Processing method of mica iron oxide

A mica iron oxide and processing method technology, applied in the direction of solid separation, grain processing, etc., can solve the problems of destroying mica iron oxide flake structure, poor crushing effect, complicated crushing process, etc., and achieves easy industrial production and narrow particle size range , to achieve the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

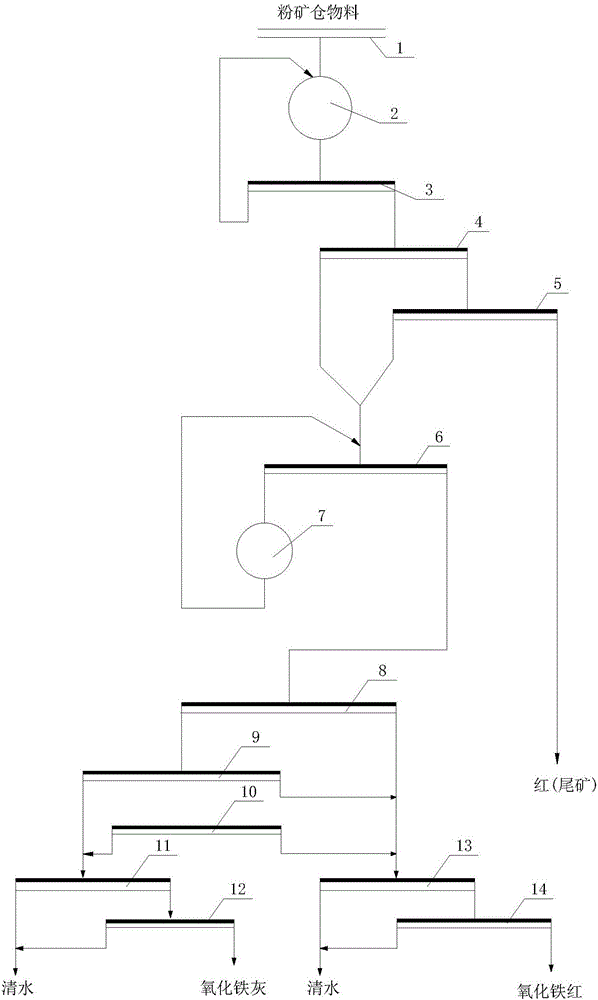

[0020] like figure 1 Shown, a kind of processing method of micaceous iron oxide comprises the following steps:

[0021] (a) Crushing of raw materials: use a double-stage crusher to crush the mica iron oxide raw materials, and send the crushed materials smaller than 150mm directly into the powder silo;

[0022] (b) The material in the step (a) is transported to the feed inlet of the ball mill 2 through the belt 1, and the material after the ball milling of the ball mill 2 enters the spiral classifier 3 through the pipeline, and the overflow after the spiral classifier 3 is classified The flow sand is pumped to cyclone-4 for the first sorting, and the returned sand from the spiral classifier 3 is returned to the feed port of the ball mill 2 for regrinding. The classifying fineness of the spiral classifier 3 is -200 mesh quality The content is controlled at 85-90%;

[0023] (c) The overflow of cyclone one 4 is sorted by sand pump to cyclone two 5 for the second sorting. Cyclone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com