Co-cr-pt-based sputtering target and method for producing same

A manufacturing method and technology for sputtering targets, which are applied in the field of sputtering targets, can solve the problems of particle size and number limitation, and achieve the effects of reducing the amount of particles, improving the yield and improving the dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

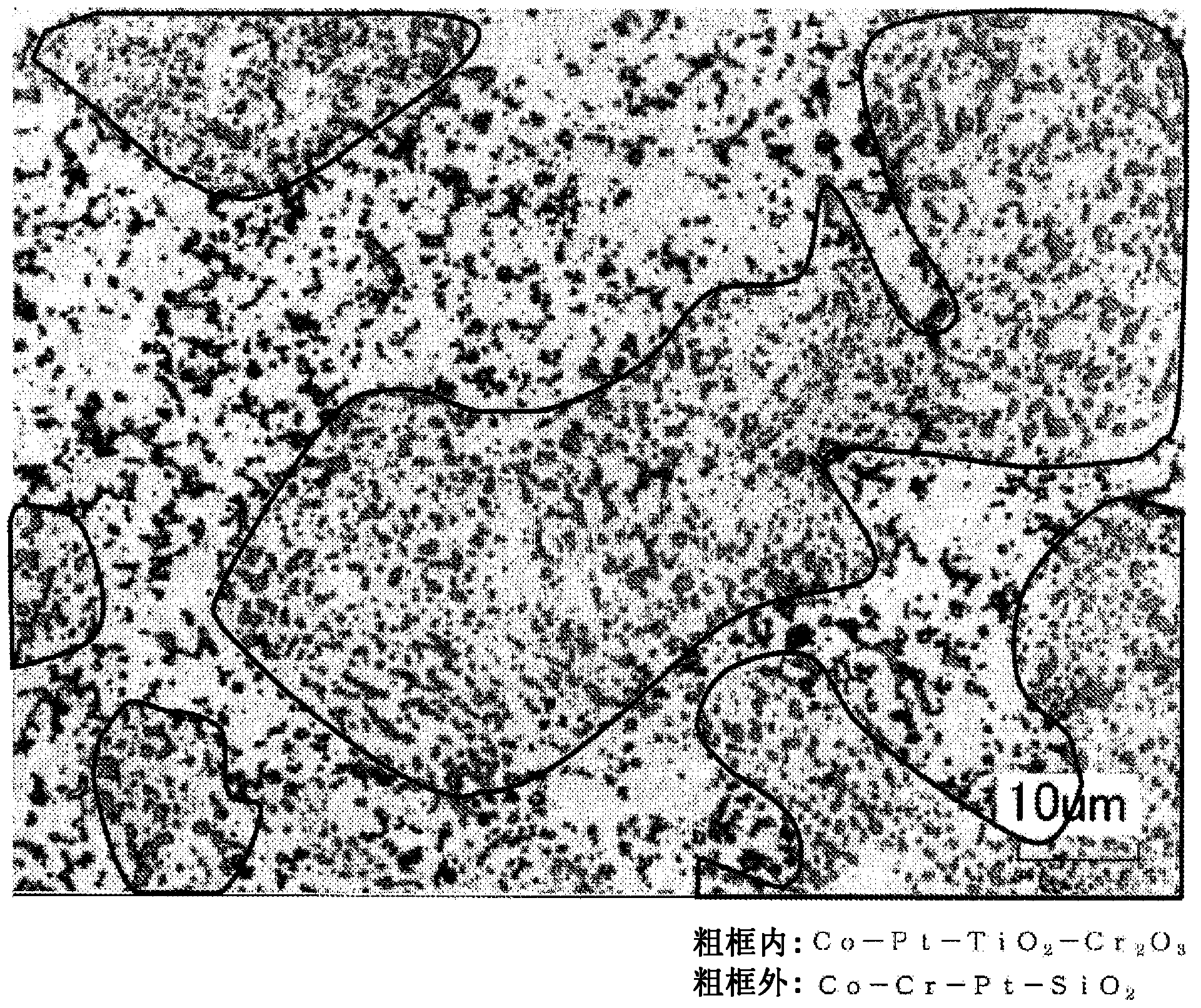

Image

Examples

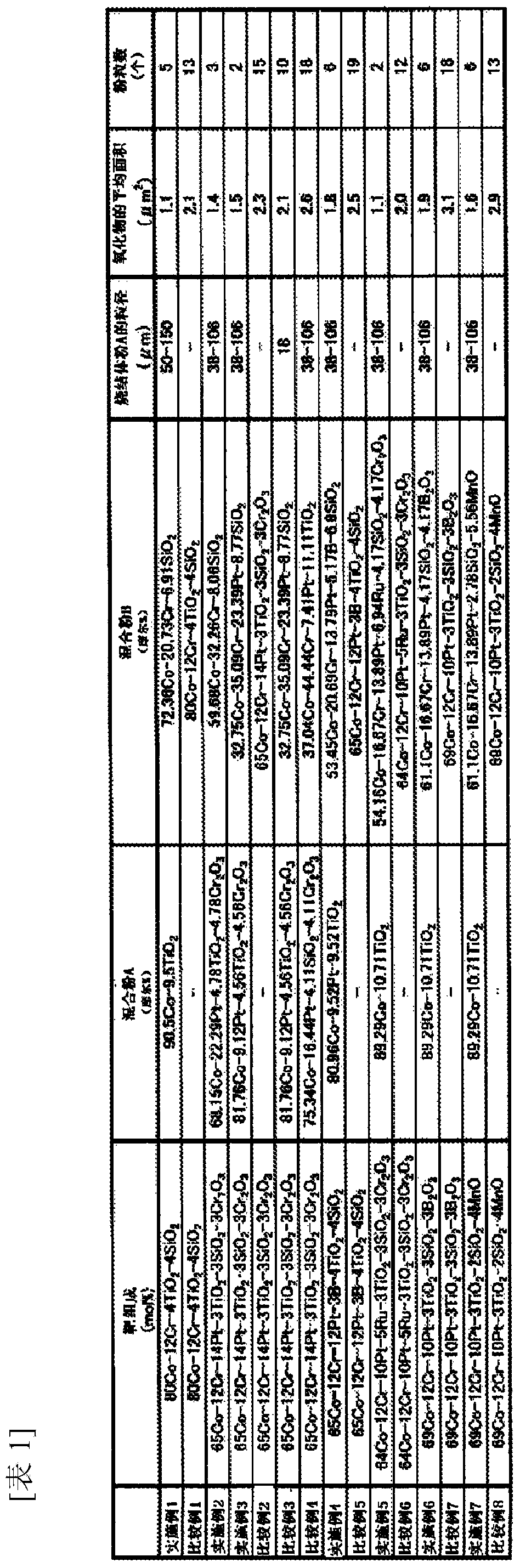

Embodiment 1

[0049] Prepare Co powder with an average particle size of 3 μm and Cr powder with an average particle size of 5 μm as metal raw material powders; prepare TiO with an average particle size of 1 μm 2 Powder, SiO with an average particle size of 1 μm 2 powder as an oxide raw material powder. Then, in order to prepare mixed powder A and mixed powder B, each 1600g was weighed according to the following composition ratio.

[0050] (Mixed powder A): 90.5Co-9.5TiO 2 (mol%)

[0051] (Mixed powder B): 72.36Co-20.73Cr-6.91SiO 2 (mol%)

[0052] Then the weighed powders were sealed together with the pulverizing medium zirconia balls in a ball mill jar with a capacity of 10 liters, and mixed by rotating for 20 hours. Then, only the mixed powder A was filled into a carbon mold, and hot-pressed under the conditions of a vacuum atmosphere at a temperature of 1000° C., a holding time of 2 hours, and a pressing pressure of 30 MPa to obtain a sintered body (sintered body A ). Then, the sin...

Embodiment 2

[0065] Prepare Co powder with an average particle size of 3 μm, Cr powder with an average particle size of 5 μm, and Pt powder with an average particle size of 2 μm as metal raw material powders; prepare TiO with an average particle size of 1 μm 2 Powder, SiO with an average particle size of 1 μm 2 Powder, Cr with an average particle size of 3 μm 2 o 3 powder as an oxide raw material powder. Then, in order to prepare mixed powder A and mixed powder B, each 2000g was weighed according to the following composition ratio.

[0066] (Mixed powder A): 68.15Co-22.29Pt-4.78TiO 2 -4.78Cr 2 o 3 (mol%)

[0067] (Mixed powder B): 59.68Co-32.26Cr-8.06SiO 2 (mol%)

[0068] Then the weighed powders were sealed together with the pulverizing medium zirconia balls in a ball mill jar with a capacity of 10 liters, and mixed by rotating for 20 hours. Then, only the mixed powder A was filled in a carbon mold, and a sintered body (sintered body A) was obtained by hot pressing in a vacuum at...

Embodiment 3

[0075] Prepare Co powder with an average particle size of 3 μm, Cr powder with an average particle size of 5 μm, and Pt powder with an average particle size of 2 μm as metal raw material powders; prepare TiO with an average particle size of 1 μm 2 Powder, SiO with an average particle size of 1 μm 2 Powder, Cr with an average particle size of 3 μm 2 o 3 powder as an oxide raw material powder. Then, in order to prepare mixed powder A and mixed powder B, each 2000g was weighed according to the following composition ratio.

[0076] (Mixed powder A): 81.76Co-9.12Pt-4.56TiO 2 -4.56Cr 2 o 3 (mol%)

[0077] (Mixed powder B): 32.75Co-35.09Cr-23.39Pt-8.77SiO 2 (mol%)

[0078] Then the weighed powders were sealed together with the pulverizing medium zirconia balls in a ball mill jar with a capacity of 10 liters, and mixed by rotating for 20 hours. Then, only the mixed powder A was filled into a carbon mold, and hot-pressed under the conditions of a vacuum atmosphere at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com