Method for preparing multi-scale ceramic phase reinforced metal composite material by 3D printing

A metal composite material, 3D printing technology, applied in the direction of additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems of difficult uniform dispersion of ceramic particles, difficult control of ceramic phase scale, poor bonding of matrix interface, etc., to achieve ceramic Uniform phase distribution, high sphericity, and the effect of solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

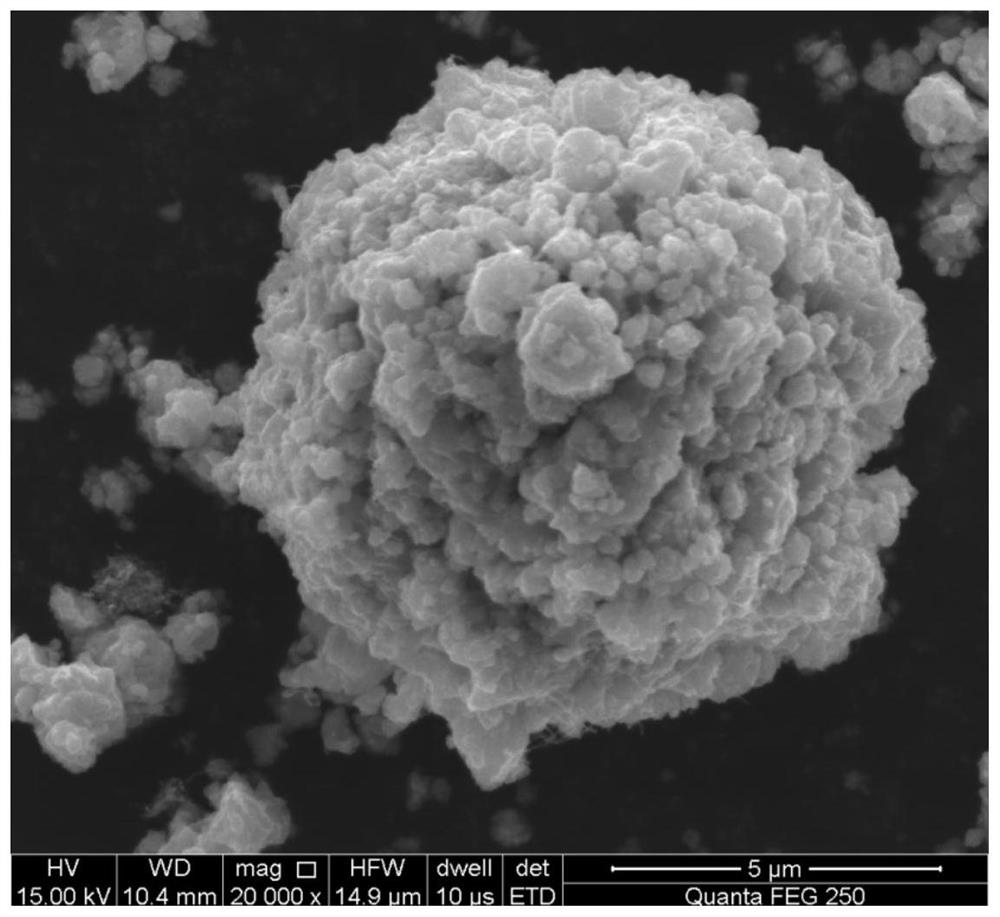

[0044] A method for preparing multi-scale ceramic phase-reinforced metal composites by 3D printing, using René 104 nickel-based superalloy as the matrix, using TiC ceramic particles with an average particle size of 2.5 μm as the reinforcing phase, and adding 3.0% by mass.

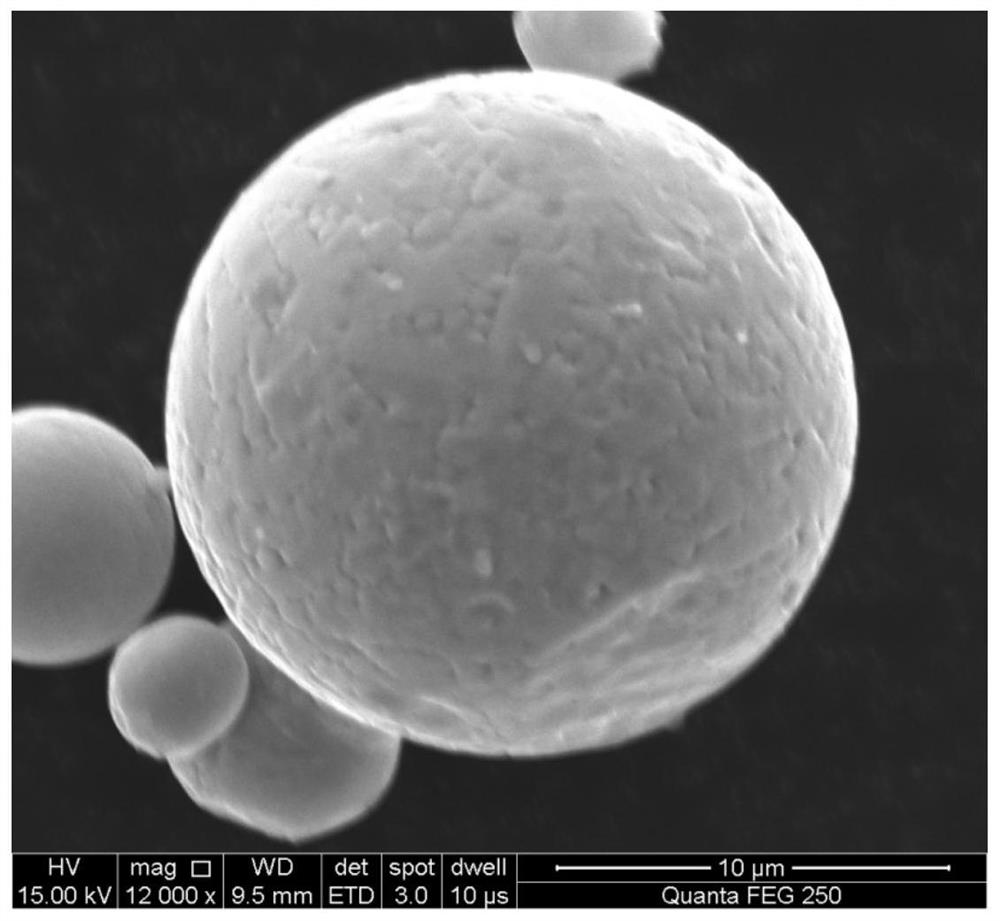

[0045] The matrix material is René104 nickel-based superalloy spherical powder with a particle size of 15-53 μm. The composition of René104 nickel-based superalloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9Nb ~0.05Zr~0.03B~0.04C~the balance is Ni.

[0046] The method for preparing a multi-scale ceramic phase reinforced metal composite material by 3D printing, the steps are as follows:

[0047] (1) Add TiC ceramic particles in two times, mix with a certain proportion of René104 nickel-based superalloy powder (ratio: 2:3), and carry out wet grinding treatment every time TiC ceramic particles are added, and the mass fraction added each time is equal to 1.5%; and then perform dry grinding treatment to ob...

Embodiment 2

[0061] The difference from Example 1 is that the step (1) adds TiC ceramic particles twice, the mass fraction of the first addition is 1.0%, and the mass fraction of the second addition is 2.0%.

[0062] Others remain unchanged.

[0063] After testing, the microhardness of the prepared multi-scale TiC / René104 composite is 598HV 0.2 , the tensile strength is 1823MPa, the friction and wear performance test shows that the friction coefficient is 0.41, and the wear amount in 30min is 5.2×10 -4 (mm3 / Nm).

Embodiment 3

[0065] The difference from Example 1 is that in the step (1), TiC ceramic particles are added three times, wet grinding is performed three times and dry grinding is performed once, and the mass fraction added each time is 1.0%.

[0066] Others remain unchanged.

[0067] After testing, the microhardness of the prepared multi-scale TiC / René104 composite material is 615HV0.2, the tensile strength is 1863MPa, the friction and wear performance test shows that the friction coefficient is 0.32, and the wear amount in 30min is 4.3×10 -4 (mm3 / Nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com