Patents

Literature

90results about How to "Narrow particle size range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

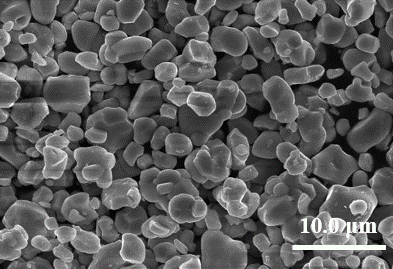

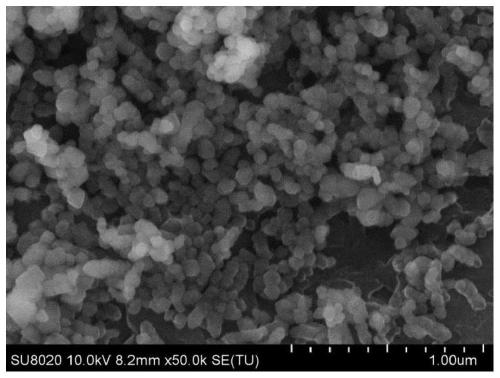

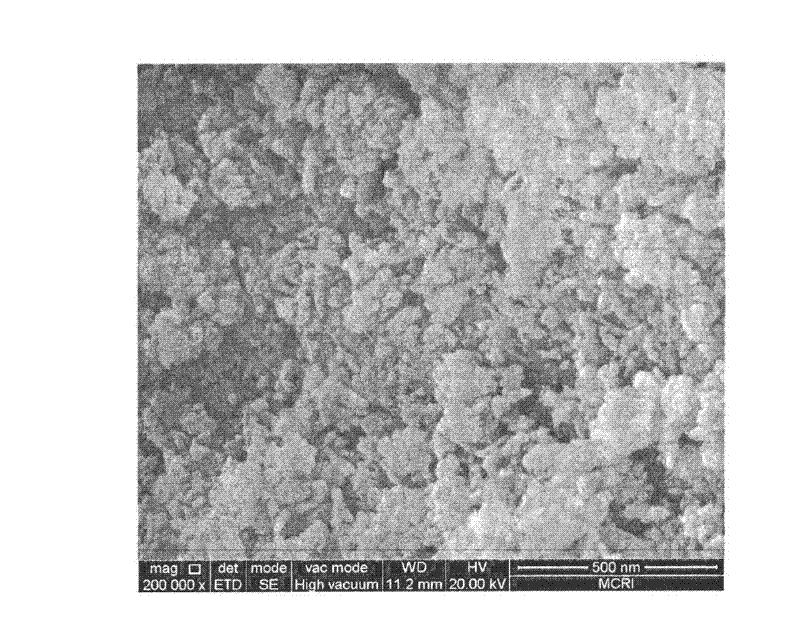

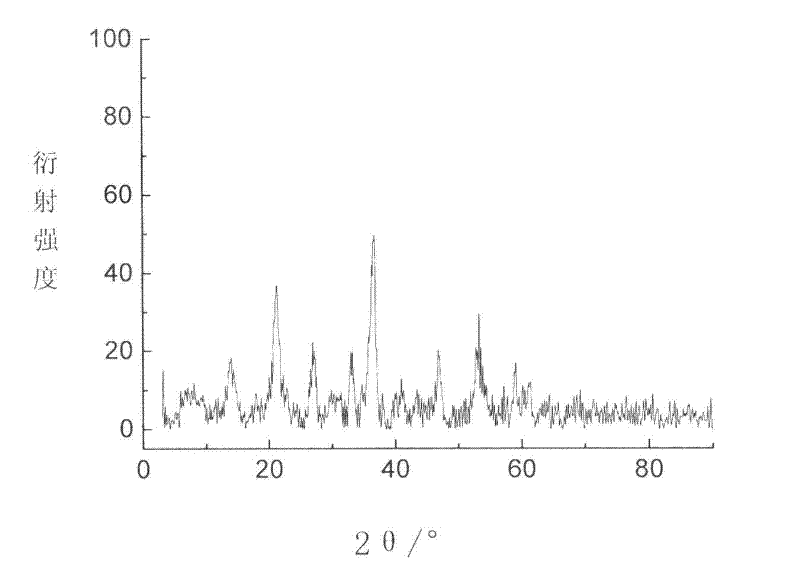

Preparation process for superfine powder of zirconium oxide

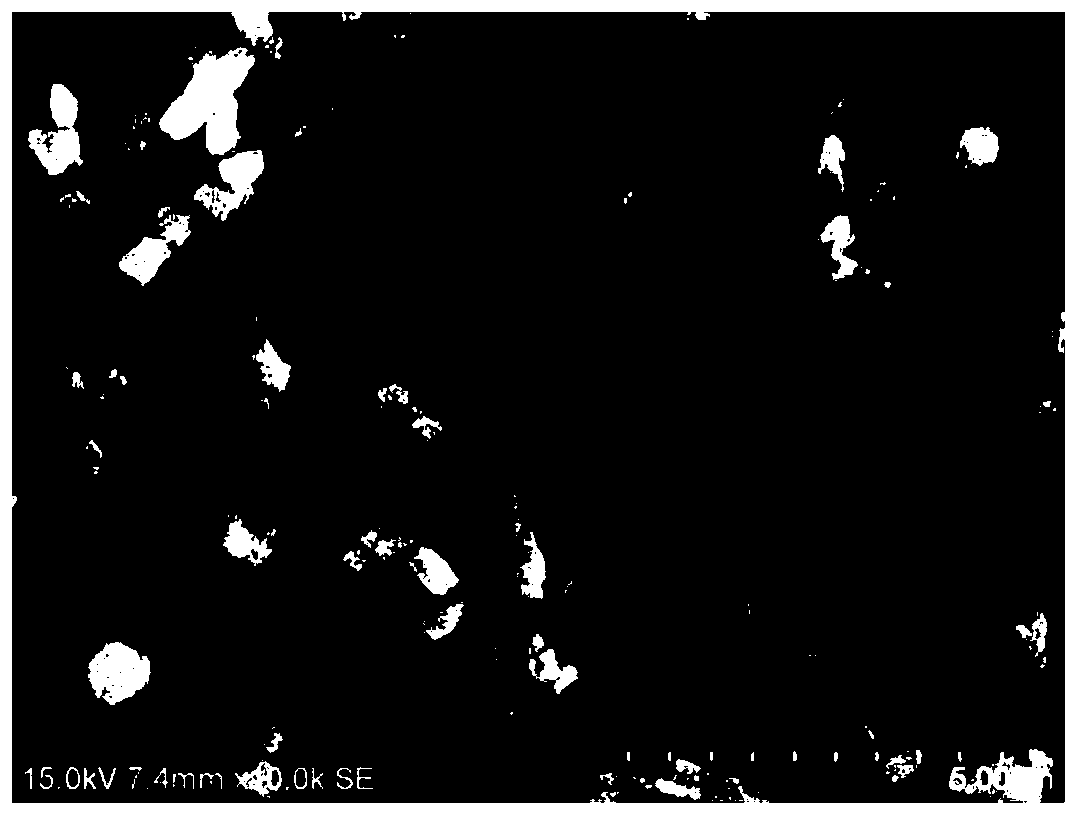

InactiveCN1559982AUniform particle size distributionNarrow particle size rangeZirconium oxidesGranularityMetallic materials

The invention relates to a ultrafine zirconium oxide (ZrO2) powder preparing method. ZrO2 is a high temperature-resistant, wearable, corrosion-resistant inorganic nonmetallic material, the proper-sized ultrafine ZrO2 powder is an important chemical raw material to prepare high-performance refined ceramics, like electronic ceramics, functional ceramics, structural ceramics, etc. and has increasingly wide applications in the technical fields of aviation, spaceflight, machinery, chemical engineering, electronics, automobiles, energy sources, etc. It adopts zirconium oxychloride and salvolatile as precursor raw material, uses uniform codeposition method to prepare wet ZrO2 gel, then drying at 100-150 deg.C at 0.3-1.0 MPa, and burning at 700-1000 deg.C to make ultrafine ZrO2 powder. It can obtain the ultrafine ZrO2 powder, particle size 0.1-0.5 mum, specific surface area 15-30 sq m / g and distribution range of particle size narrow. The ultrafine ZrO2 powder properly acts as the chemical raw material for refined ceramics.

Owner:HARBIN ENG UNIV

Method for crushing iron ore

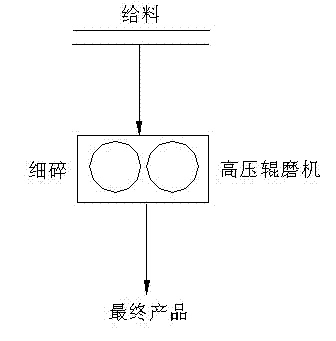

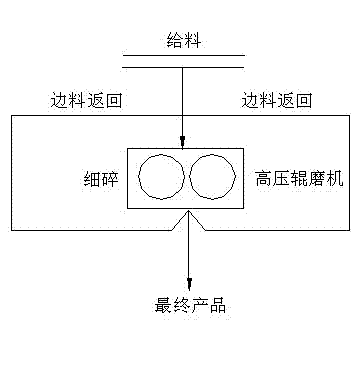

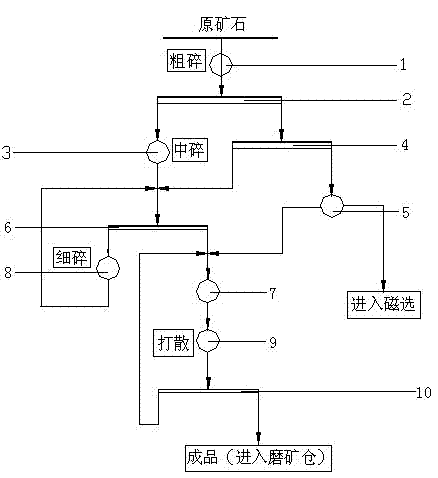

ActiveCN102179284ASmall finenessReduce processing energy consumptionGrain treatmentsIronstoneClosed loop

The invention discloses a method for crushing an iron ore, comprising the following steps of primary crushing, ore washing and high pressure roller-milling, wherein the step of primary crushing uses a multi-level sieving cycling closed loop for crushing, and the step of high pressure roller-milling also uses a closed loop method; compared with the traditional crushing process flow, the process uses the production method of high pressure roller-milling scattering sieving closed loop process flow so that the range of the particle size of a final product is ensured to be narrow and the size thereof is uniform; the material in the final product of the ore is fully rolled and pressed by a high pressure roller miller so as to reduce the fineness of the material to the maximum degree, reduce the Bond index of the milling material, efficiently decrease the procedure energy consumption and steel ball consumption in milling operation and improve the selection index; moreover, the stable production process is ensured, the energy is saved and the consumption is reduced, much crushing and less milling are really realized, and the production capability of an ore factory is greatly improved.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING +1

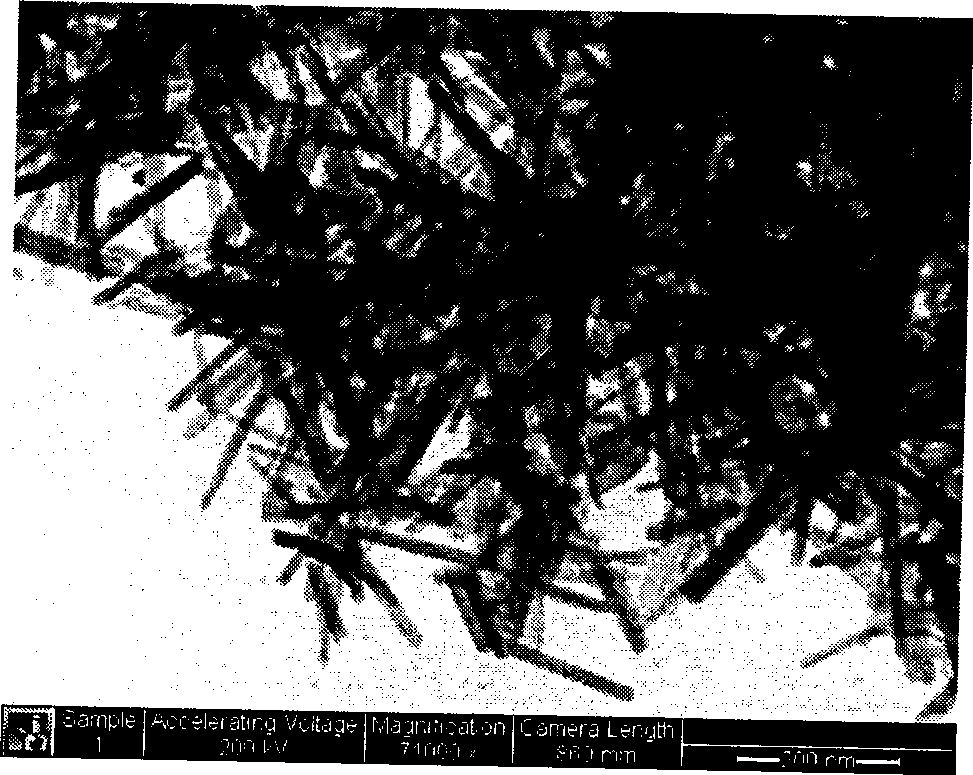

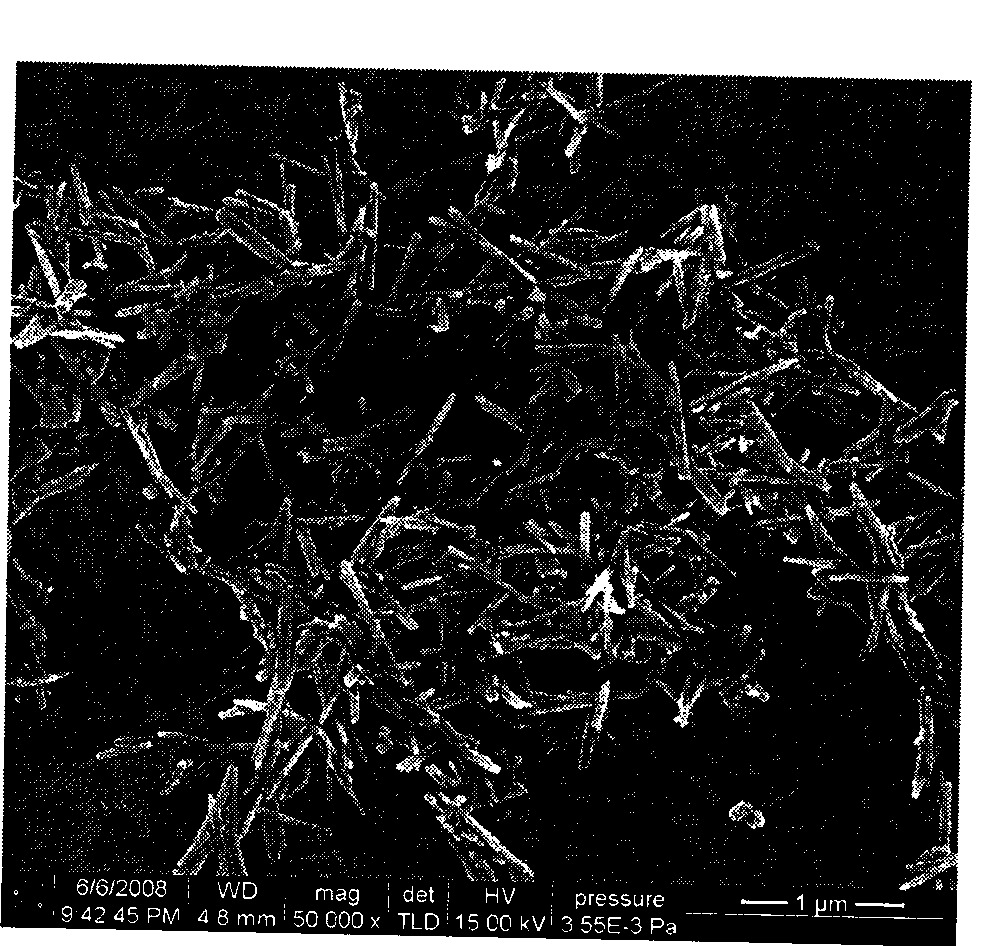

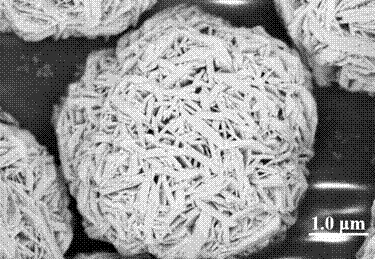

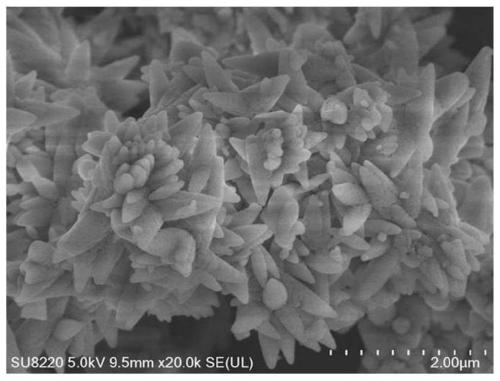

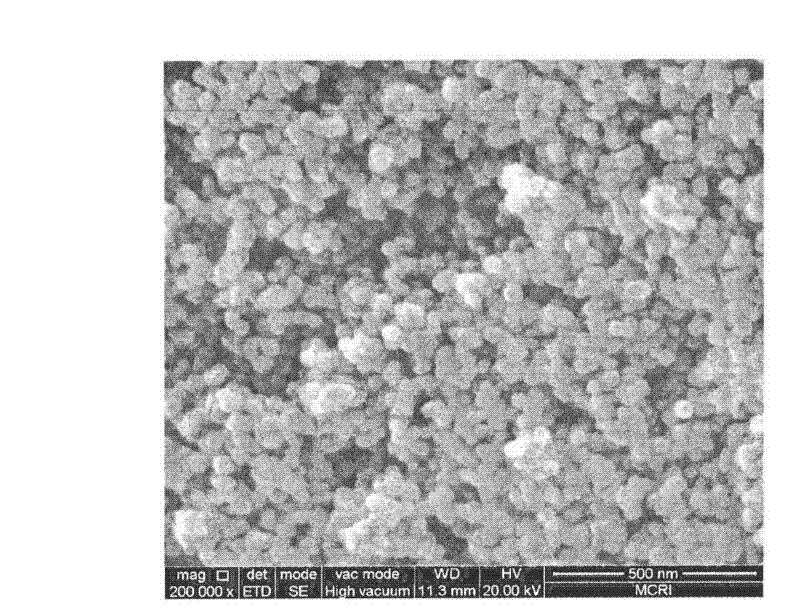

Preparation of nano hydroxylapatite powder

InactiveCN101486452AShape is easy to controlUniform particle sizePhosphorus compoundsPhosphateApatite

The invention relates to a method for preparing a nanometer hydroxyl apatite powder by utilizing hydrothermal solution, which pertains to the chemical field. Cheap calcium nitrate and phosphate which are easy to purchase in the market are taken as raw materials, the two saline solutions are mixed in accordance with certain Ca / P ratio, after adjustment and mixing by using ammonia, the pH value of the suspension comes to a certain range and then the suspension is put into a reaction kettle; under the conditions of certain stirring speed, heating temperature and holding time, reaction happens and hydroxyl apatite is generated; and the acicular or bulbiform nanometer hydroxyl apatite powder is obtained after filtration, being cleaned by a certain solvent and drying under certain conditions. The preparation method is simple and easy to be operated and has good repeatability; the obtained power has high purity and narrow particle size range and is suitable for being popularized and applied in various fields such as hard tissue repair, wastewater treatment, chromatography filler, and the like.

Owner:CHONGQING UNIV

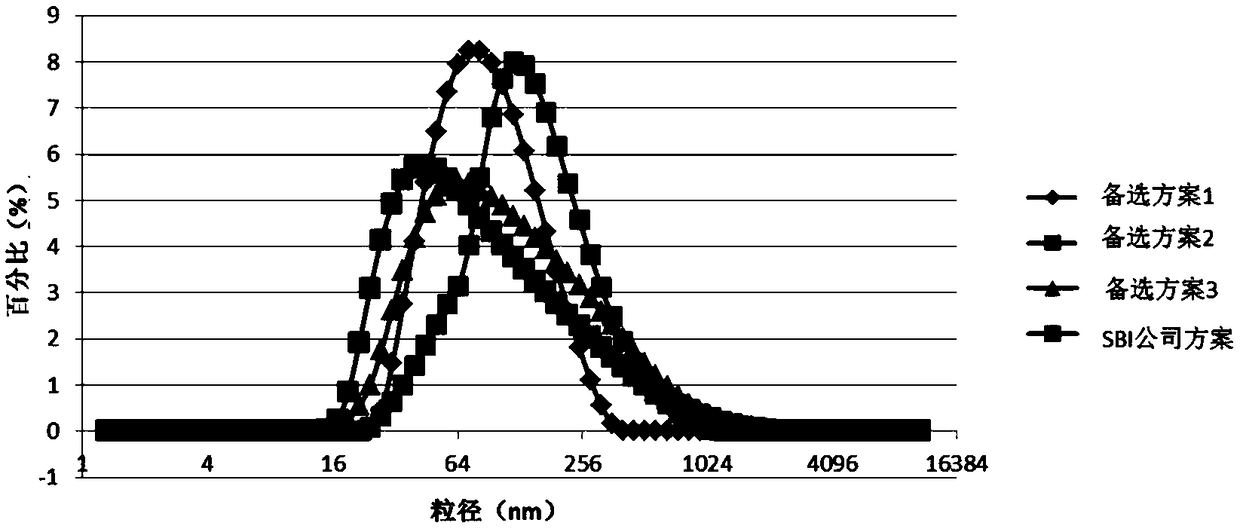

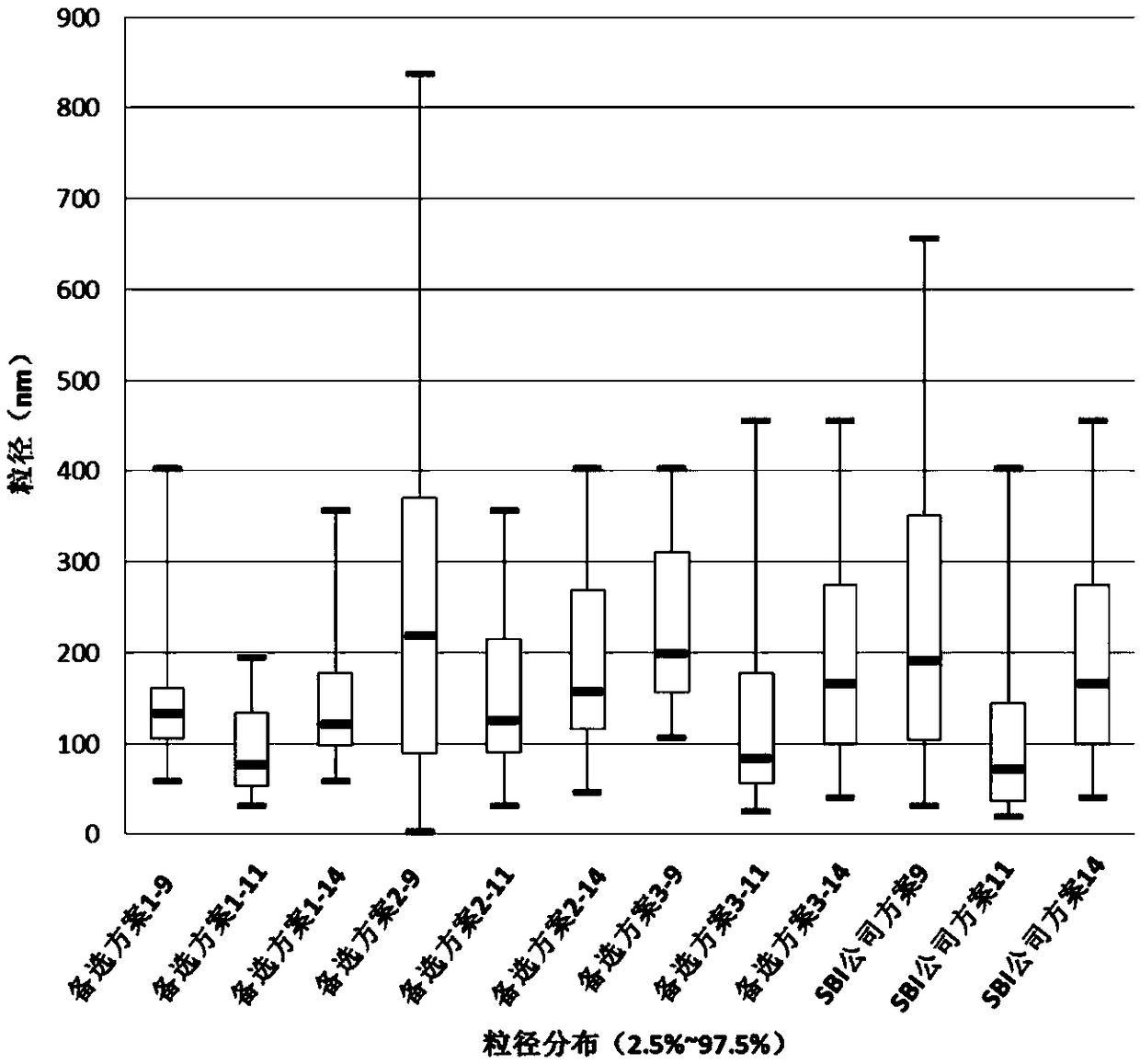

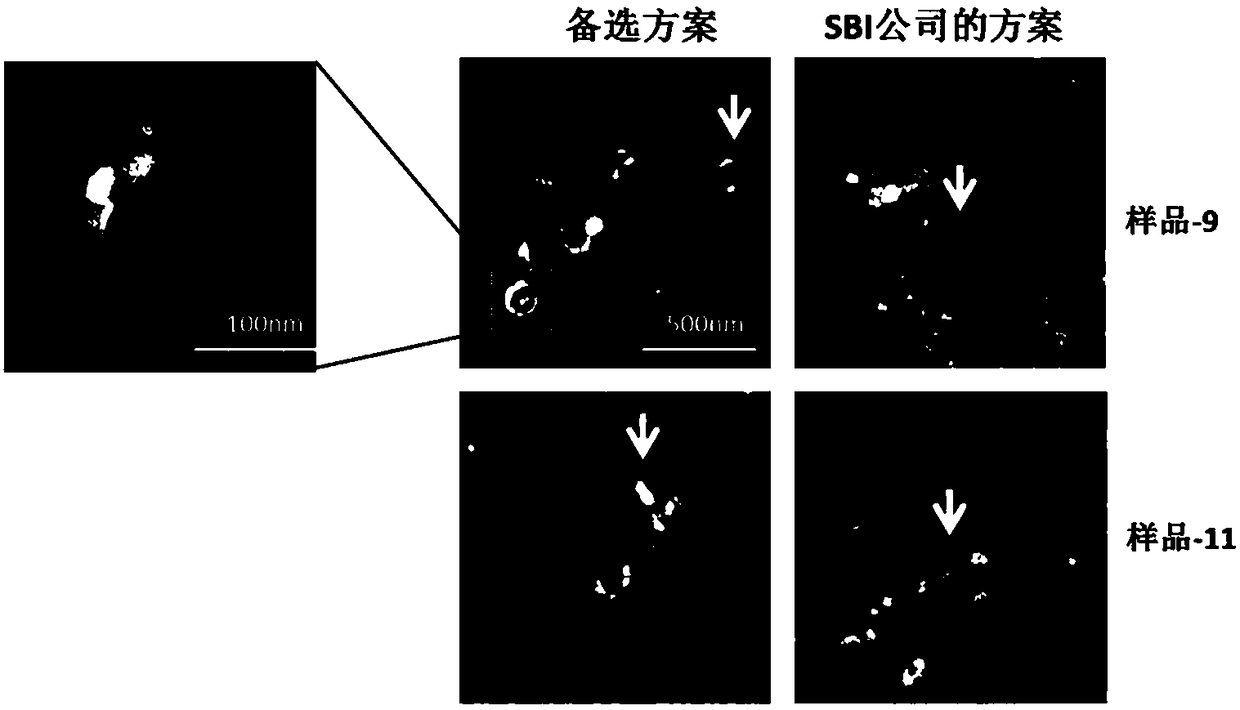

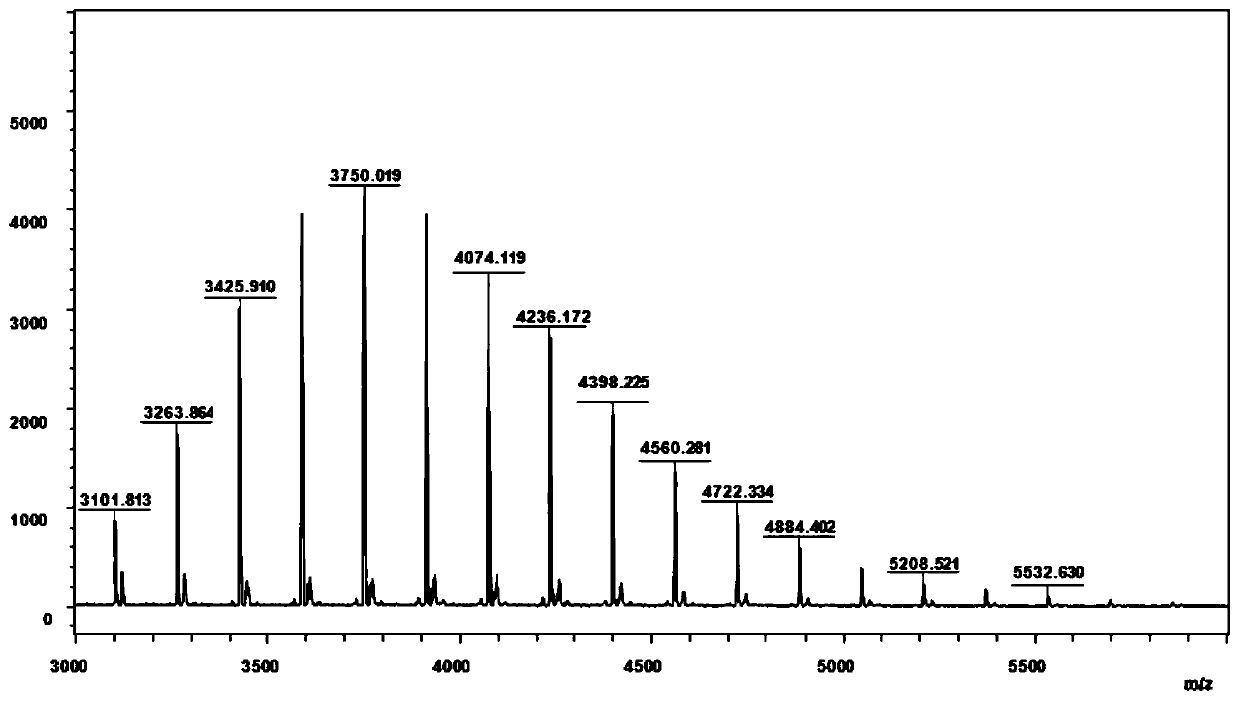

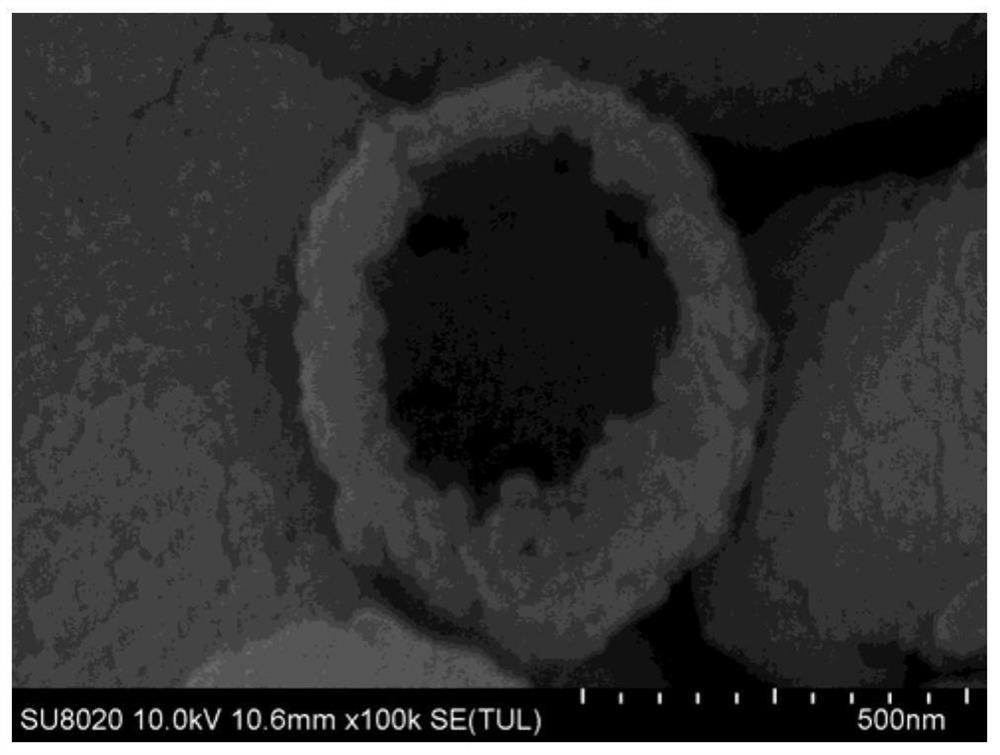

Kit and method for preparing exosomes in serum or plasma

ActiveCN108918228AConcentrated particle size distributionSimple purification processPreparing sample for investigationHydrophilic polymersPolyethylene glycol

The invention discloses a kit and method for preparing exosomes in serum or plasma. The kit comprises an exosome extracting reagent, wherein the exosome extracting reagent is a hydrophilic polymer ora solution of the hydrophilic polymer; the hydrophilic polymer comprises one or a combination of PEG (Poly Ethylene Glycol), dextran sulfate and PVP (Poly Vinyl Pyrrolidone); the molecular weight of the PEG is 20000-1200000 Daltons; the molecular weight of the dextran sulfate is 5000 to 20000 Daltons; and the molecular weight of the PVP is 10000 or 40000-700000 Daltons. The particle size distribution of the exosomes obtained by utilizing the kit is more concentrated; and according to the method for preparing the exosomes, which is provided by the invention, the step of purifying the exosomes is also optimized, so that the exosomes have less impurities and higher purity.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

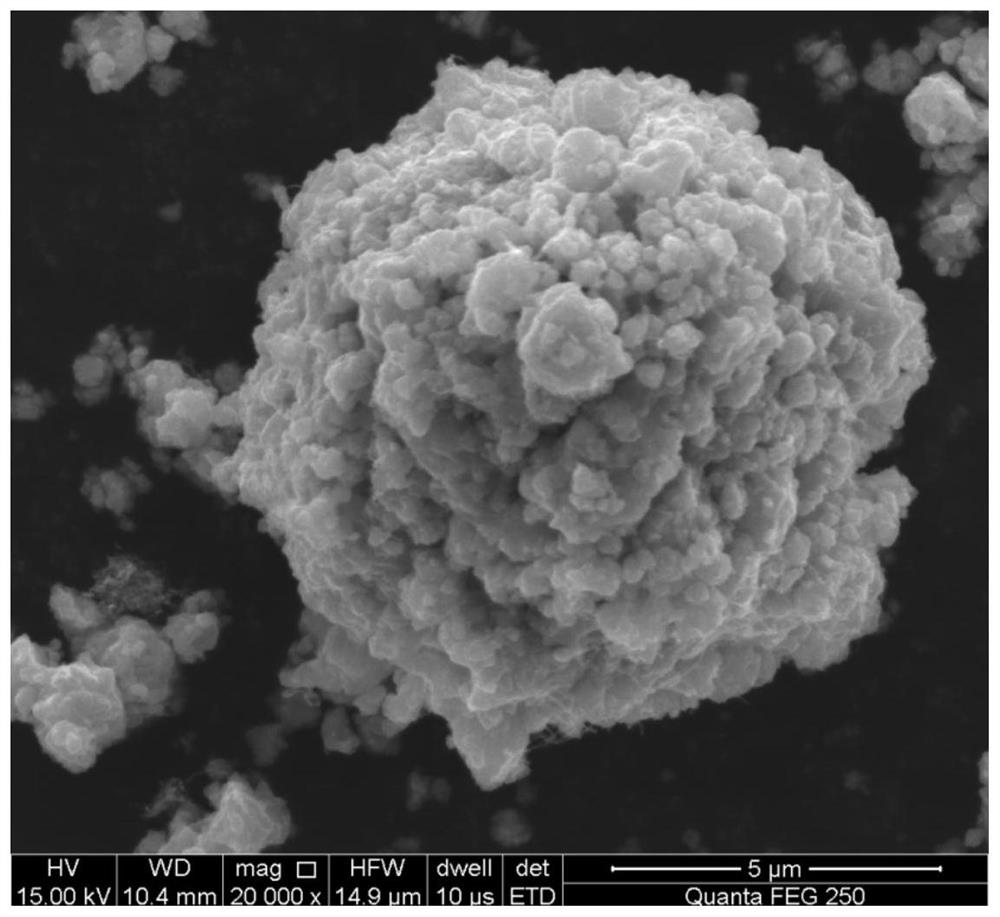

Method for preparing multi-scale ceramic phase reinforced metal composite material by 3D printing

ActiveCN111957967ANarrow particle size rangeEvenly distributedAdditive manufacturing apparatusTransportation and packagingMicron scaleMetallic materials

The invention provides a method for preparing a multi-scale ceramic phase reinforced metal composite material by 3D printing, which takes a metal material as a base body and takes ceramic particles asa reinforcement phase. The method comprises the following steps: adopting one or more ceramic particles of micro TiC, TiB2, WC, SiC, CrC and Al2O3 as raw materials, adding the ceramic particles and certain proportion of metal powder in batches, wherein mass percentage of the added ceramic particles is 0-10.0%; and performing a special ball-milling process, plasma spheroidizing, gas-flow grading and screening to obtain multi-scale uniform-ceramic-phase metal composite powder which is good in spheroidizing degree, is good in mobility and is narrow in particle size range, thereby obtaining multi-scale ceramic phase reinforced the metal composite material prepared by 3D printing. The prepared metal composite material is uniform in ceramic phase distribution, has different scales, and is excellent in mechanical property. Micro-scale ceramic particles are adopted, so that cost is low; and parts with any complex shapes can be prepared through integral forming, so that a material utilizationrate is increased.

Owner:CENT SOUTH UNIV

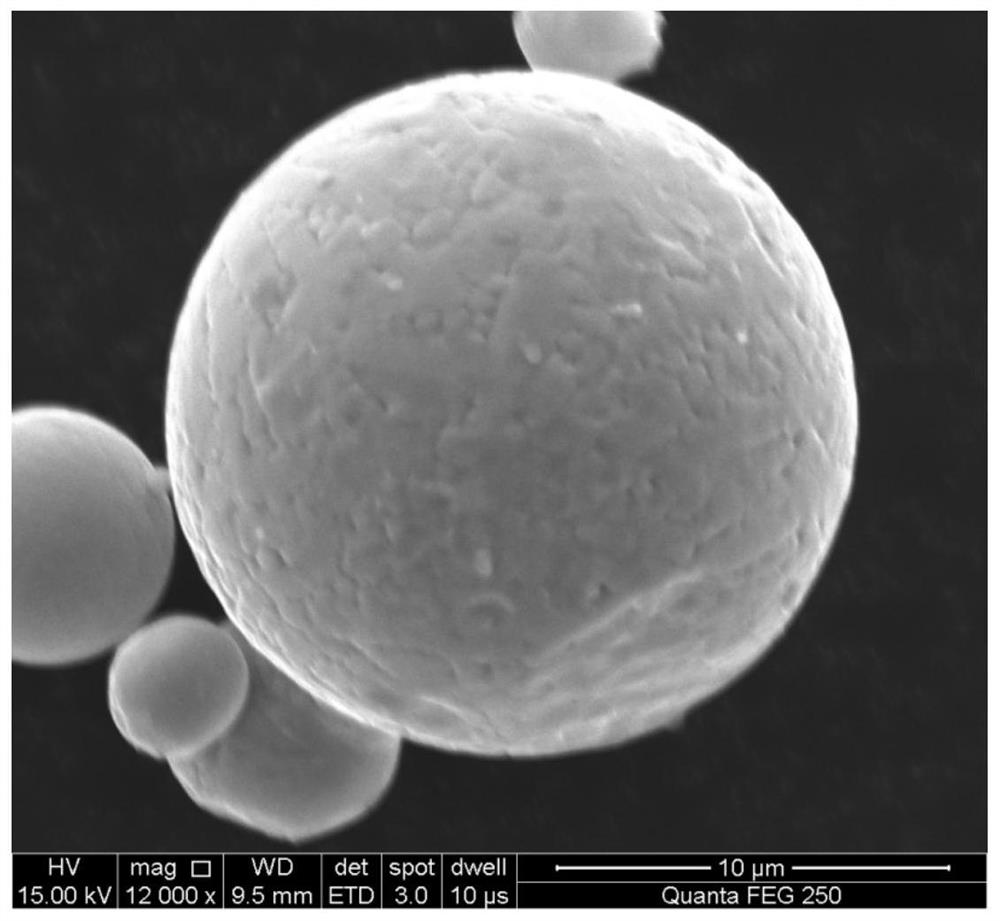

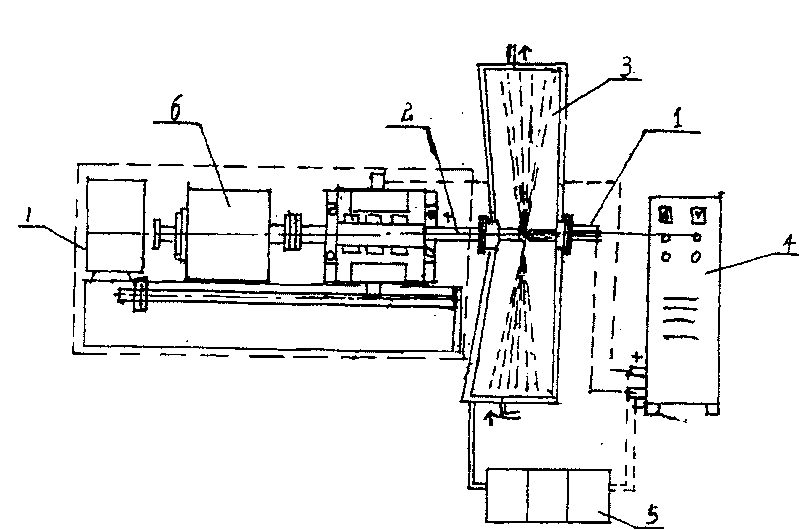

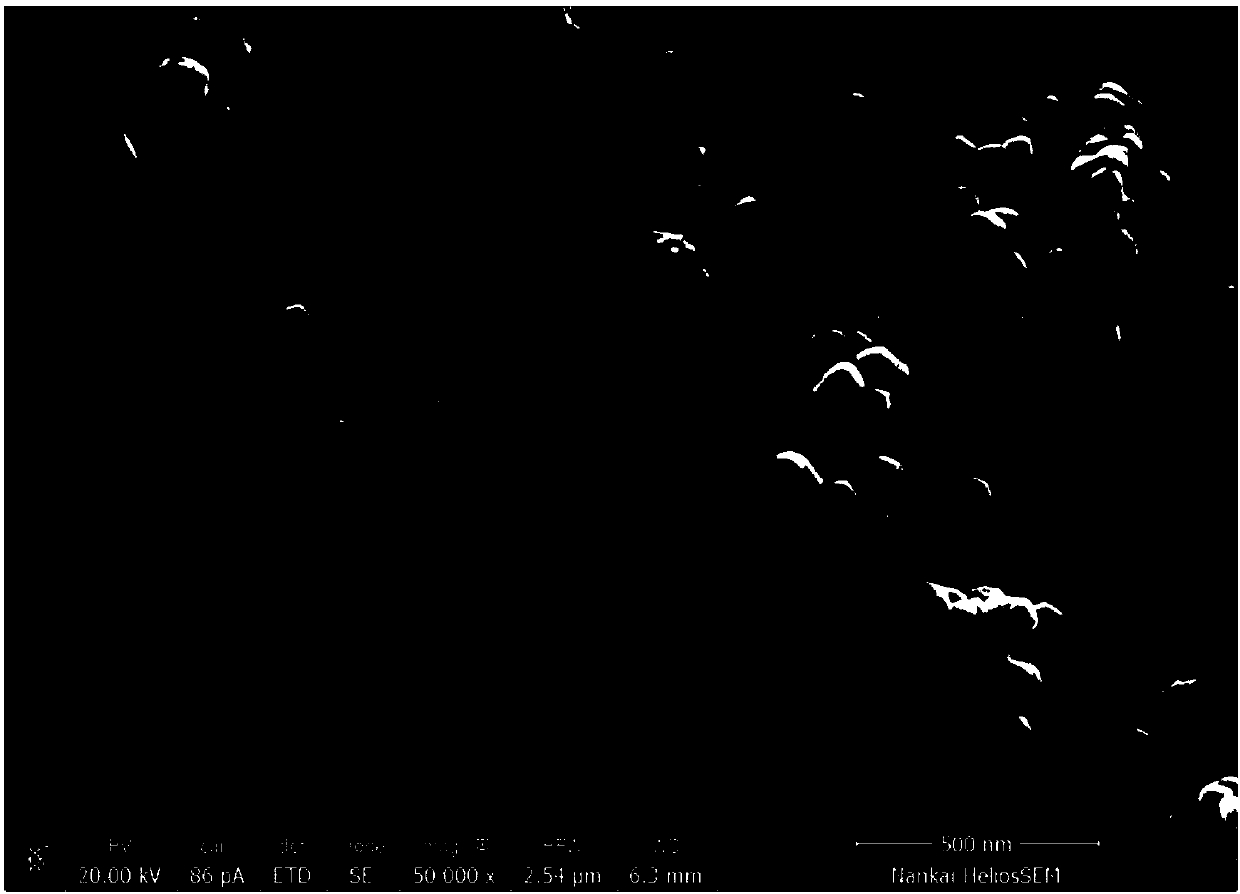

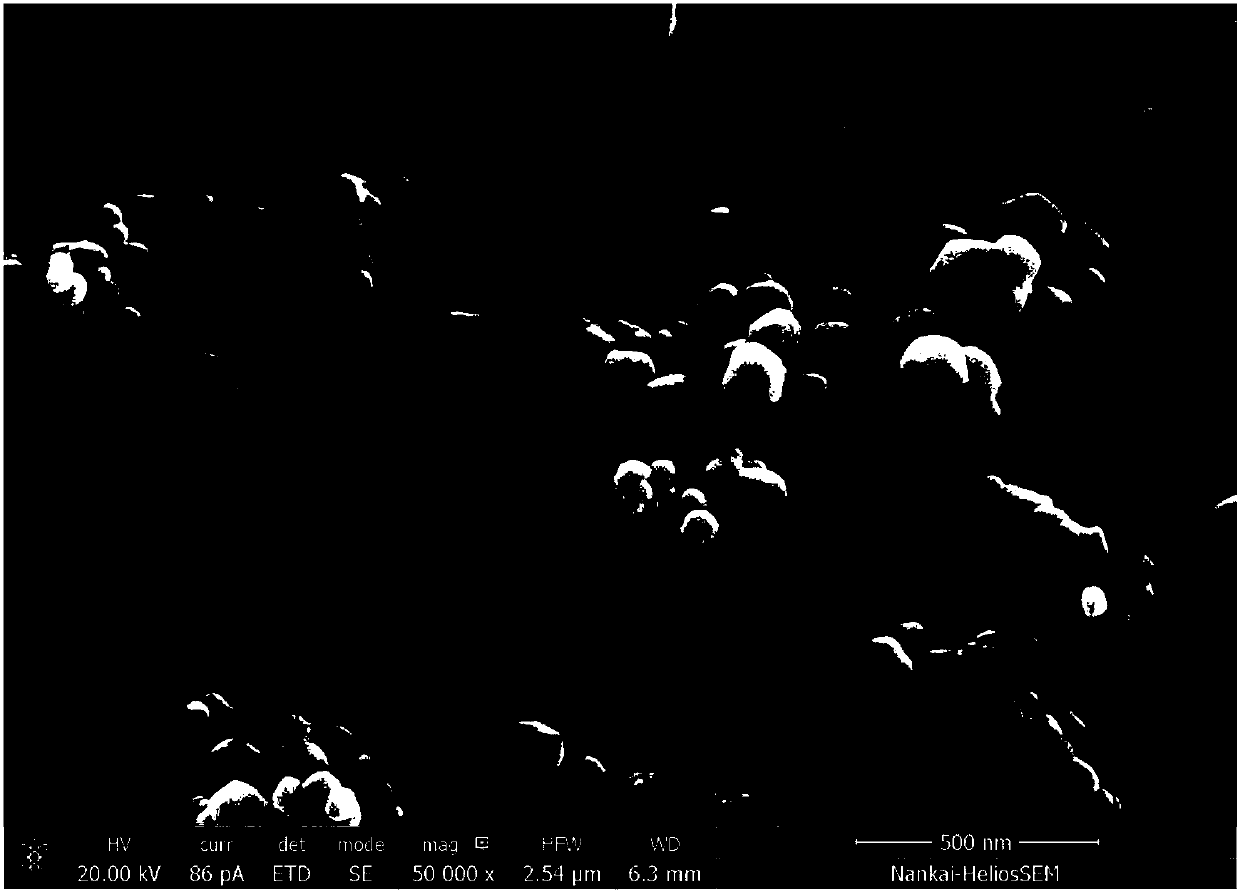

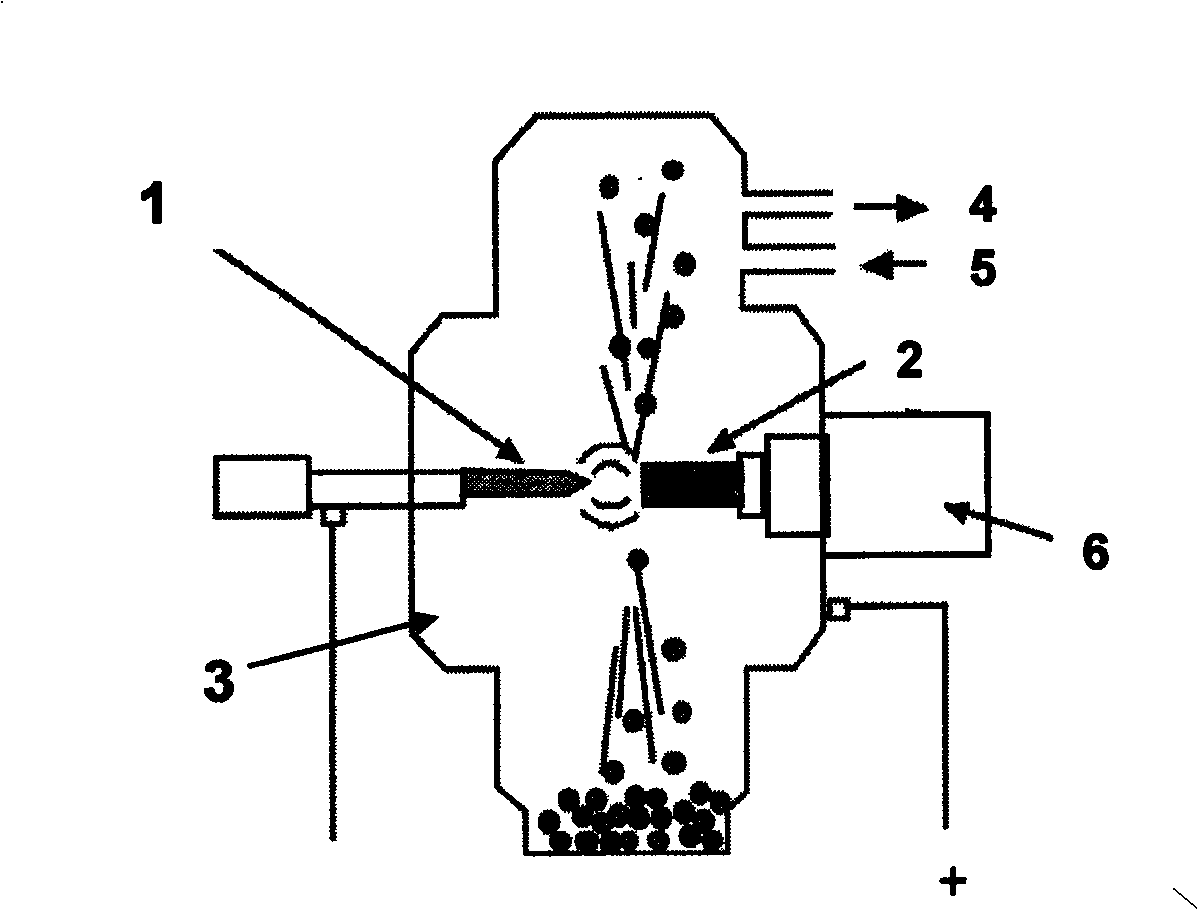

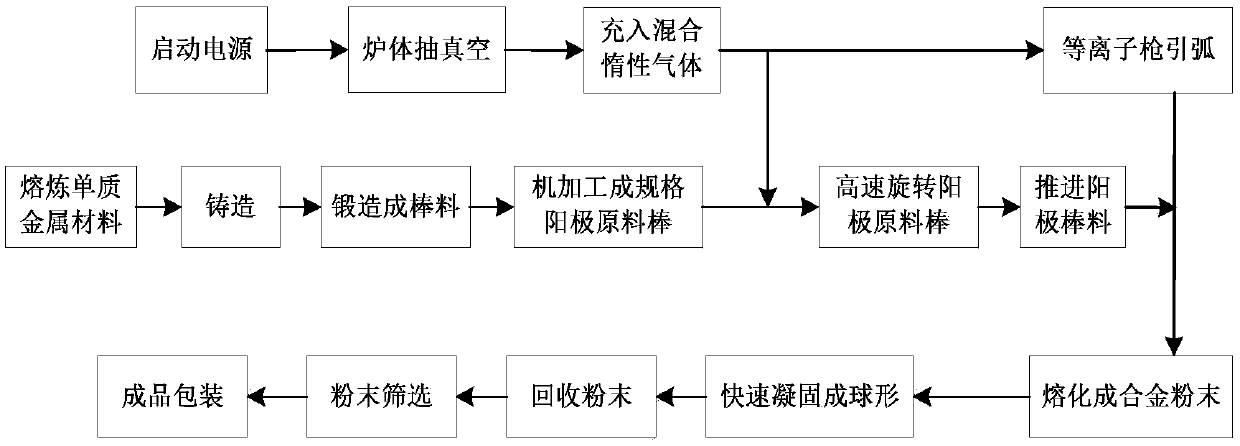

Method for preparing metal powder for 3D printing through rotating electrode with assist of plasmas

Provided is a method for preparing metal powder for 3D printing through a rotating electrode with the assist of plasmas. In a sealed container protected by an inert atmosphere, a low-voltage strong current is used for generating a plasma arc in a narrow and small space between a plasma assist electrode and the rotating cylindrical consumable electrode made from high-temperature metal. By means of the high temperature generated by the plasma arc, the section, close to the plasma arc, of the high-temperature metal electrode is made to enter a molten state, and small liquid drops of the high-temperature metal are formed. Centrifugal force generated by rotating the rotationally fed electrode made from the high-temperature metal at a high speed is used for throwing out the small liquid drops of the high-temperature metal. The small liquid drops of the high-temperature metal are air-cooled and solidified into balls in the sealed environment protected by the inert atmosphere, and the high-temperature small metal balls for 3D printing are collected from the bottom of the container.

Owner:SHAANXI YUGUANG PHELLY METAL MATERAILS CO LTD

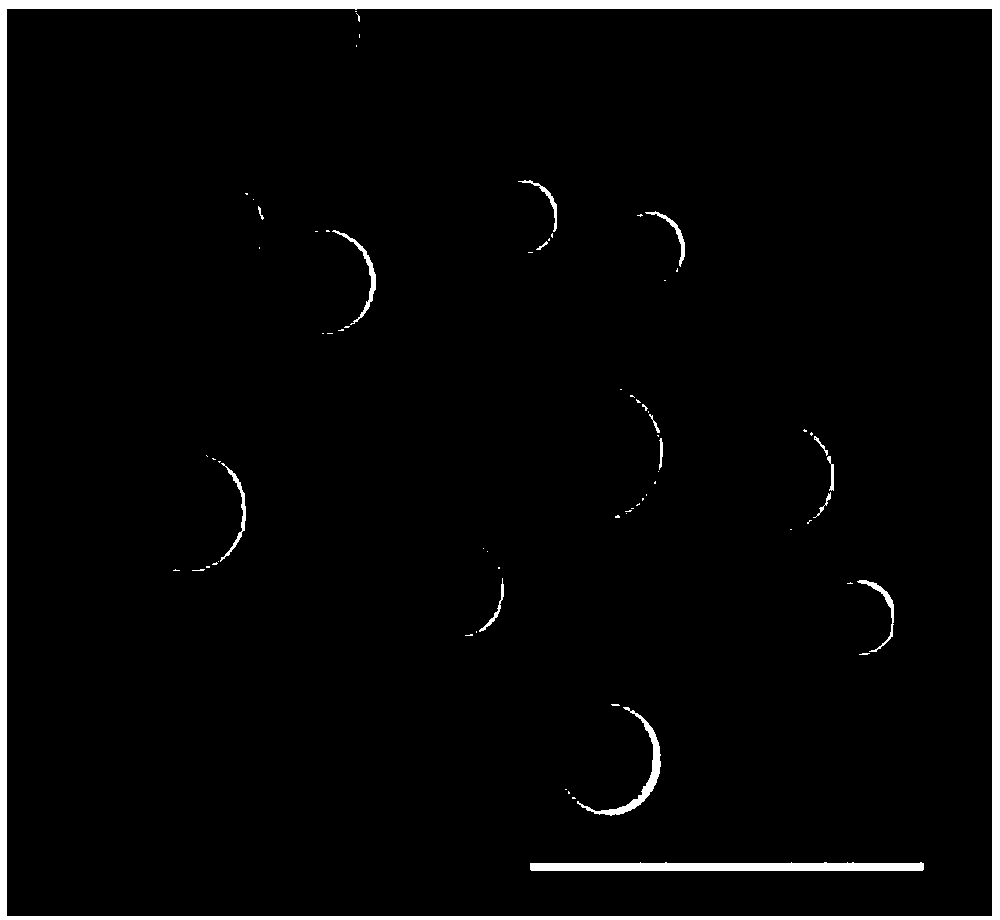

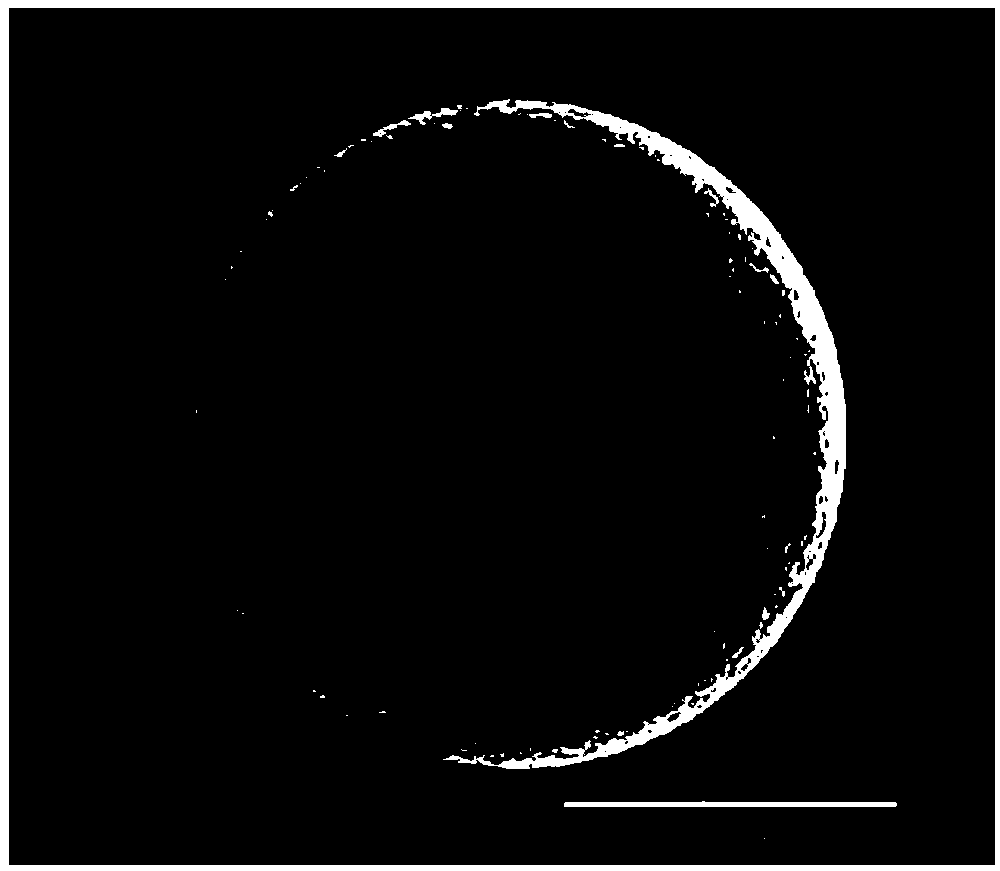

Methods for preparing titanium alloy TC4 prill by plasma auxiliary rotation electrode

The invention relates to a method for preparing a titanium alloy TC4 spherical powder by a plasma auxiliary rotation-electrode centrifugal process, comprising the following steps of: generating a glow discharge plasma arc between consumption type electrodes manufactured by a plasma auxiliary electrode and a rotational cylindrical titanium alloy TC4 in a closed container protected by inert gas, wherein a section of the titanium alloy TC4 electrode, which is close to the plasma arc, forms droplets due to high temperature generated by the plasma arc; throwing the droplets by centrifugal force; air-cooling and curing the titanium alloy TC4 droplets into a spherical shape in the inert atmosphere environment of the closed container; and obtaining a titanium alloy TC4 prill. The method can obtain the titanium alloy TC4 prill which has average sphere diameters between 0.08 mm and 1.8 mm and better monodispersity by changing technological parameters; in addition, the prepared powder prill has good sphericity, lower malformed particle proportion and controllable sphere diameter and can be used in the field of laser three-dimensional forming and for preparing special components of aerospace planes.

Owner:张建利

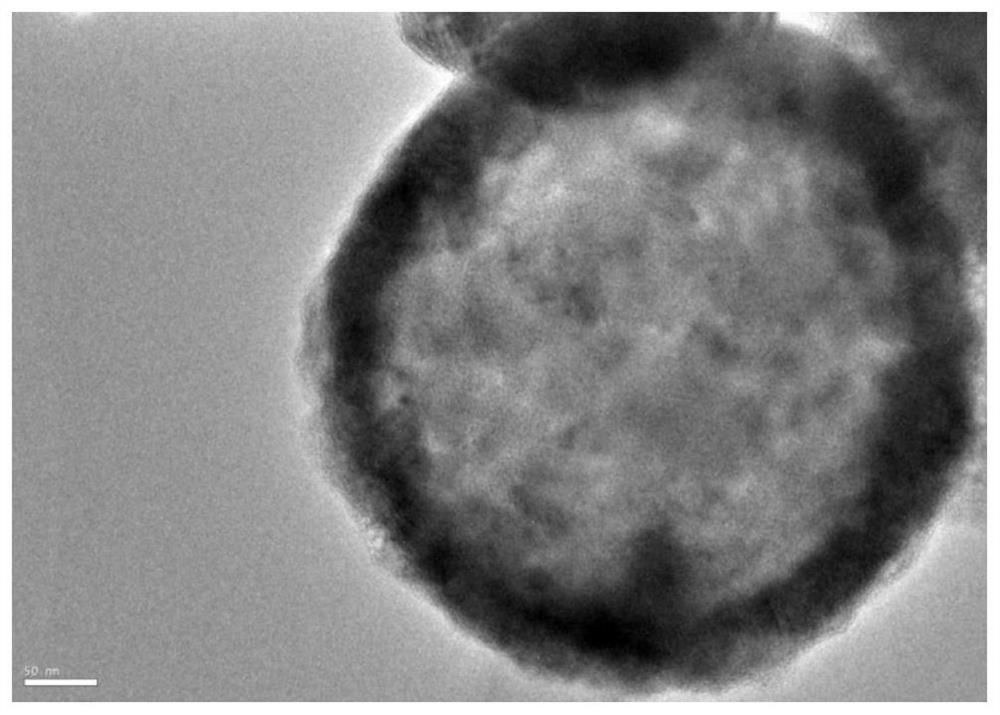

Long-circulation and high-power lithium ion battery positive electrode material and preparation method thereof

ActiveCN112768685ARaise room temperatureImprove high temperature cycle performancePolycrystalline material growthCell electrodesElectrical batteryPhysical chemistry

The invention discloses a long-circulation and high-power lithium ion battery positive electrode material, of which the molecular formula is LiNi<x>Co<y>Mn<1-x-y-z>Z O<2>. The long-circulation and high-power lithium ion battery positive electrode material comprises a single crystal or quasi-single crystal shell layer and a hollow part, wherein the single crystal or quasi-single crystal shell layer is formed by mutual fusion of primary particles, and the volume of the hollow part of secondary particles accounts for 0.8-50% of the volume of the whole secondary particles. The invention further discloses a preparation method, which comprises the following steps of: preparing a hydroxide precursor with crystallinity and morphology difference in the radial direction; and mixing the precursor with a lithium compound, and carrying out two-stage sintering on the mixture to obtain the lithium ion battery positive electrode material, wherein the first sintering is rapid heating, the temperature of the second sintering is higher than that of the first stage, and the second sintering enables the primary particles to be fused and mutually fused to form a single single crystal shell layer. The lithium ion battery positive electrode material disclosed by the invention is good in normal-temperature and high-temperature cycle performance and safety performance, can improve mechanical and electrochemical performance and compaction density, has the characteristics of quick charge, high capacity, high voltage, high cycle and low cost, and can be suitable for high-power motor vehicles.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

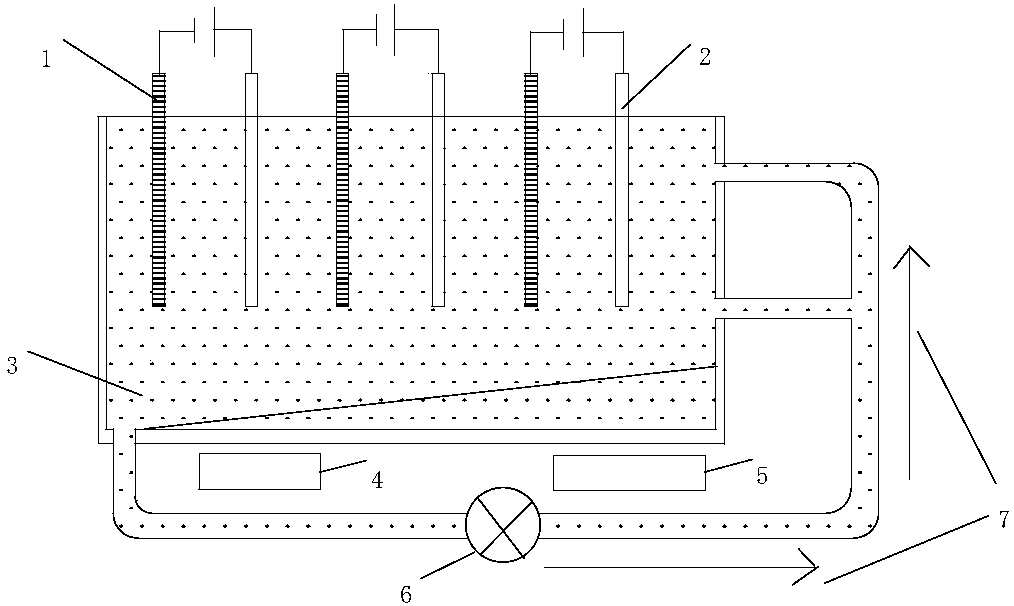

Method and device for preparing nanometer indium oxide through electrolysis

ActiveCN107935026AHigh puritySmall granularityElectrolysis componentsGallium/indium/thallium compoundsIndiumHigh density

The invention discloses a method and a device for preparing nanometer indium oxide through electrolysis. The method comprises the step of preparing indium hydroxide from an ammonium nitrate and ammonium polyacrylate mixed solution as an electrolyte, wherein a plurality of positive electrodes made of high-purity metal indium are adopted, a plurality of negative electrodes made of graphite are adopted, the positive electrodes and the negative electrodes are arranged alternately at intervals, and the electrolysis process is carried out in the existence conditions of ultrasonic waves; and after the indium hydroxide obtained through electrolysis is calcined at high temperature, nanometer indium oxide is obtained. The obtained nanometer indium oxide is high in purity, small in granularity, uniform in grain diameter, narrow in particle size range, good in particle shape and optimal in specific surface area, and a high-density sputtering target material can be prepared from indium oxide powder.

Owner:ZHENGZHOU UNIV

Coated submicron feed-grade zinc oxide and preparation method thereof

ActiveCN102318750AReduce feeding costsReduce zinc excretionAnimal feeding stuffAccessory food factorsMagnesium stearateStearic acid

The invention provides coated submicron feed-grade zinc oxide and a preparation method thereof, and belongs to the field of feed additives. The invention aims at solving the problems in the prior art that zinc oxide can influence the biological potency of active components in feed, and coating wall materials can not degrade timely in intestinal environment; through shielding treatment for three times, a product is prepared by the following components by weight: 90-120 parts of submicron feed-grade zinc oxide, 28-35 parts of composite shielding agents; the composite shielding agent comprises the following components by weight: 80-90 parts of potato starch, 4-6 parts of ethyl cellulose, 3-4 parts of anhydrous alcohol, 0.5-0.8 parts of magnesium stearate. A feed-grade zinc oxide product and a corresponding preparation method thereof are provided, wherein the product combines appropriate control of the degeneration degree of the shielding agent, can deshield and release in animal digestive tract, gastric and intestinal environment, and is effectively used by microbe in posterior digestive tracts.

Owner:巨星农牧有限公司

Method for producing beryllium prill using plasma auxiliary rotating electrode

The invention relates to a method for preparing a Be prill by centrifugal process of a plasma assisted rotary electrode. In a closed container protected by inert gases, the high temperature generated by glow discharge generated between the plasma assisted rotary electrode and a rotary cylindrical consumption Be electrode manufactured by the metal of Be is utilized for leading one section of Be electrode that is close to the voltaic arc of the plasma to form small drops of Be; the small drops of Be are thrown away by centrifugal force; the small drops of Be are cooled in air and solidified into sphere in the closed container under the environment of the inert gases, thus the Be prill is obtained. The method can obtain the prills with an average sphere diameter between 0.05mm to 2mm with good monodispersity by changing the technique parameters. The prepared Be prill has excellent sphericity and lower deformed particle proportion; besides, the sphere diameter is controllable; the Be prill can be used on the blanket or the fusion reactor of an ITER experiment for producing tritium in a solid state.

Owner:张建利 +1

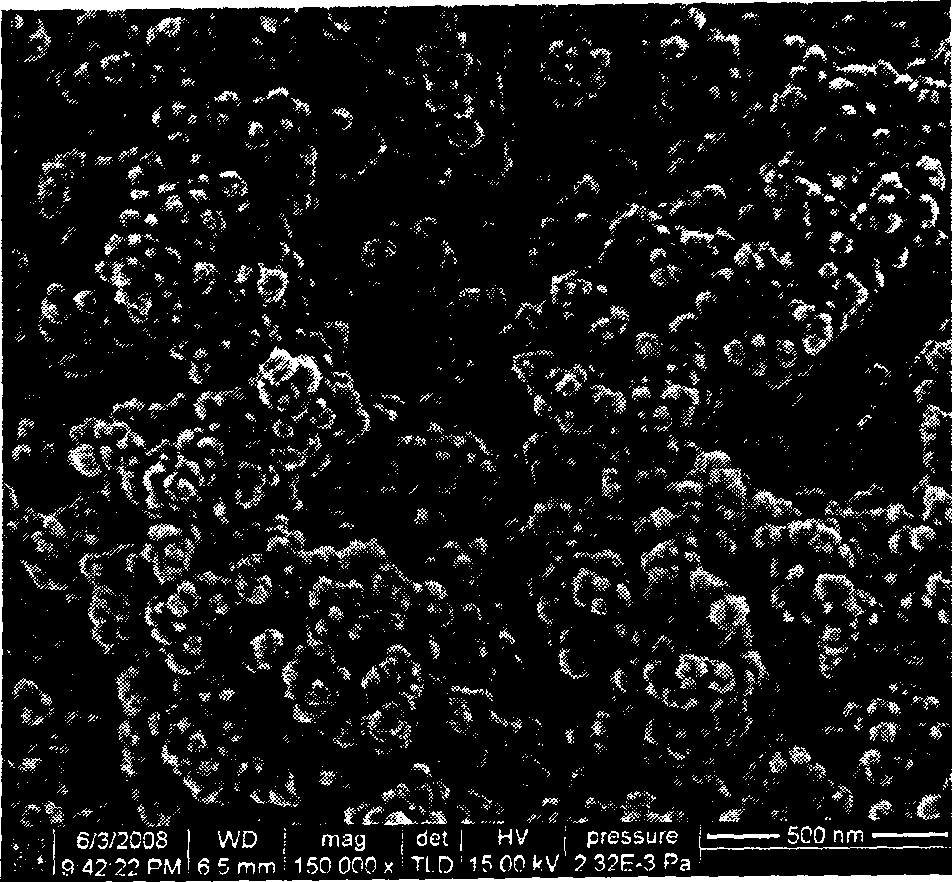

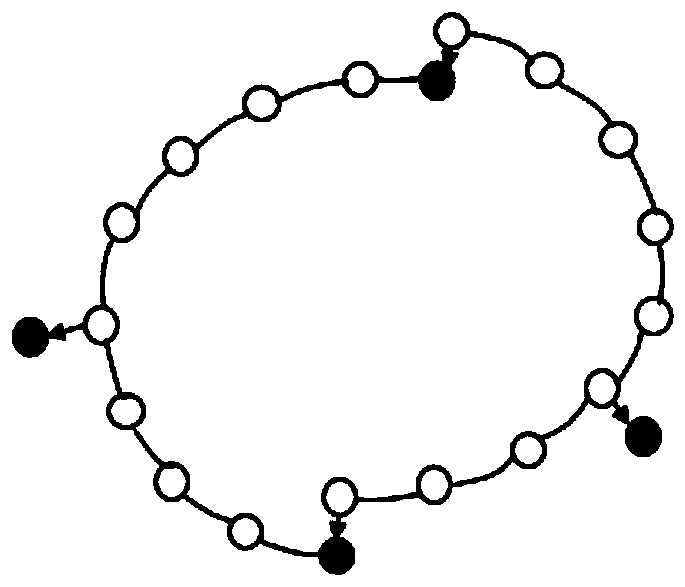

Preparation method for immune nano magnetic glucan micro-sphere

ActiveCN101143888ANarrow particle size rangeStrong magnetismPeptide preparation methodsCarrier-bound/immobilised peptidesNanometreBrown iron oxide

The present invention relates to a preparation method of immune nano-magnetic dextran microspheres, which belongs to the technical field of biological separation. In the process steps, nano-size magnetic iron oxide particles are prepared by the method of coprecipitation; a solution is prepared with ferrous ion, iron ion and nickel ion according to the molar ratio of 1:(1.0 to 4.0):(0.2 to 0.8); glucan enwraps the magnetic iron oxide particles; the proteins of the nano-magnetic dextran microspheres are linked. The present invention has the advantages of realization of the narrow diameter of particles, good reproducibility, low price and natural activity of the immune nano-magnetic dextran microspheres.

Owner:北京泽诚生物技术有限公司

Method of preparing ultrasonic contrast agent using mechanical oscillation

InactiveCN1785435AIncrease productivityLower doseNMR/MRI constrast preparationsUltrasound contrast mediaContrast medium

A process for preparing the ultrasonic contrast medium by mechanical oscillation is disclosed. Said ultrasonic contrast medium may be conventional one, target one, nano-foam one, and therapeutic one. A process for preparing aliphatic ultrasonic contrast medium is also disclosed.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

Method for preparing high-temperature alloy GH4648 prills by adopting plasma auxiliary rotary electrode

The invention relates to a method for preparing high-temperature alloy GH4648 metal spherical powder by adopting a plasma auxiliary rotary electrode centrifuging process. The method comprises the following steps of: generating a glow discharge plasma arc between a plasma auxiliary electrode and a consumption-type electrode made of rotary cylindrical high-temperature alloy GH4648 metal in a closed container protected by inert gas; forming droplets at one section of the high-temperature alloy GH4648 metal electrode close to the plasma arc by high temperature which is generated by the plasma arc; flinging the droplets out by centrifugal force; cooling the high-temperature alloy GH4648 metal droplets in air and solidifying into spheres in the inert atmosphere environment of the closed container; and collecting the high-temperature alloy GH4648 prills. The method changes process parameters so that high-temperature alloy GH4648 prills with an average sphere diameter from 0.05-1.2 mm and better monodispersity are obtained, have favorable degree of sphericity, lower malformed particle proportion and controllable sphere diameters and can be used in the field of a laser three-dimensional forming process for preparing special parts of an aerospace craft.

Owner:张建利

Blue black metallic luster glaze and preparation method thereof

The invention relates to blue black metallic luster glaze which is prepared from the following components in parts by weight: 35-45 parts of an intermediate temperature lead-free high sodium and calcium frit, 15-20 parts of quartz, 5 parts of calcium carbonate, 3 parts of barium carbonate, 10 parts of calcined zinc oxide, 7 parts of kaolin, 4 parts of titanium dioxide, 3 parts of iron sesquioxide,8-10 parts of manganese dioxide, 3 parts of copper oxide, 2-4 parts of cobalt oxide, 1-2 parts of nickel oxide and 1-2 parts of vanadium pentoxide. The invention also provides a preparation method ofthe surface glaze. The preparation method comprises the following steps: mixing and ball-milling the glaze; applying the glaze; and carrying out primary firing. According to the blue black metallic luster glaze prepared by the invention, as enough metallic oxides such as iron sesquioxide, manganese dioxide, copper oxide, cobalt oxide, nickel oxide and vanadium pentoxide are introduced into the glaze, when the oxide of manganese reaches a saturated state, metals are separated out from the glaze surface; by adding copper oxide, a metal film is formed on the glaze surface; and by adding a certain amount of cobalt oxide, the glaze surface finally shows blue black metallic luster.

Owner:FUJIAN JIAMEI GRP

Cuprous thiocyanate and production method

InactiveCN101428822AImprove particle size uniformityNarrow particle size rangeThiocyanic acidSulfateWhite powder

The invention relates to cuprous thiocyanate and a preparation method. Cuprous thiocyanate can be used as antifouling paint and paint used biological poisoning agents. The invention is characterized in that 35-50% thiocyanate water solution and 35-45% copper sulfate or hydrochloride water solution replacement-react under the protection of SO2 or CO, the mol ratio of the three is 1:1:(0.3-0.7), and white powder with grain diameter ranging from 5-25 Mum and white content being 70-80% is obtained. Compared with the prior art, the yield can be improved by 50%, and the yield and the purity can be improved to be above 99%; the output of waste water is small, and only 1-3 t waster water is generated per product; the obtained cuprous thiocyanate has good evenness and small grain diameter range reduced to be 5-25 Mum, the anti-corrosion effect is stable, and the white or off-white powder product greatly improves the commonality of color matching; and the integrated cost is reduced by 20%, thereby overcoming the defect of the prior art.

Owner:江苏燎原环保科技股份有限公司

Infrared high-radiation and energy-saving coating used for glass melting kilns, and preparation method of coating

ActiveCN106084908AHigh emissivityImprove absorption rateChemical industryCoatingsAntioxidantHigh energy

The invention relates to an infrared high-radiation and energy-saving coating used for glass melting kilns. The infrared high-radiation and energy-saving coating comprises, by weight, 5-30 parts of a high-radiation base material, 21-40 parts of quartz powder, 20-35 parts of silica sol, 1-6 parts of kaolin, 1-6 parts of bentonite, 2-12 parts of an antioxidant, 0-2 parts of a dispersant, 0-5 parts of a film forming auxiliary agent, and 5-20 parts of deionized water. The infrared radiance of the coating at a high temperature of 1500-1700 DEG C keeps at 0.86-0.96, and the coating has the advantages of high energy saving efficiency, long energy saving life, and no pollution to molten glass, and is suitable for float glass melting furnaces, container glass melting furnaces, glass fiber melting furnaces and other various types of glass melting furnaces.

Owner:SHENZHEN TRIUMPH TECH ENG +1

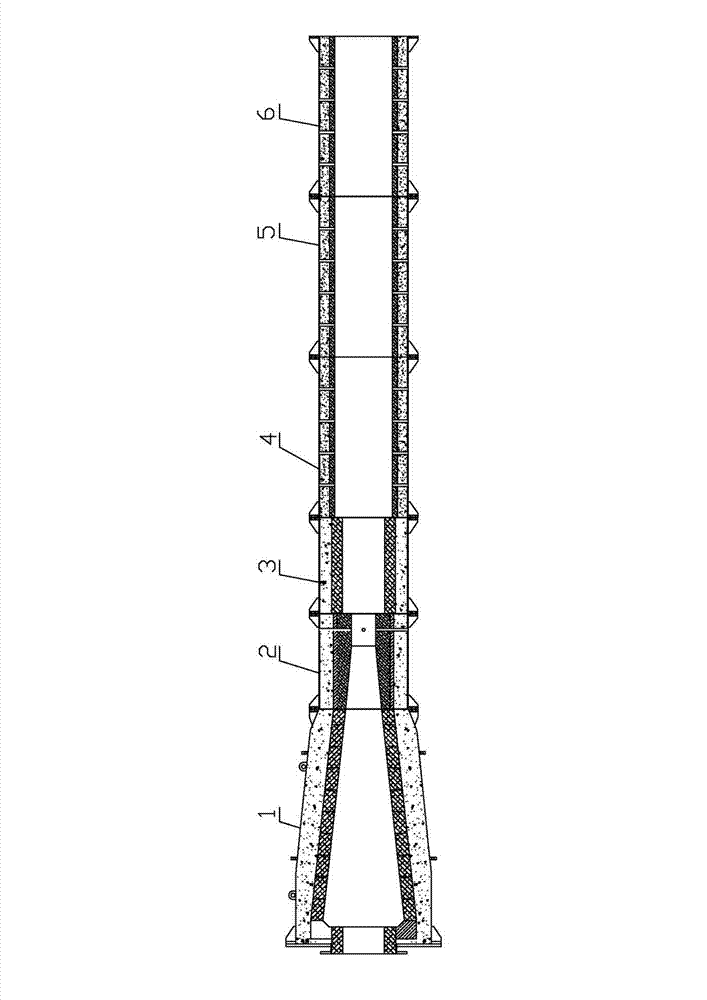

Method for preparing copper alloy powder by means of plasma rotating electrode

InactiveCN109513944AImprove qualityReduce inclusionsAdditive manufacturing apparatusCondensation processManufacturing technology

The invention discloses a method for preparing copper alloy powder by means of a plasma rotating electrode. The method comprises the steps that firstly, batching is conducted according to the chemicalproportion of copper alloy components, and alloy bars are machined and manufactured through a smelting and forging machine; the alloy bars are put into plasma rotating electrode powder preparation equipment, and a powder preparation chamber of the equipment is filled with inert protective gas after being evacuated; and the equipment is started, the ultrahigh-speed alloy bars are molten into liquid through heating of a plasma arc heat source, the liquid is cast out and crushed into high-temperature small liquid drops under the action of centrifugal force, and the small liquid drops are solidified into spheres under the surface tension action in the quick condensation process and fall into a powder collector. According to the method for preparing the copper alloy powder by means of the plasma rotating electrode, the copper alloy powder is prepared by adopting a high-speed plasma rotating electrode technology, and the prepared copper alloy powder is high in sphericity degree, narrow in particle size range, low in content of hollow powder and satellite powder, low in content of gas inclusions and high in powder quality, has the excellent physical, chemical and comprehensive mechanicalproperties, and is especially suitable for being used in an electron beam powder spreading type additive manufacturing technology.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

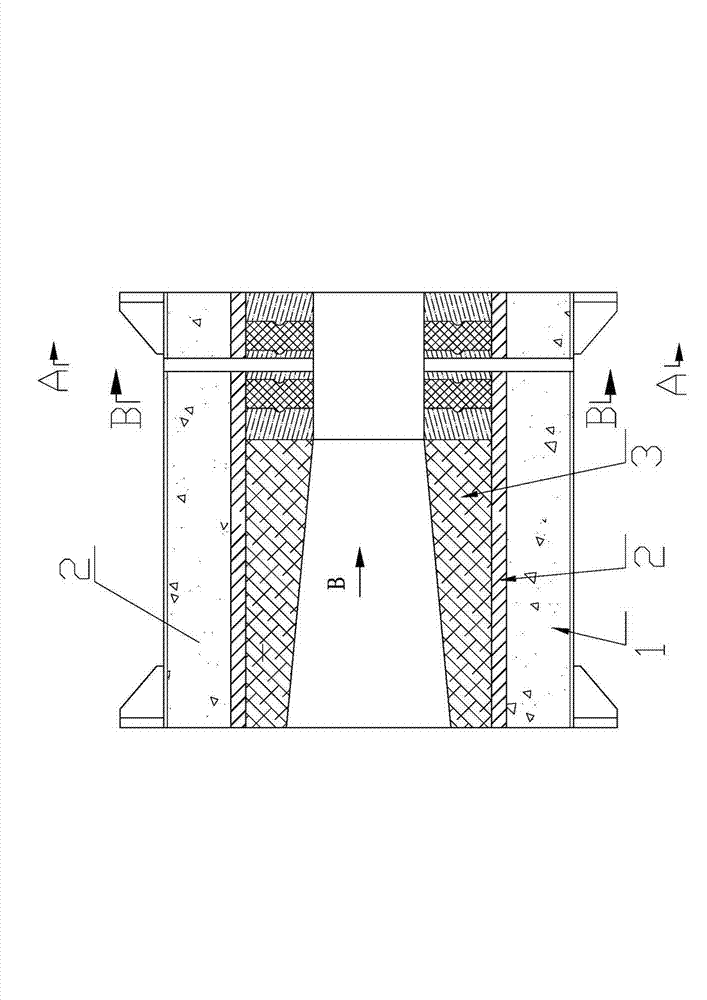

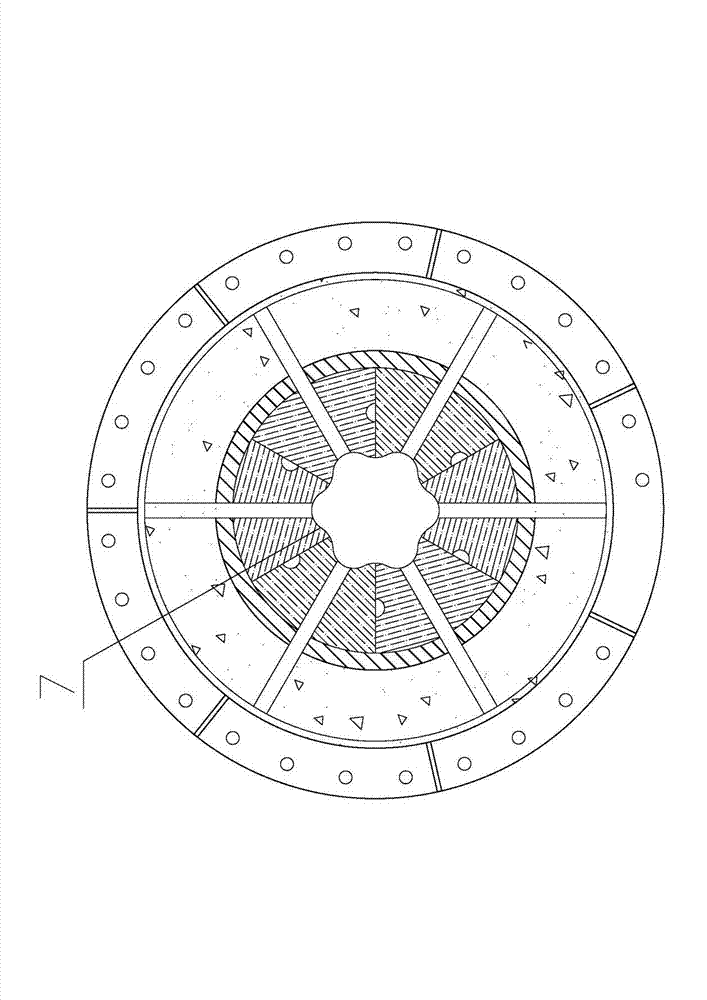

Novel polygonal carbon black reaction furnace

ActiveCN102924981AImprove carbon black qualityMinimize the generation of ineffective high-temperature gasesPigmenting treatmentCarbon blackParticle-size distribution

The invention provides a carbon black reaction furnace, and relates to a reaction furnace in the carbon black industry. The cross section of a throat section of the reaction furnace is polygonal and is shaped like a plum flower with six petals, bricks of the reaction furnace are arranged into a plurality of layers, and the layers are arranged crosswise. By means of the novel polygonal carbon black reaction furnace, carbon black with a stable narrow particle size range and high color intensity can be produced, so that the quality of the carbon black is largely improved. The novel polygonal carbon black reaction furnace has the advantages that the area of the cross section is covered to the maximum extent, the length of the flame of pyrolytic raw oil reaches the minimum value, the generation of invalid high-temperature gas is largely reduced, partial raw oil is prevented from being subject to an excessive pyrolytic reaction, and therefore the carbon black with narrow particle size distribution is obtained.

Owner:HANGZHOU FUCHUNJIANG IND

Ultrasonic spray-forming method

The invention relates to an ultrasonic spray-forming method, which is technically characterized in that: a novel molten metal atomization and deposition manner is provided according to the fundamental principle that molten metal flow is atomized into fine grains by spray-forming; and the fundamental principle of the manner is that: the molten metal flows on the surface of a tool head which vibrates at ultrasonic frequency to form a thin liquid layer; surface tension waves are surged under the action of ultrasonic vibration; liquid drops depart from wave crests when the amplitude of a vibrating surface reaches a certain value; the liquid drops rapidly hit a deposition plate or a collector and are fast solidified under the drive of high-speed inert gas; and metal blanks with required shapescan be manufactured through controlling the position and the angle of a receiver by using different shapes of collectors. The crystal grain of a microstructure of the manufactured blanks is finer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process of preparing calcium carbonate by air bubble film method and application thereof

ActiveCN109824076AIncrease chance of contactIncrease reaction rateCalcium/strontium/barium carbonatesMaterial nanotechnologyDispersityCalcium hydroxide

The invention discloses a process of preparing calcium carbonate by an air bubble film method and application thereof and belongs to the technical field of preparation of inorganic nonmetal calcium carbonate powders. The process herein comprises carbonization and surface treatment; refined calcium hydroxide slurry is quickly carbonized in an air bubble film quick carbonizing reactor; a slurry fromthe reaction is subjected to suitable surface treatment as required; the treated slurry is filtered, drying is carried out before crushing, and screening is performed to obtain calcium carbonate powder uniform in particle size. The process herein has no need for adding a crystal form control agent; the crystal morphology is controllable; the finished product has uniform particle size and good dispersity; the process is simple and feasible and has low production cost; the prepared calcium carbonate powder is applicable to the industries of plastics, rubber, papermaking, foods, medicine, and cosmetics, and has good economic and social benefits.

Owner:GUANGXI UNIV +1

Preparation method of hollow rod-like calcium carbonate

InactiveCN110844930AReduce yieldLower reaction conditionsCalcium/strontium/barium carbonatesCalcium hydroxideSlurry

The invention discloses a preparation method of hollow rod-like calcium carbonate. The preparation method comprises the following steps: S1, accurately weighing calcium oxide, dissolving the calcium oxide in water, carrying out heating, stirring and standing digesting, carrying out screening, removing residues, and concentrating the product to obtain raw material calcium hydroxide slurry, S2, transferring the prepared calcium hydroxide slurry into a reaction kettle, adding sodium D-gluconate into the prepared calcium hydroxide slurry according to the concentration molar ratio of the calcium hydroxide slurry, controlling the temperature and the rotating speed of the mixed solution, and introducing CO2 gas for reaction to obtain product slurry, and S3, carrying out suction filtration and washing on the product slurry, separating a solid product, carrying out vacuum drying on the separated solid product, taking out the product and grinding the product into powder to obtain hollow rod-likecalcium carbonate. The method has the advantages of easy control of reaction conditions, high yield, low production cost, novel morphology, narrow particle size range, stable quality, good product dispersibility, simple production equipment, environmental protection, strong operability and the like, is suitable for industrial production, and can be widely popularized and applied.

Owner:GUANGXI UNIV +1

Production method of high-quality superfine light calcium carbonate

InactiveCN107416884AConducive to reasonable recyclingGood dispersionCalcium/strontium/barium carbonatesCalcium hydroxideRoom temperature

The invention discloses a production method of high-quality ultrafine light calcium carbonate, belonging to the technical field of calcium carbonate production. A production method of high-quality ultrafine light calcium carbonate is characterized in that it comprises the following steps: (1) using limestone as raw material, putting it into a reaction furnace for heating and calcining to obtain calcium oxide, and sealing it for later use after cooling; Calcium is added to impurity-free water, stirred for 2-4h, and calcium hydroxide slurry is obtained after cooling down; (3) Carbon dioxide gas is introduced into the calcium hydroxide slurry at room temperature for carbonization, and carbonized to the pH of the calcium hydroxide slurry It is 6.5-7.5, obtains calcium carbonate slurry, stops carbonization; (4) puts the calcium carbonate slurry that step (3) obtains into storage tank and leaves standstill 10-12h, makes its pH value stabilize. The object of the present invention is to provide a production method of high-quality ultrafine light calcium carbonate, which is simple in operation, stable in quality, and capable of efficiently preparing high-quality ultrafine light calcium carbonate.

Owner:广西华洋矿源材料有限公司

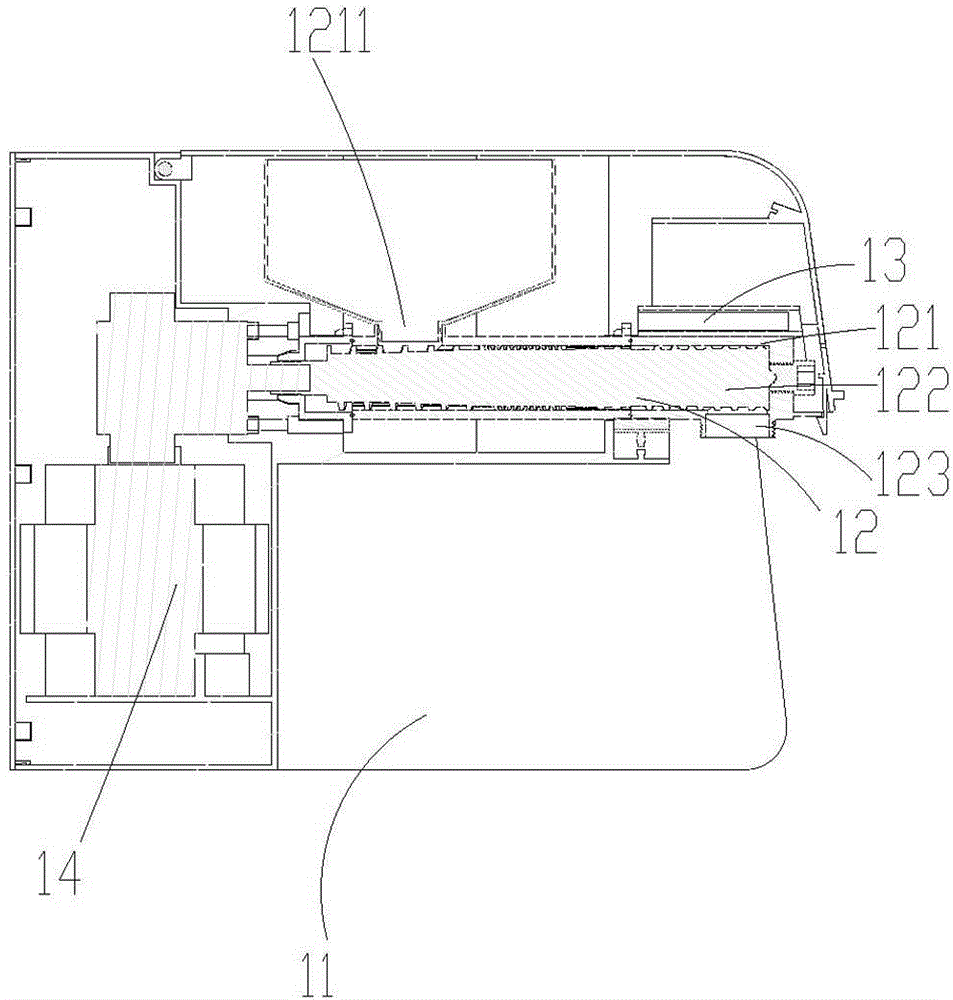

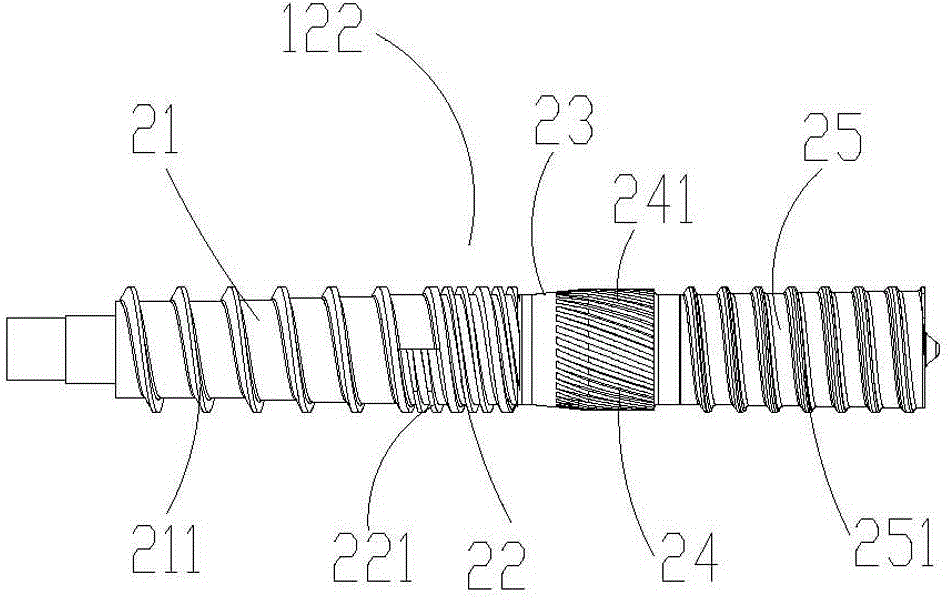

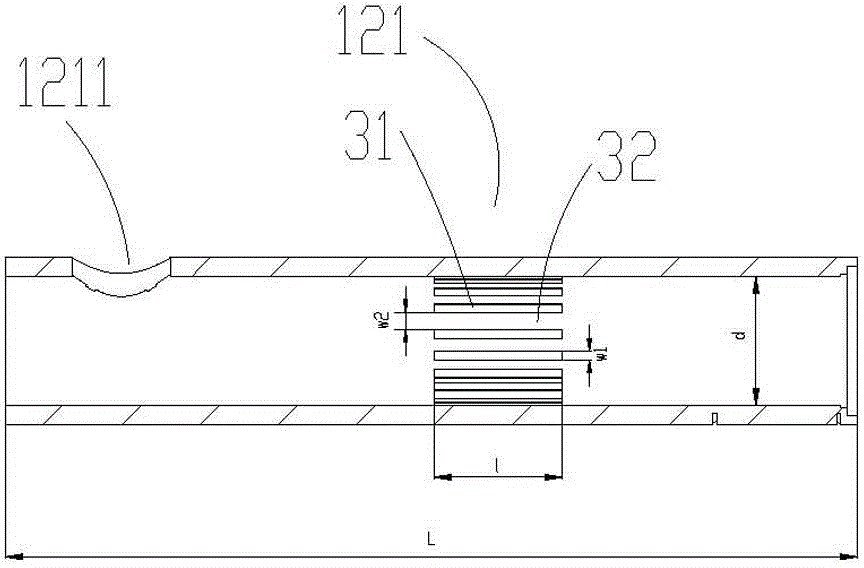

Household rice noodle machine

ActiveCN104642865APoor feedingImprove water absorptionFood shapingFood preparationEngineeringRice flour

The invention relates to a household rice noodle machine which comprises a base, a crushing, extruding and forming system, a heating device and a driving system, wherein the crushing, extruding and forming system comprises an extruding and grinding cavity, a screw rod and a forming die head; the heating device is used for heating the extruding and grinding cavity; a feed inlet is formed in one end of the extruding and grinding cavity while the forming die head is formed at the other end of the extruding and grinding cavity; the screw rod is located in the extruding and grinding cavity, and is sequentially provided with a material propelling section, a coarse crushing section, a fine crushing and grinding section and an extruding section along the direction from the feed inlet to the forming die head; the screw rod is integrally formed; grinding helical teeth are uniformly distributed in the circumferential direction of the fine crushing and grinding section; grinding straight teeth corresponding to the grinding helical teeth are formed in the extruding and grinding cavity; the grinding straight teeth are uniformly distributed on the inner surface of the extruding and grinding cavity; a grinding slot is formed between every two adjacent grinding straight teeth; and a grinding gap h1 is formed between each grinding straight tooth and the grinding helical tooth. The household rice noodle machine provided by the invention is provided with the screw rod and the extruding and grinding cavity which is matched with the screw rod, and rice noodles which are relatively good in taste and appearance are prepared.

Owner:JOYOUNG CO LTD

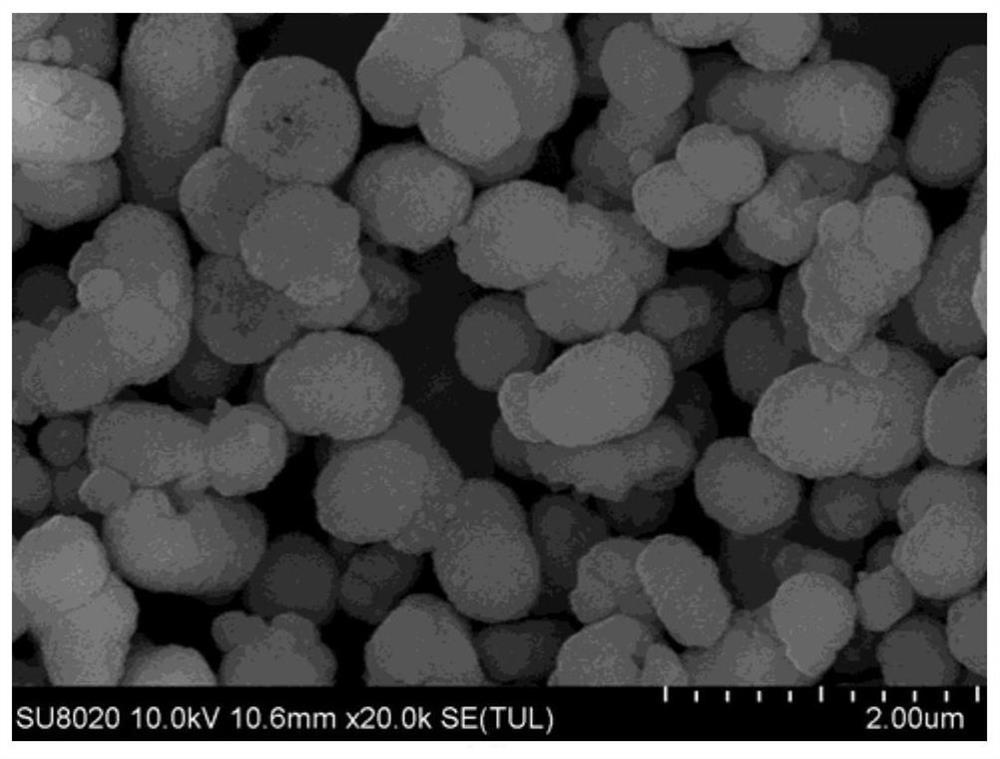

Preparation method for nano ferroferric oxide

InactiveCN102557150ASmall particle sizeUniform sizeFerroso-ferric oxidesNanotechnologyDistilled waterRoom temperature

The invention discloses a preparation method for nano ferroferric oxide. The preparation method includes the following steps that: (1) water-soluble Fe<2+> salt and water-soluble Fe<3+> salt are dissolved in distilled water according to a proportion, so that solution A is obtained, and the molar ratio of the water-soluble Fe<2+> salt to the water-soluble Fe<3+> salt is 1:(0.8 to 2); hydrazine compound is mixed with distilled water, so that solution B is obtained; and under the protection of inert gas, and with stirring at the temperature of 2 DEG C to 25 DEG C, the solution B is dripped into the solution A, and solid is separated out after reaction is finished, and is washed and dried, so that FeO(OH) is obtained; and (2) the obtained FeO(OH) is put into a reaction kettle and added with alkali liquid to react under the temperature of 100 DEG C to 200 DEG C for 10 to 24 hours, the temperature is cooled to the room temperature after reaction is finished, so that solid is separated out, and the solid is washed and dried, so that nano ferroferric oxide particles are obtained. The preparation method is mainly used for preparing the nano ferroferric oxide.

Owner:XIAN MODERN CHEM RES INST

Aluminium alloy polishing solution and preparation method thereof

ActiveCN104109482ANarrow particle size rangeGood roughness controlPolishing compositions with abrasivesActive agentCeramic membrane

The invention provides an aluminium alloy polishing solution. The aluminium alloy polishing solution is prepared from the following raw materials by weight: 92.5-97 parts of a silica sol, 1-2.5 parts of a stabilizer, 1-2.5 parts of an active agent and 1-2.5 parts of a synergist. A preparation method of the aluminium alloy polishing solution comprises the following steps of removing metal ions and other impurities from a silica sol raw material by adopting a 100 nano-scale ceramic membrane filtration system; adding the filtrated silica sol into a sealed reaction tank under a vacuum negative pressure state; adding the stabilizer, the active agent and the synergist into the sealed reaction tank under the vacuum negative pressure state; stirring thoroughly; and mixing uniformly to prepare a finished product of the aluminium alloy polishing solution. The prepared aluminium alloy polishing solution has the advantages of no corrosion, small usage amount, low cost, few scratches and high polishing rate. Besides, compared with a conventional acid polishing solution, the aluminium alloy polishing solution has no pollution and can be recycled easily.

Owner:HEBEI YUTIAN HAOYUAN NANO MATERIAL

Preparation method of CuCrZr alloy powder for three-dimensional (3D) printing

ActiveCN112719279AAvoid lossNarrow particle size rangeAdditive manufacturing apparatusTransportation and packagingZone meltingChromium Alloys

The invention discloses a preparation method of CuCrZr alloy powder for three-dimensional (3D) printing. The preparation method comprises the steps of S1, burdening: weighing Cu powder, Cr powder and Zr powder in proportion; S2, mixing the powder: stirring and mixing the Cr powder and the Zr powder, then mixing with the Cu powder, adding ethyl alcohol, conducting ball milling and powder mixing after even stirring, and obtaining mixed powder; S3, conducting cold isostatic pressing: after the ethyl alcohol in the mixed powder is completely volatilized, conducting cold isostatic pressing to obtain a copper-chromium alloy blank; S4, sintering and degassing: carrying out gradient heating on the copper-chromium alloy blank to obtain a copper-chromium alloy electrode; S5, conducting electrode induction gas atomization powder making: conducting zone melting and gas atomization powder making on the copper-chromium alloy electrode, and obtaining the CuCrZr alloy powder; and S6, screening: screening and grading the CuCrZr alloy powder, and obtaining the required powder within the 3D printing particle size range. The CuCrZr alloy powder prepared through the method provided by the invention is narrow in particle size range and high in sphericity degree, and the stability of the 3D printing process is effectively guaranteed.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

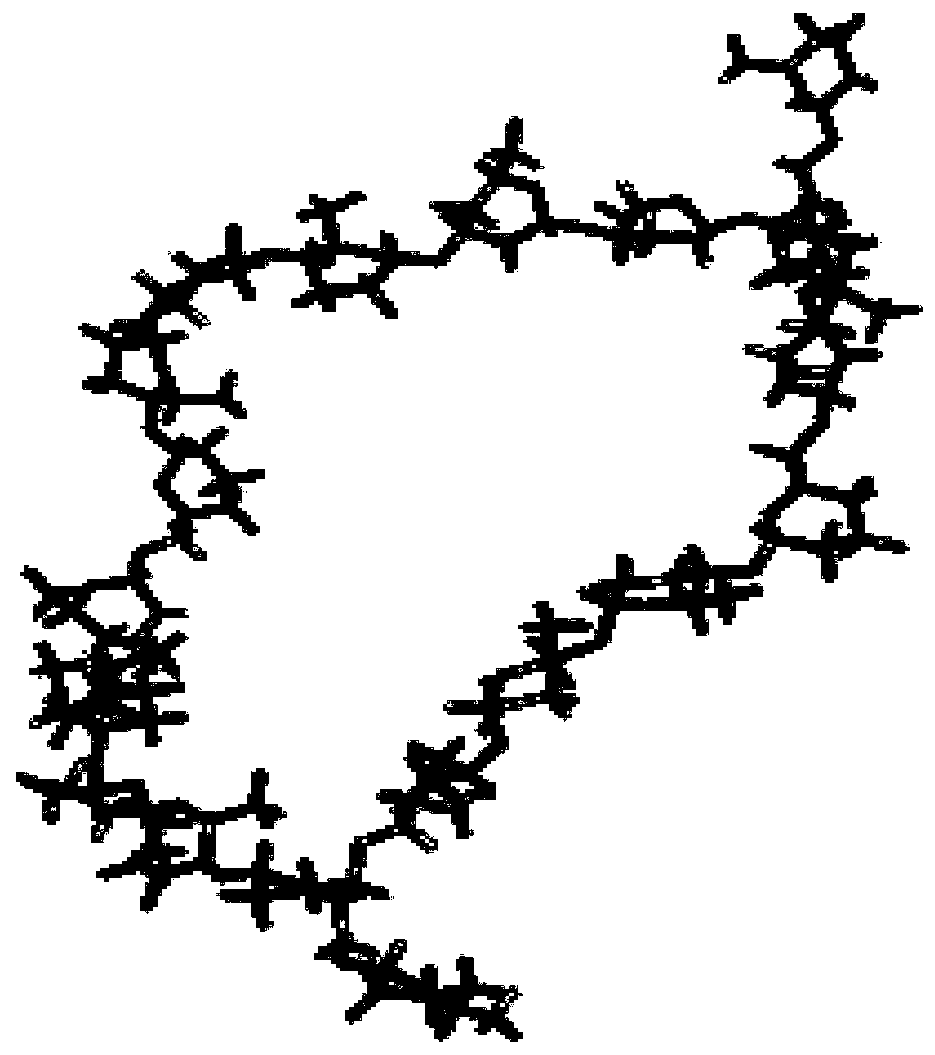

Microstrip ring dendritic starch derivative and processing method thereof

ActiveCN110408665AIncrease the degree of branchingSpecial macrocyclic structureTransferasesFermentationSolubilityWater soluble

The invention discloses a microstrip ring dendritic starch derivative and a processing method thereof, and belongs to the technical field of food processing. With starch as a raw material, the microstrip ring dendritic starch derivative is prepared through carbohydrate chain degradation and grading and glucoamylase catalysis glycoside conversion technologies and can be used as a stable carrier material of a food active factor. The method has the advantages of green environmental protection, high processing yield, low cost and the like; and the prepared product has the advantages of high branching degree, special large ring structure and good water solubility, can be applied to steady-state delivery and active protection of natural functional substances, and relates to the fields of nutritional food, medicine, daily chemicals and the like.

Owner:JIANGNAN UNIV

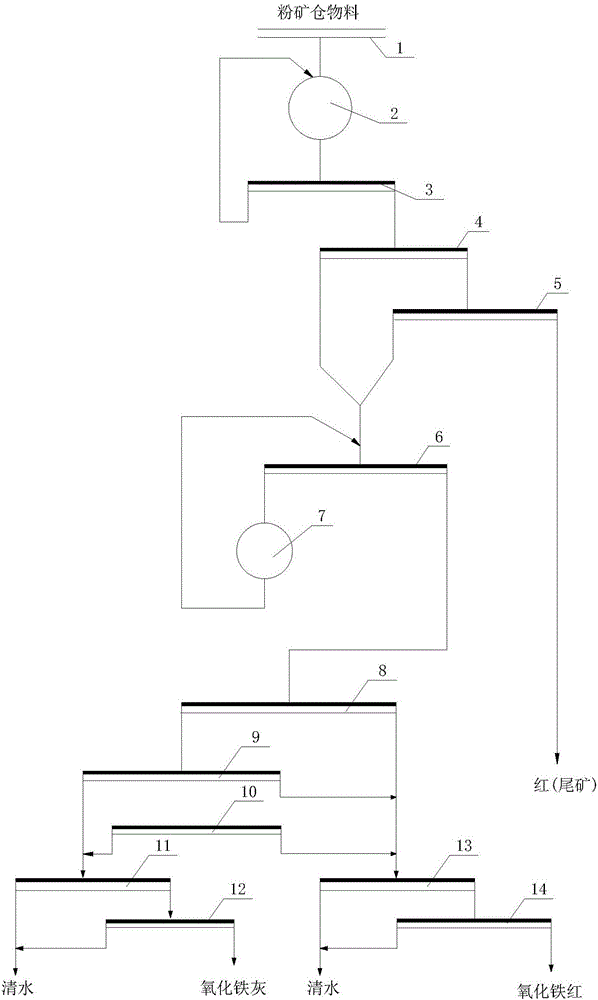

Processing method of mica iron oxide

InactiveCN106362860AHigh content of sheet structureFine particle sizeSolid separationGrain treatmentsBall millSheet structure

The invention provides a processing method of mica iron oxide. The processing method of the mica iron oxide includes the following steps that, (a) raw materials are broken; (b) the materials in the step (a) are subjected to ball-milling through a ball mill, and overflow generated after classification of a spiral classifier is fed into a first hydrocyclone for the first time of separation; (c) a second hydrocyclone is used for performing the second time of separation; (d) the third time of separation is performed in a third hydrocyclone, and fine grinding is further performed; (e) the overflow separated through a fourth hydrocyclone is iron oxide red, settled sand of the fourth hydrocyclone is iron oxide grey crude products, and the iron oxide grey crude products are concentrated through table concentrators at two times; and (f) concentration, dewatering and drying are performed on iron oxide grey and the iron oxide red, and iron oxide grey finished products and iron oxide red finished products are obtained. By means of the processing method of the mica iron oxide, prepared mica iron oxide products are large in content of sheet structures and smaller in average particle size, the particle size range is small, the purpose of producing the iron oxide red and the iron oxide grey at the same time can be achieved, and industrial production can be easily achieved.

Owner:安徽纽亚达科技有限责任公司

Preparation method of hollow microsphere calcium carbonate

InactiveCN111762807AWide variety of sourcesReduce the amount addedCalcium/strontium/barium carbonatesCalcium hydroxideMicrosphere

A preparation method of hollow microsphere calcium carbonate comprises the following steps: accurately weighing a certain amount of calcium oxide, dissolving the calcium oxide in deionized water, heating, stirring, standing for digesting, screening, and concentrating to obtain a calcium hydroxide slurry with the concentration of 2% as a raw material; transferring the prepared calcium hydroxide slurry into a high-pressure reaction kettle, adding 2-10% EDTA according to a certaub concentration molar ratio of the calcium hydroxide slurry to the EDTA, and reacting the mixed solution for 4 h at thetemperature of 80-160 DEG C and the rotating speed of 50 r.min<-1> under the condition that pure CO2 gas is introduced to make the pressure in the kettle at 1-3 MPa to obtain a product slurry; and carrying out suction filtration and washing on the product slurry, carrying out vacuum drying on the obtained solid at 80 DEG C for 10 hours, and finally grinding into powder to obtain the hollow microsphere calcium carbonate. The method has the advantages of being low in production cost, high in yield, stable in quality, good in product dispersity, environmentally friendly and the like, and is suitable for industrial production.

Owner:崇左南方水泥有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com