Composite additive for strengthening middle-high magnesium-type laterite-nickel ore direct reduction and application of composite additive

A composite additive and lateritic nickel ore technology, which is applied in the field of metallurgy and material science, can solve the problems of insufficient grain growth of ferronickel, uneven distribution of ferronickel, poor selective reduction effect, etc., and reduce the direct reduction temperature , reduce high-temperature pulverization rate, and achieve the effect of selective reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

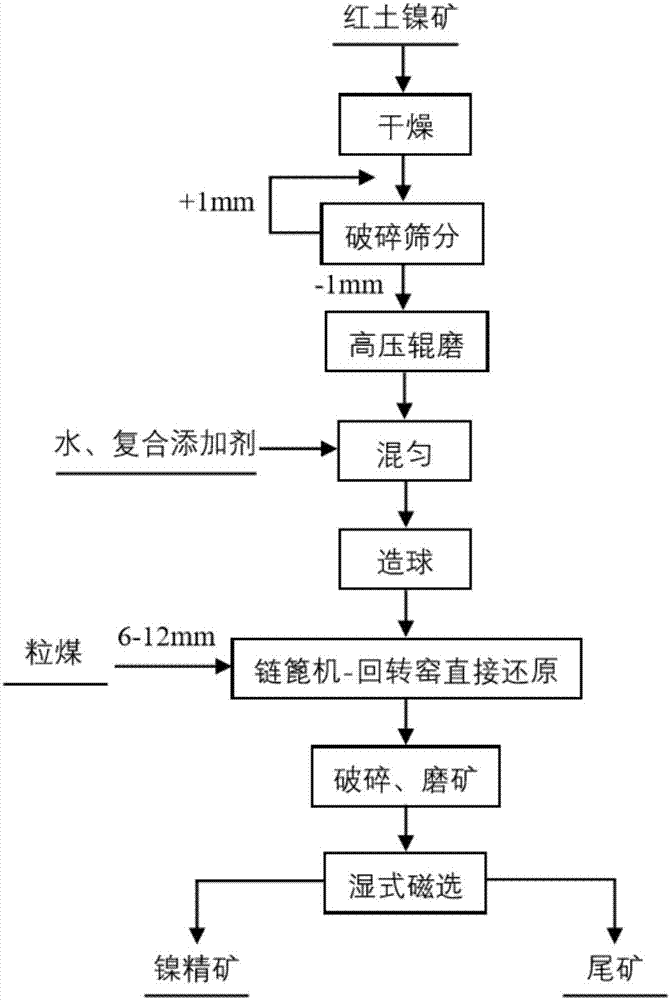

Method used

Image

Examples

Embodiment 1

[0035] A composite additive for strengthening the direct reduction of high-magnesium type medium and low-grade lateritic nickel ore of the present invention, comprising 35wt% desulfurized gypsum, 20wt% sodium carbonate, 15wt% sodium humate, 10wt% polyacrylamide, 10wt% coal powder, 5wt% calcium oxide, 5wt% iron fine powder.

[0036] A kind of application of composite additive of the present invention in laterite nickel ore direct reduction, with laterite nickel ore 1 in table 1 as reduction object, its application method comprises the following steps:

[0037] (1) Pretreatment: Dry the laterite nickel ore 1 to a moisture content of 12%, and then crush it so that 100% of the laterite nickel ore 1 particles The particle size is less than 0.074mm.

[0038] (2) Mixing: fully mix the pretreated laterite nickel ore 1 with a composite additive accounting for 20% by mass of the laterite nickel ore 1 to obtain a mixture.

[0039] (3) Pelletizing: The mixture in step (2) is formed into...

Embodiment 2

[0047] A composite additive for strengthening the direct reduction of high-magnesium type medium and low-grade lateritic nickel ore of the present invention, comprising 30wt% desulfurized gypsum, 25wt% sodium carbonate, 15wt% sodium humate, 10wt% polyacrylamide, 10wt% coal powder, 5wt% calcium oxide, 5wt% iron fine powder.

[0048] A kind of application of composite additive of the present invention in laterite nickel ore direct reduction, with laterite nickel ore 1 in table 1 as reduction object, its application method comprises the following steps:

[0049] (1) Pretreatment: Dry the laterite nickel ore 1 to a moisture content of 12%, and then crush it so that 100% of the laterite nickel ore 1 particles The particle size is less than 0.074mm.

[0050] (2) Mixing: fully mix the pretreated laterite nickel ore 1 with a composite additive accounting for 20% by mass of the laterite nickel ore 1 to obtain a mixture.

[0051] (3) Pelletizing: Use the mixture in step (2) to form pe...

Embodiment 3

[0059] A composite additive for strengthening the direct reduction of high-magnesium type medium and low-grade lateritic nickel ore of the present invention, comprising 25wt% desulfurized gypsum, 30wt% sodium carbonate, 15wt% sodium humate, 10wt% polyacrylamide, 10wt% coal powder, 5wt% calcium oxide, 5wt% iron fine powder.

[0060] A kind of application of composite additive of the present invention in laterite nickel ore direct reduction, with laterite nickel ore 1 in table 1 as reduction object, its application method comprises the following steps:

[0061] (1) Pretreatment: Dry the laterite nickel ore 1 to a moisture content of 12%, and then crush it so that 100% of the laterite nickel ore 1 particles The particle size is less than 0.074mm.

[0062] (2) Mixing: fully mix the pretreated laterite nickel ore 1 with a composite additive accounting for 20% by mass of the laterite nickel ore 1 to obtain a mixture.

[0063] (3) Pelletizing: Use the mixture in step (2) to form pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com