Patents

Literature

188 results about "Metal droplets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

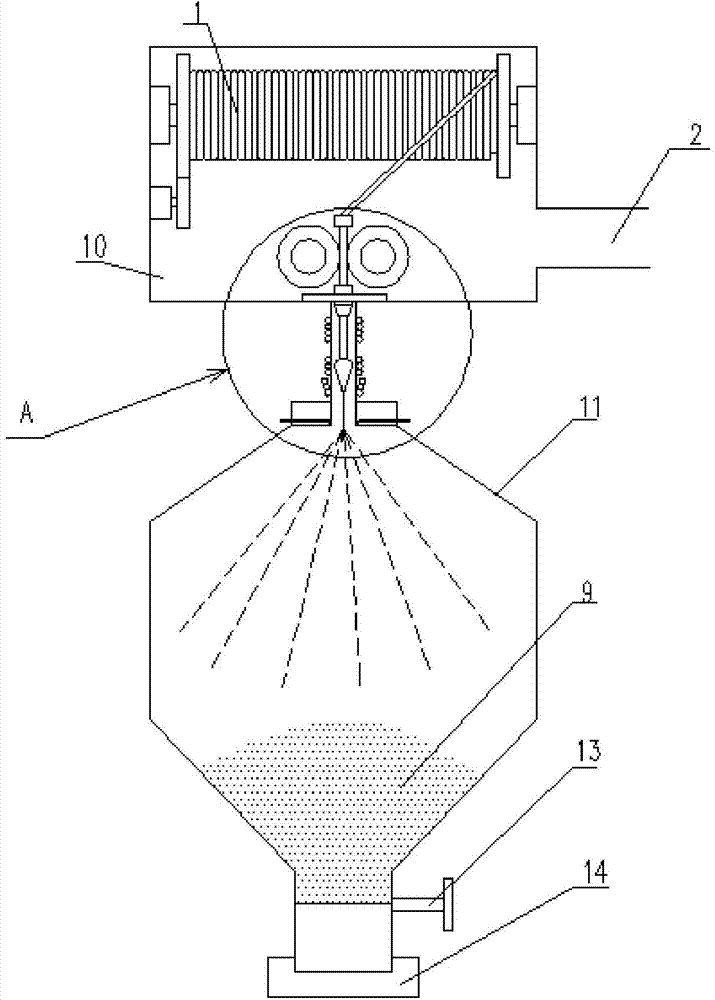

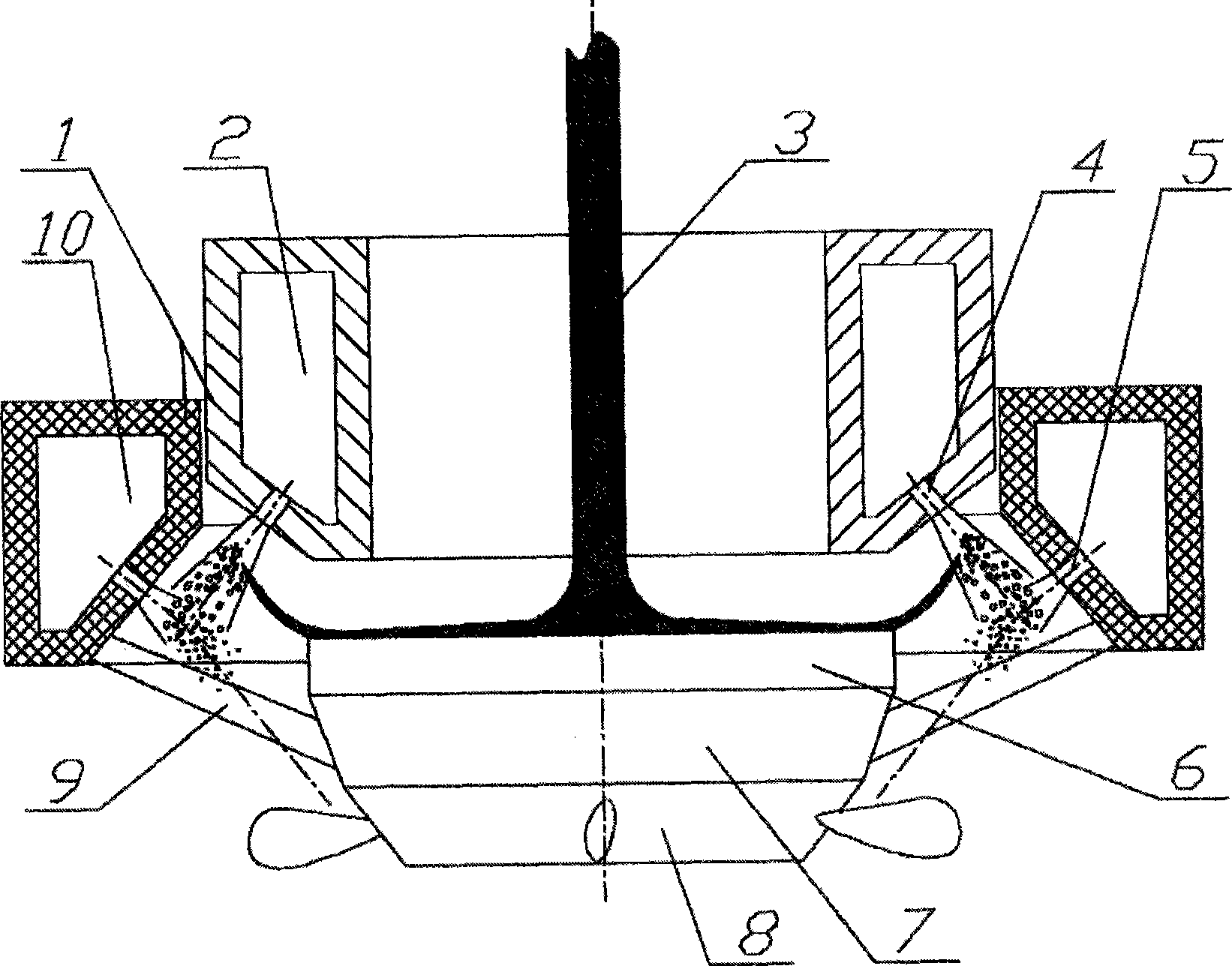

Three-dimensional rapid prototyping method and device based on pulse small hole droplet injection

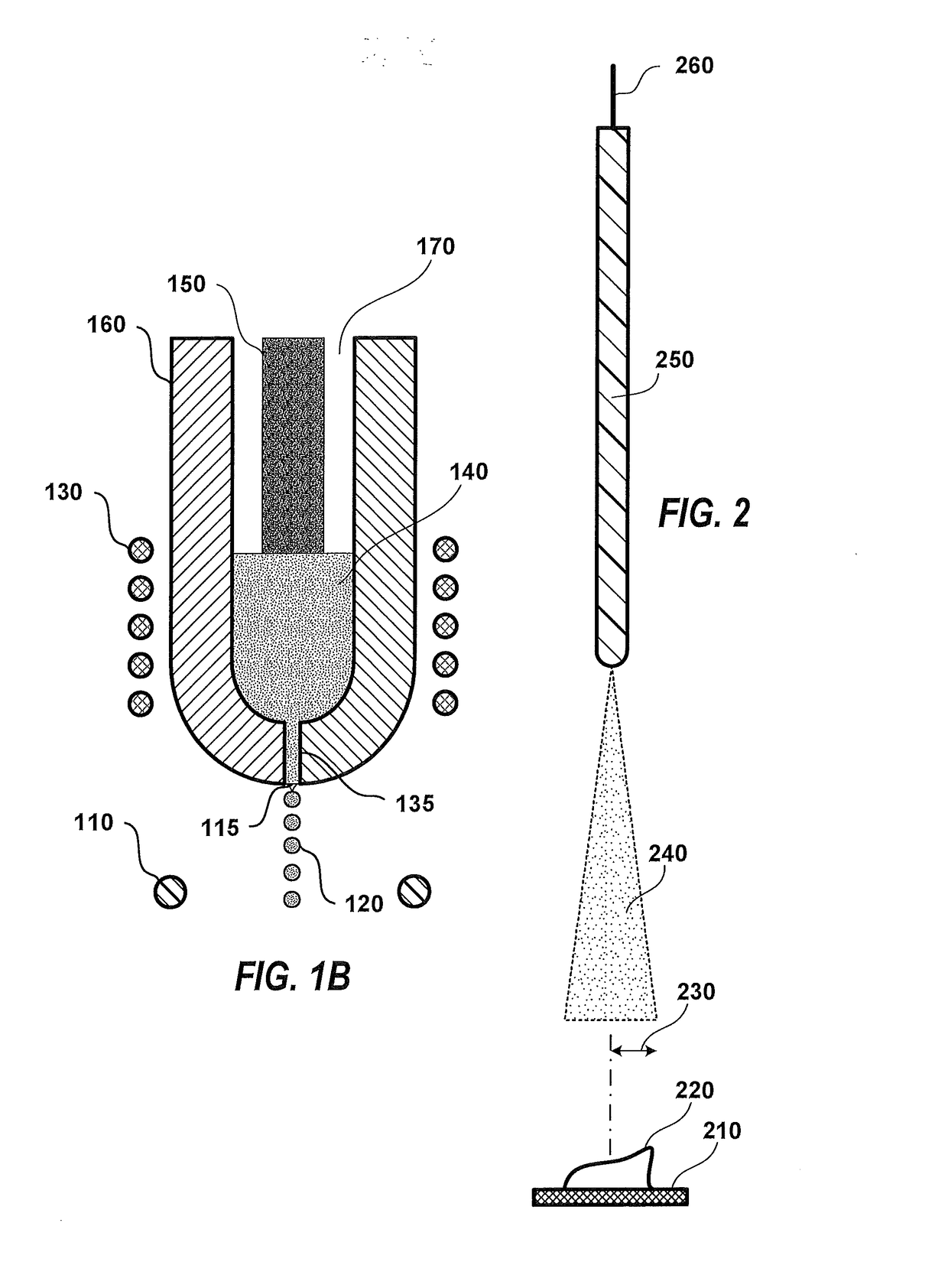

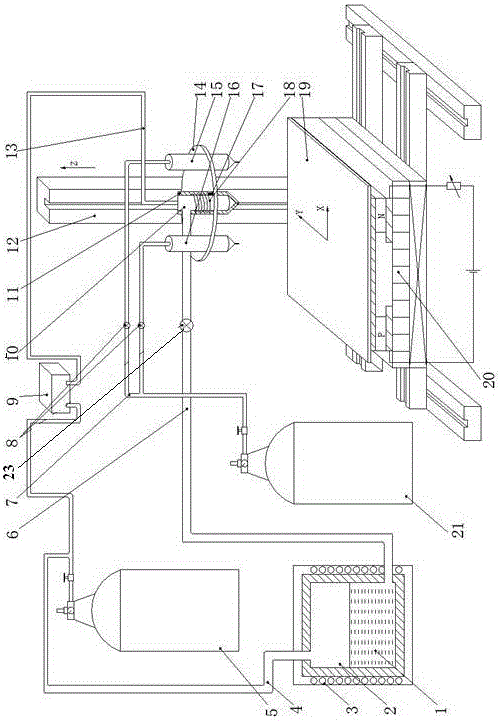

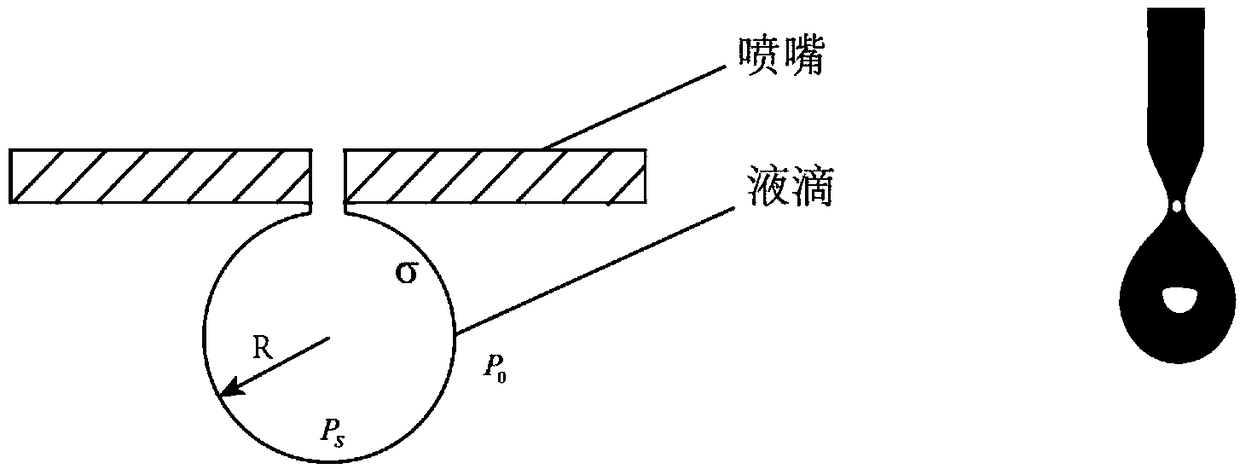

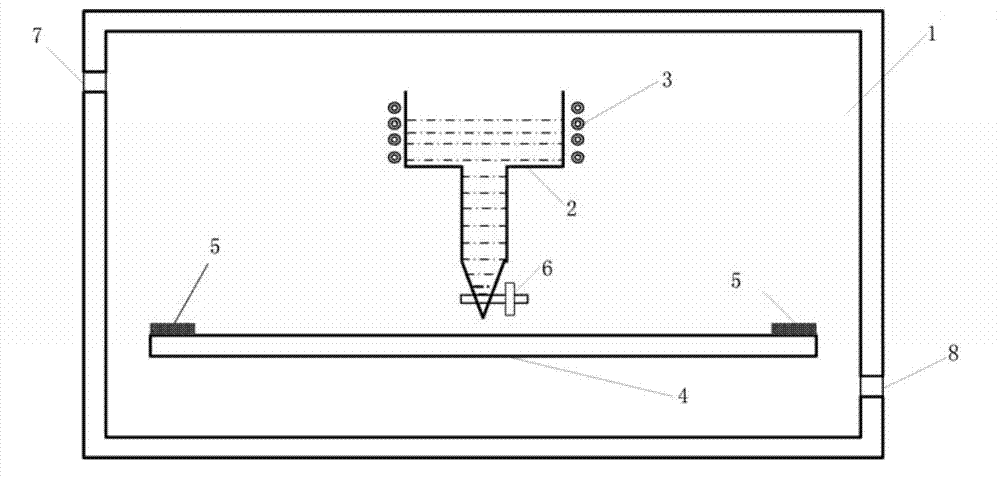

The invention relates to a three-dimensional rapid prototyping method and device based on pulse small hole droplet injection and belongs to the technical field of three-dimensional rapid prototyping. The three-dimensional rapid prototyping method is characterized in that a heater is used for heating a crucible until the metals in the crucible are in the molten state, a positive differential pressure value is set between the interior of the crucible and a vacuum chamber, simultaneously a piezoelectric ceramic driver applies certain pulse signals to piezoelectric ceramics to lead the piezoelectric ceramics to drive a transmission bar to generate longitudinal infinitesimal displacement, the infinitesimal displacement acts on the metal melt at the bottom of the crucible, tiny droplets are injected from small holes arranged at the bottom of the crucible, one droplet can be formed at the position of the small holes once the piezoelectric ceramics move for one time, size data of the droplets are timely analyzed through a photograph system, further the optimum parameter is obtained through adjustment; and the droplets fall to a moving three-dimensional motion platform to be deposited, and accordingly needed metal parts are formed through depositing. The three-dimensional rapid prototyping method and device based on pulse small hole droplet injection have the advantages that the pulse small holes inject to generate the metal droplets with uniform and controllable sizes, prototyped products are fine and uniform in microstructure, the prototyping process is strong in controllability, and the formed parts are high in accuracy.

Owner:DALIAN UNIV OF TECH

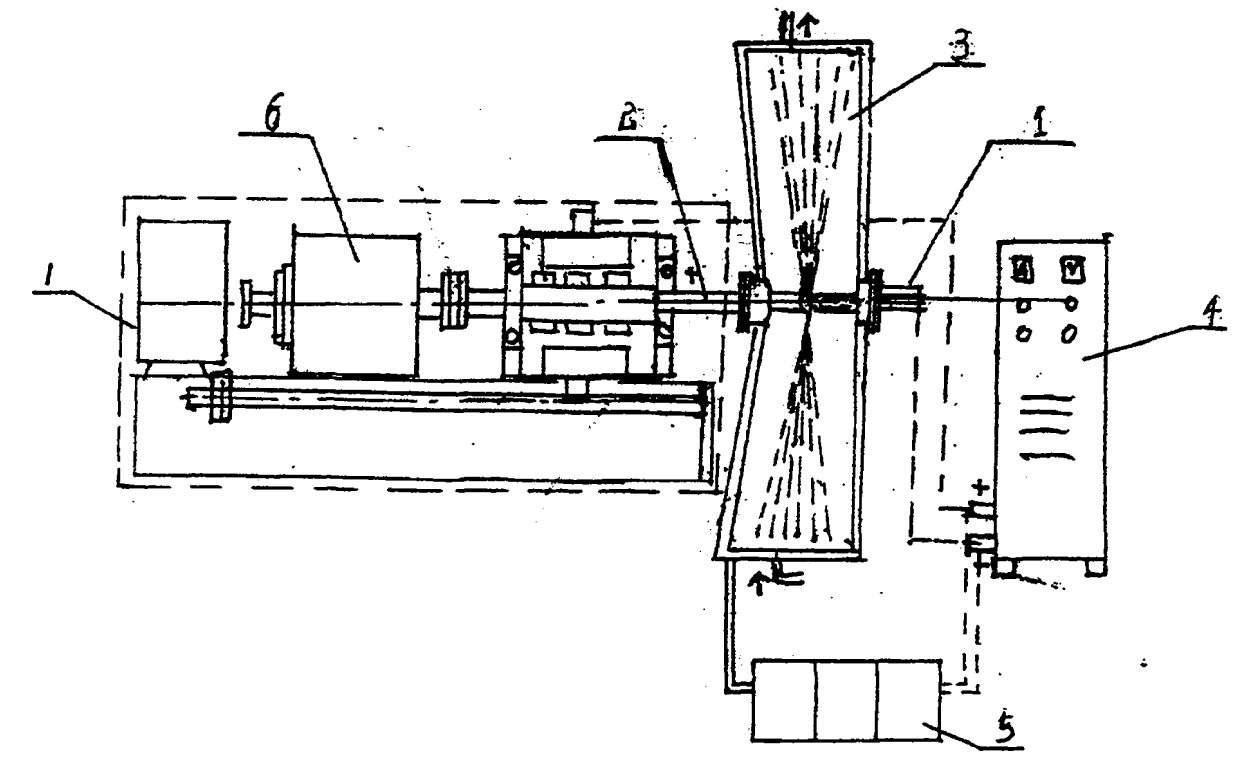

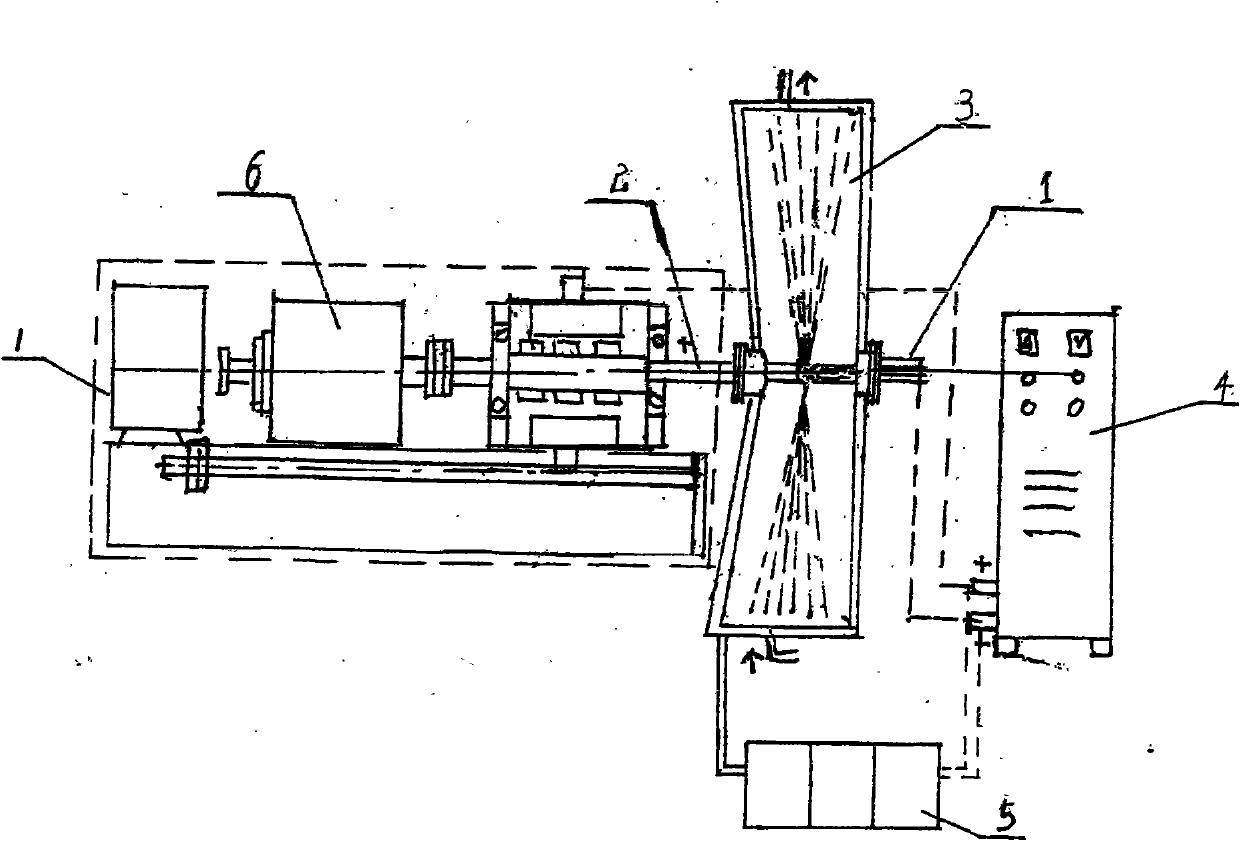

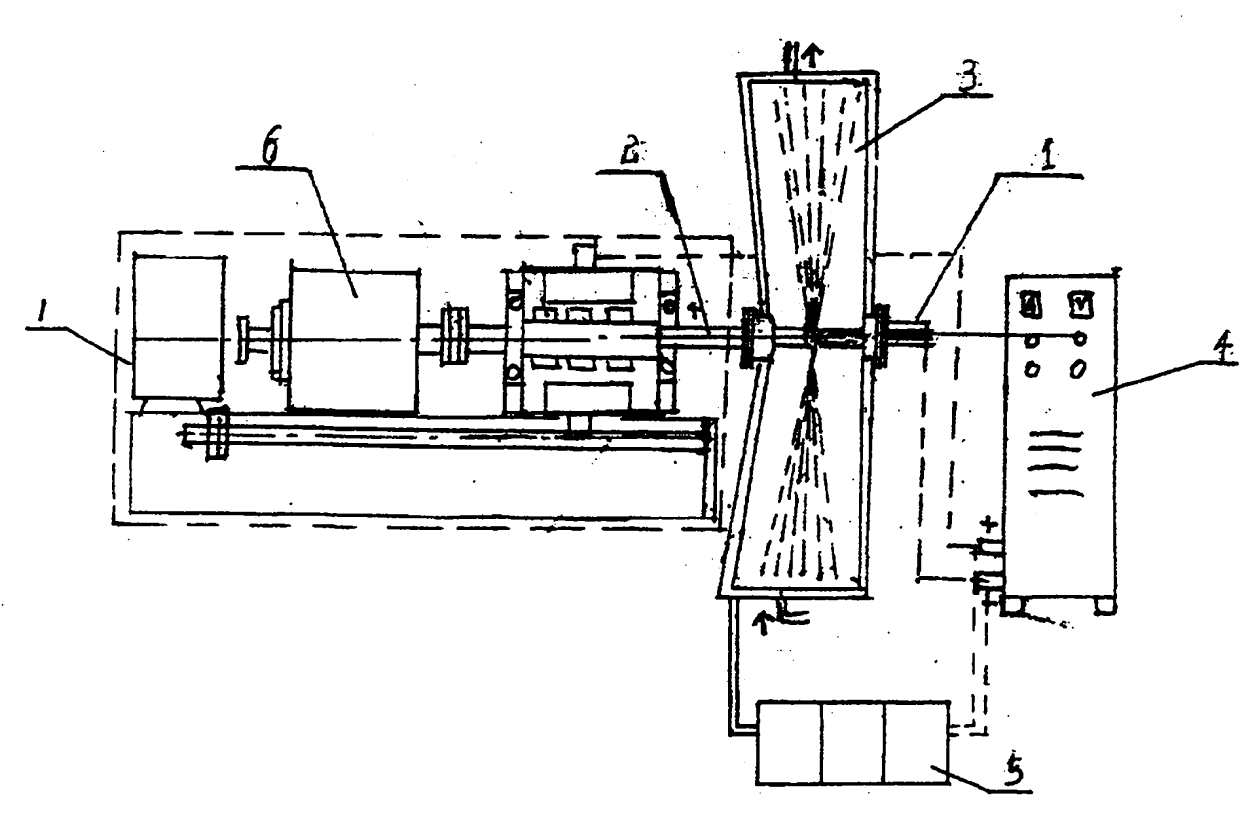

Symmetrical liquid drop injecting three-dimensional fast shaping method and apparatus thereof

The present invention belongs to rapid molding field of technology, which especially relates to a rapid shaping method and a device of metal. Inert gas used by the present invention is bled into a crucible and a vacuum tight chamber that can obtain steady differential pressure by means of pressure control system, which makes mental fusant ejected in the form of laminar jet from a micro-nozzle that is positioned on a bottom of the crucible. Vibration disturbance mental shooting flow produced by a piezoelectric oscillator turns metal shooting flow into uniform droplets. And real-time size parameters of the droplets mentioned-above can be obtained by monitoring system and computer analysis system. Subject to the size parameters of part that are input in advance, micro-computer control system has the real-time control for electrical field parameters of a deflexion polar plate, thus, controlling flight profile of the metal droplets and manufacturing metal parts with good quality in cooperation with a three-dimensional control station. The present invention is able to directly turn liquid metal into close-finished metal parts that are provided with rapid coagulation and delicate structure. The present invention has short technological process and products have good quality, which greatly reduces equipment investments.

Owner:TIANJIN UNIV

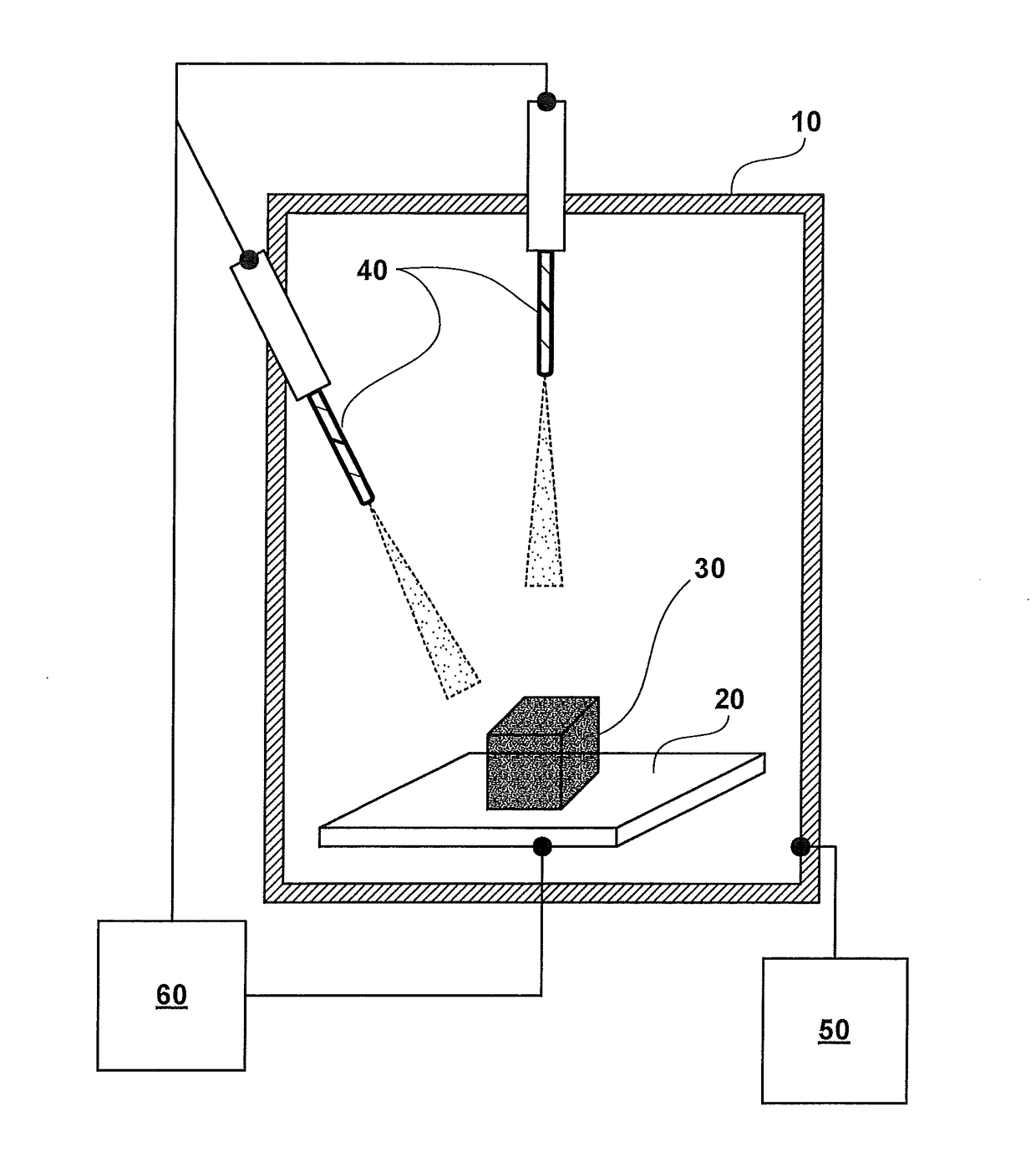

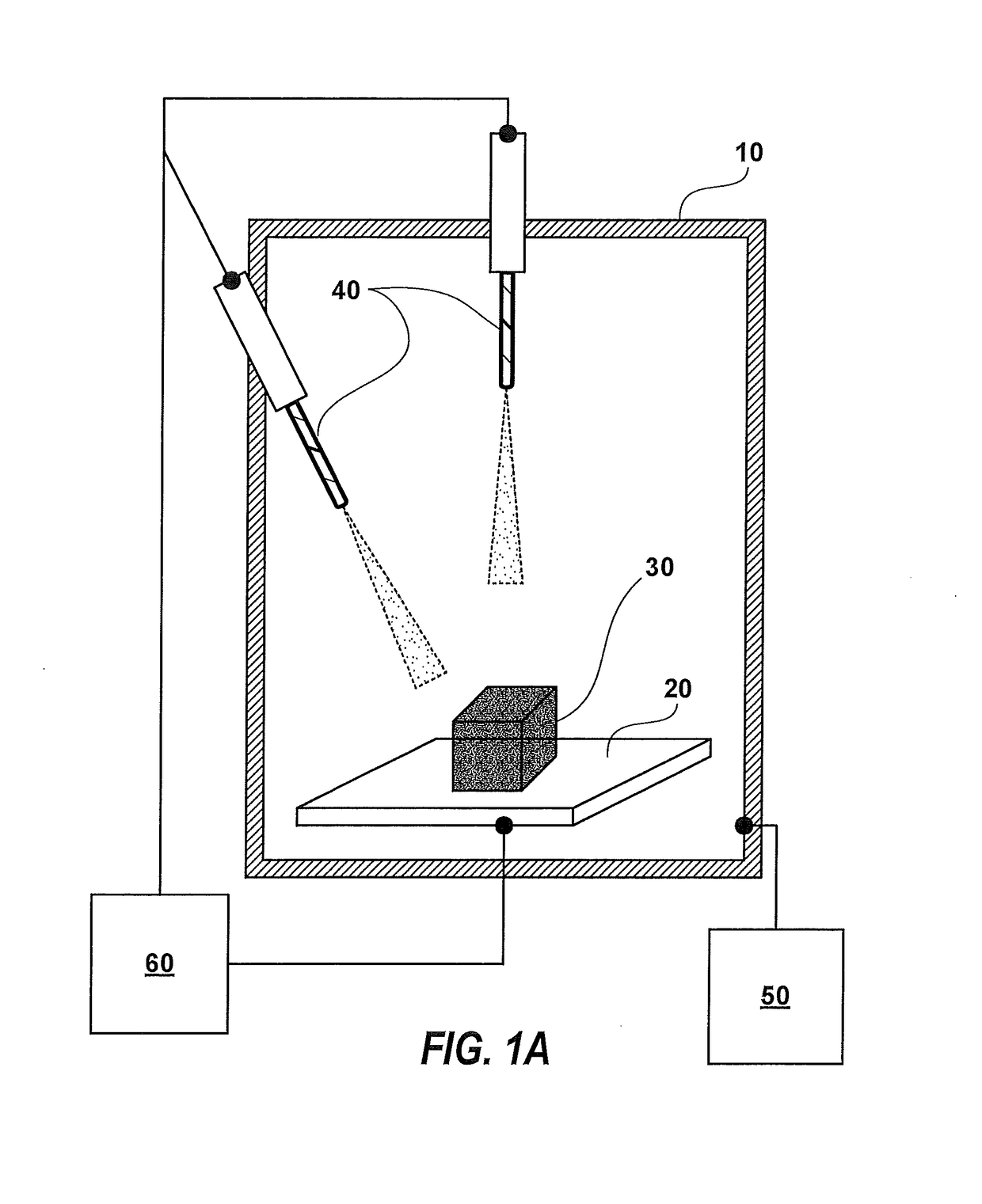

Systems and Methods For Depositing Charged Metal Droplets Onto A Workpiece

ActiveUS20170266728A1Additive manufacturing apparatusMolten spray coatingMetal dropletsVacuum chamber

Apparatus and methods are described for performing additive manufacturing. The apparatus includes a vacuum chamber for fabricating a workpiece composed of deposited metal, a table positioned within the vacuum chamber, and configured to support fabrication of the workpiece on a substrate, and one or more multiple droplet emitters coupled to the vacuum chamber, and arranged to irradiate the workpiece with a stream of molten metal droplets during fabrication.

Owner:3DAM TECH LLC

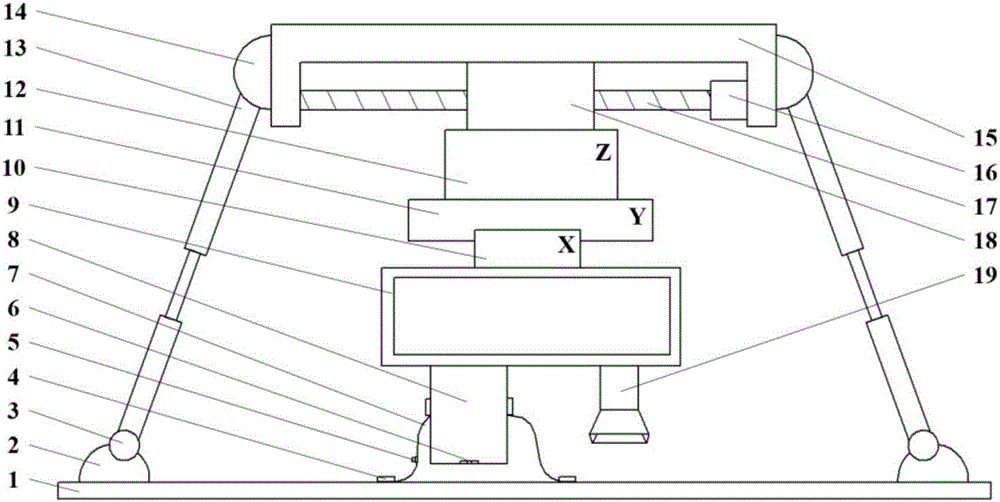

Device for realizing 3D metal printing by virtue of supporting structure

ActiveCN105618756AReasonable structureSimple structureAdditive manufacturing apparatusAutomatic controlShielding gas

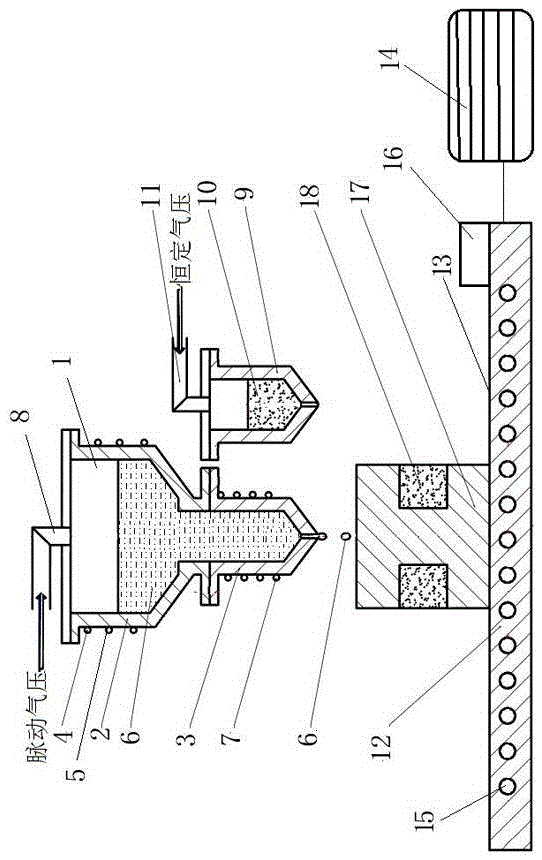

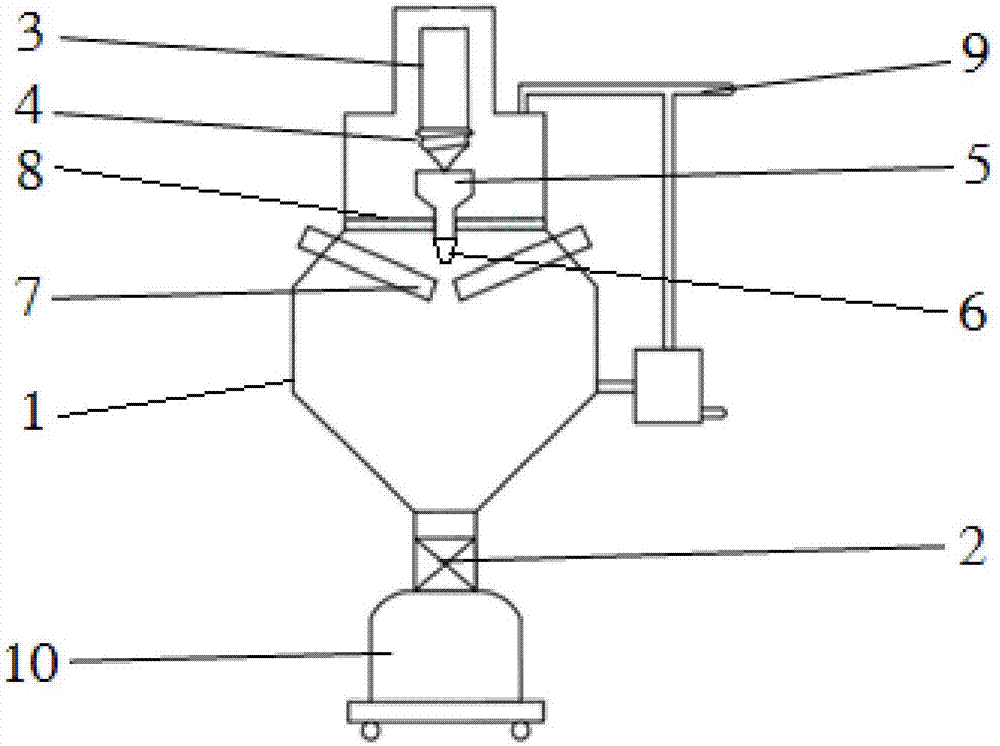

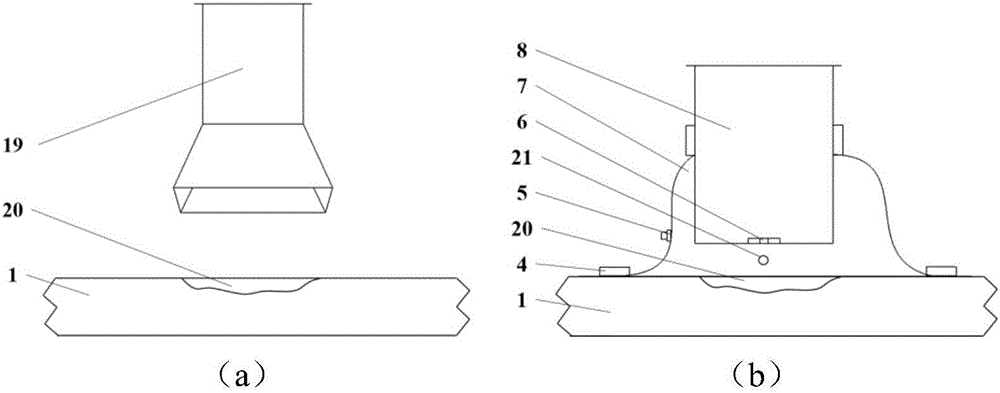

The invention relates to a device for realizing 3D metal printing by virtue of a supporting structure. The device comprises a translation stage capable of moving along the X-axis, the Y-axis and the Z-axis. Heating resistance wires and a thermocouple are arranged on a base plate of the translation stage. The heating resistance wires are used for preheating the base plate, so as to enable metal droplet layers to be tightly overlapped. The thermocouple is used for realizing the measurement and the feedback control of a temperature. An electromagnetic induction heating copper pipe and a cooling water pipe are arranged outside a graphite crucible, metallic raw materials are enabled to be molten to form molten metal, the bottom of the graphite crucible is connected with a metal printing spray nozzle, a protective gas is inputted from a gas inlet pipe at the top of the graphite crucible, and under the pulse pressure, molten metal forms regular metal droplets to drip to the base plate of the translation stage. The 3D metal droplet printing is realized through the cooperation with the movement of the translation stage. A supporting material spray nozzle is adjacent to the metal printing spray nozzle. A uniform mixture of gypsum and photosensitive resin is extruded stably under the constant pressure inputted by the gas inlet pipe so as to print the supporting part of a part. The switching between metal and the supporting material is automatically recognized and controlled by a control system. The 3D metal printing device is reasonable, high in operability, high in degree of automation, high in production efficiency, and suitable for being widely popularized, and ensures the molding quality.

Owner:STATE GRID CORP OF CHINA +5

Use of a Ni-base alloy for compound tubes for combustion plants

As tube material in waste incineration it has been found advantageous to use a composite tube wherein an inner tube component of a carbon steel or a low-alloy Cr-Mo-steel is metallurgically bonded to an outer tube component of Ni-Cr-Mo-Nb-Fe-alloy with an austenitic structure. The composite tube is fabricated by spraying finely distributed metal drops of the outer component onto the inner component in melt condition. After solidifying, the composite tube is then fabricated by joint extrusion.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

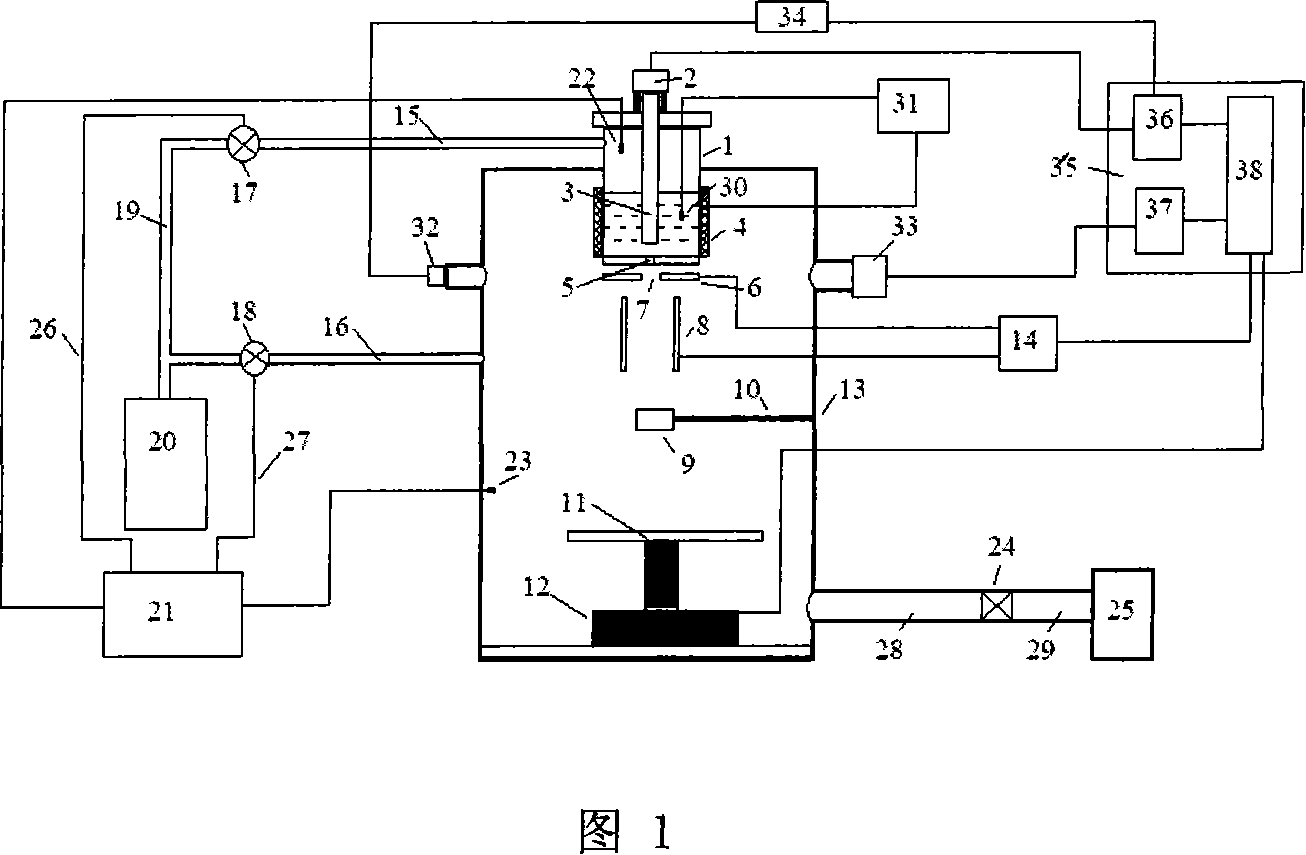

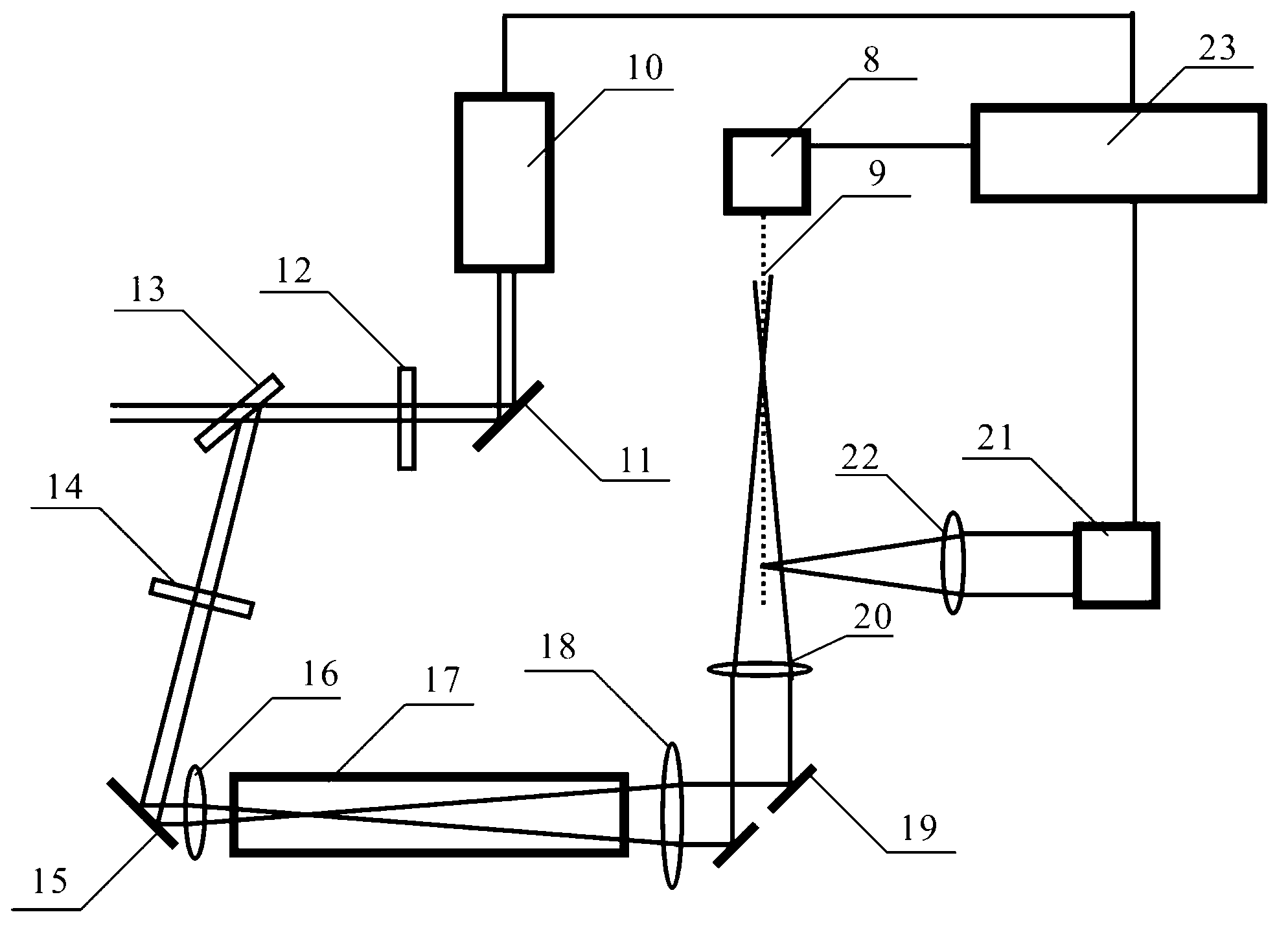

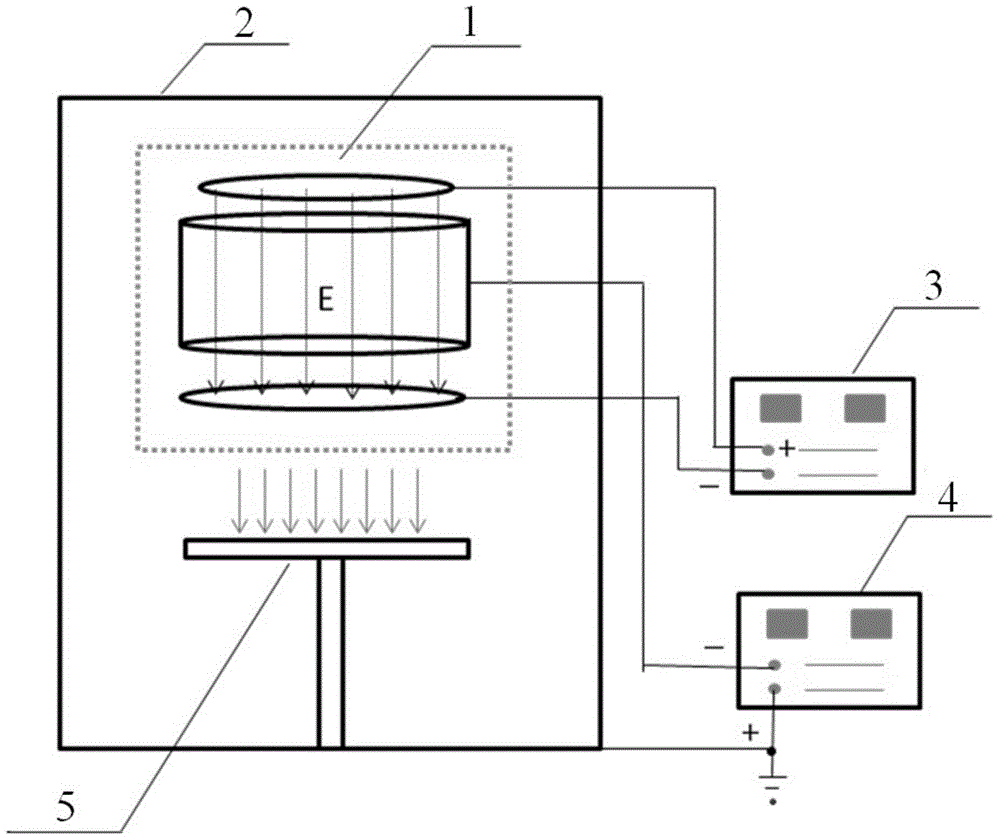

Preparation and forming integrated three-dimensional printing method and preparation and forming integrated three-dimensional printing device for amorphous alloy materials

ActiveCN105728728AGuaranteed amorphous propertiesAchieve preparationAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention relates to a preparation and forming integrated three-dimensional printing method and a preparation and forming integrated three-dimensional printing device for amorphous alloy materials, belonging to the technical field of micro-droplet jetting material increase manufacturing and amorphous alloy preparation. Crystalline molten metal is directly jetted by using a metal droplet jetting material increase manufacturing technology; environmental cooling of a substrate before metal droplet jetting and deposition droplet cooling after the metal droplet jetting are realized by adopting a method of combining a rotatable double-jetting liquid nitrogen cooling device with a cold substrate; and by using a point-to-point cooling method for two times, the molten metal can be quenched and amorphized, and further the integration of preparation of the amorphous alloy materials and three-dimensional forming of a large-size complex structure are realized. According to the preparation and forming integrated three-dimensional printing method and the preparation and forming integrated three-dimensional printing device disclosed by the invention, the limit of a traditional preparation method of an amorphous alloy in a forming critical dimension of a bulk amorphous alloy is overcome; the defects of crystallization behavior and buckling deformation generated in the selective laser melting three-dimensional printing process of amorphous alloy powder are avoided; and the problem that the amorphous alloy materials are difficult to machine is solved, and the preparation and structure forming integrated three-dimensional printing of the amorphous alloy materials is realized.

Owner:JILIN UNIV

Molten metal droplet forming device and method of utilizing same to form molten metal droplets

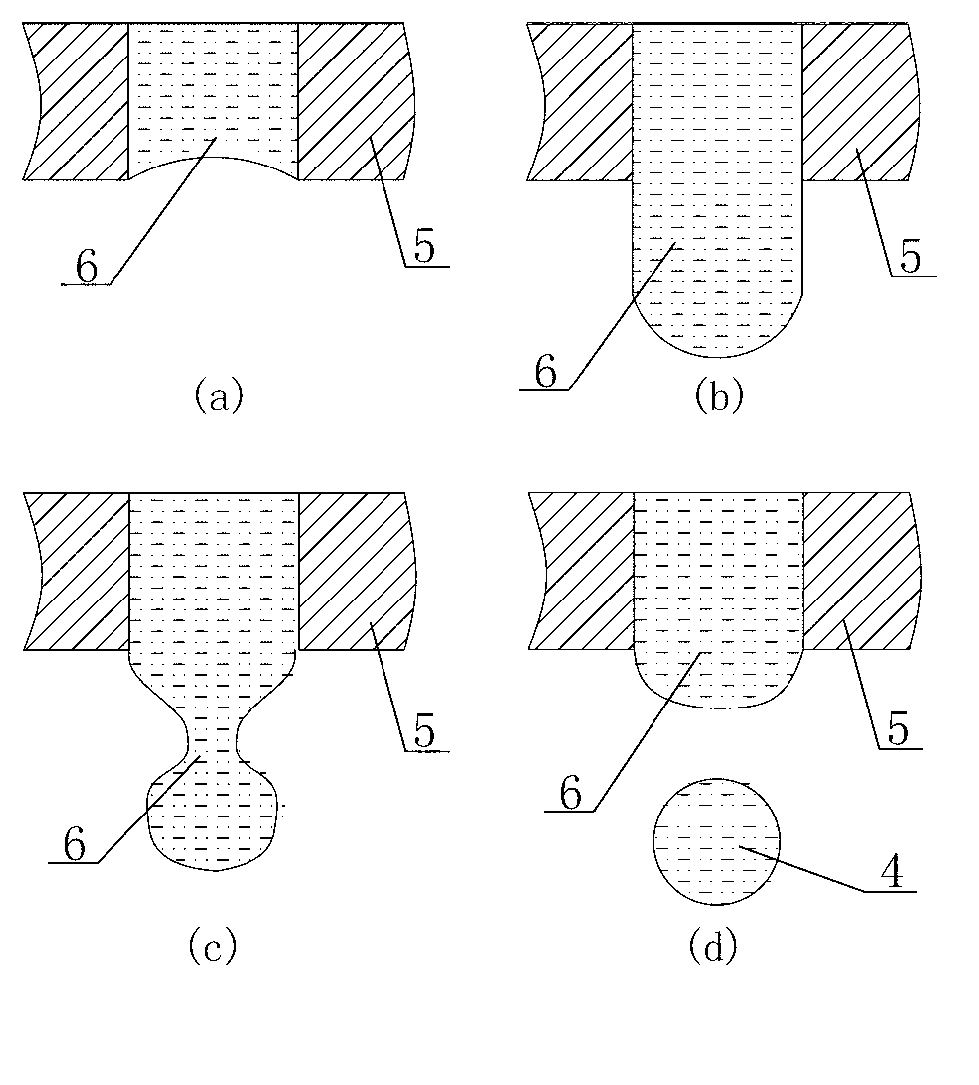

The invention discloses a molten metal droplet forming device and a method of utilizing the same to form molten metal droplets. The device and the method are used for solving the technical problem that size of molten metal drops formed by spraying by means of a molten metal drop spraying device is difficult to control. The technical scheme includes that a spherical energy focalizer in an axially concave shape is designed at the lower end of a cylindrical rod 13-b of a 'T'-shaped rod 13, by the focusing action of the 'T'-shaped rod energy focalizer, stress wave energy is enabled to intensively act on a free liquid level position of a nozzle outlet below a crucible to generate droplets, stress wave generated when an impact rod impacts the 'T'-shaped rod during droplet spraying is controlled, the size of the molten metal drops is determined by loaded stress wave, and metal droplets with the diameter smaller than that of spraying holes can be sprayed to achieve the purpose of controlling the size of the molten metal droplets by controlling relevant parameters generating the stress wave.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

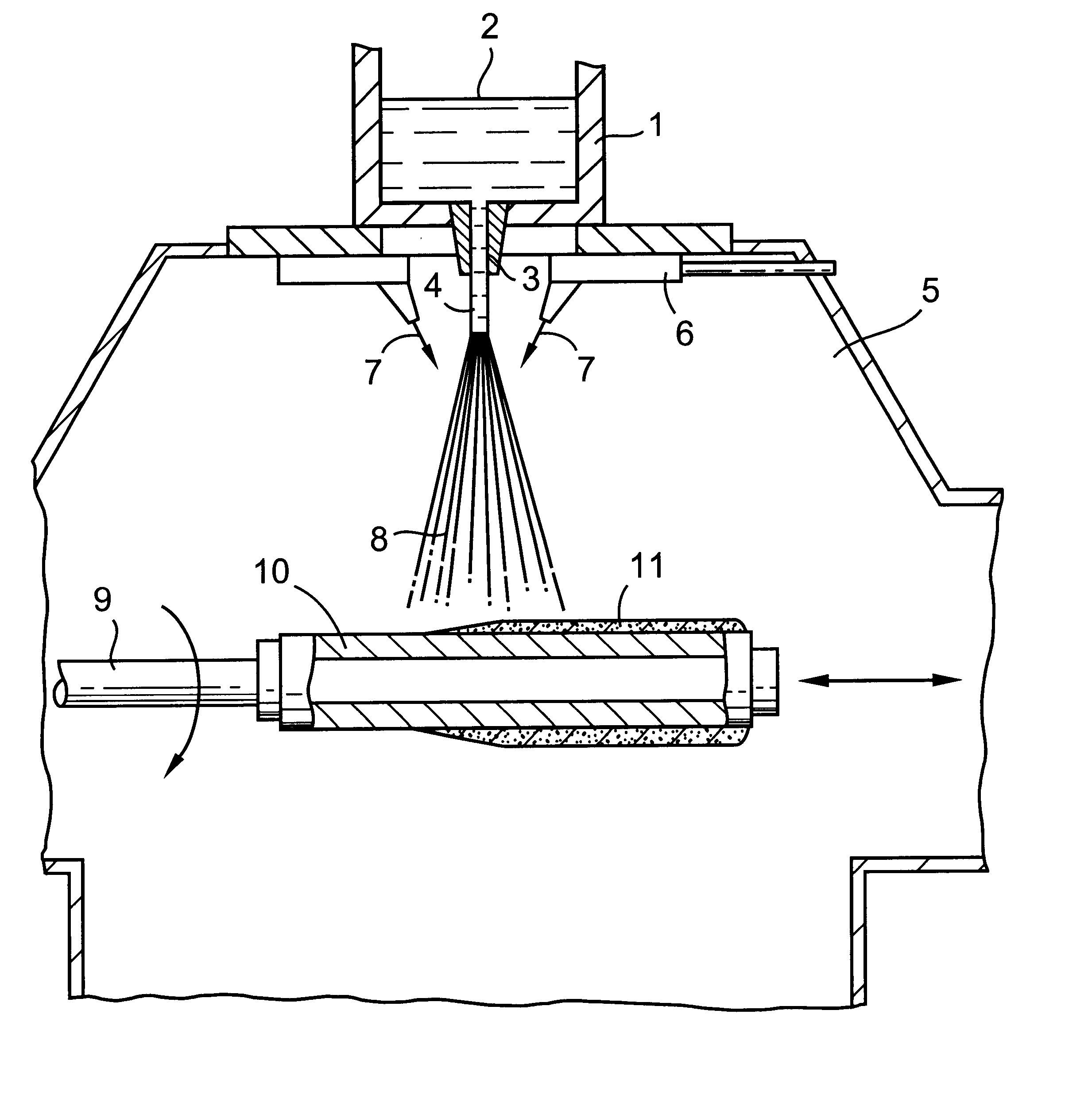

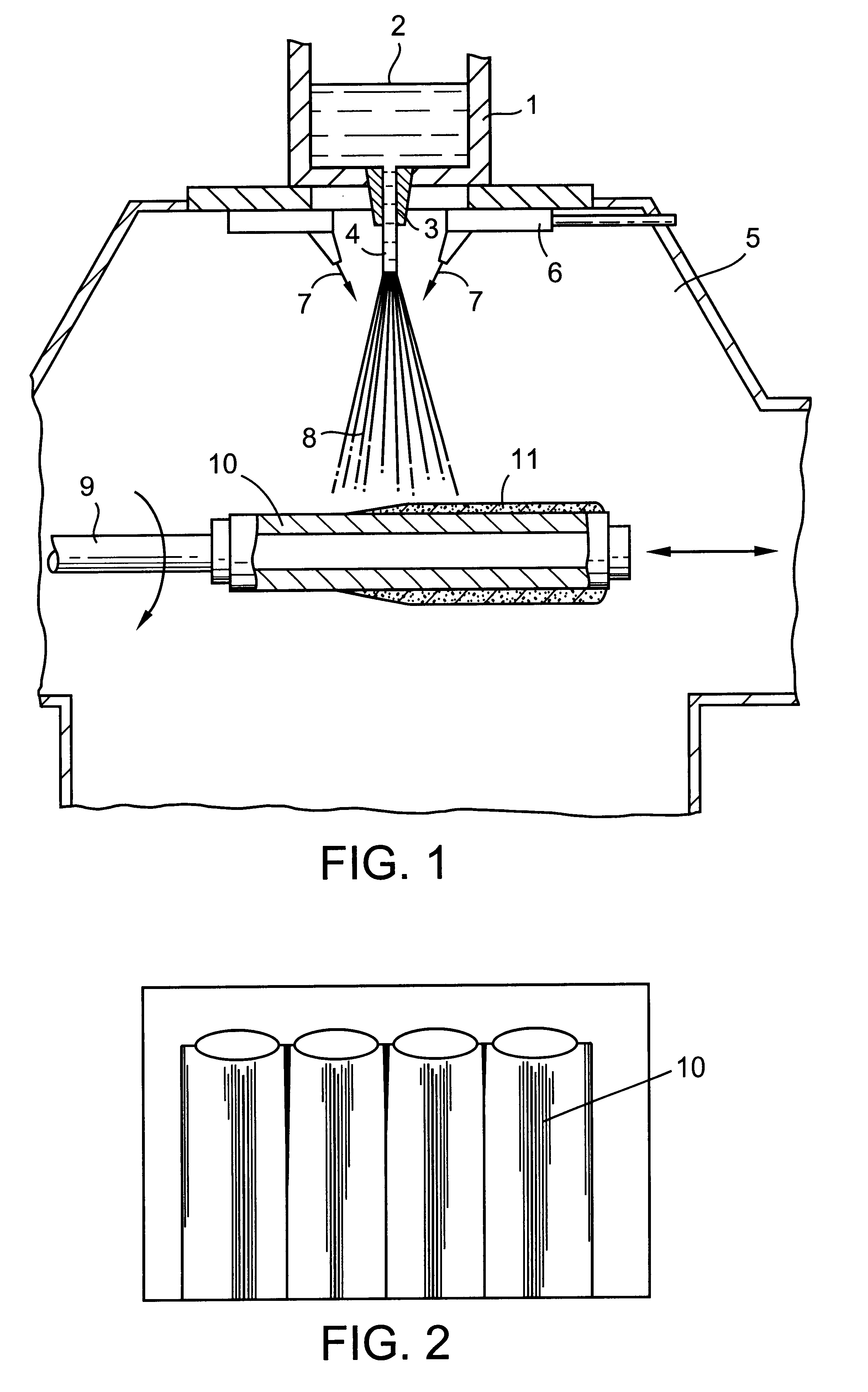

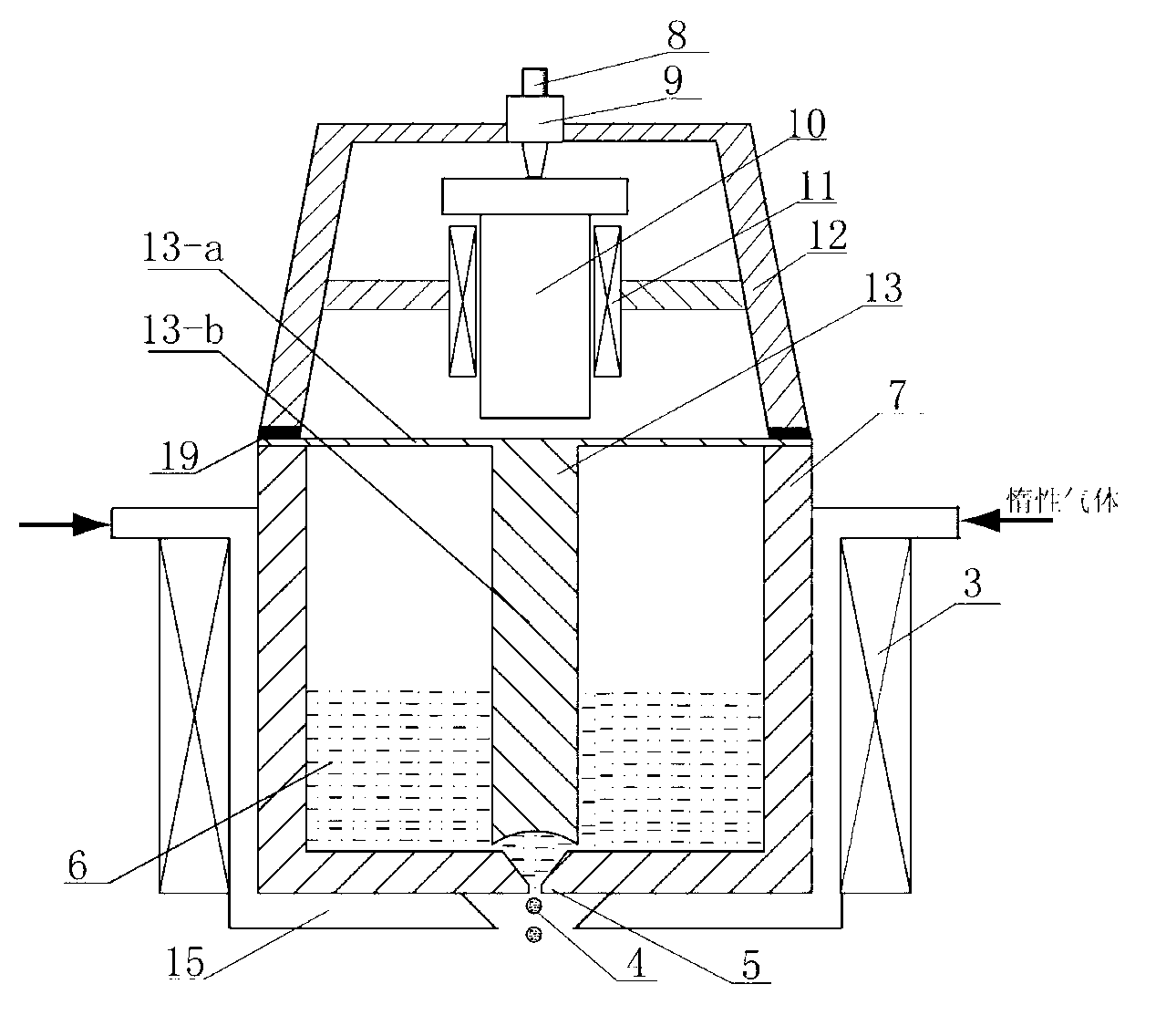

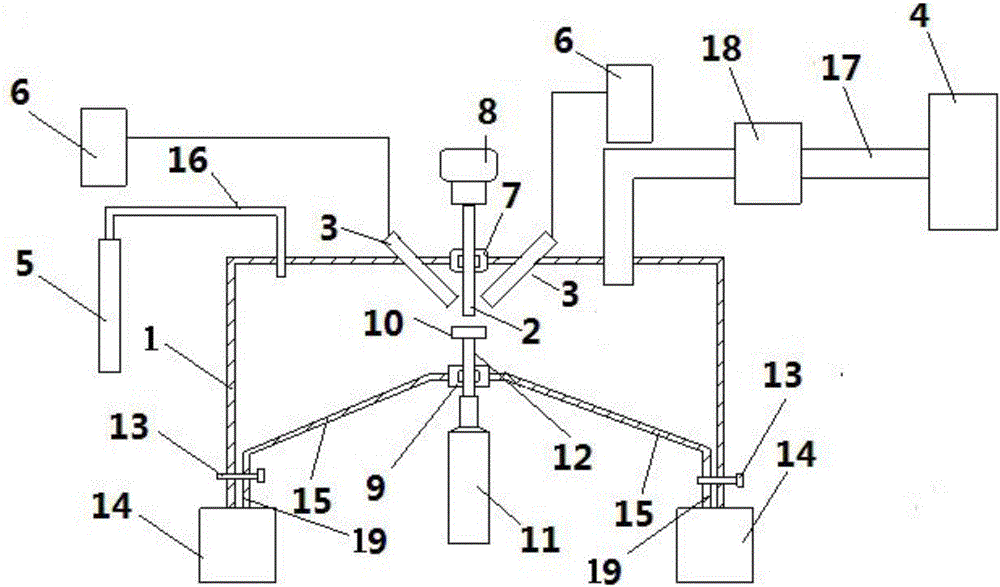

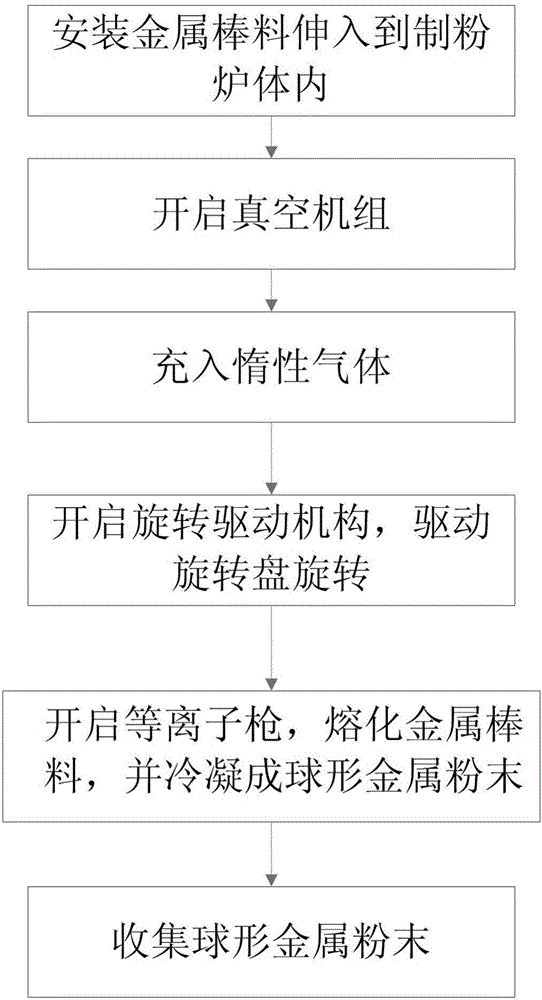

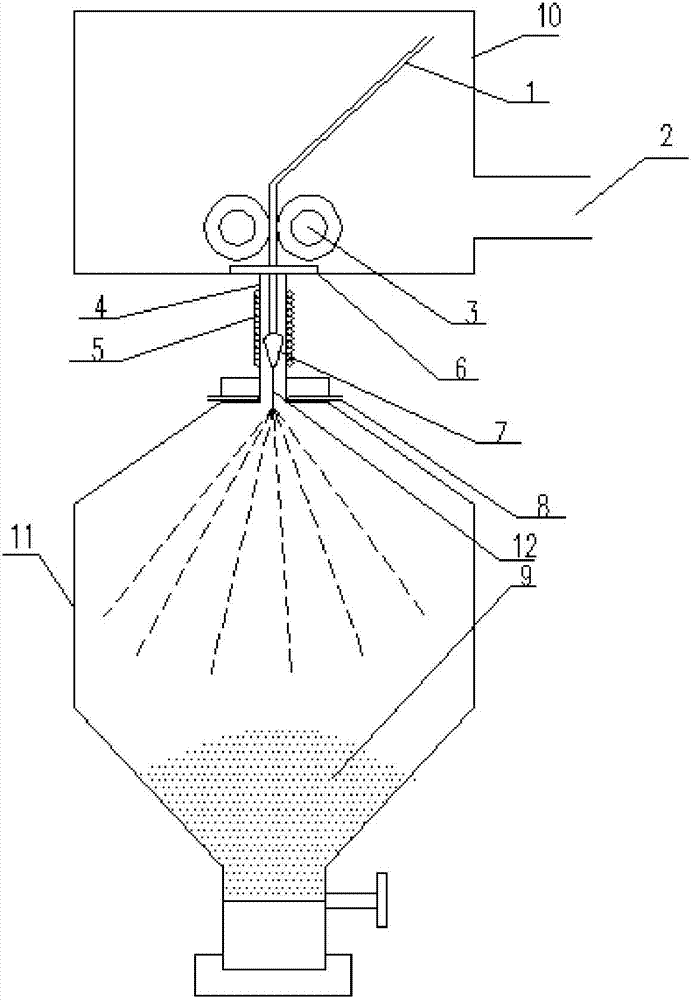

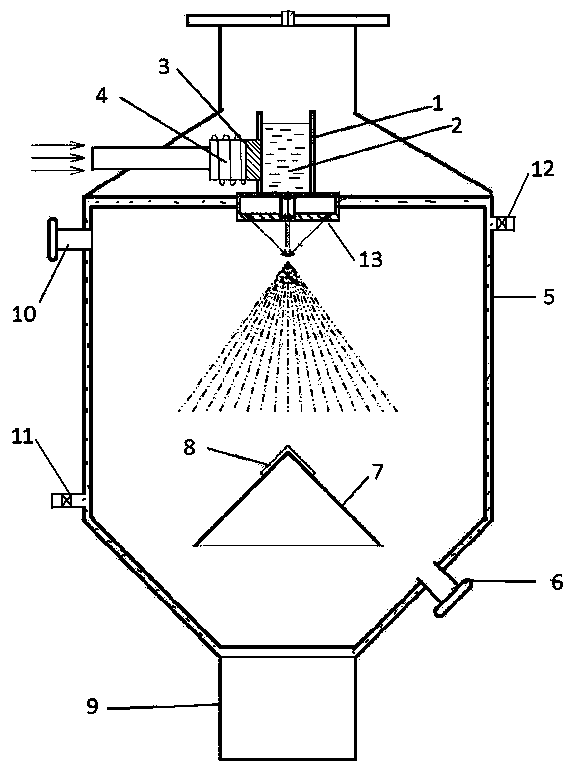

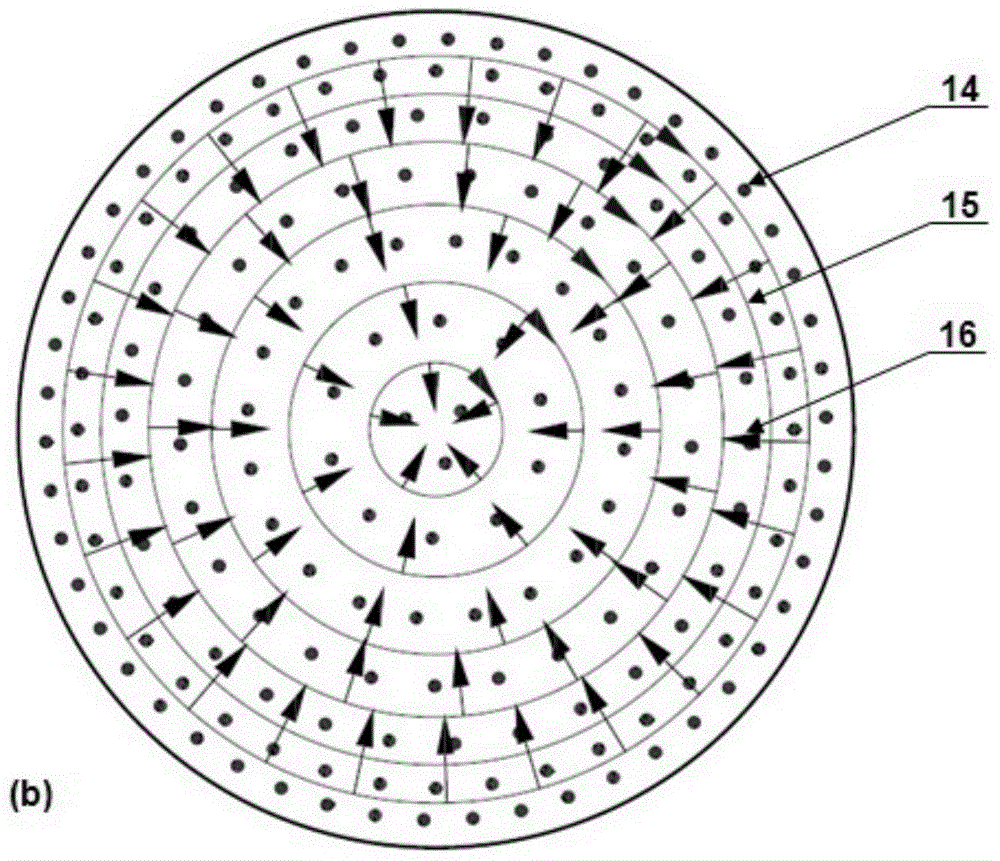

Device and method for preparing spherical metal powder

InactiveCN105665730AIncrease energy densityImprove energy utilizationTransportation and packagingMetal-working apparatusCentrifugal forceMetal powder

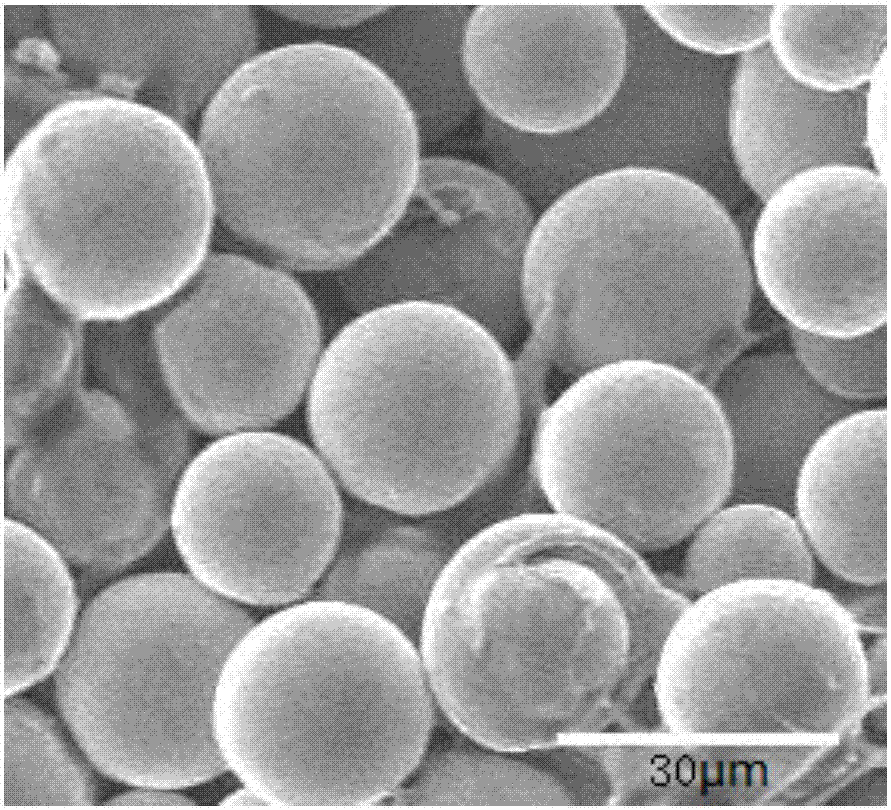

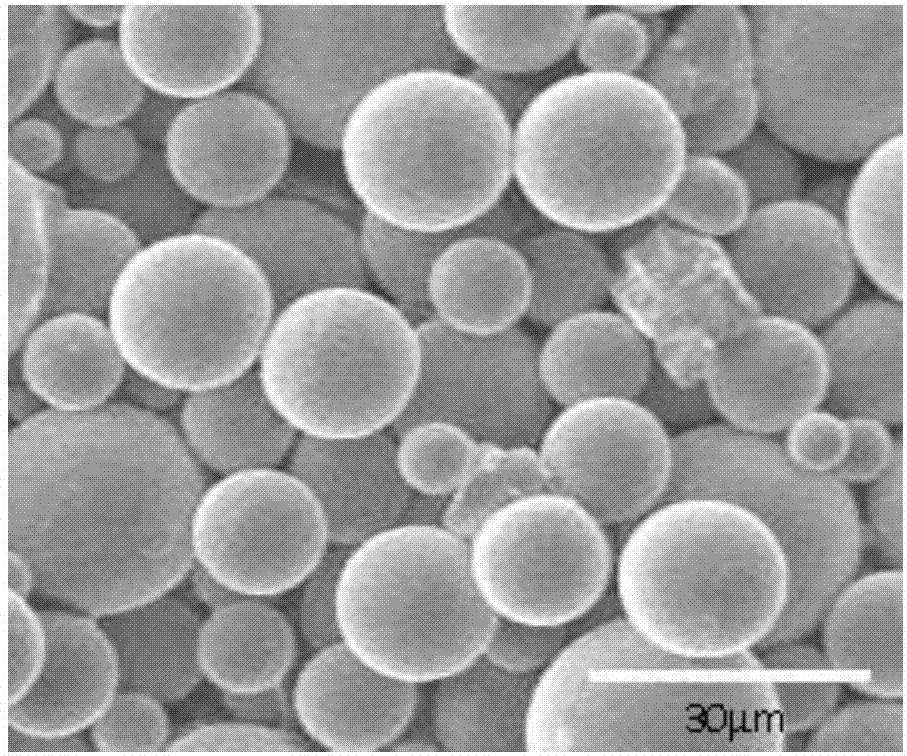

The invention belongs to the technical field of powder metallurgy, and particularly relates to a device and method for preparing spherical metal powder. The device comprises a metal bar, at least one plasma gun and a rotating disk; the metal bar is arranged in the center of the top of a furnace for preparing powder; the plasma guns are arranged around the metal bar, and predetermined angles are formed between the plasma guns and the metal bar; the rotating disk is arranged under the metal bar; the furnace for preparing the powder is filled with inert gas. According to the preparation method, plasma arcs generated by the plasma guns are adopted to melt the metal bar, generated metal droplets fall on the rotating disk rotating at a high speed, the metal droplets are thrown out and scattered through centrifugal force, and the metal powder with the fine particle size is formed after the metal droplets are cooled. According to the device and method for preparing the spherical metal powder, the structure is simple, the running cost and energy consumption are low, and the spherical metal powder prepared through the method is high in degree of sphericity, fine in particle size and high in purity.

Owner:西安赛隆增材技术股份有限公司

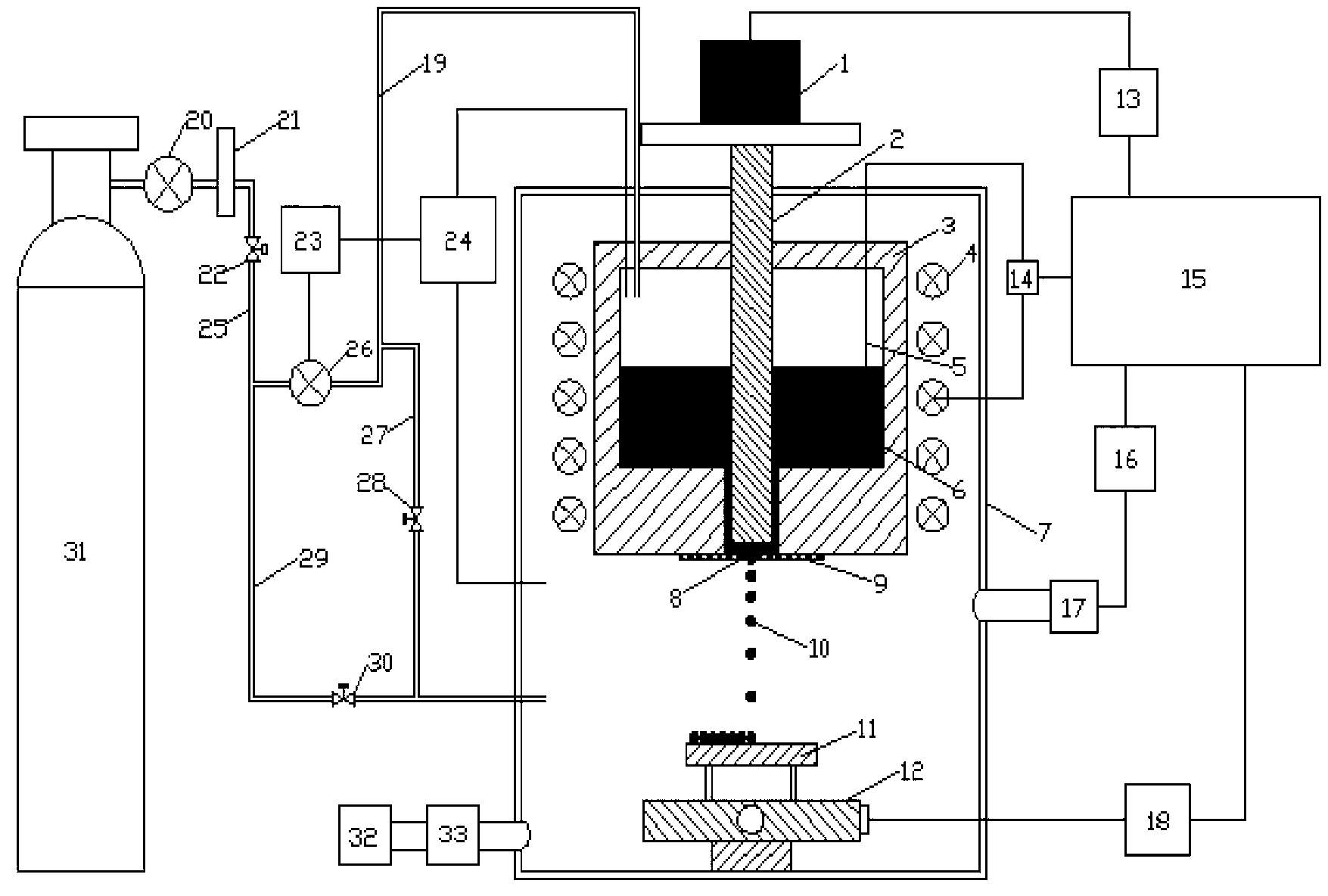

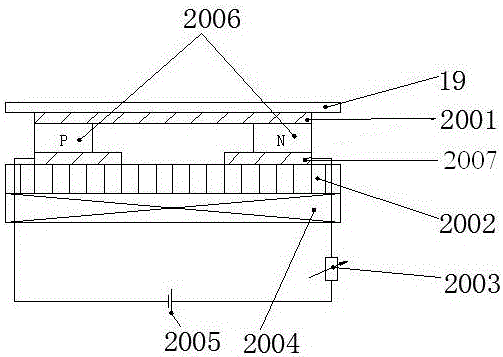

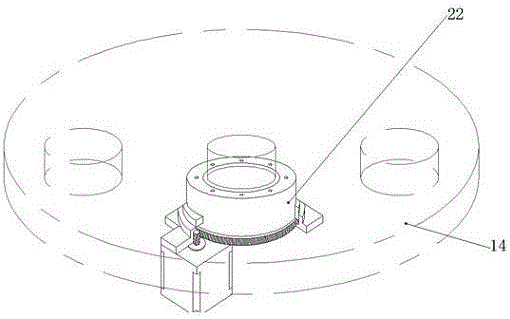

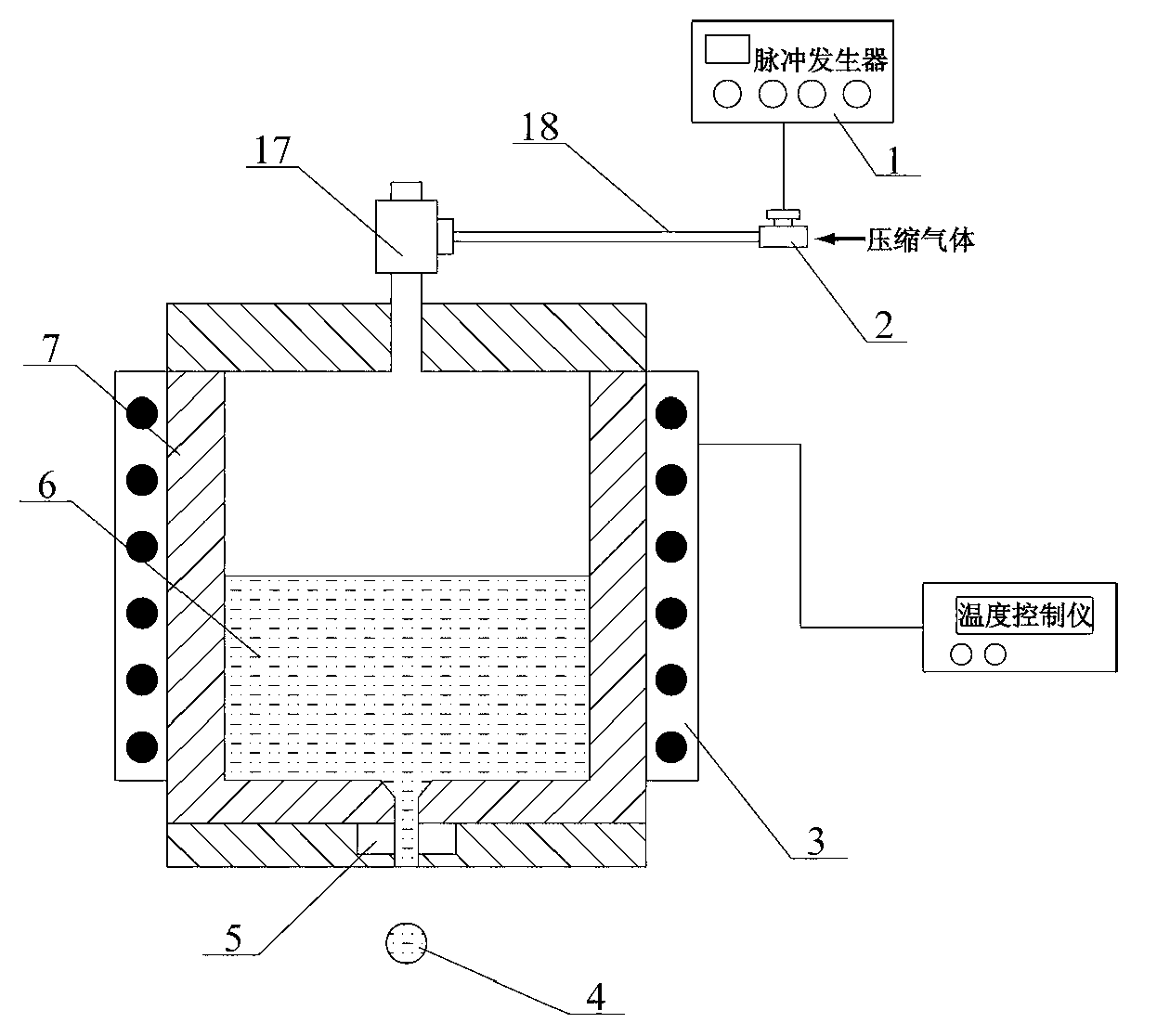

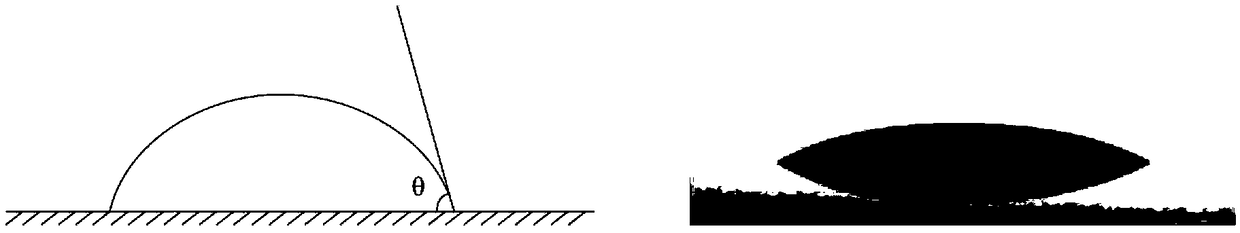

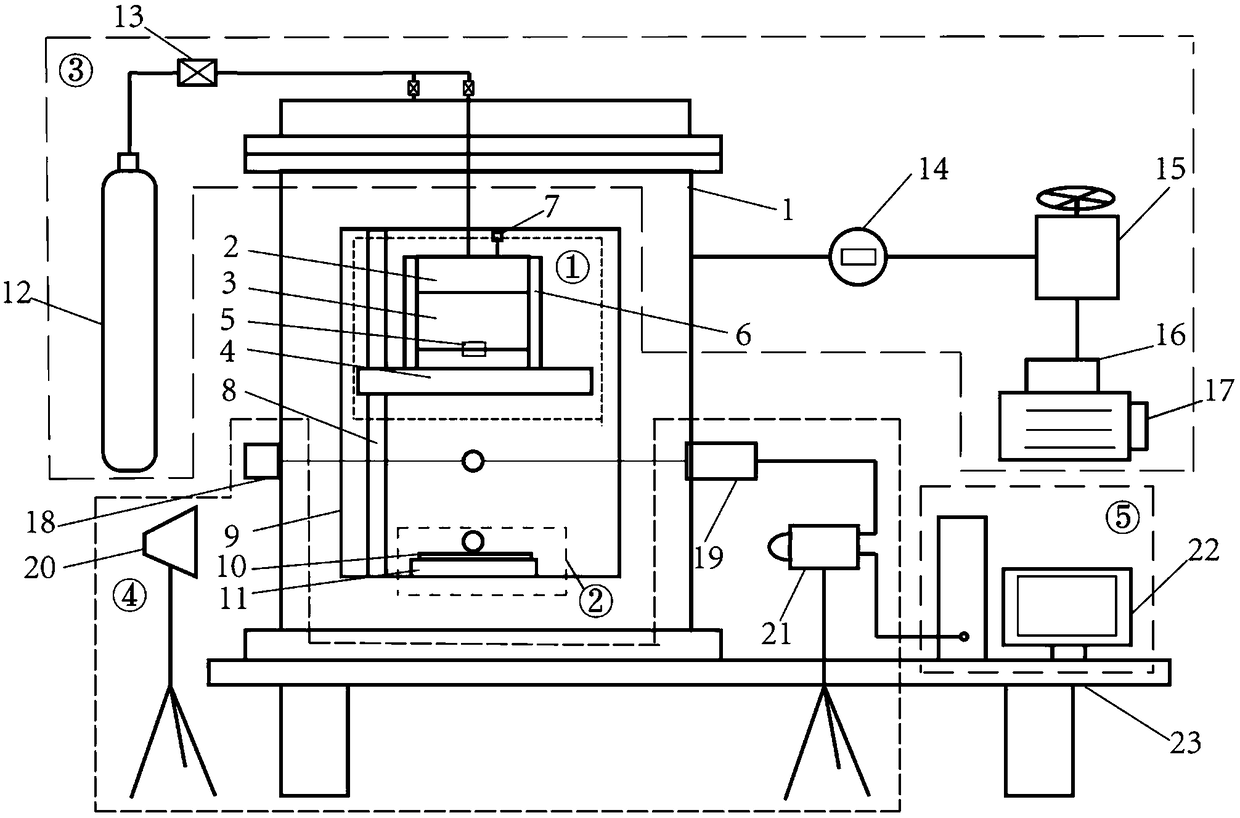

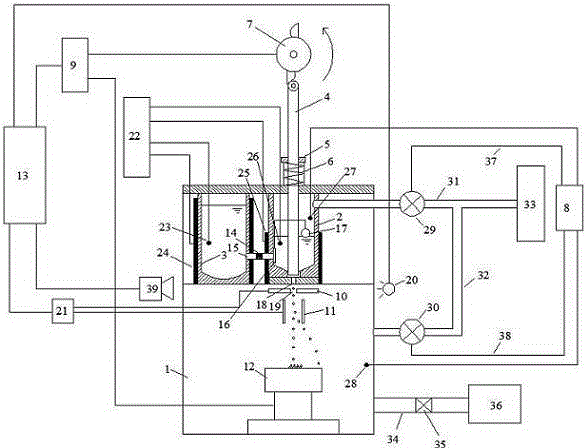

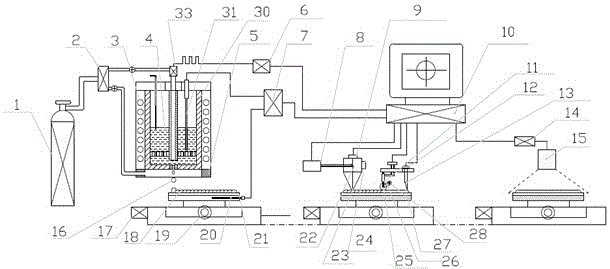

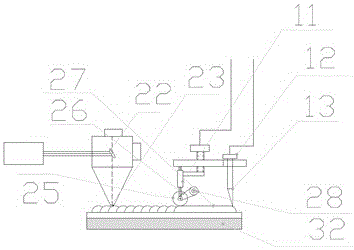

Experiment device and method of wall collision of high-temperature molten metal droplets in negative pressure environment

InactiveCN109253947AAvoid deformation and breakageEasy to replaceSurface/boundary effectImaging analysisAmbient pressure

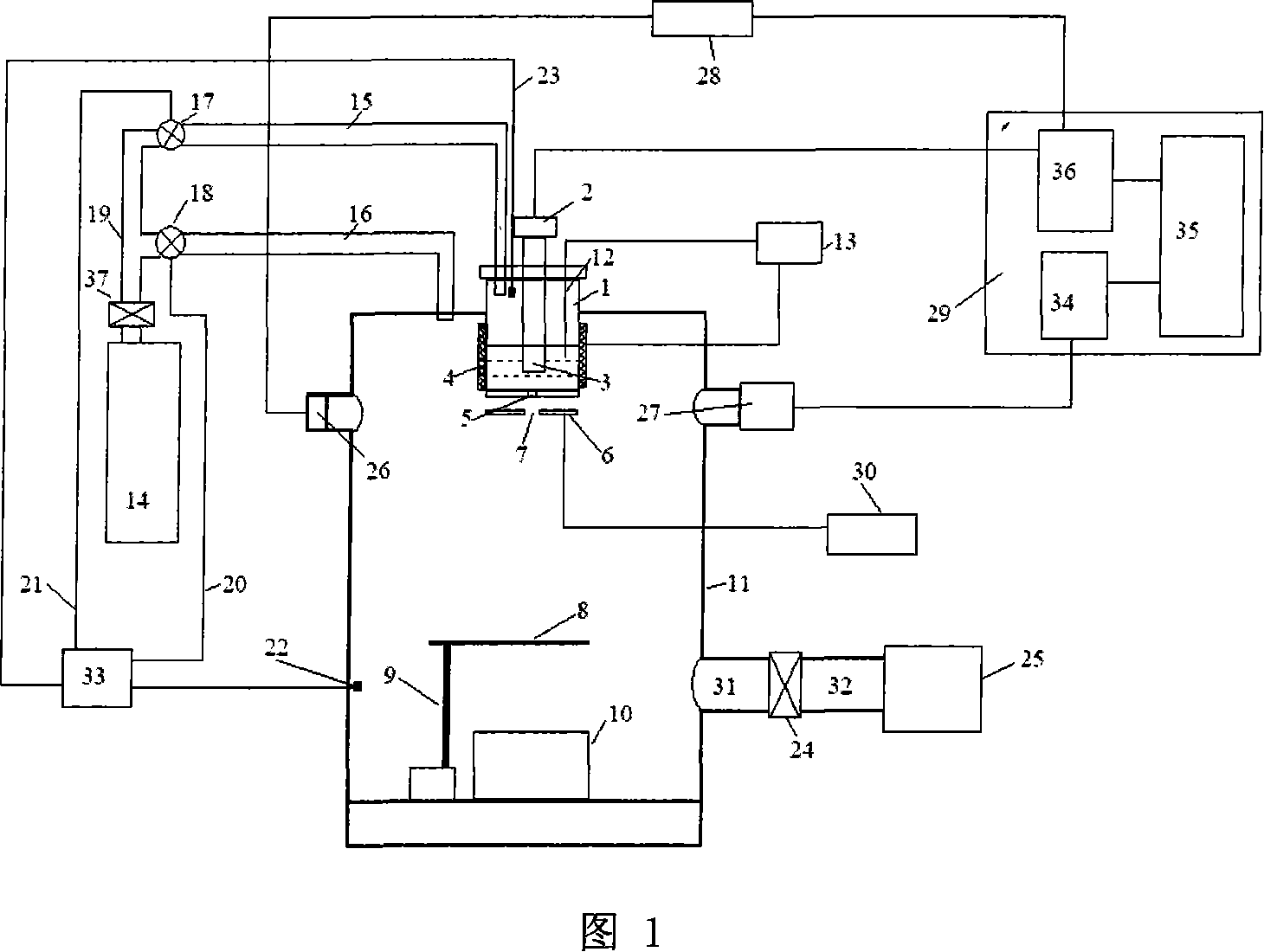

The invention discloses a visualization experiment device and method of wall collision of high-temperature molten metal droplets in a negative pressure environment. The experiment comprises: an air flotation damping experiment table, a metal droplet generation system, a temperature controllable wall surface system, an environment pressure adjustment system, an automatic trigger high-speed camera system and an image analysis system. The metal droplet generation system generates metal droplets; the environment pressure adjustment system realizes the precise control of the environment pressure within a greater negative pressure range when the droplets collide the wall surface; and the automatic trigger high-speed camera system records an image when the droplets collide the wall surface, and finally, the image analysis system performs quantitative analysis on a video to provide accurate physical variables such as a droplet speed, a droplet diameter, a spreading radius, a height and deformation characteristics. By adoption of the experiment method, the metal droplets can be generated in the negative pressure environment, and an experiment scheme is provided for the mechanism research ofthe movement characteristics when the metal droplets collide the wall surface. The method is simple in operation, safe and reliable in process, and wide in experiment research application value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

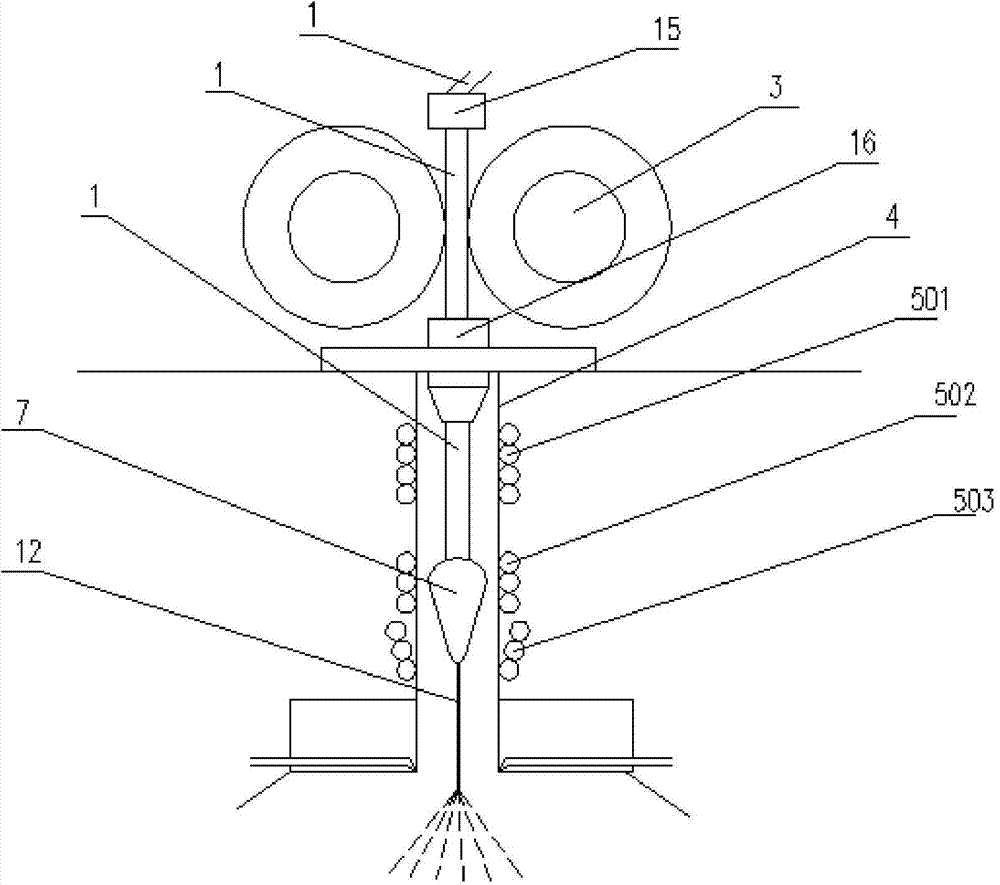

Method and device for metal powder preparation based on controllable magnetic levitation melting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

Method for preparing flaky metal powder

InactiveCN101898249AContinuous and efficient preparationReduce processing stepsLiquid metalDouble stage

The invention relates to a method for preparing flaky metal powder by deforming metal droplets by double-stage atomization, and belongs to the technical field of metal powder preparation. The method comprises the following steps of: heating metal to melt the metal, overheating the liquid metal and preserving the heat; guiding the liquid metal into a tundish crucible; pouring the liquid metal on a rotating disk atomizer with a rotation speed of between 5,000 and 50,000r / m by using a guide nozzle at the bottom of the tundish crucible at a stable flow rate (1 to 100 gram / second); atomizing the liquid metal into fine metal droplets under the action of centrifugal force; and colliding the metal droplets flying at a high speed with the inner wall of a water-cooled metal (copper, molybdenum, stainless steel and the like) roll with the rotation speed of between 1,000 and 20,000r / m (or the linear velocity of the surface of the roll is 0 to 100m / s) to deform and rapidly condensing the droplets into flaky powder. The obtained flaky metal powder is in the shape of a regular or irregular circular disk with a microcrystalline, nanocrystalline or non-crystalline structure. The method and equipment have the advantages of simple process, high efficiency, high powder quality and suitability for industrial production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation device and method for superfine metal powder

ActiveCN106914626AHigh shapeReduce consumptionAdditive manufacturing apparatusMolten stateMetal droplets

The invention discloses a preparation device and method for superfine metal powder. The preparation method comprises the steps that a metal rod is vertically fixed to a heating device and is heated and melted, molten metal droplets drop into a lower centrifugal device, and thin-layer molten state metal droplets are formed on the wall surface of the centrifugal device under the action of centrifugal force, downwards flow, and drop into lower hot gas devices; and the hot gas devices are at least three gas nozzles uniformly surrounding the lower portion of the centrifugal device, the nozzles spray hot gas onto the molten state metal droplets, hot gas breaking melting is conducted, broken droplets are solidified into small-size powder particles in the falling process, and the powder particles fall into a recycling device, so that the superfine metal powder is obtained. The metal powder obtained through the preparation method is small in particle size and high in powder sphericity degree. In addition, the preparation device is simple in structure, simple in preparation process, high in operability, low in inert gas consumption, high in production efficiency and wide in application field.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

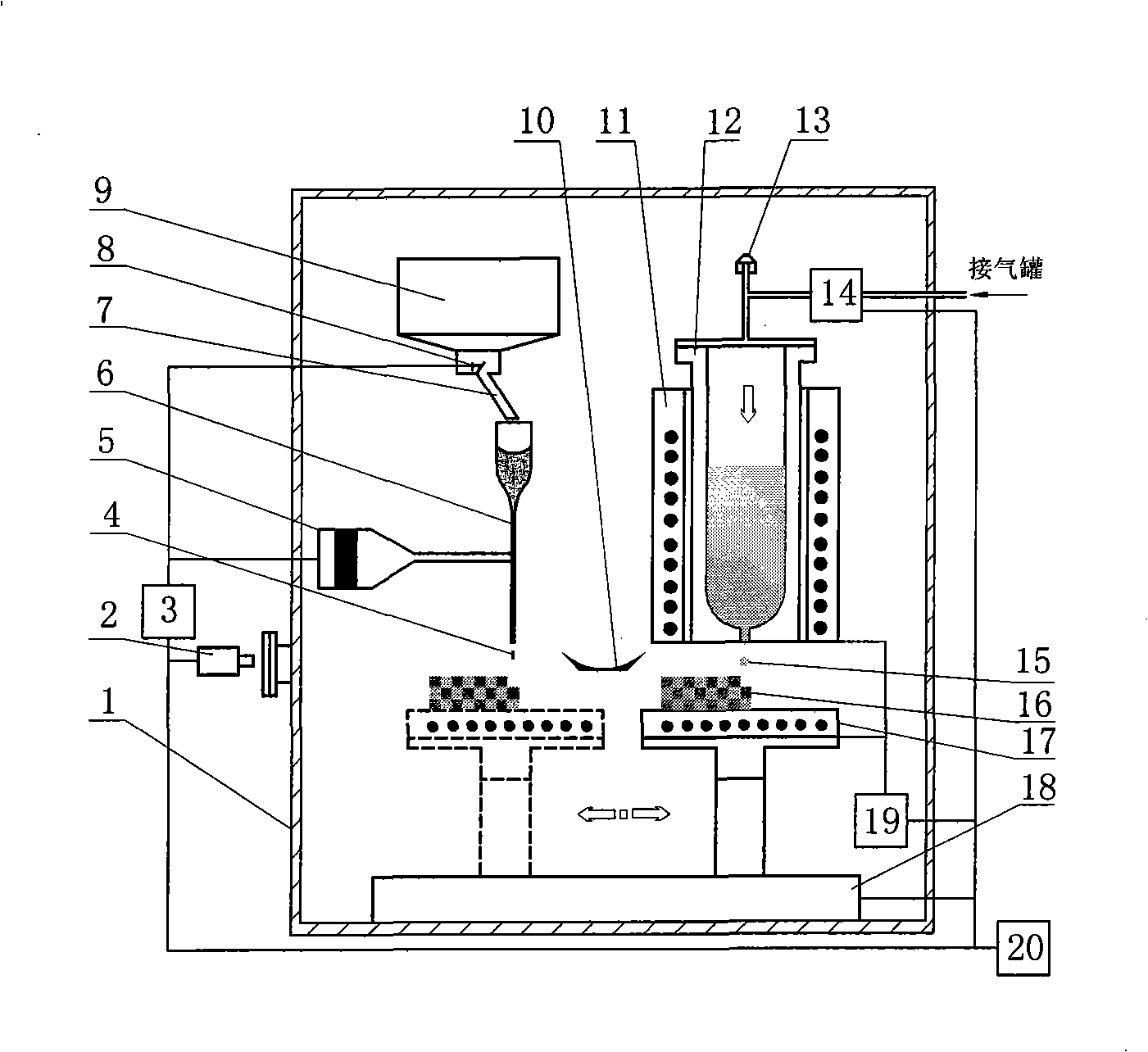

Even-sized particles producing device and method for preparing the same

The present invention belongs to technology field of manufacturing metal powder, which specifically relates to a method and a device of manufacturing spheroid metal and alloy granular by making use of uniform liquid drop spray application techniques. Inert gas used by the present invention is bled into a crucible and a vacuum tight chamber that can obtain steady differential pressure by means of pressure control system, which makes mental fusant ejected in the form of laminar jet from a micro-nozzle positioned on a bottom of the crucible. Vibration disturbance mental shooting flow produced by a piezoelectric oscillator turns metal shooting flow into uniform droplets. And real-time size parameters of the droplets mentioned-above can be obtained by camera system and computer analysis software. Subject to the optimum parameters, frequency of control oscillator is fed back, thereby reducing size error of the metal droplets and predetermined droplets. The present invention is able to directly manufacture granular that is homogenized in size, shape and thermodynamic condition. The present invention has short technological process and products have good quality, which greatly reduces equipment investments.

Owner:TIANJIN UNIV

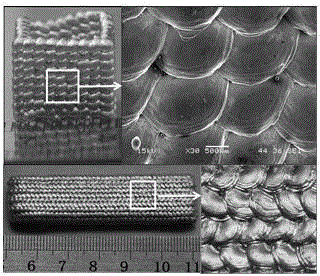

Method and device for preparing lattice structure parts from uniform metal droplets

InactiveCN105945285AQuality assuranceSolve build problemsAdditive manufacturing apparatusLiquid metalPressure difference

Owner:江西瑞曼增材科技有限公司

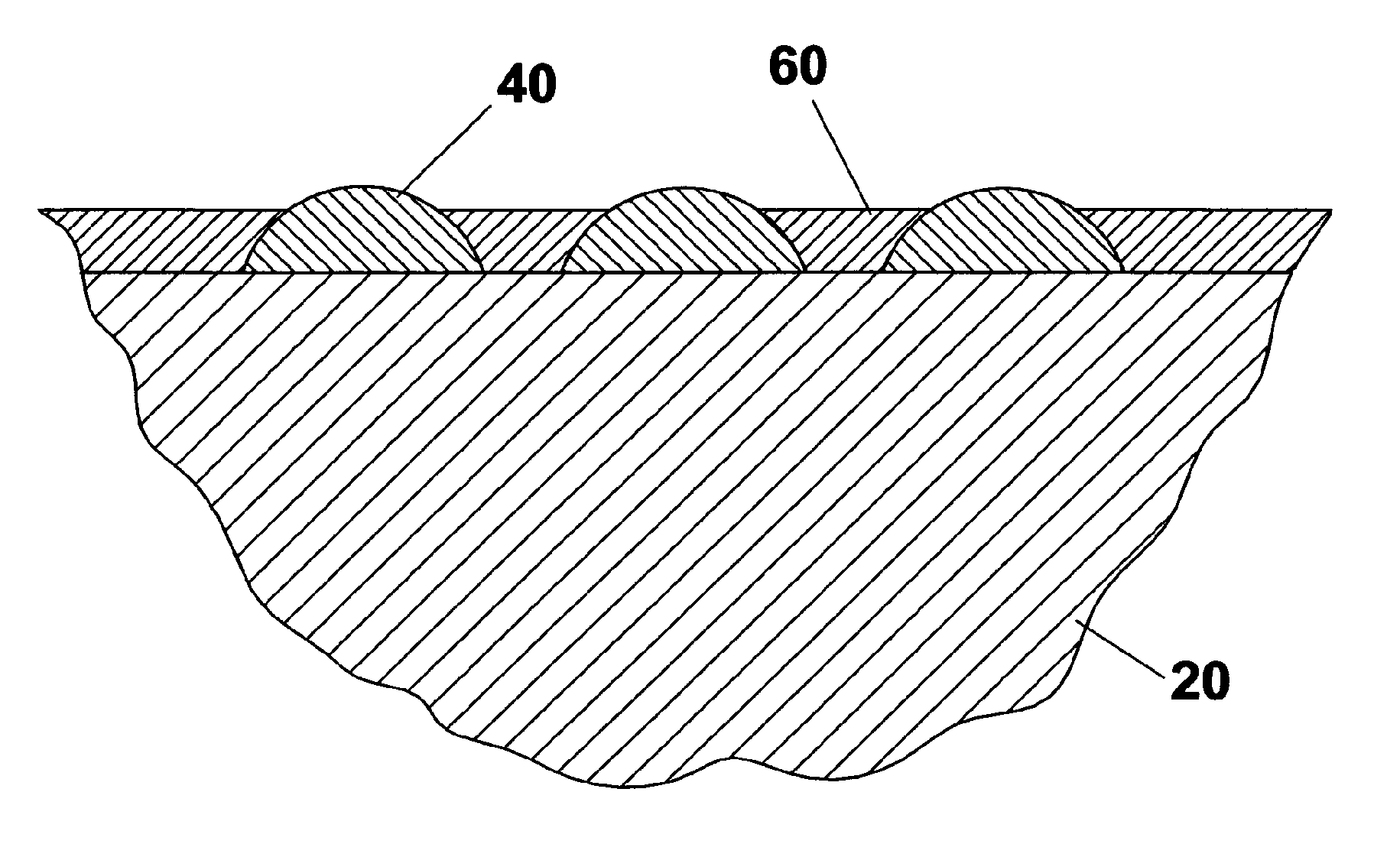

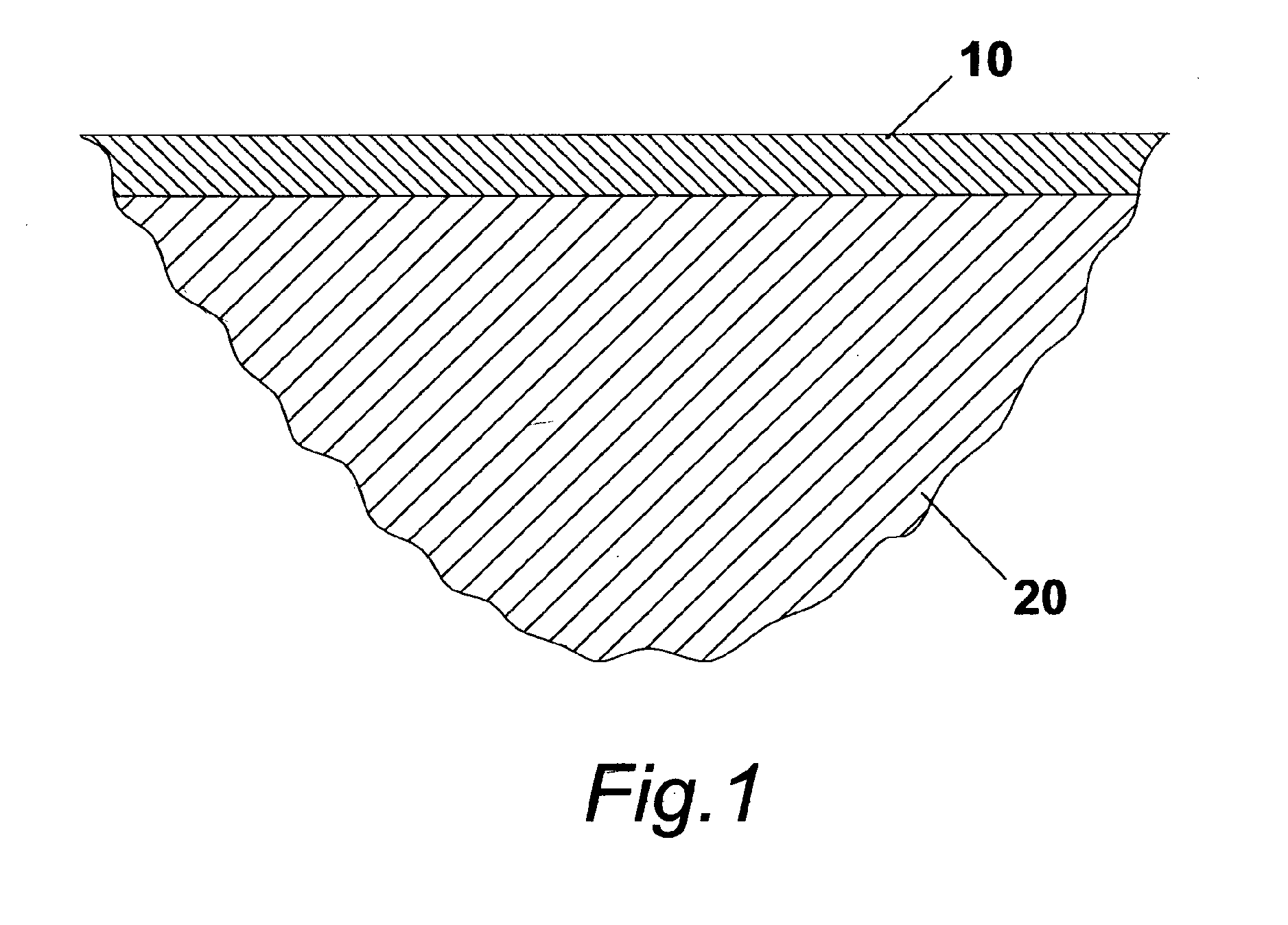

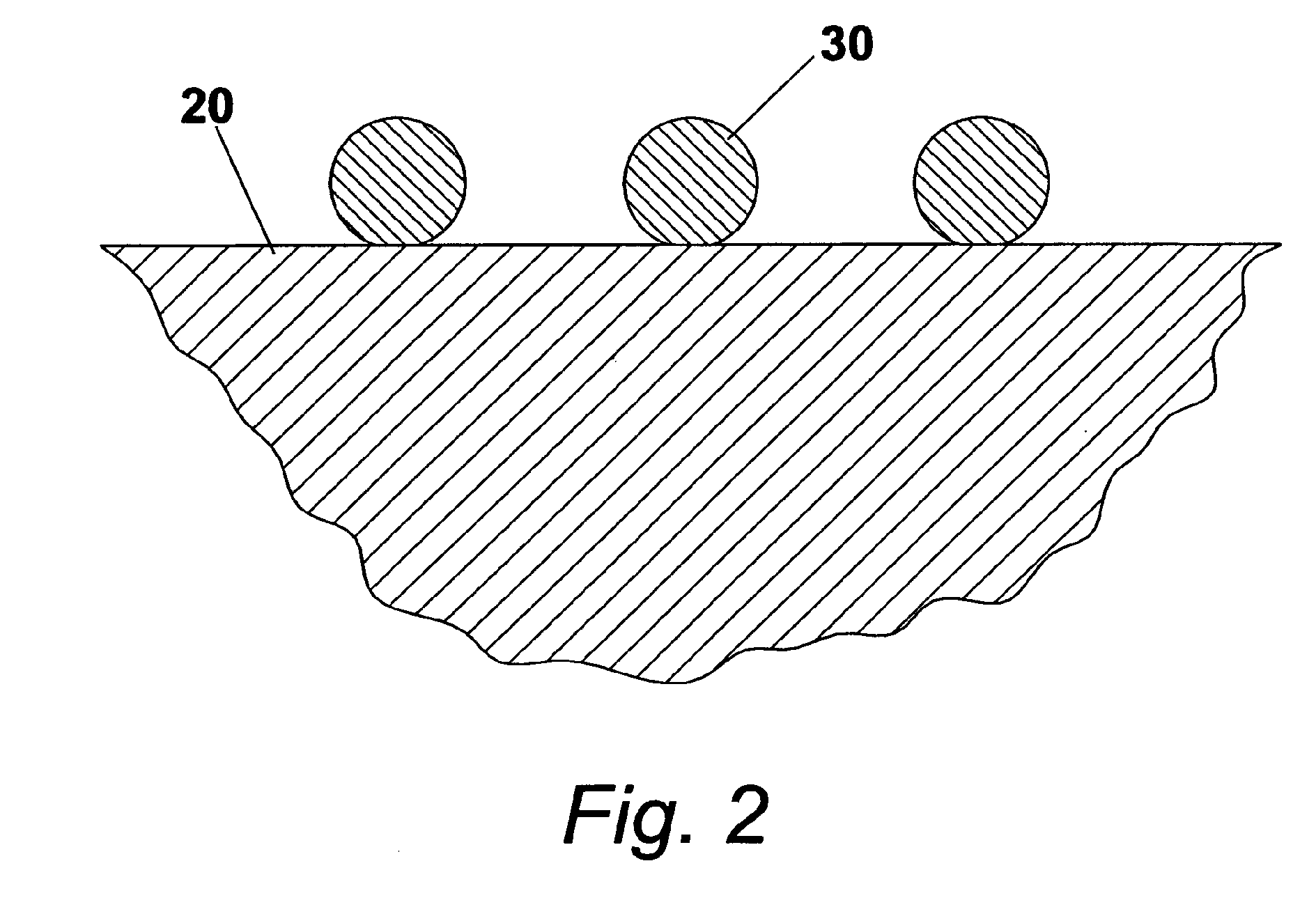

Continuous or discrete metallization layer on a ceramic substrate

InactiveUS20110045209A1High bonding strengthImprove conductivityFurnaces without endless coreDielectric heatingOxide ceramicLiquid state

Owner:SELEZNEV MAXIM

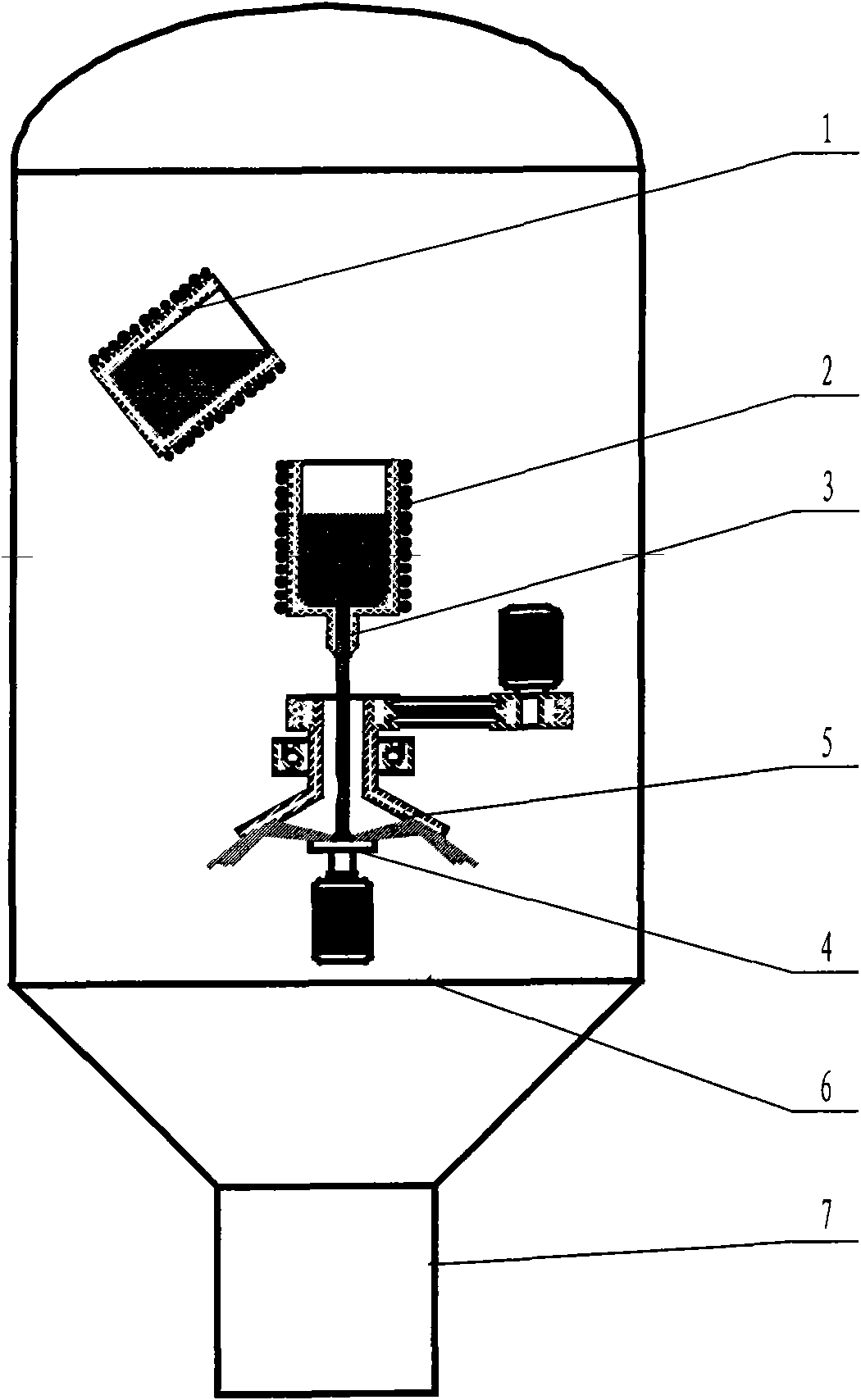

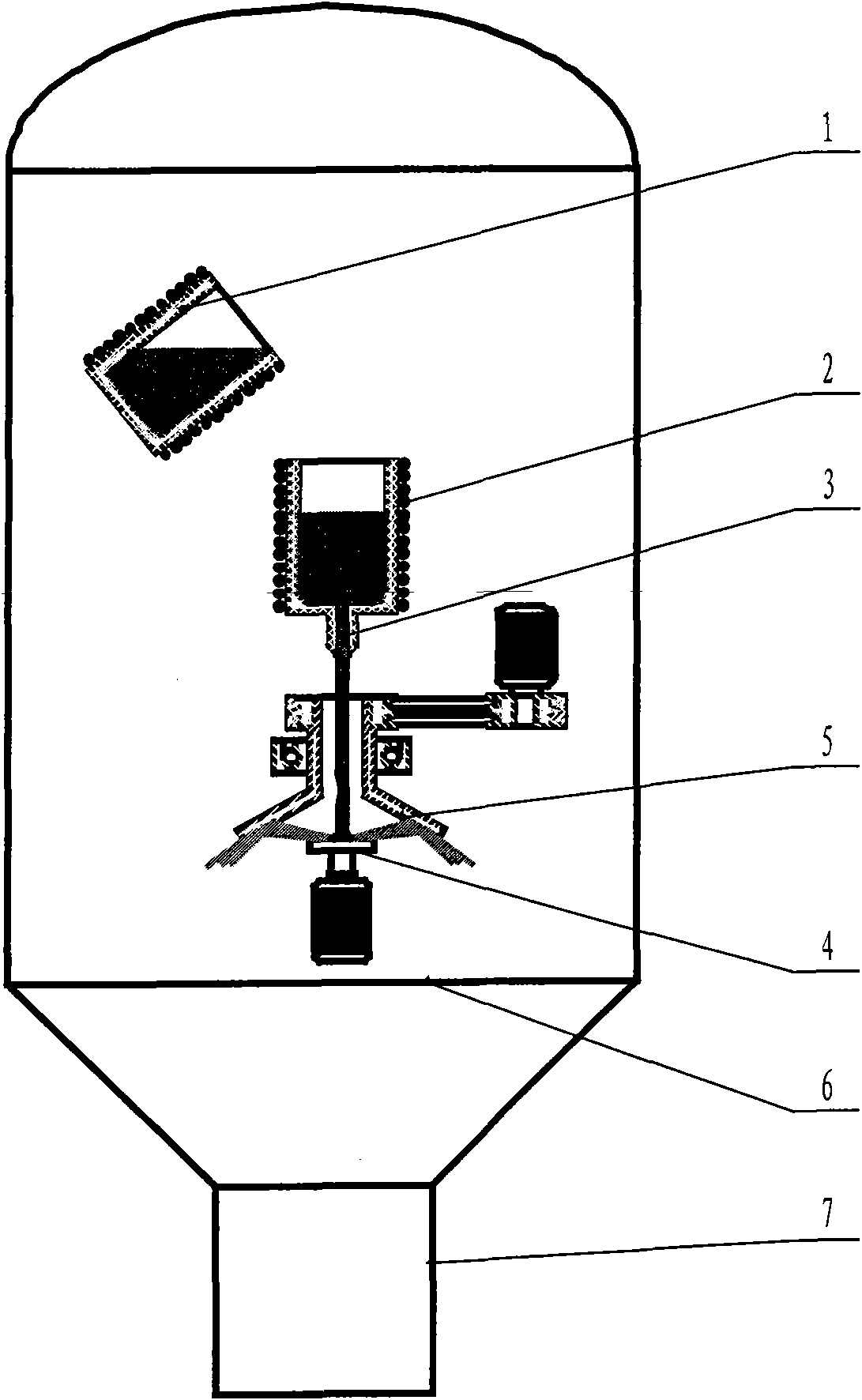

Preparation method and device of ceramic particle reinforced metal matrix composite powder

The invention discloses a preparation method of ceramic particle reinforced metal matrix composite powder. A metal matrix and a ceramic particle reinforced raw material are put in a high-frequency inductive smelting furnace for smelting; ceramic reinforced particles are uniformly distributed in molten metal by an ultrasonic generator; a valve at the bottom of the high-frequency inductive smelting furnace is opened; the molten metal freely drops down; inert gas sprayed out from a high-pressure airflow nozzle crushes the molten metal to form spherical metal droplets; and the spherical metal droplets drop into a powder collecting tank after cooling and solidification. The preparation device comprises the high-frequency inductive smelting furnace and an aerosol can; the high-frequency inductive smelting furnace and the ultrasonic generator are arranged in the top center of the aerosol can; the ultrasonic generator is mounted on the side wall of the high-frequency inductive smelting furnace, and is connected with an amplitude transformer; and the bottom of the aerosol canis connected with the collecting tank. The metal matrix composite powder with uniformly distributed reinforced particles can be obtained by metal aerosol melting and ultrasonic stirring; and the preparation device is simple in operation and low in cost, and can effectively prevent physical damage to the matrix powder or the reinforced particles in the powder preparation process.

Owner:石京

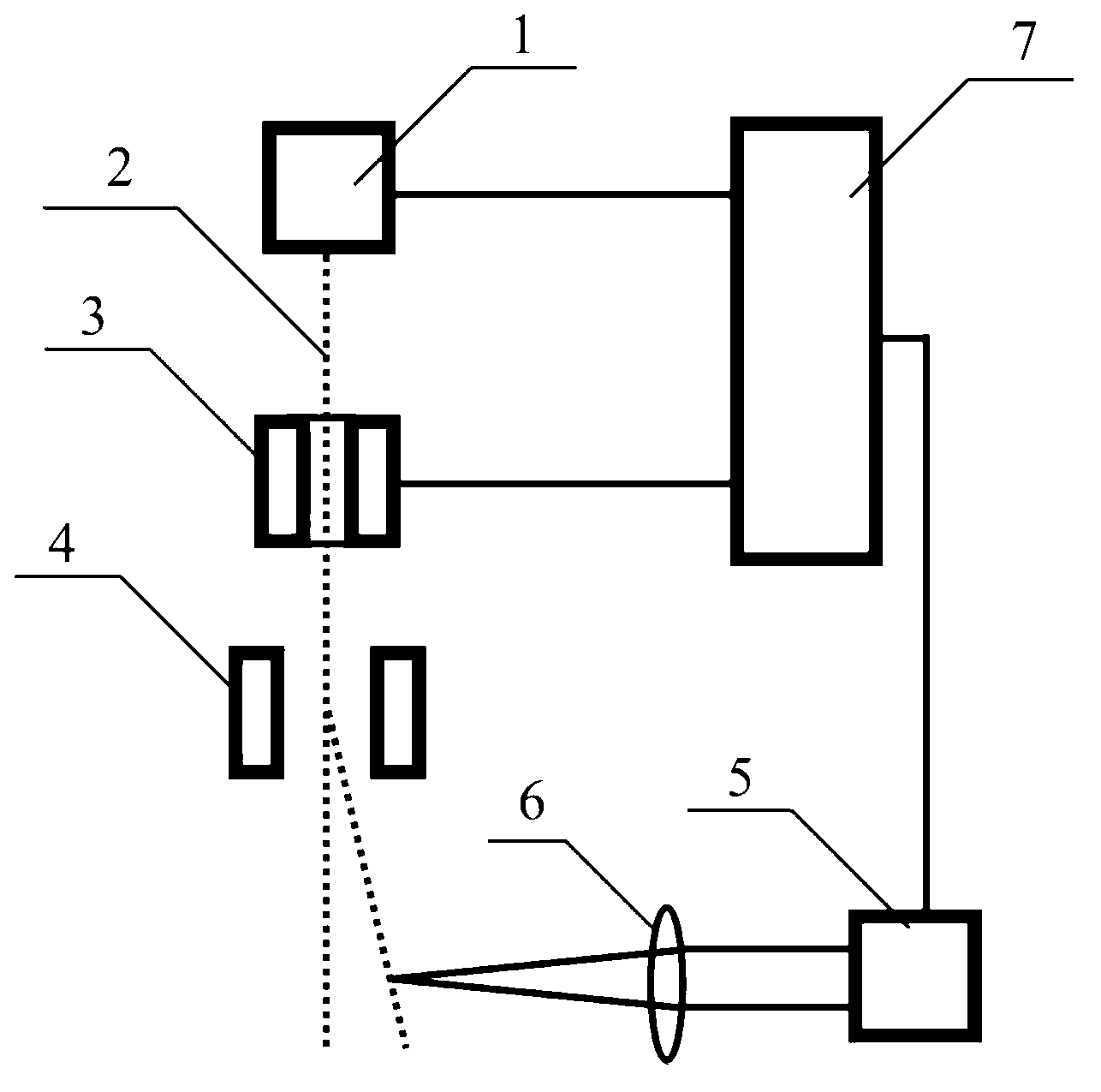

Droplet target control system guided by laser beam

ActiveCN103217870AStrong tractionNo electrification requirementPhotomechanical exposure apparatusMicrolithography exposure apparatusTime delaysMetal droplets

The invention discloses a droplet target control system guided by a laser beam. The droplet target control system comprises a droplet nozzle, a high-power pump laser, a third focusing lens and a time delay pulse generator, and further comprises a laser source, a first reflector, a half valve plate, a Brewster angle polarizing film, a quarter wave plate, a second reflector, a first focusing lens, a vacuum tube, a second focusing lens, an annular plane reflector and an annular focusing lens. A dropping track of metal droplets in 20 micron dimension can be precisely controlled by the droplet target control system, and the dropping speed of the droplets can be regulated. The system is capable of stably working for a long time, the time synchronization and the space coincidence of the droplets and the high-power pump laser are guaranteed.

Owner:上海中科神光光电产业有限公司

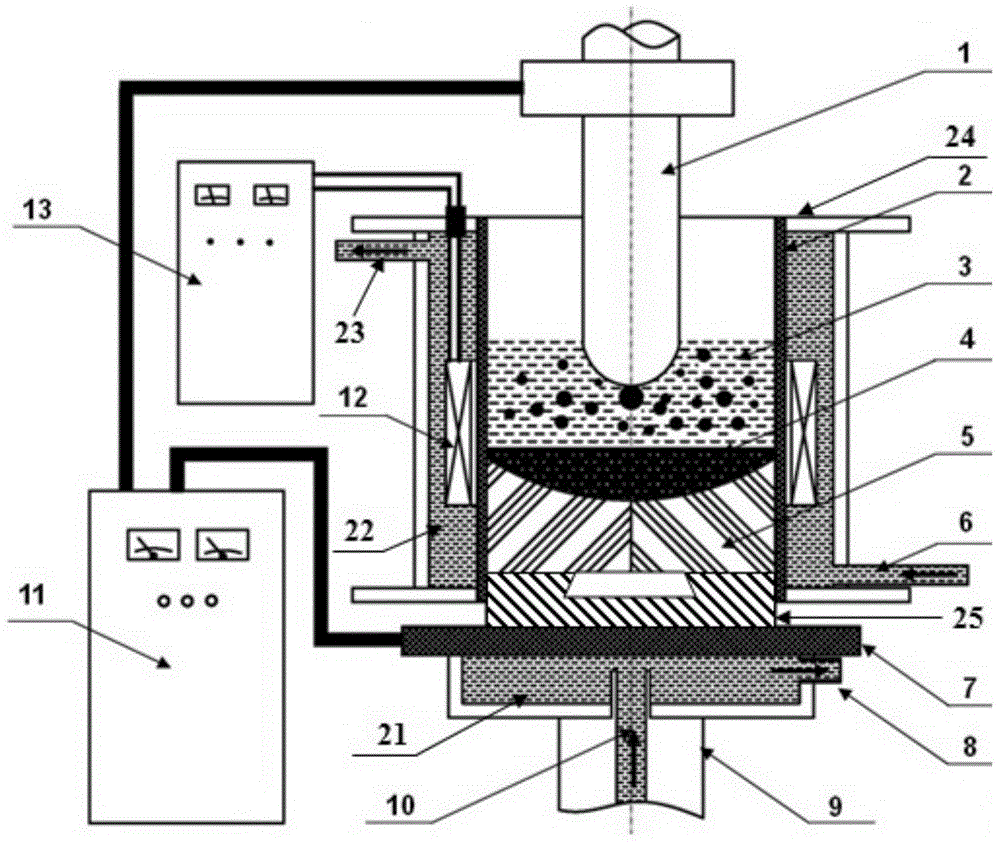

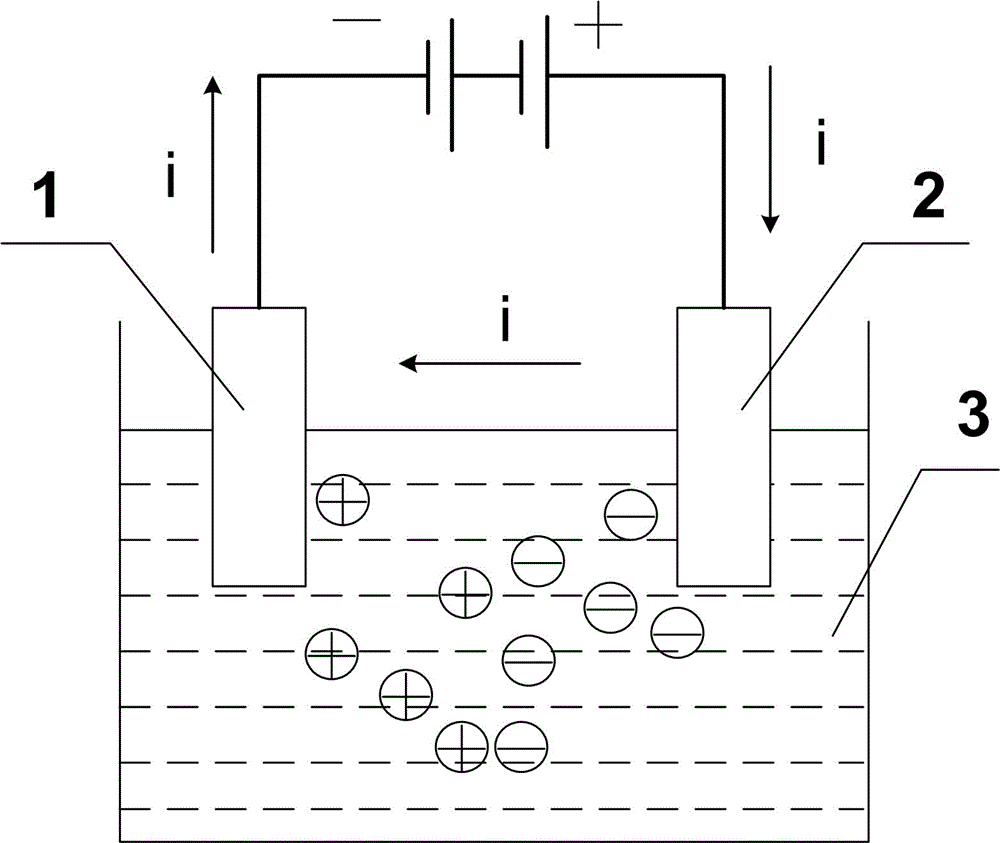

Method and device for casting electromagnetic compound control electroslag remelting fine grains

The invention relates to a method and a device for casting electromagnetic compound control electroslag remelting fine grains, and belongs to the field of preparation of metal materials. According to the method, metallic melt generates forced convection by using the action of exerted pulse magnetic field and periodic electromagnetic force which is generated by compounding of induced current in the melt and electroslag remelting current; a metal material solidification structure is fined; and composition segregation is reduced. Metal droplets can be crushed into fine liquid drops under the action of the electromagnetic force with direction and size in periodic change; the contact area and the contact time of the metal droplets and slag liquid are improved; and a good purification effect is achieved. The device comprises an electroslag remelting work power supply, a pulse power supply and an electromagnetic compound control electroslag remelting crystallizer, wherein the crystallizer is provided with a crystallizer red copper inner sleeve, a side cooling jacket, a bottom cooling jacket and a magnet exciting coil. The method and the device can be applied to electroslag remelting and refining of metal materials such as high-temperature alloy and high alloy steel; the alloy solidification structure can be fined; the segregation is reduced; the refining effect of the electroslag remelting process is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Quadric injection metal atomization device of rotary-forming film

The invention relates to a metal atomization device for the secondary injection of a rotary film, which comprises an input liquid metal jet supplying part; a ring-shaped atomization combined nozzle is formed concentrically with an input liquid metal jet center; a rotating impact platform is arranged at the lower part of the ring-shaped atomization combined nozzle which is provided with an upper nozzle and a lower nozzle; the airstream jetting direction of the upper nozzle is in a downward centrifugal direction to impact the rotary film formed when the impact platform is impacted by the input metal jet, thereby breaking a formed film; the airstream jetting direction of the lower nozzle is in a downward central direction and forms an effective cross angle with the airstream jetting direction of the upper nozzle, thereby impacting the broken liquid metal particles of the formed film and realizing secondary breaking. By adopting the device, better atomization effect and finer metal droplets and powders can be obtained.

Owner:江苏今越控股集团有限公司

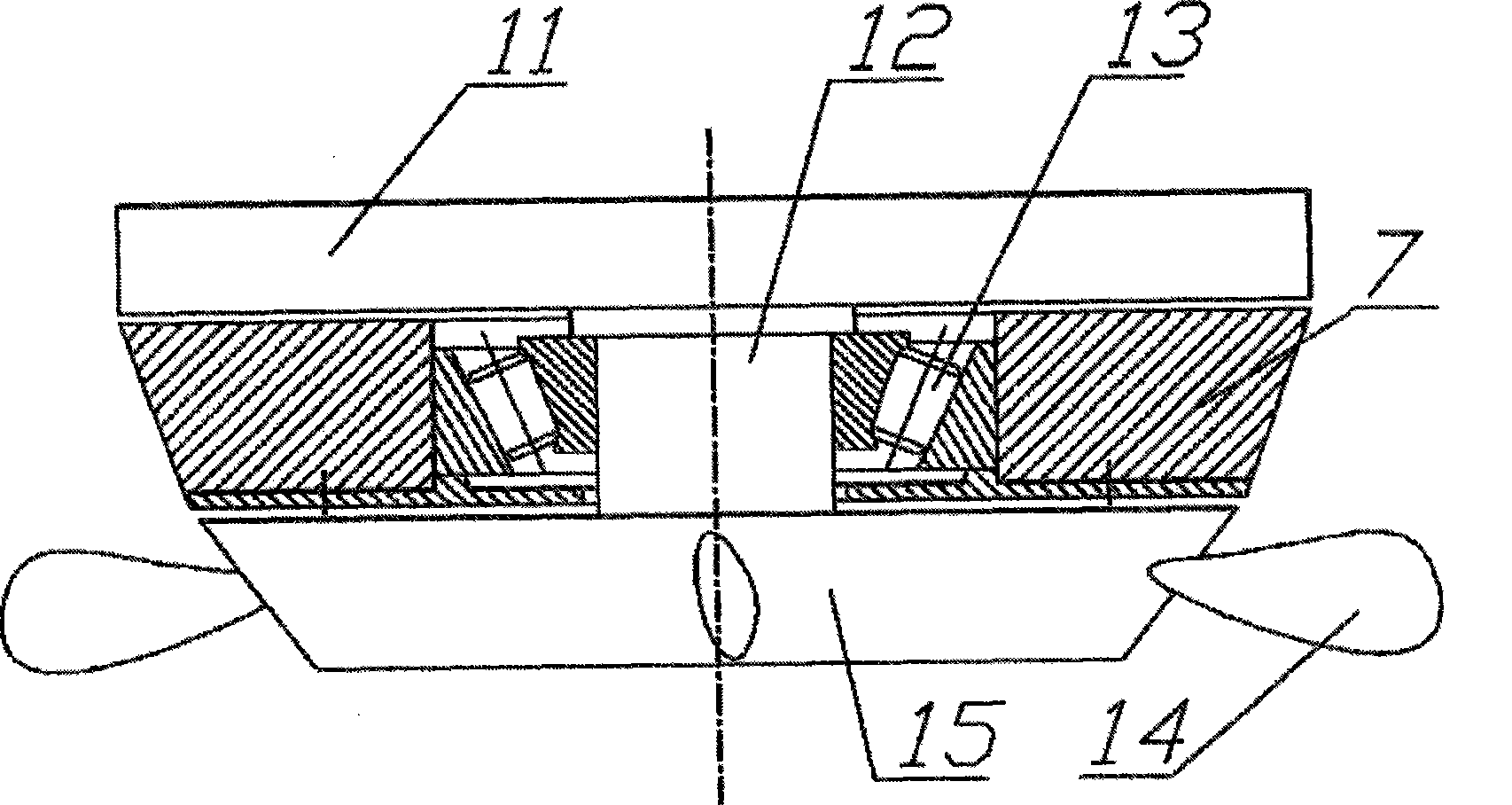

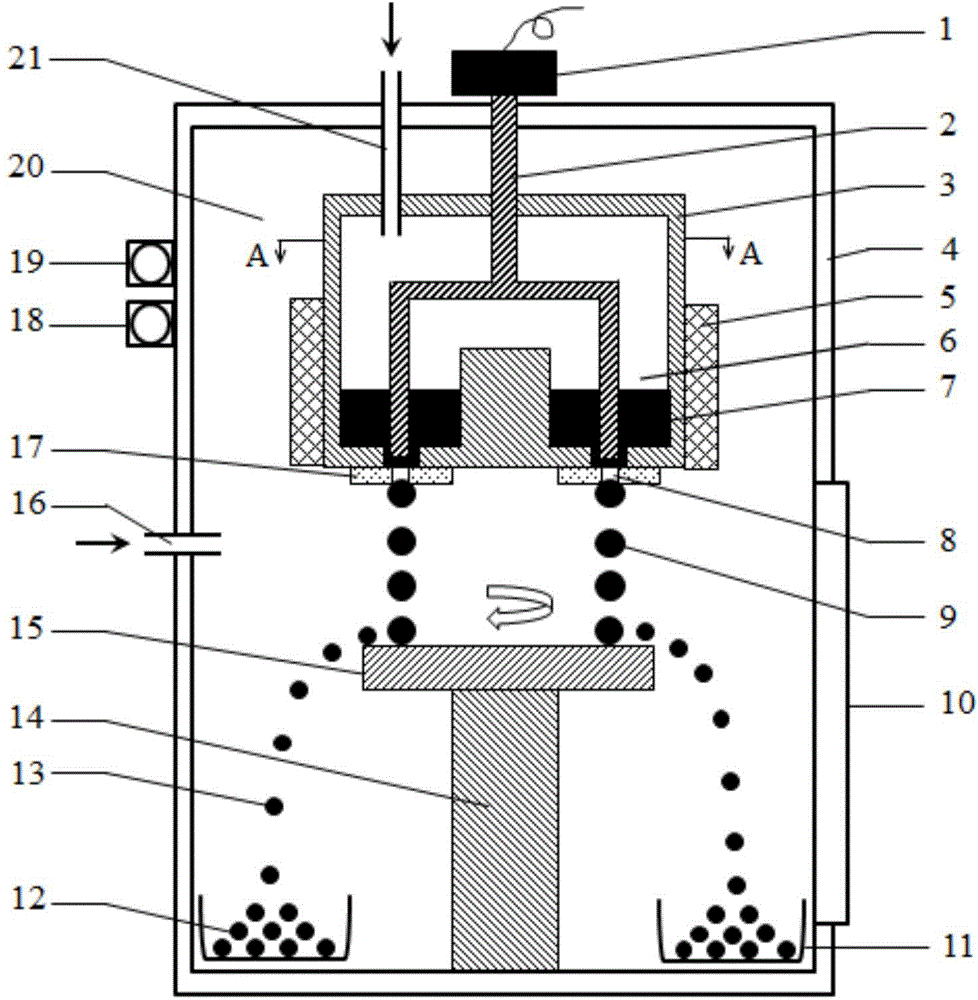

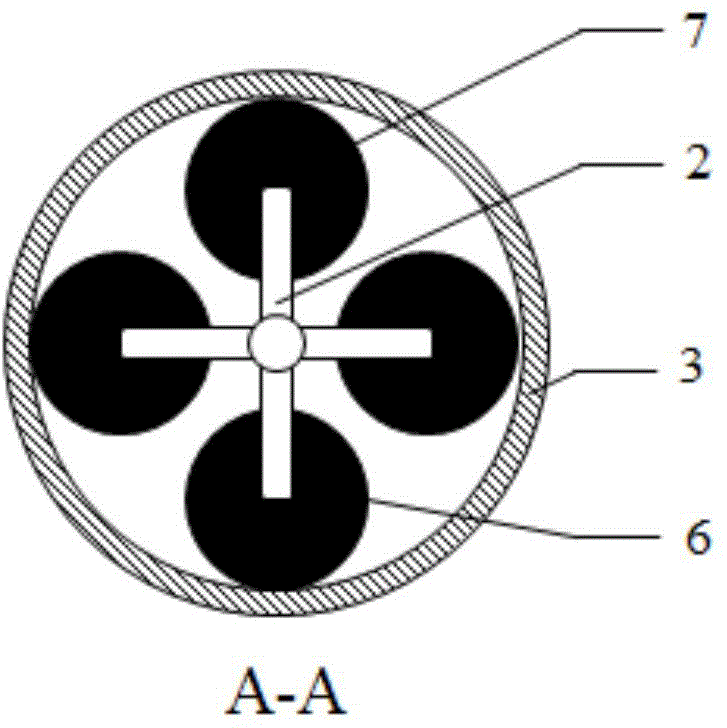

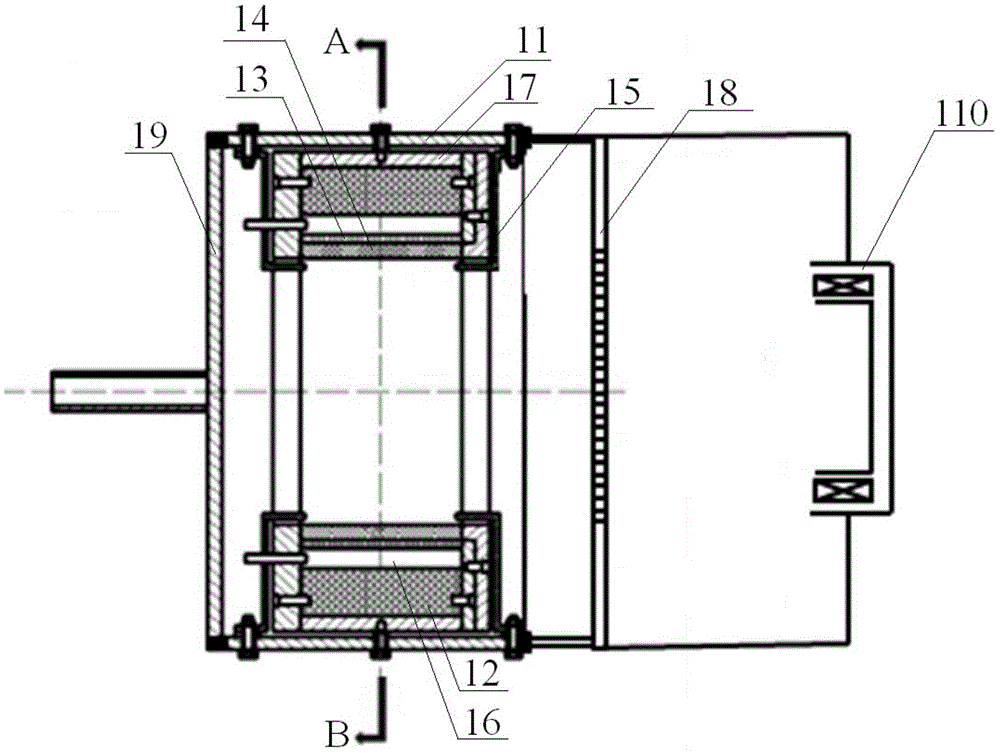

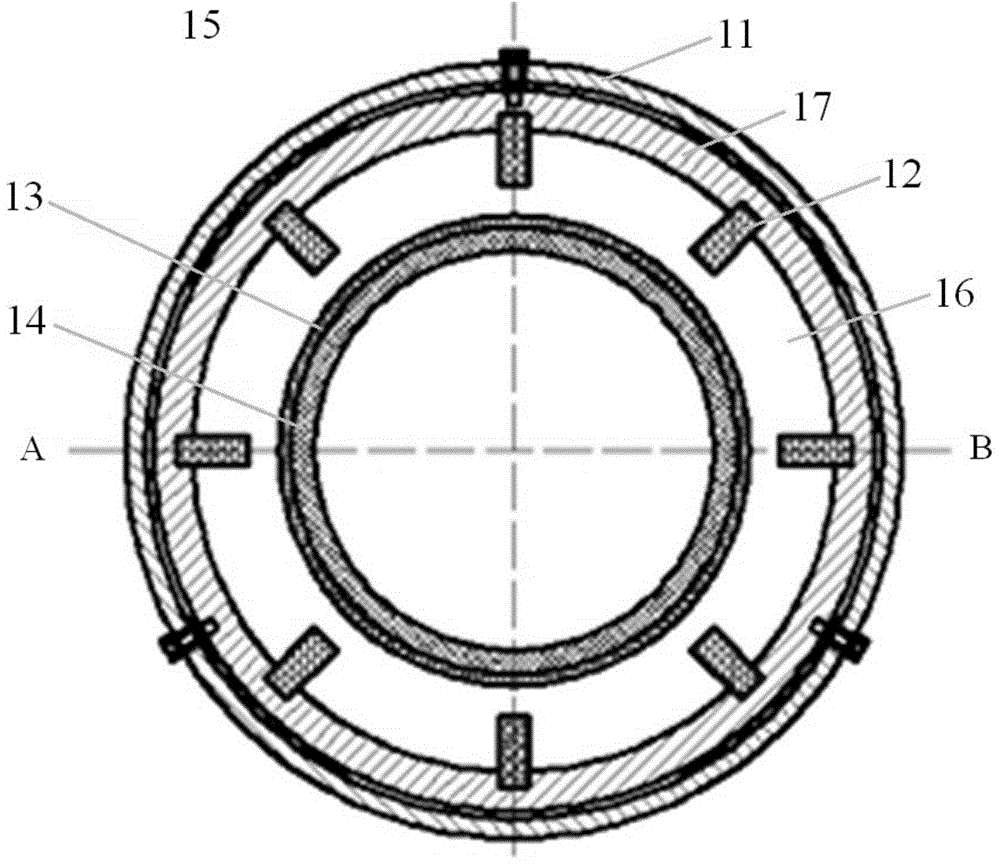

Method and device for efficiently preparing superfine spherical metal powder with high melting point

The invention discloses a device for efficiently preparing superfine spherical metal powder with a high melting point. The device comprises a shell, and a crucible and a powder collecting area which are arranged in a chamber of the shell, and is characterized in that a plurality of melting pools with the same volume are formed inside the crucible, and gaskets with small holes which are communicated with the chamber are fixed at the bottoms of the melting pools; a transmission rod comprises transmission support rods with the number the same as that of the melting pools, and the bottoms of the transmission support rods are aligned with circular holes in the gaskets with small holes; a thermocouple is arranged inside the crucible, and an induction heater is arranged outside the crucible; and the powder collecting area comprises a rotating disk which is used for atomizing metal droplets and is arranged at the bottom of the chamber and connected with a motor, and a collecting tank is also formed in the bottom of the chamber. The invention also discloses a method for efficiently preparing superfine spherical metal powder with the high melting point. By mainly combining a pulse micropore injection method with a centrifugal atomization method, the method can be used for preparing superfine spherical metal powder which is narrow in particle size distribution interval, high in sphericity, good in spreadability and liquidity, and high in production efficiency, and meets the 3D printing and using requirements.

Owner:DALIAN UNIV OF TECH +1

Aircraft damage metal micro-droplet jetting 3D printing in-situ rapid repairing method

ActiveCN106399898ARapid in-situ flexibilitySimple processAdditive manufacturing apparatusMolten spray coatingMulti materialInternal pressure

The invention discloses an aircraft damage metal micro-droplet jetting 3D printing in-situ rapid repairing method which is used for solving the technical problem that existing aircraft damage repairing methods are poor in practicability. According to the technical scheme, a metal melt jets single uniform micron-grade metal droplets through a nozzle under the action of the internal pressure of the metal melt, the uniform metal micro-droplets are controlled to be directionally accumulated point by point and layer by layer according to the specified trajectory based on the dispersed accumulation principle, and then rapid repairing forming of damaged metal parts is completed. According to the aircraft damage metal micro-droplet jetting 3D printing in-situ rapid repairing method, large-size energy equipment and special raw materials are not needed; in-situ repairing of multi-material damaged parts including active metal can be achieved; repairing equipment is portable; the process is simple; the cost is low; in-situ flexible rapid repairing of aircraft damage can be completed; and the practicability is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

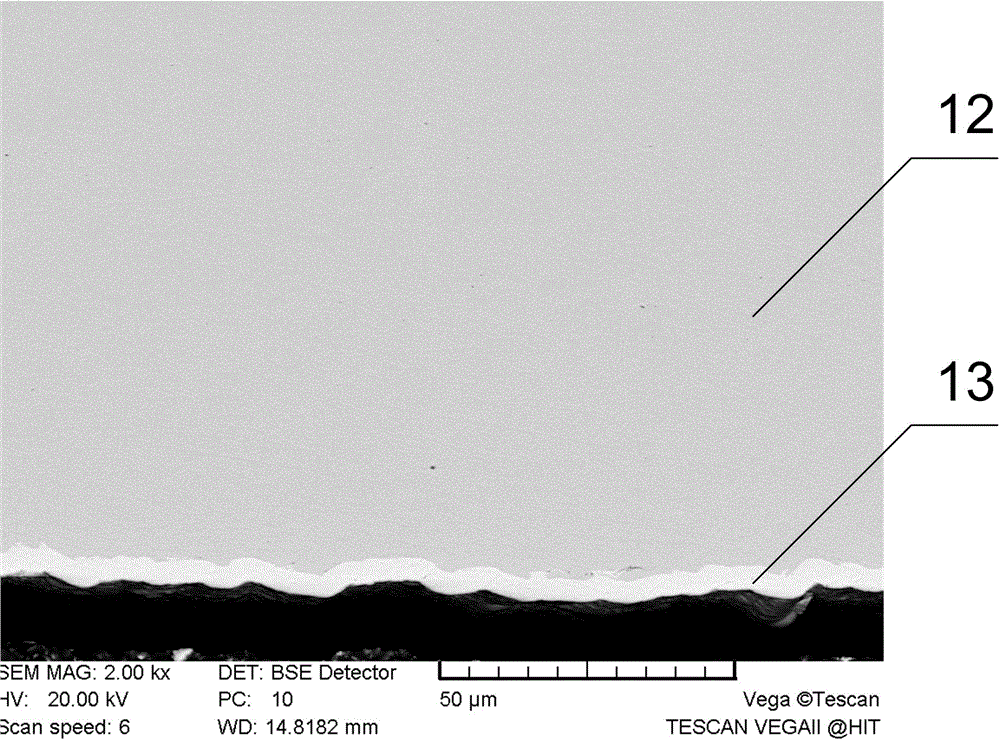

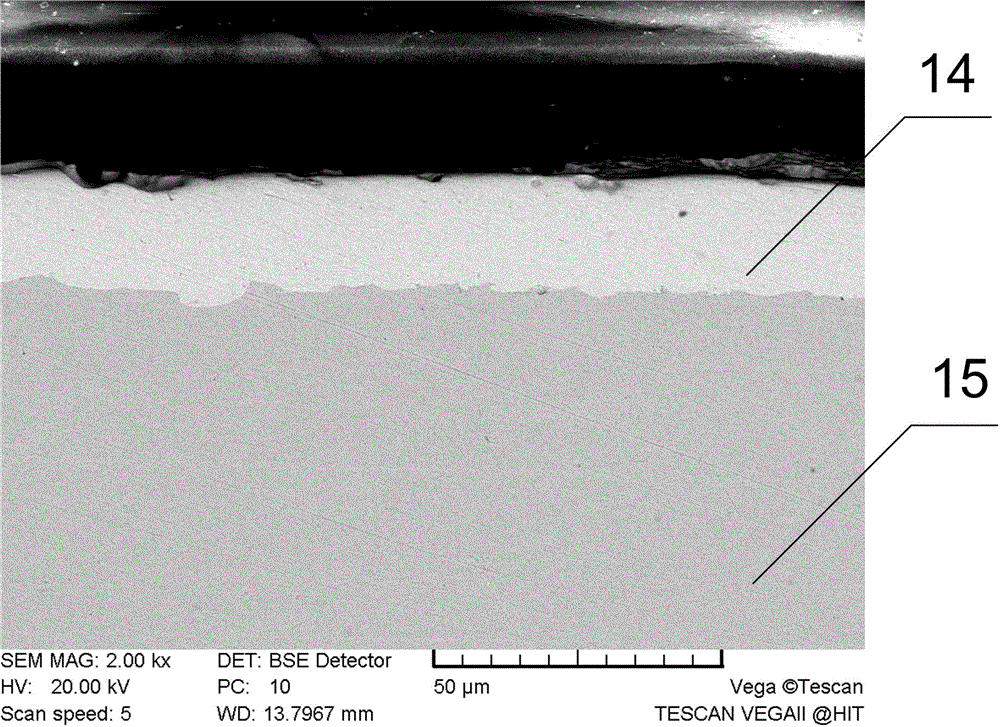

Plating assisting regulation type magnesium and steel dissimilar metal laser welding-brazing method

InactiveCN106270879AImprove mechanical propertiesMeet application needsSoldering apparatusWelding/soldering/cutting articlesReaction layerUltimate tensile strength

The invention provides a plating assisting regulation type magnesium and steel dissimilar metal laser welding-brazing method and particularly relates to preparation of plating assisting regulation type welding materials. The problems of easiness in causing weld joints, difficulty in shaping control, magnesium alloy melting loss and low bonding strength at the joint interfaces of an existing magnesium alloy and steel welding method are to be solved. The plating assisting regulation type magnesium and steel dissimilar metal laser welding-brazing method includes electroplating nikel on the surface of steel, and welding according to a laser welding-brazing method by adjusting the technological parameters such as wire feed positions and angles, laser beam positions and defocusing amount. In the presence of the nickel plating on the surface of the steel, metal droplets wet and spread easily during welding, and weld joints are alloyed through addition of nickel elements to generate an intermetallic compound and a reaction layer at the interface, so that the weld joints excellent in shaping and performance can be obtained. The plating assisting regulation type magnesium and steel dissimilar metal laser welding-brazing method solves the key and common problems about inhibiting improvement in welding quality of immiscible dissimilar metals such as Mg / Fe and widens the application range of laser welding-brazing.

Owner:HARBIN INST OF TECH AT WEIHAI

Metal ion source and vacuum coating system

ActiveCN104131259ABeam realizationSmall beam areaVacuum evaporation coatingSputtering coatingTarget surfaceHigh energy

The invention discloses a metal ion source and a vacuum coating system. In the metal ion source, a magnetic-control target is designed into a cylinder shape and is mounted in an outer shell of the cylinder; magnetic components and a cooling system are correspondingly mounted in the outer shell, and a leading-out gate is used for leading out an ion beam flow. In the metal ion source, magnetic-control discharge is relatively closed in the cylinder; when in work, the leading-out gate is used for leading out the ion beam flow, 100% of the ion beam flow can be led out, and the beam flow does not contain 'metal droplets'; at the same time, the target surface area is far greater than the led-out beam flow area, and the led-out beam flow density is greatly improved, so that the vacuum coating system has the superiorities of no need of a filter device, fast deposition or large-dose injection, and can be used for fast routine 'beam linear' thin film deposition or large-dose high-energy ion injection.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Method for preparing non-homogenous parts by deposition

InactiveCN101514438ALow equipment requirementsPreparation of Ideal Heterogeneous PartsMolten spray coatingMathematical modelUltrasonic vibration

The invention discloses a method for preparing non-homogenous parts by deposition, which adopts a pneumatic injection method based on droplets as required to obtain uniform metal droplets and adopts a method of capillary micro-feeding powders by ultrasonic vibration to realize powder feeding. The method comprises the following steps: geometry information and material information on each layer of the parts are extracted by level algorithm according to mathematical models of the parts, substrate movement trajectory corresponding to the level of each layer is simultaneously generated; substrate movement, droplet injection and powder deposition are harmoniously controlled by programming, thus finishing the preparation of the non-homogenous parts. As the droplet and the powder are directly combined together, the non-homogenous parts can be obtained without carrying out secondary sintering. Smooth injection can be ensured only by heating one of the metals to the temperature over the melting point, without carrying out high temperature solid infiltration and sintering; the preparation temperature of the non-homogenous parts is lowered from 1300-1600 DEG C in the prior art to the temperature within 1000 DEG C and the requirements on the equipments are lower. Meanwhile, injection of fixed amount in fixed points as required can be carried out based on the special using requirements of the parts, thus realizing the preparation of ideal non-homogenous parts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Device and method for preparing metal microballoons by using ultrasonic surface standing waves

The invention discloses a device and method for preparing metal microballoons by using ultrasonic surface standing waves, relates to a device and a method for preparing the metal microballoons, and aims to solve the problems that the conventional device for preparing the metal microballoons is complicated, and the size cannot be controlled flexibly. The device consists of an air storehouse and a titanium alloy casting die, a heating element, a base plate, two ultrasonic surface wave emission devices and a droplet flow control device which are positioned in the air storehouse. The method comprises the following steps of: 1, completely dissolving a metal material to obtain a metal solution, gradually dropping the metal solution on the surface of the base plate, and forming spherical metal droplets with the same size under the action of ultrasonic waves; and 2, cooling the metal microballoons by an air-cooling system until the metal microballoons are cooled to be solids, and thus obtaining the metal microballoons with the same size. By the device and the method, various metal microballoons with relatively small sizes can be prepared; the preparation process takes 1 to 2 minutes at one time, so that the production efficiency is greatly improved; and the device and the method are applied to the field of preparation of the metal microballoons.

Owner:HARBIN INST OF TECH

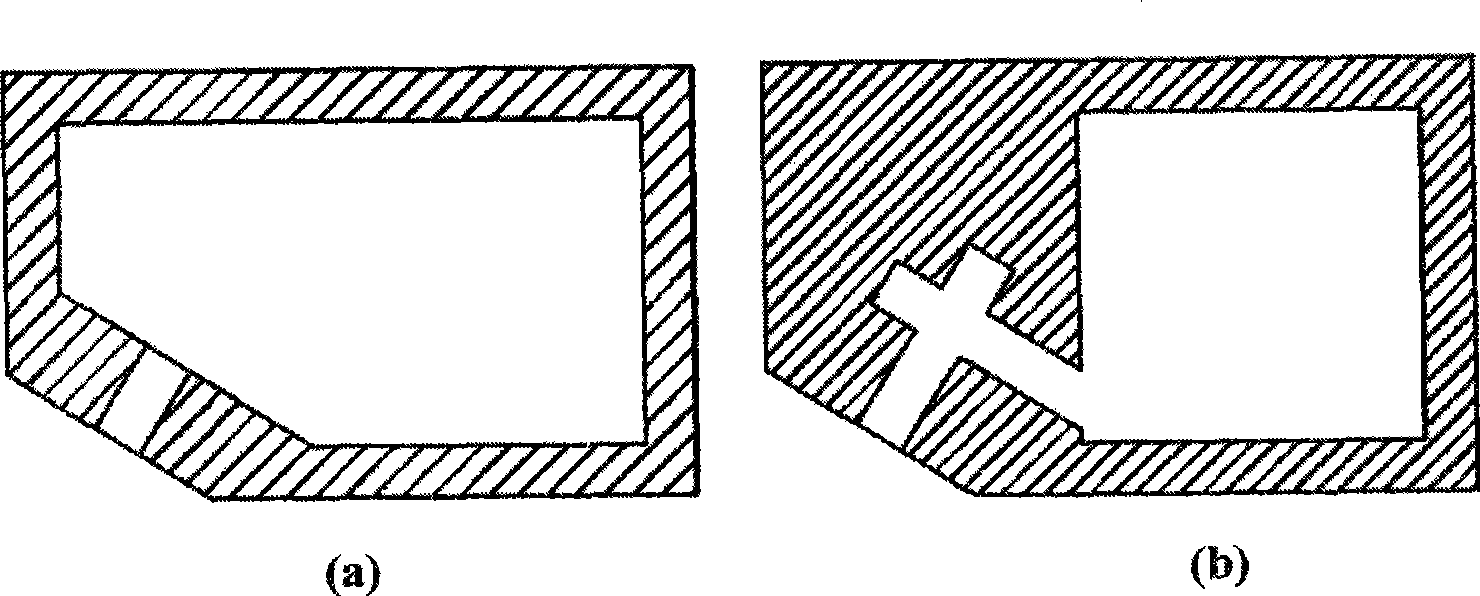

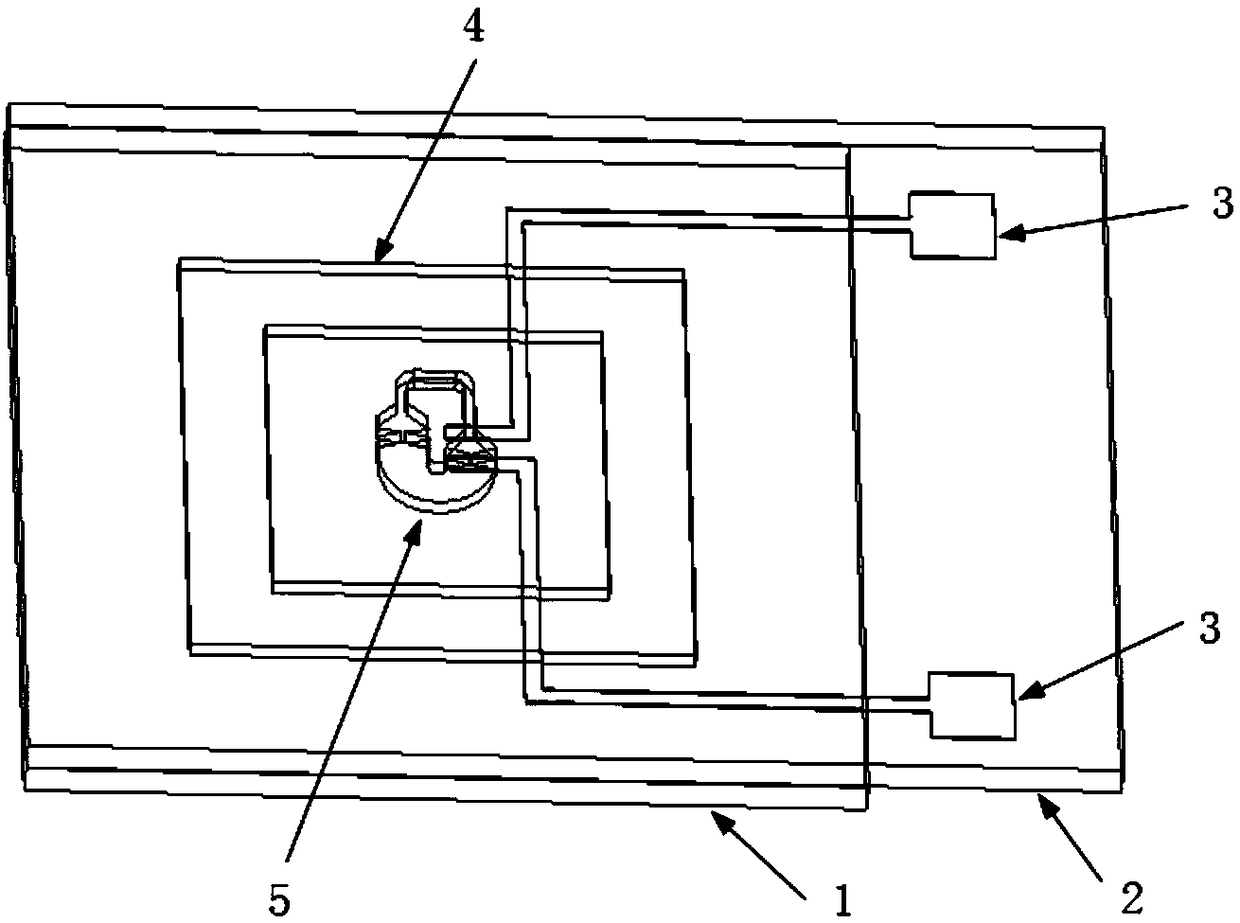

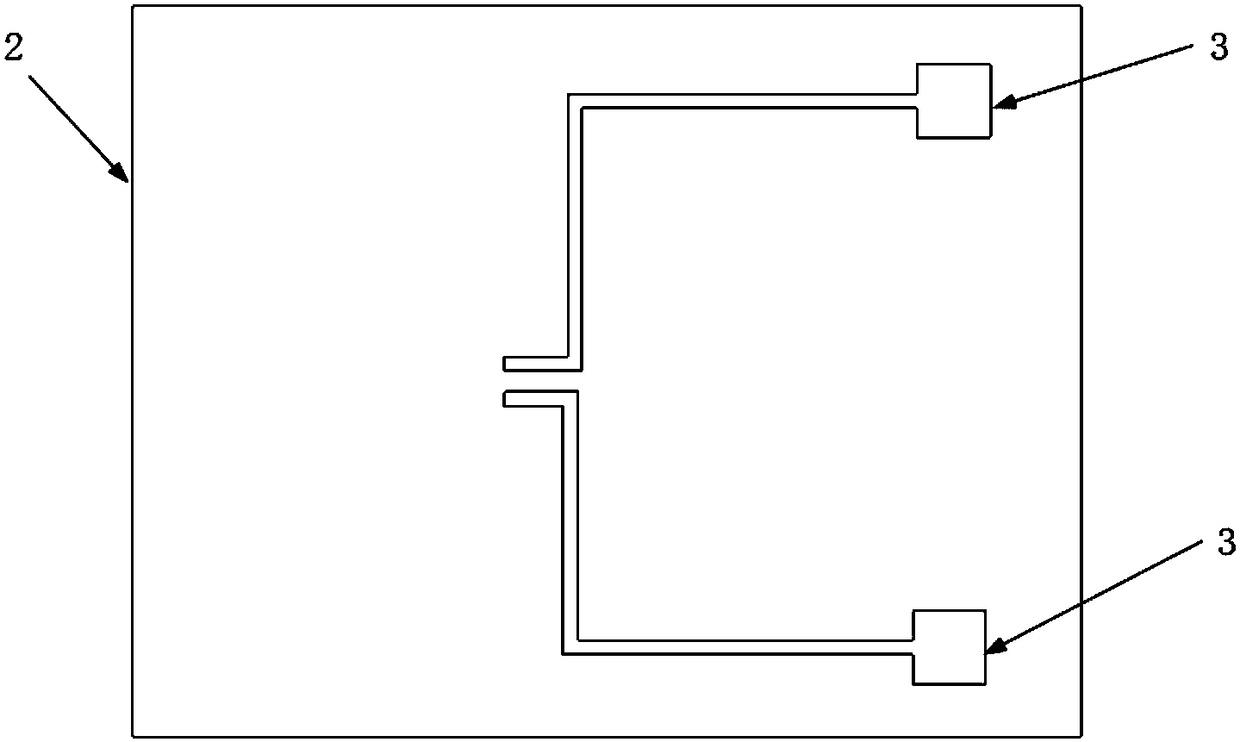

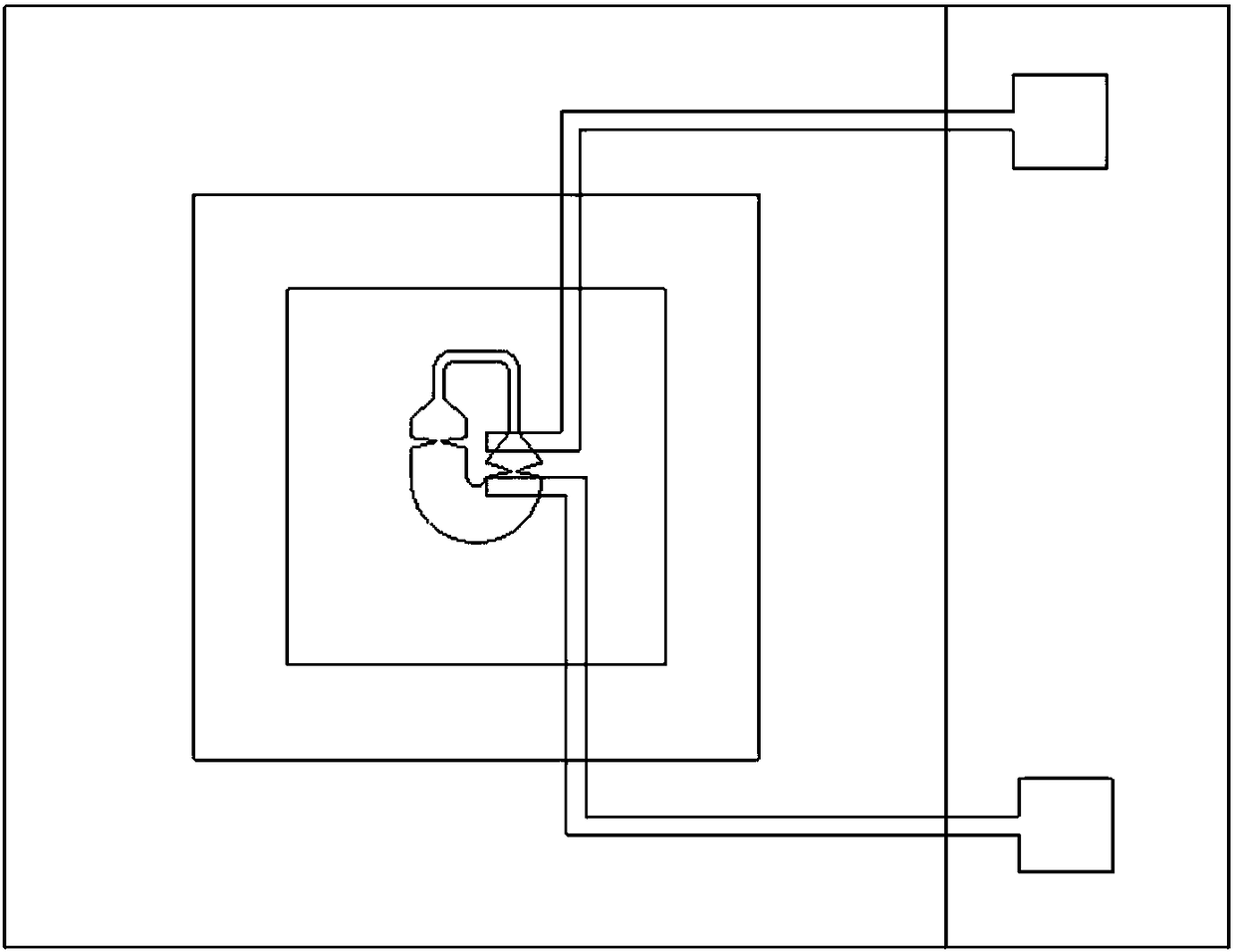

High impact inertia micro-fluid power connection switch and manufacturing method thereof

The invention discloses a high impact inertia micro-fluid power connection switch and a manufacturing method thereof. The high impact inertia micro-fluid power connection switch comprises a base, a cover plate, a metal electrode, a micro-channel and metal droplets. The cover plate is arranged on the upper end of the base. The micro-channel is arranged on the base. The metal electrode is arranged on the cover plate. The micro-channel comprises a U-shaped liquid storage tank, capillary valves and an air guide channel. The metal droplets are arranged in the U-shaped liquid storage tank. The firstcapillary valve is connected with the U-shaped liquid storage tank. The second capillary valve is connected with the first capillary valve, and the other end is connected with the third capillary valve. The third capillary valve is connected with the second capillary valve, and the other end is connected with the fourth capillary valve. The fourth capillary valve is connected with the third capillary valve. The fifth capillary valve is connected with the sixth capillary valve. The other end of the sixth capillary valve is connected with the seventh capillary valve. The seventh capillary valveis connected with the sixth capillary valve, and the other end is connected with the eighth capillary valve. The eighth capillary valve is connected with the seventh capillary valve, and the other end is connected with the U-shaped liquid storage tank. The fourth capillary valve and the fifth capillary valve are connected through the air guide channel. The switch can identify the fuze ambient force.

Owner:NANJING UNIV OF SCI & TECH

Device and method for controlling surface quality of metal droplet printed 3D part

InactiveCN106475564AAvoid flattening defectsIncrease productivityAdditive manufacturing apparatusTemperature controlSurface layer

The invention discloses a device and a method for controlling surface quality of a metal droplet printed 3D part. The device comprises a computer system, a metal droplet injection head, a laser, a scanning galvanometer, a galvanometer motor, a moving platform, a deposition substrate, a driving motor, a leveling roller, a roller motor and a charge coupled device (CCD) camera and is characterized by further comprising a laser power regulator, a leveling roller height regulator, a substrate temperature control device, an edge scraper and the like. The laser is used as an energy source, rapid surface cladding of a formed layer by a laser beam is realized through the scanning galvanometer, the leveling depth and pressure of the roller are controlled through the leveling roller height regulator, in the state that the surface layer metal droplets or melt is not solidified at all, directional scraping pressing is performed on the rapidly cladded metal surface by controlling the speed of the moving platform and the speed of the leveling roller, secondary spreading and filling are realized, then the original uneven formed layer is subjected to roller flattening, the surface quality of the layer is controlled, and real-time detection and feeding back of the roller flattening effect are realized.

Owner:XUCHANG UNIV

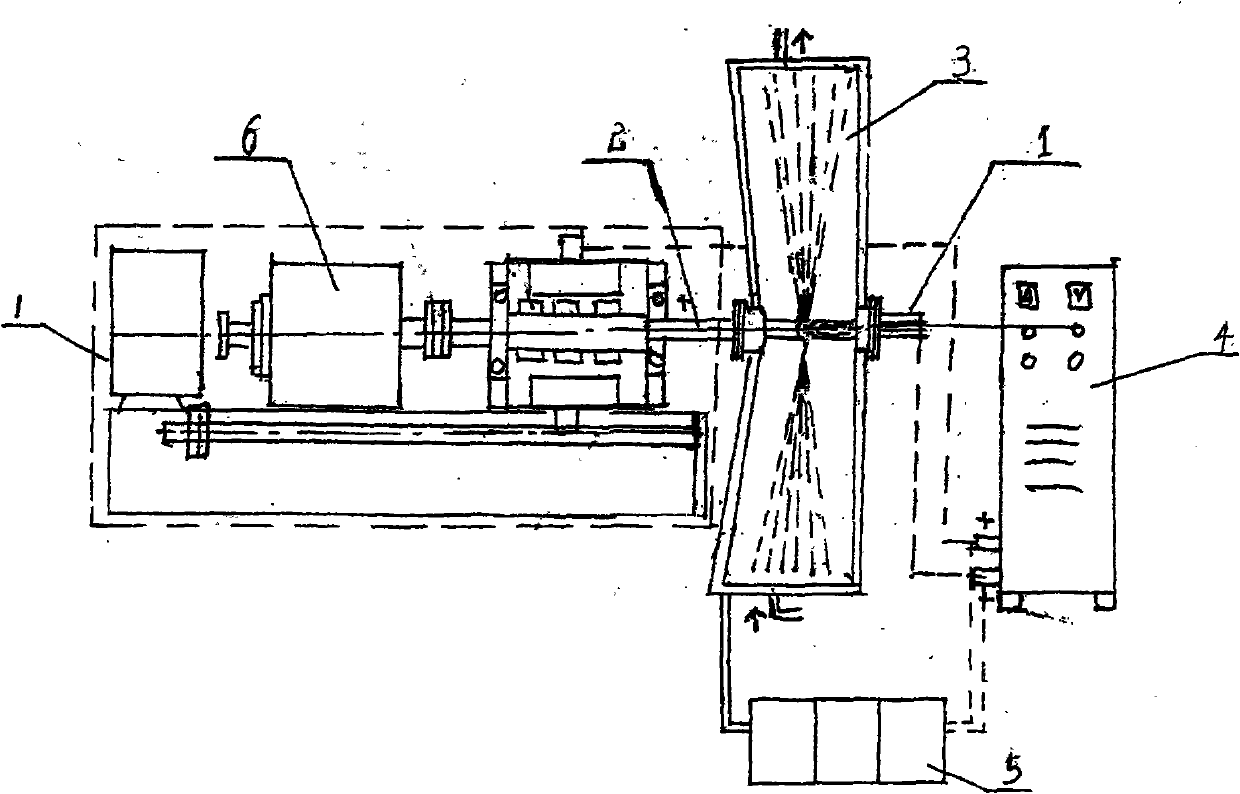

Method for preparing titanium alloy Ti60 prills by adopting plasma auxiliary rotary electrode

The invention relates to a method for preparing titanium alloy Ti60 metal spherical powder by adopting a plasma auxiliary rotary electrode centrifuging process. The method comprises the following steps of: generating a glow discharge plasma arc between a plasma auxiliary electrode and a consumption-type electrode made of rotary cylindrical titanium alloy Ti60 metal in a closed container protected by inert gas; forming droplets at one section of the titanium alloy Ti60 metal electrode close to the plasma arc by high temperature which is generated by the plasma arc; flinging the droplets out by centrifugal force; cooling the titanium alloy Ti60 metal droplets in air and solidifying into spheres in the inert atmosphere environment of the closed container; and collecting the titanium alloy Ti60 prills. Process parameters are changed in the method so that titanium alloy Ti60 prills with an average sphere diameter from 0.02 mm to 1.5 mm and better monodispersity are obtained. The titanium alloy Ti60 prills have favorable degree of sphericity, lower malformed particle proportion and controllable sphere diameters and can be used in the field of laser three-dimensional forming processes for preparing special parts of aerospace crafts.

Owner:张建利

Method for preparing high-temperature alloy GH4648 prills by adopting plasma auxiliary rotary electrode

The invention relates to a method for preparing high-temperature alloy GH4648 metal spherical powder by adopting a plasma auxiliary rotary electrode centrifuging process. The method comprises the following steps of: generating a glow discharge plasma arc between a plasma auxiliary electrode and a consumption-type electrode made of rotary cylindrical high-temperature alloy GH4648 metal in a closed container protected by inert gas; forming droplets at one section of the high-temperature alloy GH4648 metal electrode close to the plasma arc by high temperature which is generated by the plasma arc; flinging the droplets out by centrifugal force; cooling the high-temperature alloy GH4648 metal droplets in air and solidifying into spheres in the inert atmosphere environment of the closed container; and collecting the high-temperature alloy GH4648 prills. The method changes process parameters so that high-temperature alloy GH4648 prills with an average sphere diameter from 0.05-1.2 mm and better monodispersity are obtained, have favorable degree of sphericity, lower malformed particle proportion and controllable sphere diameters and can be used in the field of a laser three-dimensional forming process for preparing special parts of an aerospace craft.

Owner:张建利

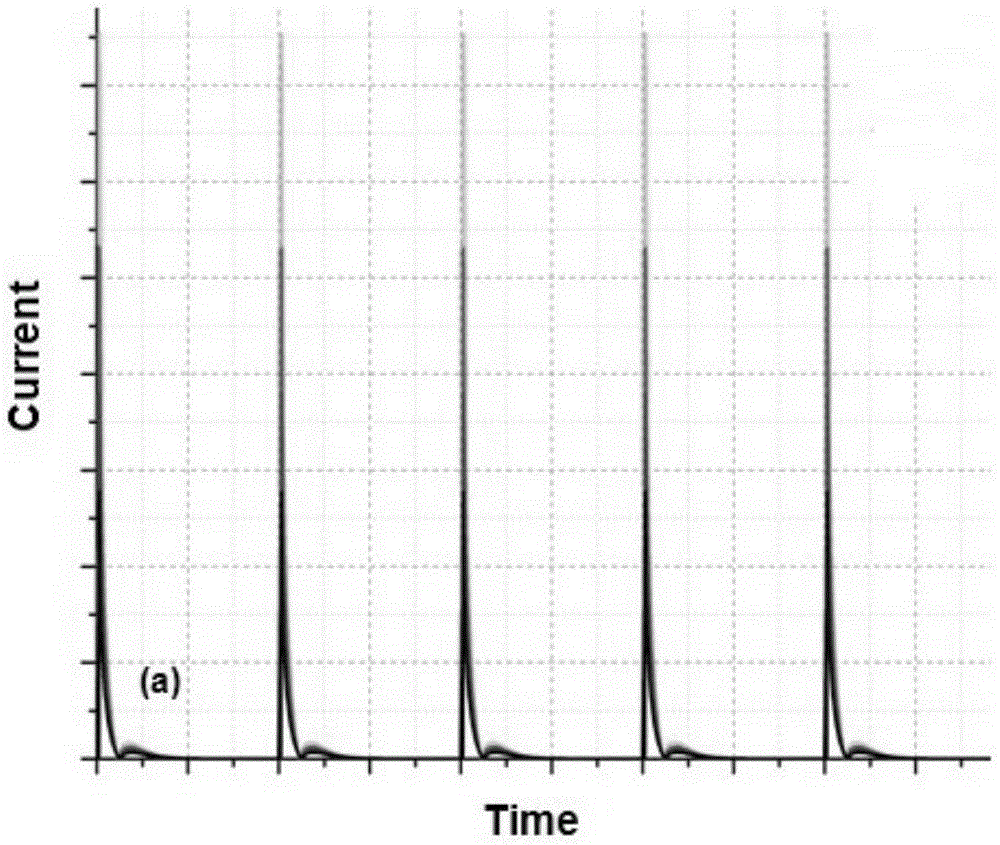

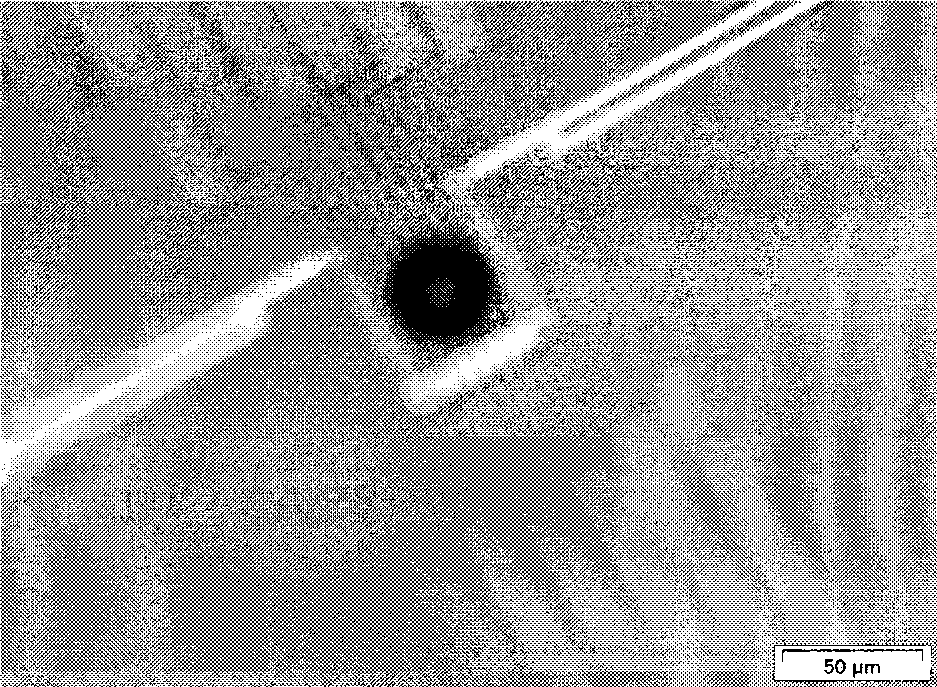

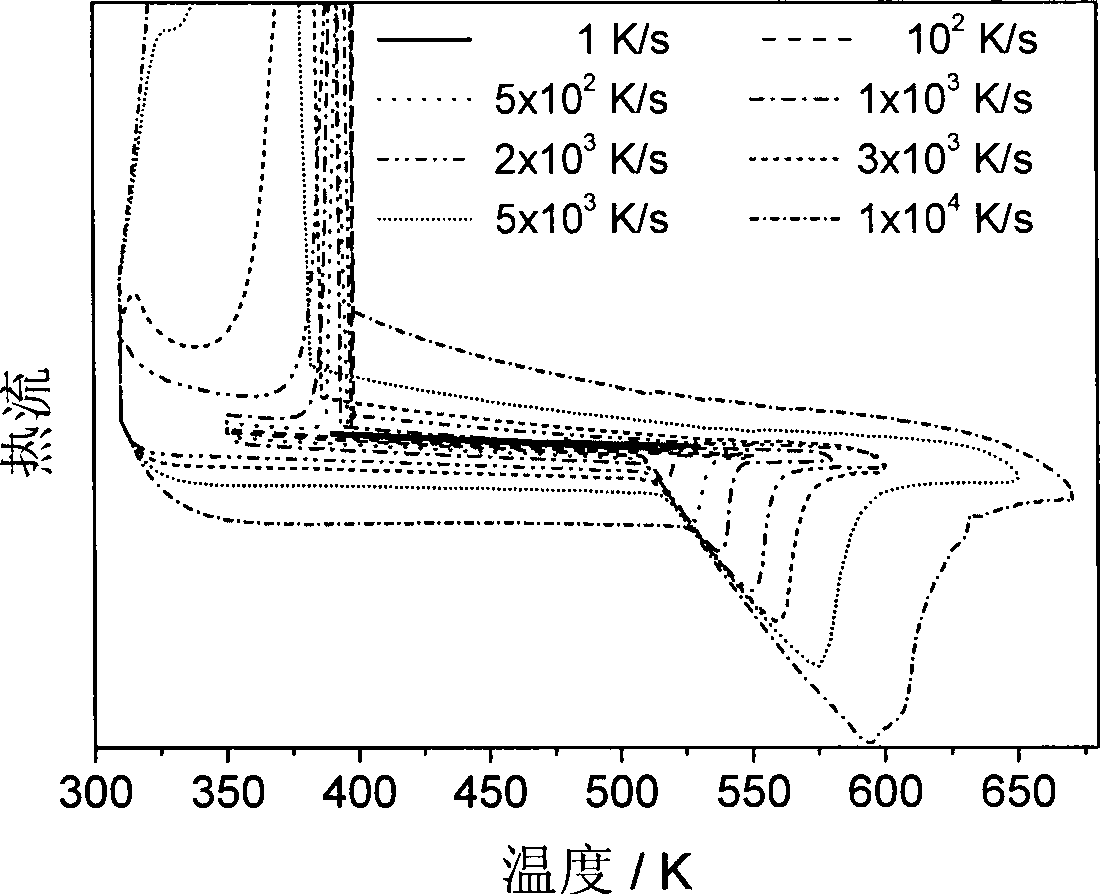

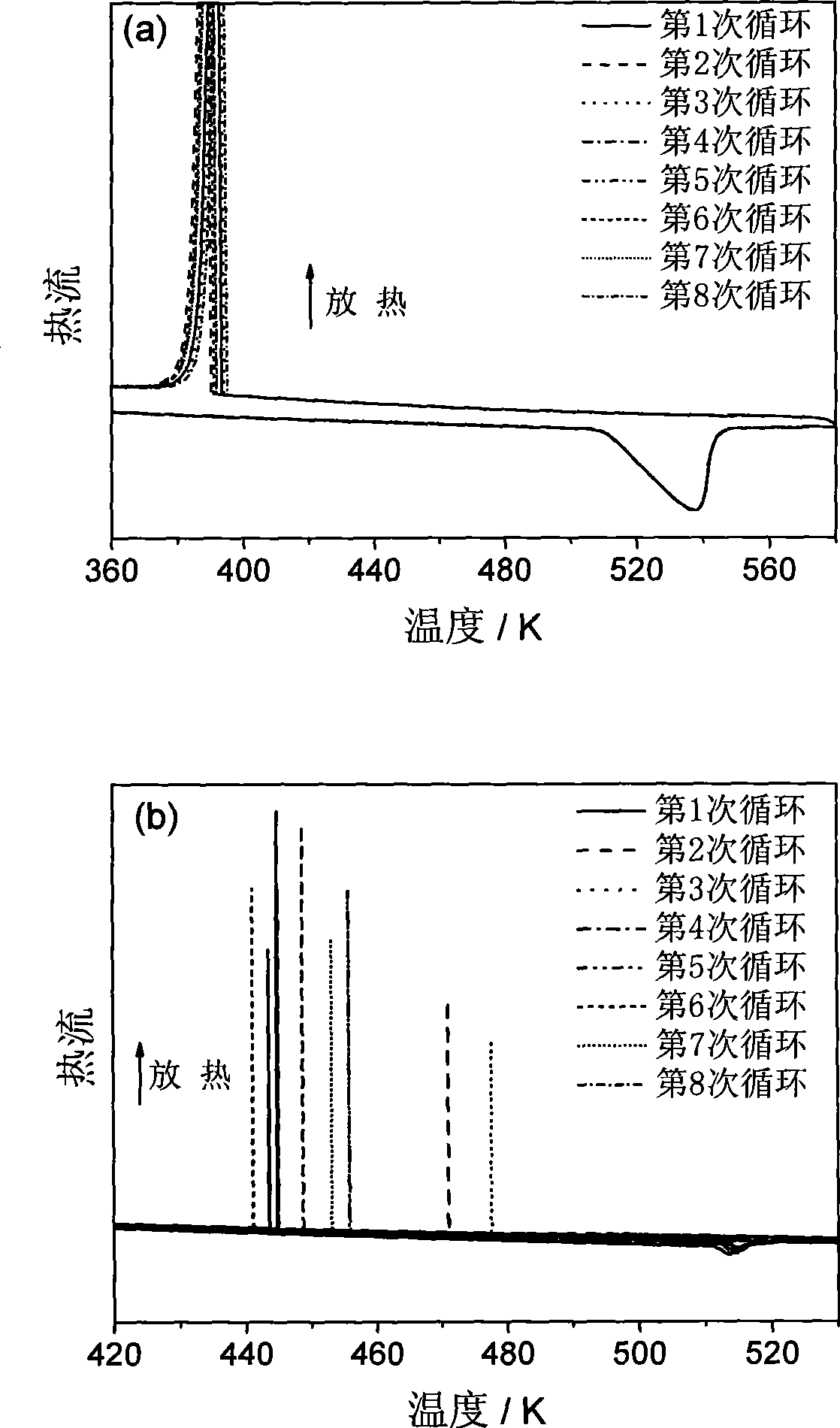

Method for single metal droplet supercooling degree measurement by large cooling speed in situ fast thermal analysis

The invention relates to a method for mensurating supercooling degree by single metallic microsphere high cooling speed in-situ fast thermal analysis and belongs to the technical field of physical performance test and measurement. The method is characterized in that real-time in-situ fast thermal analysis test is carried out on the single metallic microsphere at a high heating-cooling speed, thereby directly obtaining the solidification supercooling degree of the metallic microsphere under the condition of high cooling speed by experimental means; and the method is different from the existing method which only can obtain the solidification supercooling degree of microsphere under the fast cooling condition by theoretical calculation. The invention uses a fast thermal analyzing device to measure the heating and cooling curves of the single metallic microsphere at real time; the heating-cooling speed is 1 to 1*10<4>K / s; the obtained heating and cooling curves are analyzed to obtain the melting and solidifying temperatures of the single metallic microsphere; and the real-time solidification supercooling degree of the single metallic microsphere can be obtained.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com