Polyamide resin as well as preparation method and application thereof

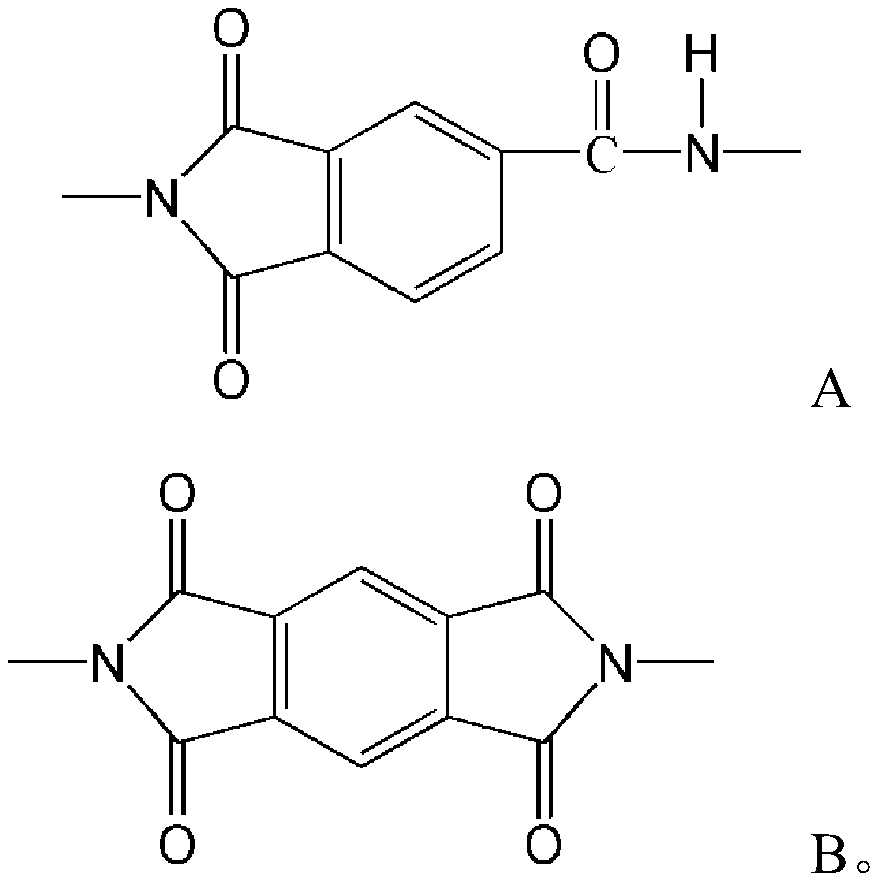

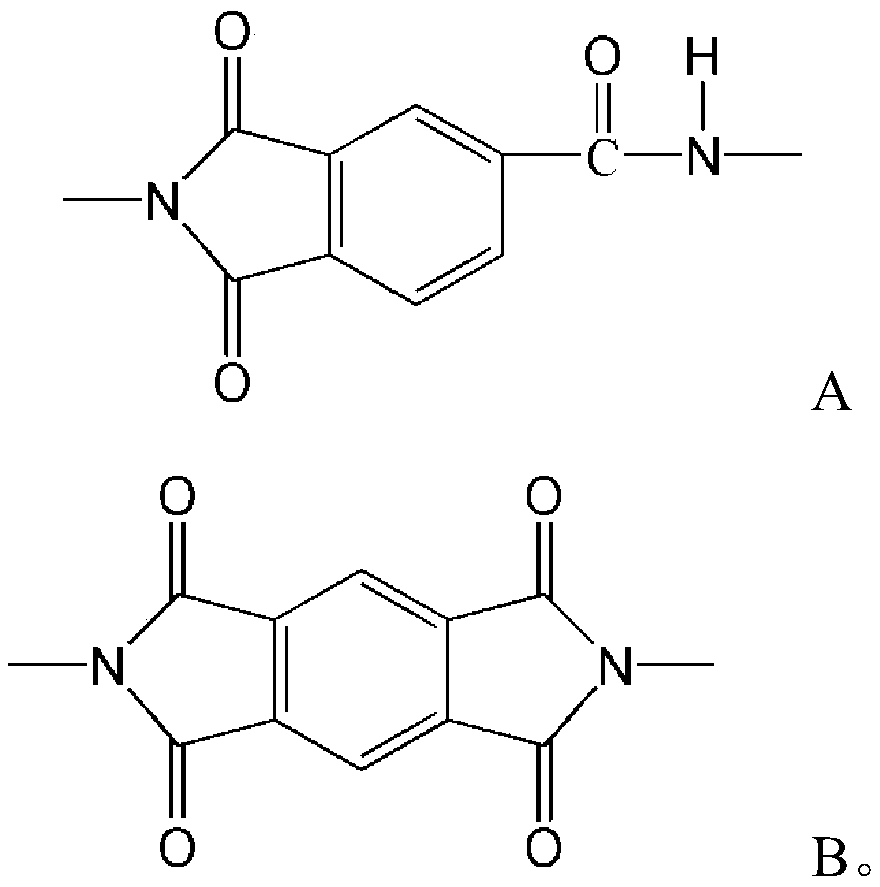

A technology of polyamide resin and aliphatic polyamide, which is applied in the field of polyamide resin and its preparation, can solve problems such as difficulty in meeting heat resistance requirements, inability to heat and melt processing, difficulty in large-scale production and application, and achieve high mechanical strength Performance and dimensional stability, easy control of the reaction process, and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

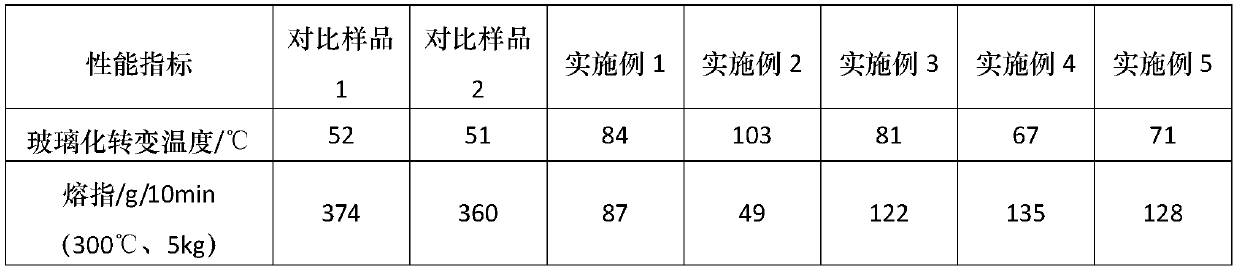

Examples

Embodiment 1

[0061] (1) 16.6 g of adipoyl chloride and 3.3 g of pyromellitic acid chloride were dissolved in 200 g of dichloromethane solution to obtain a transparent organic oil phase solution.

[0062] (2) Add 11.6g of hexamethylenediamine, 8.8g of sodium hydroxide, 0.5g of tetrabutylammonium bromide, and 200g of deionized water into a three-necked flask equipped with a stirring device and a thermometer, and stir to dissolve it to form a colorless and transparent alkaline aqueous solution.

[0063] (3) Stir at a rotation speed of 800 rpm, slowly (0.5 h) drop the prepared organic solution into the aqueous solution, react at 20° C. for 1.5 h, and stop the reaction.

[0064] (4) Pour 1000g of diethyl ether into the vigorously stirred reaction solution for precipitation, use a Buchner funnel to vacuum filter to remove the reaction solvent water, dichloromethane and precipitant diethyl ether, and use 1% alkaline aqueous solution and 1% dichloromethane to precipitate the precipitate respective...

Embodiment 2

[0066] (1) 12.8 g of adipoyl chloride and 8.0 g of trimellitic acid chloride were dissolved in 500 g of 1,2-dichloroethane solution to obtain a transparent organic oil phase solution.

[0067] (2) Add 11.6g of hexamethylenediamine, 23g of sodium carbonate, 5g of cetyltrimethylammonium bromide, and 100g of deionized water into a three-necked flask equipped with a stirring device and a thermometer, and stir to dissolve it to form a colorless Transparent alkaline aqueous solution.

[0068] (3) Stir at a rotation speed of 600 rpm, slowly (1 h) drop the prepared organic solution into the aqueous solution, react at 10° C. for 3 h, and stop the reaction.

[0069] (4) Pour 5000g of ethanol into the vigorously stirred reaction solution for precipitation, use a Buchner funnel to vacuum filter to remove the reaction solvent water, 1,2-dichloroethane and precipitant ethanol, and separate the precipitates with 5% alkali Wash with alkaline aqueous solution, 5% HCl aqueous solution and dist...

Embodiment 3

[0071] (1) 16.8 g of sebacoyl chloride and 10.0 g of pyromellitic acid chloride were dissolved in 350 g of chloroform solution to obtain a transparent organic oil phase solution.

[0072] (2) Add 17.2g decanediamine, 20g sodium bicarbonate, 3g phenyltrimethylammonium chloride, and 300g deionized water into a three-necked flask equipped with a stirring device and a thermometer, and stir to dissolve it to form a colorless and transparent alkaline aqueous solution.

[0073] (3) Stir at a rotation speed of 1200 rpm, slowly (0.1 h) drop the prepared organic solution into the aqueous solution, react at 30° C. for 0.5 h, and stop the reaction.

[0074] (4) Pour 2000g of ethyl acetate into the vigorously stirred reaction solution for precipitation, use the Buchner funnel to vacuum filter to remove the reaction solvent water, chloroform and precipitant ethyl acetate, and use 0.06% alkaline Wash with aqueous solution, 0.06% HCl aqueous solution and distilled aqueous solution until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com