Rotator for powder conveyance and toner cartridge

A technology of toner box and rotating body, which is applied in the direction of electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, and electrography, etc., which can solve the problem of the reduction of the ability of the agitator to transport the toner and the impact Problems such as toner transfer, toner volume increase, etc., to achieve the effects of small gaps, prevention of aggregation and accumulation, and reduction of powder volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

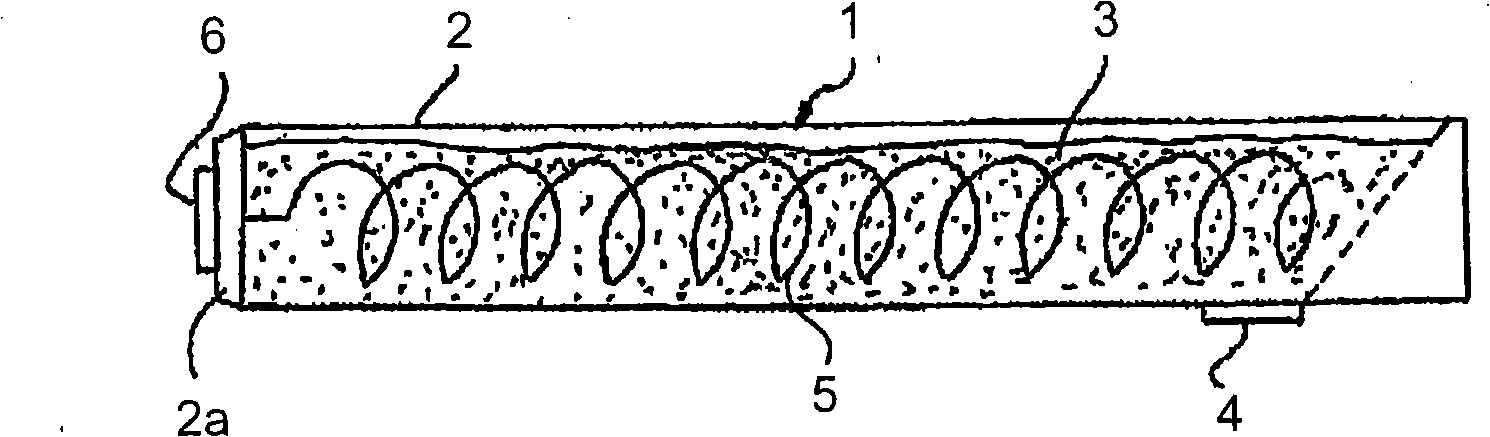

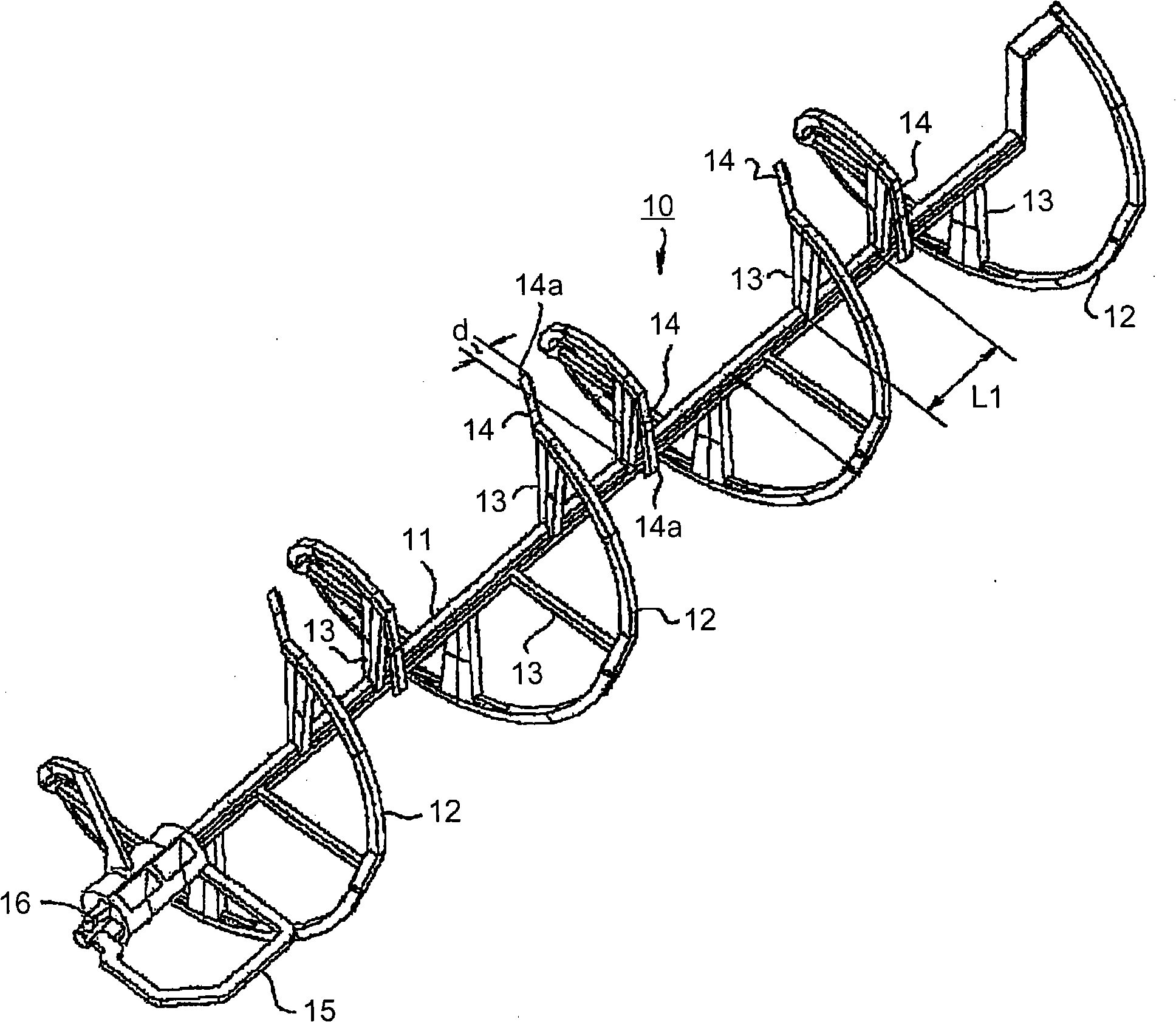

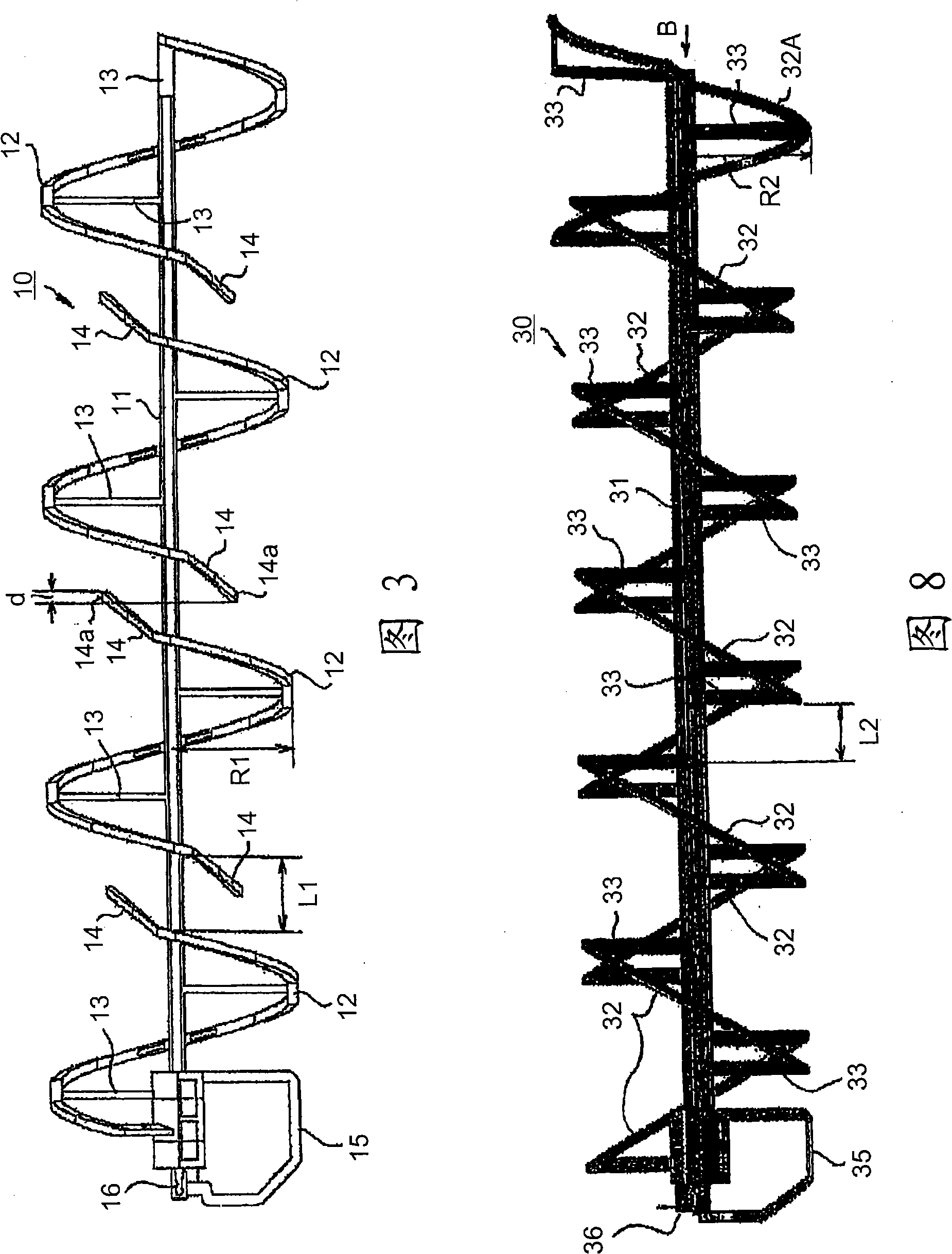

[0038] Refer below Figure 2 to Figure 5 A first exemplary embodiment of a rotary body for powder conveyance and a toner cartridge using the same according to the present invention will be described. It should be noted that the rotary body for powder conveyance and the toner cartridge using the same according to the present invention are not limited to the exemplary embodiments described below.

[0039] figure 2is an external view of the rotating body for powder transfer according to the first exemplary embodiment of the present invention. 3 is a plan view of a rotating body for powder transfer according to a first exemplary embodiment of the present invention. 4 is an oblique perspective view of a main body portion of a rotating body for powder transfer fixed in a container according to a first exemplary embodiment of the present invention. Figure 5 is an oblique perspective view of a toner cartridge in which the rotating body for powder conveyance according to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com