Method for preparing titanium alloy Ti60 prills by adopting plasma auxiliary rotary electrode

A technology of auxiliary rotation and metal balls, which is applied in the field of metal material preparation, can solve the problems that cannot meet the needs of laser three-dimensional forming technology, and achieve the effect of smooth and clean powder particle surface, low ratio of deformed particles, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

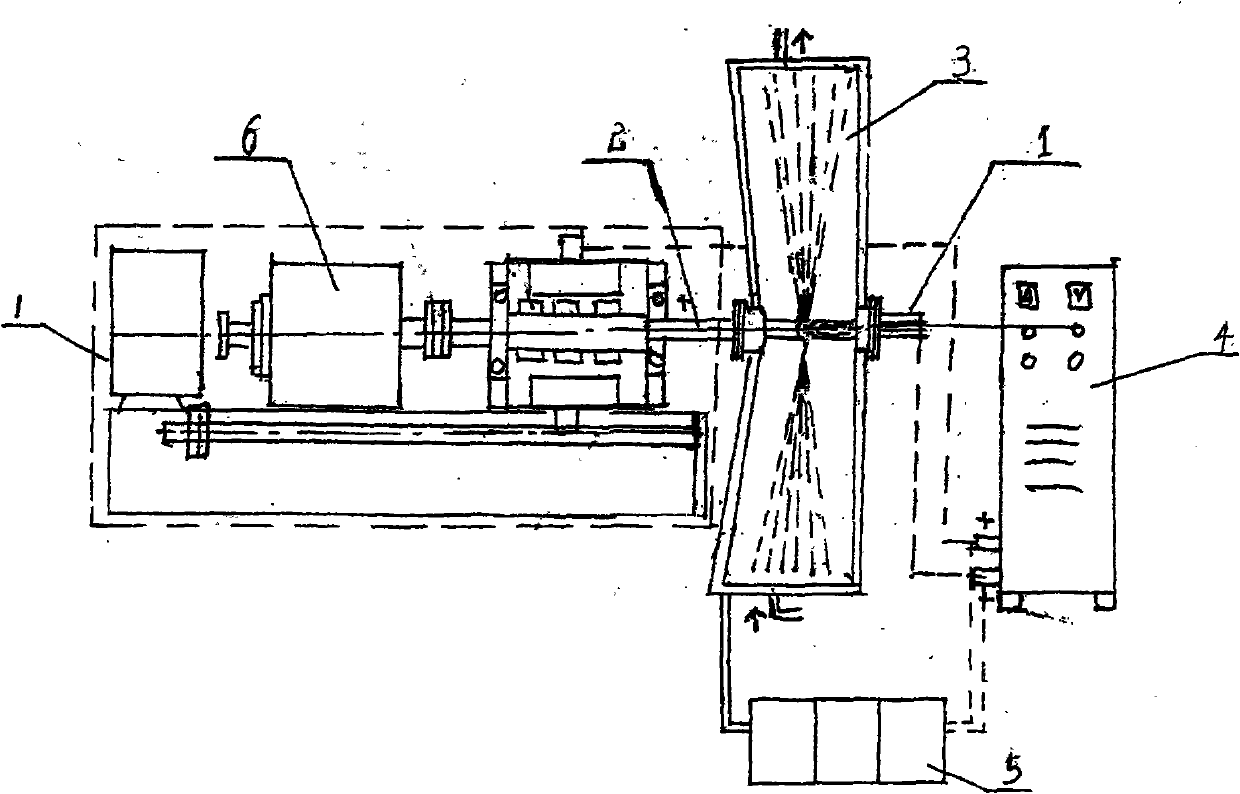

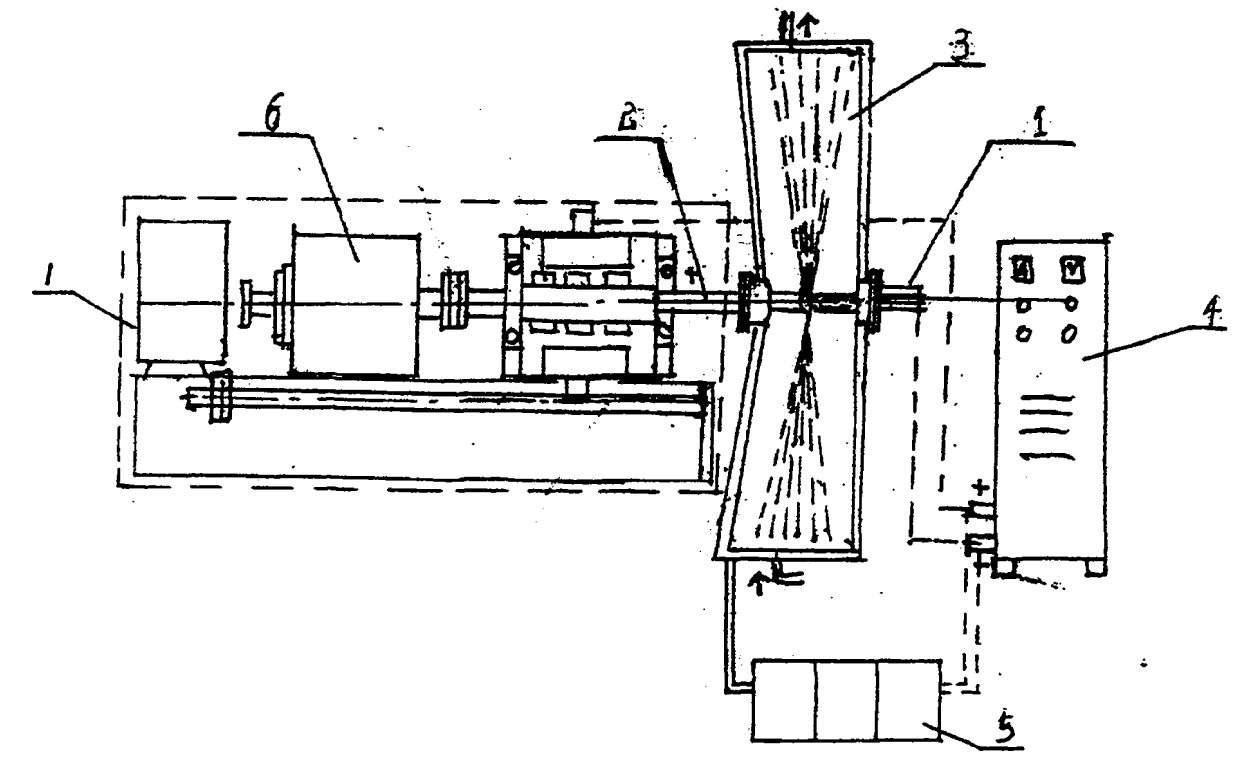

[0018] The method for preparing titanium alloy Ti60 metal pellets by using a plasma-assisted rotating electrode is implemented according to the following steps:

[0019] (1) Preparation of anode electrode rod: the titanium alloy Ti60 metal is refined into a standard rod, and then it is refined into a plasma gun rotating electrode that can run at a high speed of 12000-14000 revolutions per second to prepare spherical powder. The motor rod running smoothly in the dynamic seal of the equipment; the preparation process of the electrode rod is: a. Proportioning titanium alloy Ti60 metal according to the chemical composition required by the actual material to obtain the melting and casting raw material; b. Vacuum melting the qualified melting and casting raw material , to obtain an ingot-shaped blank with a relative density of more than 85%; c, the vacuum-smelted ingot-shaped blank is hot-forged to obtain a titanium alloy Ti60 metal rod with a relative density greater than 98%; d, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com