Patents

Literature

77results about How to "Reduce the amount of powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing multi-scale ceramic phase reinforced metal composite material by 3D printing

ActiveCN111957967ANarrow particle size rangeEvenly distributedAdditive manufacturing apparatusTransportation and packagingMicron scaleMetallic materials

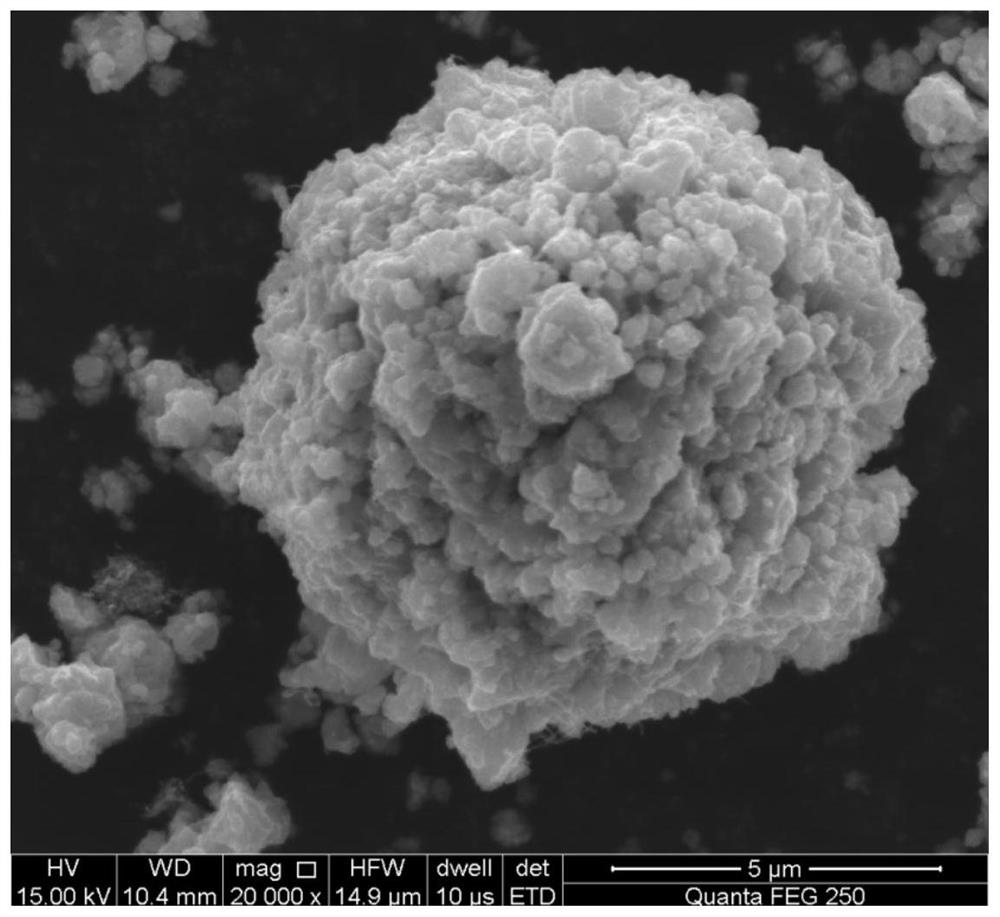

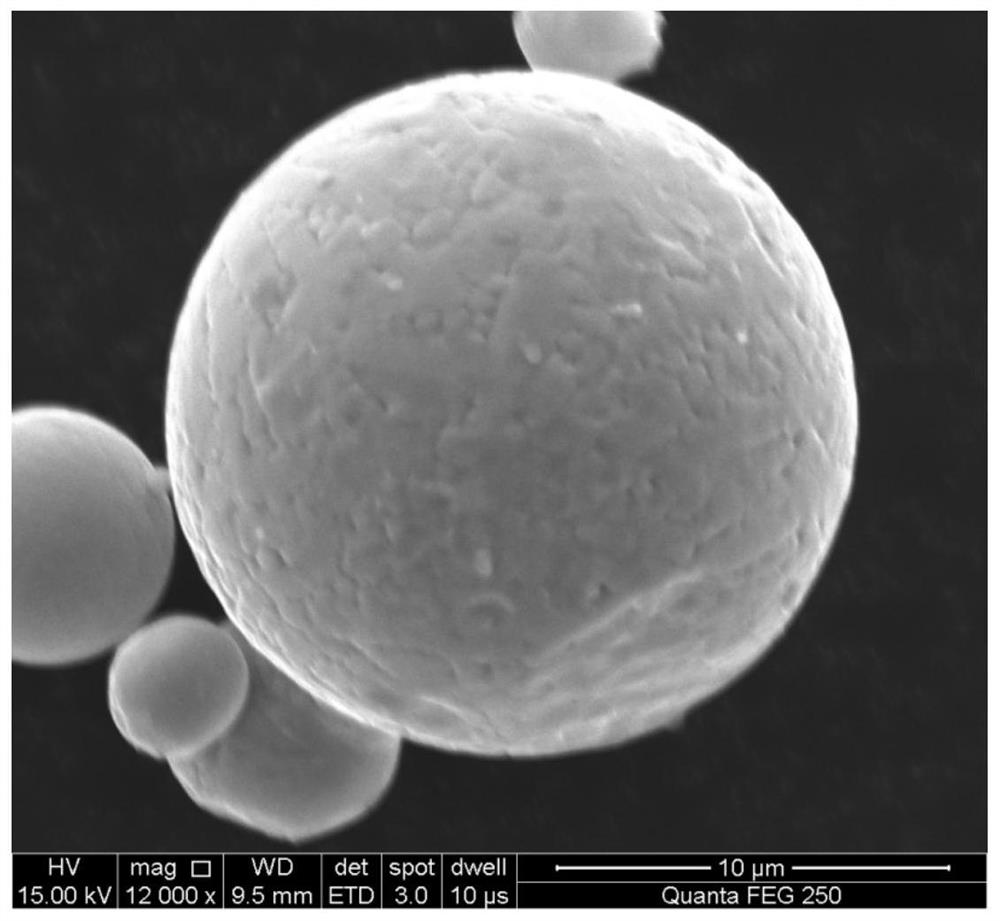

The invention provides a method for preparing a multi-scale ceramic phase reinforced metal composite material by 3D printing, which takes a metal material as a base body and takes ceramic particles asa reinforcement phase. The method comprises the following steps: adopting one or more ceramic particles of micro TiC, TiB2, WC, SiC, CrC and Al2O3 as raw materials, adding the ceramic particles and certain proportion of metal powder in batches, wherein mass percentage of the added ceramic particles is 0-10.0%; and performing a special ball-milling process, plasma spheroidizing, gas-flow grading and screening to obtain multi-scale uniform-ceramic-phase metal composite powder which is good in spheroidizing degree, is good in mobility and is narrow in particle size range, thereby obtaining multi-scale ceramic phase reinforced the metal composite material prepared by 3D printing. The prepared metal composite material is uniform in ceramic phase distribution, has different scales, and is excellent in mechanical property. Micro-scale ceramic particles are adopted, so that cost is low; and parts with any complex shapes can be prepared through integral forming, so that a material utilizationrate is increased.

Owner:CENT SOUTH UNIV

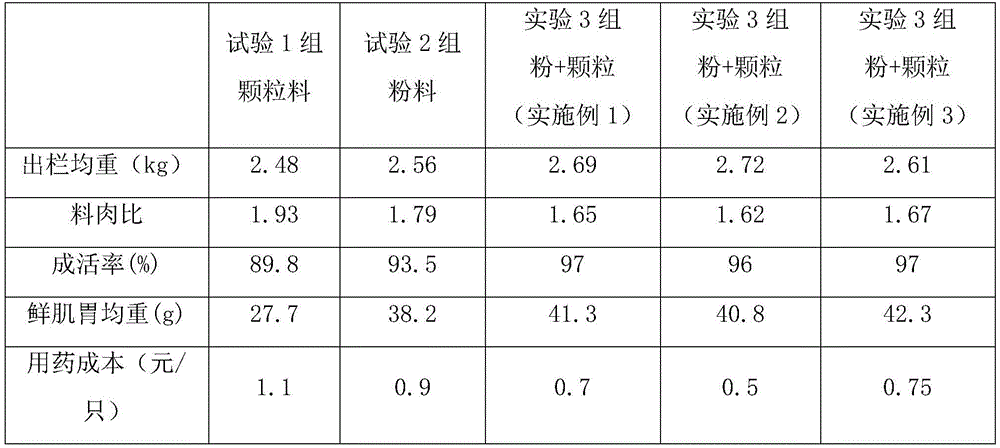

Compound feed for promoting development of muscular stomach of broiler and preparation method of compound feed

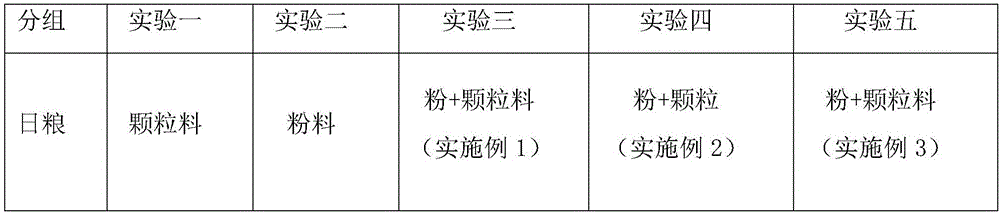

The invention belongs to the fields of a feed composition and feed processing, particularly relates to a compound feed for promoting the development of the muscular stomach of a broiler, and further provides a preparation method of the feed. The content of crude fibers in percentage by mass of the compound feed is greater than or equal to 4%, and the compound feed is mainly prepared from the following raw materials in parts by weight: 45-60 parts of corn, 3-15 parts of whole wheat grains, 1-3 parts of tropina, 1-5 parts of cottonseed meal, 1-5 parts of oat hull, 0.8-2 parts of calcium hydrogen phosphate, 1-2.5 parts of amino acids, 0.05-0.3 part of sodium humate, 0.05-0.1 part of a mycotoxin adsorbent, 0.02-0.1 part of betaine, 0.1-0.5 part of choline chloride, 0.05-0.3 part of a compound enzyme preparation, 0.5 part of a compound premix, 3-6 parts of fat, and 0.5-5 parts of probiotics. The compound feed disclosed by the invention can notably increase the weight of fresh chicken's gizzards, compared with the weight of each fresh chicken's gizzards of a broiler fed with a common feed, the weight of each fresh chicken's gizzard of the broiler fed with the compound feed is increased by 2-5 grams, and compared with the weight of each fresh chicken's gizzards of a broiler fed with granular feeds, the weight of each fresh chicken's gizzard of the broiler fed with the compound feed is increased by 8-15 grams.

Owner:LIAONING WELLHOPE AGRI TECH

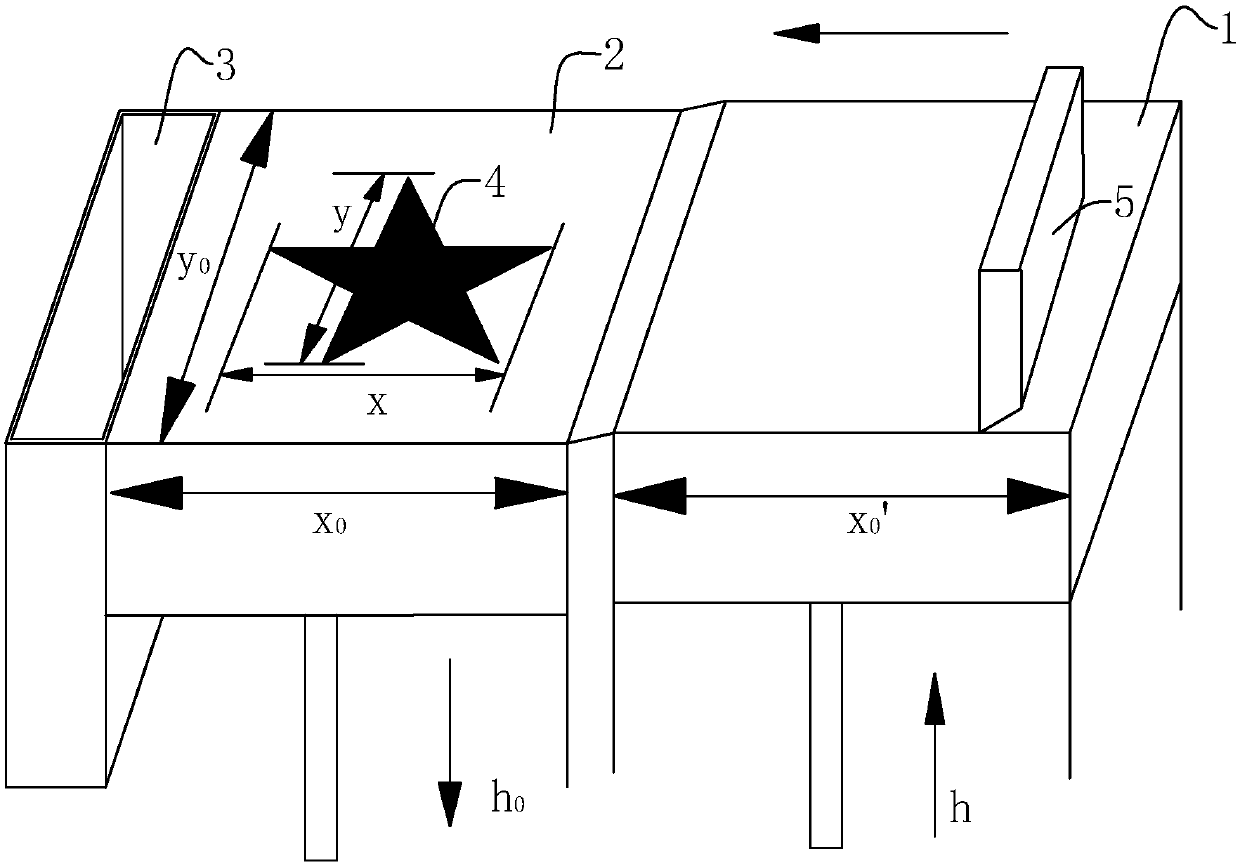

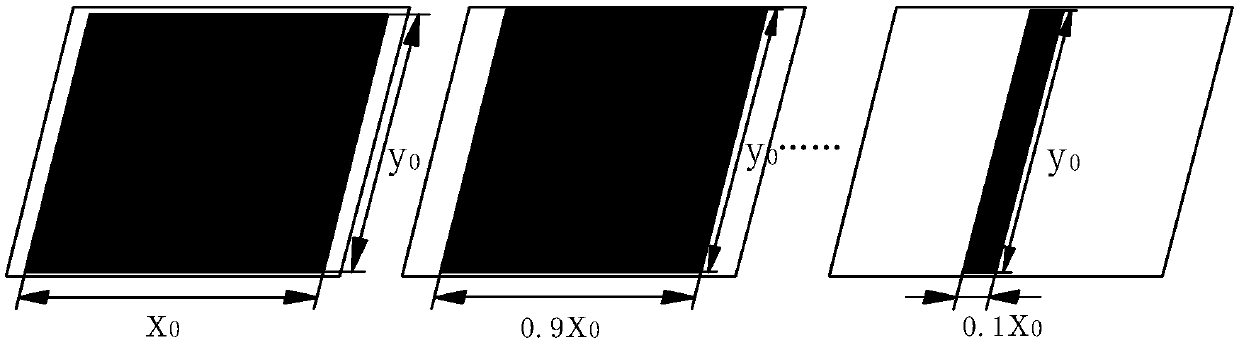

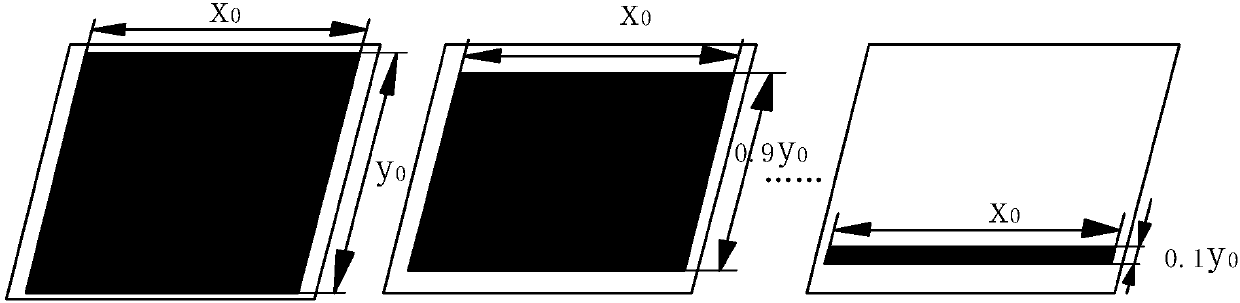

Method for automatically adjusting powder supplying amount of metal 3D printing machine

ActiveCN107774994AReduced powder supply balanceAvoid molding failureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLayer thickness

The invention discloses a formula for automatically adjusting the powder supplying height of a metal 3D printing machine. The formula includes the following steps that S1, the size parameters x0 and y0 of a forming cylinder and the size parameter x0' of a powder supplying cylinder are input; S2, the values of x and y are obtained and input according to the contour of a current printing layer; S3,the layer thickness h0 of the current printing layer is obtained; S4, the powder supplying height is changed in real time according to the formula (please see the formula in the specifications); and S5, when the S1, the S2, the S3 and the S4 are conducted for the fifteenth time, the coefficient A is multiplied before the current powder supplying height calculating formula according to the waste material amount in a waste material collecting box, the value ranges from 0.9 to 1.5, and the powder supplying height is increased or reduced according to the waste material amount. The powder supplyingheight of the current printing layer can be dynamically adjusted in real time according to the part section area, the part placing position, the powder batch, the powder density changes in the forming cylinder and the powder supplying cylinder and changes of operators and other factors, and therefore the size of waste materials can be minimized on the premise that powder is fully spread on the current printing layer.

Owner:BEIJING E PLUS 3D TECH CO LTD

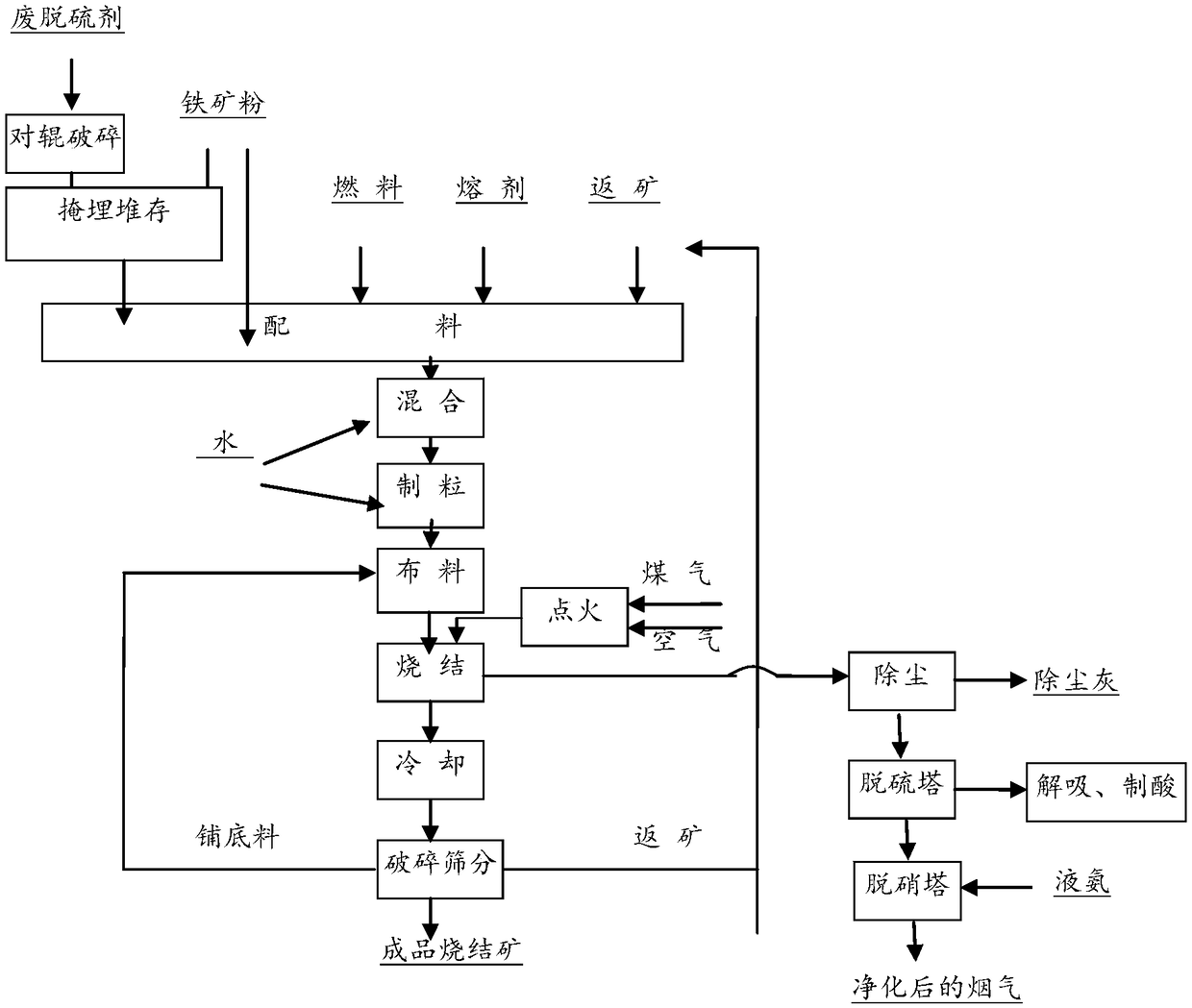

Processing method of applying waste desulfurizing agents to sintering

ActiveCN108715930ASintering is safe and reliableReduce processing costsGas treatmentDispersed particle separationActivated carbonResource utilization

The invention discloses a processing method of applying waste desulfurizing agents to sintering. The processing method includes the following steps that the waste desulfurizing agents are crushed intoparticles with the granularity smaller than 8 mm accounting for 100%, and with the granularity smaller than 1 mm accounting for 10%; evenly mixed powder is obtained by evenly mixing the crushed wastedesulfurizing agents and iron ore powder; evenly mixed ore powder is obtained by burying the evenly mixed powder in an iron ore powder pile; evenly mixed sintering powder is obtained by mixing the evenly mixed ore powder, iron ore powder, solid fuel, fluxing agents and return fines; water is added to the evenly mixed sintering powder to be subject to mixing and pelletizing to form evenly mixed sintering powder; sintered ore and sintering flue gas are obtained by sintering the pelletized materials; and the sintering flue gas is exhausted into the atmosphere after being subjected to desulfurization and denitrification. According to the processing method, the waste desulfurizing agents are crushed and then matched with the iron ore powder for sintering, the sintered ore is obtained for blastfurnace ironmaking, and iron, calcium and magnesium are recycled. Activated carbon absorbing sulfur dioxide can be used for desorbing the sulfur dioxide and making acid so as to recover sulfur. Thus,harmless disposal of the waste desulfurizing agents is carried out, and resource utilization of the waste desulfurizing agents is achieved.

Owner:CENT SOUTH UNIV

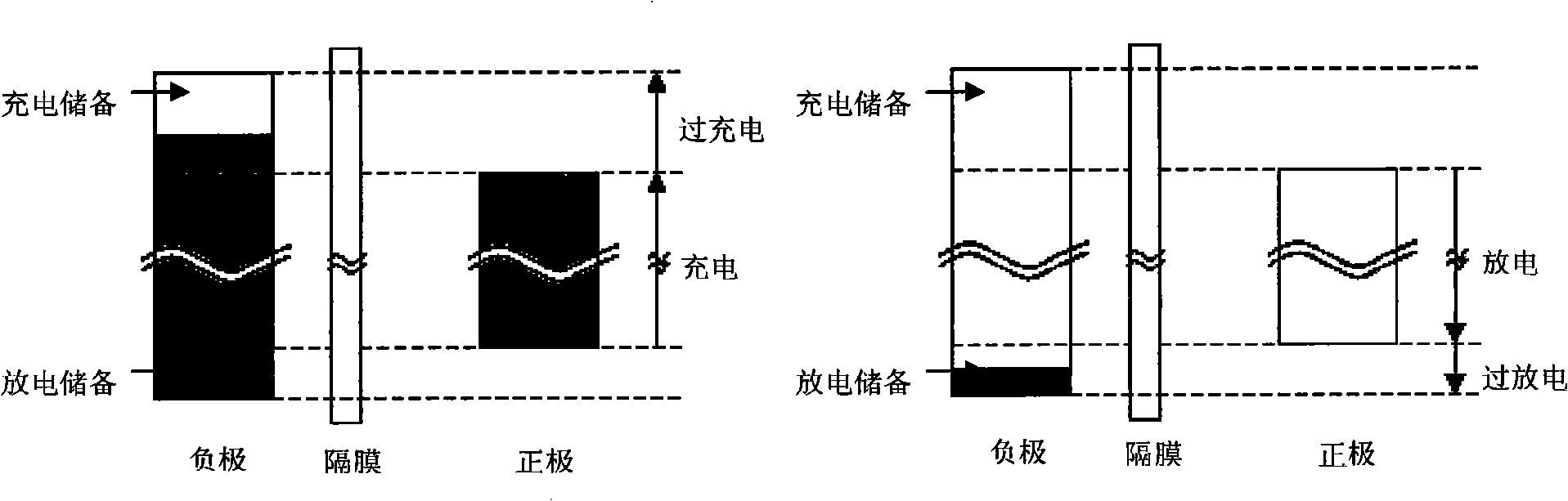

Nickel-hydrogen battery and preparation method for anode material

ActiveCN101320805AReduce the effective capacity ratioReduce design capacityElectrode manufacturing processesFinal product manufactureCapacitancePartial oxidation

A nickel-hydrogen battery and a production method for positive pole material of the nickel-hydrogen battery are disclosed, the method comprises the following steps of: 1) production of the positive pole, at first, the surface of spherical nickel hydroxide as positive pole active substance is covered with a gamma-CoOOH covering layer, then the spherical nickel hydroxide whose surface is covered with the gamma-CoOOH is partially oxidized, average chemical valence of the nickel after oxidization is controlled as 2.08-2.20; 2) production of the negative pole, proportion of the capacitance of the negative pole to the capacitance of the positive pole is (1.15-1.25):1; 3) assembly for the negative pole, the positive pole and membrane; 4) formation of the battery, 0.05C-0.2C of current is adopted to activate the battery for 3 to 10 weeks with charge and discharge capacitances during each week being between 30% and 100%, and the current amount of the battery at the time of discharging in the first week is discharged to zero. The positive pole uses the partially-oxidized spherical nickel hydroxide whose surface is covered with the gamma-CoOOH, when the designed capacitance proportion of the positive and negative poles is fixed, the designed capacitance of the negative pole can be reduced correspondingly, powder applying amount of the negative pole is lessened, manufacturing cost of the battery is saved, and the battery is able to maintain the characteristics of long service life and resistance to overcharge.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

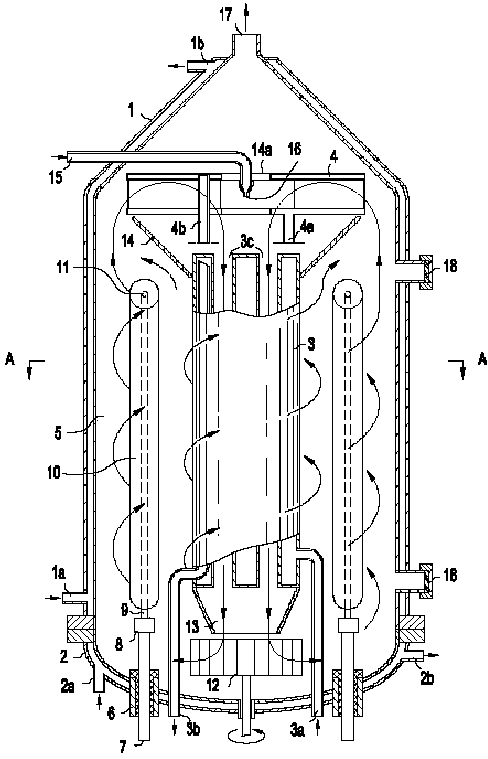

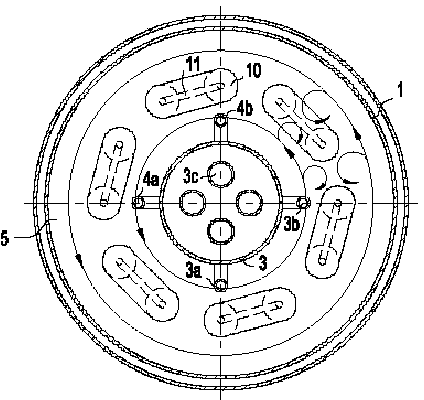

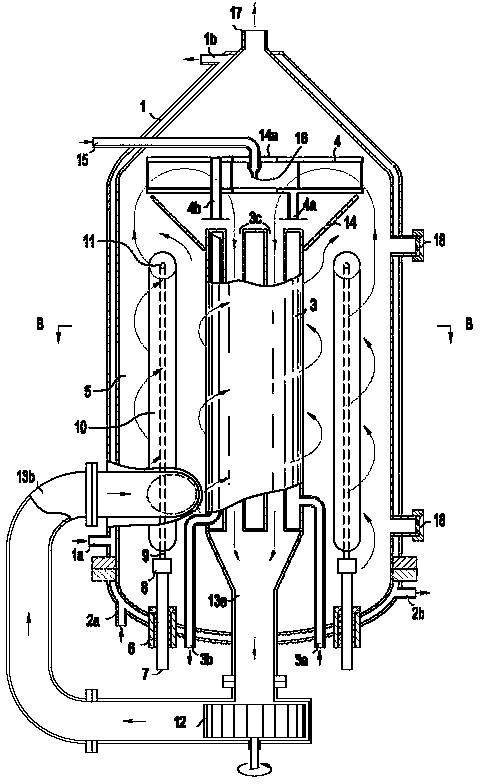

Production apparatus and production method for polysilicon rod

The invention discloses a production apparatus and a production method for a polysilicon rod. The production apparatus comprises a hearth consisting of a bell jar and a chassis, an interior cooling space giving play to cooling and separation of an air flow, high-temperature silicon rods uniformly distributed in an annular space, a silane mixing dilution system consisting of a low-temperature mixing zone and a high-speed stirring zone, and a wind wheel capable of generating a circulation air flow in the hearth and generating a high-speed whirlwind air flow in the annular space; and the wind wheel drives silane and a decomposition by-product hydrogen to form the highly-diluted high-speed whirlwind circulation air flow, the air flow is orthogonally contacted with silicon rods, so that transportation and reaction of silane to a high-temperature deposition surface, and the compact homogeneous high-purity polysilicon rod is formed through rapid deposition under the condition that generation of dust is inhibited, and energy consumption is reduced.

Owner:姚迅

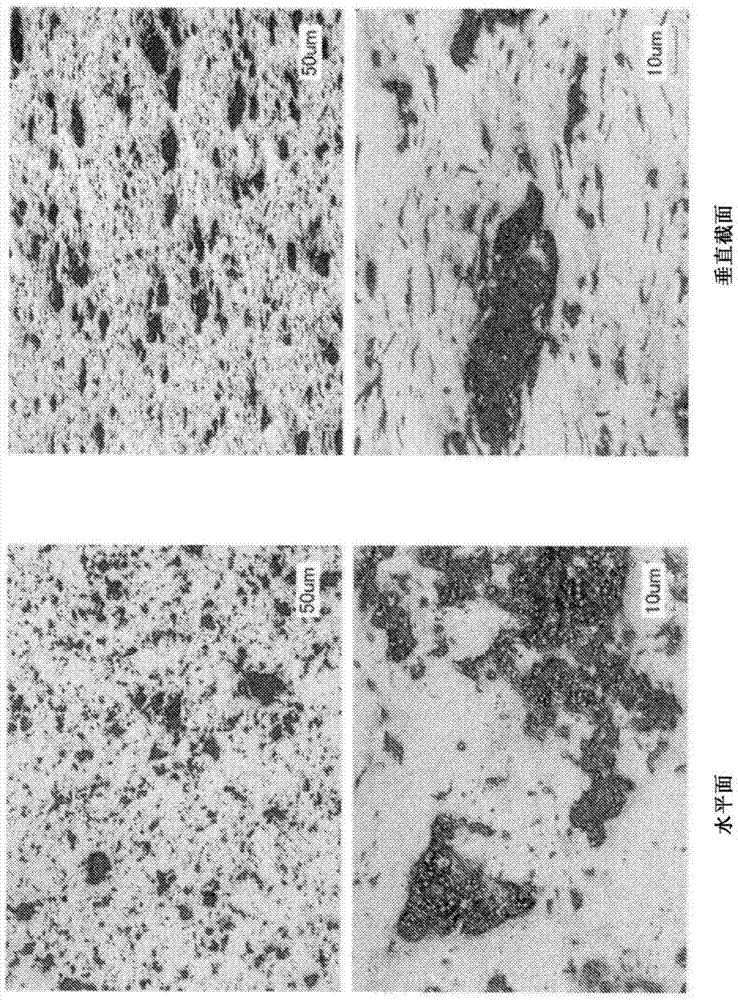

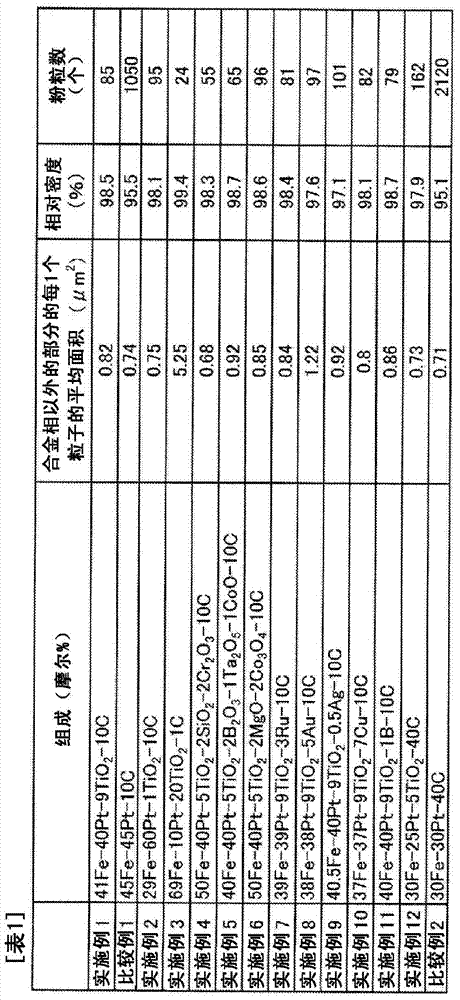

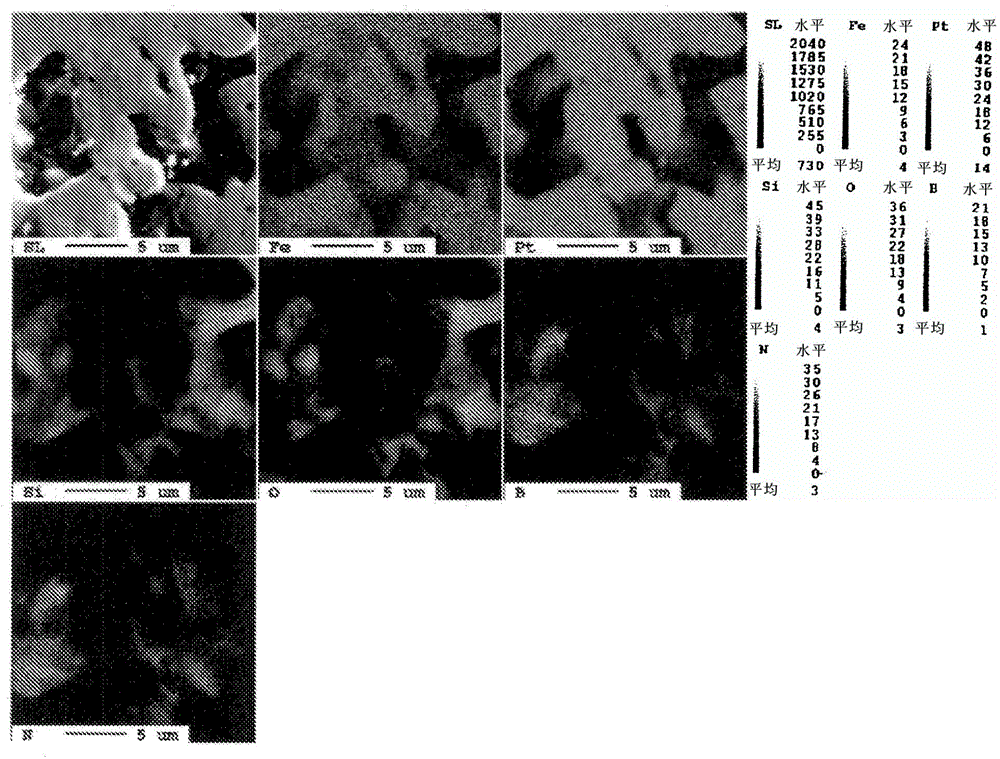

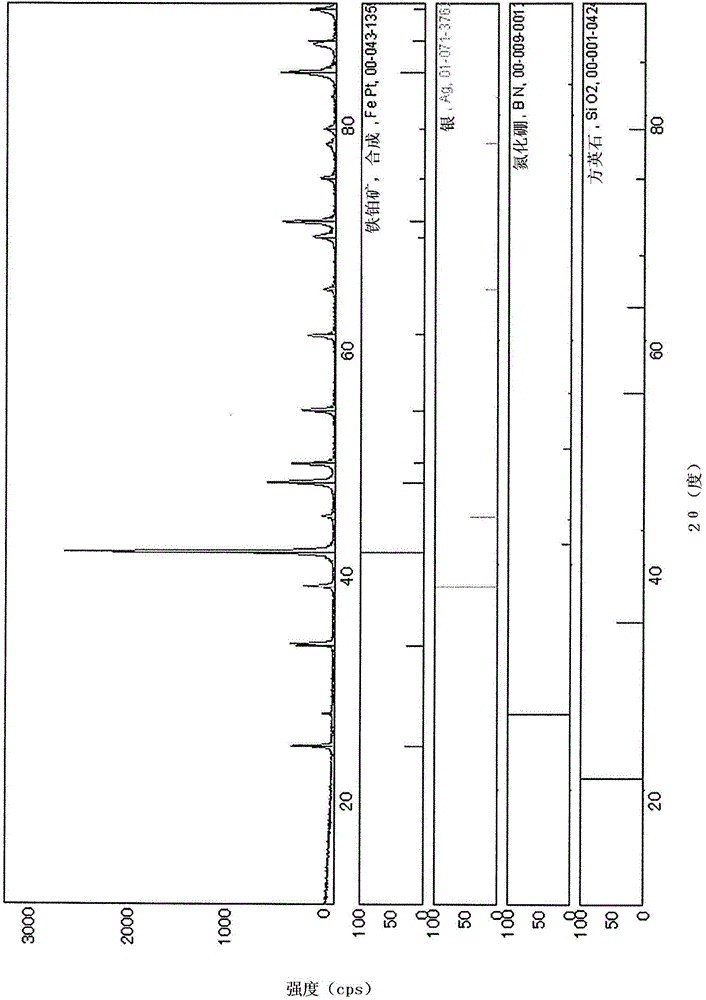

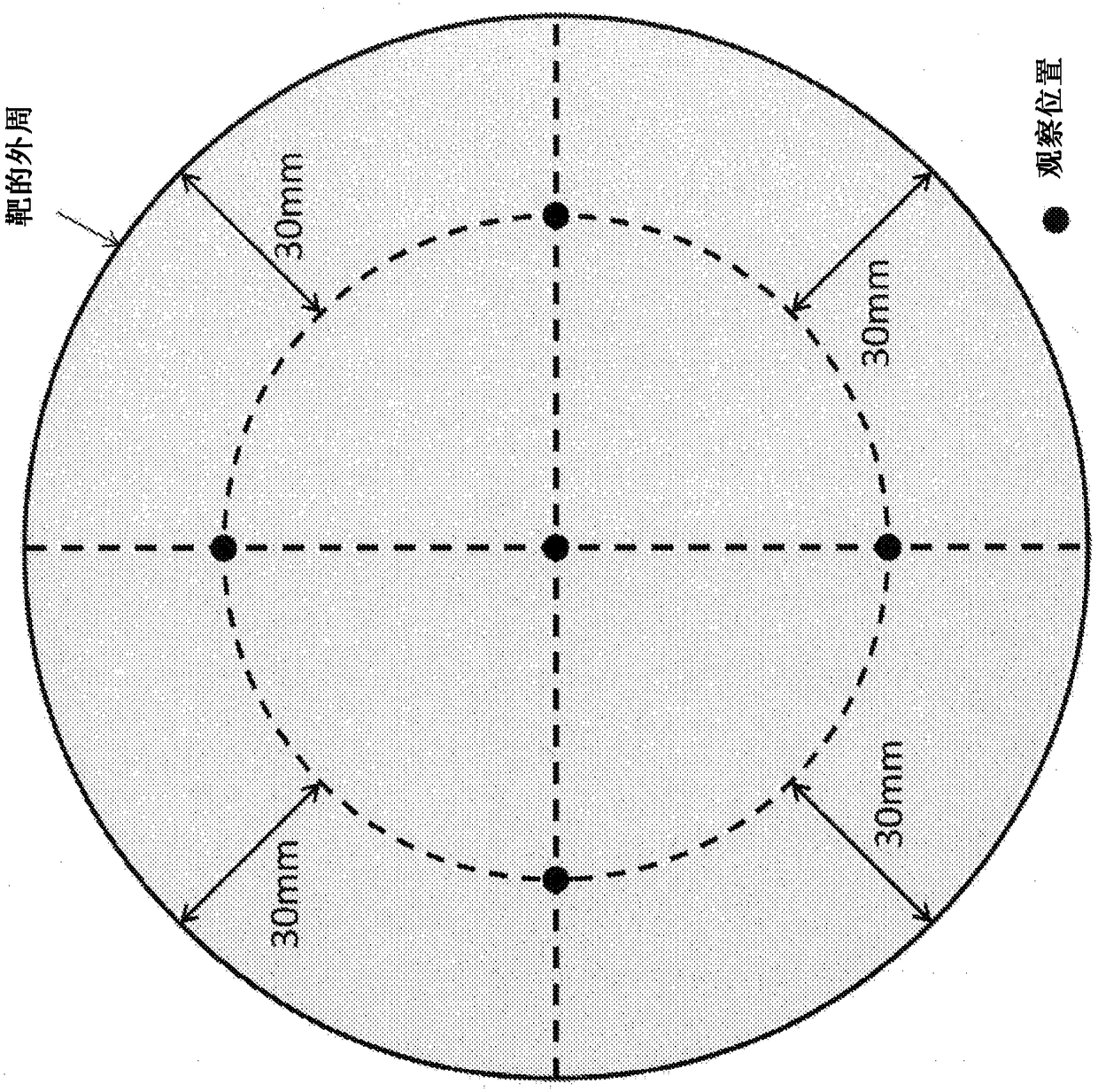

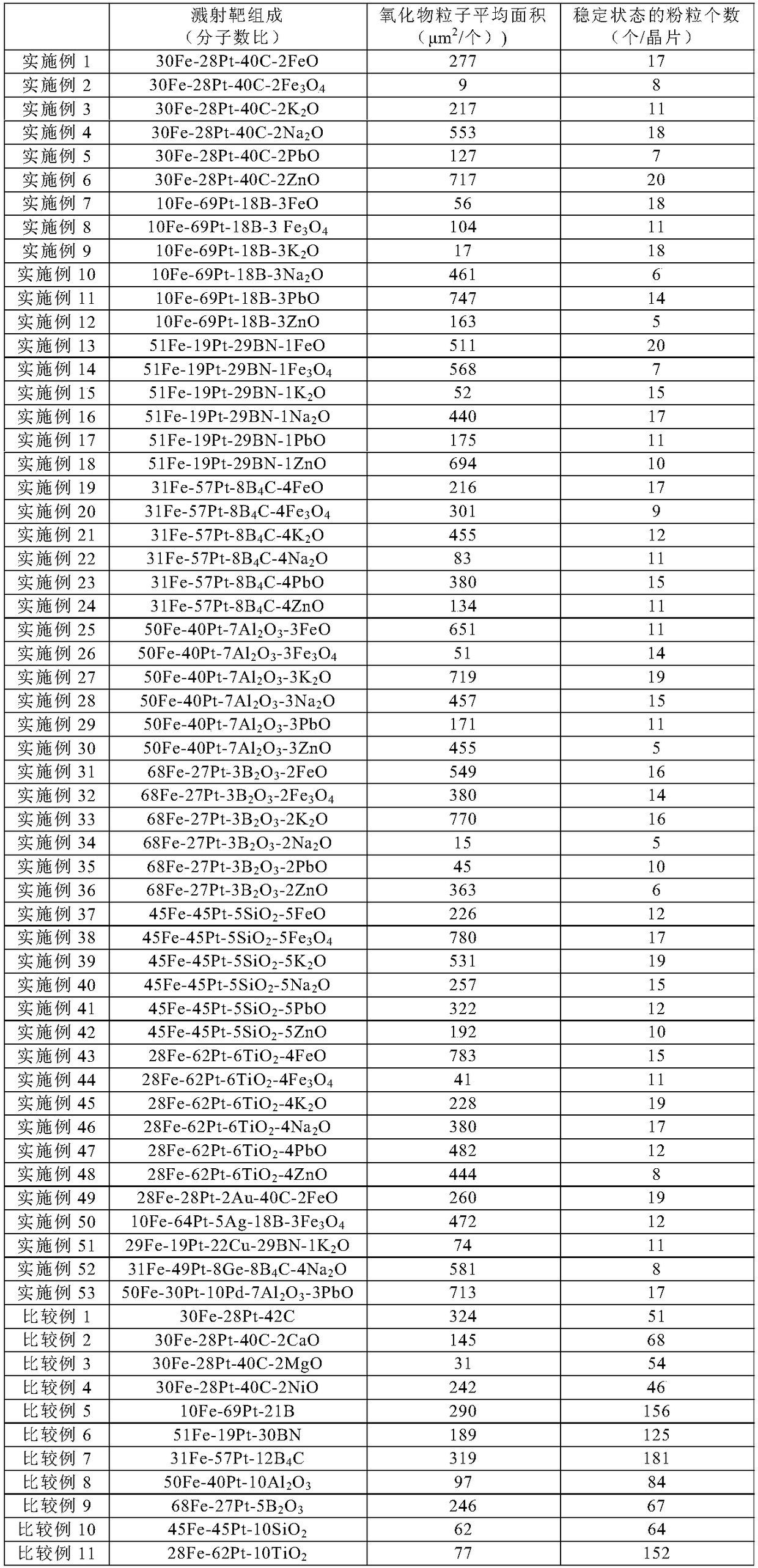

Fe-Pt sintered compact sputtering target and manufacturing method therefor

ActiveCN104781446AGood orientationSuppress abnormal dischargeVacuum evaporation coatingSputtering coatingSputteringHeat-assisted magnetic recording

An Fe-Pt sintered compact sputtering target containing BN characterized in that the intensity ratio of the X-ray diffraction peak intensity of a hexagonal BN (002) plane in a plane level with the sputtering surface with respect to the X-ray diffraction peak intensity of a hexagonal BN (002) plane in a cross-section perpendicular to the sputtering surface is 2 or more. The present invention addresses the problem of providing a sputtering target with which manufacture of a magnetic film in thermally assisted magnetic recording media is possible and particles that are generated during sputtering are reduced.

Owner:JX NIPPON MINING & METALS CO LTD

Powder quantity recognition coffee machine

InactiveCN108433546AAvoid imbalanceIncrease the amount of powderBeverage vesselsEngineeringScrew cap

The invention discloses a powder quantity recognition coffee machine which comprises a bean grinder, a bean box and a brewing system, wherein the brewing system comprises a brewing cup, a brewing plug, a first motor, a rotation number sensor and a controller; a thread is arranged at the peripheral surface of the brewing plug, a screw cap is sleeved on the peripheral surface of the brewing plug, and the brewing plug is in sealed connection with the brewing cup; the first motor is used for driving the screw cap to rotate to drive the brewing plug to move downwards; the rotation number sensor isused for sensing the rotation number n of the screw cap; a datum line is arranged on the brewing cup, and a corresponding screw cap datum turn number n0 is arranged on the controller. When the rotation number n of the screw cap is larger than n0, the powder quantity is too small, so that bean grinding time t is prolonged in the next grinding to improve the powder quantity; when the rotation numbern of the screw cap is smaller than n0, the powder quantity is too large, so that the bean grinding time t in the next grinding can be shortened to reduce the powder quantity. By means of a control process, the coffee powder quantity can be controlled within a standard range, and the phenomenon that the coffee powder quantity is unbalance is avoided.

Owner:TUNBOW GRP

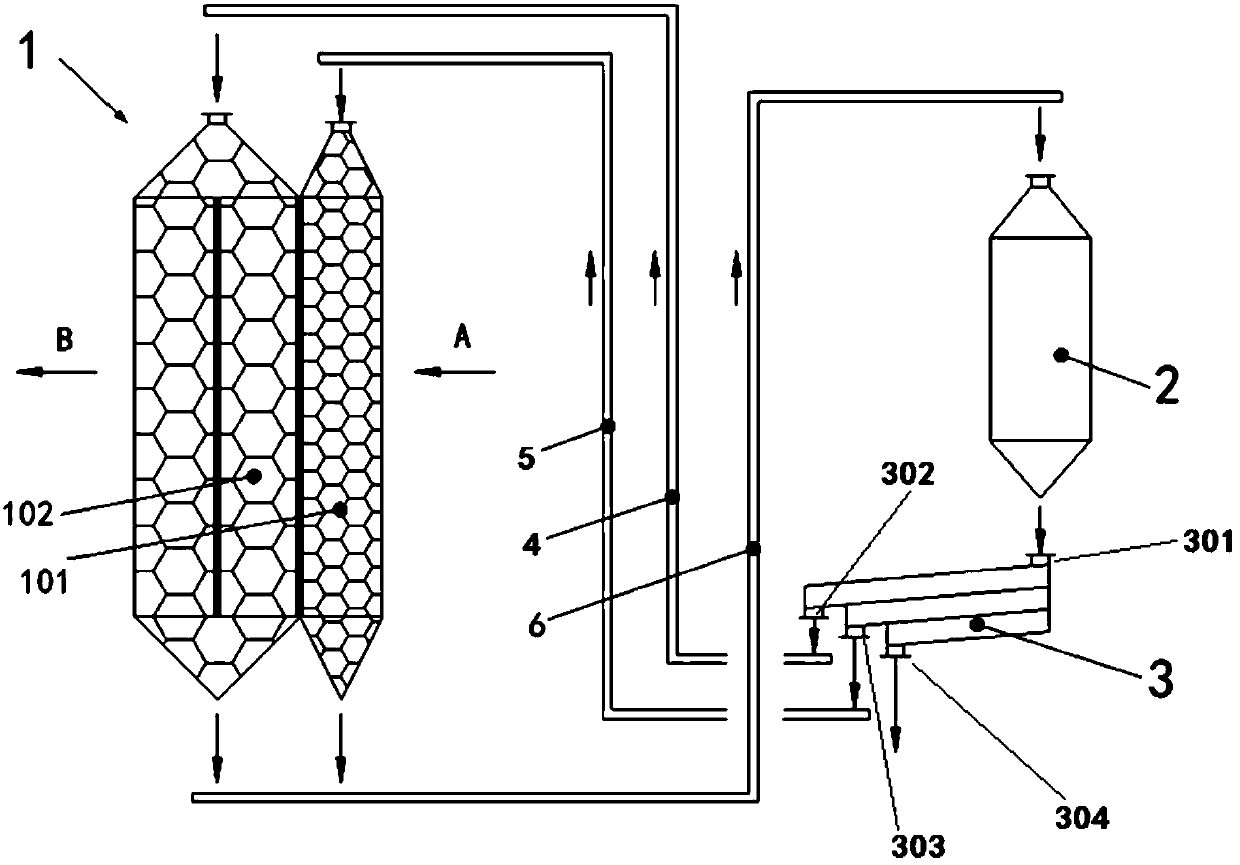

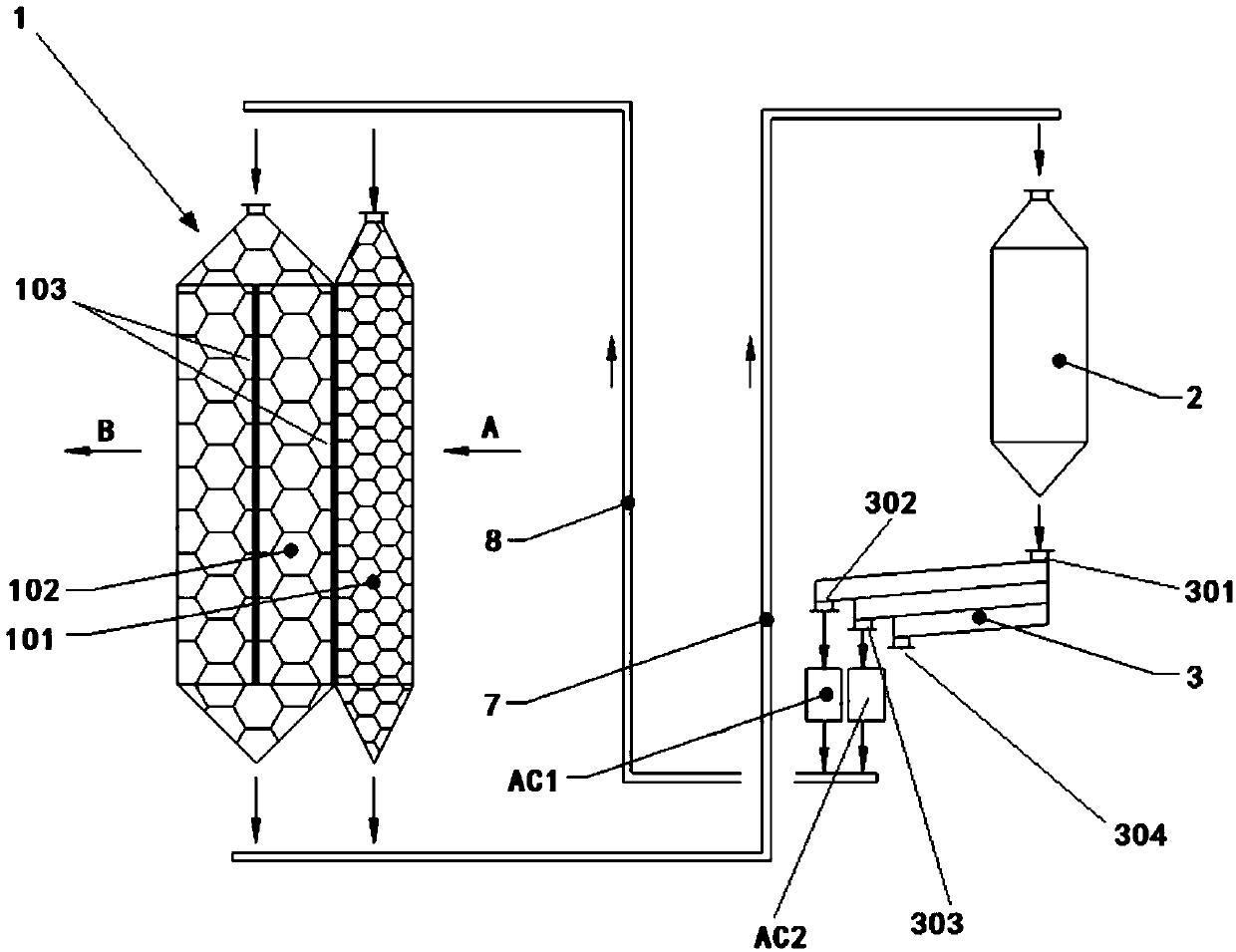

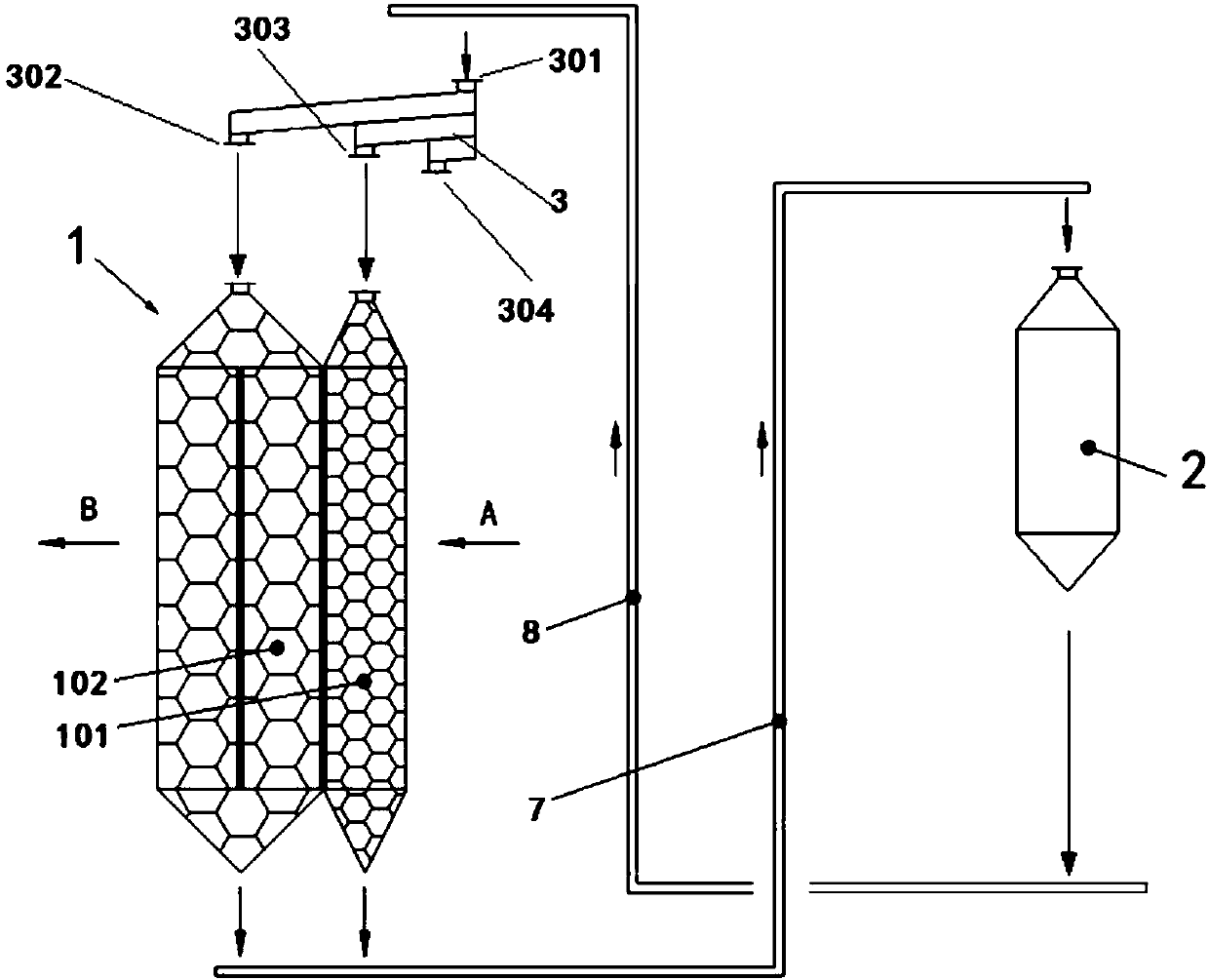

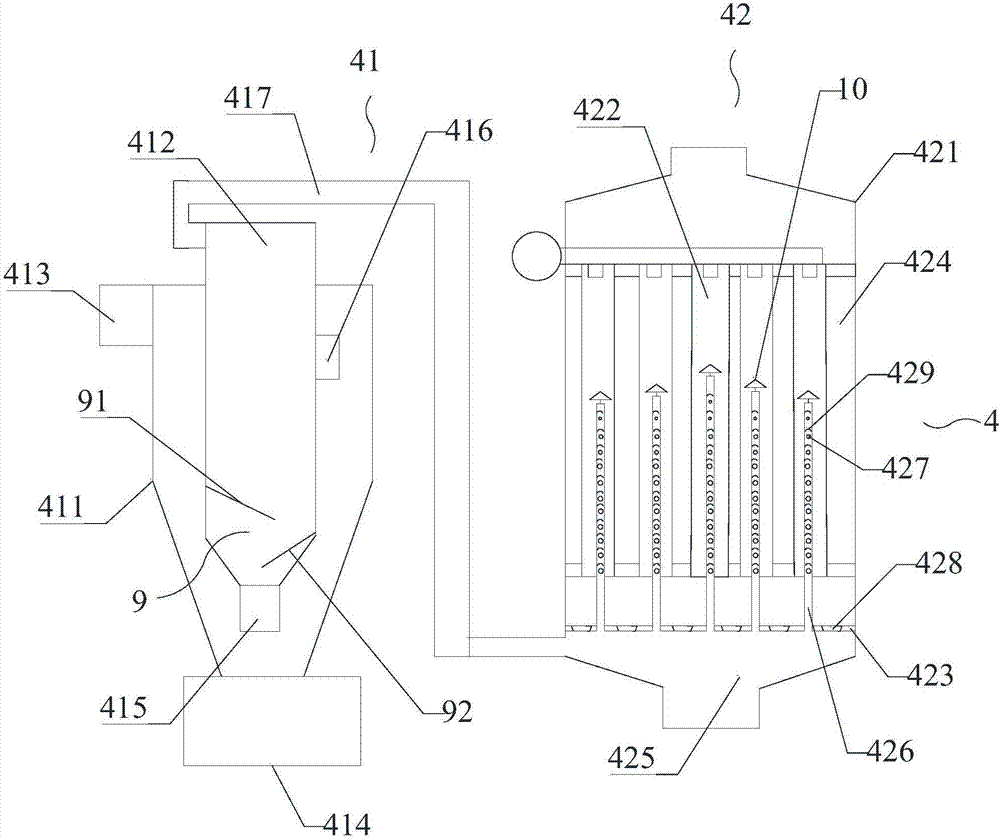

Desulfurization and denitrification system

ActiveCN108371873AEffective entrainmentEasy dischargeGas treatmentDispersed particle separationActivated carbonDesorption

The invention relates to a desulfurization and denitrification system. The system comprises an adsorption tower, a desorption tower, a graded sieving machine, a first activated carbon conveying machine, a second activated carbon conveying machine and a third activated carbon conveying machine, wherein a smoke inlet is formed in one side of the desorption tower; a smoke outlet is formed in the other side of the desorption tower; an adsorption layer front cavity and an adsorption layer rear cavity are formed in the adsorption tower; the first activated carbon conveying machine is connected witha first discharging hole of the graded sieving machine and a feeding hole of the adsorption layer rear cavity; the second activated carbon conveying machine is connected with a second discharging holeof the graded sieving machine and a feeding hole of the adsorption layer front cavity; and the third activated carbon conveying machine is connected with a discharging hole of the adsorption tower and a feeding hole of the desorption tower; and a discharging hole of the desorption tower is connected with a feeding hole of the graded sieving machine. According to the desulfurization and denitrification system, large-particle activated carbon is placed at the rear part of an activated carbon bed layer in the adsorption tower, and small-particle activated carbon is placed at the front part of the activated carbon bed layer in the adsorption tower, so that the situation that activated carbon powder is blown out of the bed layer by smoke can be prevented, and the aim that the smoke dust at theoutlet is reduced can be realized.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

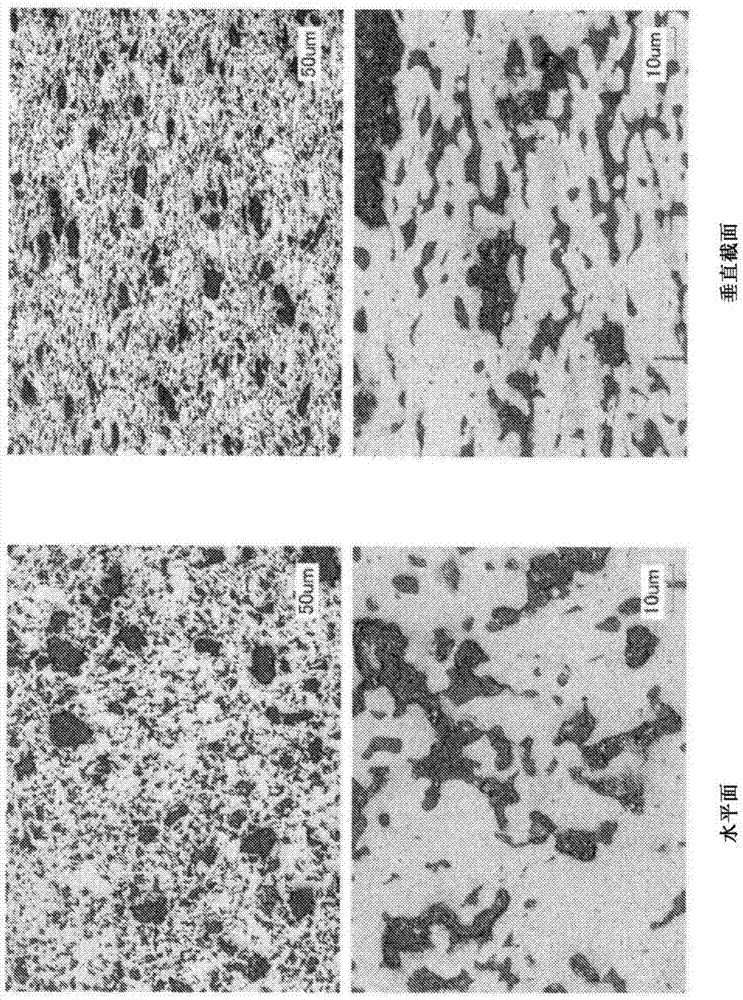

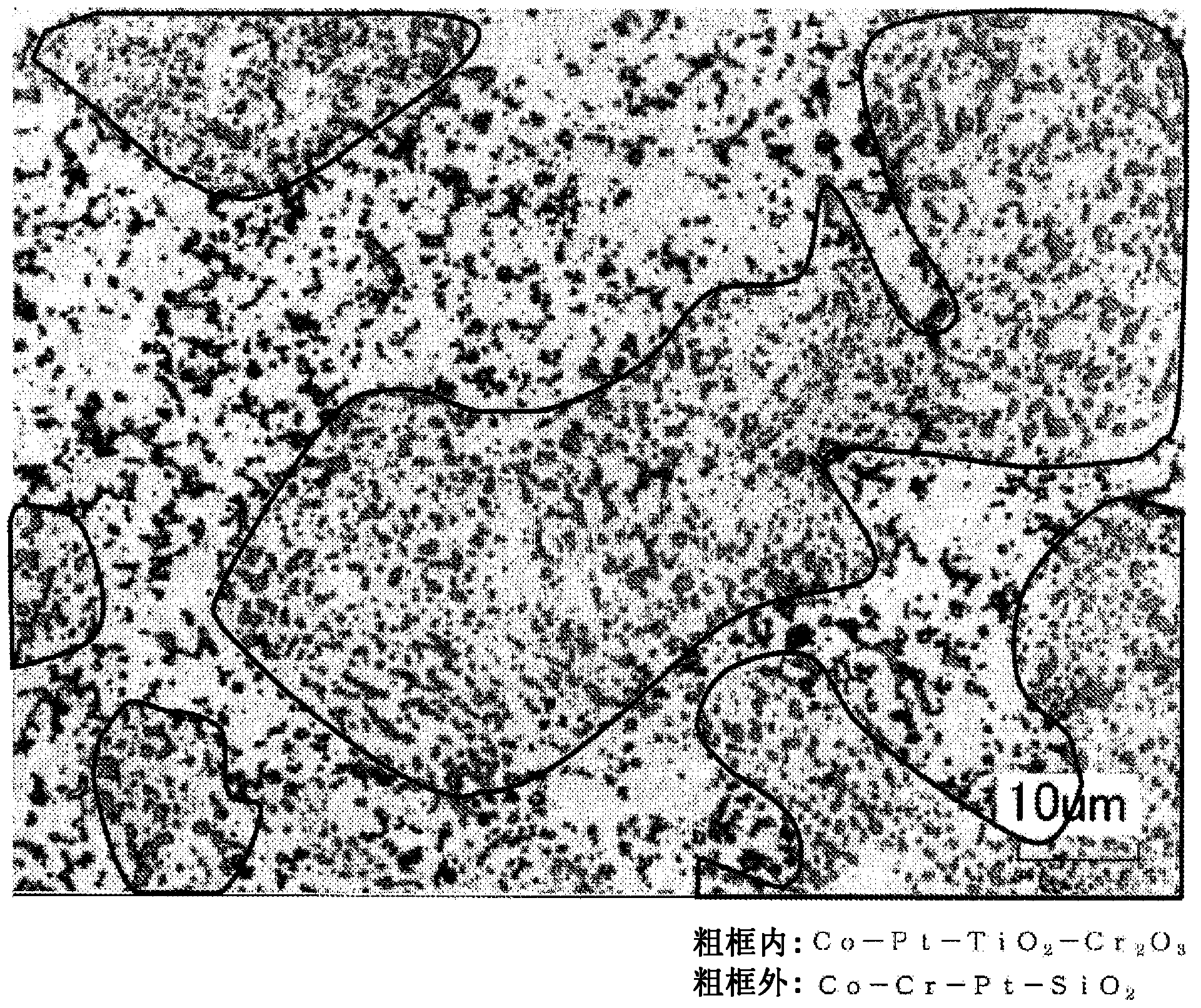

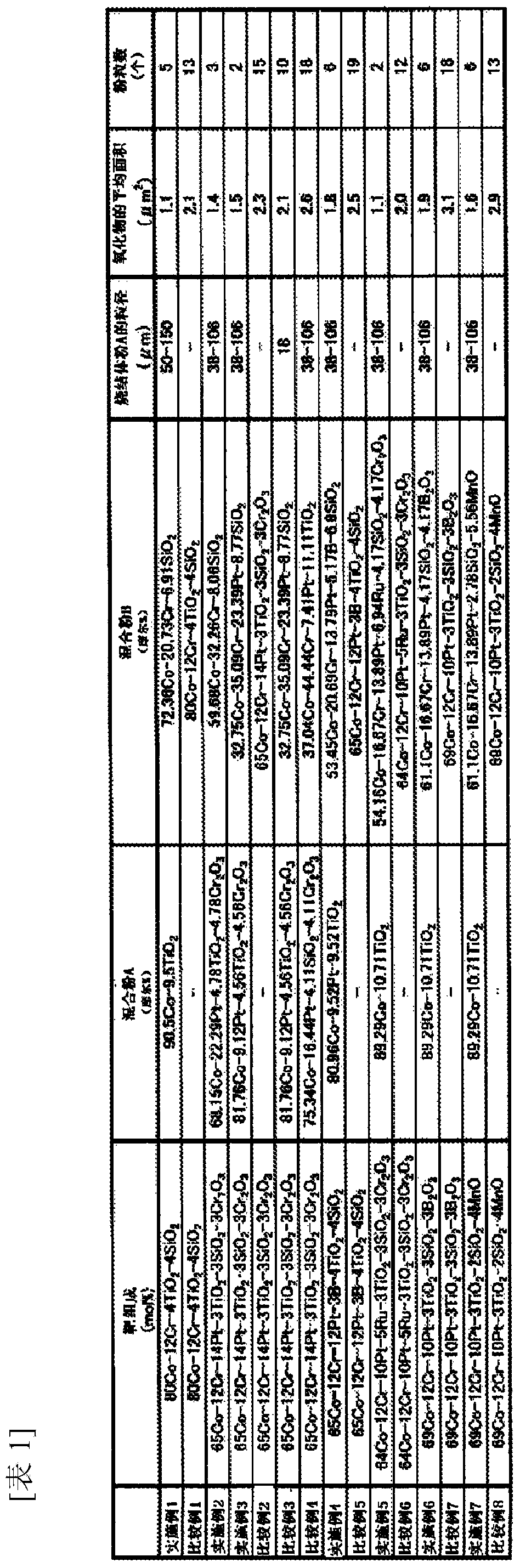

Co-cr-pt-based sputtering target and method for producing same

ActiveCN104081458AGood dispersionInhibition formationElectric discharge tubesVacuum evaporation coatingSputteringMetal

A sputtering target which contains, as metal components, 0.5-45 mol% of Cr and the balance of Co, while containing, as non-metal components, two or more oxides including Ti oxide. This sputtering target is characterized in that: the structure thereof is composed of regions where oxides including at least Ti oxide are dispersed in Co (non-Cr regions) and a region where oxides other than Ti oxide are dispersed in Cr or Co-Cr (a Cr region); and the non-Cr regions are scattered about in the Cr region. The present invention addresses the problem of providing a sputtering target for forming a granular film, which suppresses the formation of coarse complex oxide particles and generates less particles during the sputtering.

Owner:JX NIPPON MINING & METALS CORP

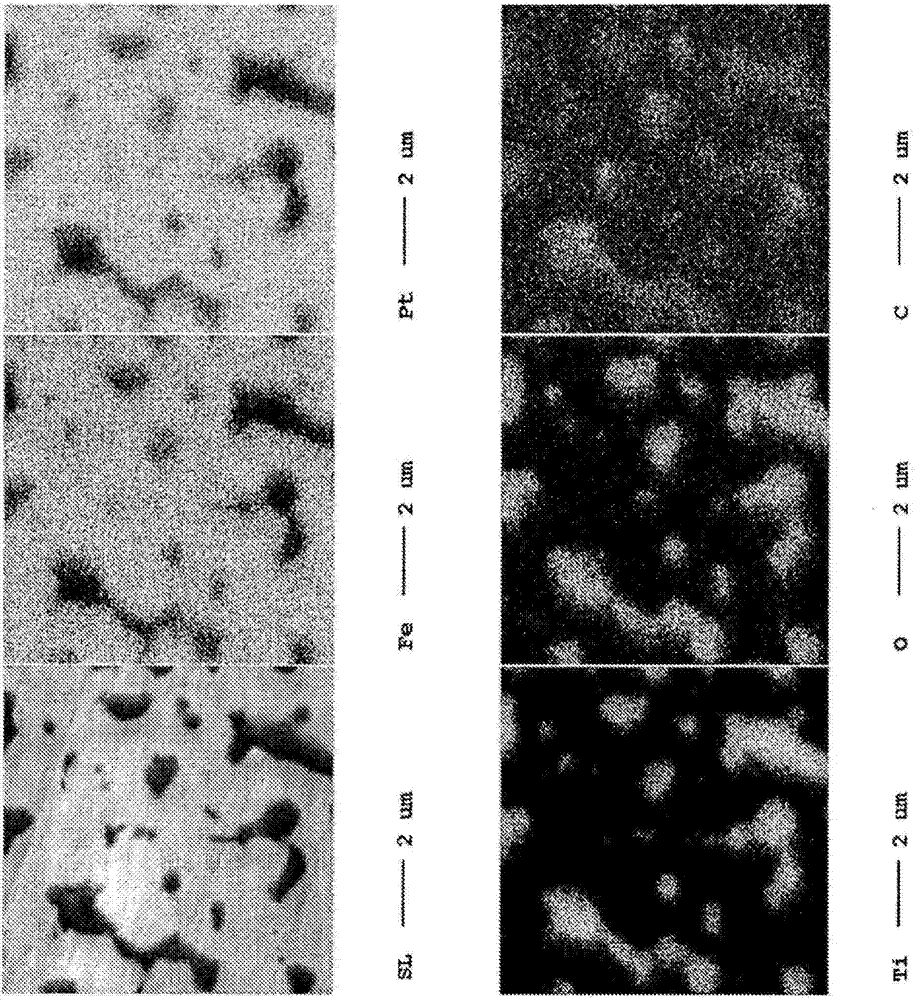

Fe-Pt-based sputtering target in which C particles are dispersed

ActiveCN103930592AEvenly dispersedReduce the amount of powderVacuum evaporation coatingSputtering coatingSputteringHigh density

A sputtering target for magnetic recording films, which is characterized by containing from 5 mol% to 60 mol% (inclusive) of Pt, from 0.1 mol% to 40 mol% (inclusive) of C and from 0.05 mol% to 20 mol% (inclusive) of titanium oxide, with the balance made up of Fe. The present invention addresses the problem of providing a high-density sputtering target which enables the formation of a magnetic thin film having a granular structure without using an expensive co-sputtering system, while reducing the amount of particles generated during the sputtering.

Owner:JX NIPPON MINING & METALS CORP

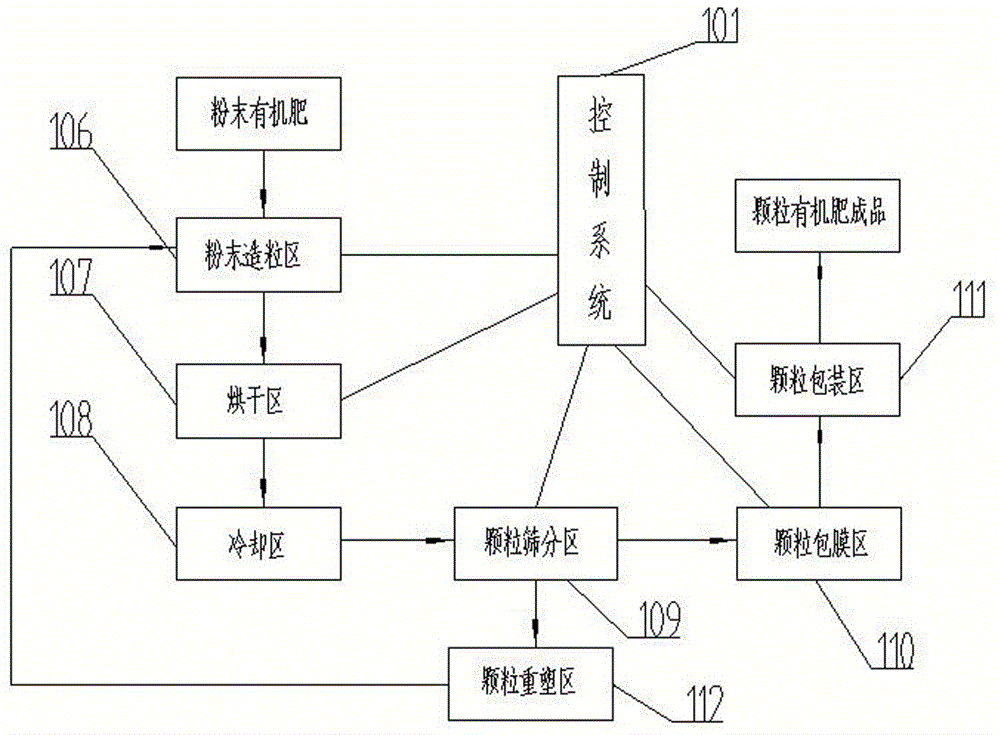

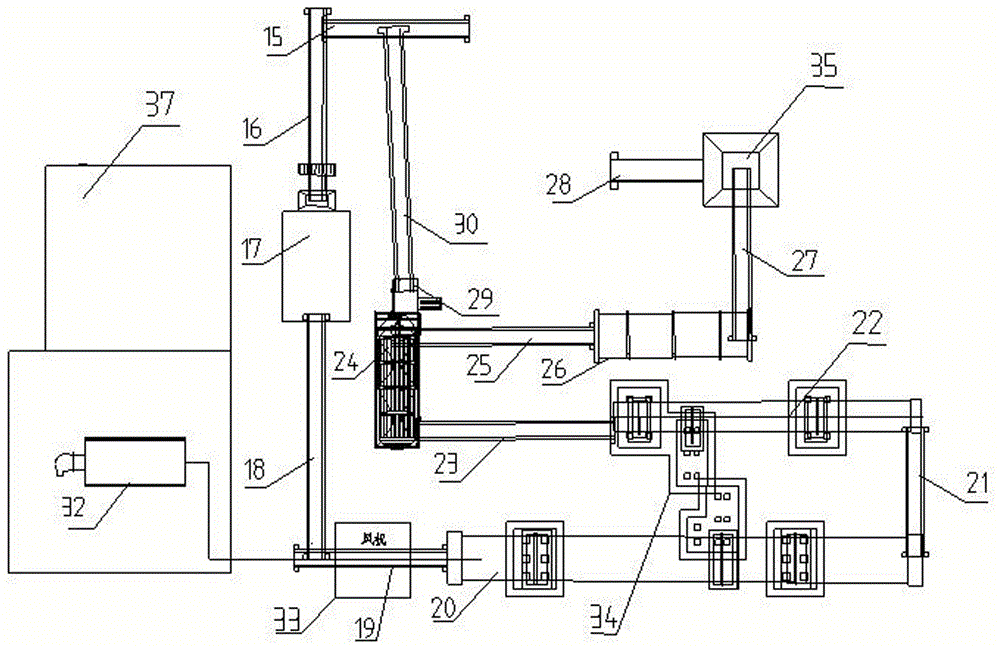

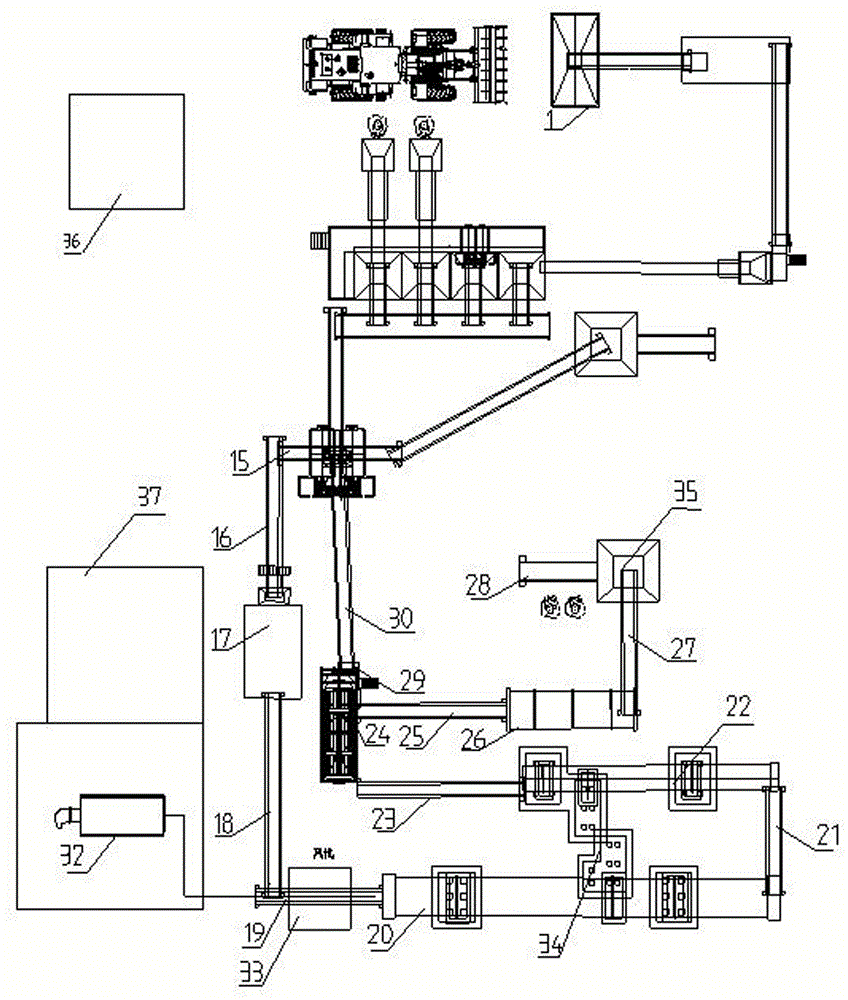

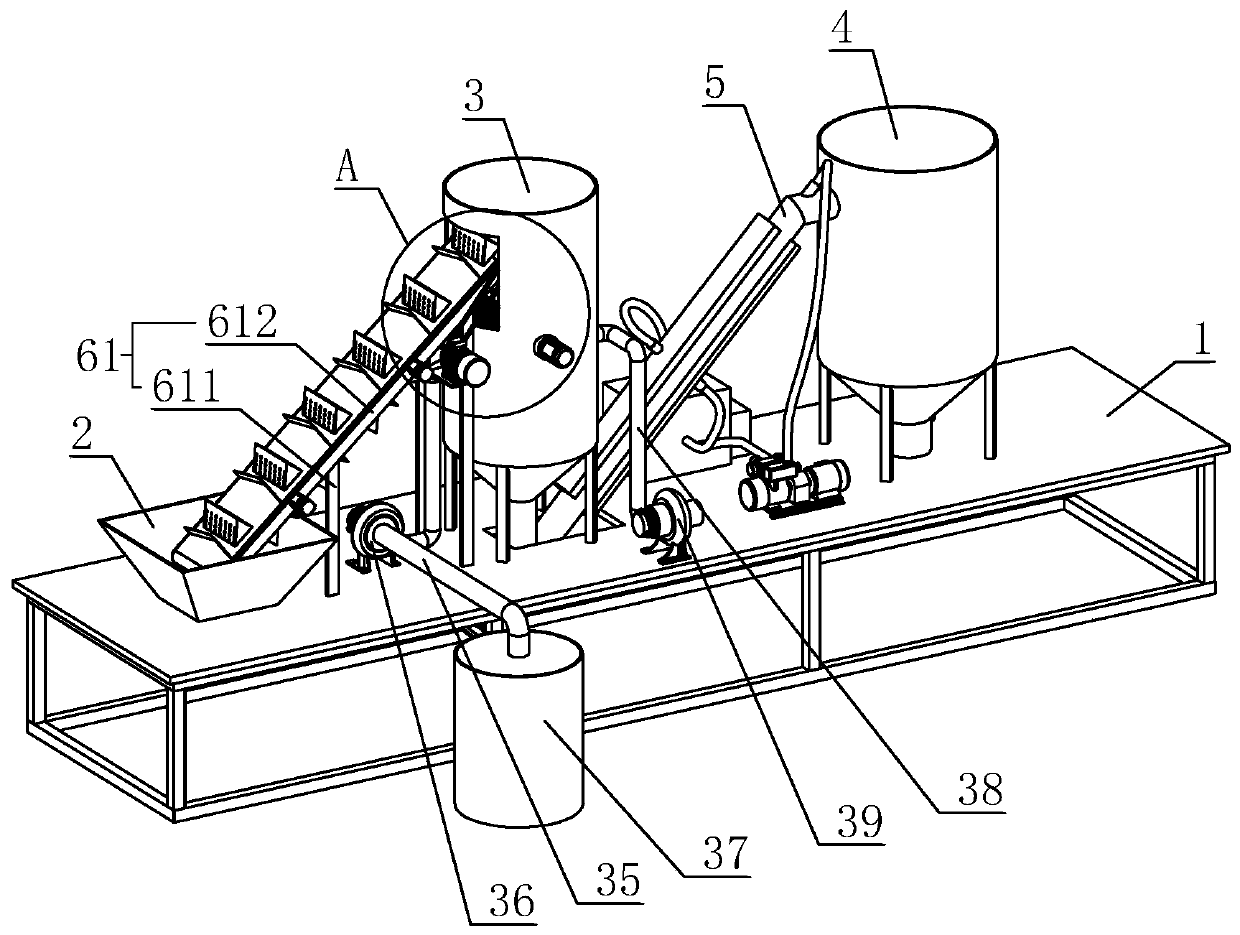

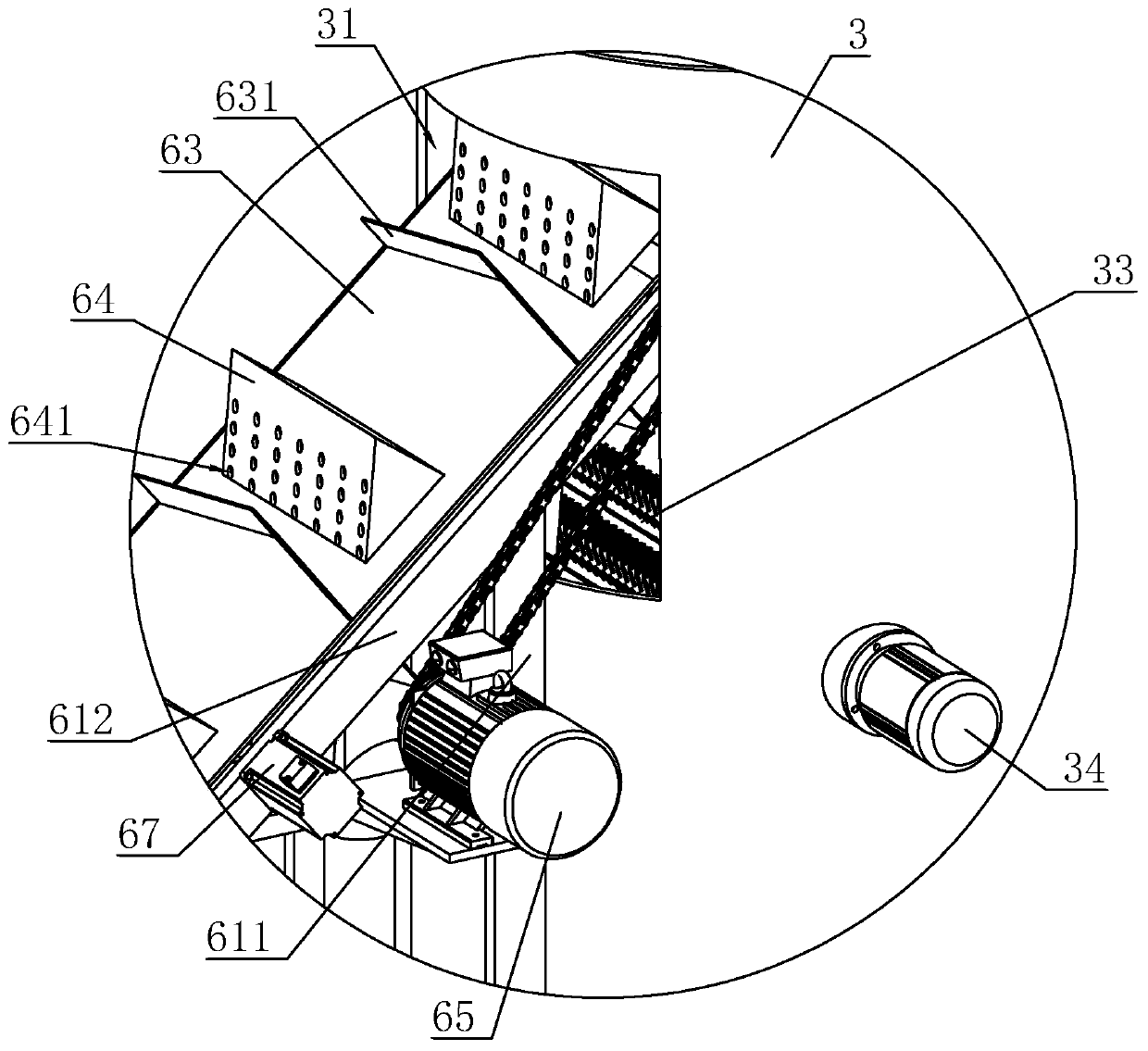

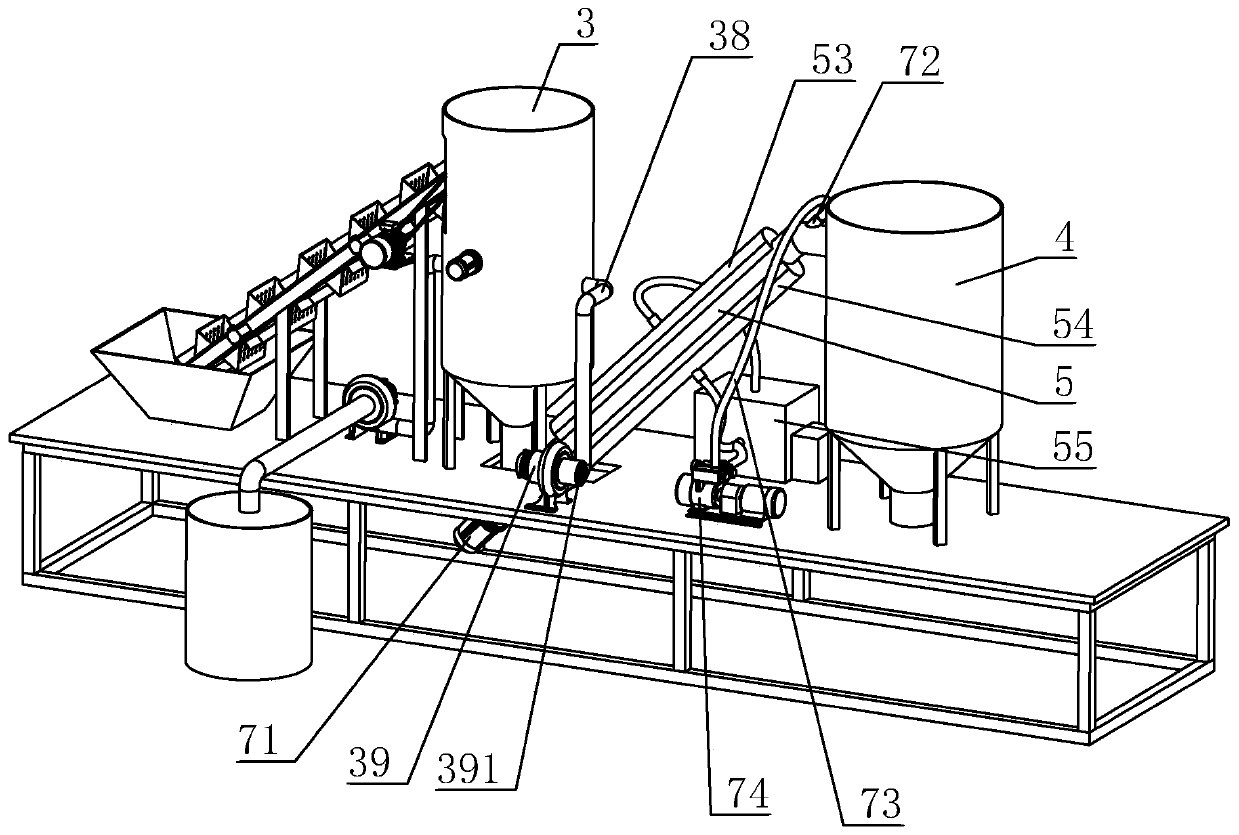

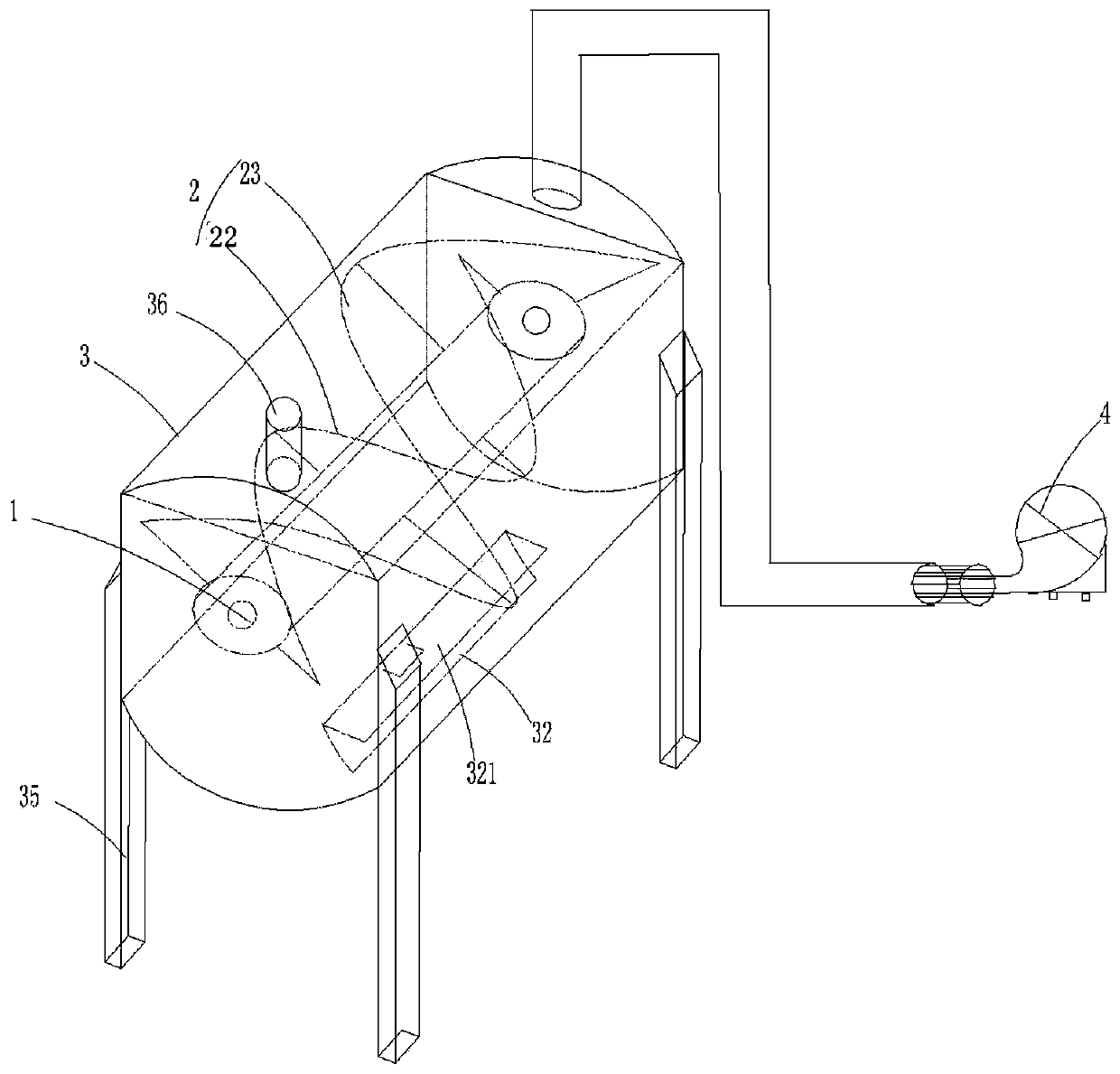

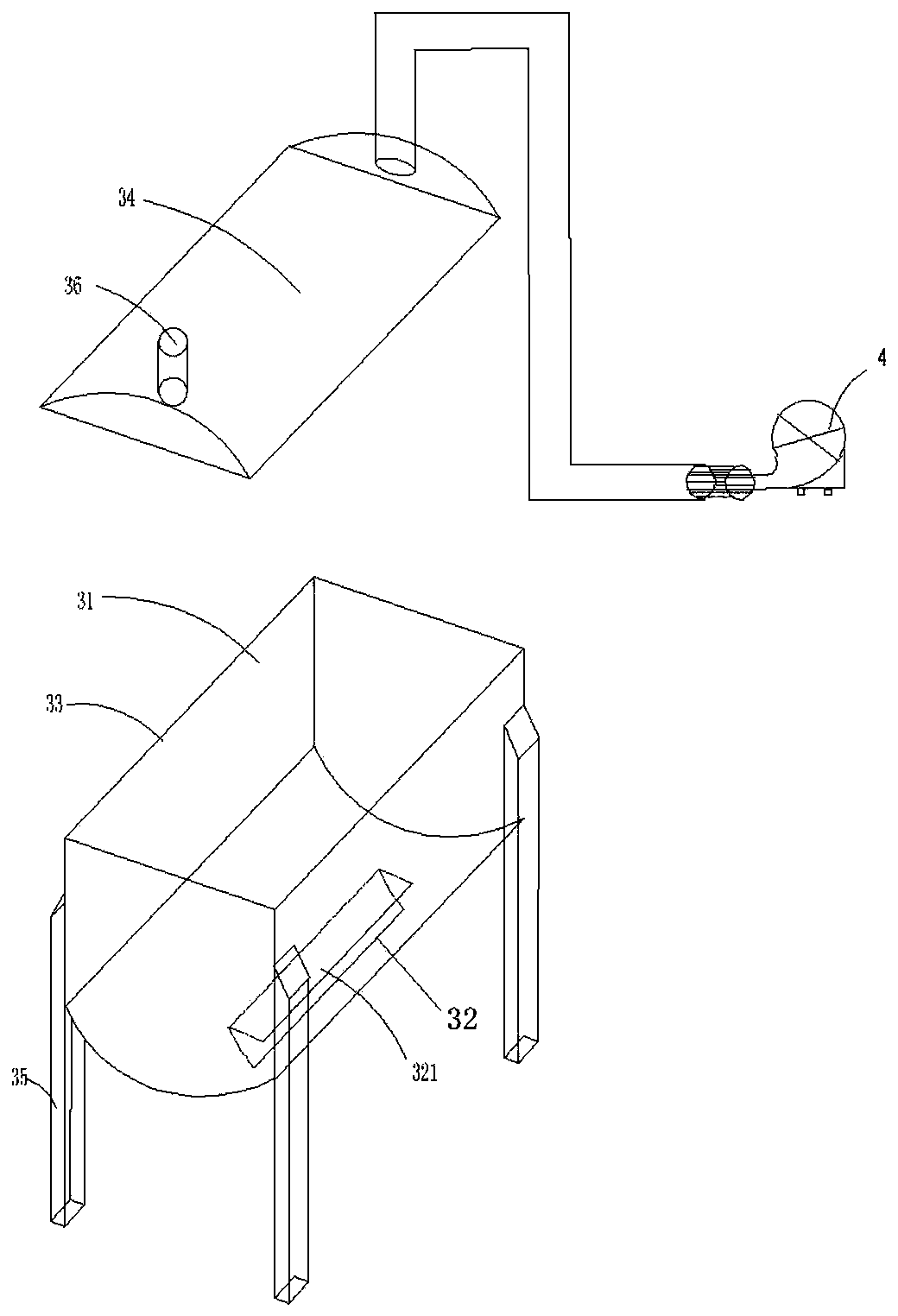

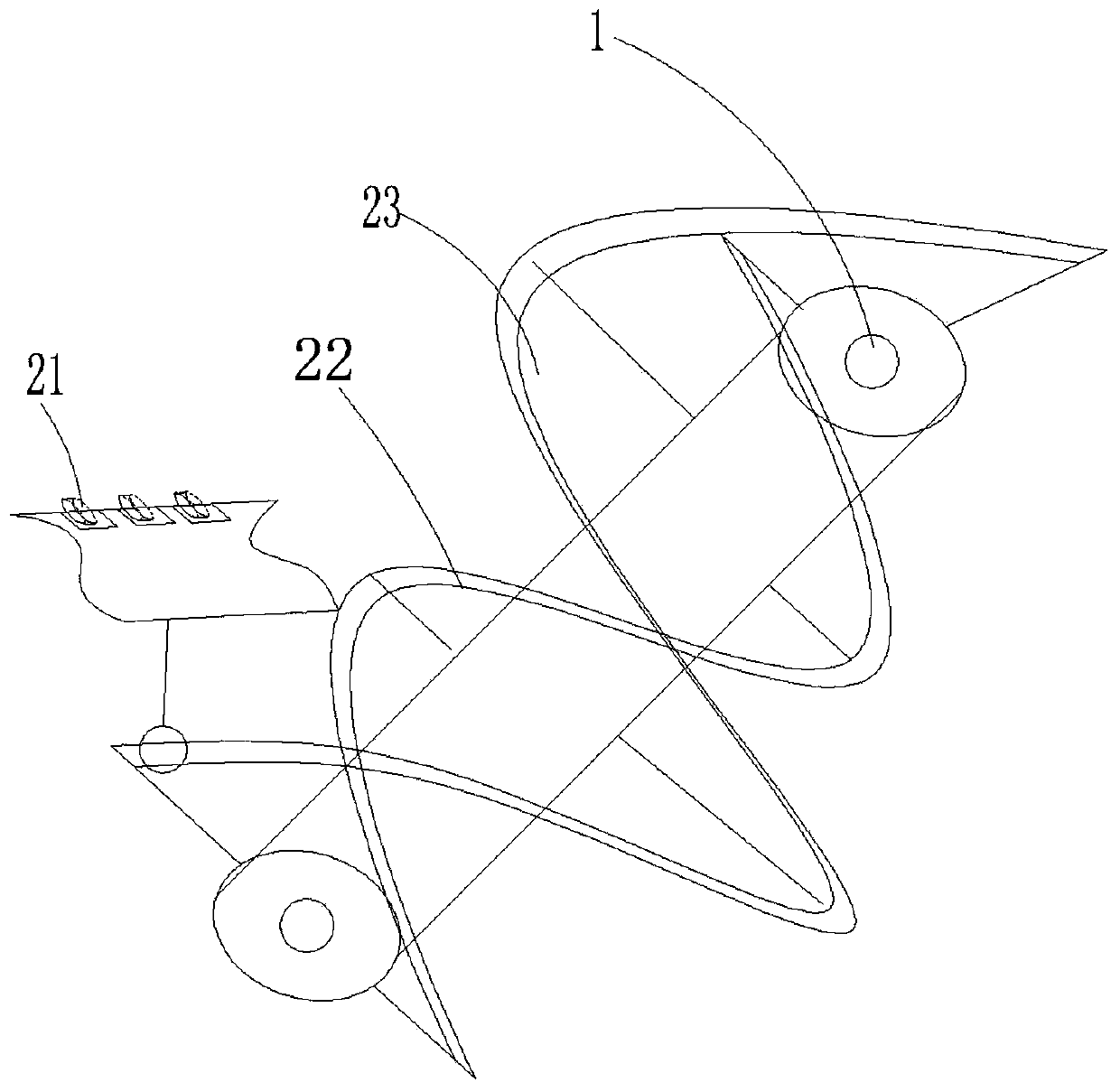

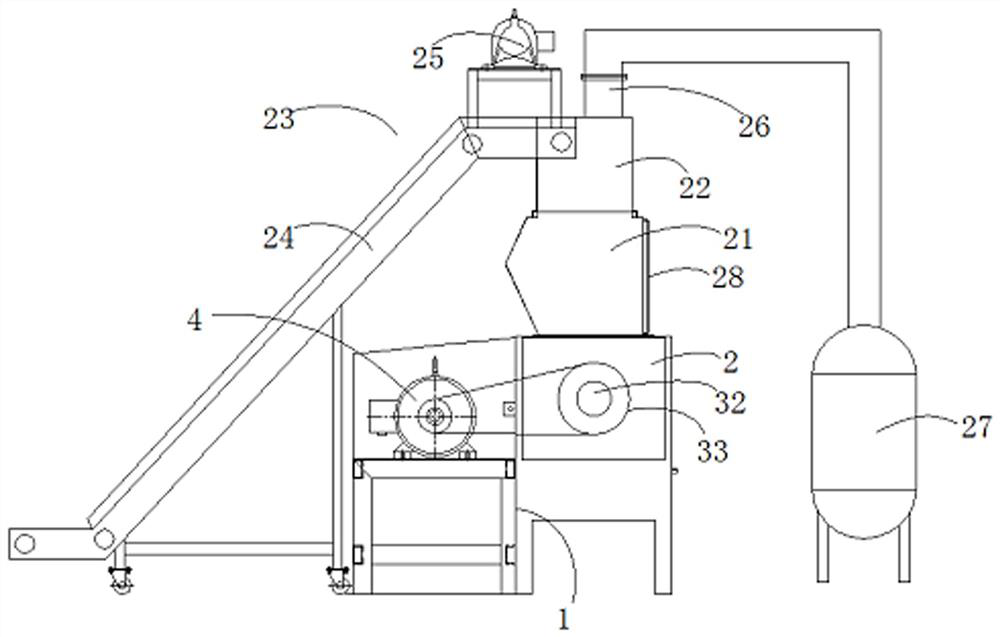

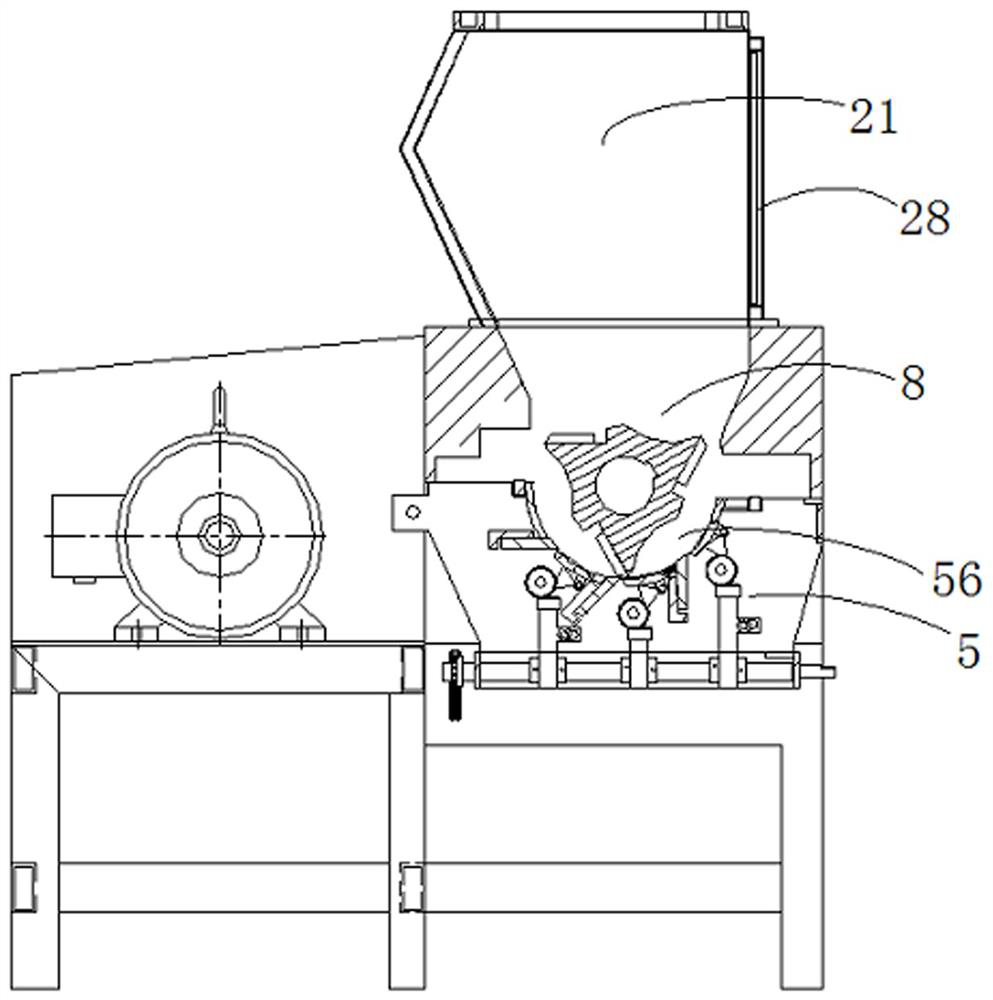

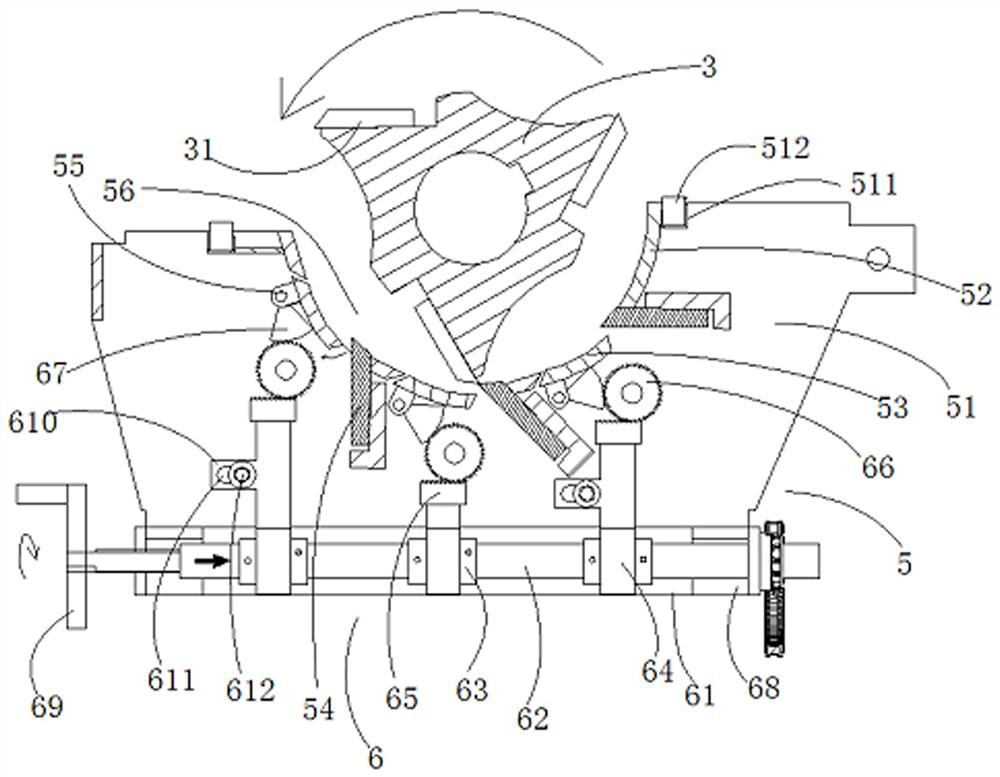

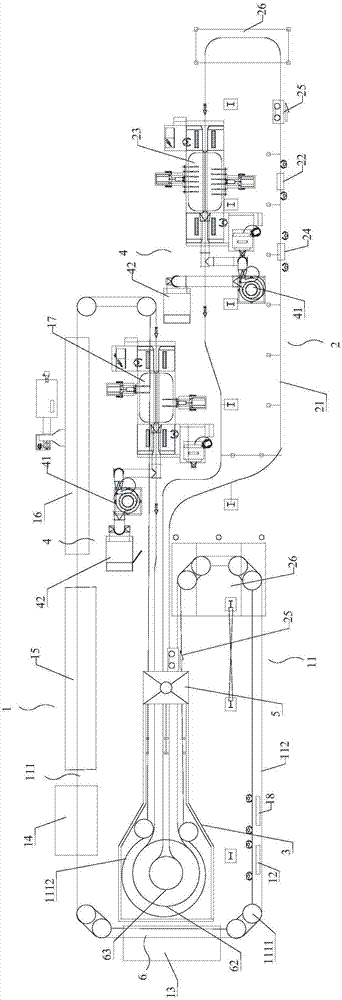

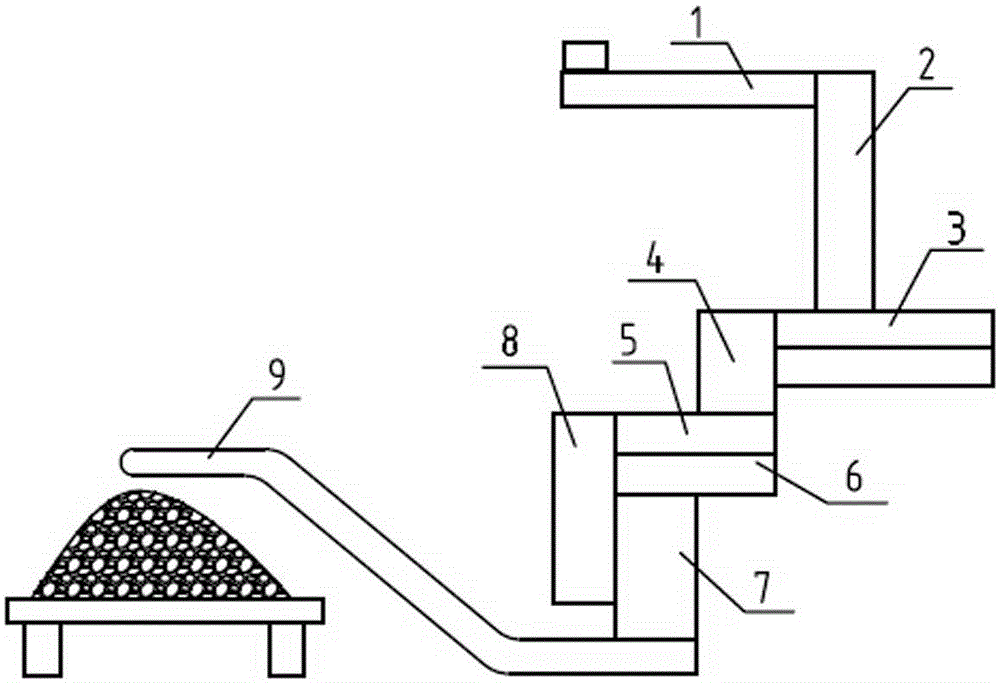

Automatic production and packaging production line for particulate biological organic fertilizer

PendingCN106431711AHigh ball rateGood particle shapeClimate change adaptationOrganic fertilisersEngineeringParticle coating

The invention discloses an automatic production and packaging production line for particulate biological organic fertilizer and relates to the technical field of kitchen waste recycling. The production line comprises a powder granulating region, a drying region, a cooling region, a particle screening region, a particle coating region, a particle packaging region, a particle remoulding region, a control system and environment-friendly equipment matched with each processing region, powdery organic fertilizer sequentially enters the powder granulating region, the drying region, the cooling region, the particle screening region, the particle coating region and the particle packaging region and then is made into a packaged particulate organic fertilizer finished product. The production line disclosed by the invention has the advantages that the whole production process structure is firm, service is reliable, automation of all the powder granulating region, the drying region, the cooling region, the particle screening region, the particle coating region, the particle packaging region and the particle remoulding region is realized, operation is simple, yield is high, labor cost of the whole technology is greatly saved.

Owner:河北绿碳生物科技有限公司

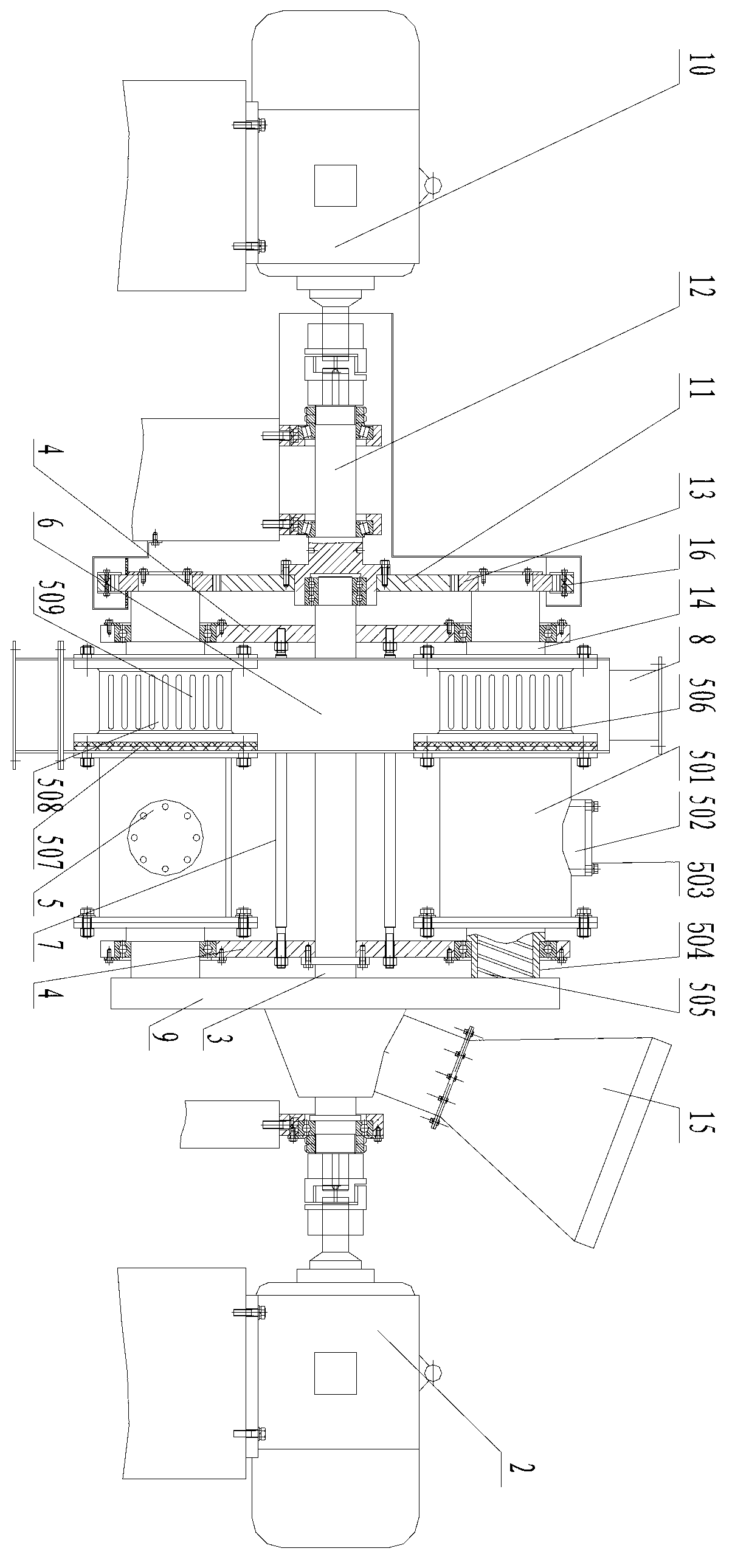

Pulverizer

The invention discloses a pulverizer which comprises a rack. The rack is movably provided with a spindle driven by a revolution power device; the spindle is sleeved with two revolution disks; a plurality of grinding devices are arranged between the two revolution disks and are peripherally and uniformly distributed; the spindle is sleeved with a material divider communicated with the feed ends of the grinding devices; the material divider is communicated with a feed hopper arranged on the rack; the rack is provided with a driving gear driven by a rotation power device; the discharge end of each grinding device is provided with a driven gear meshed with the driving gear; each grinding device comprises a grinding cylinder body; the side of each grinding cylinder body, which is close to the revolution power device, is provided with a feeding device; the end part of each feeding device is inserted in the corresponding revolution disk and is communicated with the material divider; the other side of each grinding cylinder body is provided with a discharge device; and the discharge devices on the grinding cylinder bodies on the spindle are sleeved with two discharge cover plates; and discharge bins are arranged outside the discharge cover plates on the rack. The invention provides the pulverizer with high working efficiency and low energy consumption.

Owner:JIANGSU PUGE MACHINERY

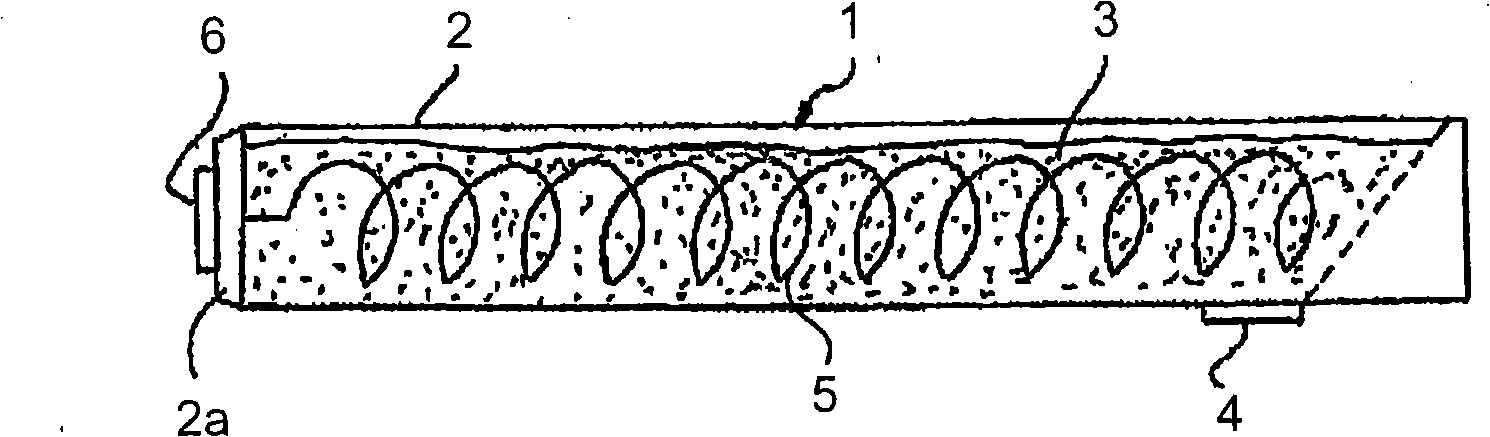

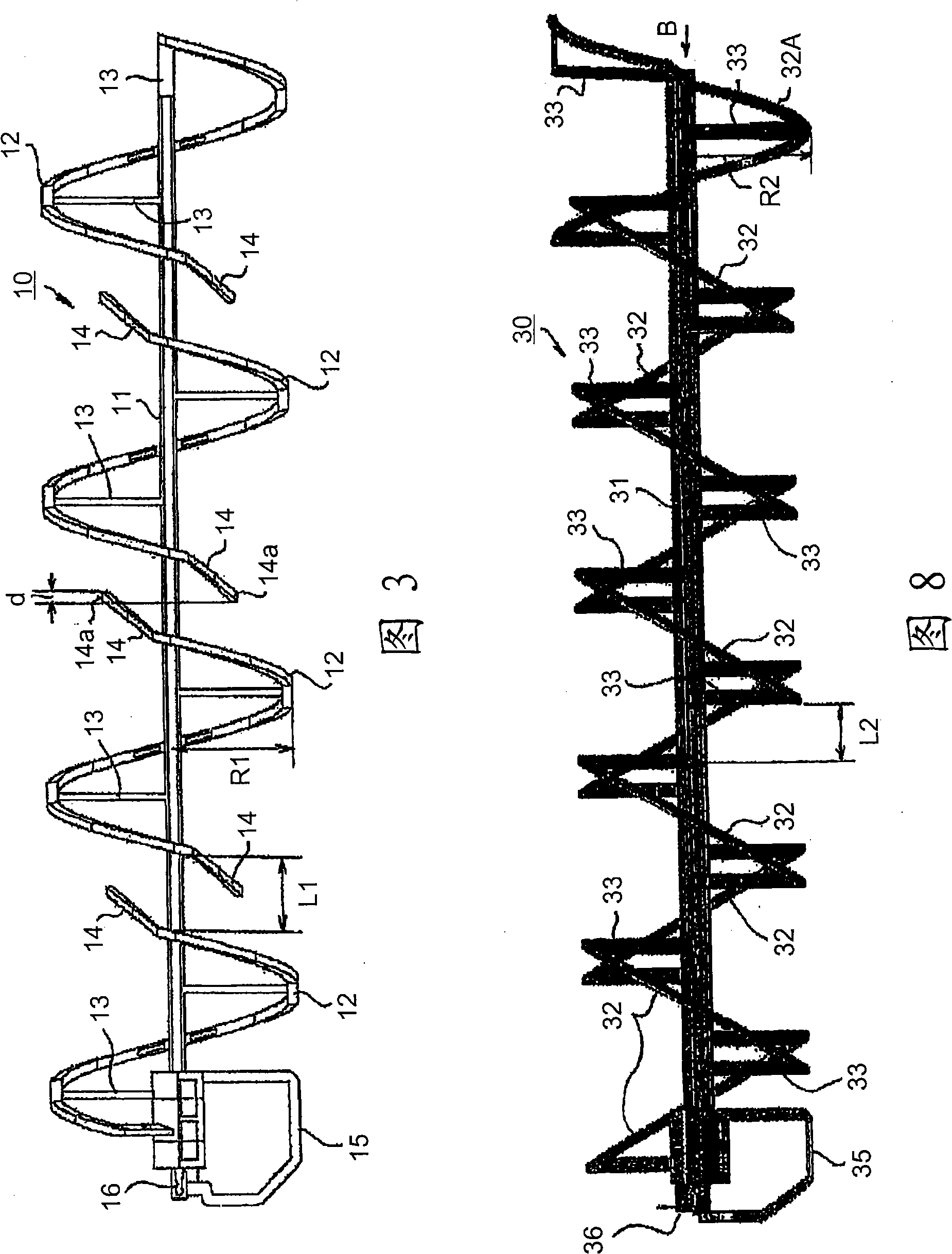

Rotator for powder conveyance and toner cartridge

ActiveCN101276184ASmooth transmissionReduce gapElectrographic process apparatusEngineeringSolid of revolution

A rotator for powder conveyance includes a substantially linear rotary supporting shaft and plural stirring / conveying pieces. The plural stirring / conveying pieces are separated from each other and arranged in a longitudinal direction along the rotary supporting shaft, are placed at positions separated from a central axis of the rotary supporting shaft in a radial direction of the rotary supporting shaft, have a spiral configuration along an outer peripheral surface of the rotary supporting shaft, and are respectively connected to the rotary supporting shaft via a connecting piece at plural points.

Owner:FUJIFILM BUSINESS INNOVATION CORP

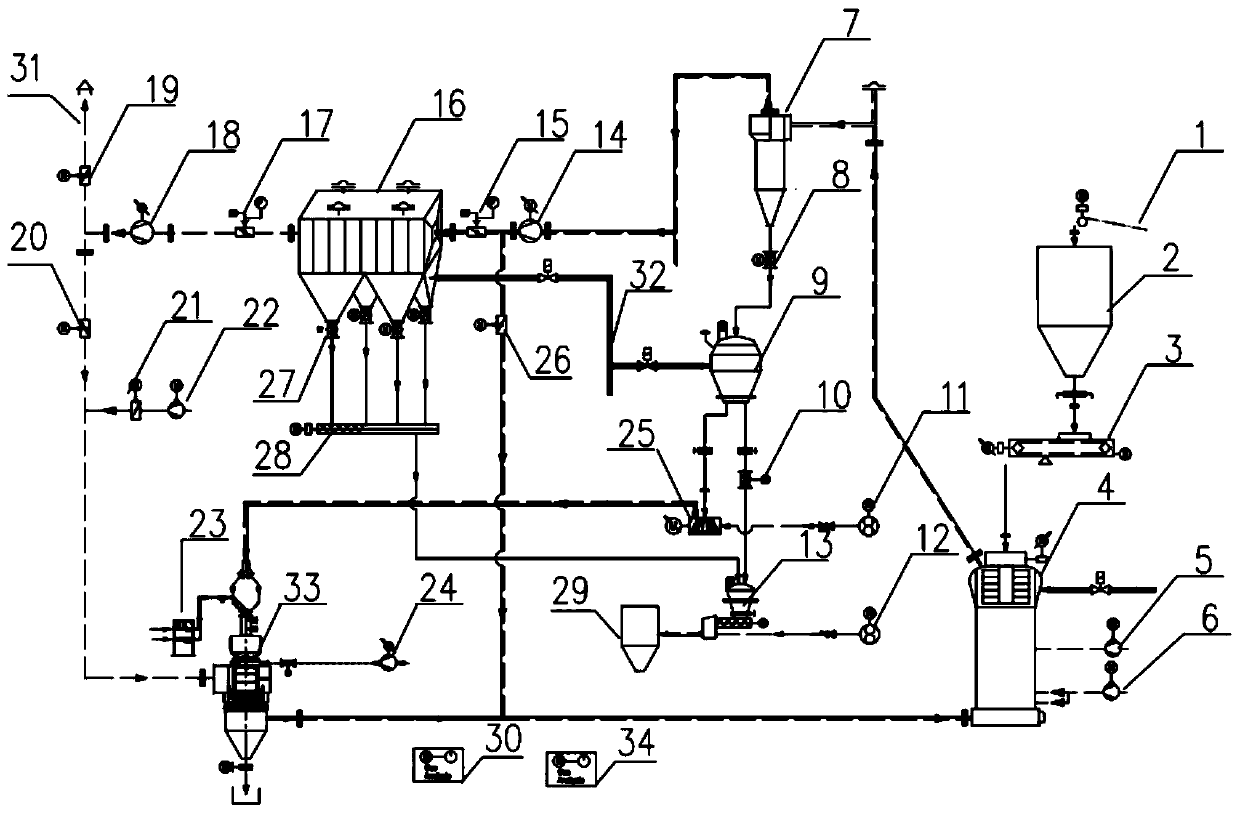

Coal grinding system and method for safely and efficiently preparing lignite

ActiveCN110404650AImprove collection effectReduce the amount of powderGrain treatmentsLump/pulverulent fuel preparationProcess engineeringMachining system

The invention discloses a coal grinding system and method for safely and efficiently preparing lignite. The coal grinding system comprises a raw coal feeding system, a hot blast stove system, a pneumatic conveying system, a finished product conveying system, a coal grinding machine system and a safety system, wherein the raw coal feeding system conveys the lignite to be ground to the coal grindingmachine system, and the pneumatic conveying system conveys qualified lignite powder to the finished product conveying system. Compared with the prior art, the coal grinding system and method for safely and efficiently preparing the lignite have the advantages that the preparation capability is high, the system drying capacity is large, the consumption of the hot blast stove is low, the safety guarantee is high, and the coal grinding system and method are suitable for preparing the coal powder of the lignite.

Owner:国能绿色能源股份有限公司

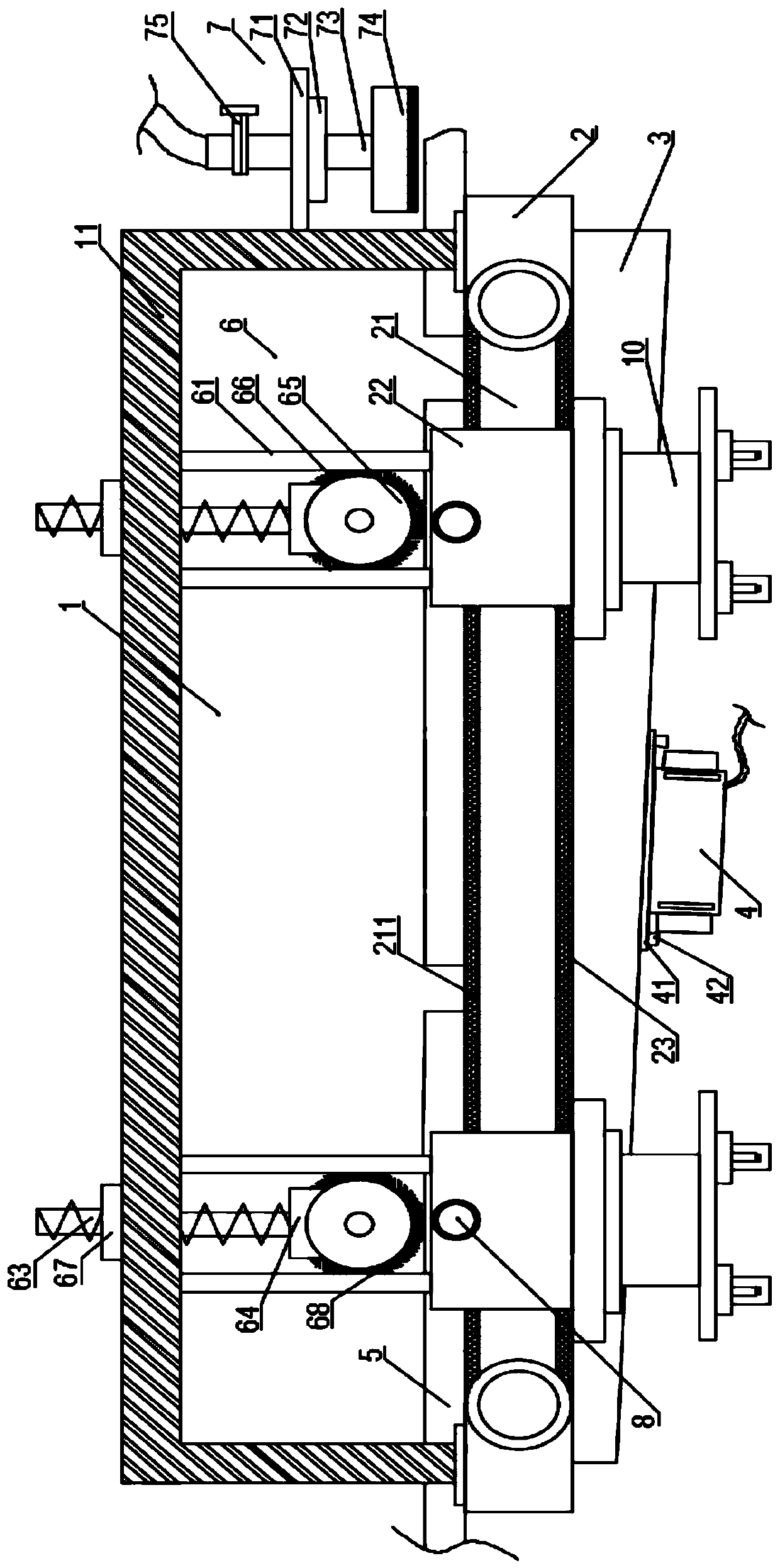

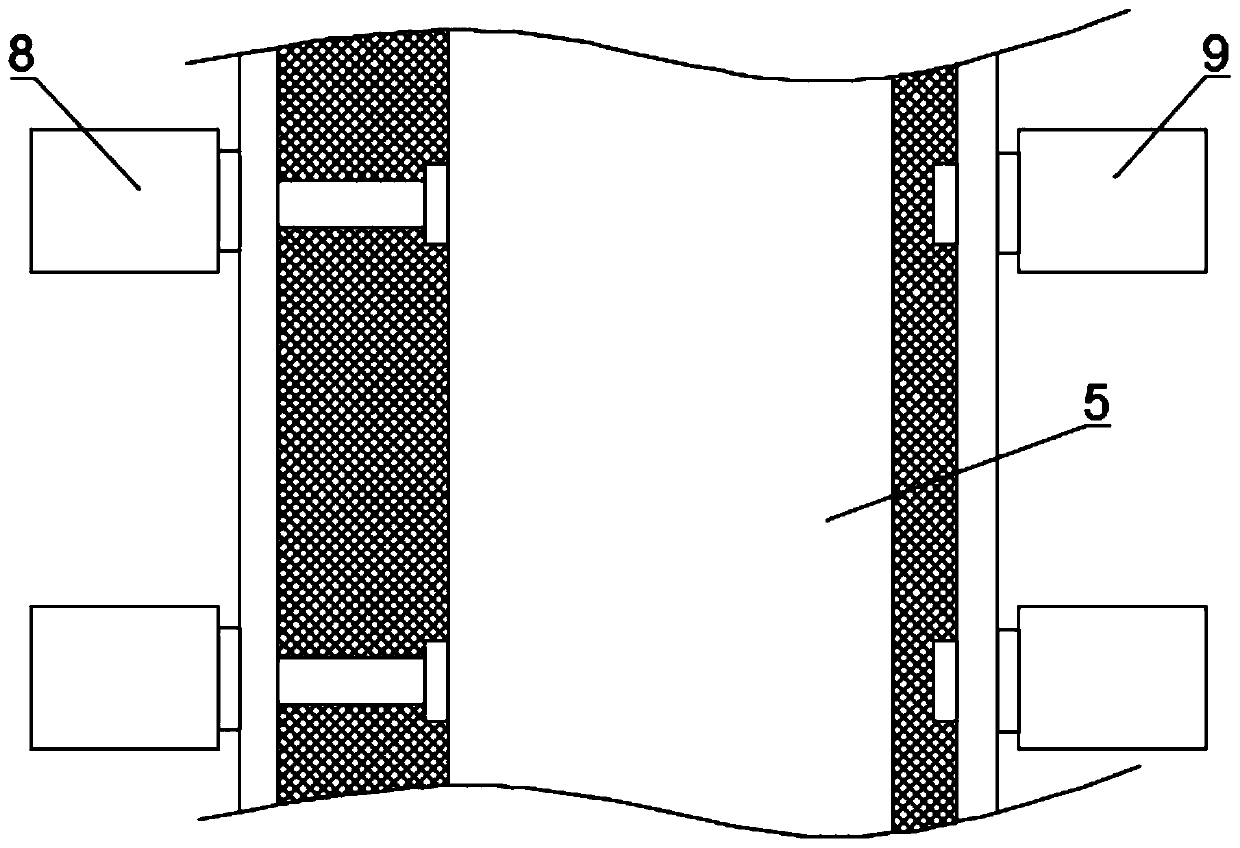

Feeding system for polyester slices

The invention relates to a feeding system for polyester slices, and relates to the technical field of fiber manufacturing equipment. The feeding system comprises a rack, wherein a discharge hopper, acharge box and a drying box are arranged on the rack; a charge hole is formed in the charge box; a feeding mechanism is arranged on the rack; the feeding mechanism comprises a connecting frame arranged on the rack, a conveying wheel arranged on the connecting frame, a conveyor belt which sleeves the conveying wheel, a plurality of containing hoppers which are arranged on the conveyor belt, a feeding motor arranged on the connecting frame, a cam arranged on the connecting frame, and a shaking motor arranged on the connecting frame; a chip outlet is formed in each containing hipper; and a chip guide plate is arranged on the surface of the conveyor belt among the containing hoppers. According to the feeding system disclosed by the invention, powder in the containing hoppers leaks and drops from the chip outlets through flap of the cam, and powder in slices is removed, so that powder entering the charge box is reduced, and therefore, generation amount of high-melting-point substances in follow-up drying is greatly reduced, uniformity of polyester melt and spinning quality are improved, and the service life of a spinning assembly is prolonged.

Owner:浙江恒冠化纤有限公司

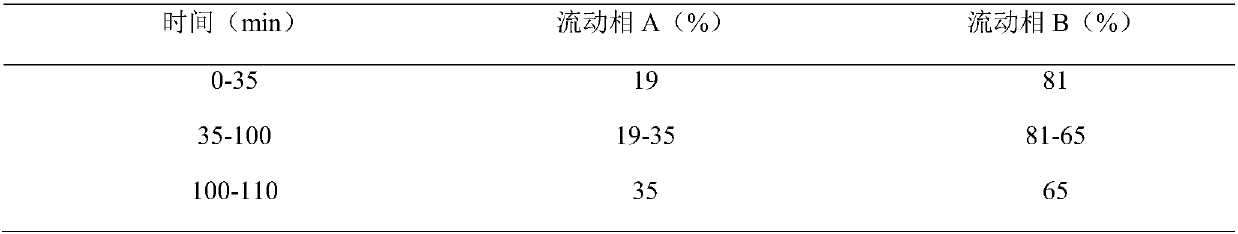

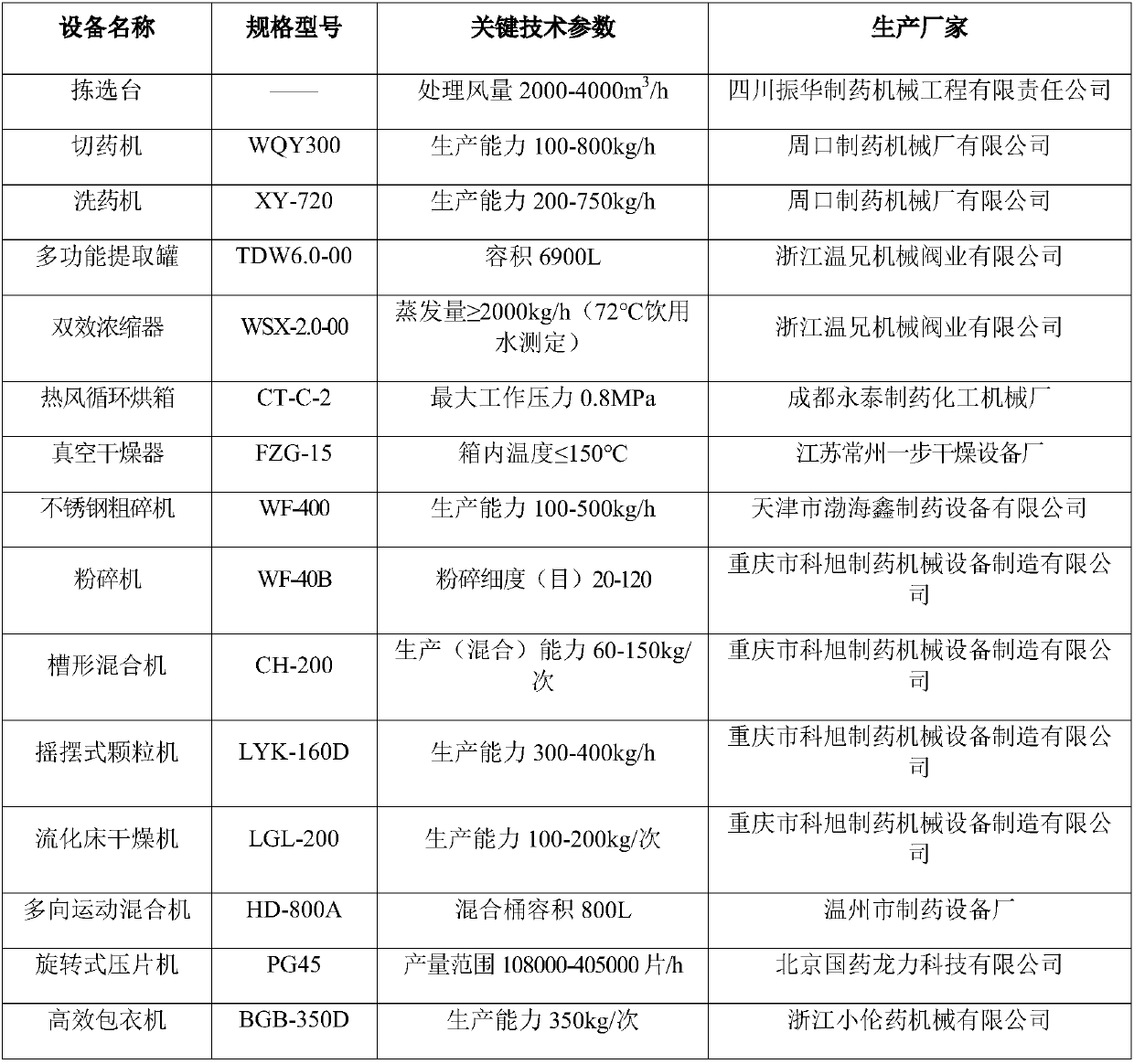

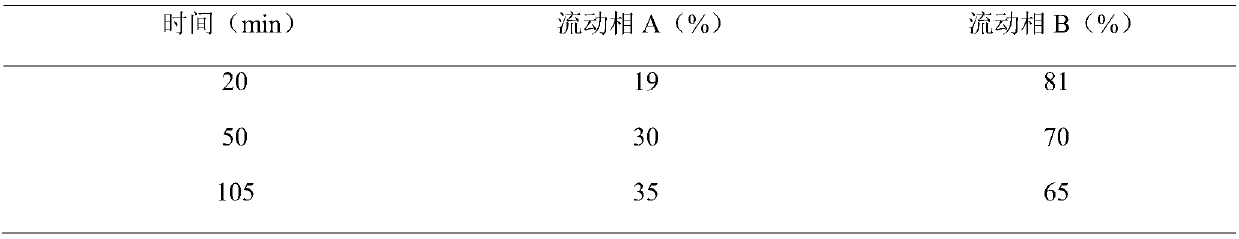

Process for preparing Hongjin stasis elimination tablet

ActiveCN109528901AReduce the risk of growthShorten the production cycleAnthropod material medical ingredientsComponent separationLow-substituted hydroxypropylcelluloseMagnesium stearate

The invention provides a process for preparing Hongjin stasis elimination tablets and belongs to the technical field of pharmacy. To solve various problems in concentration modes in the prior art, drying modes of concentrated ointments, auxiliary materials and identification, a preparation process of the Hongjin stasis elimination tablets is further improved, including steps of directly concentrating extracts, independently drying ointments, increasing amounts of auxiliary materials such as low-substituted hydroxypropylcellulose, povidone K30 and magnesium stearate, and changing medicine identification items and content testing items, and furthermore the purposes of shortening production cycle, reducing energy consumption, reducing pollution risks and improving product quality are achieved.

Owner:四川维奥制药有限公司

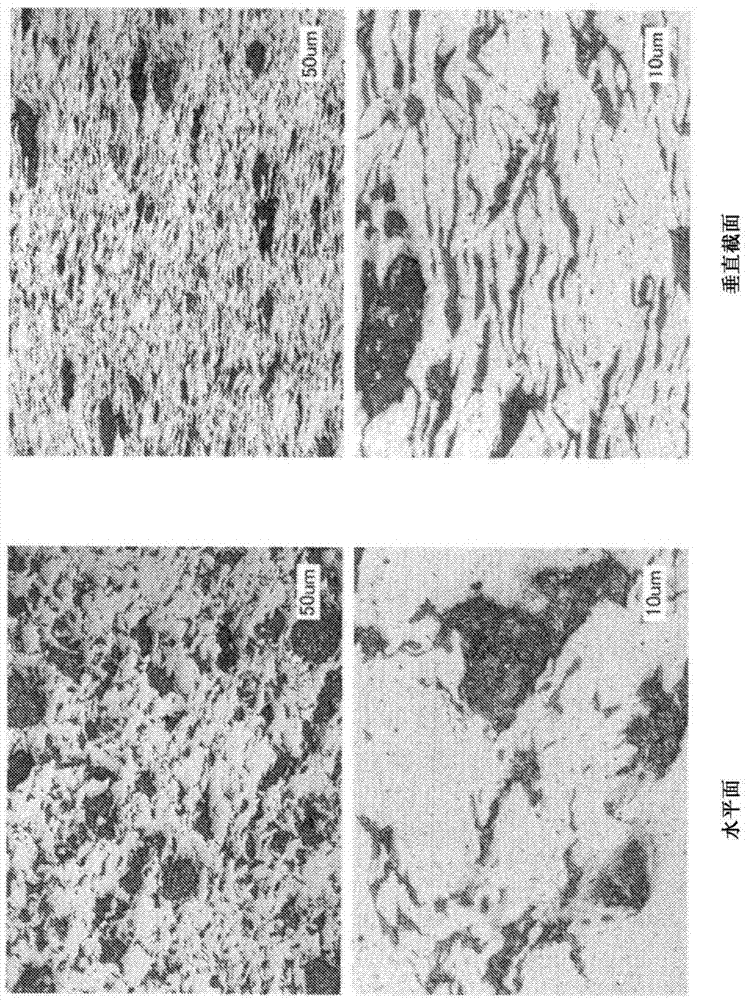

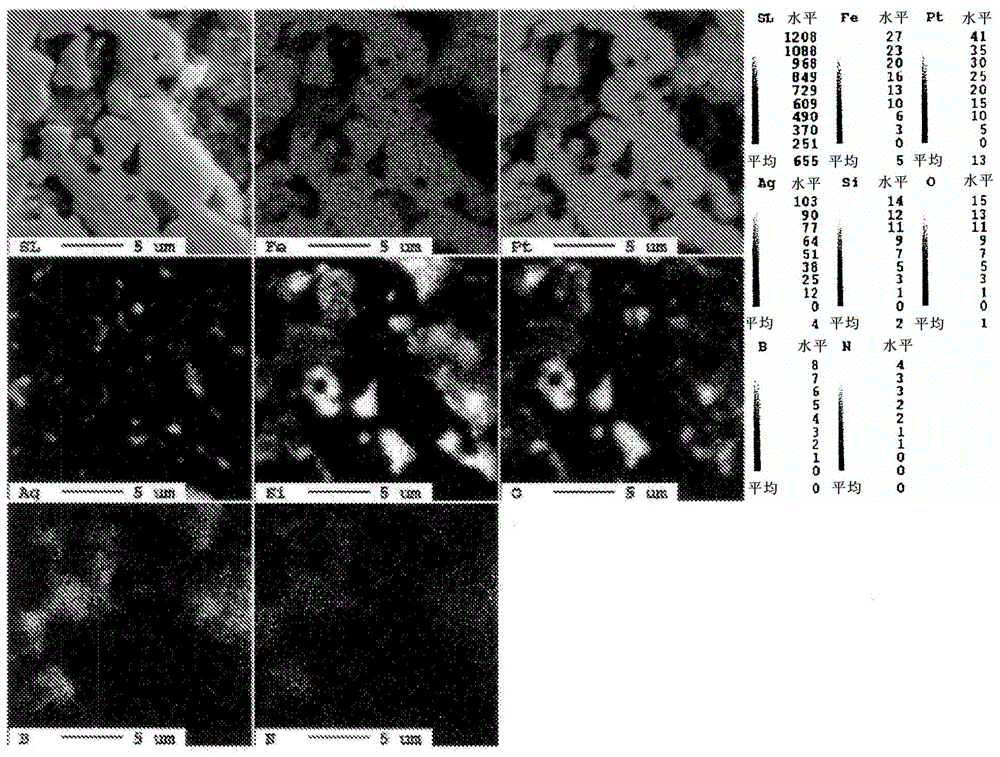

Sintered Fe-Pt-based magnetic material

ActiveCN104662606AReduce generationReduce the amount of powderPolycrystalline material growthVacuum evaporation coatingSputteringHigh density

A sintered Fe-Pt-based magnetic material which contains BN and SiO2 as non-magnetic materials, said sintered Fe-Pt-based magnetic material being characterized in that Si and O exist in a B- or N-existing region on a cross section of the sintered material. The present invention addresses the problem of making it possible to produce a magnetic thin film in a thermally-assisted magnetic recording medium and the problem of providing a high-density sputtering target in which the amount of particles formed upon sputtering is reduced.

Owner:JX NIPPON MINING & METALS CORP

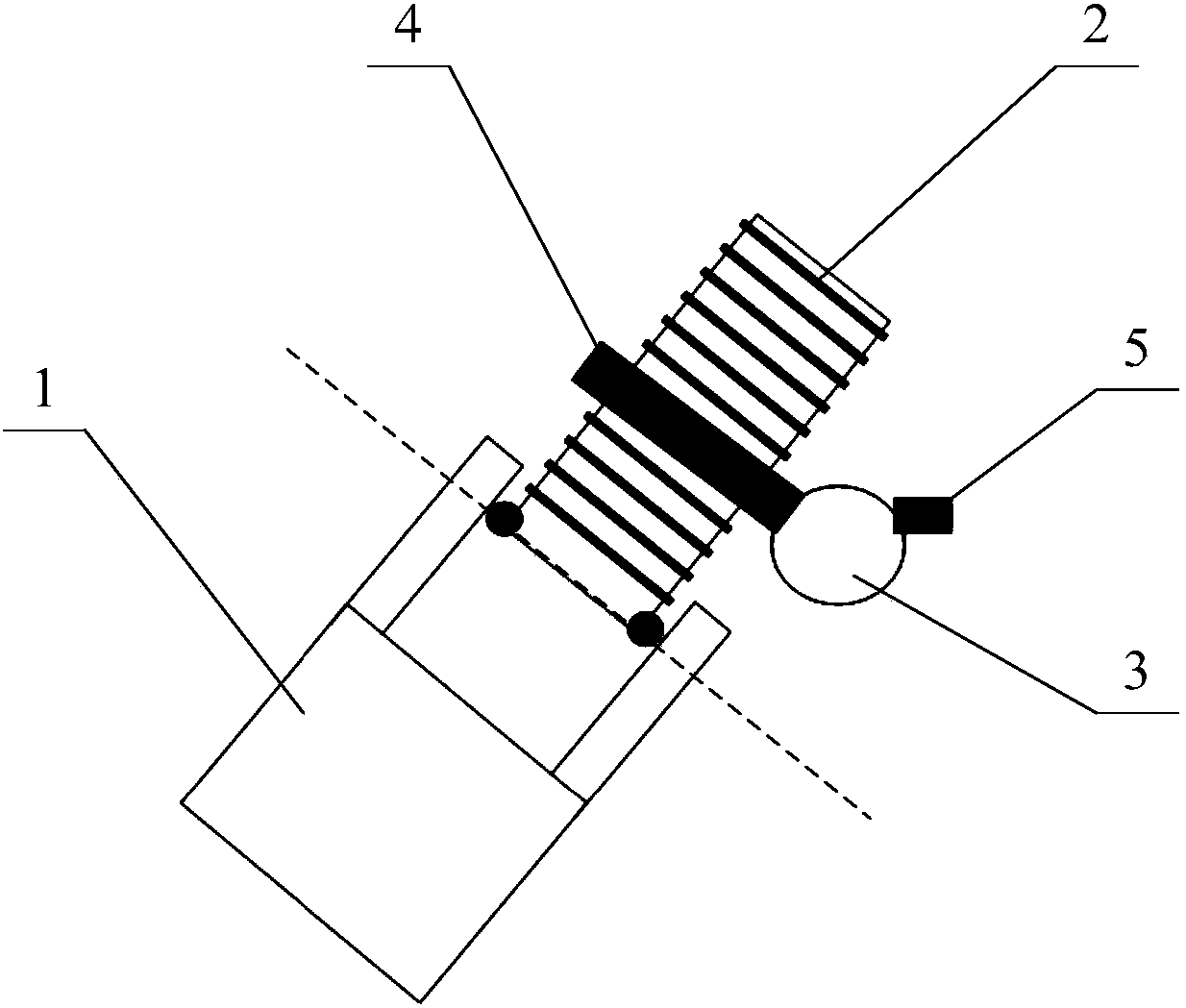

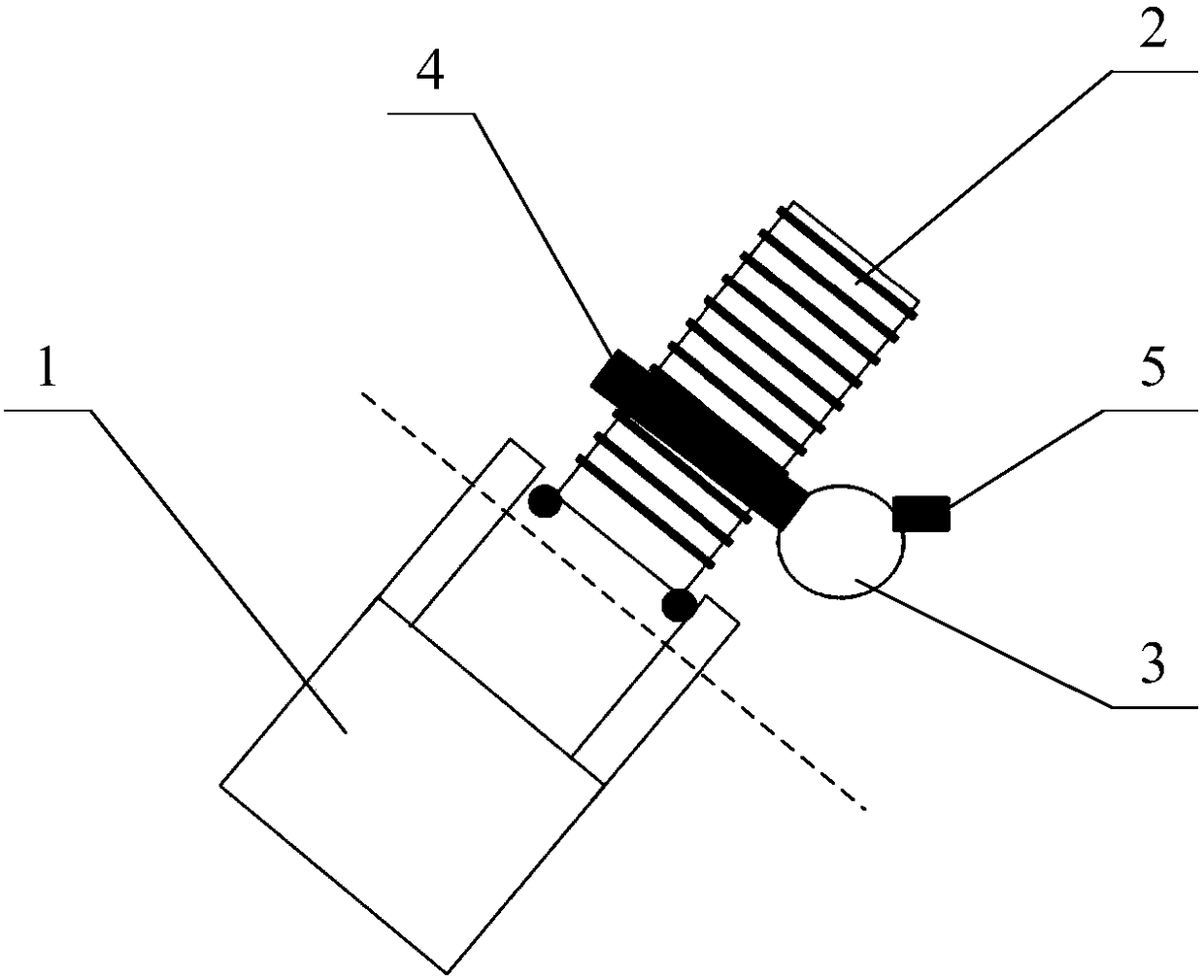

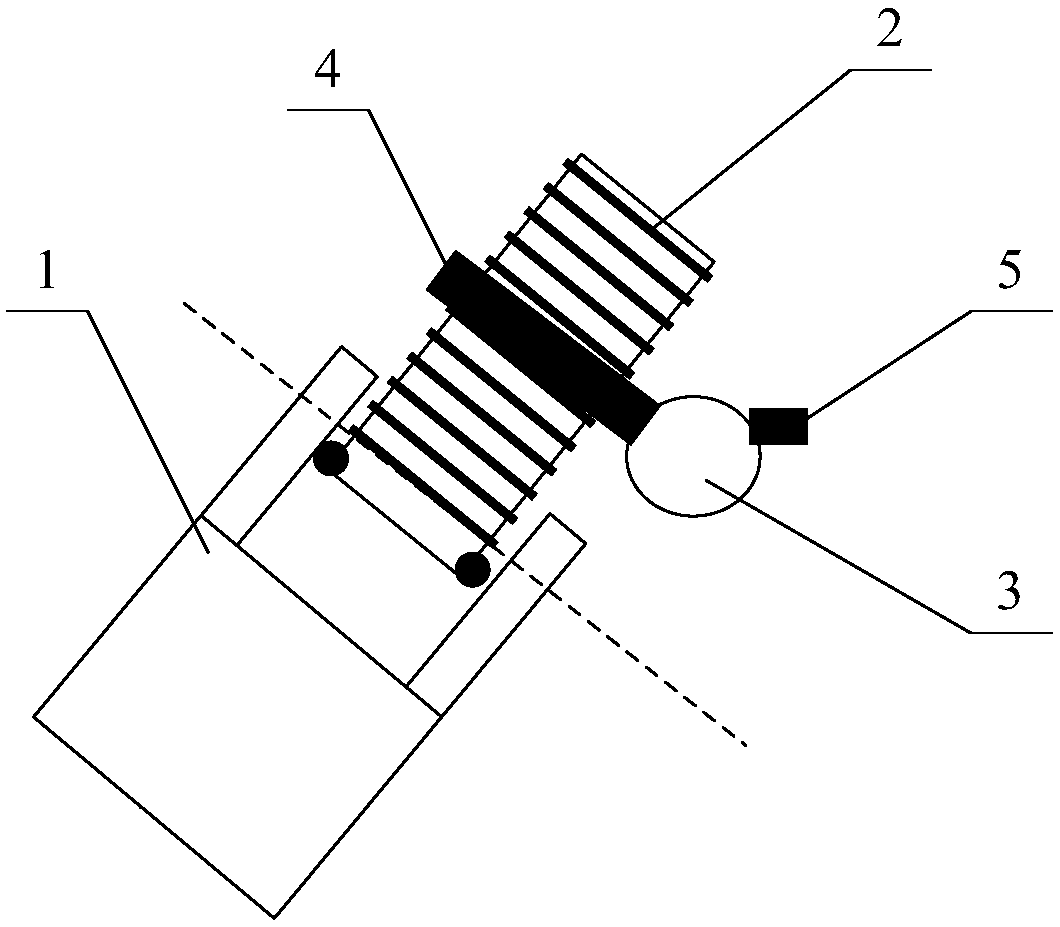

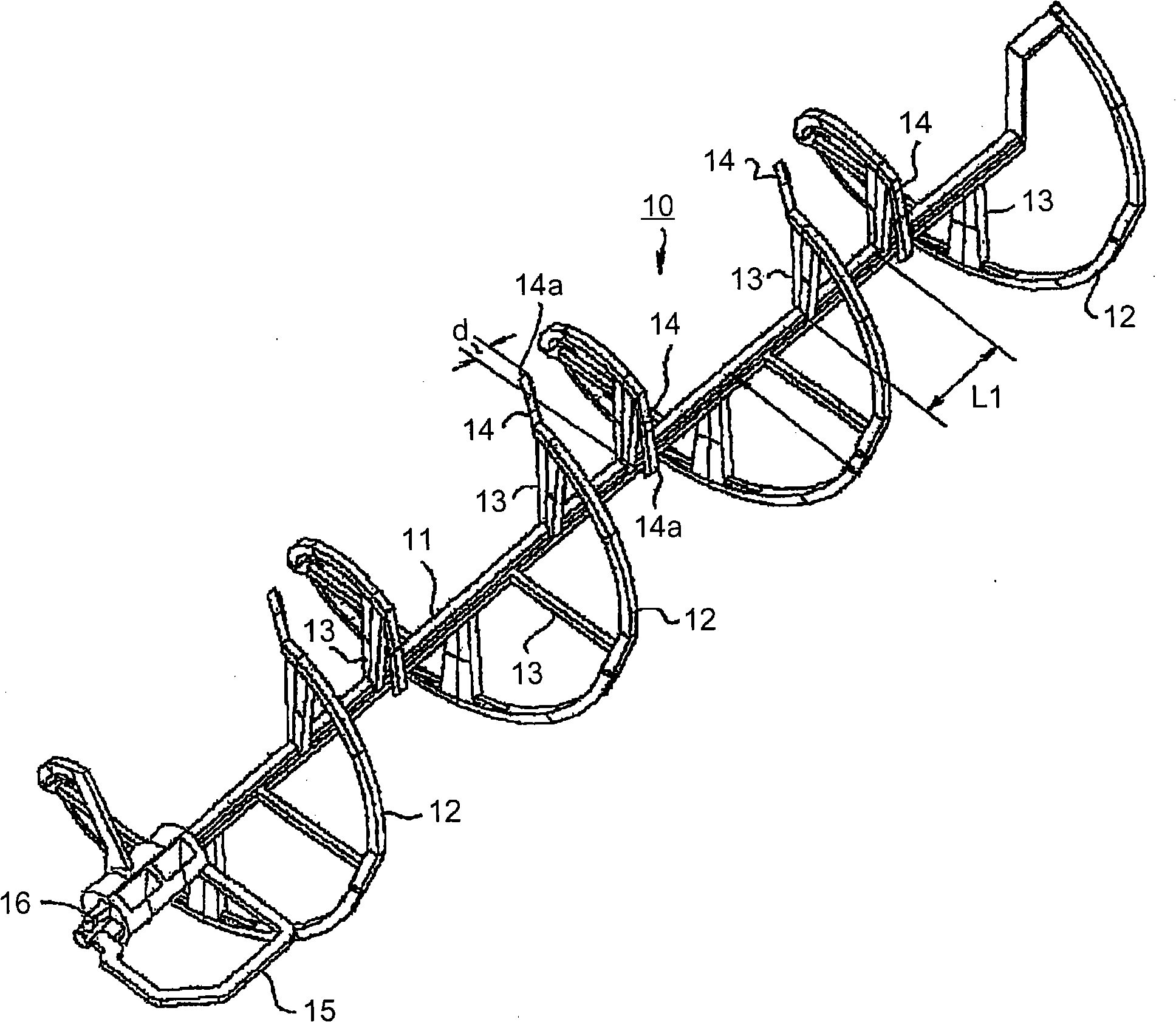

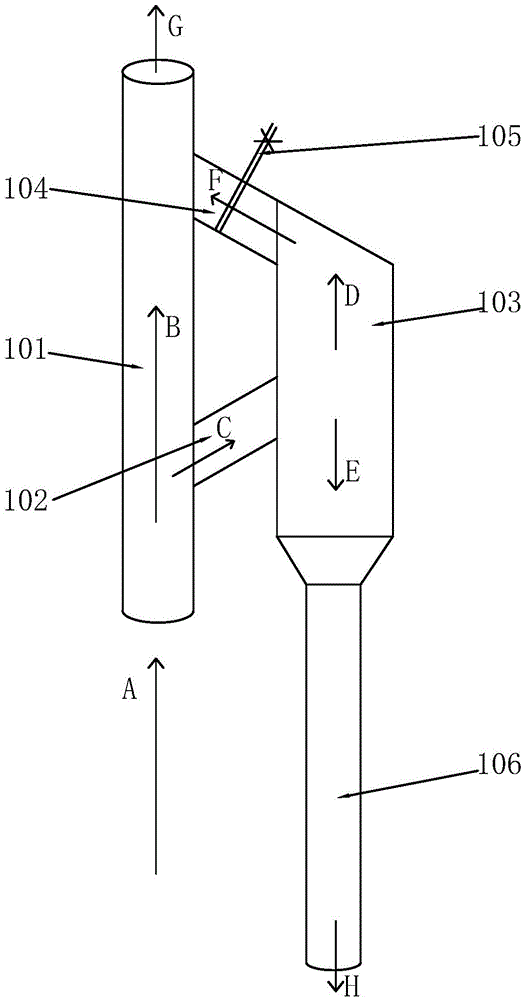

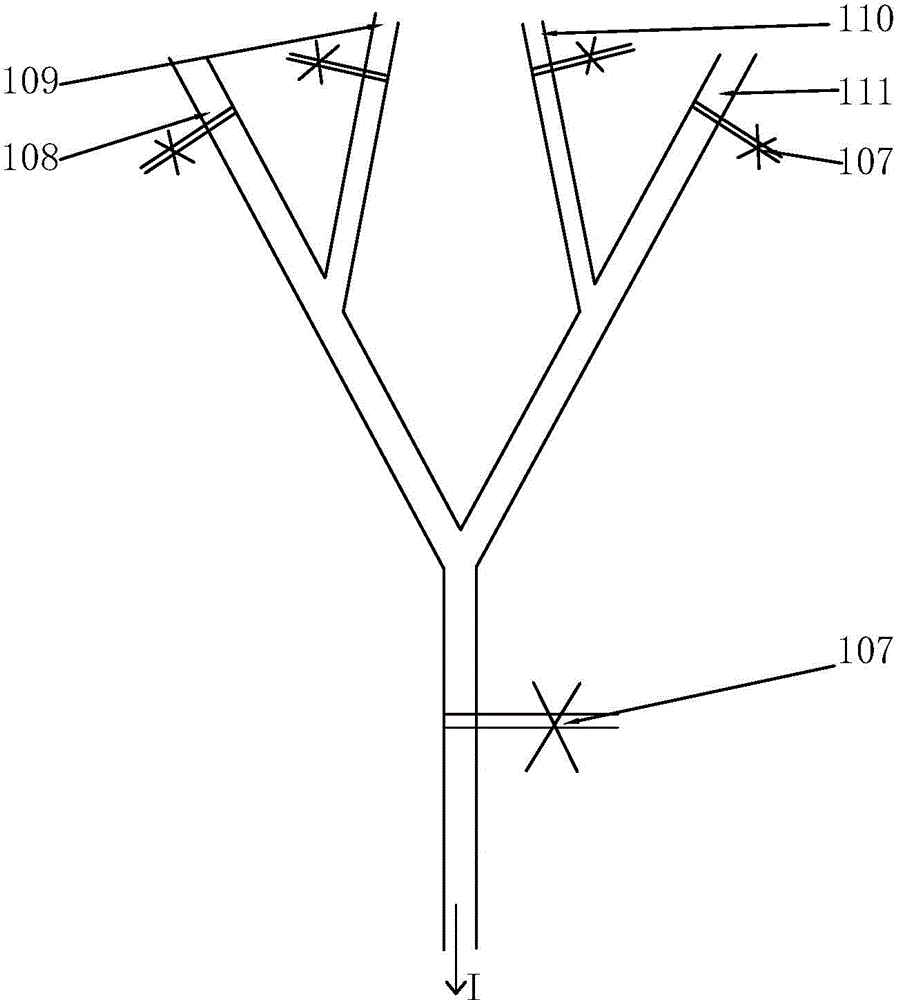

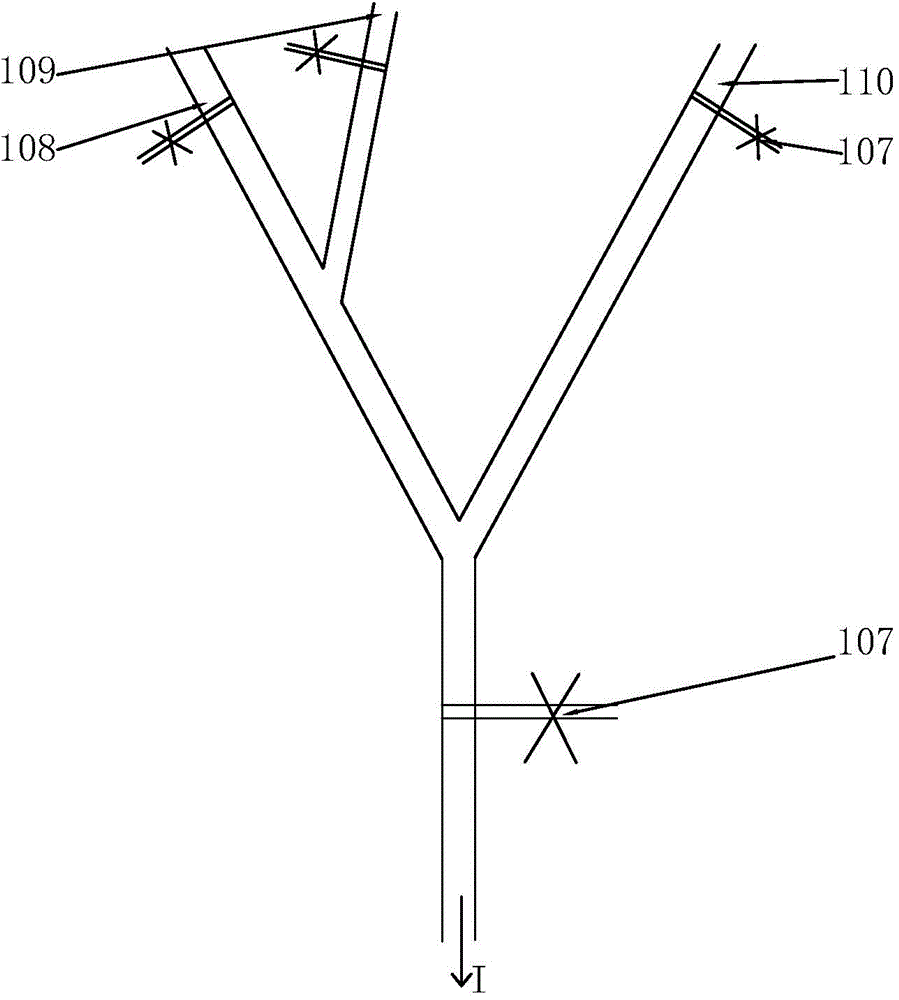

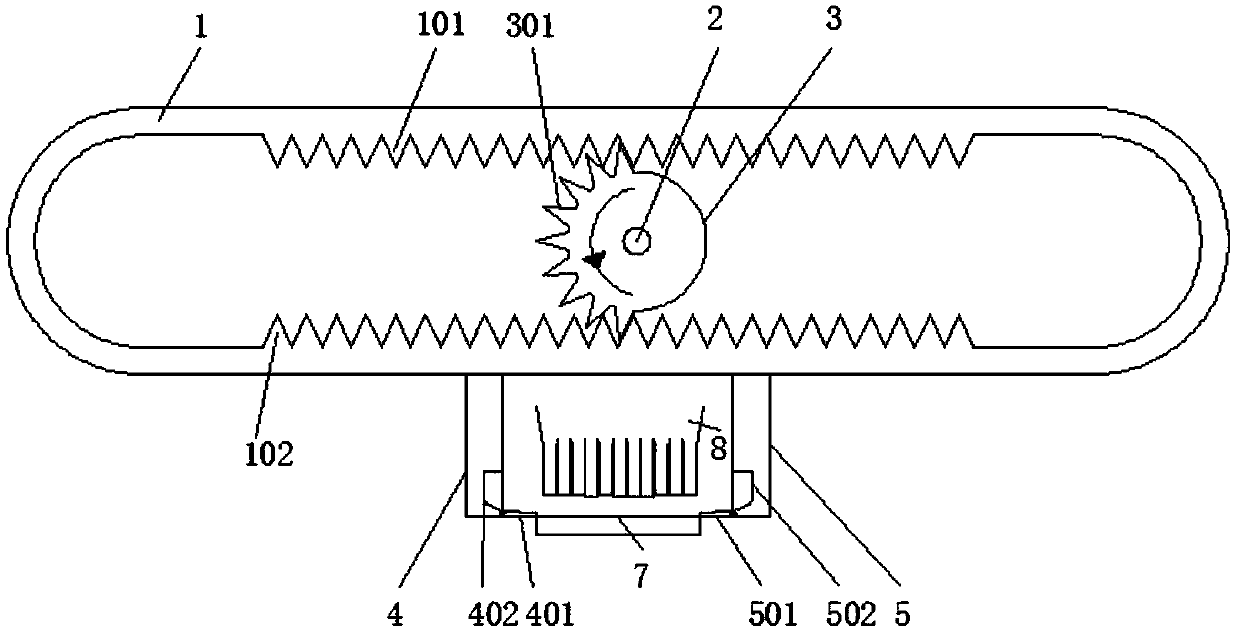

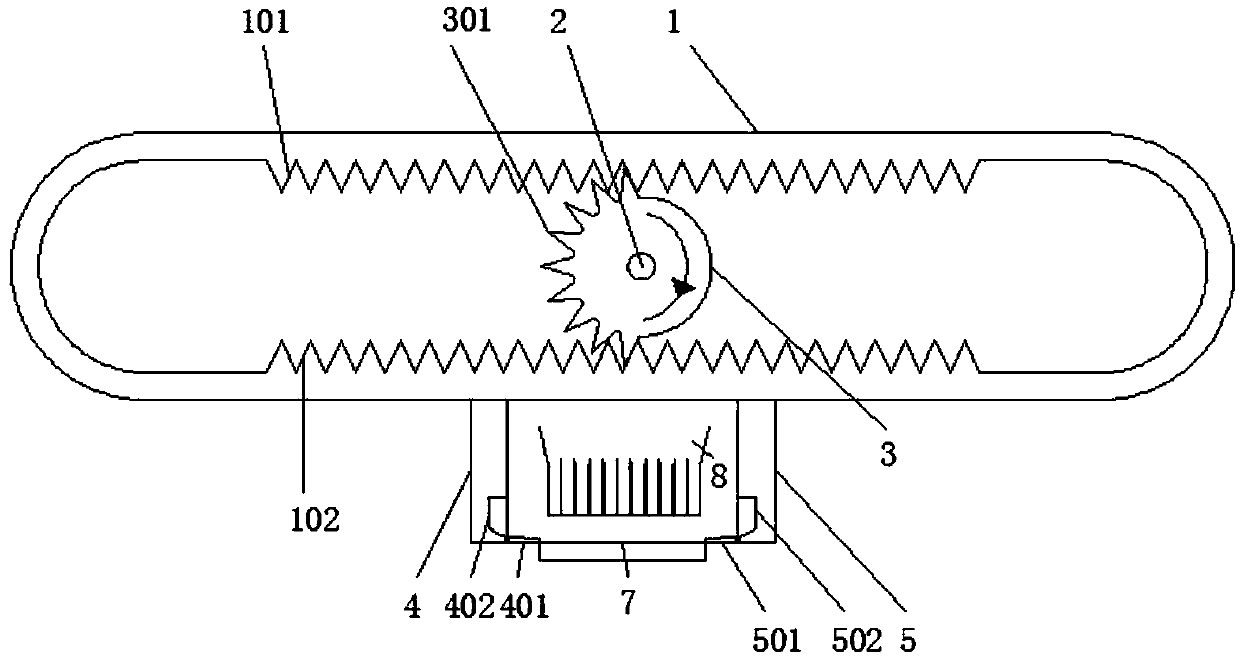

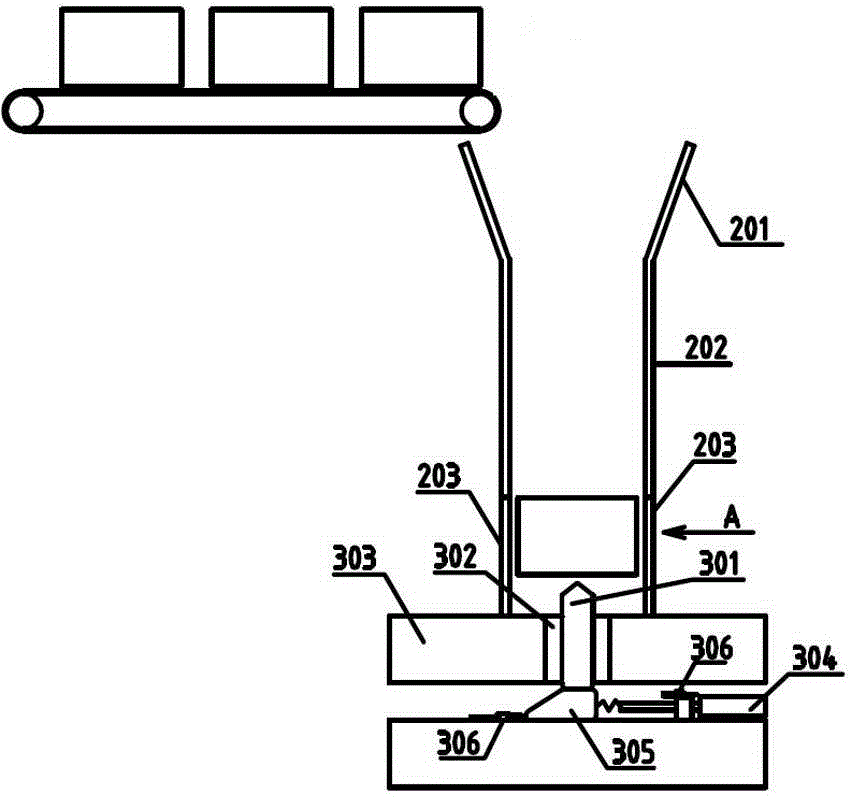

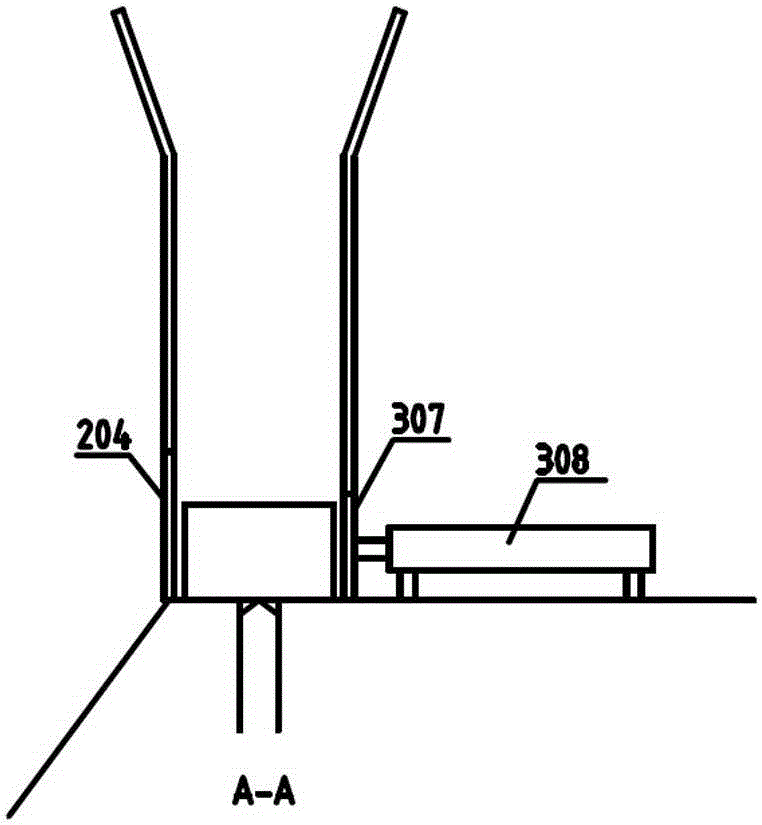

Device and method for adjusting powder quantity deviation of powder pipes of direct blowing type pulverizing system

ActiveCN104896496ASimple structureEasy to operateLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationMetallurgyCoal dust

The invention discloses a device for adjusting the powder quantity deviation of powder pipes of a direct blowing type pulverizing system. The device comprises a main powder pipe, an air and powder separating barrel is arranged on one side of the main powder pipe, the main powder pipe is connected with the upper end of the air and powder separating barrel through a second branch pipe, the main powder pipe is connected with the lower portion of the air and powder separating barrel through a first branch pipe, the lower end of the air and powder separating barrel is connected with a coal dust descending pipe, and a bypass regulation door is arranged on the second branch pipe; meanwhile, a method for adjusting the powder quantity deviation of the powder pipes of the direct blowing type pulverizing system is disclosed. Leveling of the powder quantity of the powder pipes and leveling of heat-state primary air adjustment of a boiler can be achieved at the same time, simultaneous leveling of primary air and powder of one grinding device can be achieved, and the commonly-occurring heat deviations caused by the unbalanced powder quantity of the powder pipes of the same grinding device at present are eliminated.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

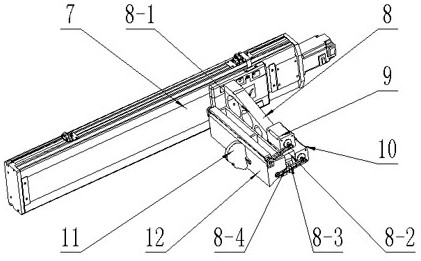

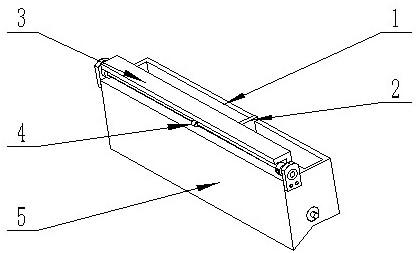

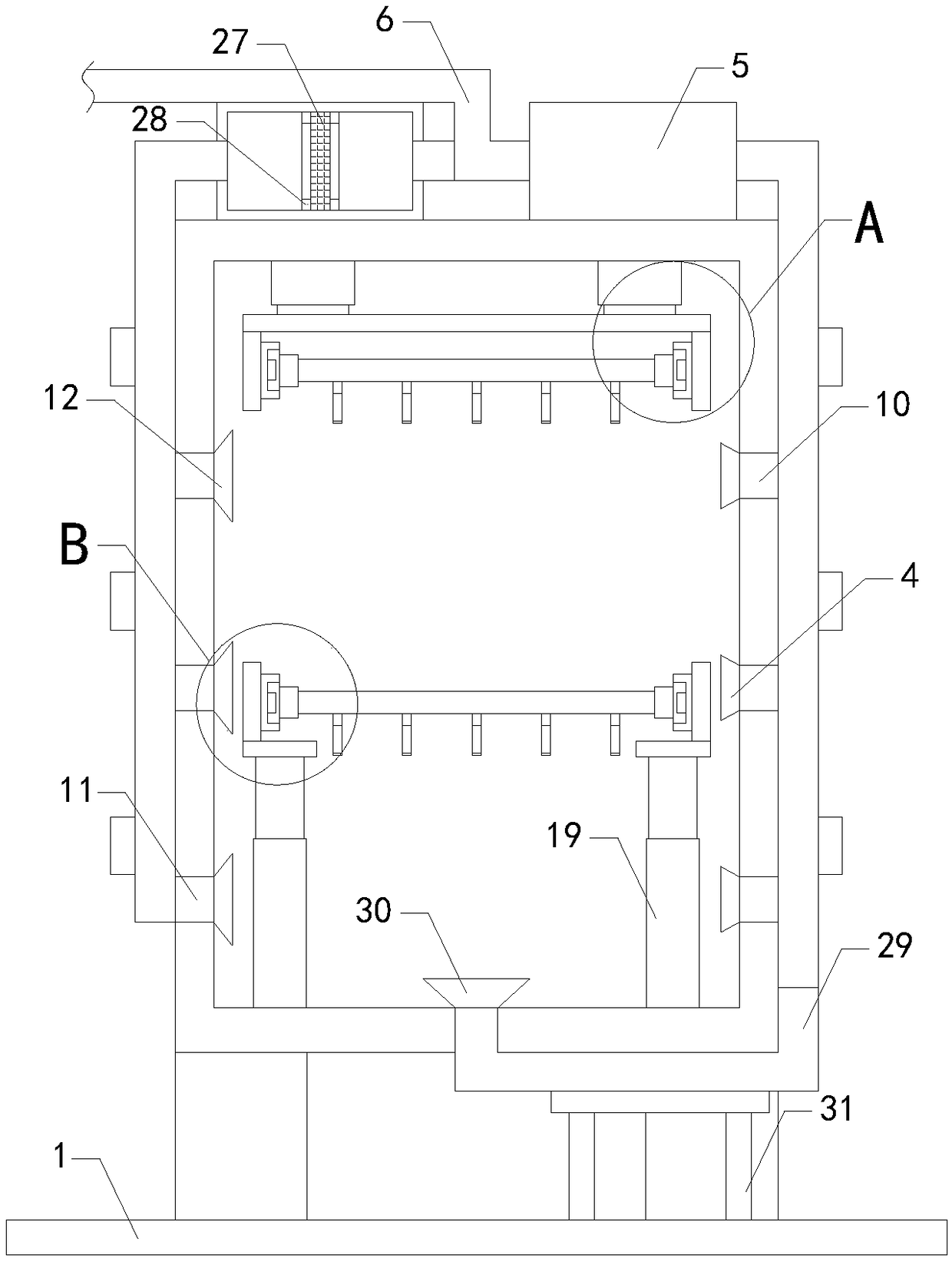

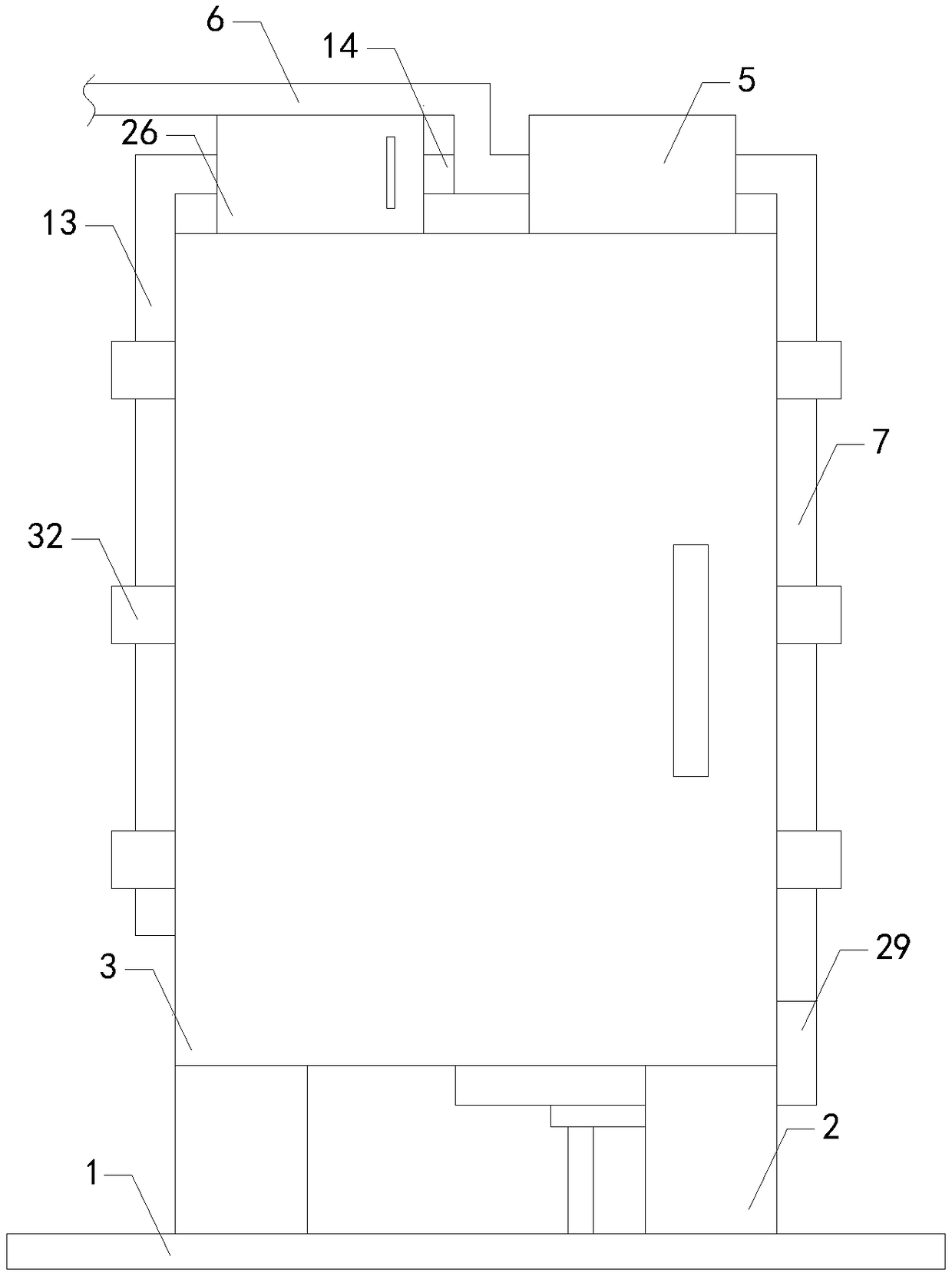

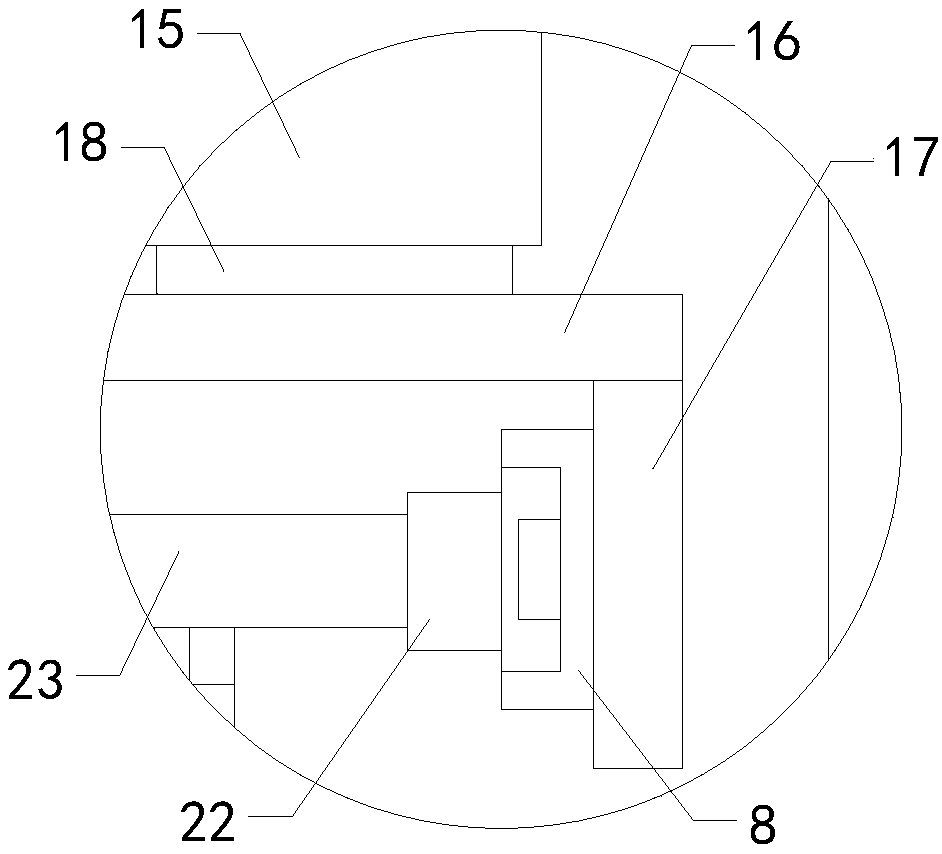

Powder spreading device for 3D printer

ActiveCN113118471AReduce pollutionReduce recycling workloadAdditive manufacturing apparatusLinear motionComputer printing

The invention discloses a powder spreading device for a 3D printer. The method comprises the steps that a powder falling module is mounted on one side of a linear motion module and comprises a powder spreading bin, a powder spreading roller, a switch control panel, a cam control shaft and an isolation baffle; a vertical plate is arranged in the powder spreading bin, and the lower end of the vertical plate is separated from a bottom plate of the powder spreading bin; the powder spreading roller is arranged between the lower end of the vertical plate and the bottom plate of the powder spreading bin and divides the powder spreading bin into a powder storage bin and a powder falling bin together with the vertical plate, the two ends of the powder spreading roller are movably mounted in the powder spreading bin, and powder can be conveyed from the powder storage bin to the powder falling bin through rotation of the powder spreading roller; the switch control panel is movably mounted in the powder falling bin and is provided with a boss; a cam is arranged on the cam control shaft and is tangent to the boss, and the two ends of the cam control shaft are movably mounted in the powder falling bin; the isolation baffle is arranged in the powder storage bin and divides the powder storage bin into an empty bin and a powder adding bin. Reasonable powder feeding can be carried out according to the number of parts, the powder cleaning workload is reduced, the iteration speed of product research and development is increased, and the research and development efficiency is improved.

Owner:ZHONGBEI UNIV

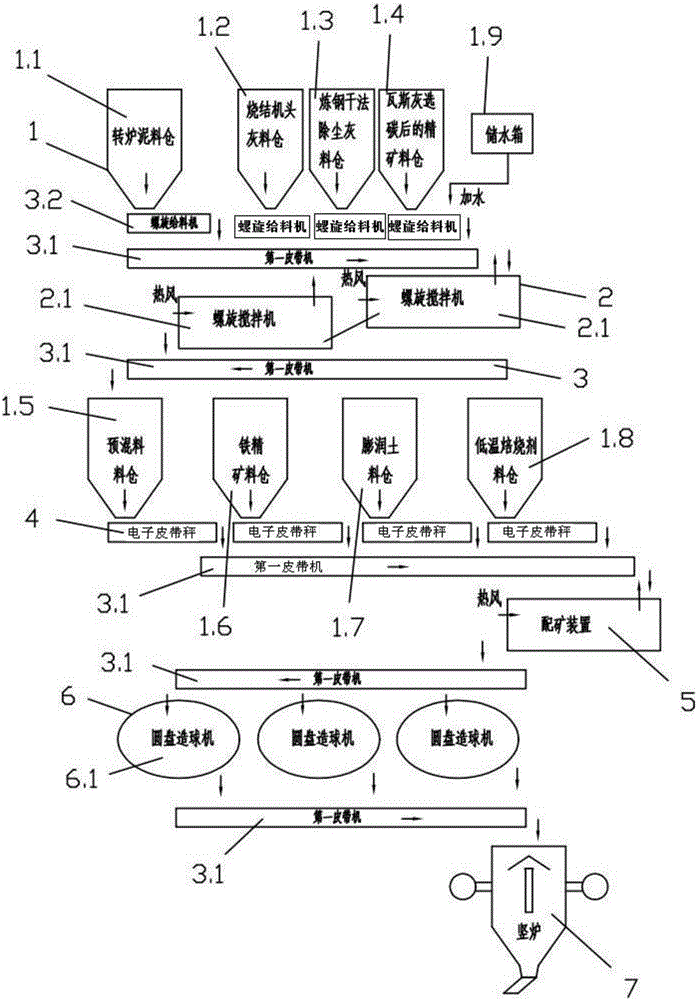

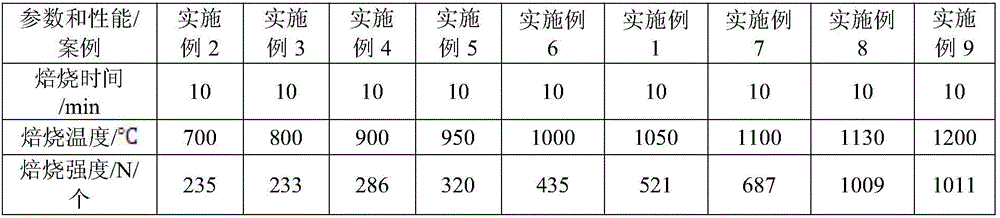

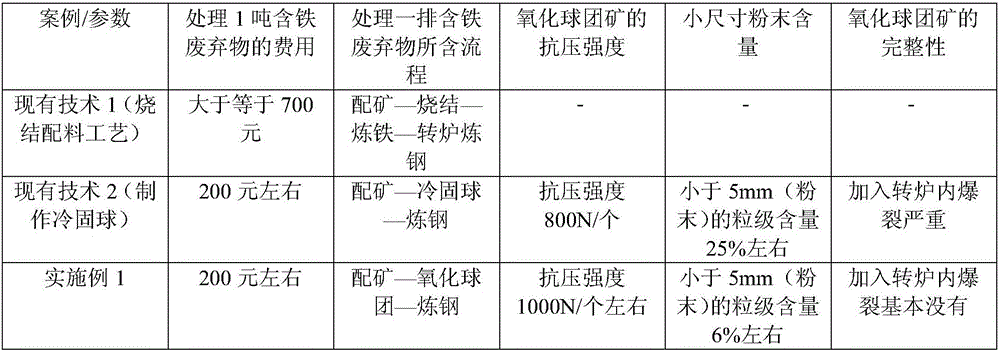

Iron-contained waste treatment method and equipment adopting same

InactiveCN106435164AImprove performanceLow melting pointManufacturing convertersShaft furnaceWaste treatment

The invention provides an iron-contained waste treatment method. The iron-contained waste treatment method comprises the steps of: (1) raw material premixing; (2) raw material ore blending; (3) pelletizing; and (4) shaft furnace treatment; and the specific treatment process is as follows: green balls obtained in the step (3) are dried, preheated and roasted in a shaft furnace in sequence to obtain oxidized pellets as a steel production converter cooling agent, wherein the drying temperature is 400-500 DEG C, the drying time is 3-8 minutes, the preheating temperature is 800-950 DEG C, the preheating time is 10-15 min; the roasting temperature is 1050-1130 DEG C; and the roasting time is 10-15 min. The treatment method is simple in steps, easy to control process parameters and low in cost. The invention further discloses equipment adopting the treatment method; and the equipment includes a storage device, a raw material premixing device, a conveying device, an electronic belt scale, an ore blending device, a pelletizing device and the shaft furnace. The equipment is convenient for assembly, process parameter control in the treatment process and operation.

Owner:RUITONG PELLETIZING CO LTD OF XIANGTAN

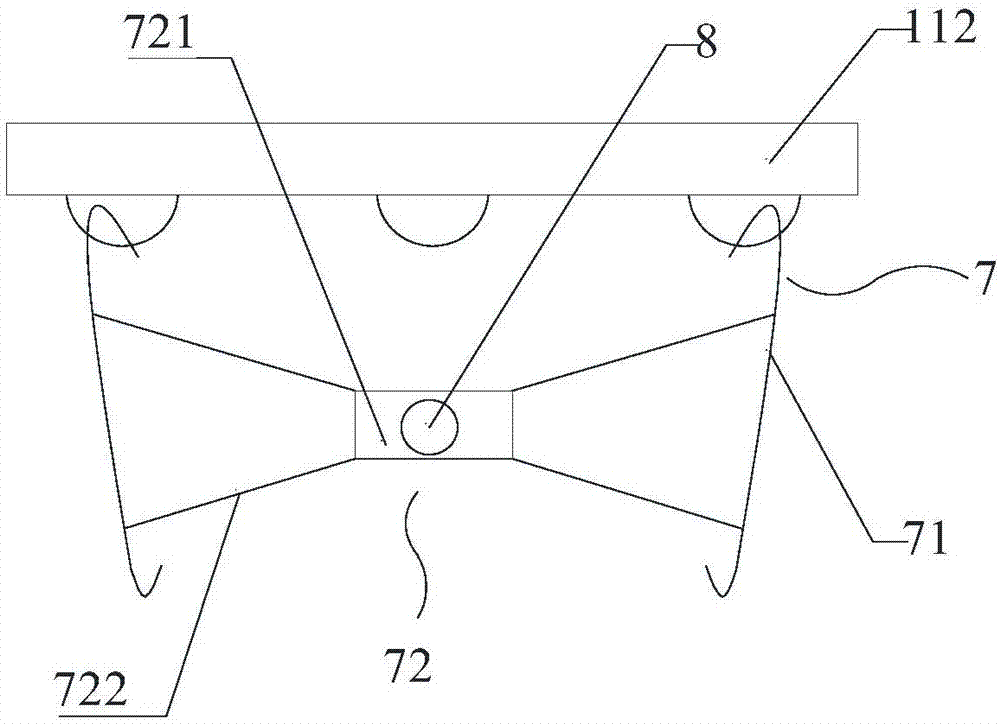

Stirring mechanism, stirring device, mixing and deodorizing system and using method

The invention provides a stirring mechanism, a stirring device, a mixing and deodorizing system and a using method, which are used for solving the problem that mixing materials are easily crushed by the stirring device in the prior art. In order to achieve the above object and other related objects, the invention provides a stirring mechanism. The stirring mechanism comprises a rotating shaft anda stirring piece; the stirring piece is fixed to the rotating shaft; a plurality of rolling pieces are arranged at the radial end of the stirring piece; and the rolling pieces partially protrude fromthe maximum rotating outer diameter of the stirring piece. The integrity of the mixing materials is ensured.

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

Crusher capable of conveniently controlling crushed particles of traditional Chinese medicinal materials and crushing method of crusher

ActiveCN112844698AReduce the amount of powderImprove cutting effectPlastic recyclingGrain treatmentsMedicinal herbsStructural engineering

The invention discloses a crusher capable of conveniently controlling crushed particles of traditional Chinese medicinal materials and a crushing method of the crusher. The crusher comprises a rack, a crushing bin mounted on the rack, a first crushing cutting mechanism mounted in the crushing bin and a motor mounted on the rack and used for driving the first crushing cutting mechanism to work; and the crusher is characterized in that one end of the crushing bin is provided with a second crushing cutting mechanism cooperating with the first crushing cutting mechanism and capable of adjusting the crushing cutting thickness of the medicinal materials, and an adjusting structure used for adjusting the second crushing cutting mechanism. Through arrangement and cooperative use of the second crushing cutting mechanism and the adjusting mechanism on the second crushing cutting mechanism, a plurality of adjusting plates can be synchronously adjusted to rotate through the adjusting mechanism, so that gaps between the adjusting plates and fixed cutters are adjusted, the crushing cutting size of the medicinal materials can be adjusted by adjusting the sizes of the gaps, the medicinal materials can directly fall out from the gaps after being crushed and cut once instead of remaining in a crushing cutting cavity and rotate along with a roller at a high speed, therefore, the amount of medicinal material powder is reduced, and the crushing cutting effect of the medicinal materials is improved.

Owner:HANGZHOU FUYANG KANGHUA PHARMA MACHINERY CO LTD

Powder removal brushing part for artware processing course

InactiveCN111530798AHigh precisionReduce the amount of powderDirt cleaningCleaning using toolsEngineeringStructural engineering

The invention discloses a powder removal brushing part for an artware processing course and relates to the field of artware processing equipment. The powder removal brushing part comprises an operating cabin and a supporting plate. Brushing mechanisms for laminating a to-be-processed panel are arranged at the left and right ends of the supporting plate, a worktable is arranged below the supportingplate, a conveyor belt, the conveying direction of which is from left to right, is arranged on the workable, the conveyor belt is a plastic conveyor belt with a falling grid, a material collecting cabin is arranged below the worktable, and a dust collecting device is arranged at an outlet in the right side of the operating cabin. By arranging an electric motor on the brushing mechanisms, a compression roller is driven to move clockwise, so that bristles can brush power on the panel from right to left. The powder is shook off by means of a first push air cylinder and a second push air cylinder. In addition, the dust collecting device is then arranged, so that the dust amount on the surface of the panel is improved, and it is convenient for refined processing.

Owner:福建展拓创意家居有限公司

Selective laser melting equipment

InactiveCN107626921AReduce dosageImprove efficiencyAdditive manufacturing apparatusSelective laser meltingOptoelectronics

The invention discloses selective laser melting equipment and relates to the field of elective laser melting equipment. The elective laser melting equipment comprises a scraper device, a powder feeding device, recovery devices and a selective laser melting table, wherein the recovery devices are arranged on two sides of the selective laser melting table; the scraper device is arranged above the selective laser melting table; and the powder feeding device is arranged right above the selective laser melting table. By adoption of the selective laser melting equipment disclosed by the invention, the powder utilization ratio can be improved; the scraper device is equipped with double scraper plates used for spreading powder to and fro, so that the powder spreading efficiency can be guaranteed;through the recovery of redundant powder, not only can a complete plane be obtained, but also the length of the selective laser melting table can be reduced, and then the powder consumption and the amount of recovered powder can be reduced; and a traditional powder feeding mechanism is arranged on one side of the selective laser melting table, however, the powder feeding device of the selective laser melting equipment is arranged right above the selective laser melting table, so that the whole surface of the selective laser melting table can be covered through pipelines which are distributed in a lattice, the total volume of the selective laser melting table can be reduced, and the powder utilization ratio can be improved.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

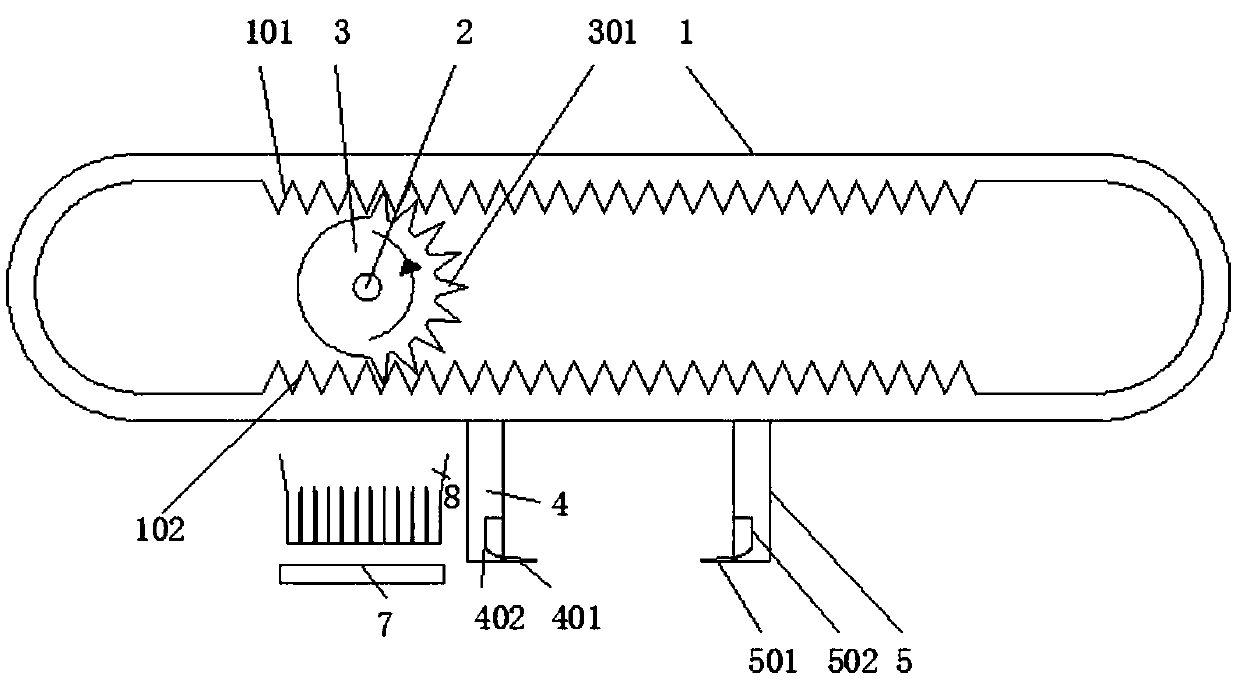

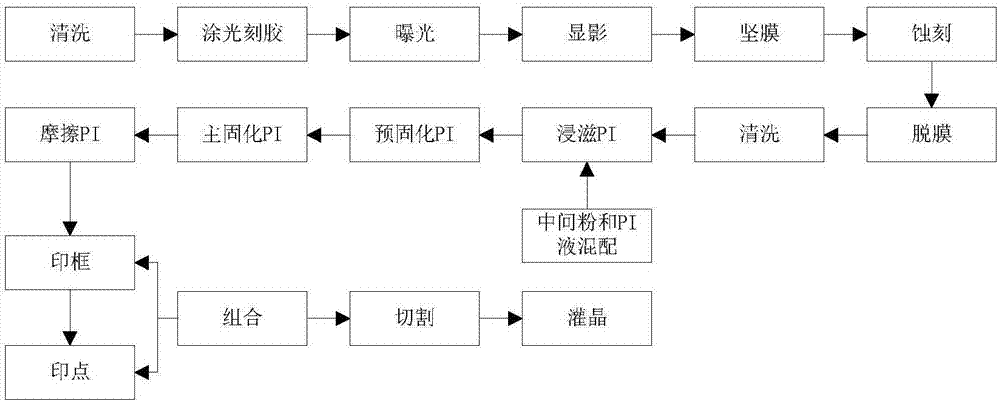

LCD screen manufacturing technology making PI liquid and spacer mixed

InactiveCN107479221ASolve increased problemsImprove the mixing effectNon-linear opticsProduction rateResist

The invention discloses an LCD screen manufacturing technology making PI liquid and spacer mixed and belongs to the field of LCD production. The technology comprises the following steps that pretreatment is conducted, wherein the processes of first cleaning, resist coating, exposure, development, hardening, etching, stripping and second cleaning are conducted in sequence, and an ITO glass substrate is obtained; PI is dipped and cured, wherein the PI is dipped and then cured on the ITO glass substrate, and dipping and curing are completed; after-treatment is conducted, wherein the processes of PI rubbing, box printing, dot printing, combination of box printing and dot printing, cutting and liquid crystal injection are conducted in sequence, and an LCD screen is obtained. In the technology, the step of PI dipping comprises the steps that the PI liquid and the spacer are mixed two times and the PI is infiltrated, and the step of PI curing comprises the steps of PI pre-curing and main curing of the PI. According to the technology, in the PI dipping process, the spacer and the PI liquid are mixed two times, and the spacer is fixed into the PI liquid after pre-curing and main curing, so that the mixing effect is ensured; while the production rate of degraded products is reduced, the consumption of the spacer is reduced, and the cost is reduced.

Owner:SICHUAN ROSTAR ELECTRONICS TECH

Double-loop sound barrier production line

ActiveCN107983561AReduce energy consumptionImprove compactnessCombination devicesGas treatmentSound barrierProduction line

The invention belongs to the technical field of a sound barrier and discloses a double-loop sound barrier production line. The double-loop sound barrier production line comprises a heavy part loop anda light part loop; the heavy part loop and the light part loop share the same powder solidification furnace; the heavy part loop consists of a first part feeding device, a sand blasting device, a spraying device, a water washing device, a drying device, a first spray-coating device, the powder solidification furnace and a first part discharging device which are sequentially connected through a heavy part hanging chain to form a closed-loop type spray-coating production line connected end to end; the light part loop consists of a second part feeding device, a second spray-coating device, the powder solidification furnace and a second part discharging device which are sequentially connected through a light part hanging chain to form a closed-loop type spray-coating production line connectedend to end; the heavy part hanging chain and the light part hanging chain are both in inflected U-shaped distribution inside the powder solidification furnace; and the parts, inside the powder solidification furnace, of the heavy part hanging chain and the light part hanging chain are arranged in parallel with each other. The double-loop sound barrier production line provided by the invention isingenious in conception, simple and convenient to operate and capable of solving the technical problems that the sound barrier in the prior art is large in floor area and high in energy consumption.

Owner:HEBEI JINBIAO CONSTR MATERIALS TECH CORP LTD

Sputtering target for magnetic recording medium, and magnetic thin film

ActiveCN108699677AImprove featuresReduce the amount of powderElectric discharge tubesVacuum evaporation coatingThin membraneRecording layer

Owner:JX NIPPON MINING & METALS CORP

Electrostatic workpiece spraying device

The invention relates to the technical field of electrostatic spraying equipment, in particular to an electrostatic workpiece spraying device; and the electrostatic workpiece spraying device can conveniently hook workpieces to improve the usability, meanwhile, can adjust the positions of a first support frame and a second support frame according to the sizes of the workpieces to improve the adaptability and to reduce the use limitation, improves the spraying effect of the workpieces hooked on the first support frame and the second support frame, improves the use effect, and reduces sprayed powder remained in a working box to relieve the labor intensity during cleaning to improve the usability. The electrostatic workpiece spraying device comprises a base, a bracket, a working box, a box door, a nozzle, a first support frame, a second support frame, an air blower and an input pipe, further comprises a first adjusting piece and a second adjusting piece, further comprises two sets of firstslide rails and two sets of second slide rails, further comprises multiple sets of discharge pipes, and further comprises multiple sets of feed pipes, multiple sets of suckers, a first communicatingpipe, a second communicating pipe and a filter box.

Owner:太仓市联华静电喷涂厂(普通合伙)

Metallic silicon crushing system

InactiveCN105149074ARound and beautiful grain shapeImprove uniformityGrain treatmentsFailure rateEngineering

The invention relates to a metallic silicon crushing system which comprises a feeding system, a dropping pipeline, a crushing system, a screening system, a primary crushing system, a secondary crushing system, a particle producing system, a dust removing system and a discharging system, wherein the feeding system is connected with the upper end of the dropping pipeline; the lower end of the dropping pipeline is connected with the crushing system; the screening system is arranged below the crushing system; the primary crushing system is arranged below the screening system, and is connected with the secondary crushing system; the secondary crushing system is connected with the particle producing system; the discharging system is arranged below the particle producing system; the dust removing system is connected with the primary crushing system, the secondary crushing system and the particle producing system. The metallic silicon crushing system is simple and practical in overall structure, low in yield, high in production efficiency, lower in energy consumption, low in cost, low in failure rate and long in service life; the produced discharged small silicon particles are round and aesthetic in particle shape, good in uniformity, free of violent struck crushing, small in powder amount, low in possibility of impurity introduction, and free of dust pollution problems.

Owner:怒江宏盛锦盟硅业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com