Micaceous iron oxide dry-method processing method

A dry processing technology of mica iron oxide, which is applied in the direction of grain processing, etc., can solve the problems of wide particle size range, poor crushing effect, complicated crushing process, etc., and achieve narrow particle size range, high flake structure content, and fine average particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Using Tongling specular iron ore powder in Anhui Province as raw material, the iron content after beneficiation is greater than 65 (mass fraction).

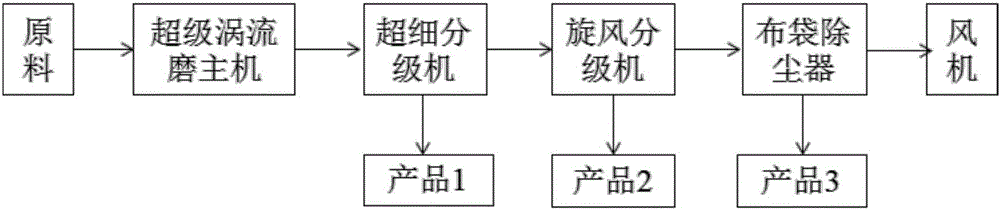

[0017] Such as figure 1 As shown, a dry processing method of mica iron oxide includes a raw material storage device, and the raw material storage device is connected to a super vortex mill main engine, an ultra-fine classifier, a cyclone classifier, a bag filter and a fan in sequence through pipelines. The processing method comprises the following steps:

[0018] (2) After the raw material specularite powder is dried, it enters the main frame of the super vortex mill through a feeder to be pulverized, the feeding speed of the feeder is adjusted to be 30kg / min, and the rotating speed of the super vortex mill main frame is set to Set at 2632r / min;

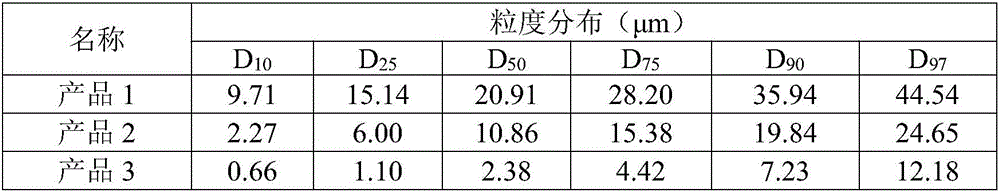

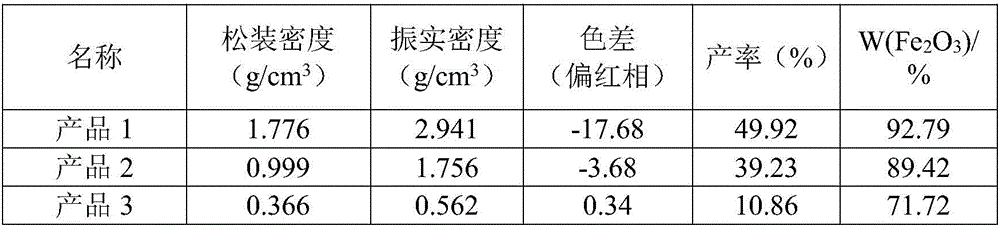

[0019] (2) the rotating speed of setting blower fan is 1043r / min, and the material after pulverizing enters superfine classifier under the drive of airflow, regulates the gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com