Patents

Literature

143results about How to "Good particle shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

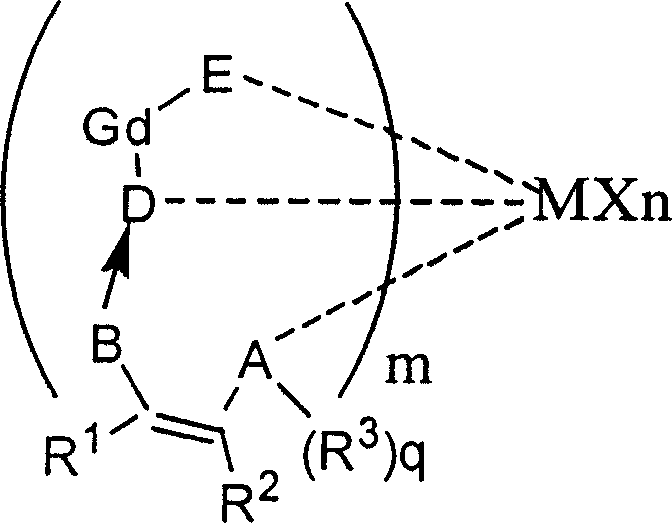

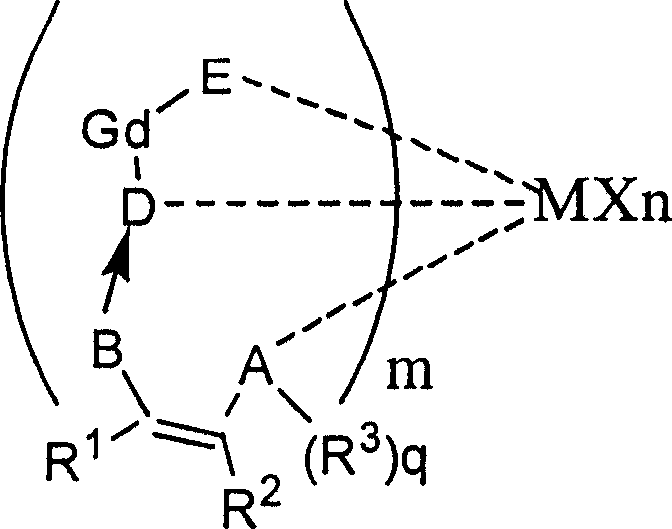

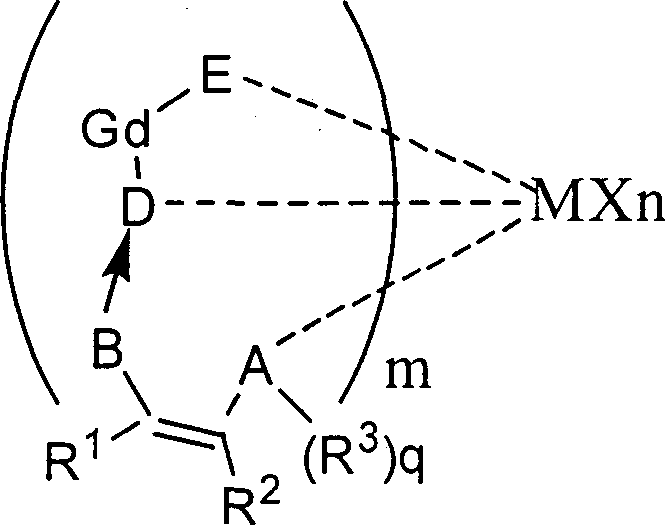

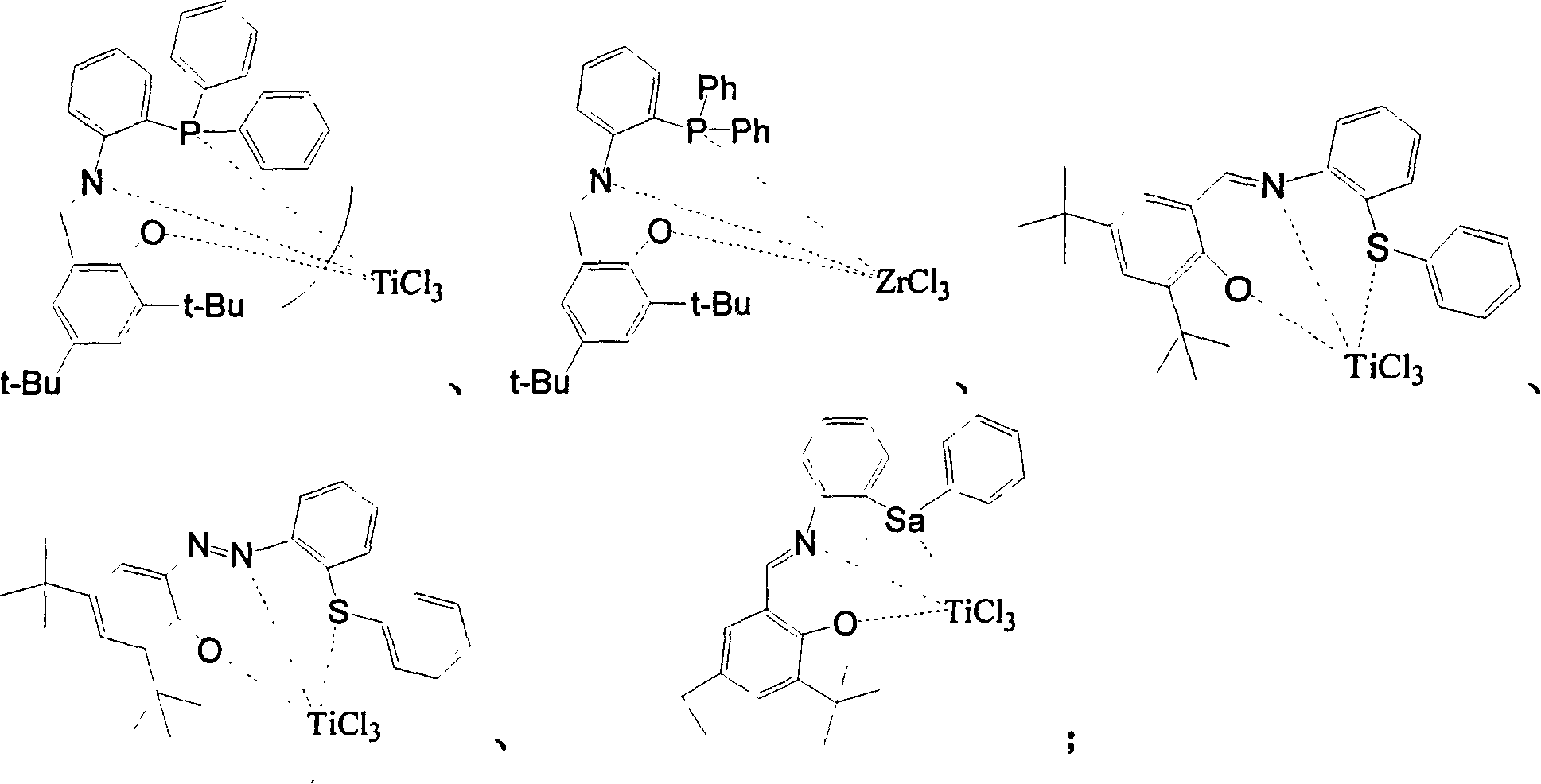

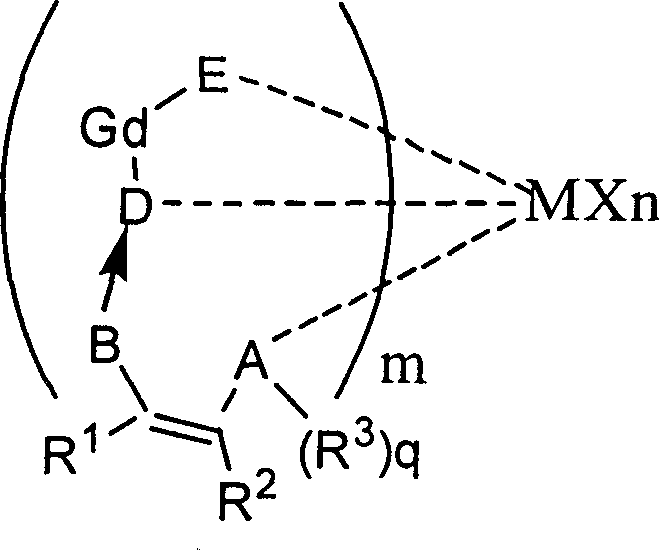

Loaded method of load type Non-metallocene catalyst-and polymerizing application

A carrying process for the carried non-metallocene catalyst includes activating the porous carrier, washing, filtering, drying and directly carrying the nno-metallocene catalyst used for olefine polymerization. Said catalyst can be used for the slurry-type or gas-phase homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

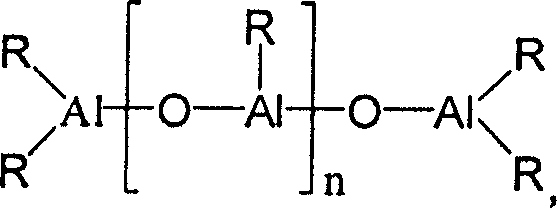

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

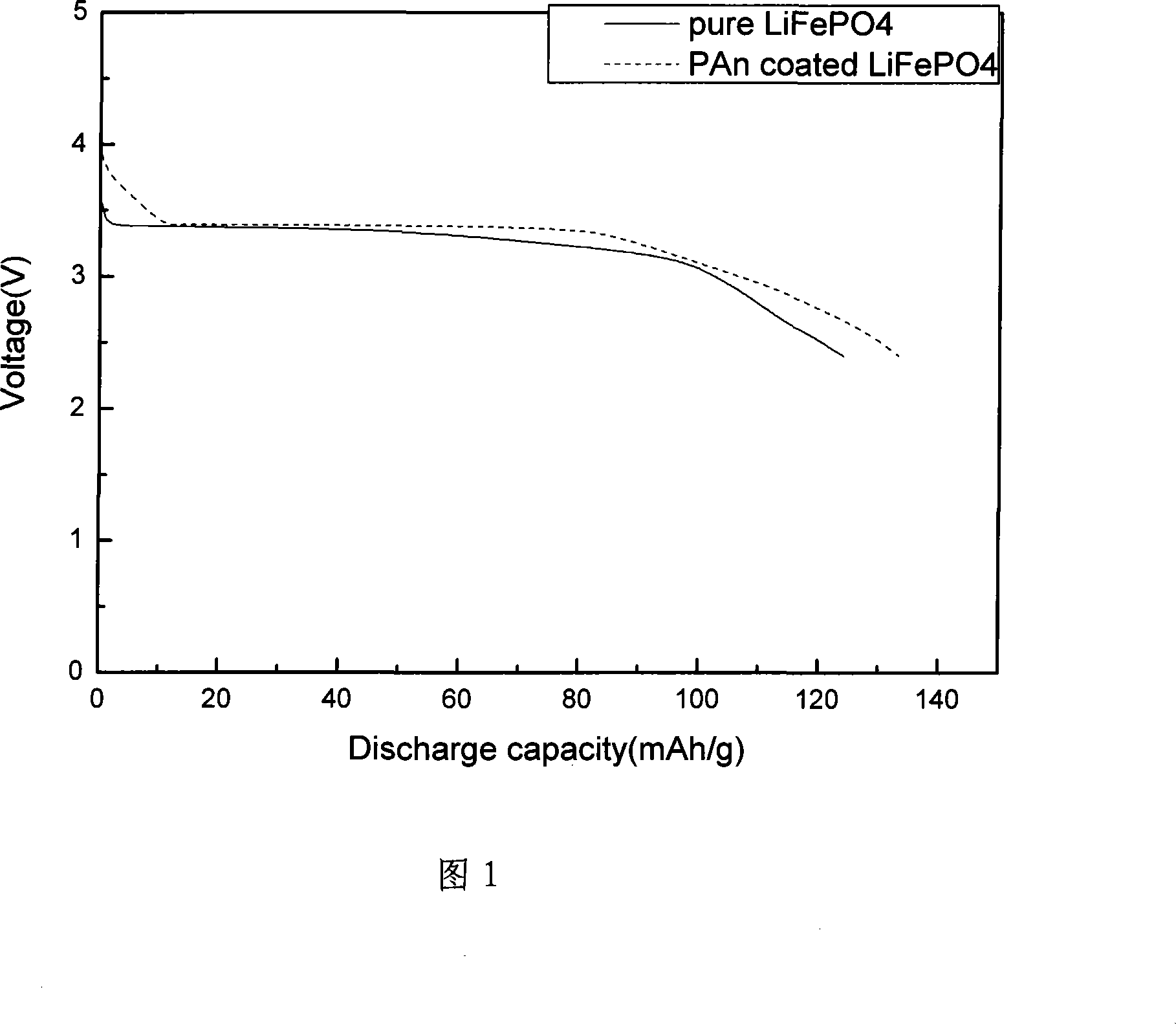

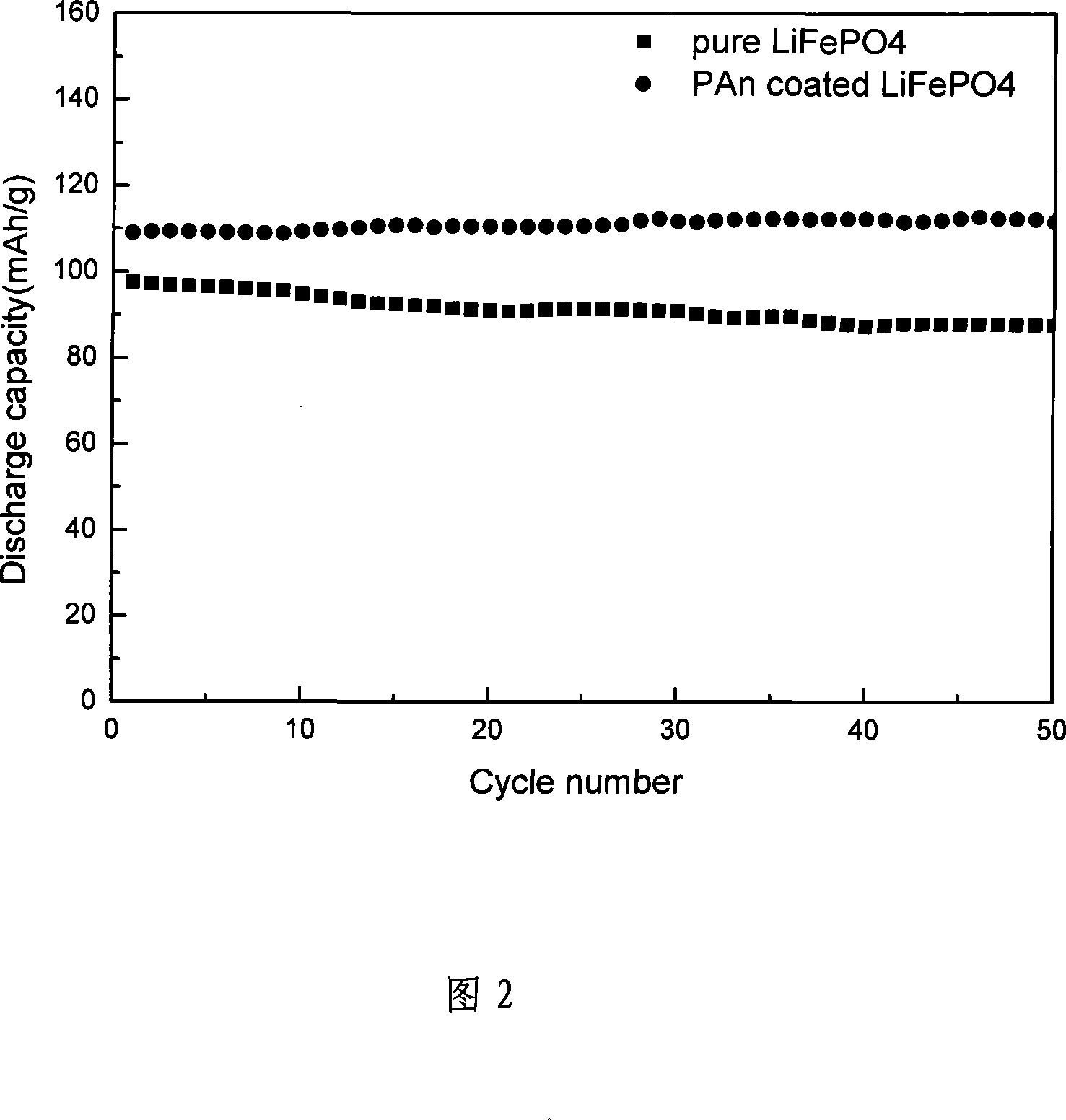

Making method for positive material LiFePO4 of poly-aniline coated lithium ion battery

InactiveCN101237036AStable discharge voltage platformHigh specific capacityElectrode manufacturing processesPhosphorus compoundsGranularitySodium-ion battery

The invention discloses a method for preparing polyaniline coating Li-ion battery anode material LiFePO4. The method is coating polyaniline on the in-situ surface of the powder of Li-ion battery anode material LiFePO4. The method has the following favorable effects: the discharging voltage platform of the polyaniline coating anode material LiFePO4obtained is stable, the battery has higher specific capacity up to one hundred and forty point three mAh / g, the granularity is distributed evenly, the grains are in good appearance and high in discharging capacity and long in cycling life, etc.

Owner:XIANGTAN UNIV

Pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement

ActiveCN105129744AImprove decomposition efficiencyIncrease concentrationSulfur compoundsClinker productionDecompositionPhosphogypsum

The invention relates to the technical field of industrial production of sulfuric acid and cement, the field of industrial solid waste comprehensive utilization, and the field of environment protection and treatment, and particularly relates to a pre-heating decomposition method of producing sulfuric acid from phosphogypsum with co-production of cement. The method includes the steps of powder grinding of raw materials, multi-stage cyclic pre-heating, high-effective decomposition and kiln gas separation and purification. The method is used for preparing a cement raw material from the phosphogypsum subjected to pre-heating decomposition with clay, sand rock, coke and such auxiliary materials in the process of producing the sulfuric acid from the phosphogypsum with co-production of the cement. The method solves the problems that a pre-heating decomposition technology in the prior art is low in decomposition ratio of phosphogypsum, is low in productivity of sulfuric acid and clinker, is liable to cause crusting and blocking in a kiln and is high in production energy consumption, can reduce the decomposition efficiency of the phosphogypsum and accelerate escape of SO2, and further increase the productivity of the sulfuric acid and cement clinker. The pre-heating decomposition method of producing the sulfuric acid from the phosphogypsum with co-production of the cement can significantly reduce sintering temperature and energy consumption of the clinker, can reduce production cost of sulfuric and cement clinker, and can further increase comprehensive utilization rate of the phosphogypsum.

Owner:湖北湖大天沭新能源材料工业研究设计院有限公司

Making method of radix-codonopsis broken-wall decoction piece

InactiveCN107019718AGood particle shapeModerate tightnessUnknown materialsPlant ingredientsPulverizerNutritional composition

The invention discloses a making method of a radix-codonopsis broken-wall decoction piece. The making method comprises the following contents of first soaking a radix-codonopsis medicinal material in a soaking solution, then oven-drying a radix-codonopsis decoction piece, and then crushing the radix-codonopsis decoction piece through a crusher with a 100-mesh sieve, so as to subsequently make medicinal-material coarse powder of 80 to 120 meshes; afterwards, subjecting the medicinal-material coarse powder to microwave oven-drying in sequence, grinding the medicinal-material coarse powder into ultrafine powder, afterwards, further carrying out granulation through an ethanol-water wetting method, carrying out extrusion molding at a certain rotational speed, and carrying out drying, thereby making the radix-codonopsis broken-wall decoction piece. The radix-codonopsis broken-wall decoction piece provided by the invention is first soaked by adopting the soaking solution; the nutritive value of radix codonopsis is improved; the primary processing is carried out; afterwards, the granulation is further carried out through the ethanol-water wetting method; the grain of the made radix-codonopsis broken-wall decoction piece is better in grain type; the tightness is moderate; the stability is high; the disintegration is good; meanwhile, in comparation with a conventional ultramicro wall breakage crushing method, the making method is used for greatly improving the wall breakage rate of the radix codonopsis; a nutrient substance is maximally maintained; the beneficial effects that the wall breakage rate is high and a nutritional ingredient is stored completely are achieved.

Owner:天马(安徽)国药科技股份有限公司

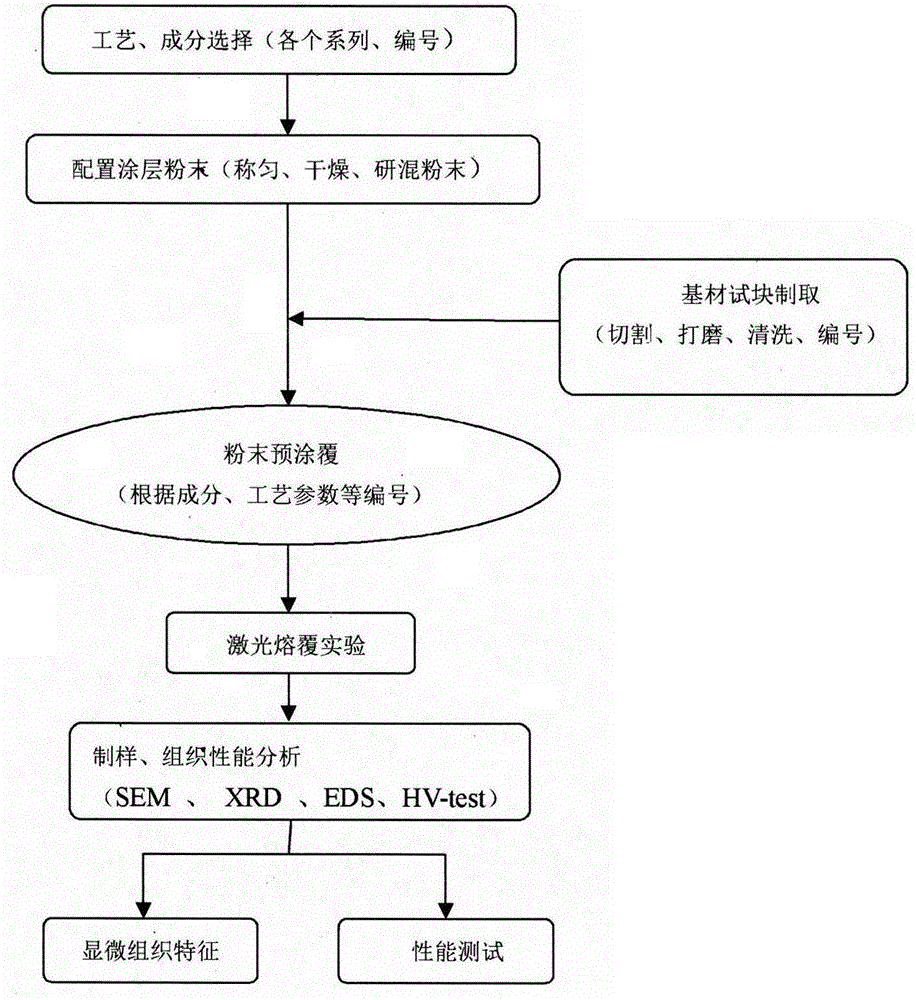

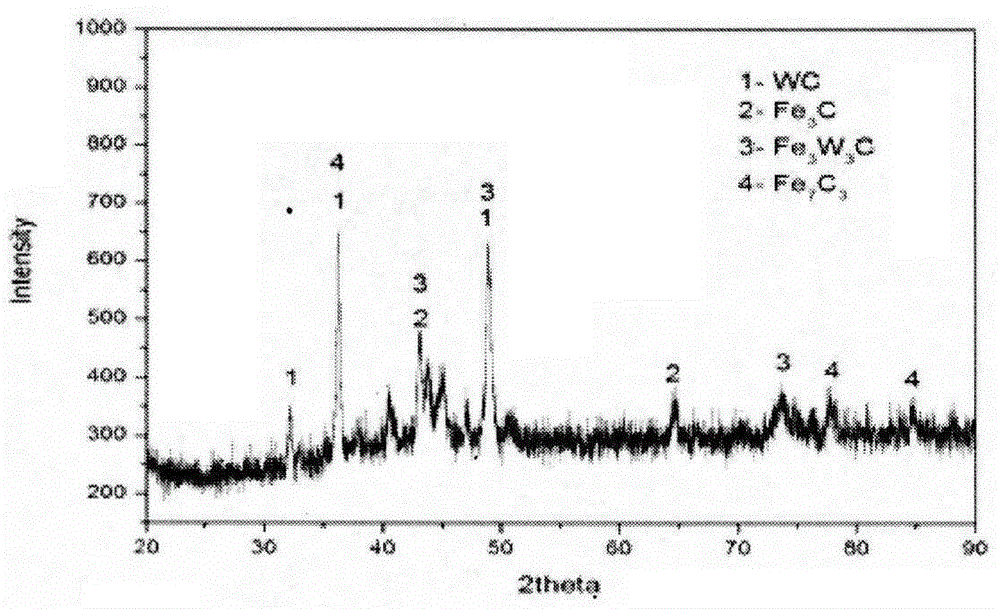

Laser-cladding tungsten carbide ceramic particle reinforced metal-based coating and processing method thereof

ActiveCN105112908AImprove bindingImprove wettabilityMetallic material coating processesAlloyMetallic Nickel

The invention discloses a laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. The coating comprises alloy powder; the alloy powder comprises tungsten powder and graphite with the mole ratio of 2:1 and further comprises reduced iron powder, chromium powder, nickel powder, boron powder, silicon powder and copper powder; further, the alloy powder preferentially comprises the following components in percentage by mass: 55-60% of tungsten powder, 7-9% of graphite, 23-30% of reduced iron powder, 0-3% of chromium powder, 2-6% of nickel powder, 0.3-1% of boron powder and 0.4-1% of silicon powder. The invention further discloses a processing method for the laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. According to the invention, a tungsten carbide particle reinforcing phase for reinforcing the iron-based composite is successfully prepared through a laser cladding in-situ synthesis technology, and a transition layer is arranged between the coating and the matrix, so that atom binding between the coating and the matrix is realized and the bonding strength is relatively high.

Owner:WENZHOU UNIVERSITY

Method for preparing high-softening point asphalt for coating natural graphite cathode material of lithium-ion battery

ActiveCN103897714ANo damageImprove discharge capacityWorking-up pitch/asphalt/bitumen by chemical meansCell electrodesElectrical batteryPhysical chemistry

The invention relates to a method for preparing an isotropous high-softening point asphalt. The method comprises the following steps: (1) oxidizing an asphalt raw material in at least two stages under vacuum negative pressure at a temperature which is higher than an asphalt melting temperature and lower than or equal to 335 DEG C; (2) oxidizing the asphalt obtained in the step (1) under vacuum negative pressure at 340-350 DEG C. The invention also relates to the isotropous high-softening point asphalt obtained by the method, use of the isotropous high-softening point asphalt in preparation of a cathode material of a lithium-ion battery and a method for preparing a carbon cathode material of the lithium-ion battery by use of the isotropous high-softening point asphalt.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

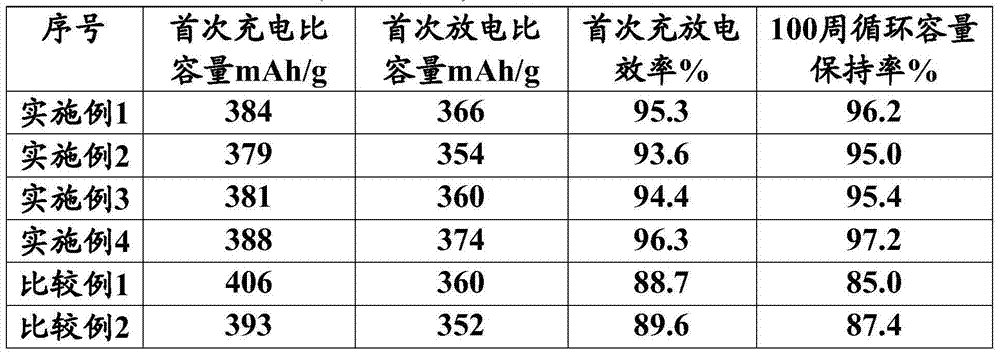

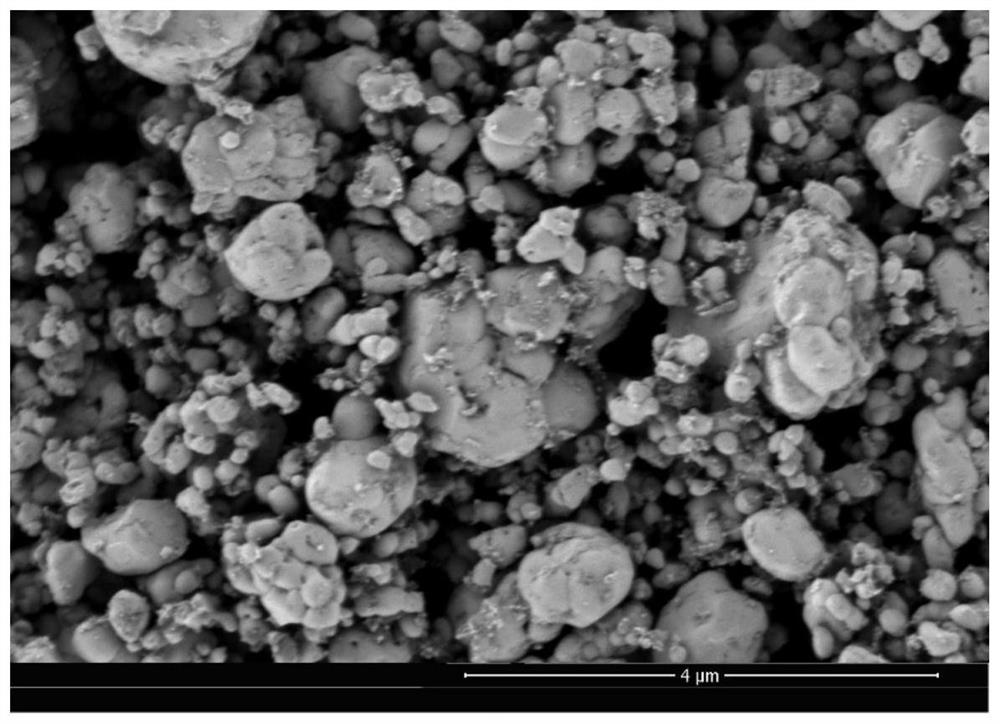

Wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and preparation method thereof

ActiveCN110127777AIncrease capacityImprove cycle stabilityNickel compoundsConcentration gradientCobalt

The invention discloses a wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and a preparation method thereof. The nickel-cobalt-aluminum ternary precursor hasa chemical general formula of NixCoyAlz(OH)2, wherein x+y+z=1, 0.3<=x<=0.9, 0.01<=y<=0.4, and 0.01<=z<=0.4; the Zr element accounts for 0.001%-3% of the total mass of the nickel-cobalt hydroxide precursor, the ternary precursor consists of three layers, and the inner layer is a zirconium-doped nickel-cobalt binary precursor with a molecular formula of NixCoy(OH)2; and the outer layer is a zirconium-doped nickel-cobalt-aluminum ternary precursor with a molecular formula of NixCoyAlz(OH)2, and the intermediate layer is a concentration-gradient precursor between the zirconium-doped nickel-cobaltbinary precursor and the zirconium-doped nickel-cobalt-aluminum ternary precursor. The invention also includes the method for preparing the nickel-cobalt-aluminum ternary precursor. The zirconium-doped nickel-cobalt-aluminum ternary precursor has a narrow particle size distribution and good particle morphology, the doped element is distributed uniformly through complex controlled crystallizing co-precipitation, and a positive-electrode precursor prepared from the zirconium-doped nickel-cobalt-aluminum ternary precursor has high specific capacity, good cycling stability, good processability andstable performance.

Owner:ZHUJI PAWA NEW ENERGY

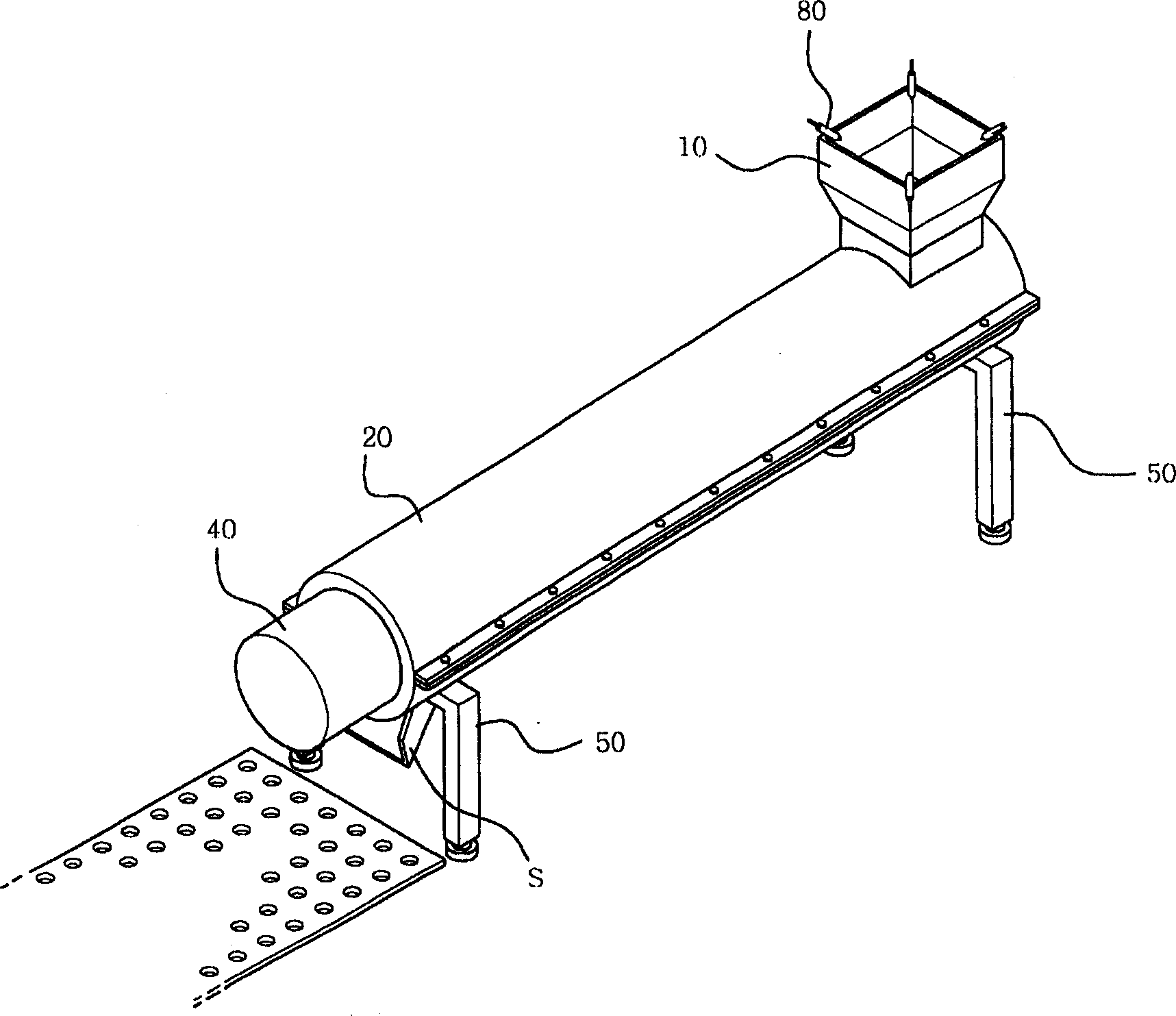

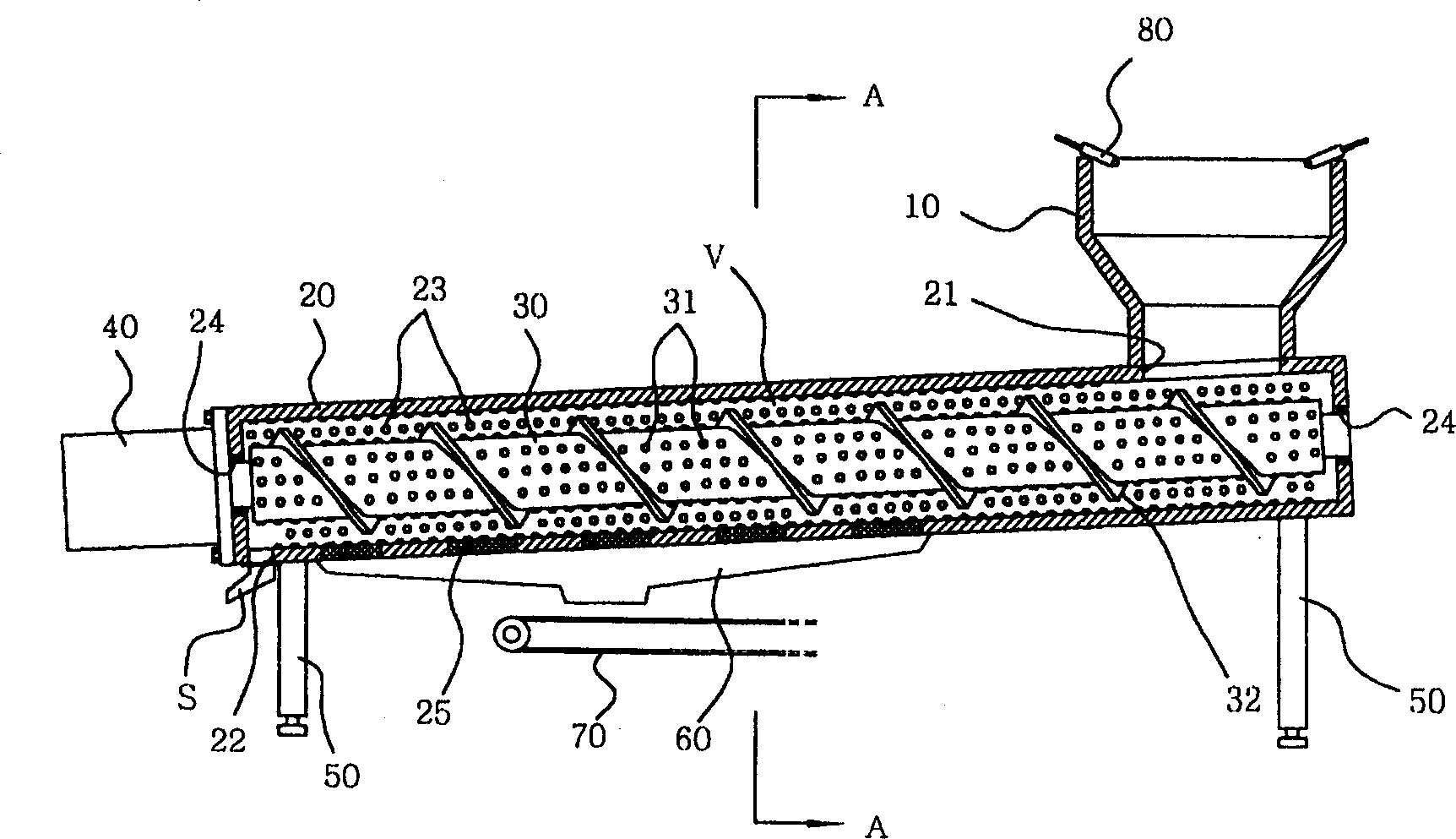

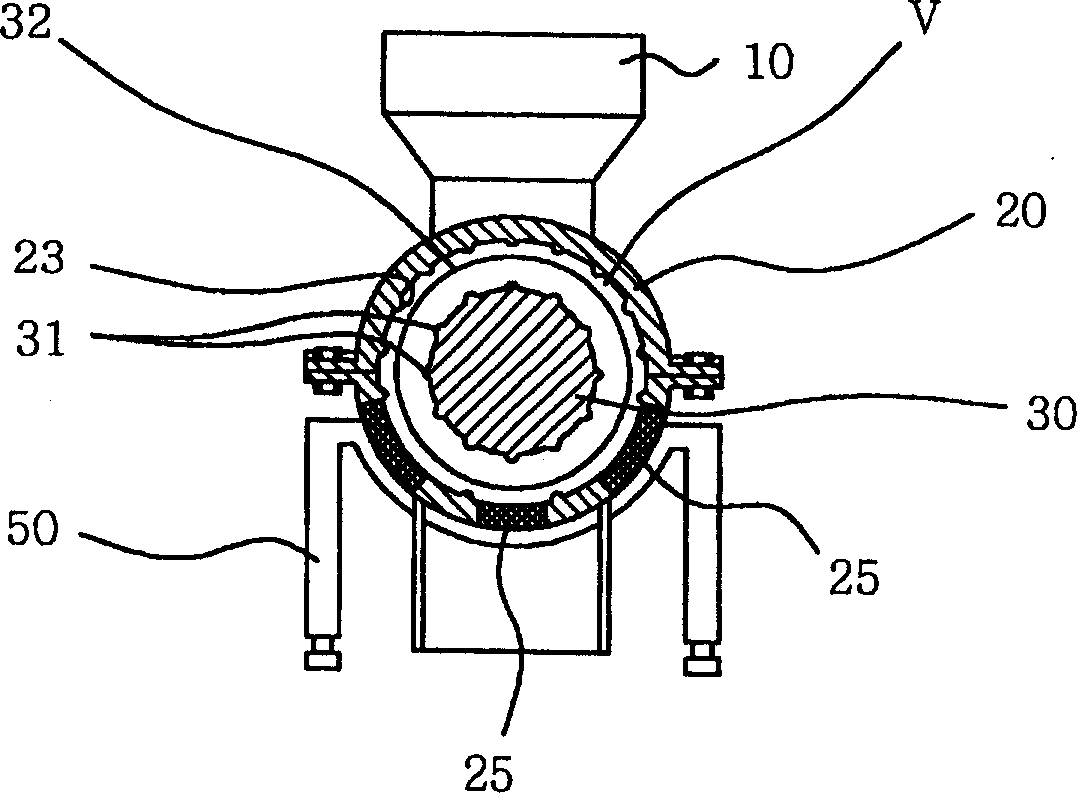

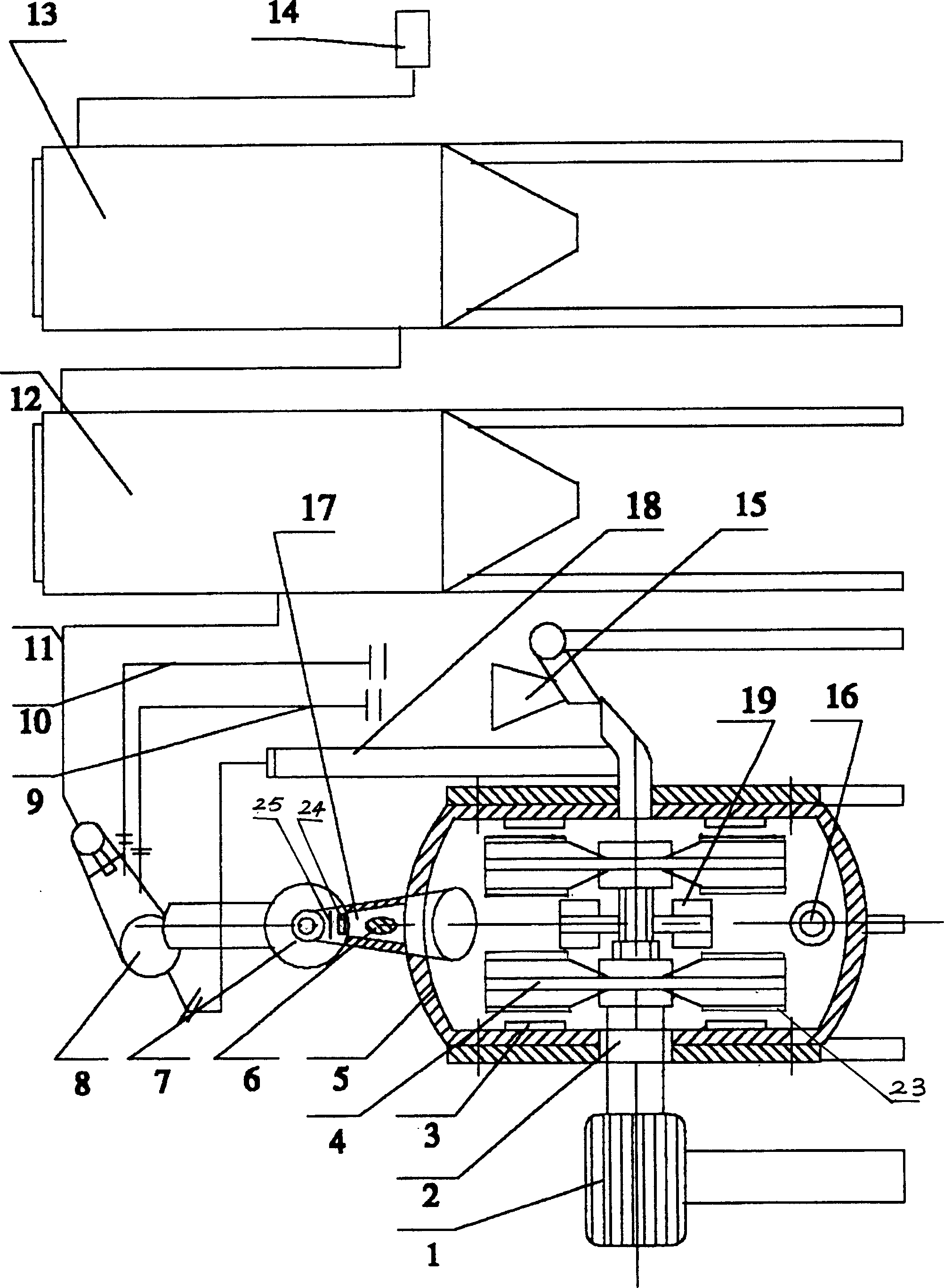

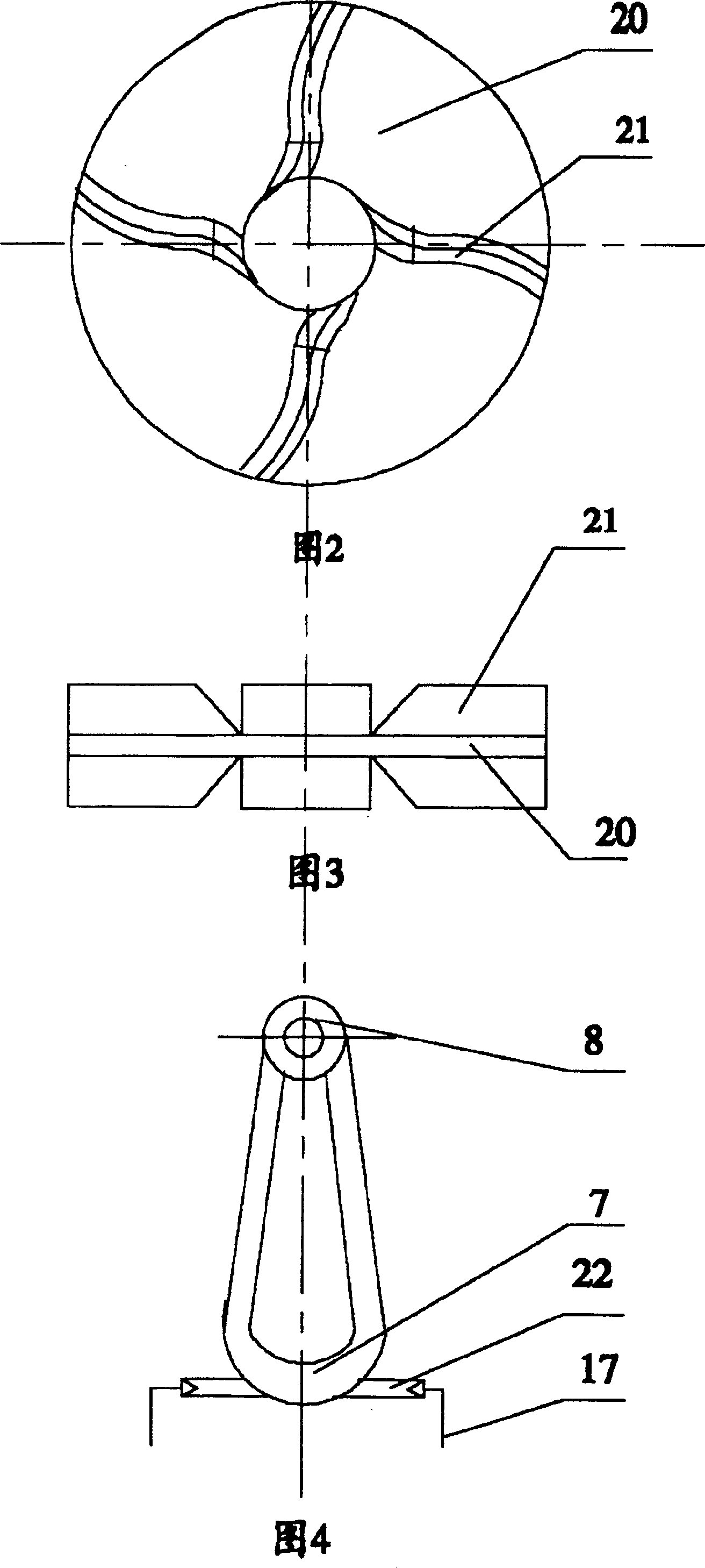

Stripping device for recycled aggregate

InactiveCN1727086AQuality improvementGood particle shapeSievingConveyorsEngineeringConstruction aggregate

The present invention provides a stripping device for recycled aggregate strips recycled aggregate, improving the quality of the recycled aggregate that is produced through a construction-waste processing operation. The stripping device includes a hopper into which the recycled aggregate is input, a casing, a rotary drum, drive means, and support legs. The casing includes an inlet hole provided at a predetermined position on the casing so that the aggregate dropping through the hopper takes into the inlet hole, an outlet hole is positioned at opposite from the inlet hole so that the recycled aggregate is discharged through the outlet hole, and uneven part provided on an inner circumferential surface of the casing. The rotary drum is installed in the casing, and includes a feed screw formed around it, which allows rotating and feeding the recycled aggregate. The drive serves to drive the rotary drum. The support legs serve to support the casing.

Owner:SAMHEUNG ENVIRONMENTAL

Nanometer silicon dioxide thin film base polished section and preparation method thereof

ActiveCN104128896AUniform particle size distributionUniform polishing effectAbrasion apparatusGrinding devicesWork in processCutting force

The invention discloses a nanometer silicon dioxide thin film base polished section and a preparation method of the nanometer silicon dioxide thin film base polished section. The preparation method includes the following steps that (1) nanometer silicone sol is prepared; (2) a precoating is coated on a PET tape base and a processed base material is obtained; (3) the nanometer silicone sol, soluble resin, and a soluble curing agent are mixed and then abrasive coating liquid is obtained; (4) the abrasive coating liquid is evenly coated on the base material processed in the step (2), a semi-finished product is obtained and is solidified under 80 DEG C to 100 DEG C for 40 hours to 60 hours, and the nanometer silicon dioxide thin film base polished section is obtained. The nanometer silicon dioxide thin film base polished section is even in cutting force, and good in polishing effect when the polished section is applied to an optical fiber connector.

Owner:绍兴自远磨具有限公司

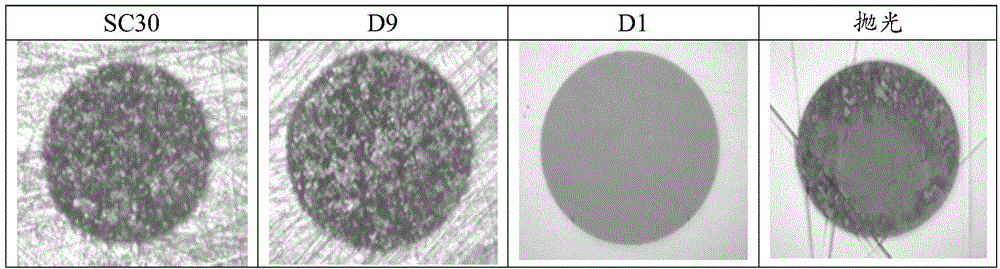

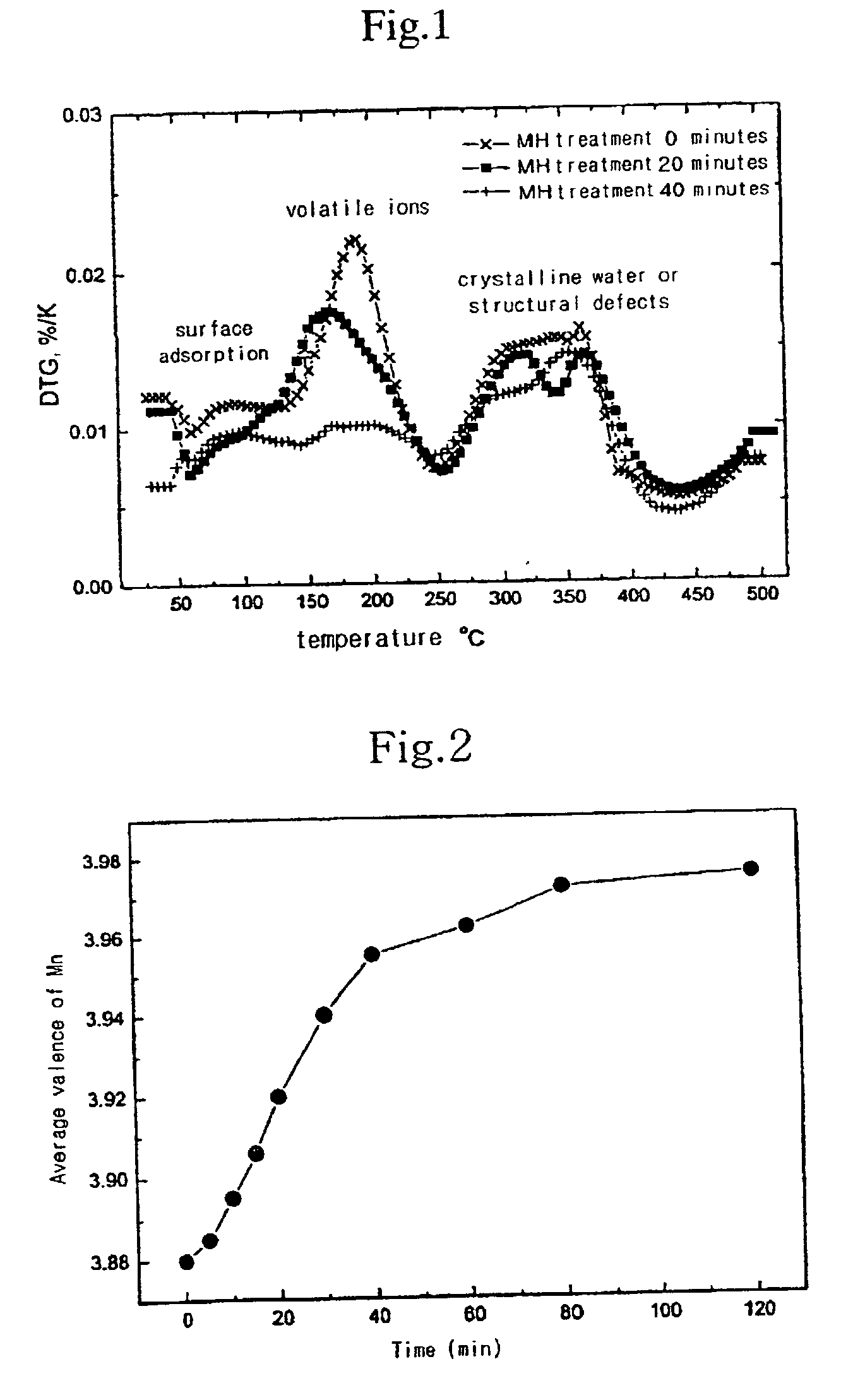

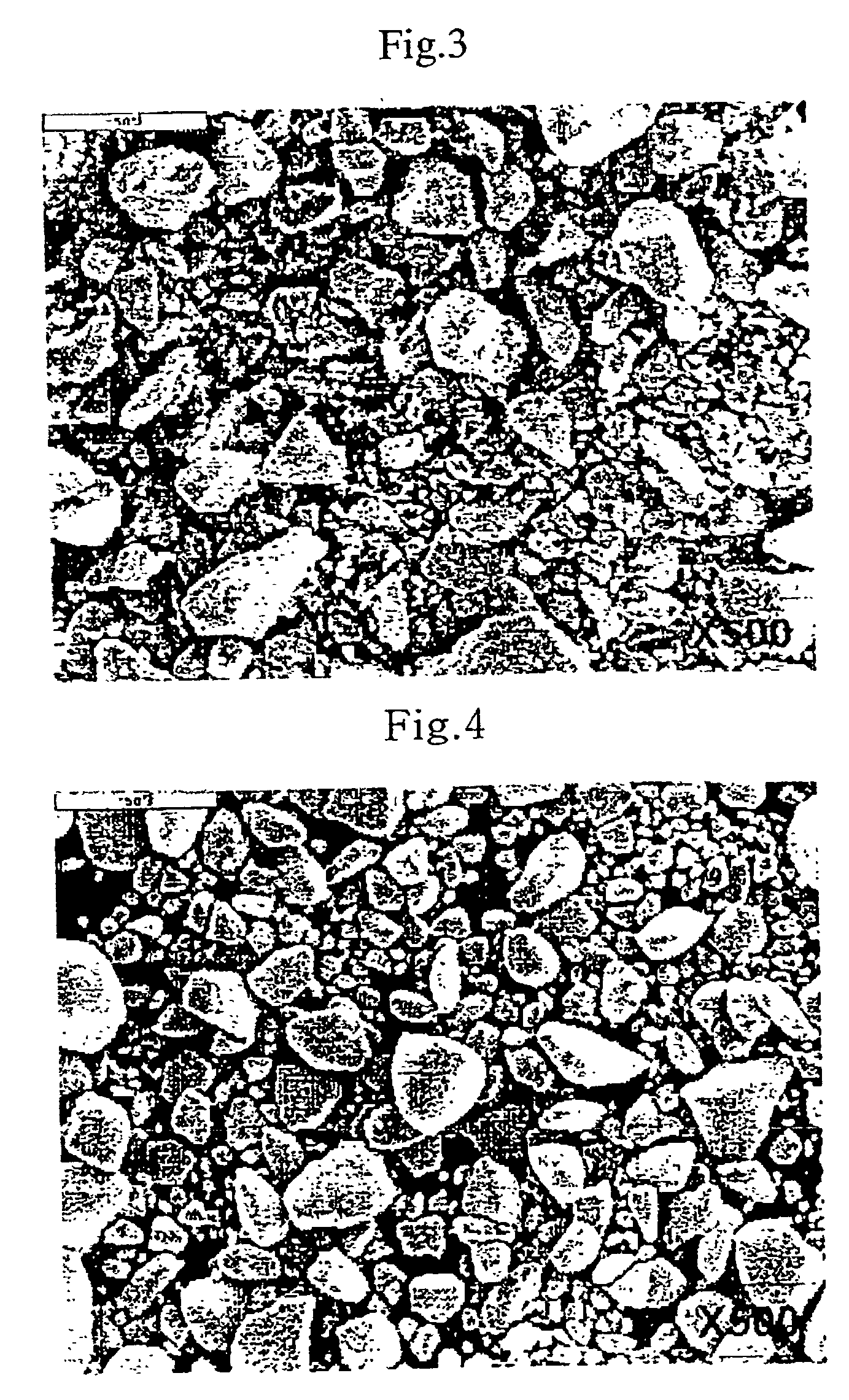

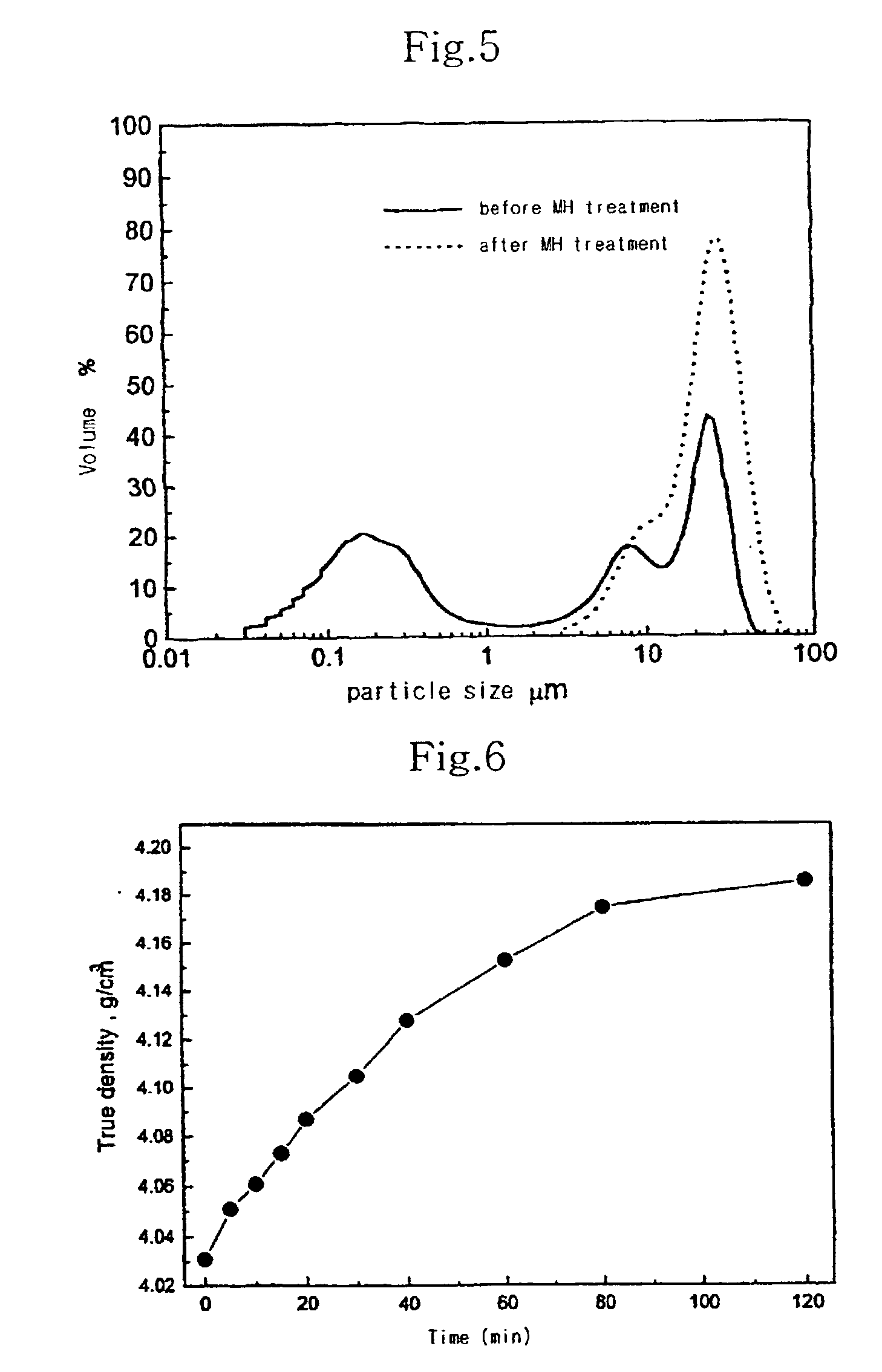

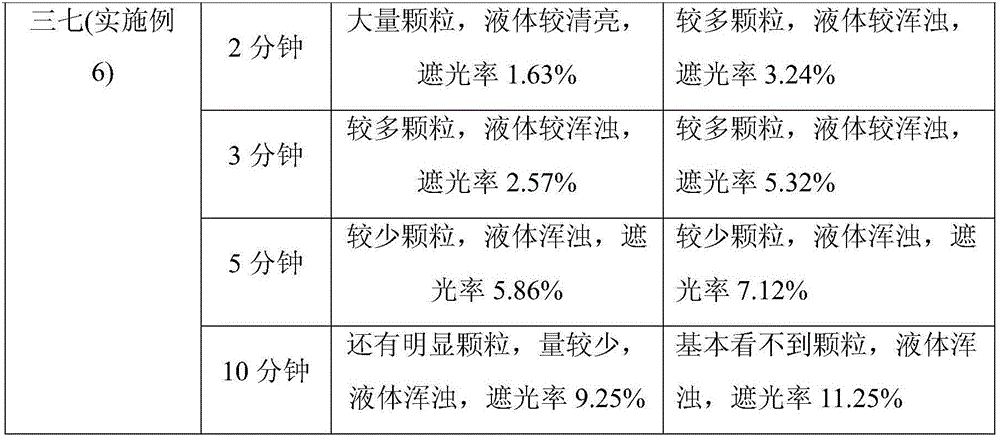

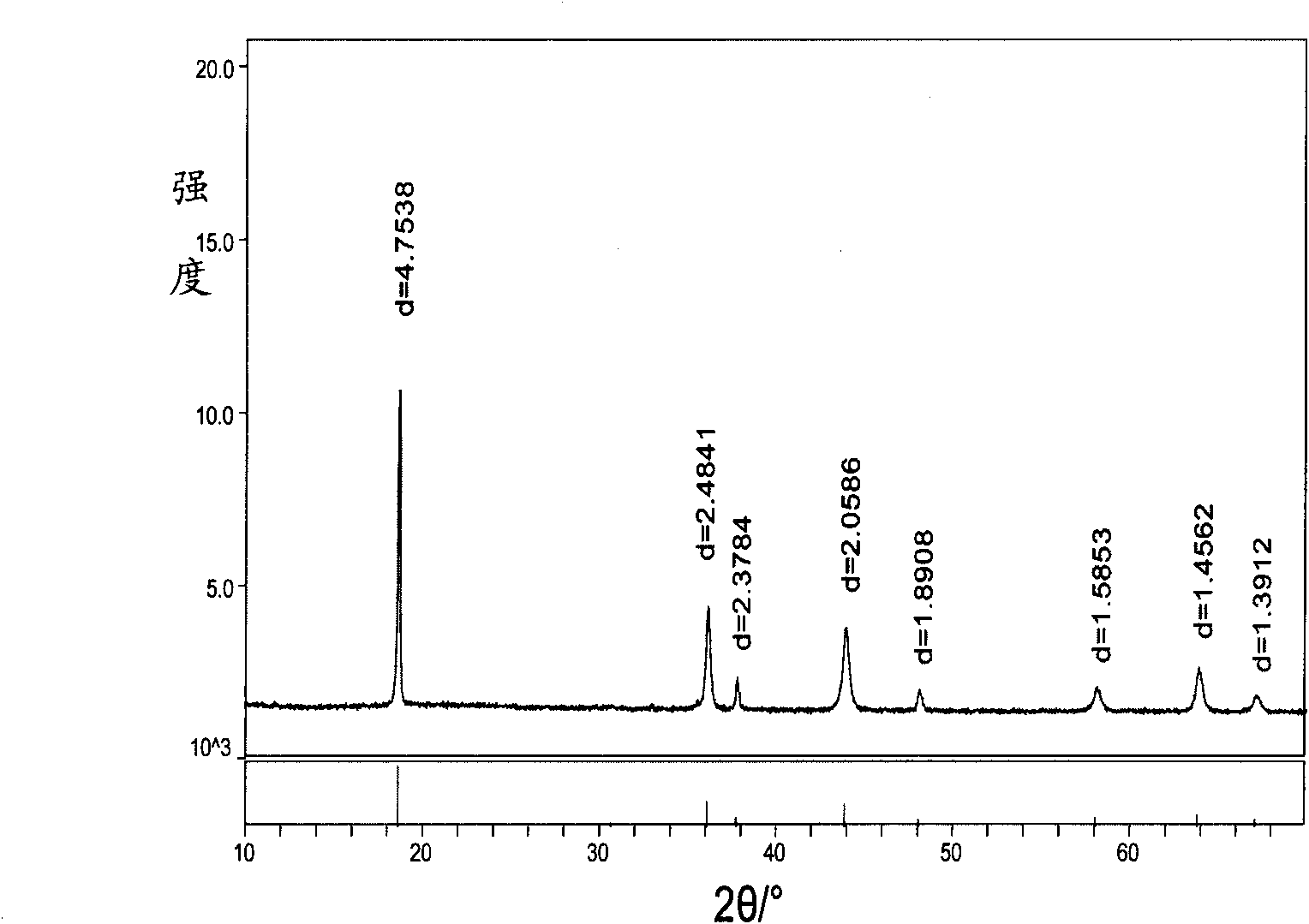

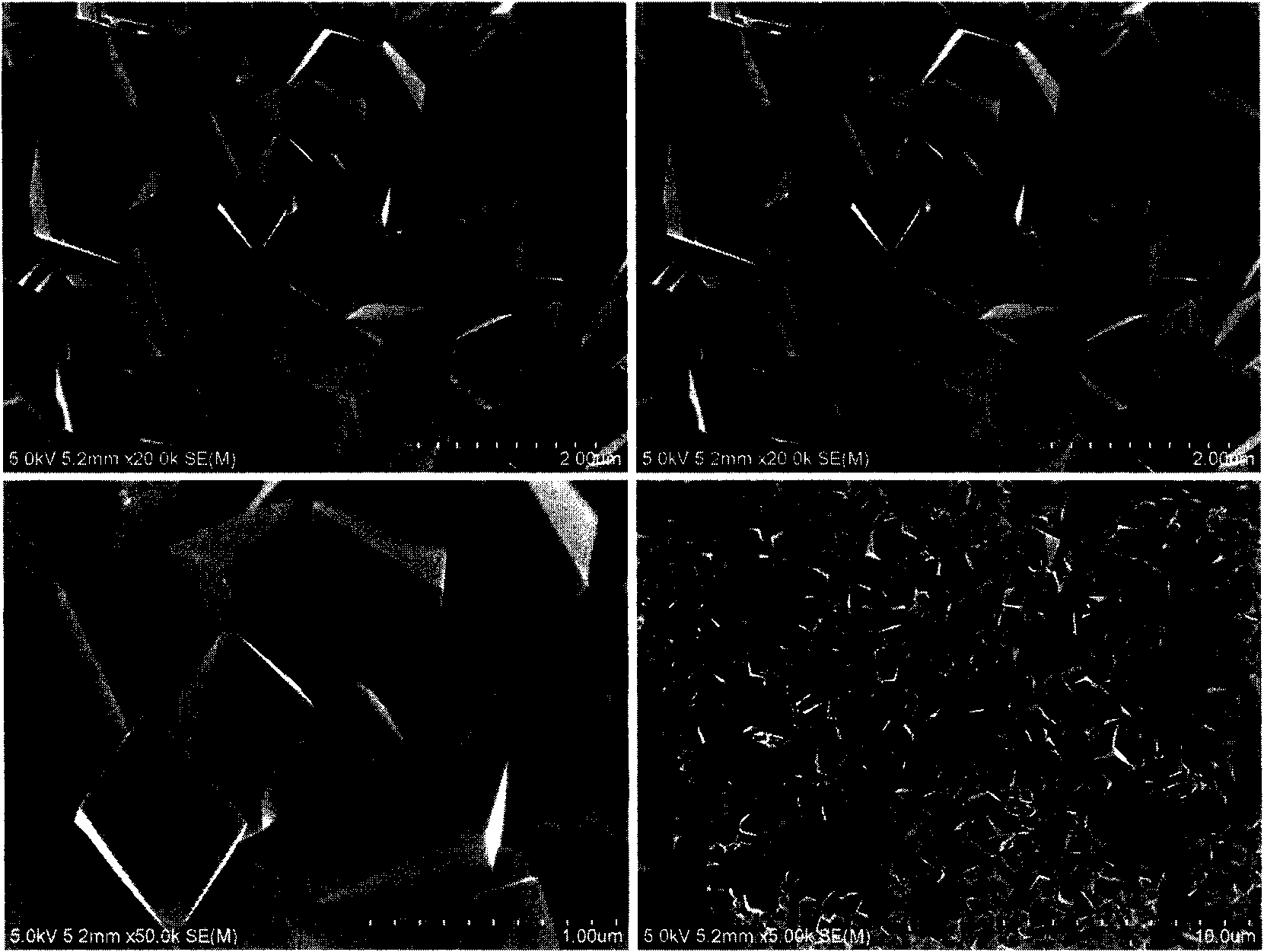

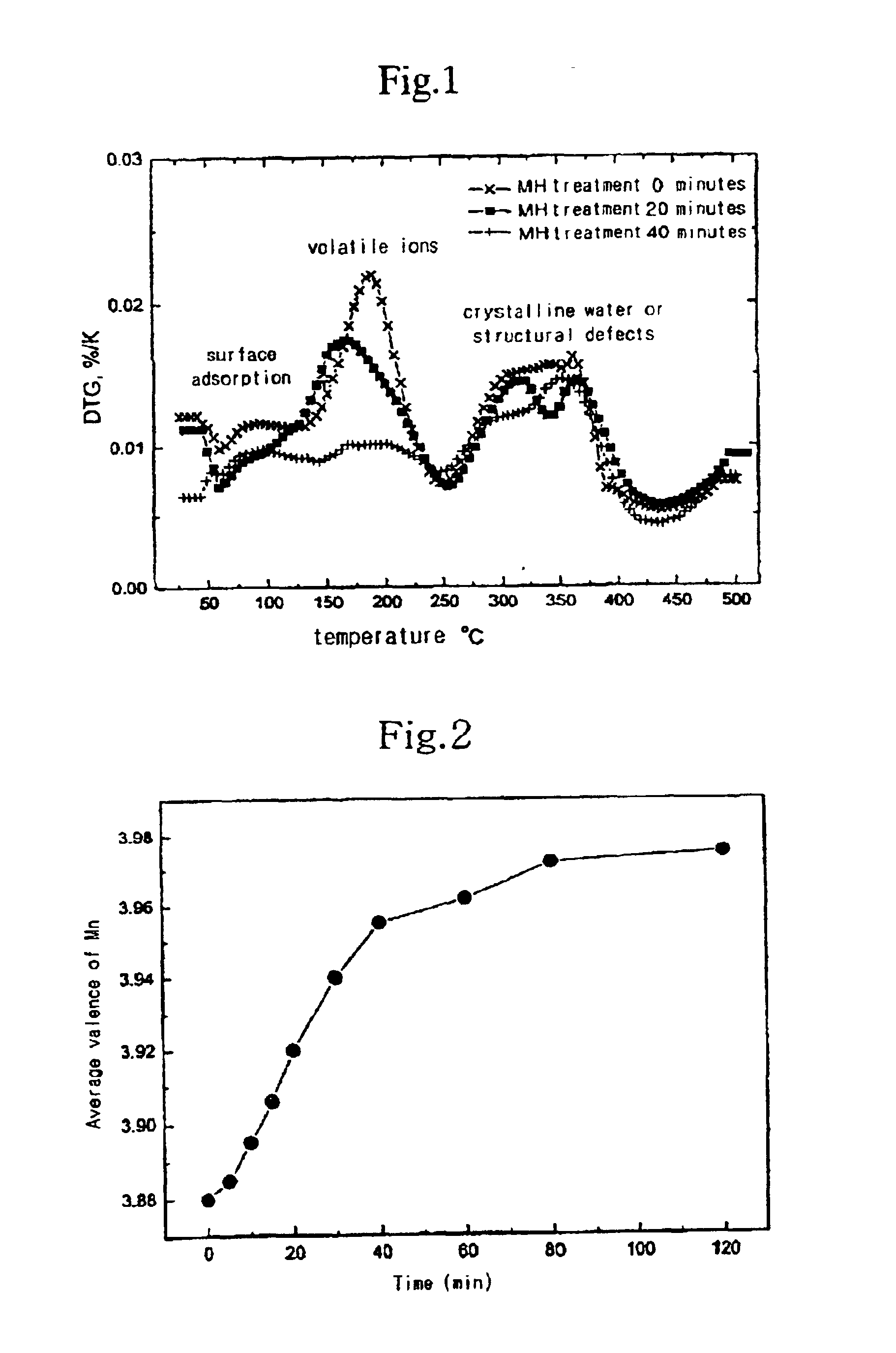

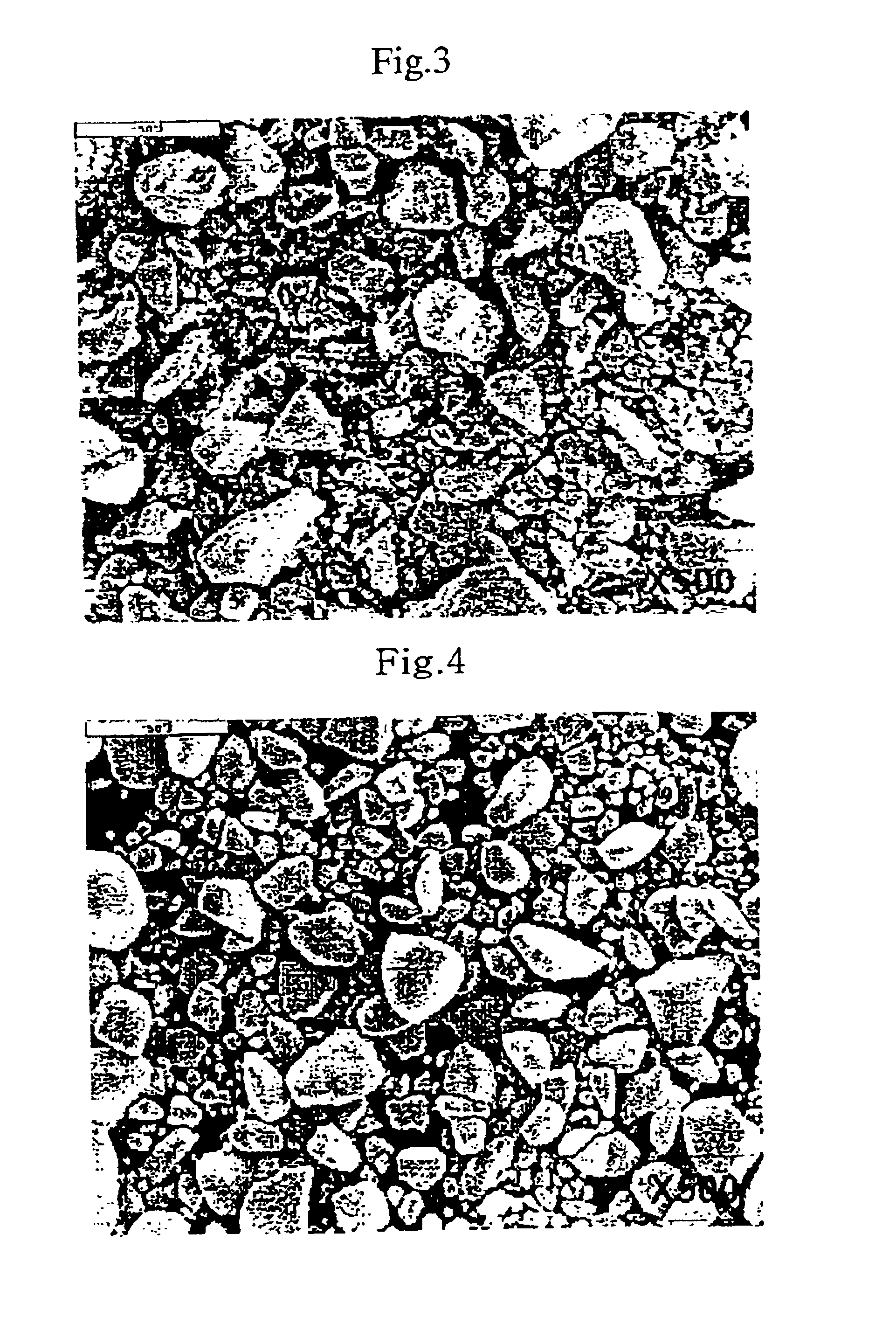

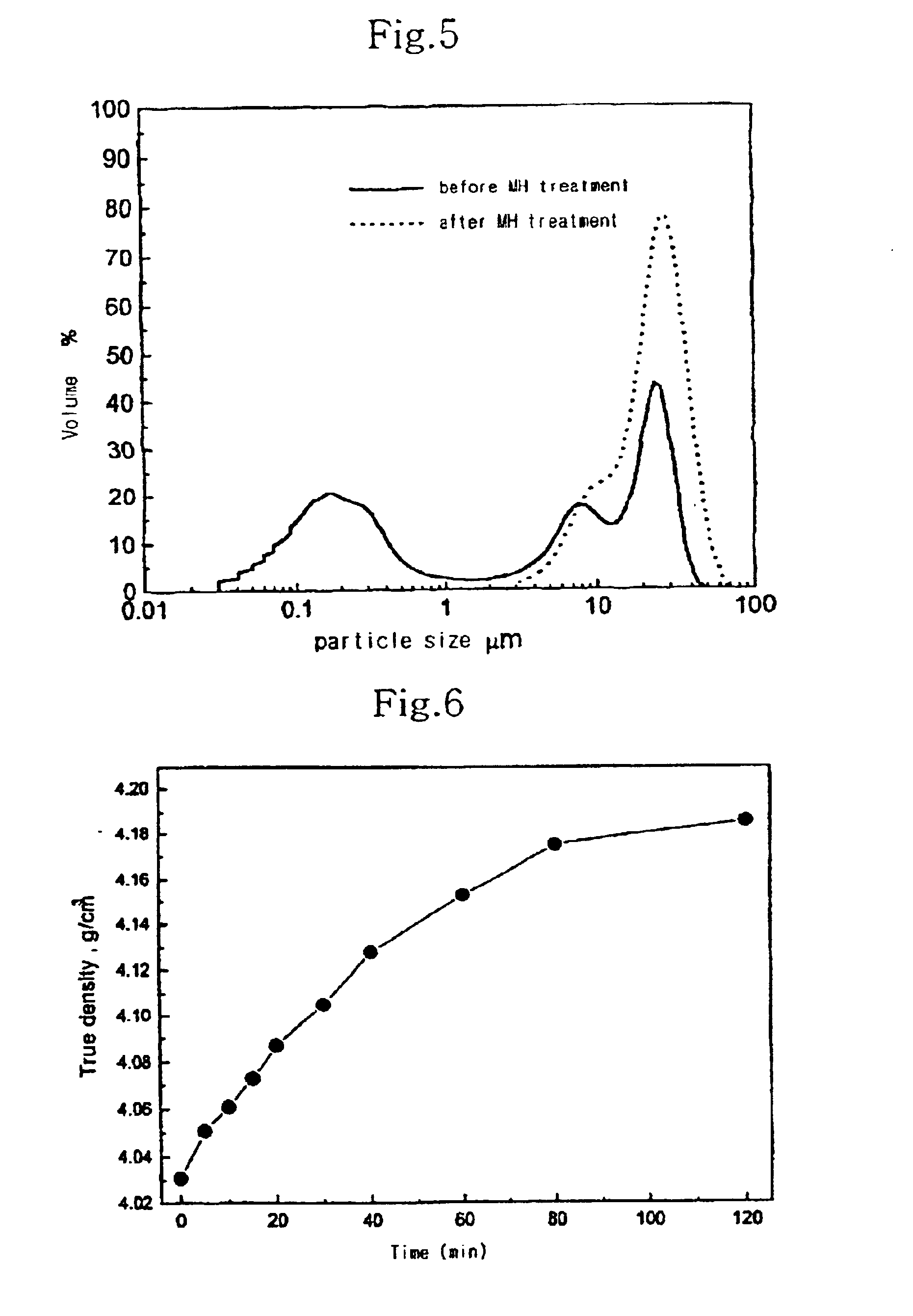

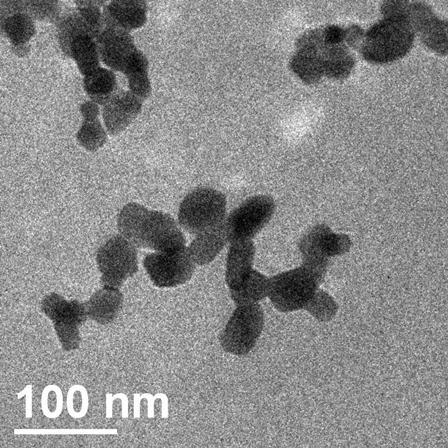

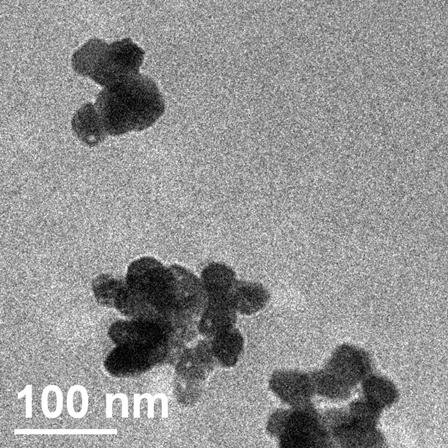

Method for preparing lithium manganese spinel oxide having improved electrochemical performance

InactiveUS20020136955A1Improve performanceGood particle shapeNon-aqueous electrolyte accumulatorsManganese oxides/hydroxidesLithiumManganese

The present invention relates to a method for preparing a lithium manganese complex oxide Li1+xMn2-xO4 (0x0.12) used as a cathode active material of a lithium or lithium ion secondary battery. The present invention provides a method for preparing a manganese compound comprising the step of simultaneously applying a mechanical force and heat energy to a manganese compound to remove defects present in particles of the manganese compound and to control the aggregation of particles and the shape of the aggregated particles, a method for preparing a lithium manganese complex oxide with a spinel structure using the manganese compound prepared by the above method as a raw material, and a lithium or lithium ion secondary battery using the lithium manganese complex oxide with a spinel structure prepared by the above method as a cathode active material. A lithium or lithium ion secondary battery using the lithium manganese complex oxide with a spinel structure prepared from the manganese compound without defects inside particles as a cathode active material has excellent charge / discharge characteristics and cyclic performance.

Owner:LG ENERGY SOLUTION LTD

Process for preparing polyurea polyol

A polyurea polyol is prepared through mixing polyether polyol, polyamine and solvent, stirring while adding aliphatic or aromatic polyisocyanate or the mixture of said polyisocyanate and polyol, reaction, and vacuum separation. Its advantages are high dispersity and good granular shape. The foam polyurethane plastics made of it has high load-bearing power and better flame-retarding nature.

Owner:SOUTH CHINA UNIV OF TECH

Blue ssuperindividual corundum and preparation method thereof

ActiveCN101906663AChemically stableNo pollution in the processPolycrystalline material growthSingle crystal growth detailsAluminium fluorideZirconium dioxide

The invention discloses a blue superindividual corundum and a preparation method thereof. The preparation method comprises the following steps of: carrying out mixing, smelting, temperature reduction solidification, blowing-in grinding, magnetic separation impurity removal, screening and secondary magnetic separation impurity removal on one ton of alumina powder, anatase titanium dioxide, titanium stone powder, aluminium fluoride and zirconium dioxide powder; and then carrying out magnetic separation by using a magnetic separator so as to obtain the blue superindividual corundum. Because iron ores are not used, the smelting process causes no smoke and odour, and the processing process of a product causes no hydrogen sulfide gas, therefore the whole production process causes no pollution to the environment; in addition, because a right amount of the zirconium dioxide is added, the zirconium dioxide and the alumina appear in a crystal combining way, therefore true specific weight and granularity are obviously increased, chemical property is more stable, strength achieves 33 N, density achieves 4.02 g / cm<3>, the content of Al2O3 contained in the blue superindividual corundum achieves more than 99.55 percent, and the content of various impurities is lower.

Owner:XIXIA ZHENGHONG MONOCRYSTALLINE CORUNDUM

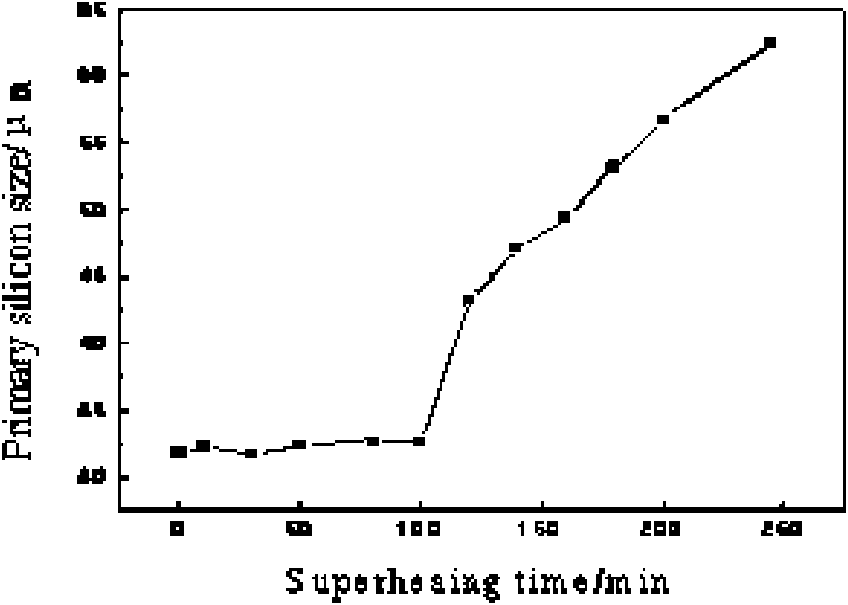

Physical-method modification process for high-silicon aluminum alloy or other alloy containing second hard brittle phase

The invention provides a physical-method modification process for high-silicon aluminum alloy or other alloy containing second hard brittle phase, which belongs to the field of metal materials, and solves the disadvantage that modification processes in the prior art are complex, difficult to control, pollution-causing, high in cost, unsuitable for large-scale industrial production and the like. The process comprises the steps of mixing two alloy melts different in components and temperature pro rata, forming another type of melt with required components and performing overheating treatment on the mixed melt to refine or modify a second coarse hard brittle phase contained by the melt. After the component-complementation melt temperature treatment process, the size of primary Si-phase grains in aluminum-silicon alloy containing Si of 20 percent can be stabilized at about 40 mu m while heat is preserved within 100 minutes. The process has the advantages of obviously improving the form, size and distribution of silicon particles and improving mechanical properties thereof, along with simple procedure, strong flexibility, environmental protection and no pollution, and can finally manufacture high-silicon aluminum alloy materials which can satisfy various uses and are excellent in comprehensive performance.

Owner:FUZHOU UNIV

Rubble production line

InactiveCN104069926AGood particle shapeReasonable gradationGrain treatmentsFineness modulusElectric control

The invention discloses a rubble production line. The rubble production line is composed of a vibration feeder, a jaw breaker, a cone breaker I, a vibration screen I, a cone breaker II, a vibration screen II, an impact breaker and an assorted belt conveyor and an electric control system, wherein the jaw breaker is used for primary breaking, the cone breaker I is used for secondary breaking, and the cone breaker II is used for the third-level breaking. According to the rubble production line provided by the invention, the particle shape is good; the gradation is reasonable, and the fineness modulus is adjustable; the indicators for the rubble product meet the national standard, and the rubble product is concrete aggregate of high quality; the production cost is low, and the benefit is good.

Owner:WUXI WEIHAIDA MACHINERY MFG

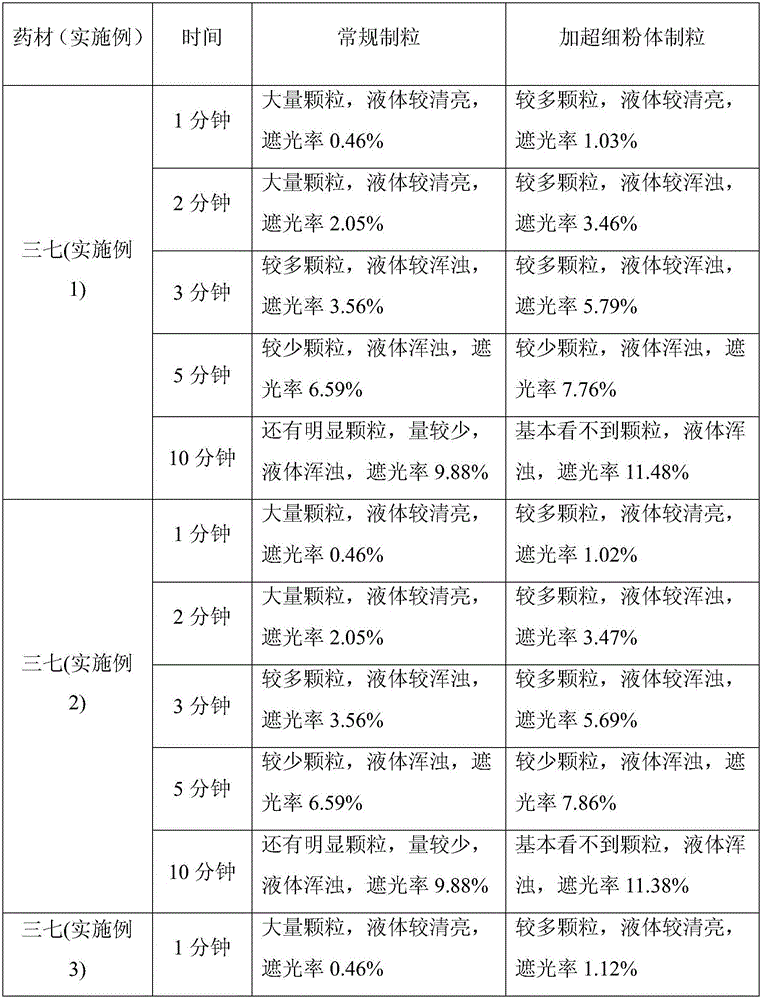

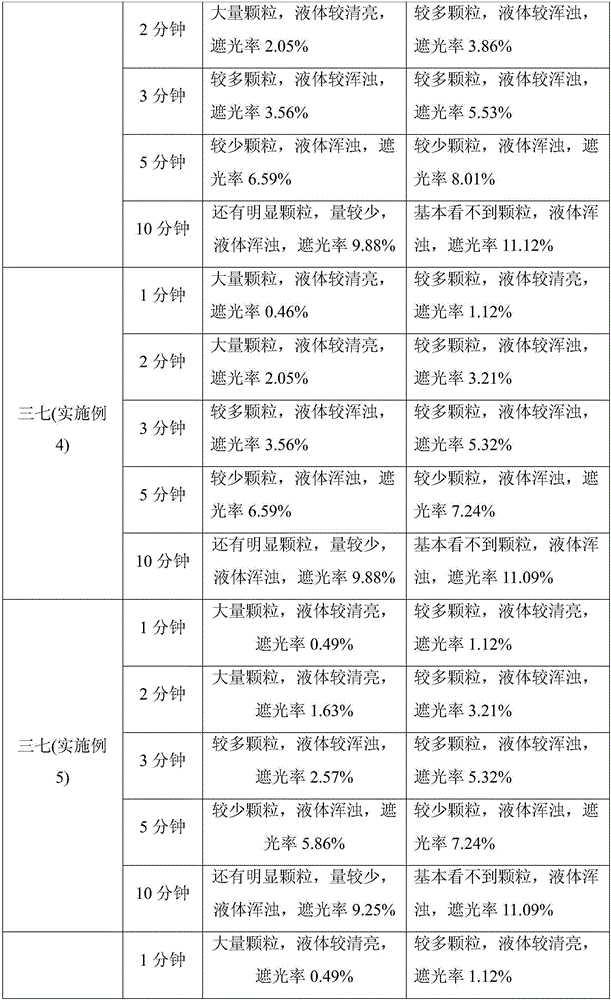

Preparation method of radix notoginseng cell-ruptured decoction piece

The invention provides a preparation method of a radix notoginseng cell-ruptured decoction piece. The preparation method comprises the steps of sorting medicinal materials, cleaning, processing, drying, breaking, smashing through a 100-mesh-sieve pulverizer, intermittent sterilizing, rupturing cells, pelleting, and drying to obtain the radix notoginseng cell-ruptured decoction piece; particles of the prepared decoction piece has better shapes and moderate tightness degree, and the prepared particles can be dried easily and dissolved quickly, and can be easily dispersed when a user take the decoction piece; through intermittent sterilizing, the decoction piece meets the requirement of a microbial limit, and solves the problems that a radix notoginseng cell-ruptured decoction piece in the current market is hard to dissolve, and the microbial limit is hard to reach the standard.

Owner:湖南盟合投资管理有限公司

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

InactiveCN101209828AGood particle shapeSmall granularityCell electrodesPhosphorus compoundsFerrous iron compoundLithium iron phosphate

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in anode of lithium-ion secondary batteries. The method comprises that a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered, cooled to obtain sintering product; wherein, the iron compound comprises ferrous iron compound and ironic phosphate; the sintering method is one-time sintering which is carried out at constant temperature in inert atmosphere or reducing atmosphere. The lithium iron phosphate acquired by the method of the invention has good appearance, small grain size and big tap density, and batteries made of the lithium iron phosphate have high capacity and good cycling performance.

Owner:BYD CO LTD

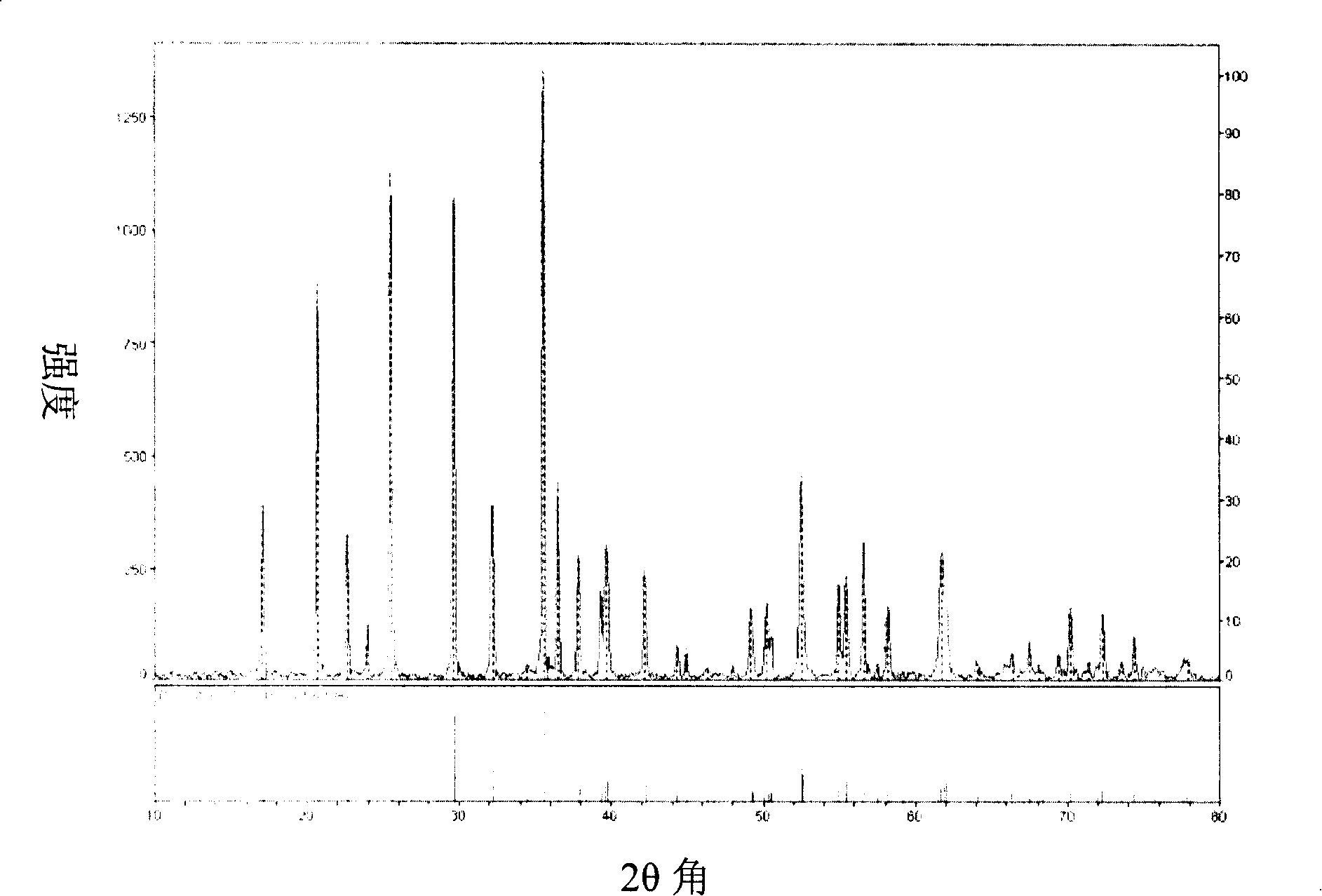

Processing device of ultramicro-tea powder

InactiveCN107912545AOnline work is uniqueFeed size is largePre-extraction tea treatmentCycloneFluidized bed

The invention relates to a processing device for tea powder. A processing device for ultrafine tea powder, which includes sequentially connected compressed air power source and oil-water separator, gas storage tank, primary filter, gas dryer, precision filter and sterilizing filter, material bin, fluidized bed Jet Mill, Cyclone Collector, Bag Collector and High Pressure Induced Fan. The device integrates crushing, grading, mixing and homogenizing, and realizes the unique advantages of on-line operation.

Owner:宁波市纯韩花漫生物科技有限公司

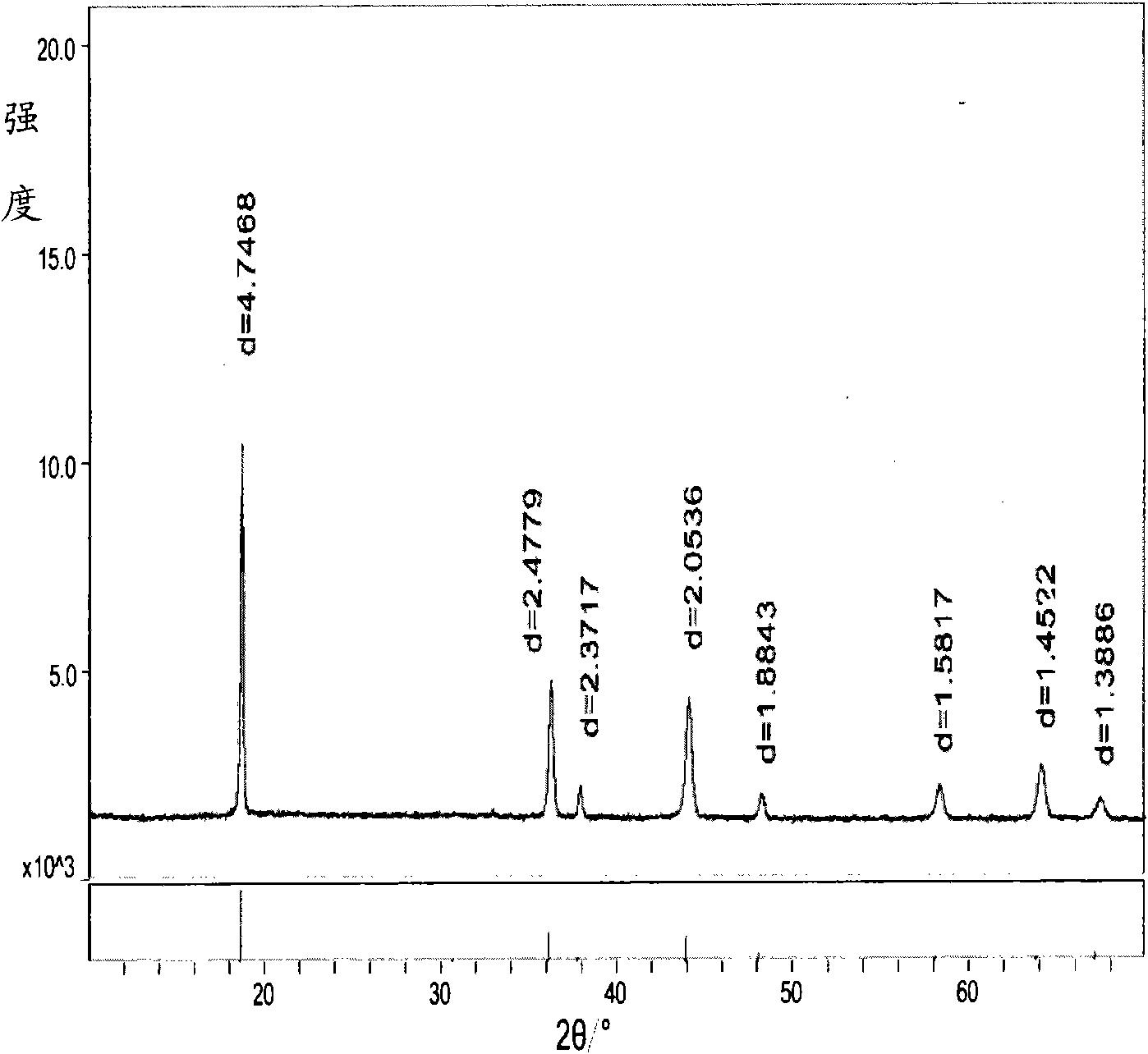

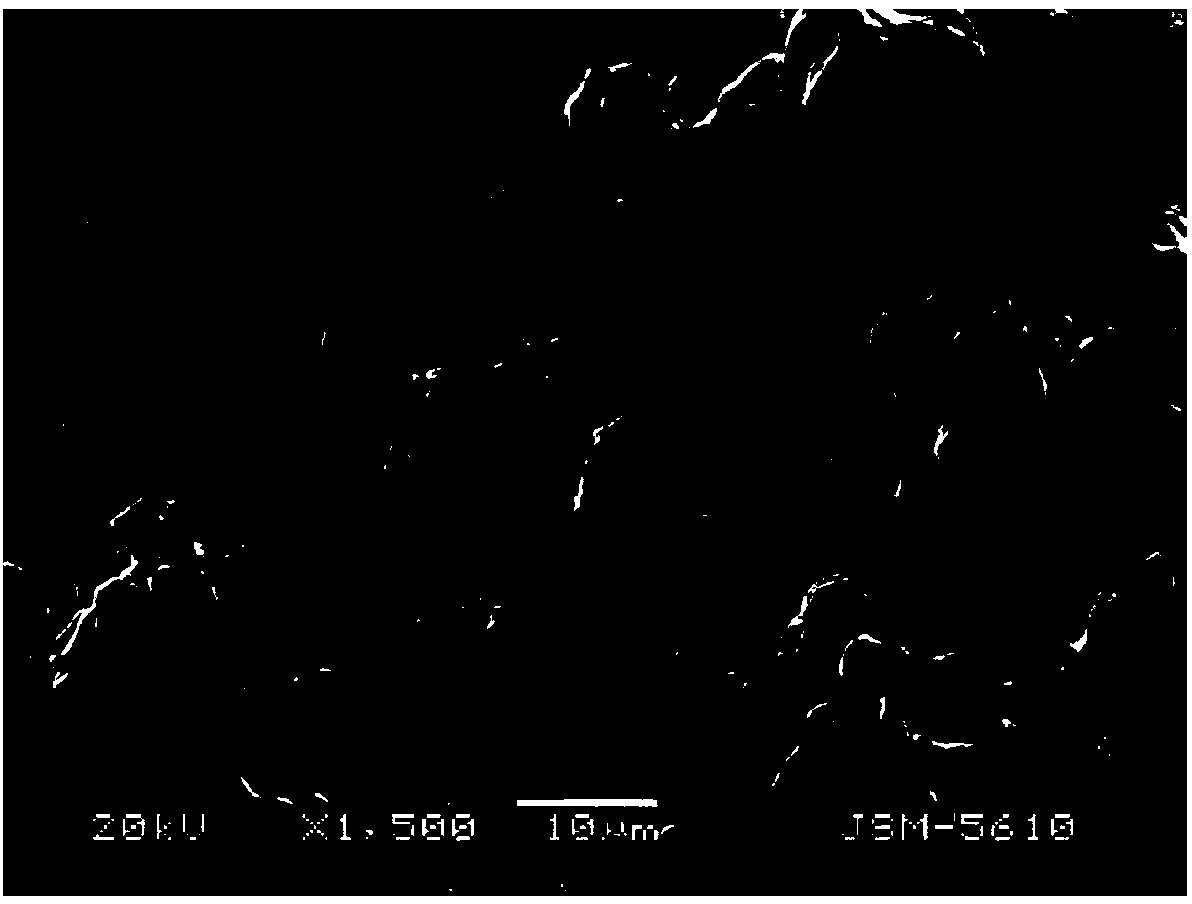

Preparation method of spinel type lithium manganate

The invention discloses a preparation method of spinel type lithium manganate, comprising the following steps of: leading lithium salt and manganese salt to be loaded on the surface of carbon particles; and roasting the carbon particles loaded with lithium salts and manganese salts. Compared with the solid-phase reaction method in the prior art, the preparation method adopts carbon particles as reacting carriers, thus greatly shortening reaction time and reducing reaction temperature; and the result shows that the spinel type lithium manganate crystal with high purity and good particle appearance is prepared.

Owner:BEIJING NORMAL UNIVERSITY +1

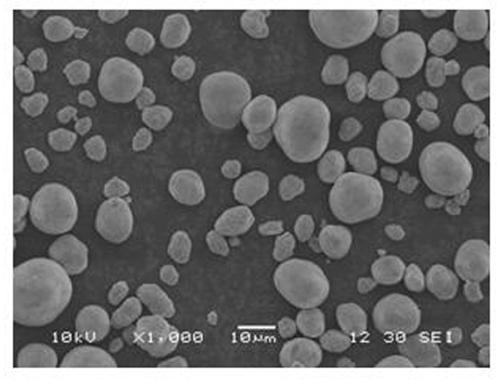

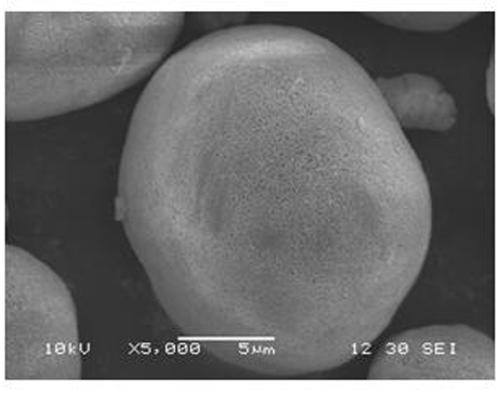

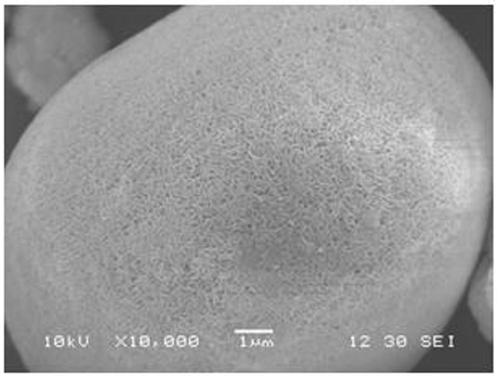

High-voltage tantalum powder and preparation method thereof

ActiveCN104209511AGood particle shapeImproved Leakage Current PerformanceElectrolytic capacitorsCapacitorParticle-size distribution

The invention belongs to the field of preparation of capacitor-level high-voltage tantalum powder and particularly relates to high-voltage tantalum powder and a preparation method thereof. The tantalum powder provided by the invention is spherical or ball-like tantalum powder, is round in corner angle, uniform in particle size distribution, relatively small in leakage current and high in breakdown voltage, and can be applied under a relatively high voltage.

Owner:NINGXIA ORIENT TANTALUM IND +1

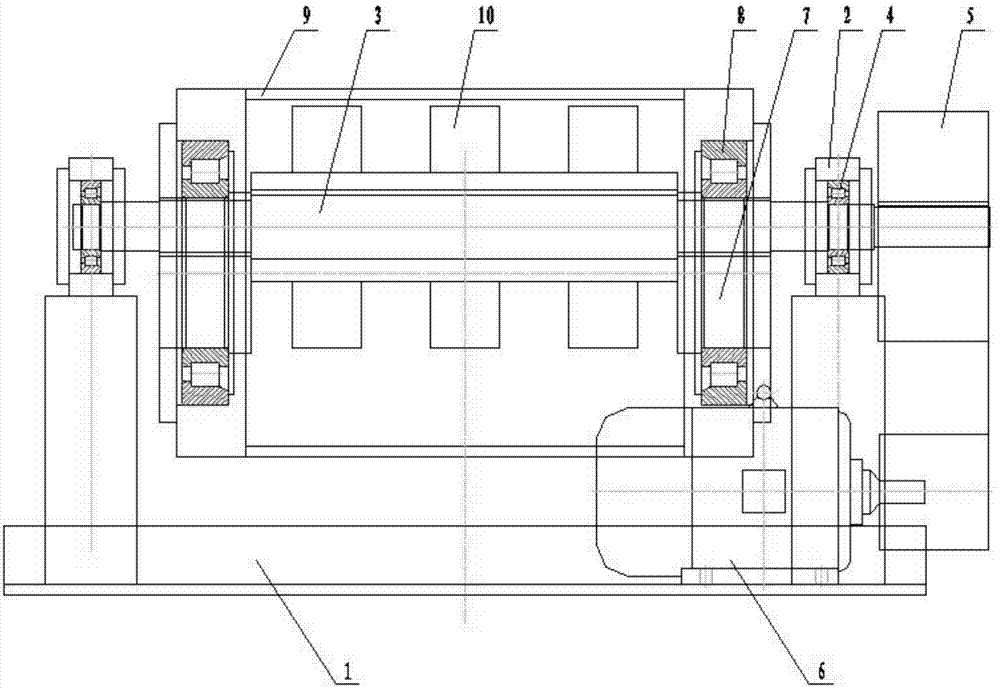

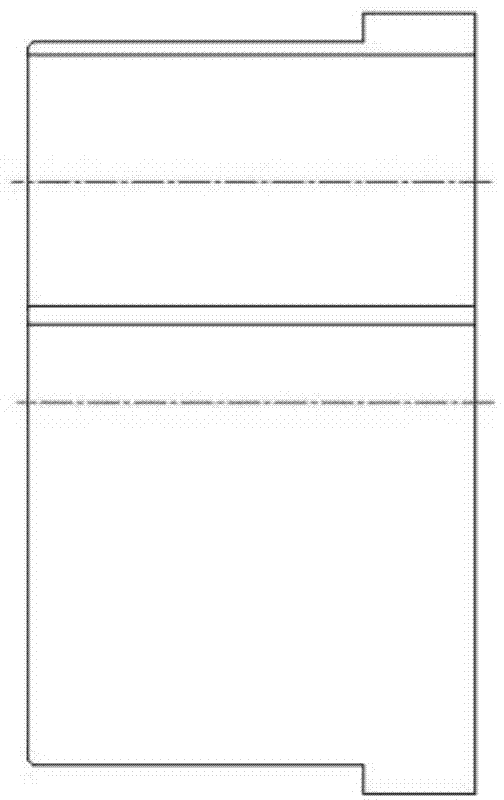

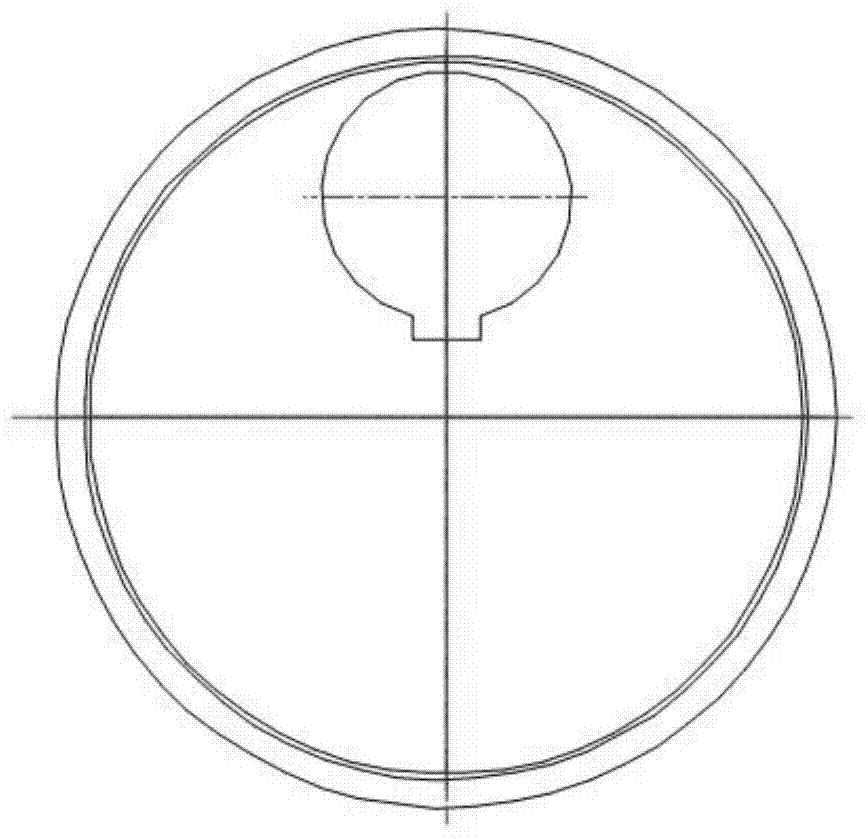

Eccentric stirring ball mill

InactiveCN104772193AImprove grinding effectSmall grinding effectRotating receptacle mixersTransportation and packagingBall millElectric motor

The invention belongs to the technical field of milling equipment and particularly relates to an eccentric stirring ball mill. The ball mill comprises a rack, wherein first bearing holders are symmetrically arranged on brackets at two ends of the rack in the horizontal direction, a main shaft is arranged in first bearings in the two first bearing holders; one end of the main shaft extends out of one first bearing holder and is driven to rotate through a belt wheel; the belt wheel is connected with a motor; a cylinder body is arranged on the main shaft through a pair of eccentric blocks and second bearings; the main shaft is fixedly connected into the eccentric blocks; the axis of the main shaft is in parallel to but not overlapped with the central lines of the eccentric blocks; the eccentric blocks are fixedly connected onto the inner rings of the second bearings; the second bearings are arranged at two ends of the cylinder body; the central line of the cylinder body is overlapped with those of the eccentric blocks; a stirrer is fixedly connected onto the part, in the cylinder body, of the main shaft. The size and weight of the eccentric stirring ball mill are reduced, and the manufacturing and mounting costs are greatly lowered; product grains produced by the ball mill are good in shape and strong in adaptability; the speed and efficiency are high and the energy saving effect is remarkable.

Owner:胡光耀

High-speed airflow multi-stage ultra-thin powder mill

The invention relates to a kind of ultramicro fine-powder mechanical grinding apparatus, which contains motive power driving mechanism, grinding cave, recovery device of fine powder and so on. There is a turbulence disc set in the main shaft of the grinding cave in the same shaft, which is composed with rim plate and same rotating direct blade in both sides of the rim plate, and there is a wear-prevention air cushion in both sides of the turbulence disc blade. There is a rotator settled in the outset of the lay making in the grinding cave, and above the rotator there is an atmospheric pressure screen. The invention has low energy consumption, high productive output, fine product fineness, little wastage, great effective grinding function, and long service life.

Owner:任良勇

Preparation method for carbon cathode material of lithium ion battery

InactiveCN103346326ARaise the ratioImprove electrical performanceCell electrodesOrganosolvCarbolineum

The invention provides a preparation method for a carbon cathode material of a lithium ion battery. The method comprises the following steps of: performing polyreaction on petroleum asphalt or coal pitch used as a raw material at the temperature of 400-460 DEG C; at the later stage of reaction, sampling and observing by use of a polarizing microscope; when the system interphase content reaches 20-80%, terminating the reaction; cooling and then smashing so as to obtain a raw material A; preparing a raw material B from powdered carbon, natural graphite powder, artificial graphite powder or a mixture thereof, wherein the average grain diameter of any of the powdered carbon, the natural graphite powder and the artificial graphite powder is 10-25 mu m; preparing a raw material C from organic solvents such as heavy oil, absorber oil and anthracene oil; mixing the raw material A, the raw material B and the raw material C at a temperature of 150-200 DEG C according to the condition that A / B is equal to (5-70) / (30-95) or (A+B) / C is equal to (20-70) / (30-80); then performing thermal treatment at a temperature of 400-600 DEG C while stirring; and finally performing carbonizing treatment and graphitization treatment. The carbon cathode material prepared by the preparation method provided by the invention has the advantages of high capacity and long cycle life.

Owner:大连宏光锂业有限责任公司

Production method for blue SA (single alundum)

ActiveCN101748486AGood particle shapeImprove grinding abilityPolycrystalline material growthSingle crystal growth detailsSingle crystalProduct processing

The invention discloses a production method for blue SA (single alundum). The production method includes the following steps of: a. material mixing; b. smelting; c. temperature reduction and solidification; d. blowing-in and crushing, e. magnetic separation and impurities removing; f. screening; g. secondary magnetic separation and impurities removing. As the blue SA which is produced by the production method does not use iron ores, no smoke and smell are caused in the smelting process, no hydrogen sulphide gas is generated during the product processing, no pollution is caused to the atmosphere, no sewage is discharged, and no pollution is caused to the environment in the whole production process. The number of monocrystals produced during the later period is up to 95%, which is 50% higher than the original number of the monocrystals (the monocrystals of the original SA accounts for 65% or so); the intensity exceeds 26N; and the toughness is up to 90.5%, which is 25% higher than that of the original SA.

Owner:西峡县正弘单晶刚玉有限公司

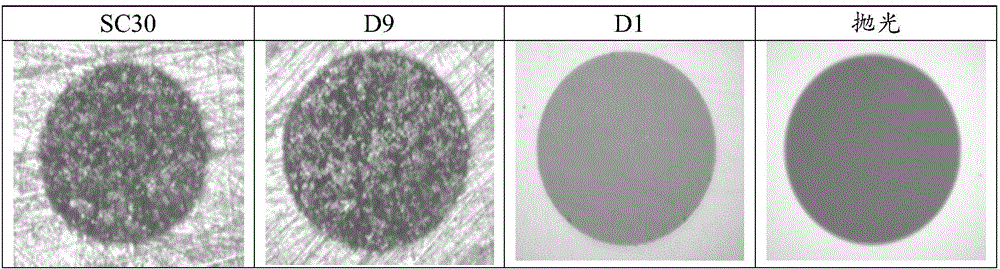

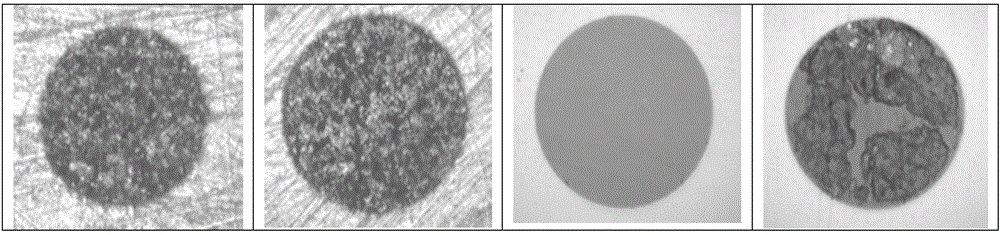

Method for preparing lithium manganese spinel oxide having improved electrochemical performance

InactiveUS6929788B2Easy to shapeImprove performanceNon-aqueous electrolyte accumulatorsManganese oxides/hydroxidesElectrical batteryManganese

The present invention relates to a method for preparing a lithium manganese complex oxide Li1+xMn2−xO4 (0≦x≦0.12) used as a cathode active material of a lithium or lithium ion secondary battery.The present invention provides a method for preparing a manganese compound comprising the step of simultaneously applying a mechanical force and heat energy to a manganese compound to remove defects present in particles of the manganese compound and to control the aggregation of particles and the shape of the aggregated particles, a method for preparing a lithium manganese complex oxide with a spinel structure using the manganese compound prepared by the above method as a raw material, and a lithium or lithium ion secondary battery using the lithium manganese complex oxide with a spinel structure prepared by the above method as a cathode active material.A lithium or lithium ion secondary battery using the lithium manganese complex oxide with a spinel structure prepared from the manganese compound without defects inside particles as a cathode active material has excellent charge / discharge characteristics and cyclic performance.

Owner:LG ENERGY SOLUTION LTD

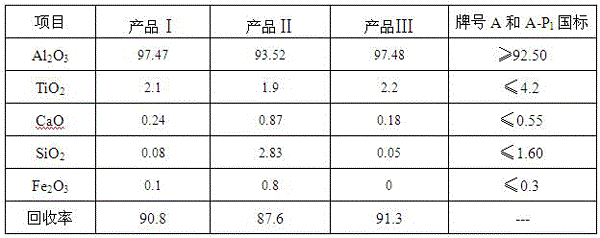

Method of melting aluminum ash to prepare brown aluminum oxide

InactiveCN106747301AAchieving processing powerImplement resourcesCeramic materials productionClaywaresCoesiteHigh-temperature corrosion

The invention discloses a method of melting aluminum ash to prepare brown aluminum oxide. At first, aluminum ash is subjected to an acidification treatment and an alkalization treatment in sequence; then solid-liquid separation is performed to obtain aluminum ash; the obtained aluminum ash is subjected to drying dehydration and high temperature burning; after the aluminum ash is cooled, the aluminum ash is mixed with iron chips and coke, and finally the mixture is sintered to obtain brown aluminum oxide. In the melting step, burned aluminum ash, iron chips, and coke are mixed according to a ratio of 100:3-4:8-13, the mixture is melted for 2 to 3 hours at a high temperature of 2300 to 2700 DEG C, and finally the mixture is ground and graded to obtain the brown aluminum oxide. The aluminum ash is subjected to a harmless treatment and converted into valuable resources. The problem of shortage of high aluminum bauxite is solved, and the production cost of brown aluminum oxide is also reduced.

Owner:HENAN UNIV OF SCI & TECH

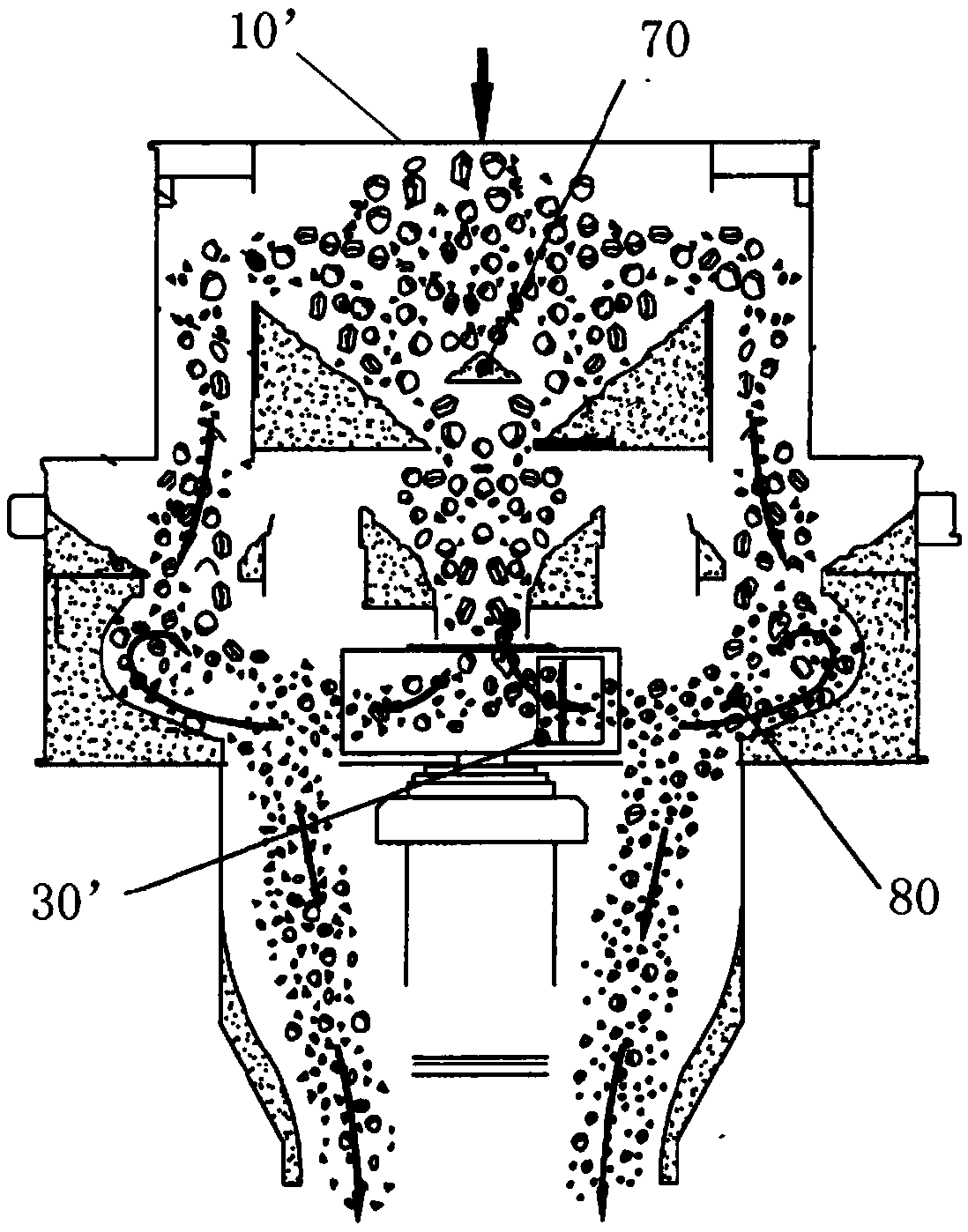

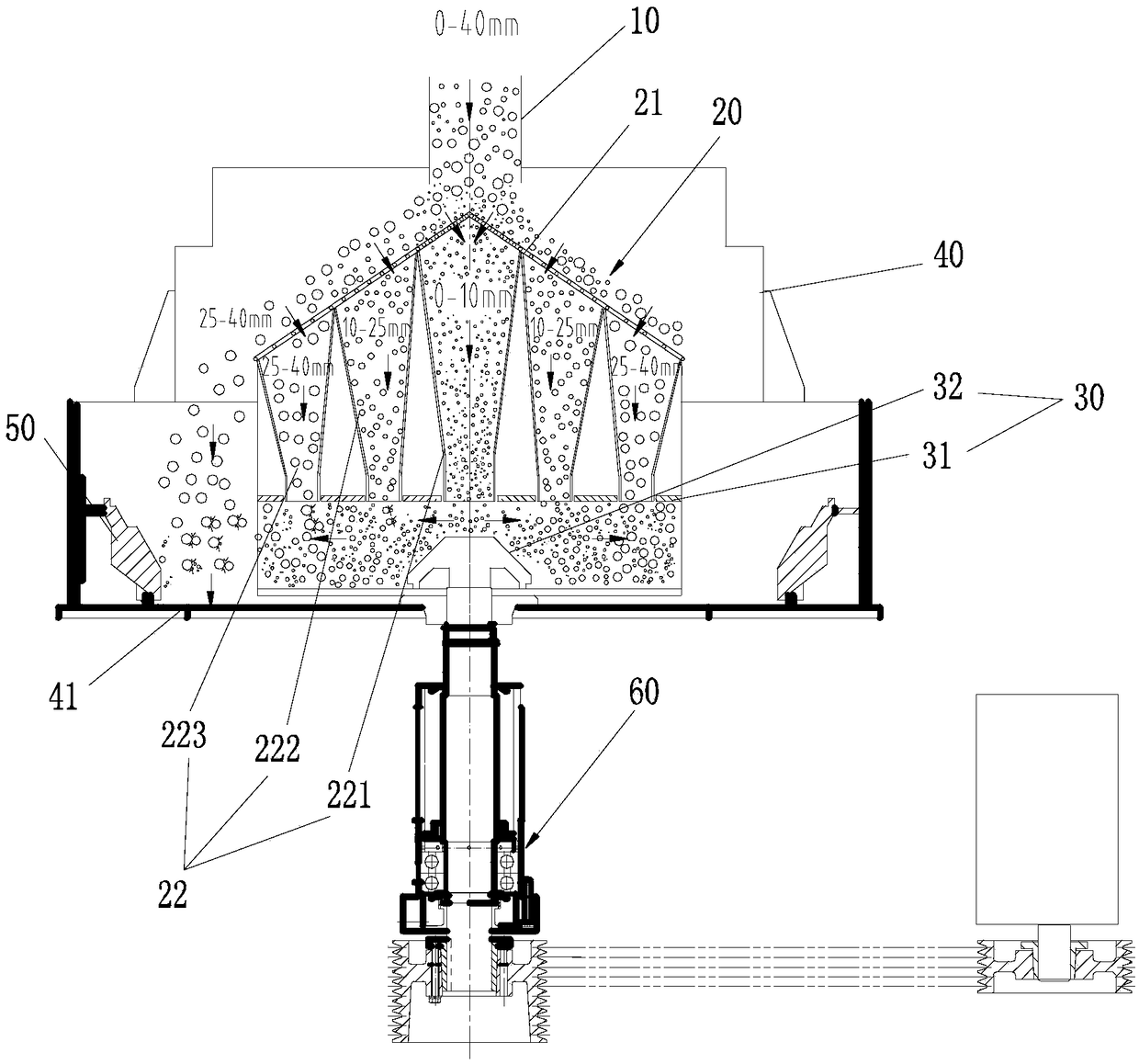

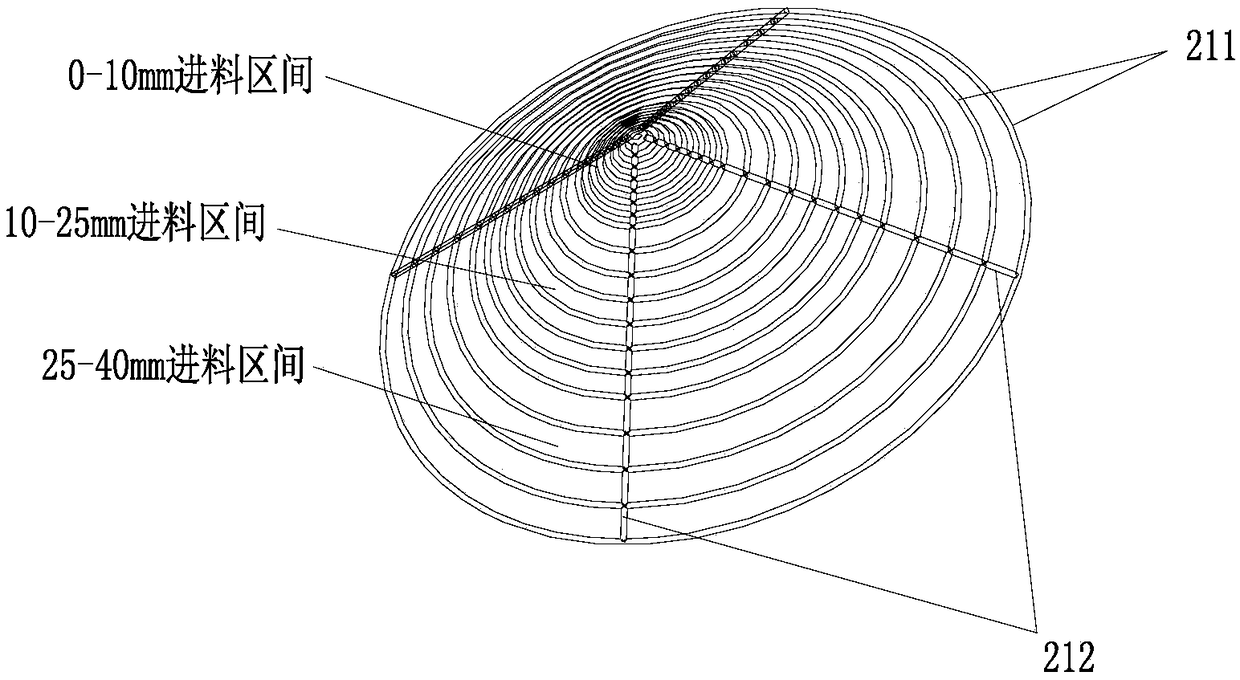

Sand making machine

The invention relates to the field of engineering construction, and discloses a sand making machine. The sand making machine comprises a feeding inlet (10), a dividing section (20) and an impeller section (30). The feeding inlet is used for downward feeding. The dividing section comprises a dividing part (21) and a plurality of feeding cavities (22), the dividing part is arranged below the feedinginlet and used for dividing materials entering from the feeding inlet into multiple groups according to the particle size and introducing into the inlets of the feeding cavities correspondingly, theoutlets of the feeding cavities extend to the different radial positions of the impeller section correspondingly, and the particle size of the materials in the feeding cavity, away from the center ofthe impeller section, of the outlet is larger than that in the feeding cavity, close to the center of the impeller section, of the outlet. According to the sand making machine, the materials with different particle sizes can be correspondingly accelerated to just the speed needed to be crushed, and thus the working efficiency and final crushing effect of the impeller section are improved.

Owner:ZOOMLION HEAVY IND CO LTD

Preparation method of nanometer lutecium oxide with large specific surface area

InactiveCN109019655AUniform particle sizeGood dispersionRare earth metal oxides/hydroxidesImpurityNanotechnology

The invention relates to a preparation method of nanometer lutecium oxide with large specific surface area. According to the present invention, the lutecium oxide prepared by using the method has theparticle size of 30-50 nm and the specific surface area of more than 30 m<2> / g, and further has characteristics of less impurities, uniform particle size, large specific surface and good dispersion.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

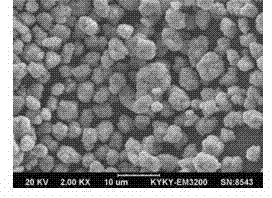

High-density doped trimanganese tetroxide and preparation method thereof

ActiveCN103050680AGood doping uniformityGood particle shapeCell electrodesManganates/permanganatesHigh densityRare earth

The invention discloses high-density doped trimanganese tetroxide. The chemical formula of the high-density doped trimanganese tetroxide is Mn3O4*zMxOy, wherein z is within the range of 0.01-0.3; and MxOy is one or several of MgO, Ni2O5, Co3O4, Cr2O3, Al2O3, ZrO2, V2O5 and TiO2, or rare earth oxide. The physical indexes of the high-density doped trimanganese tetroxide are as follows: D50 (particle size) is within the range of 3-25 microns; the tap density is within the range of 2.1-2.6 g / cm3; BET is within the range of 1 to 4 m<2> / g; and the particle morphology is a spherical shape. The invention further discloses a preparation method for the trimanganese tetroxide; the method enables manganese to be continuously agglomerated with doped oxide in the process of being converted to the trimanganese tetroxide; and the growth direction and the growth speed of agglomerates are controlled by using the pH value, the reaction temperature and the adding quantity of ammonium salt catalyst to obtain the doped trimanganese tetroxide with good doping uniformity, good particle morphology and high density.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

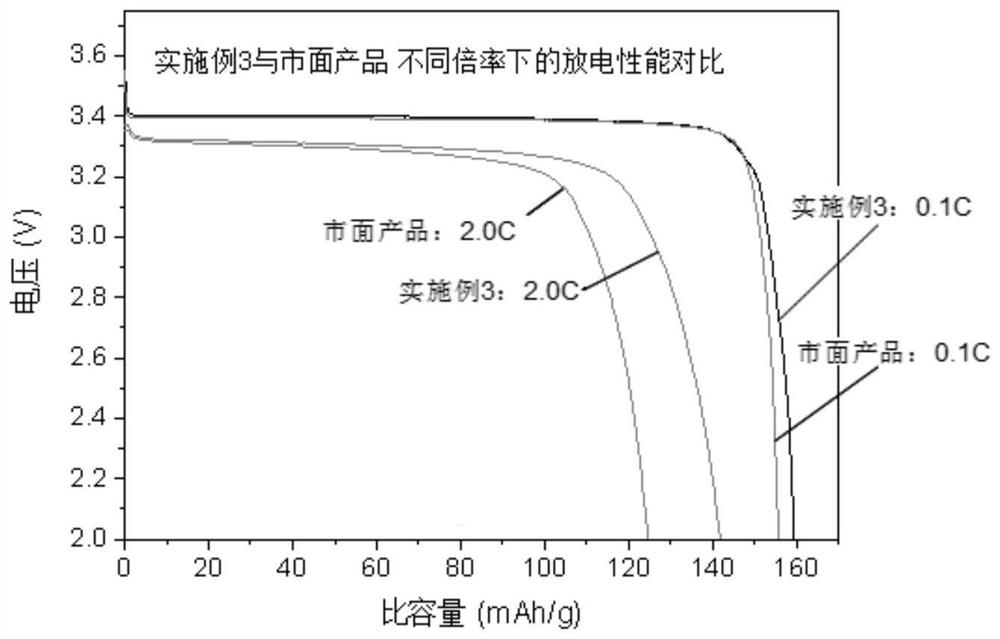

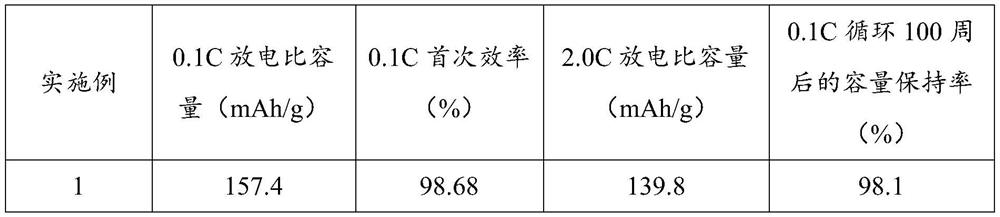

Preparation method and application of lithium iron phosphate positive electrode material

ActiveCN112897491AGood product performanceSimple preparation processSecondary cellsPositive electrodesCarbon coatingCarbon source

The invention belongs to the technical field of lithium ion battery material preparation, and provides a preparation method and application of a lithium iron phosphate positive electrode material, and the preparation method comprises the following steps: (1) mixing and refining an iron source, a phosphorus source, a lithium source, a carbon source and an additive by a dry method to obtain a mixed material; (2) sintering the mixed material for the first time, and then crushing to obtain a crushed material; and (3) sintering the crushed material for the second time, introducing a gasifiable organic carbon source during sintering, and then cooling to obtain the lithium iron phosphate positive electrode material. According to the invention, high-efficiency mixing equipment is used for carrying out one-step mixing refining, sintering and crushing on the raw materials, then secondary sintering is carried out, and a gasifiable organic carbon source is used for supplementing carbon coating, so that the material has better carbon coating layer and particle morphology, the obtained product has better performance, the performance is greatly improved compared with the same type of products on the market, the cycling stability is good, and the general requirements of high-performance lithium iron phosphate batteries can be met.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com