Symmetrical liquid drop injecting three-dimensional fast shaping method and apparatus thereof

A droplet spraying and forming device technology is applied in the field of rapid prototyping methods and devices for metal parts, which can solve the problems of poor compactness of formed parts, unsatisfactory product quality, and high porosity, and achieve dense structure, rapid solidification structure characteristics, accurate high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

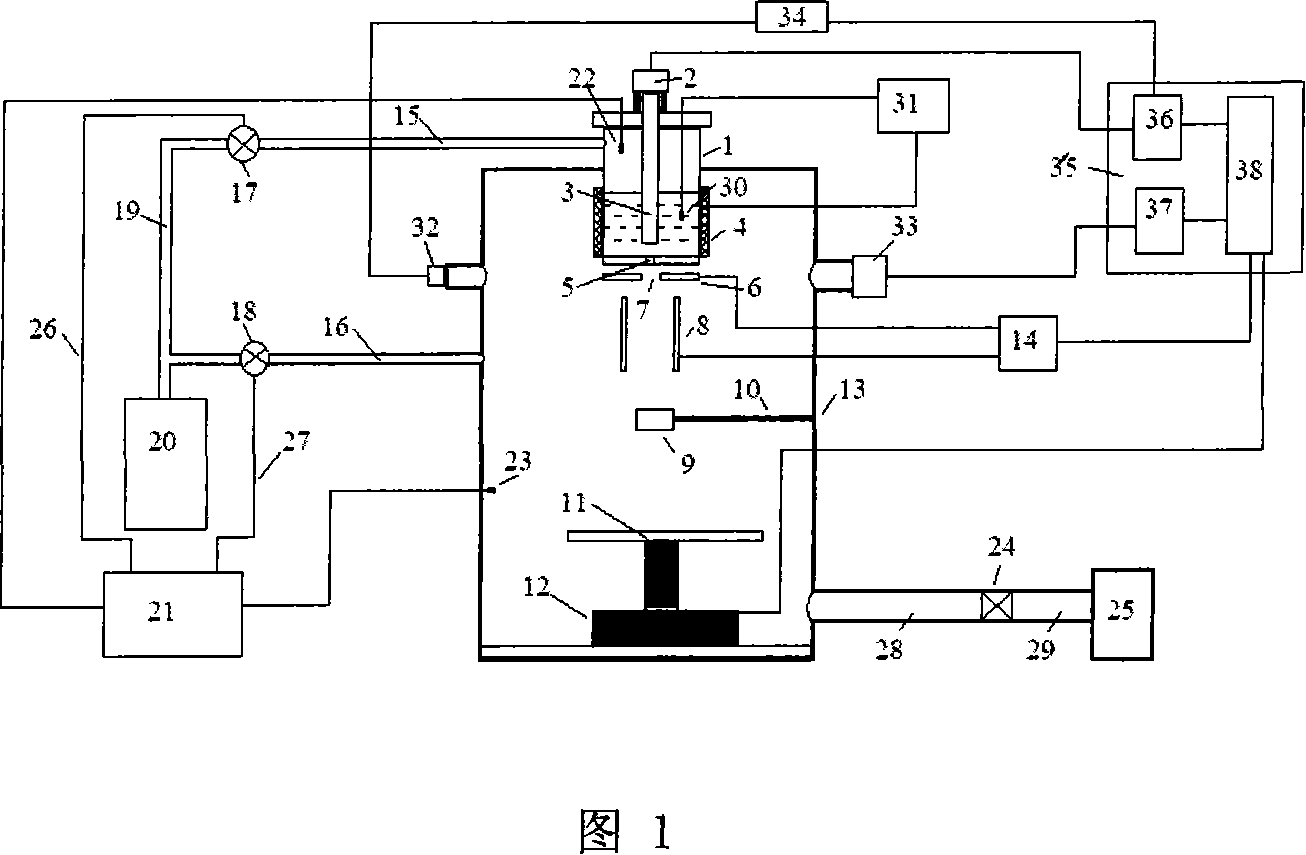

[0023] The present invention mainly injects inert gas (such as nitrogen) into the crucible and the vacuum-sealed chamber, and utilizes the pressure control system to make the crucible and the vacuum-sealed chamber reach a stable pressure difference, so that the metal melt flows from the micro-nozzle at the bottom of the crucible to According to the principle of Rayleigh jet instability, the vibration generated by the piezoelectric oscillator is used to disturb the metal jet, so that the metal jet breaks into uniform droplets. The real-time size parameters of the generated droplets are obtained through the monitoring system combined with the computer analysis system, and then for the optimized parameters, the frequency of the oscillator is feedback-controlled to reduce the error between the generated metal droplets and the set droplet size. The metal droplets are charged by the electrode plate induction, and the microcomputer control system controls the electric field parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com