bottleneck that the traditional testing measure can not simultaneously acquire the total grain number and the filled grain number and realizing the detection to the grain-size parameters of the paddy rice at the same time of calculating the paddy rice grain number. The invention can be also widely applied to the seed testing work of other grain crops.

Owner:HUAZHONG UNIV OF SCI & TECH

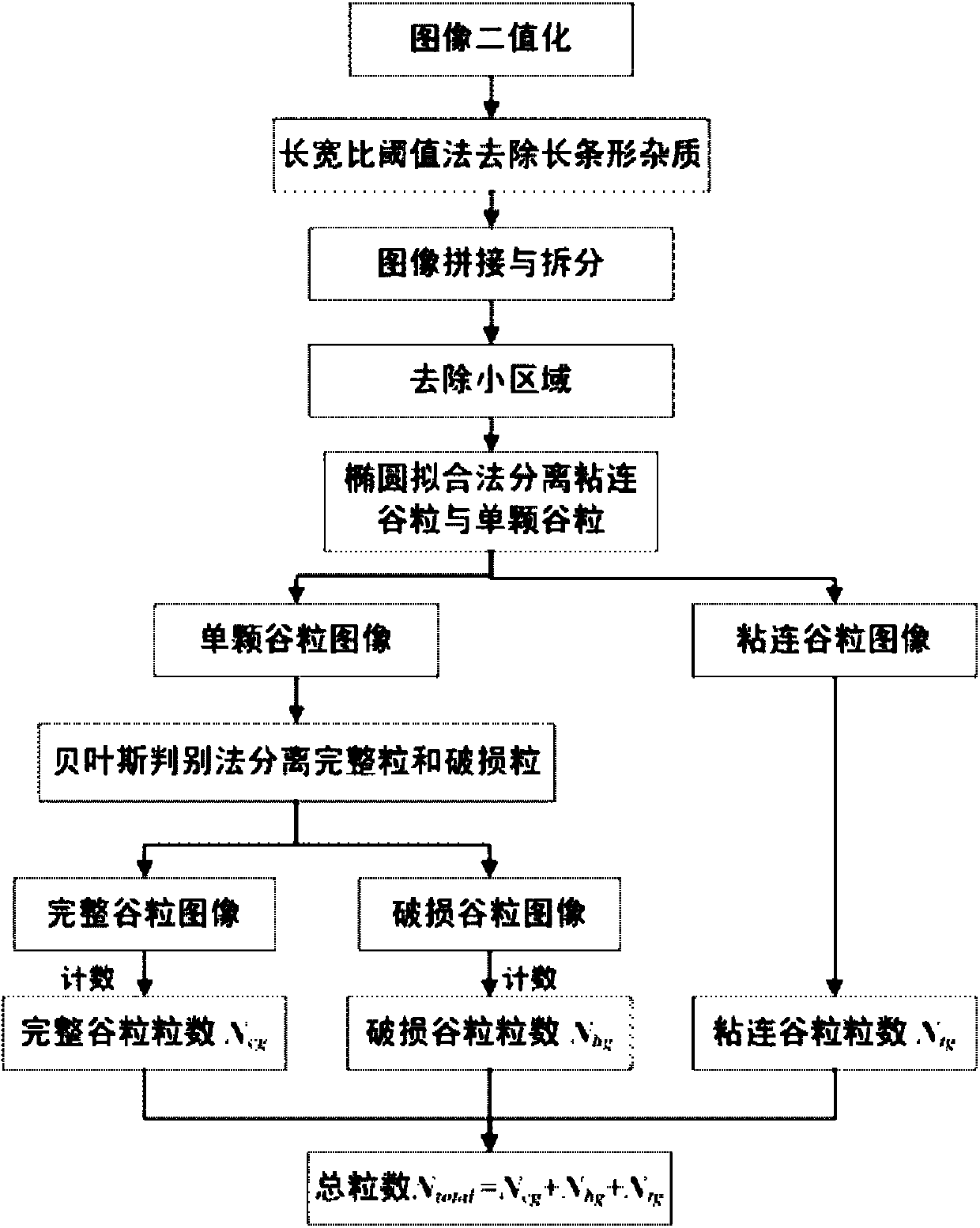

System and method for measuring section shape and size of heavy caliber steel pipe

InactiveCN1734233ATrue reflection of geometric featuresReflect geometric featuresMeasurement devicesInformation processingSize measurement

This invention discloses such a measurement and method of a large caliber steel tube cross-section shape, which belongs to the domain of geometric measurement technique. The measurement system of information processing mode and measurement mode is located in the small moving car, with the small car moving on the datum circular orbit. The input and output mode connect the information processing mode through the serial port. The measurement method is like this: testing a series of the steel tube surface and the radial distance of a certain known datum circular orbit radius in order to get a configuration point coordinates of the steel tube cross-section. When the amount of sampling points is abundant enough, we can get the accurate outline of steel tube. Then the information-processing mode counts the steel tube cross-section shape and dimension parameter.

Owner:TSINGHUA UNIV

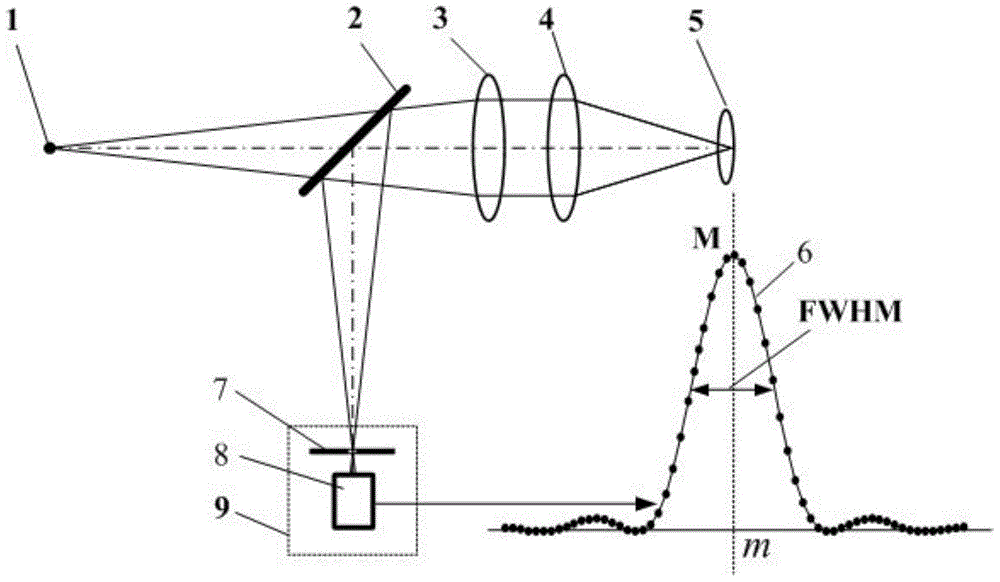

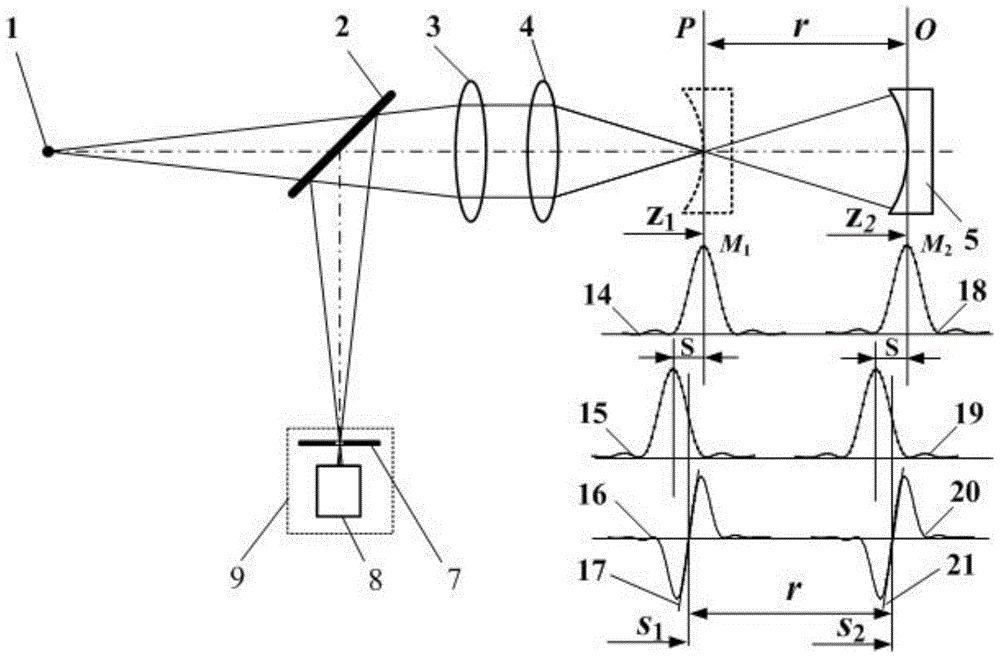

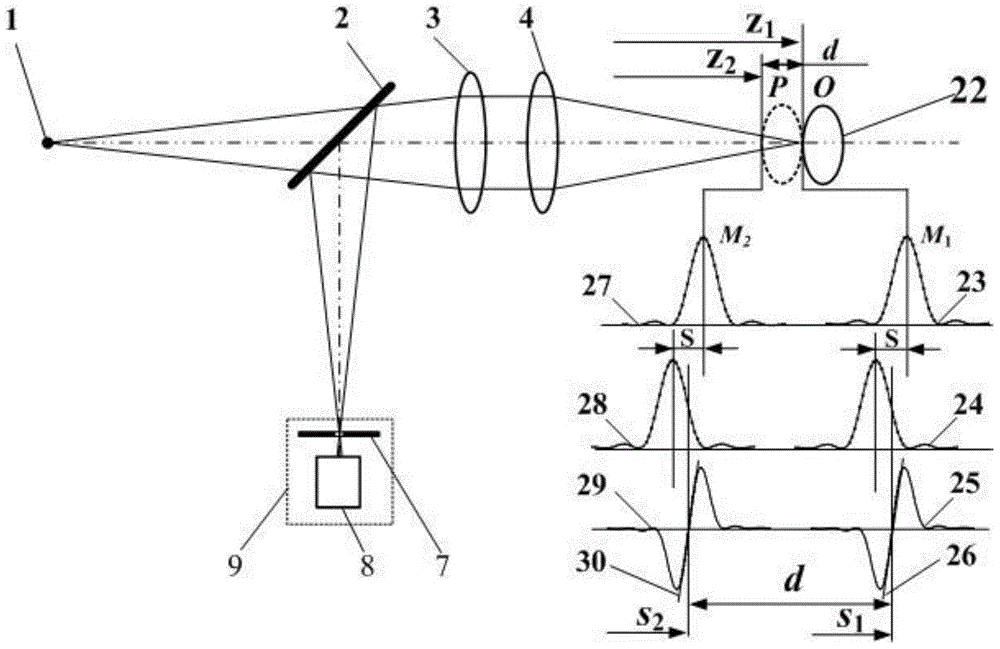

Bilateral dislocation differential confocal element parameter measuring method

ActiveCN104568389AIncrease the radius of curvatureHigh measurement accuracyTesting optical propertiesAxial displacementRefractive index

The invention belongs to the technical field of optical imaging and detecting and relates to a bilateral dislocation differential confocal element parameter measuring method. The method includes the steps that dislocation differential subtracting processing is conducted on the two sides of a confocal axial characteristic data set measured by the starting points and the ending points of all various size parameters including the curvature radius, the lens thickness, the refractive rate, the focal distance and the interval, and therefore the positioning precision of the starting points and the ending points of the size parameters is improved, and the measuring precision of optical elements of the curvature radius, the lens thickness, the refractive rate, the focal distance, the interval and the like is improved. According to the bilateral dislocation differential confocal element parameter measuring method, due to the fact that two sections of data, close to the position of the full width at half maximum and very sensitive to axial displacement, of a confocal characteristic curve are used for conducting the dislocation differential subtracting processing, the position, calculated by the data sections, of the extreme point of the confocal characteristic curve is more sensitive and more accurate than the position, calculated through an existing confocal characteristic curve top fitting method, of the extreme point of the confocal characteristic curve, according to the result of the bilateral dislocation differential confocal element parameter measuring method, under the condition that the confocal element parameter system structure is not changed, the axial focusing capability, the signal-to-noise ratio and the like of the system can be obviously improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

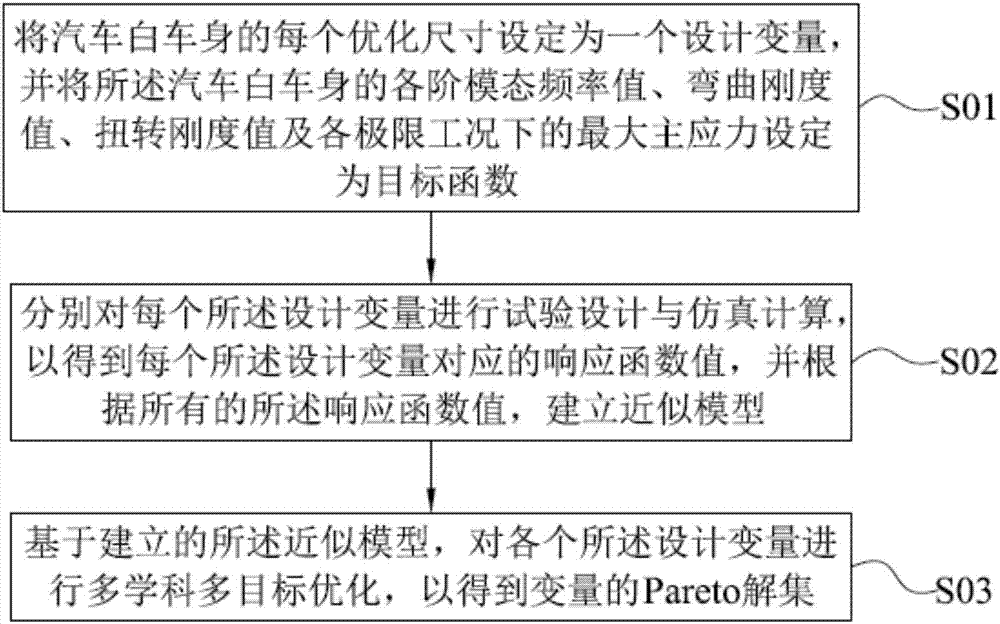

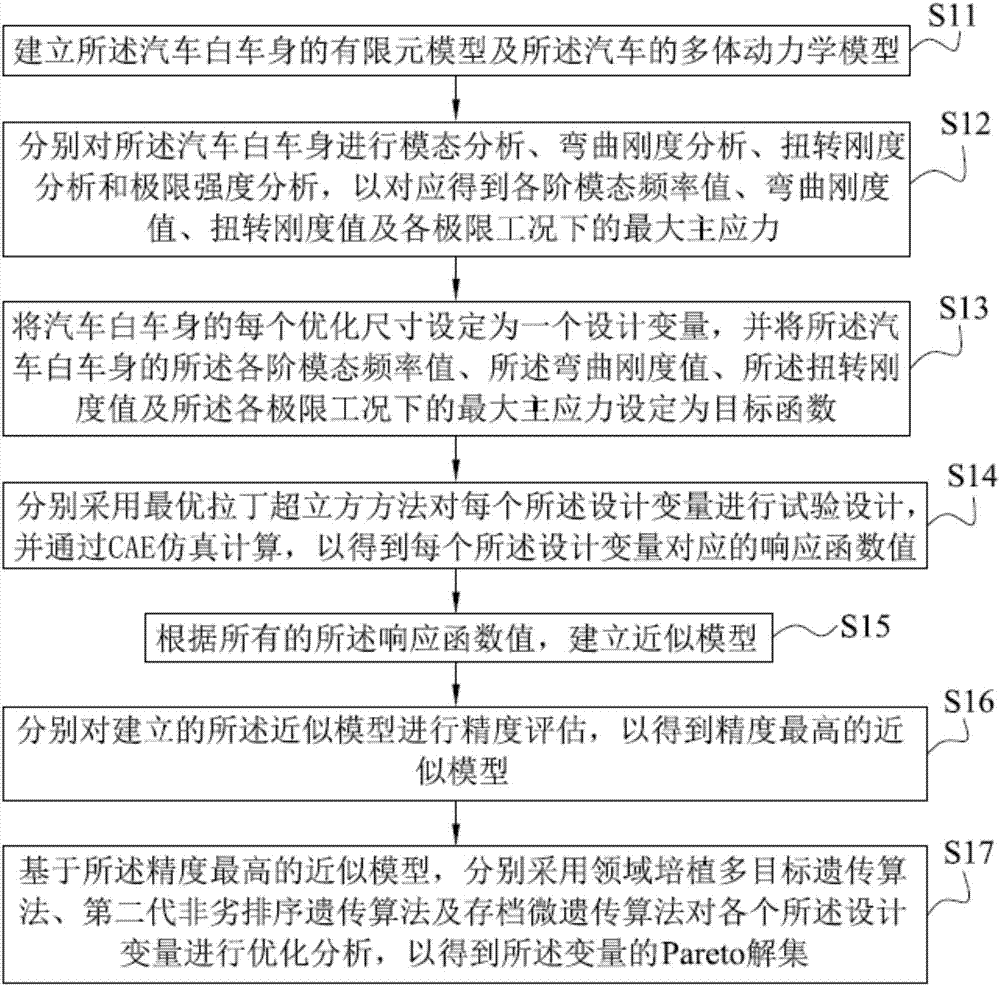

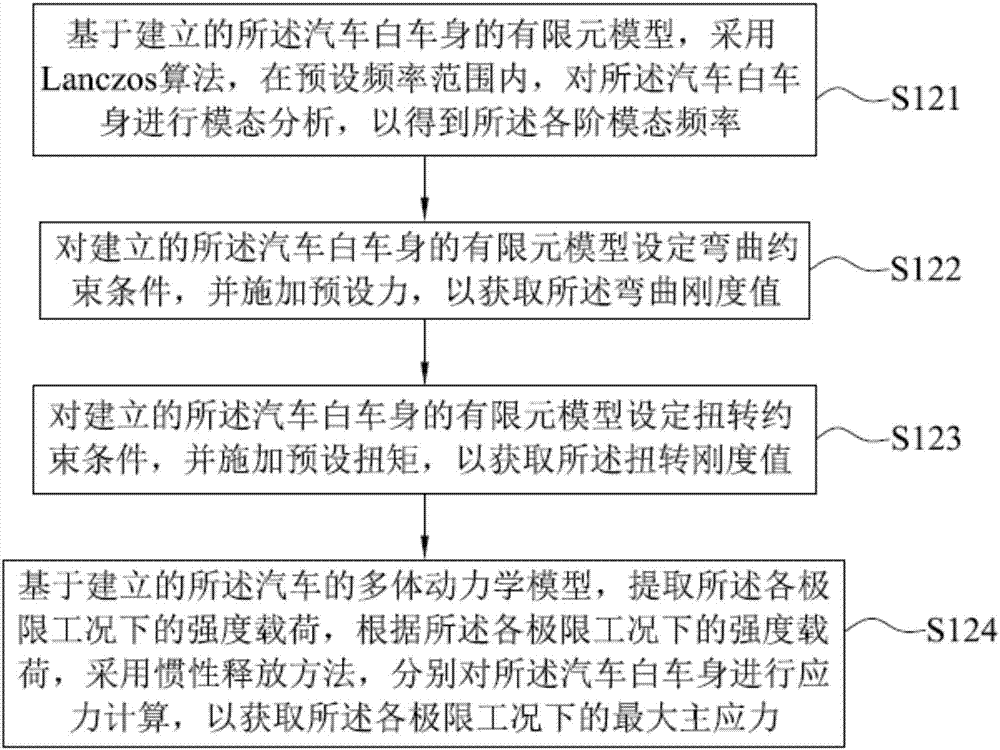

Automobile body-in-white light weighting analysis method

The invention provides an automobile body-in-white light weighting analysis method. The method comprises following steps: setting each optimization size of automobile body-in-white as a design variable and setting the modal frequency value of each stage, bending rigidity value, torsional rigidity value and maximum principal stress at all extreme work conditions of the automobile body-in-white as target functions; performing experiment design and simulation calculation on each design variables to obtain response function values corresponding to each design variable and according to the response function values, establishing a simulation model; based on the simulation model, performing multiple discipline and multi-target optimization on the design variables to obtain Pareto solution set of the variables. According to the automobile body-in-white light weighting analysis method of the invention, through selecting proper design variables, analysis methods and technical routes, the light weighting of automobile body-in-white is realized and at the same time, on the basis of satisfying multiple discipline and multi-target, the optimized size parameters of the automobile body-in-white among all performances can be found.

Owner:JIANGLING MOTORS

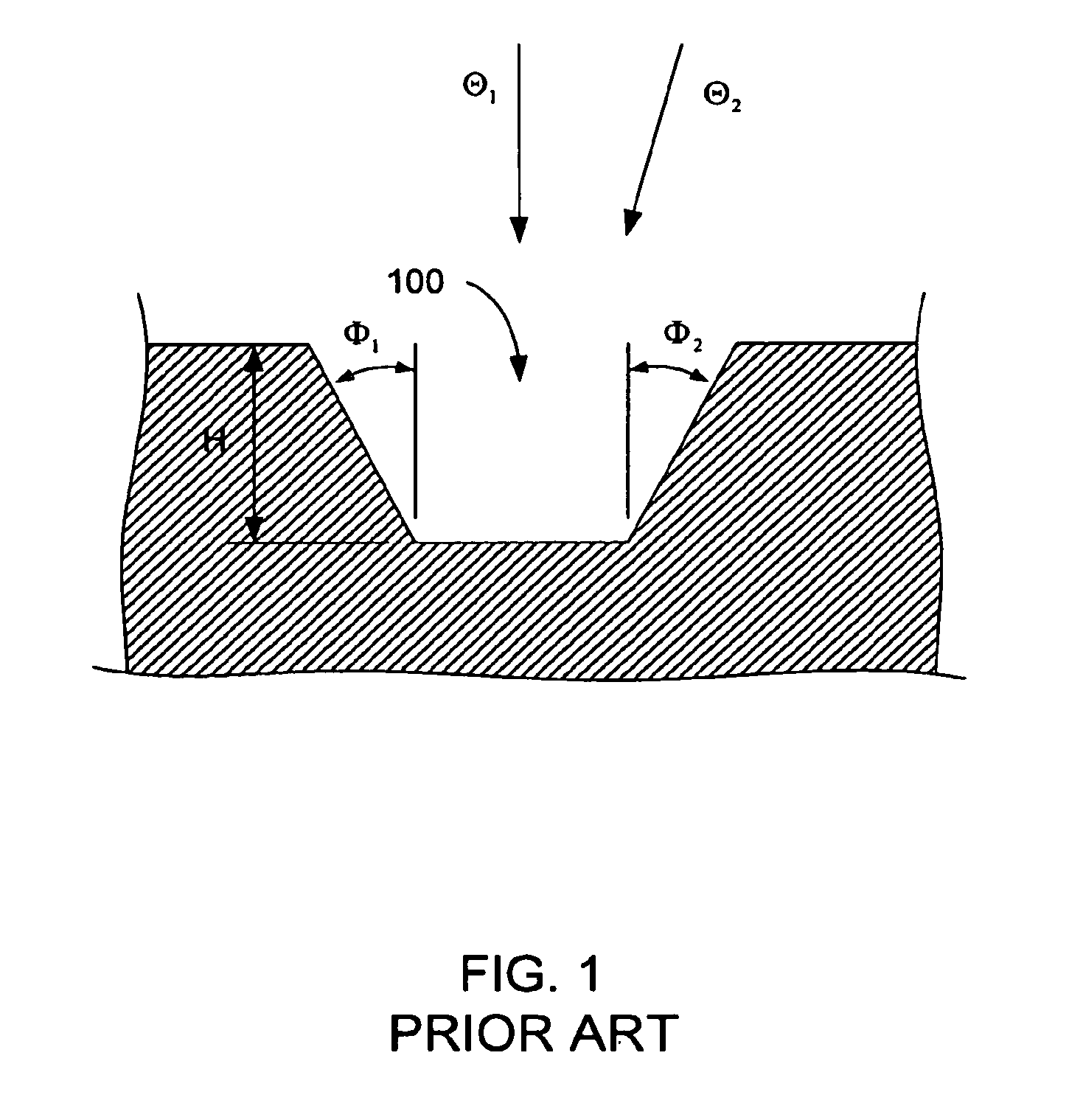

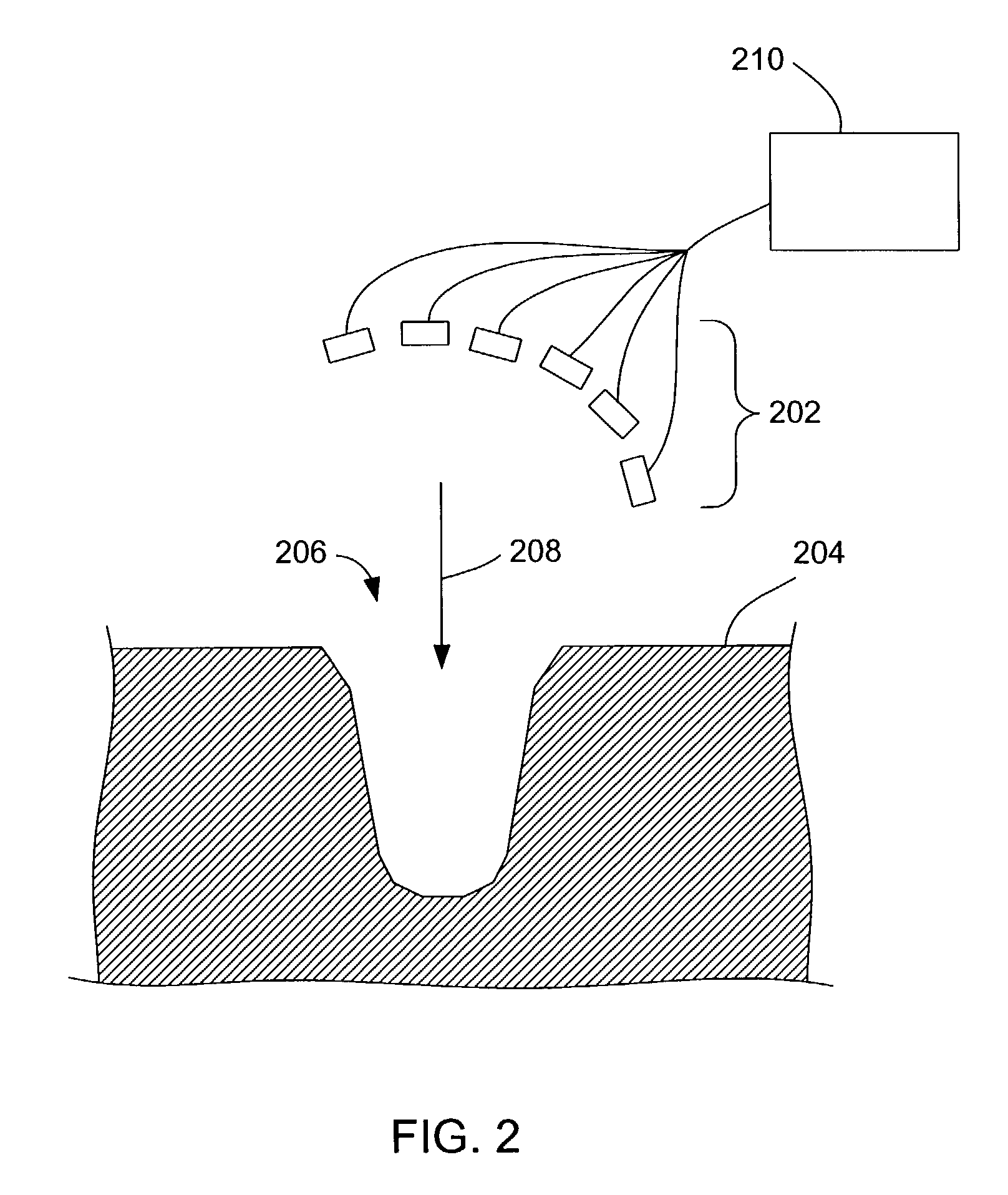

SEM profile and surface reconstruction using multiple data sets

InactiveUS6930308B1Accurate estimateMaterial analysis using wave/particle radiationElectric discharge tubesData setScanning tunneling microscope

A highly accurate technique for inspecting semiconductor devices is described. The technique involves utilizing multiple sets of measurement data obtained by a scanning electron microscope (SEM) to determine the dimensional parameters of a semiconductor device. The SEM collects each set of data from a different angular orientation with respect to the device. The dimensional parameters of the semiconductor device are determined by analyzing the relationship between the SEM inspection angle and the collected data sets. Various configurations of an SEM can be used to implement this invention. For instance an electron beam inspection system of the present invention can have at least two sets of deflectors for guiding the electron beam, a swiveling specimen stage, and / or a set of detectors set about the specimen at different angular orientations.

Owner:KLA TENCOR TECH CORP

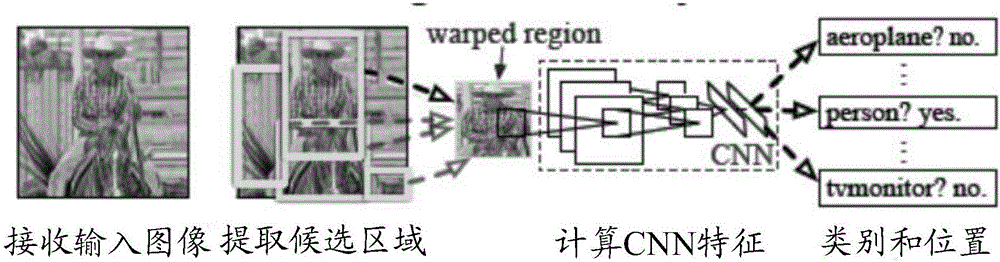

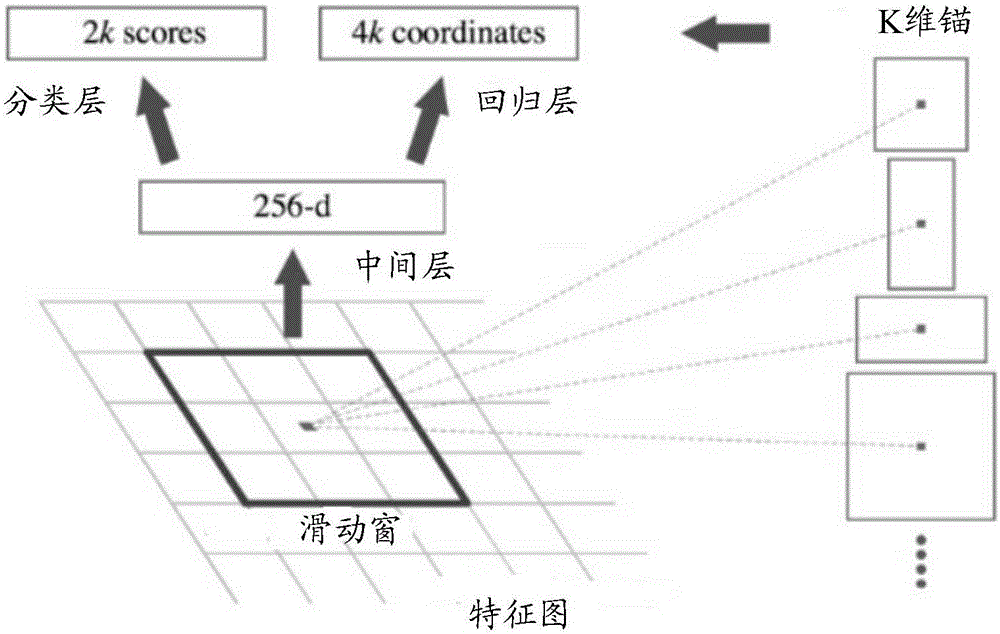

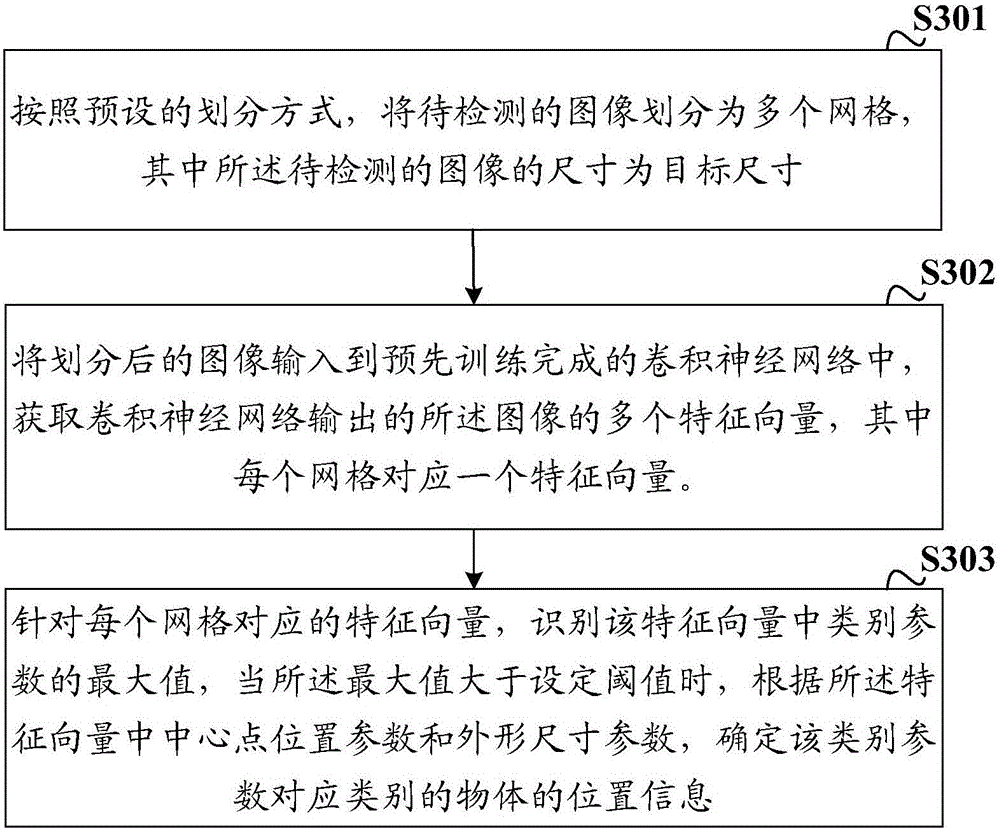

Method and device for detecting object in image

ActiveCN106803071AEasy to optimizeShorten the timeImage enhancementImage analysisFeature vectorEuclidean vector

The embodiment of the invention discloses a method and device for detecting an object in an image for improving the real-time performance of target detection. The method comprises dividing the image to be detected into a plurality of grids according to a preset division method, inputting the divided image into a convolutional neural network (CNN) trained in advance, obtaining the eigenvectors, output by the CNN, corresponding to respective grids of the image, determining the maximum value of a category parameter in each eigenvector, determining the positional information of an object with a category corresponding to the category parameter according to the central point position parameter and the boundary dimension parameter in the eigenvector when the maximum value is greater than a set threshold. By determining the category and the position of the object in the image with the CNN trained in advance, the method may simultaneously detect the category and the position of the object, does not need to select multiple feature regions, saves detection time, improves detection real-time performance and detection efficiency, and facilitates overall optimization.

Owner:ZHEJIANG DAHUA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com