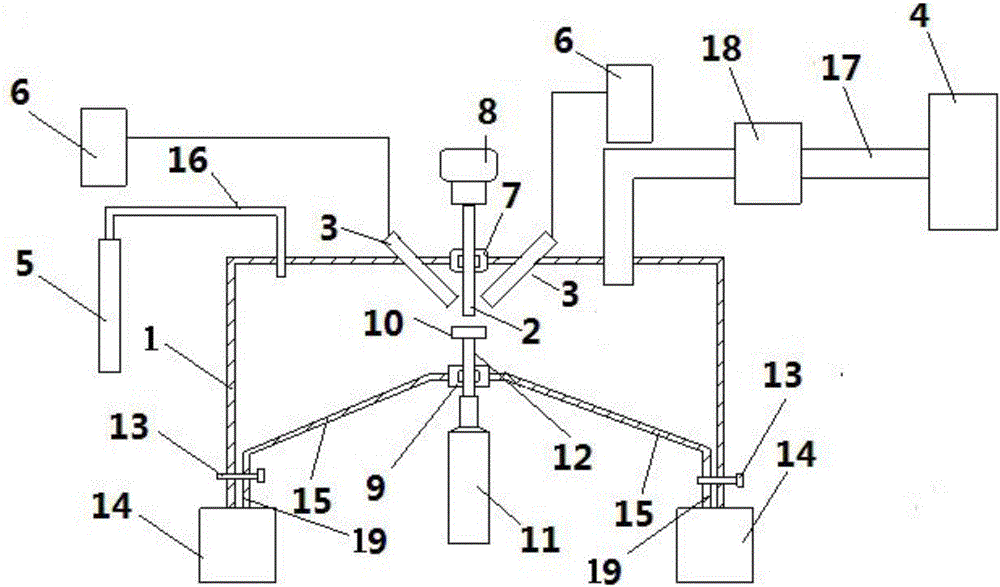

Device and method for preparing spherical metal powder

A metal powder and spherical technology, applied in the field of powder metallurgy, can solve the problems of wide particle size distribution of metal powder, large gas consumption and high production cost, and achieve the effects of uniform particles, high energy density and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

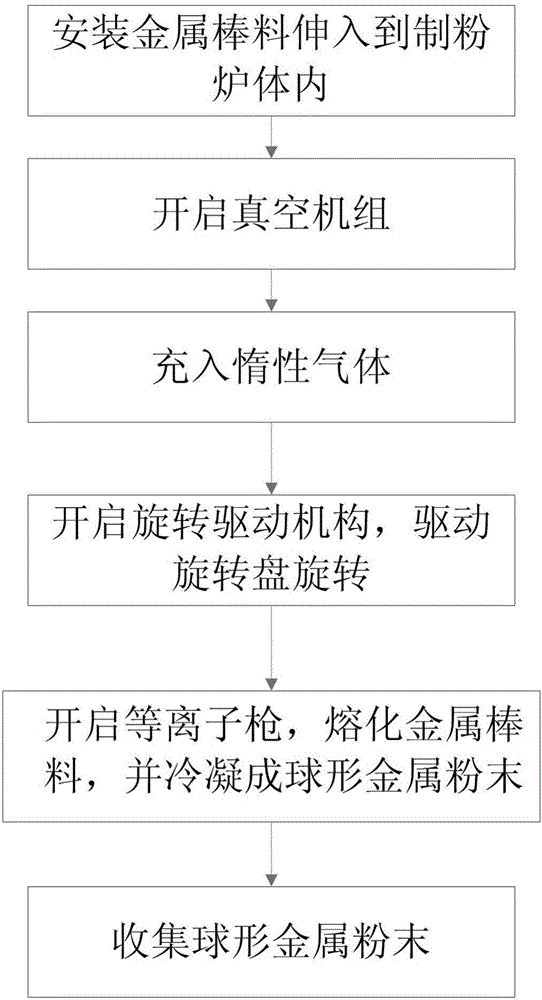

[0071] A method for preparing spherical metal powder using the device, comprising the following steps:

[0072] Step 1. First, degrease the molybdenum alloy bar with a diameter of 30 mm and a length of 300 mm with a detergent, and perform surface treatment to remove impurities with absolute ethanol; then pass the metal bar through the pulverizing furnace body The center position of the top and the dynamic seal arranged at the center position of the top, so that a part of the metal bar is located outside the pulverizing furnace body, forming a connection end, so that the other part of the metal bar is located at the The inside of the pulverizing furnace body is described as a free end, and the connection end is fixedly connected with the rotary feed mechanism to drive the rotary feed mechanism. The rotating speed of the rotary feed mechanism is 80r / min, and the feed speed is 5mm / s, the metal bar is rotated at a constant speed and inserted into the pulverizing furnace body;

[...

Embodiment 2

[0078] A method for preparing spherical metal powder using the device, comprising the following steps:

[0079] Step 1. First, degrease the niobium metal bar with a diameter of 60 mm and a length of 1000 mm with a detergent, and perform surface treatment to remove impurities with absolute ethanol; then pass the metal bar through the pulverizing furnace body The center position of the top and the dynamic seal arranged at the center position of the top, so that a part of the metal bar is located outside the pulverizing furnace body, forming a connection end, so that the other part of the metal bar is located at the The inside of the powder-making furnace body is described as a free end, and the connection end is fixedly connected with the rotary feed mechanism, and the rotary feed mechanism is driven. The rotating speed of the rotary feed mechanism is 70r / min, and the feed speed is 3mm / s, the metal bar is rotated at a constant speed and inserted into the pulverizing furnace body...

Embodiment 3

[0085] A method for preparing spherical metal powder using the device, comprising the following steps:

[0086] Step 1. First, degrease the superalloy metal bar with a diameter of 80 mm and a length of 2000 mm with a detergent, and perform surface treatment with absolute ethanol to remove impurities; then pass the metal bar through the pulverizing furnace The center position of the top of the body and the dynamic seal arranged at the center position of the top, so that a part of the metal bar is located outside the pulverizing furnace body, forming a connection end, so that the other part of the metal bar is located The inside of the powder-making furnace body forms a free end, and the connection end is fixedly connected with the rotary feed mechanism to drive the rotary feed mechanism. The rotating speed of the rotary feed mechanism is 60r / min, and the feed speed 2mm / s, the metal bar is rotated at a constant speed and inserted into the pulverizing furnace body;

[0087] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com