Patents

Literature

50results about How to "Polymerization reaction temperature is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

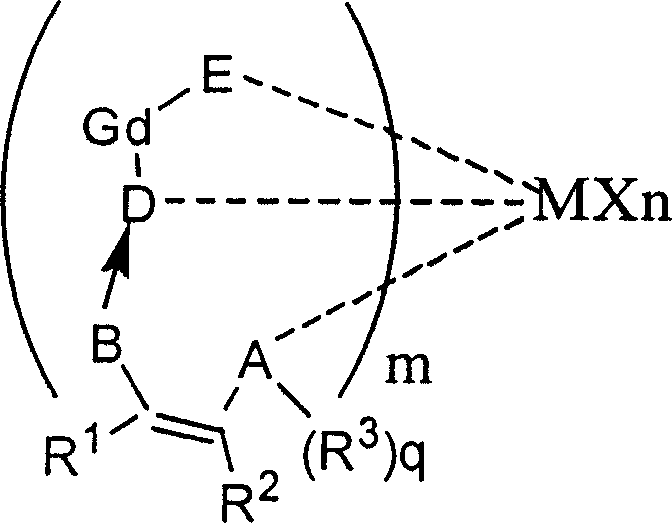

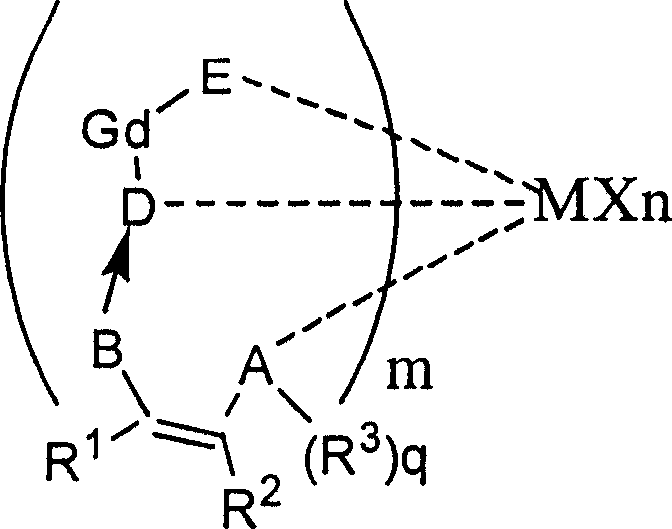

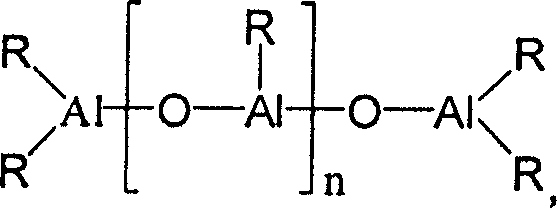

Loaded method of load type Non-metallocene catalyst-and polymerizing application

A carrying process for the carried non-metallocene catalyst includes activating the porous carrier, washing, filtering, drying and directly carrying the nno-metallocene catalyst used for olefine polymerization. Said catalyst can be used for the slurry-type or gas-phase homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

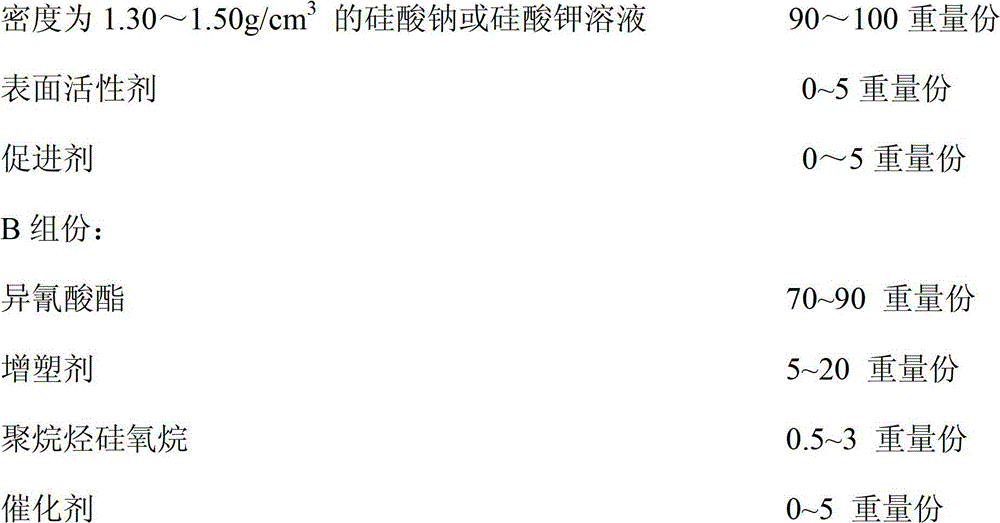

Chemical grouting material for reinforcing loose and broken bedrock

The invention relates to a chemical grouting material for reinforcing loose and broken bedrock. The invention provides a chemical grouting material for reinforcing the loose and broken bedrock, in order to improve the flash point, the burning point and the antistatic performance of the grouting material, reducing the temperature in polymerization reaction and lowering the cost. According to the technical scheme provided by the invention, the chemical grouting material for reinforcing the loose and broken bedrock comprises two components, including a component A and a component B; according to the formulas of the raw materials, the component A comprises 90 to 100 parts by weight of sodium silicate or potassium metasilicate solution, 0 to 5 parts by weight of surface active agent, and 0 to 5 parts by weight of accelerator; the component B comprises 70 to 90 parts by weight of isocyanate, 5 to 20 parts by weight of plasticizer, 0.5 to 3 parts by weight of polyalkane silicone, and 0 to 5 parts by weight of catalyst; the components A and B are uniformly mixed respectively; and in use, the components A and B are mixed according to the volume ratio of 1: 1. The chemical grouting material can be applied to quickly reinforcing the broken coal bed and rock bed and blocking water leakage.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

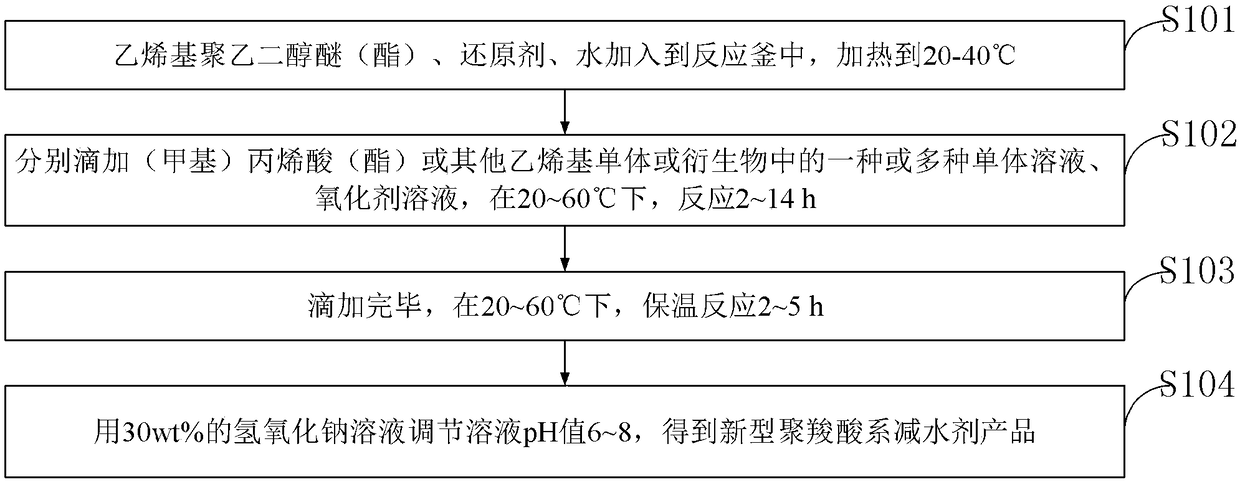

Preparation method for polycarboxylate high-performance water reducer

Provided is a preparation method for a polycarboxylate high-performance water reducer. The water reducer is prepared by copolymerization reaction of macromolecule monomer methoxy polyethylene glycol mono(meth) acrylate ester, small molecule monomer (meth)acrylic acid and sodium styrene sulfonate in an aqueous solution under the protection of inert gas and the action of a redox initiation system and a chain transferring agent. According to the invention, a high-activity redox initiation system is employed, which enhances the polymerization rate, reduces polymerization temperature, shortens reaction time, ensures non-hydrolysis of macro-molecular polyester monomers in the process of polymerization and a high conversion rate of raw materials, and guarantees that polymers have long side chains arraying at uniform intervals and an ideal comb shaped molecular structure. The water reducer prepared in the invention has the characteristics of a high water-reducing rate, a small slump loss and the like, and enables concrete with the water reducer to have high strength; simultaneously, the copolymerization reaction is carried out in water in the method, and therefore the method has the characteristics of simple preparation technology, environmental protection, low cost, etc.

Owner:江苏天音化工有限公司 +1

Low-temperature synthesis polycarboxylate superplasticizer and preparation method thereof

The invention discloses a low-temperature synthesis polycarboxylate superplasticizer and a preparation method thereof. The low-temperature synthesis polycarboxylate superplasticizer comprises 150-250 parts by weight of unsaturated polyether, 2-30 parts by weight of unsaturated hydroxyl ester, 1-2 parts by weight of vinyl ether, 10-30 parts by weight of acyclic acid, 2-10 parts by weight of potassium hydroxide solution with the mass concentration of 30-35%, 0.5-2 parts by weight of chain transfer agent, 0.2-0.8 part by weight of low-temperature reducing agent, 0.1-0.5 part by weight of sodium sulfoxylate formaldehyde, 0.1-0.5 part by weight of ascorbic acid, 1-5 parts by weight of hydrogen dioxide solution with the mass concentration of 30-35%, 0.01-0.1 part by weight of ferrous sulfate, 12-20 parts by weight of sodium hydroxide solution with the mass concentration of 30-35% and 240-340 parts by weight of deionized water. The polycarboxylate superplasticizer can well adapt to a novel polyether raw material and is good in dispersibility and dispersibility keeping capability.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Preparation method of heat curing fluorosilicone raw rubber

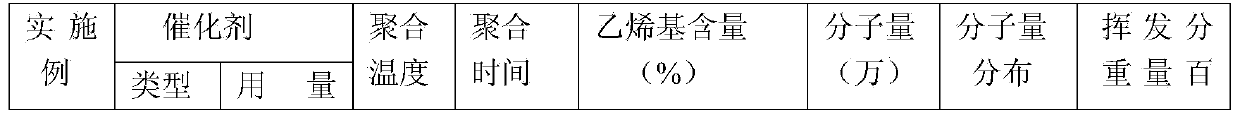

The invention relates to a preparation method of heat curing fluorosilicone raw rubber. The preparation method comprises the following steps: adding D3F and D4Vi into a reactor and then dehydrating D3F and D4Vi, adding prepared potassium silanolate catalyst pre-polymer, heating, introducing nitrogen and stirring to carry out polymerization, wherein the temperature is 60-115 DEG C and the reaction time is 20-100min, neutralizing with a neutralizer until the reactant is neutral, and finally, removing small molecular substances from the material, reducing temperature and discharging. Due to the adoption of the potassium silanol catalyst pre-polymer with high activity, the reaction temperature is low, the accelerant is not required, an end-capping reagent is not required in the polymerization process, and the nitrogen purging manner is adopted in the stage of removing the small molecular substances from the material, the volatile matter of the heat curing fluorosilicone raw rubber is reduced; the prepared heat curing fluorosilicone raw rubber can be widely used in the fields of aerospace, petrochemical industry, automobiles, artificial organ, and the like, and has a good promotional value.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Norbornene, acrylonitrile and perfluoromethyl vinyl ether ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, acrylonitrile and perfluoromethyl vinyl ether ternary polymerization catalyst and a ternary polymerization method. The invention is characterized in that the preparation method of the catalyst includes: in a glove box of nitrogen atmosphere, dissolving vanadium trichloride and a ligand in a first solvent in a conical flask to obtain a mixed solution; then under magnetic stirring, dripping alkyl aluminum into the mixed solution, then further performing stirring for 30-60min at 30-60DEG C, steaming off part of the first solvent, conducting standing and filtering to obtain solid crystals, i.e. a vanadium-aluminum complex catalyst; adding a norbornene monomer, acrylonitrile and a perfluoromethyl vinyl ether monomer into a repeatedly vacuumized and nitrogen charged high pressure kettle, and adding a second solvent for dissolution; then adding the vanadium-aluminum complex catalyst for reaction; washing and filtering the reaction product, and conducting drying, thus obtaining a norbornene, acrylonitrile and perfluoromethyl vinyl ether terpolymer.

Owner:宁波市大学科技园发展有限公司

Norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and binary copolymerization method

The invention relates to a norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and a binary copolymerization method. The preparation method of the catalyst is characterized by comprising the following steps: in a container of dry inert gas atmosphere, dissolving antimony pentachloride and ligand in a first solvent; dropwise adding tetra-isopropoxy titanium at 200-300rpm, and then continuously stirring for 30-50 minutes at 30-50 DEG C to obtain an antimony-titanium complex catalyst; adding a norbornene monomer and a perfluoromethyl vinyl ether monomer in a molar ratio of 1:1 into an autoclave after repeated vacuumizing and nitrogen charge; adding a second solvent and dissolving; adding the antimony-titanium complex catalyst, and reacting for 1-6 hours at 30-120 DEG C and under the pressure of 0.1-8MPa; pouring the reaction product into an ethanol solution containing 4-5wt% of hydrochloric acid; washing the obtained precipitate with ethanol to neutrality; and performing vacuum drying to obtain a norbornene-perfluoromethyl vinyl ether binary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Norbornene, tetrafluoroethylene and perfluoromethyl vinyl ether ternary copolymerized catalyst and ternary copolymerization method

The invention relates to a norbornene, tetrafluoroethylene and perfluoromethyl vinyl ether ternary copolymerized catalyst and a ternary copolymerization method, and is characterized in that the preparation method of the catalyst comprises the following steps: in a dry container with an inert gas atmosphere, dissolving di(t-butylcyclopentadienyl)titanium (IV) dichloride and a ligand in a first solvent, to obtain a mixed solution; then dropping alkyl aluminum into the mixed solution, and stirring for 30-60 minutes at the temperature of 30-60 DEG C, to obtain a titanium-aluminum complex catalyst; taking a norbornene monoer, tetrafluoroethylene and a perfluoromethyl vinyl ether monomer according to the molar ratio of 1:1:1, adding the components into a high pressure kettle vacuumized for multiple times and filled with nitrogen, adding a second solvent, and dissolving; then adding the titanium-aluminum complex catalyst, and completing a reaction under certain conditions; and washing and drying the reaction product to obtain the norbornene, tetrafluoroethylene and perfluoromethyl vinyl ether ternary copolymerized catalyst.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Technological method for synthesizing biologically degradable poly(succinic acid-co-polybutylene terephthalate) through organic guanidine catalysis

Provided is a technological method for synthesizing biologically degradable poly(succinic acid-co-polybutylene terephthalate) (PBST50-50) through organic guanidine catalysis. According to the technological method, a non-poisonous organic biomass compound is used as a main catalyst and non-poisonous zincate is used as a promoter to form a two-component high-activity catalysis system, succinic acid(SA), terephthalic acid (TA) and 1,4-diethylene glycol (BDO) are used as monomers, and the biodegradable PBST50-50 is synthesized through direct melting and condensation and then solid-phase polycondensation. The weight average molecular weight Mw of the PBST50-50 synthesized by adopting the method can be 1.0 * 105-1.2 * 105, Tm is 170 DEG C or above, and the product has a white color.

Owner:NANJING UNIV

Norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymerization catalyst and ternary copolymerization method

The invention relates to a norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymerization catalyst and a ternary copolymerization method. In a three-neck flask with dry inert gas atmosphere, bis-(1,5-cyclooctadiene) nickel and ligand are dissolved into a first solvent, so that a mixed solution is obtained; then, under stirring, titanium tetraisopropanolate is dripped into the mixed solution, the mixed solution continues to be stirred under 30 DEG C to 70 DEG C for 30 to 70 minutes, and thereby a nickel-titanium complex catalyst is obtained; a norbornene monomer, vinylcyclohexane and a perfluoromethyl vinyl ether monomer are added into a high-pressure kettle which is vacuumized multiple times and filled with nitrogen, and a second solvent is added for dissolution; the nickel-titanium complex catalyst is then added, and reaction takes place under certain temperature and pressure for 1 to 8 hours; the product obtained by the reaction is poured into ethanol solution containing 4 to 5wt percent of hydrochloric acid, the obtained precipitate is washed with ethanol to become neutral, and after vacuum drying, a norbornene, vinylcyclohexane and perfluoromethyl vinyl ether ternary copolymer is obtained.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

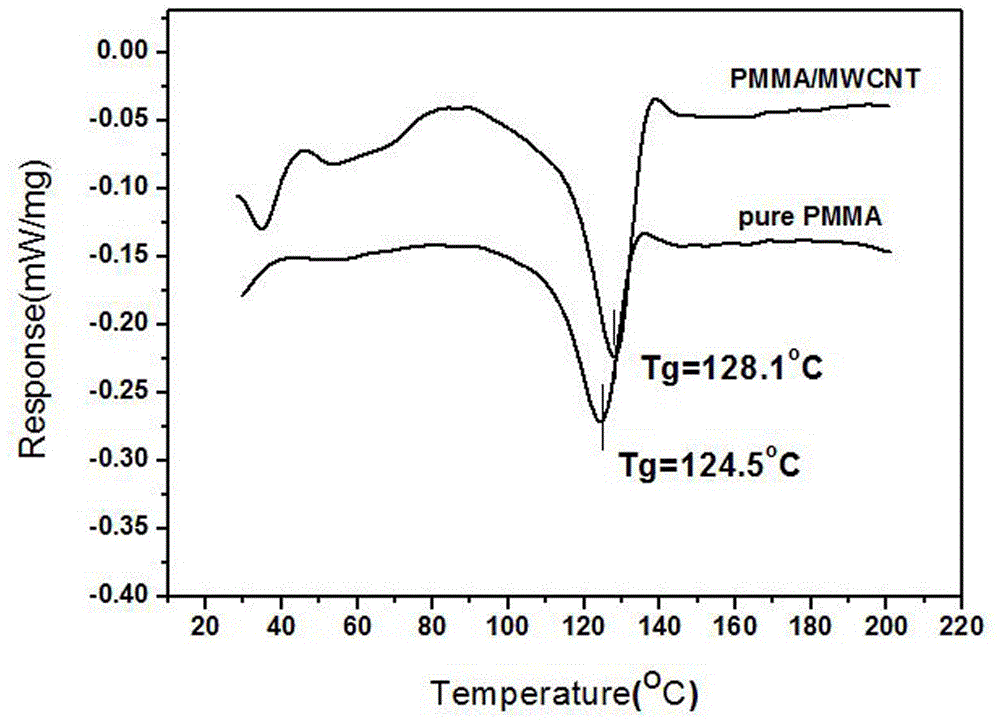

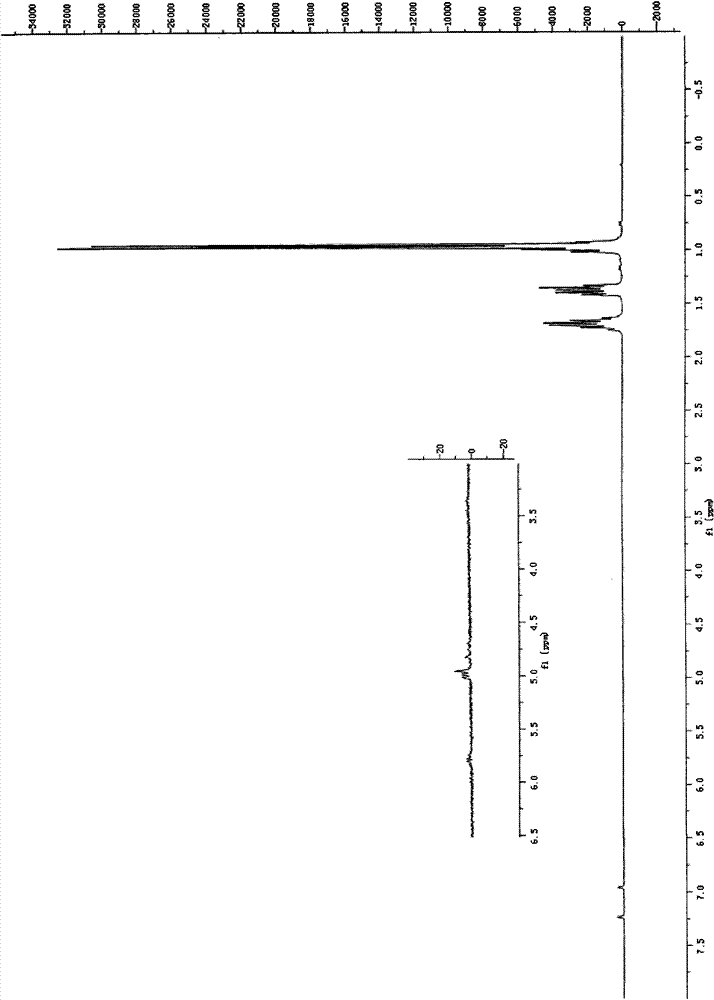

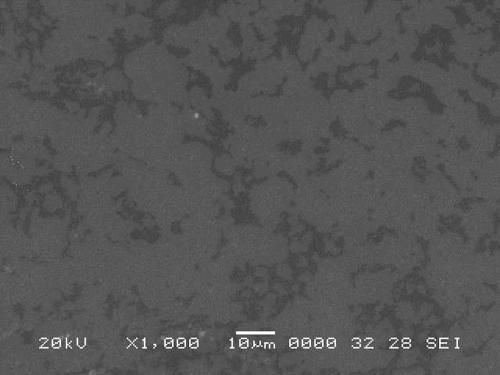

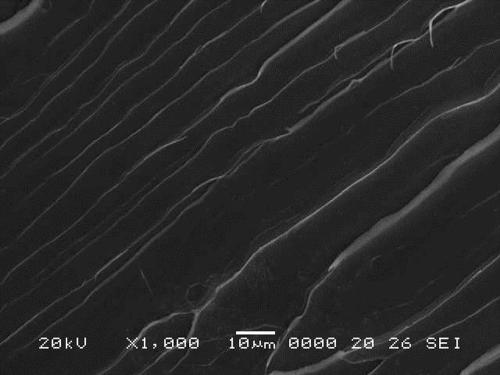

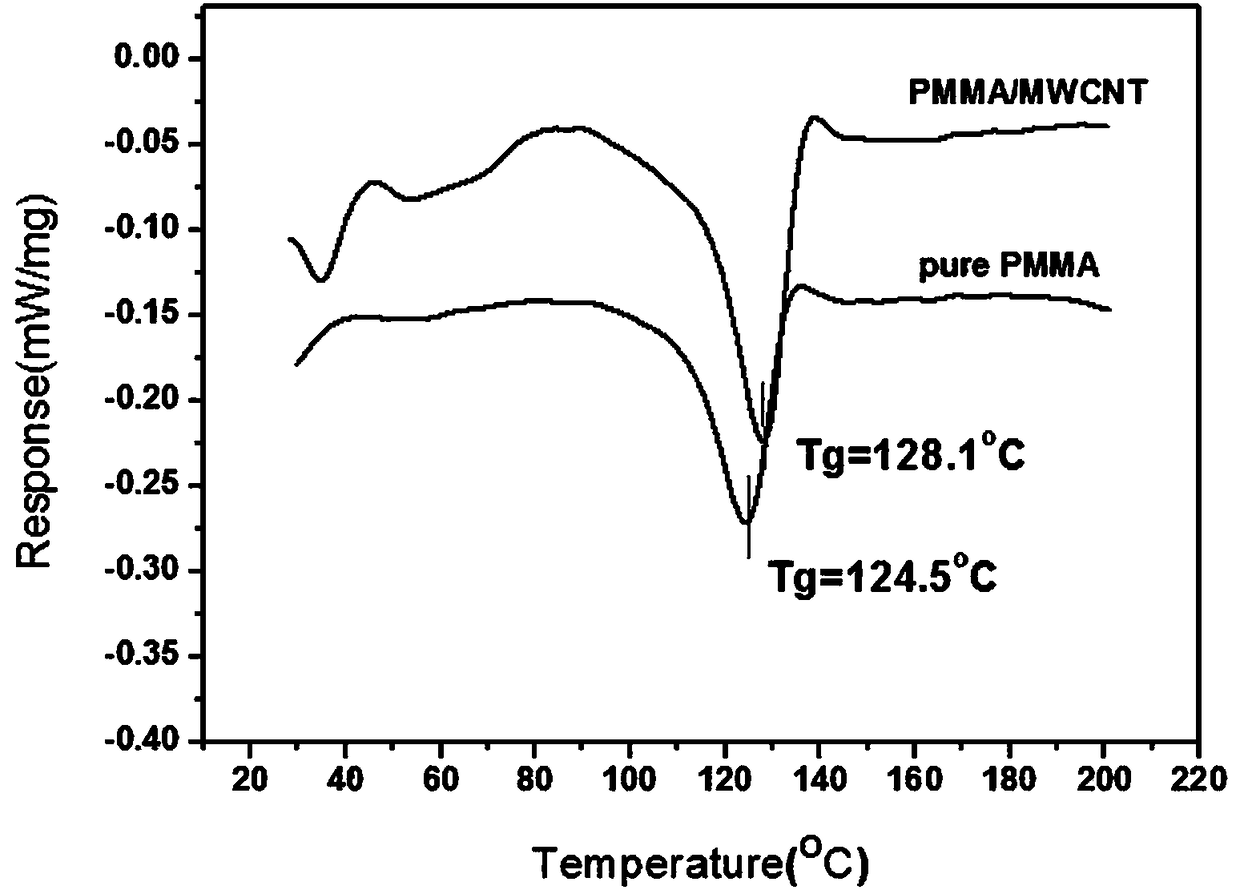

Method for preparing PMMA (polymethyl methacrylate)/CNTs (carbon nanotubes) composite materials

The invention provides a method for preparing PMMA (polymethyl methacrylate) / CNTs (carbon nanotubes) composite materials. The method includes: preparing surface-modified carbon nanotubes from carbon nanotubes and auxiliaries such as organosilicon compounds, polycarboxylate, polyoxyethylene ether and acrylic resin under certain conditions by a physical blending process; adding the surface-modified carbon nanotubes and initiators into methyl methacrylate matrixes; uniformly dispersing the carbon nanotubes, the initiators and the methyl methacrylate matrixes to obtain mixtures and polymerizing the mixtures by means of standing under low-temperature conditions to obtain the PMMA / CNTs composite materials. The method has the advantages that monomer MMA (methyl methacrylate) is polymerized in a standing state under the effect of ultrasonic waves and the joint effects of the carbon nanotubes (CNTs) and the initiators at the low polymerization temperatures of 15-80 DEG C; reaction conditions are mild, surface chemical modification by the aid of strong oxidizing agents such as strong acid can be omitted, polymerization reaction can be carried out at the low temperatures, the method is low in energy consumption, technological conditions are simple, and operation is easy to implement; self-acceleration and implosion phenomena can be prevented in reaction procedures, the reaction procedures are stable and mild, the surfaces of products obtained by the aid of the method are smooth and flat, the carbon nanotubes are excellently dispersed, and the glass-transition temperatures of the obtained PMMA is increased.

Owner:GUILIN UNIV OF ELECTRONIC TECH

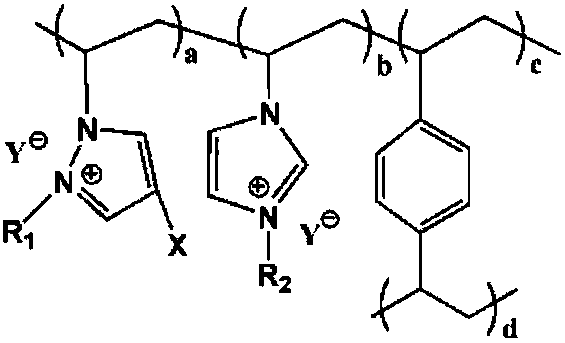

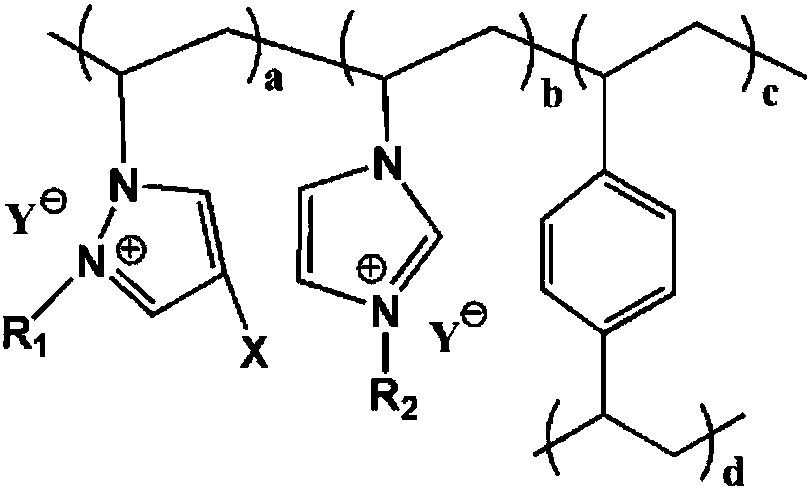

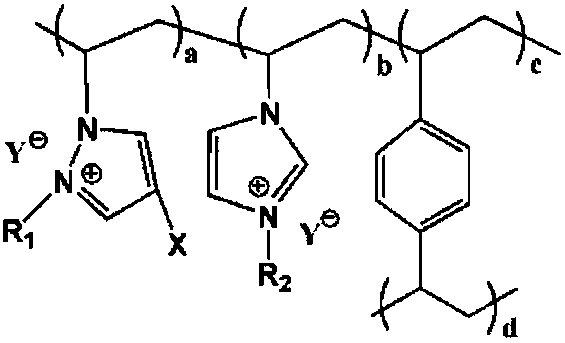

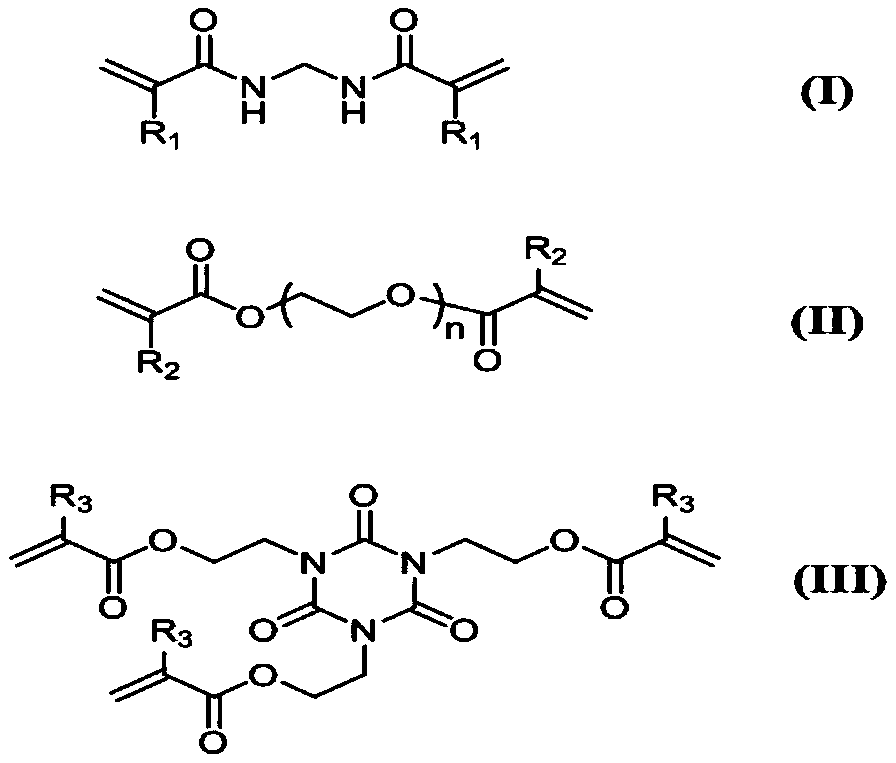

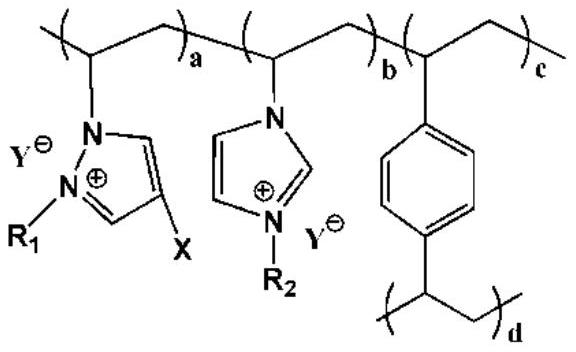

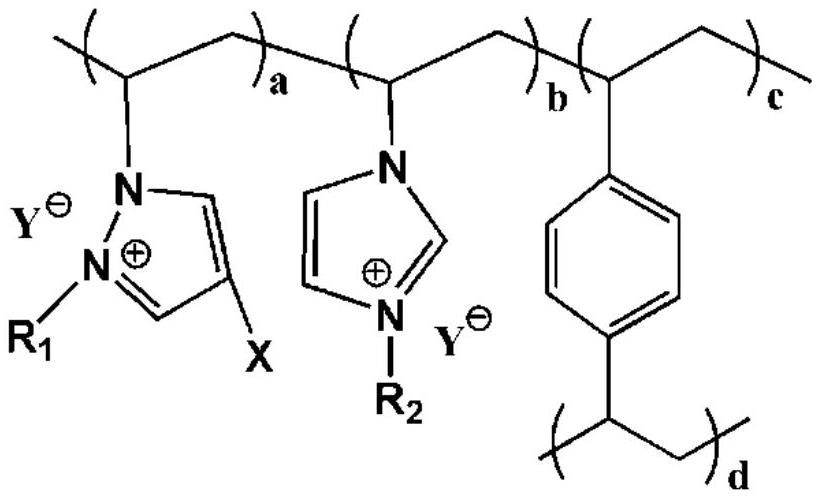

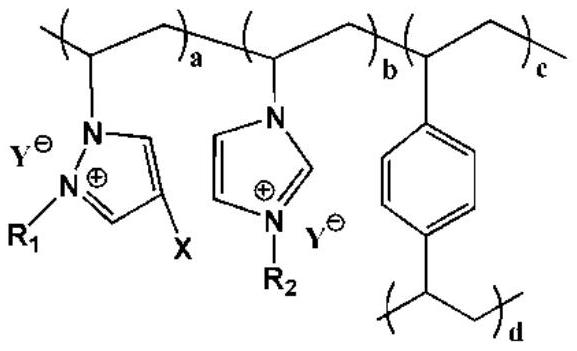

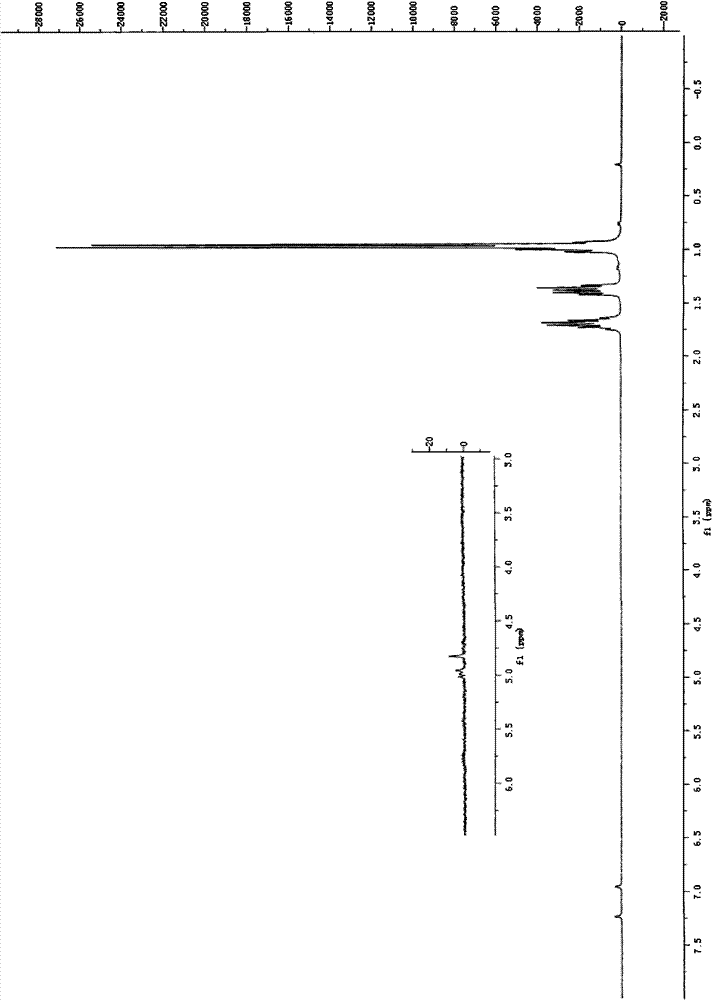

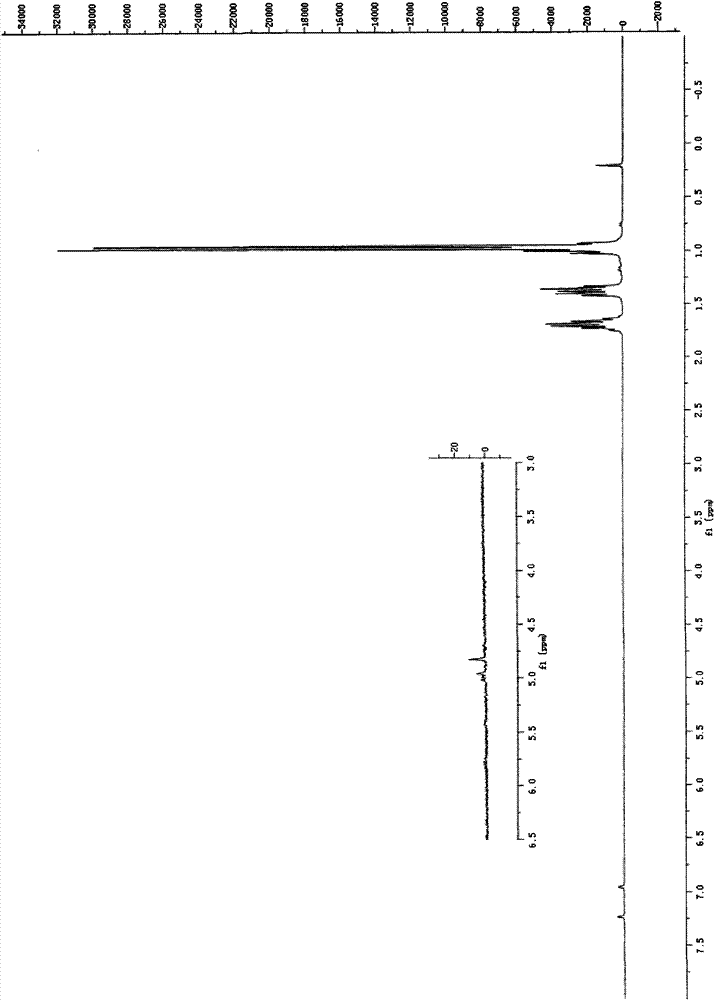

Cross-linking polymerization acidic ionic liquid alkylating catalyst and preparation method thereof

ActiveCN108579807AEnhanced acid sites and acid strengthReduce the temperatureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsIonIon exchange

The invention relates to a cross-linking polymerization acidic ionic liquid alkylating catalyst. The catalyst is obtained through the steps that a 4-halogenated-1-vinyl pyrazole monomer, 1-vinyl-3-alkyl imidazole bromide and crosslinkers crosslinkers are subjected to copolymerization to obtain cross-linking polymer ionic liquid, the cross-linking polymer ionic liquid reacts with halohydrocarbon toobtain substituted cross-linking polymer ionic liquid, and finally the substituted cross-linking polymer ionic liquid and organic acid are subjected to ion exchange to obtain the catalyst, wherein the general molecular formula is defined in the description, R1 is -CH2(CH2)2CH3 or -CH2(CH2)4CH3, R2 is -CH2(CH2)mCH3, m is 0, 2, 4 and 6, X is one of Cl, Br and I, Y<-> is SO3CF3<-> or CF3COO<->, thepolymerization degree is 2-50, a polymer b is 2-50, a polymer c is 2-50, and a polymer d is 2-50. Serving as a novel environmentally-friendly solid acid heterogenous catalyst for an alkylation reaction, the catalyst has the excellent catalytic performance, the catalytic efficiency can be effectively improved, and when styrene and o-xylene are catalyzed to generate the alkylation reaction, the yield of a diphenylethane product is larger than 90%.

Owner:江苏棋成化工有限公司 +2

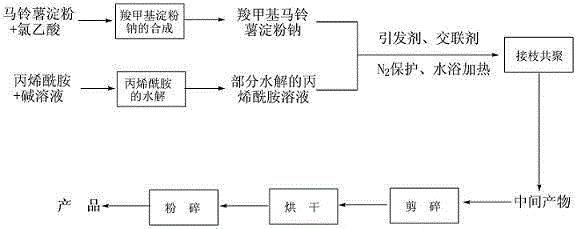

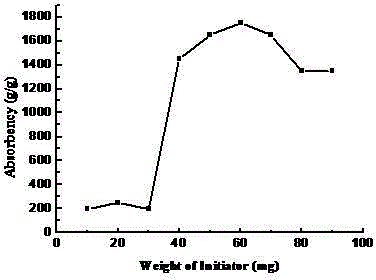

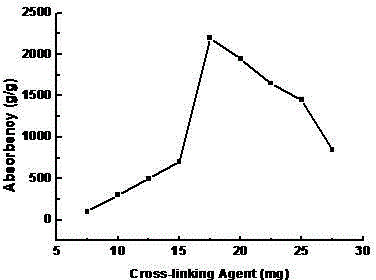

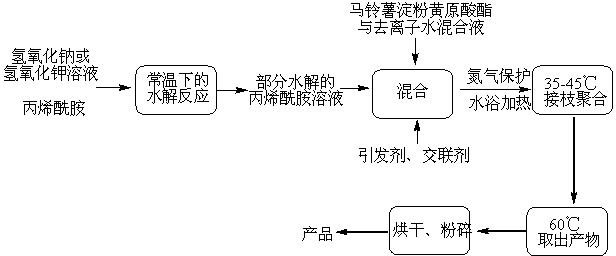

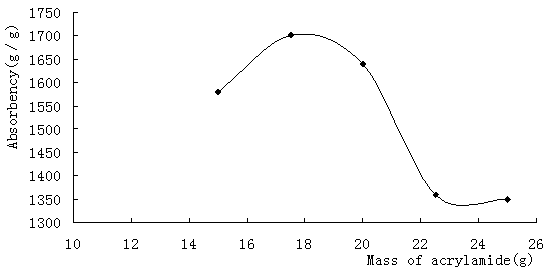

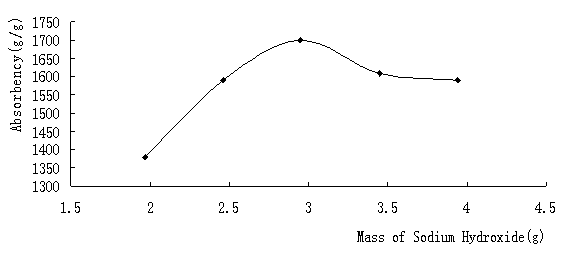

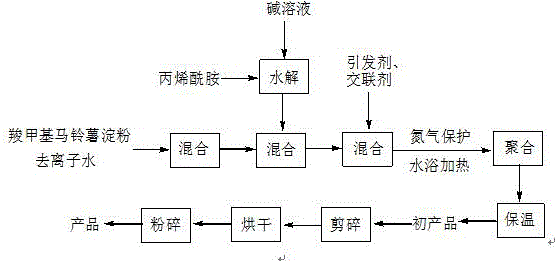

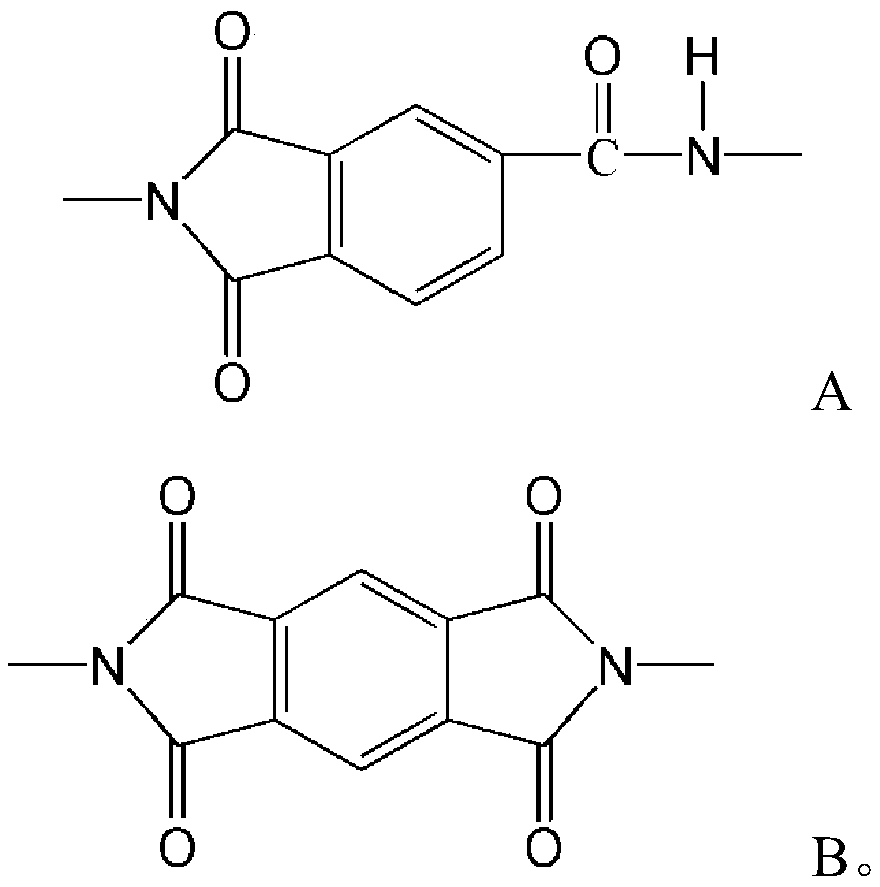

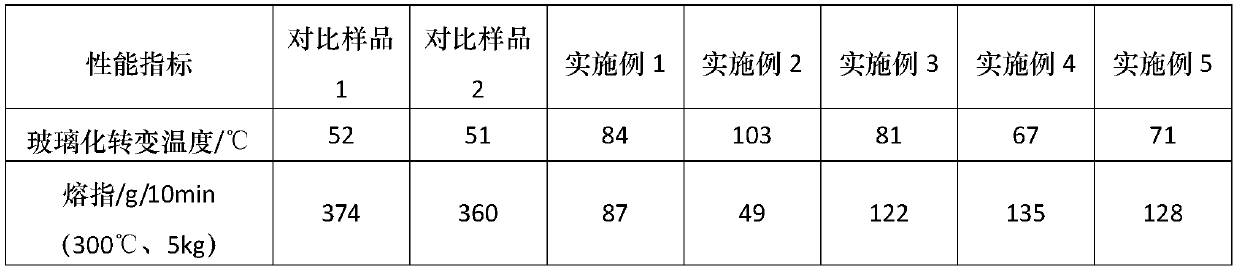

Novel technology for preparing high-potassium-content and high-water-absorption resin by using carboxymethyl potato starch and acrylamide as raw materials

ActiveCN105713139AReduce consumptionPolymerization reaction temperature is lowWater bathsPotato starch

The invention discloses a method for synthesizing nitrogen-containing, potassium-containing and high-water-absorption resin by using carboxymethyl potato starch and acrylamide. The method is mainly characterized by comprising the following steps: firstly, hydrolyzing the acrylamide by using potassium hydroxide; then heating in water bath under the protection effect of nitrogen; and carrying out graft polymerization on the carboxymethyl potato starch and the partially hydrolyzed acrylamide at the temperature of 30-60 DEG C and preparing the high-water-absorption resin. The maximum water absorption of the optimal product in 5,000 times of deionized water can reach 3,500 g / g. Moreover, through a result of an orthogonal experiment, the product of which the water absorption reaches 3,575 g / g is obtained, and the potassium content of the product is 15.59%. The result and the condition of the orthogonal experiment are analyzed to obtain the sequence of factors which affect the water absorption of the nitrogen-containing, potassium-containing and high-water-absorption resin and are arrayed from large to small. The high-water-absorption resin has the advantages that the carboxymethyl potato starch as a matrix can be dissolved in water so that gelatinization is not required, and graft polymerization reaction temperature is low. Therefore, the high-water-absorption resin is simple in synthesize technology, easy to operate, low in performance and suitable for being produced in a large scale and popularized.

Owner:INNER MONGOLIA UNIVERSITY

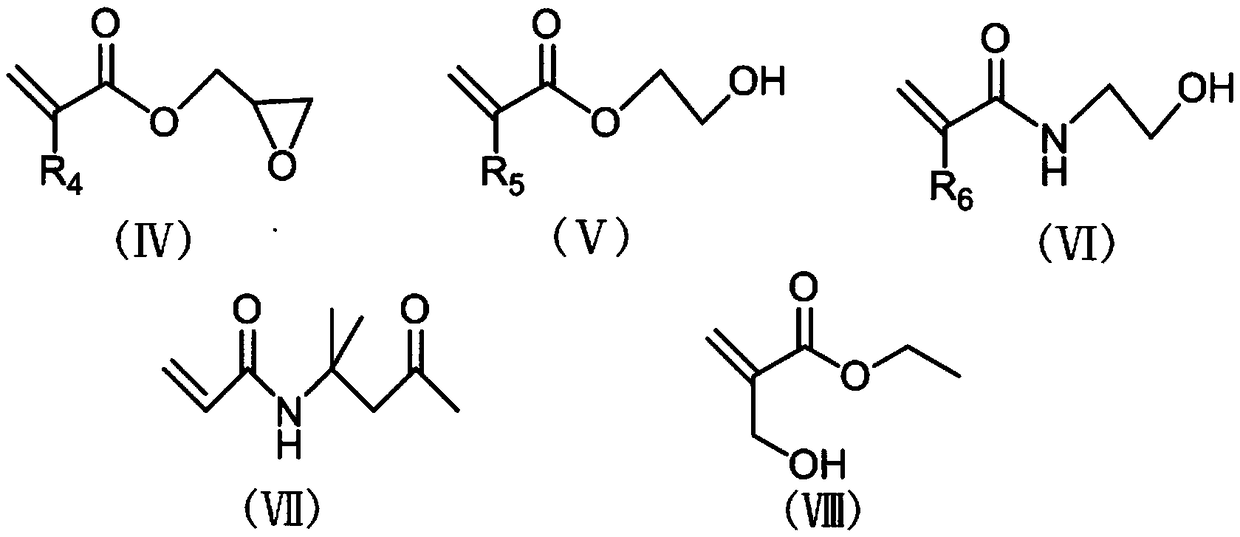

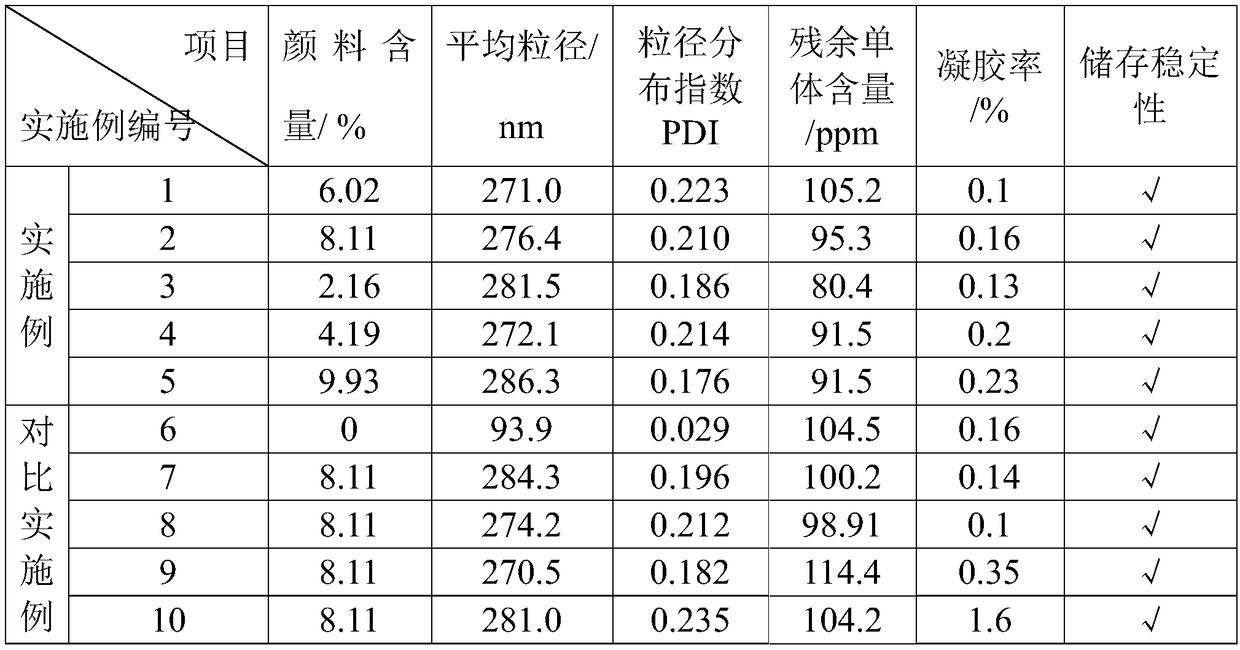

Acrylate polymer emulsion containing pigment particles and preparation method thereof

ActiveCN106349424BImprove conversion rateNarrow particle size distributionFibre treatmentPolymer scienceLatex particle

Owner:SUZHOU SUNMUN TECH CO LTD

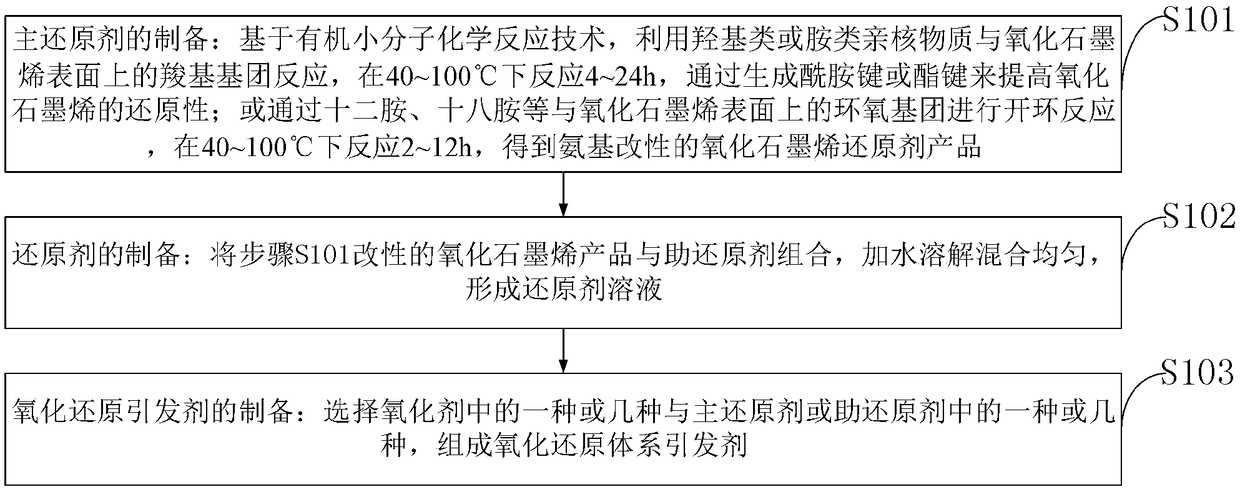

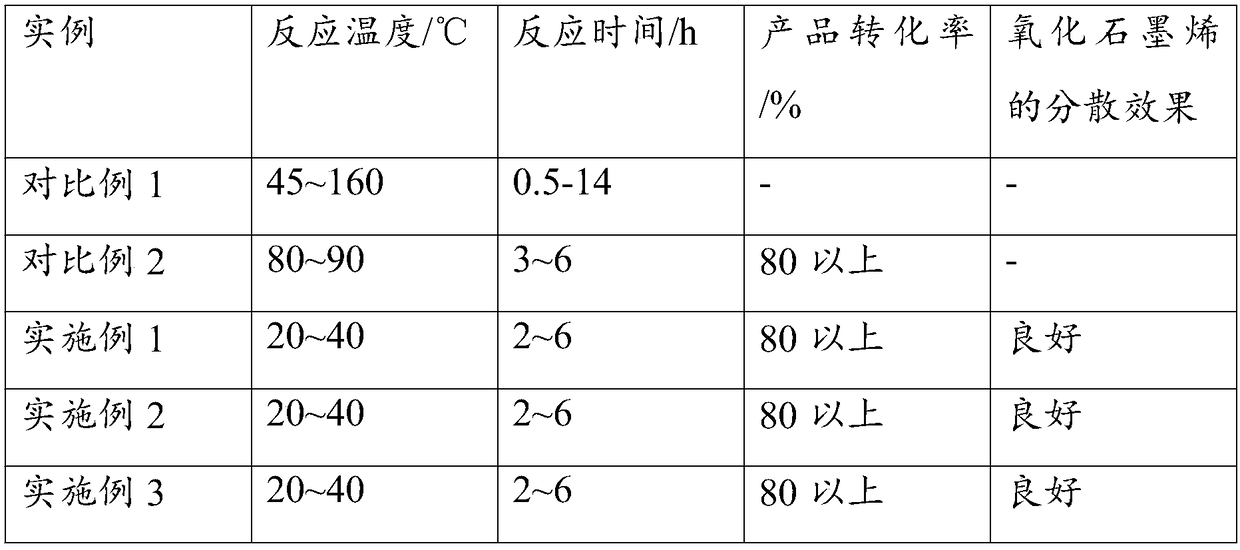

Graphene oxide-based redox system initiator and preparation and use method thereof

InactiveCN109096413APolymerization reaction temperature is lowImprove conversion rateCvd grapheneElastic modulus

The invention belongs to the technical field of graphene materials, and discloses a graphene-oxide-based redox system initiator and a preparation and use method thereof. The initiator is composed of the following components by mass: 50-60 parts of oxidant, 40-50 parts of main reducing agent, 0-10 parts of assistant reducing agent and 50-100 parts of water. The oxidant is mainly one or more of an organic peroxy oxidant, an inorganic peroxy oxidant and a tetravalent cerium salt. The initiator greatly reduces the polymerization temperature, and the polymerization temperature can be in the range of 0-60 DEG C. The introduction of the graphene oxide can utilize the reducibility of a large number of organic functional groups on the surface of the graphene oxide and fully utilize structural characteristics of the graphene oxide to introduce high strength, high elasticity modulus, high toughness and other characteristics into a product.

Owner:CHINA BUILDING MATERIALS ACAD

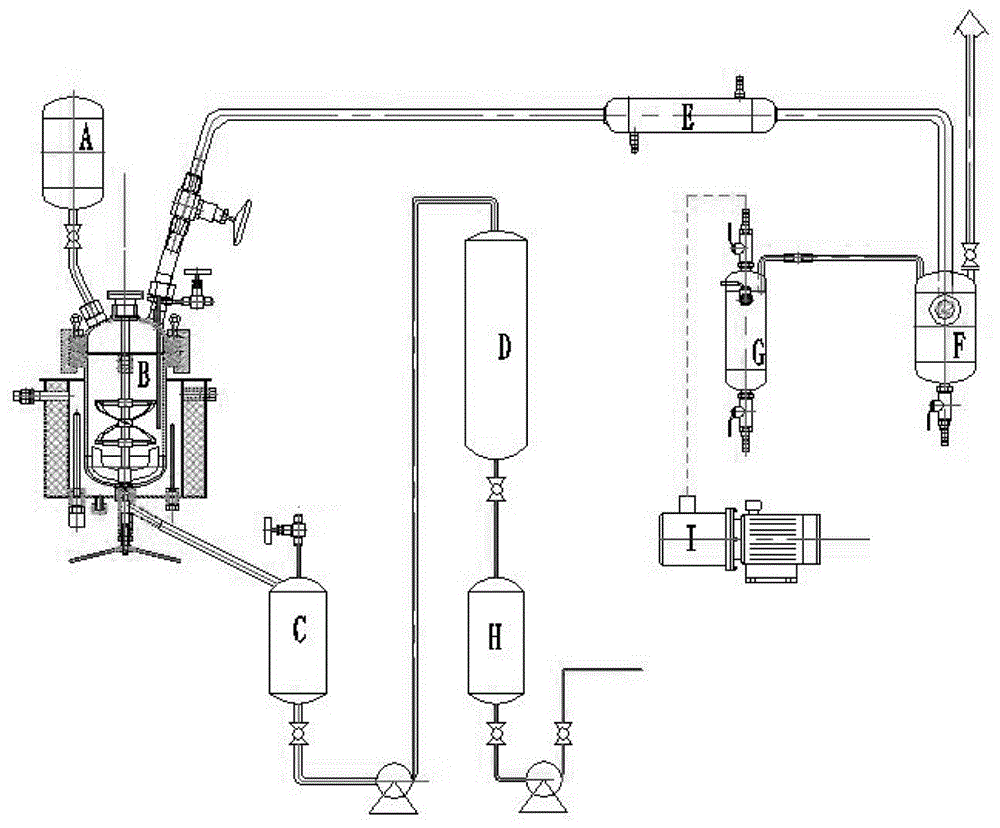

Novel polycarboxylate based superplasticizer and preparation method thereof

The invention belongs to the technical field of concrete admixtures and discloses a novel polycarboxylate based superplasticizer and a preparation method thereof. The polycarboxylate based superplasticizer comprises the following components: vinyl polyethylene glycol ether (ester), (meth) acrylic acid (acrylate) or other vinyl monomers and derivatives, an oxidizing agent, a reducing agent and water. The preparation method comprises the following steps: adding the vinyl polyethylene glycol ether (ester), the reducing agent and the water into a reactor, and heating; respectively dropping one ormore monomer solutions in the (meth) acrylic acid (acrylate) or other vinyl monomers and derivatives and an oxidizing agent solution, and reacting; maintaining the temperature and reacting after dropping completion; regulating the pH value of the solution with a sodium hydroxide solution, thereby obtaining the novel polycarboxylate based superplasticizer. According to the method disclosed by the invention, graphene oxide is introduced into the molecular structure of the polycarboxylate based superplasticizer, so that the dispersion problem of the graphene oxide in the admixture and cement-based materials can be fundamentally solved, and the mechanical property and durability of the cement-based materials are improved.

Owner:CHINA BUILDING MATERIALS ACAD

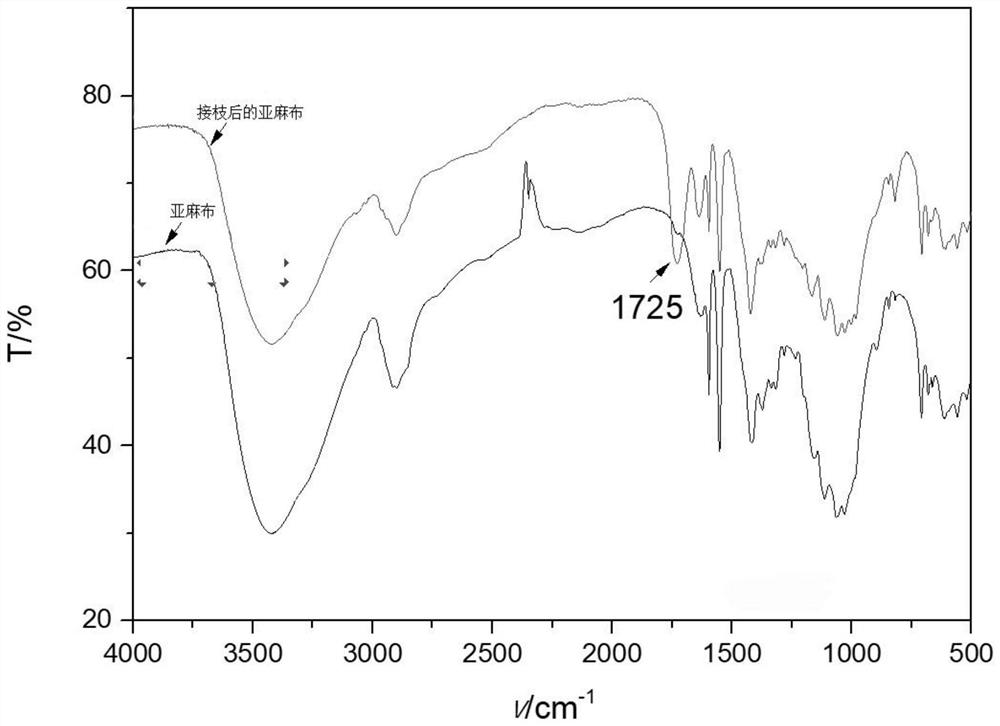

A kind of method of photocatalytic maleic anhydride grafted linen

A method for photocatalyzing maleic anhydride grafted linen, which relates to the field of composite material preparation, the specific scheme is as follows: a method for photocatalyzing maleic anhydride grafted linen, comprising the following steps: Take it out in 16% sodium hydroxide aqueous solution for 30 seconds, wash it with distilled water until neutral, put it in a vacuum drying oven and dry it; step 2, soak the dried linen in a maleic anhydride solution containing a photocatalyst for 15 minutes Take it out, and then irradiate each side of the linen cloth with ultraviolet light for 2-4 minutes; step 3, after the irradiation is completed, take out the linen cloth, wash it with distilled water to neutrality, put it into a vacuum drying oven and dry it to obtain the linen cloth grafted with maleic anhydride. The ultraviolet photocatalytic photografting method grafts maleic anhydride on the surface of linen cloth, which overcomes the shortcomings of traditional melting method and solution method such as high energy consumption, complicated process, and large pollution. The process is simple and the grafting rate is high.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for producing trifluoro-propyl silicone oil by aid of ion exchange resin

The invention discloses a method for producing trifluoro-propyl silicone oil by the aid of ion exchange resin. The method includes pretreating cyclo-rectification byproducts and water to obtain supernatant oil layers, then feeding the supernatant oil layers into a container, feeding 1, 3, 5 (3, 3, 3-trifluoro-propyl) trimethyl cyclo-trisiloxane into the container, uniformly stirring and mixing the supernatant oil layers and the 1, 3, 5 (3, 3, 3-trifluoro-propyl) trimethyl cyclo-trisiloxane with one another to obtain first mixtures, heating the first mixtures, dehydrating the first mixtures under vacuum conditions, adding end-capping agents into the first mixtures after the vacuum is eliminated, adding catalysts into the container to obtain second mixtures, continuing to heat the second mixtures, carrying out reaction under the conditions of the normal pressure and the stirring speed of 200-230 r / min for 1-3 h, then carrying out suction filtration by the aid of filter bags and measuring the conversion rate of filter liquor; pouring filtered liquid materials in three-mouth flasks, then heating the filtered liquid, removing low-boiling-point substances for 1-5 h, placing filtered resin in containers and hermetically storing the filtered resin in the containers. Products are sampled, and indexes of the appearance, the viscosity, the density, volatile matters, the flashing points and the like of the products are detected. The method has the advantages that processes for producing the trifluoro-propyl silicone oil are simple, the trifluoro-propyl silicone oil can be continuously industrially produced by the aid of the method, the products are stable in quality, and index requirements on the indexes of the conversion rate, the viscosity, the density, the volatile matters, the flashing points and the like of the products can be met.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Norbornene and perfluoromethyl vinyl ether binary copolymerization catalyst and binary copolymerization method

The invention relates to a norbornene-perfluoromethyl vinyl ether binary copolymer catalyst and a binary copolymerization method. The preparation method of the catalyst is characterized by comprising the following steps: in a container of dry inert gas atmosphere, dissolving antimony pentachloride and ligand in a first solvent; dropwise adding tetra-isopropoxy titanium at 200-300rpm, and then continuously stirring for 30-50 minutes at 30-50 DEG C to obtain an antimony-titanium complex catalyst; adding a norbornene monomer and a perfluoromethyl vinyl ether monomer in a molar ratio of 1:1 into an autoclave after repeated vacuumizing and nitrogen charge; adding a second solvent and dissolving; adding the antimony-titanium complex catalyst, and reacting for 1-6 hours at 30-120 DEG C and under the pressure of 0.1-8MPa; pouring the reaction product into an ethanol solution containing 4-5wt% of hydrochloric acid; washing the obtained precipitate with ethanol to neutrality; and performing vacuum drying to obtain a norbornene-perfluoromethyl vinyl ether binary copolymer.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

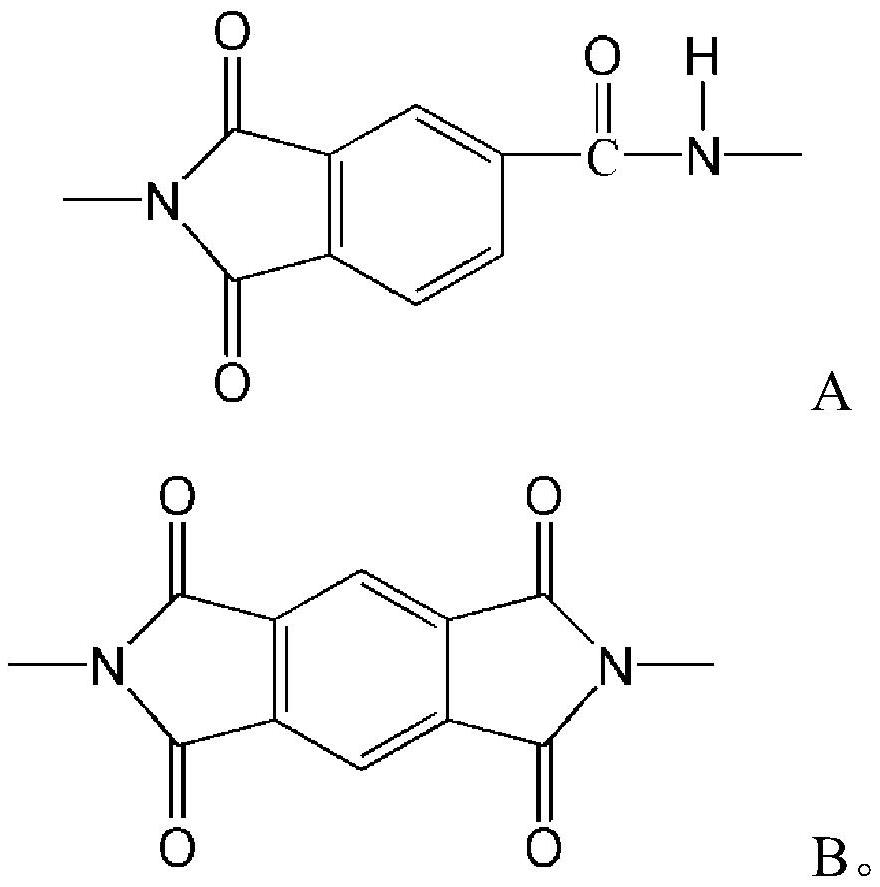

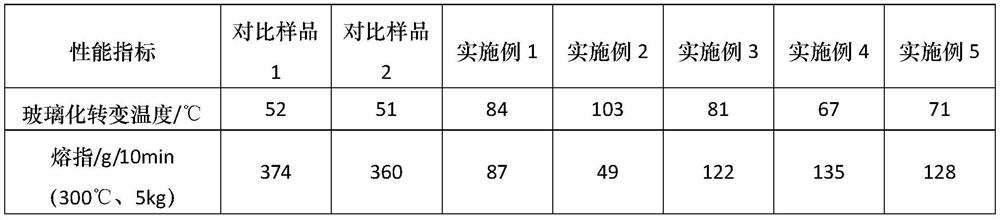

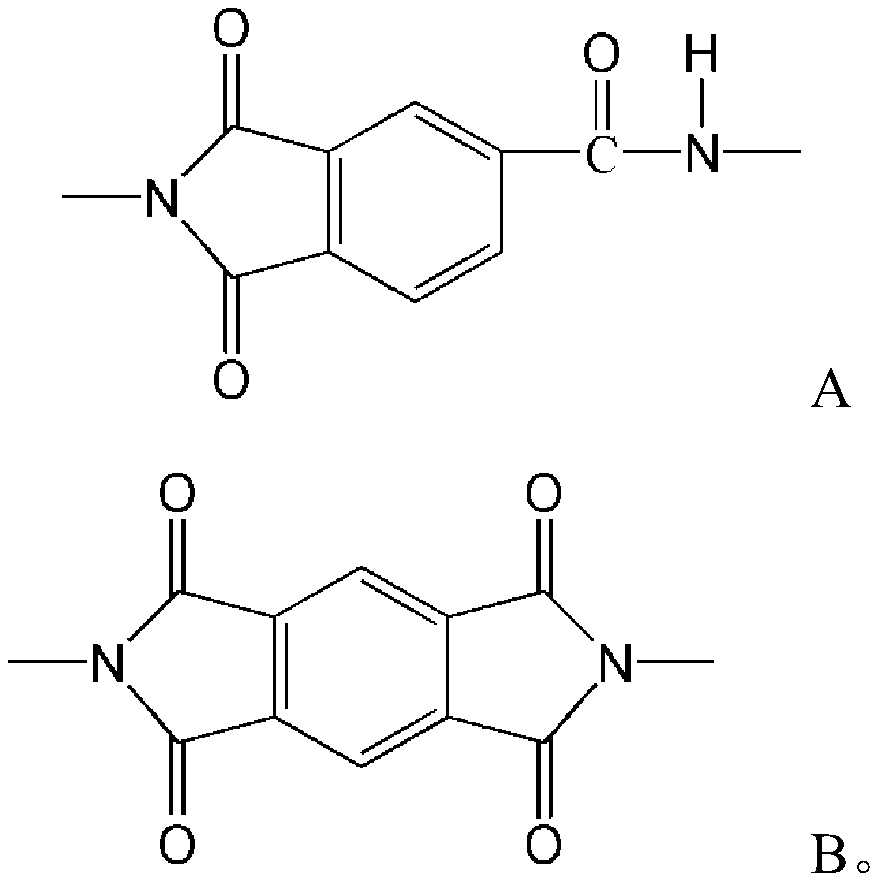

A kind of polyamide resin and its preparation method and application

The present invention relates to a polyamide resin and its preparation method and use. The polyamide resin contains aliphatic polyamide molecular chain segments, and aromatic imide units and aromatic imide units are embedded in the aliphatic polyamide molecular chain segments. amide unit. The polyamide resin is prepared by controlling the polymerization reaction conditions and combining precipitation, washing and drying. The polymerization reaction temperature of the polyamide resin in the invention is relatively low, the reaction process is easy to control, and is suitable for large-scale production and application. The product has excellent heat resistance, which can meet the heat resistance requirements of electronic and electrical reflow soldering (SMT) process and the periphery of automobile engine for plastic products.

Owner:ZHONGLUN PLASTIC IND FUJIAN

Method for synthesizing high water absorbent polymer by using potato starch xanthate and acrylamide

The invention discloses a method for synthesizing a high water absorbent polymer by using potato starch xanthate and acrylamide. The method is mainly characterized by comprising the following steps of: firstly hydrolyzing the acrylamide by using alkaline, and subsequently heating in water bath under the protection of nitrogen, so the starch xanthate and a part of the hydrolyzed acrylamide are subjected to graft polymerization at 35 to 45 DEG C so as to prepare the high water absorbent polymer. The maximum water absorbing capacity of an optimal product in deionized water of 2500 times can be 2160g / g, and the water absorbing capacity in deionized water of 10000 times can be 5000g / g; and meanwhile the high water absorbent polymer prepared by the method is high in nitrogen content. The methodfor preparing the high water absorbent polymer has the following advantages that the parent potato starch xanthate does not need to be gelatinized, the graft polymerization reaction is low in temperature, and high temperature reaction is not needed, so that the method for synthesizing the high water absorbent polymer provided by the invention is simple in process, easy to operate, low in cost andexcellent in product performance, so that the method is more applicable for scale production and popularization of products.

Owner:INNER MONGOLIA UNIVERSITY

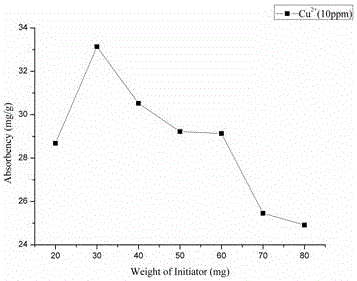

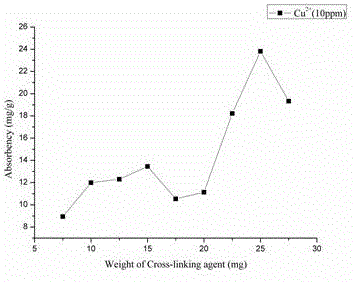

Method for synthesizing Cu2+ adsorption resin from carboxymethyl potato starch and acrylamide

InactiveCN106008832ASimple processReduce consumptionOther chemical processesWater contaminantsPotato starchPhysical chemistry

The invention discloses the preparation of adsorbed Cu by using carboxymethyl potato starch and acrylamide as raw materials 2+ The method of ionic resin, the main feature is firstly hydrolyzing acrylamide with sodium hydroxide solution, and then heating in a water bath under the protection of nitrogen, so that carboxymethyl potato starch and partially hydrolyzed acrylamide are grafted and polymerized at 30-60°C to prepare adsorption Cu 2+ resin. Best product in 1000mlCu 2+ Cu in a solution with a concentration of 10ppm 2+ The adsorption capacity is 33.13mg / g, the removal rate is 98.78%, in 1000mlCu 2+ Cu in a solution with a concentration of 400ppm 2+ The adsorption capacity is 918.79mg / g, and the removal rate is 94.42%. The present invention adsorbs Cu 2+ The preparation of ion resin has the following advantages: the parent carboxymethyl potato starch is soluble in water, thus no gelatinization is required, the process is simple and easy, the graft polymerization reaction temperature is low, and the practicability is strong, and the obtained adsorbed Cu 2+ Resin to Cu 2+ High ion adsorption capacity.

Owner:INNER MONGOLIA UNIVERSITY

A kind of crosslinking polymerization acidic ionic liquid alkylation catalyst and preparation method thereof

ActiveCN108579807BIncrease acidityHigh acid strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPolymer scienceHalohydrocarbon

The invention relates to a cross-linked polymerization acidic ionic liquid alkylation catalyst. The catalyst is first composed of 4-halogenated-1-vinyl pyrazole monomer, 1-vinyl-3-alkylimidazole bromide salt and cross-linked The cross-linked polymerized ionic liquid is obtained by free radical copolymerization of the agent, and then the cross-linked polymerized ionic liquid is reacted with a halogenated hydrocarbon to obtain a substituted cross-linked polymerized ionic liquid. Finally, the substituted cross-linked polymerized ionic liquid is ion-exchanged with an organic acid to obtain, as A new green and environmentally friendly solid acid heterogeneous catalyst for alkylation reaction. It has excellent catalytic performance and can effectively improve catalytic efficiency. When catalyzing the alkylation reaction of styrene and o-xylene, the diaryl group The yield of ethane product is greater than 90%.

Owner:江苏棋成化工有限公司 +2

Preparation method of polypropylene containing homoallylic end group

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of pmma/cnts composite material

The invention provides a method for preparing PMMA (polymethyl methacrylate) / CNTs (carbon nanotubes) composite materials. The method includes: preparing surface-modified carbon nanotubes from carbon nanotubes and auxiliaries such as organosilicon compounds, polycarboxylate, polyoxyethylene ether and acrylic resin under certain conditions by a physical blending process; adding the surface-modified carbon nanotubes and initiators into methyl methacrylate matrixes; uniformly dispersing the carbon nanotubes, the initiators and the methyl methacrylate matrixes to obtain mixtures and polymerizing the mixtures by means of standing under low-temperature conditions to obtain the PMMA / CNTs composite materials. The method has the advantages that monomer MMA (methyl methacrylate) is polymerized in a standing state under the effect of ultrasonic waves and the joint effects of the carbon nanotubes (CNTs) and the initiators at the low polymerization temperatures of 15-80 DEG C; reaction conditions are mild, surface chemical modification by the aid of strong oxidizing agents such as strong acid can be omitted, polymerization reaction can be carried out at the low temperatures, the method is low in energy consumption, technological conditions are simple, and operation is easy to implement; self-acceleration and implosion phenomena can be prevented in reaction procedures, the reaction procedures are stable and mild, the surfaces of products obtained by the aid of the method are smooth and flat, the carbon nanotubes are excellently dispersed, and the glass-transition temperatures of the obtained PMMA is increased.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Polyamide resin as well as preparation method and application thereof

The invention relates to a polyamide resin as well as a preparation method and application thereof. The polyamide resin comprises an aliphatic polyamide molecular chain segment, wherein an aromatic imide unit and an aromatic amide unit are embedded into the aliphatic polyamide molecular chain segment. The polyamide resin is prepared by controlling polymerization reaction conditions together with precipitation, cleaning and drying treatment. The polyamide resin provided by the invention is low in polymerization reaction temperature, easy in reaction process control and applicable to large-scaleproduction and application. The product has very good thermal resistance, and is capable of meeting requirements of electronic and electrical reflow soldering (SMT) processes and automobile engine accessories on thermal resistance of plastic products.

Owner:ZHONGLUN PLASTIC IND FUJIAN

Norbornenes, vinyl ethyl ether and perfluoromethyl vinyl ether terpolymerization catalyst and terpolymerization method

The invention relates to a norbornene, vinyl ethyl ether and perfluoromethyl vinyl ether ternary copolymerized catalyst and a ternary copolymerizing method. The preparation method of the catalyst comprises the following steps: dissolving bis(cyclopentadiene) vanadium and ligand in a first solvent in a dried container at an inert gas atmosphere to obtain a mixed solution; dripping diethyl zinc into the mixed solution, and stirring for 30-60 minutes at 30-60 DEG C after dripping to obtain a vanadium-zinc complex catalyst; adding norbornene, vinyl ethyl ether and perfluoromethyl vinyl ether into an autoclave which is vacuumized for multiple times and inflated with nitrogen, adding a second solvent and dissolving; adding the vanadium-zinc complex catalyst, and reacting for 1-6 hours at certain temperature and pressure; and pouring the product obtain in reaction into a hydrochloric acid-containing alcohol solution, washing the precipitate to be neutral with alcohol, and drying in vacuum to obtain the norbornene, vinyl ethyl ether and perfluoromethyl vinyl ether ternary copolymerized catalyst.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

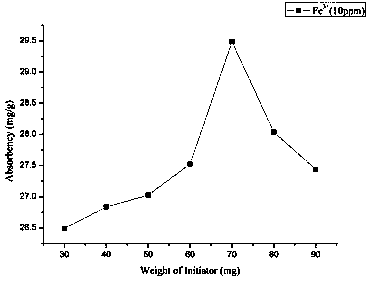

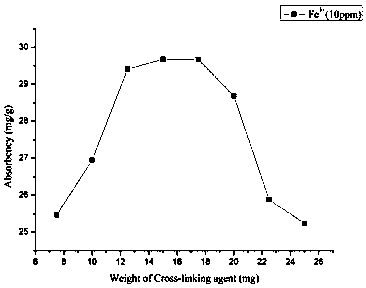

Taking carboxymethyl potato starch and acrylamide as the method for raw material synthesis adsorption Fe3+ resin

ActiveCN106008837BSimple processReduce consumptionOther chemical processesWater contaminantsWater bathsPotato starch

The invention discloses a method for synthesizing Fe3+ adsorption resin from carboxymethyl potato starch and acrylamide. The method is mainly characterized in that firstly, acrylamide is hydrolyzed by means of sodium hydroxide solution, and then water-bath heating is conducted under the protection of nitrogen, so that graft polymerization of carboxymethyl potato starch and parts of hydrolyzed acrylamide is achieved at 30-60 DEG C to prepare the Fe3+ adsorption resin. For the best product, Fe3+ adsorption capacity is 36.86 mg / g and removal rate is 88.05% in 1000 ml solution with Fe3+ concentration of 10 ppm, and Fe3+ adsorption capacity is 1072.65 mg / g and removal rate is 94.91% in 1000 ml solution with Fe3+ concentration of 400 ppm. The method has the advantages that the parent carboxymethyl potato starch can be dissolved in water so that gelatinization is not needed, the process is simple and easy to implement, graft polymerization reaction temperature is low, practicality is high, and the Fe3+ adsorption capacity and removal rate of the prepared Fe3+ adsorption resin are high.

Owner:INNER MONGOLIA UNIVERSITY

A kind of low-temperature catalytic modified asphalt and its preparation method

ActiveCN111607421BThe activation energy of the polymerization reaction is lowReduce energy consumptionWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansDistillationPhysical chemistry

The invention relates to a low-temperature catalytic modified asphalt and a preparation method thereof. The technical scheme is: put 100 parts by mass of medium-temperature coal tar pitch in a reaction kettle with a distillation device, stir for 5 to 10 minutes under the conditions of 100-105°C and 100-300rpm; then add 0.001 ~0.002 parts by mass of anhydrous aluminum trichloride, stirred at 280~300°C and 150~200rpm for 150~200min; then distilled at 280~300°C, 100~150rpm and a vacuum of -0.09MPa After 20-30 minutes, light components are distilled off under reduced pressure to obtain low-temperature catalytically modified asphalt. The invention has the characteristics of simple process, low cost, low polymerization reaction temperature, avoiding ax bottom coking and prolonging the service life of the reactor, and the prepared products meet the standards, have stable product quality and good performance.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing polydiallyl itaconate and dimer acid

ActiveCN101293829BReduce dosageEasy to removeOrganic compound preparationCarboxylic acid esters preparationCatalytic methodDistillation

The invention relates to a method for preparing dimeric acid methyl ester and dimer acid thereof. The method comprises the following steps: performing dimerization reaction of mixed fatty acid methyl ester having high unsaturated fatty acid methyl ester content or mixed fatty acid in the presence of concentrated sulfuric acid as co-catalyst and anhydrous aluminum chloride or anhydrous zinc chloride as catalyst using two step catalytic method; and solving with weak alkali diluted solution (the pH value is 7-8), washing for removing the catalyst to obtain coarse dimmer (yield of more than 80%),and further performing molecular distillation of coarse dimeric fatty acid methyl ester or coarse dimeric fatty acid in certain condition for removing monomer to reach dimmer content of greater than 90%. The method is carried out at normal pressure with less catalyst which can be removed easily. The coarse product is separated using an advanced molecular distillation device to avoid dimmer decomposition and occurrence of other byproducts at high temperature, and improve product purity. The method has simple process, easy operation, reduced energy source and reduced cost.

Owner:溧阳常大技术转移中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com