Preparation method of hollow rod-like calcium carbonate

A calcium carbonate, rod-shaped technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of difficult control of hollow particle calcium carbonate reaction conditions, low yield, etc., to achieve The effect of reducing the cost of preparing calcium carbonate, low production cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

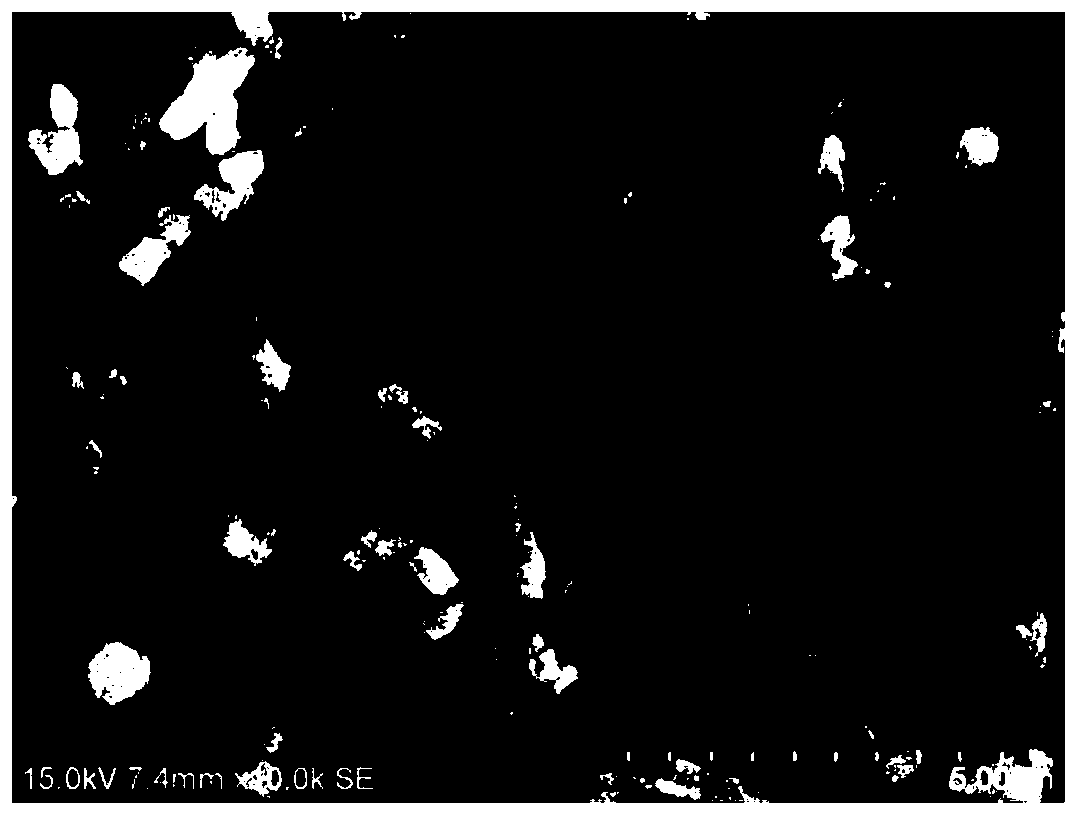

Image

Examples

Embodiment 1

[0034] A preparation method of calcium carbonate, comprising the following steps:

[0035] S1. Accurately weigh calcium oxide and dissolve it in deionized water, heat it to 80°C in a constant temperature water bath, stir for 2 hours, let it stand for digestion for 24 hours, remove the residue after sieving through 200 meshes, adjust the concentration, and obtain a raw material with a concentration of 1%. Calcium hydroxide slurry;

[0036] S2. Get 180ml of the prepared calcium hydroxide slurry and move it into the high-pressure micro-reactor, add 1% D-sodium gluconate according to the concentration molar ratio of the calcium hydroxide slurry, seal the high-pressure micro-reactor, open the heating device and the stirring device, The mixed solution is heated at a temperature of 100°C and a speed of 50V min -1 and access to CO 2 The gas increases the pressure in the reactor by 1.5 MPa to react for 4 hours to obtain the product slurry;

[0037] S3. After the slurry is suction fi...

Embodiment 2

[0039] The process for preparing calcium carbonate is basically the same as in Example 1, except that the reaction temperature in step S2 is 120°C.

Embodiment 3

[0041] The process for preparing calcium carbonate is basically the same as in Example 1, except that the reaction temperature in step S2 is 140°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com