Patents

Literature

38results about How to "Meet heat resistance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Addition-type heat-resistant silicon rubber and preparation method thereof

InactiveCN103087532AMeet heat resistance requirementsIncrease productivityPtru catalystMethyl benzene

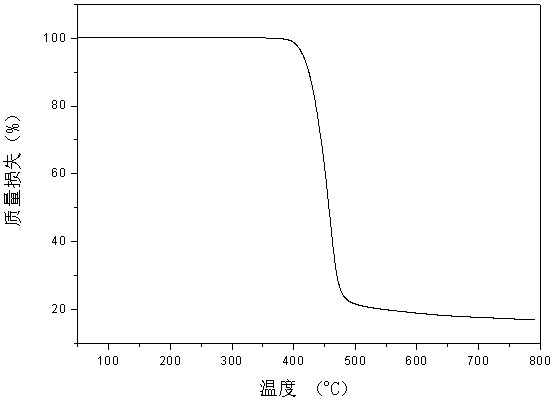

The invention discloses addition-type heat-resistant silicon rubber and a preparation method thereof. The heat-resistant silicon rubber comprises a component A and a component B, wherein the component A is prepared from the following ingredients in parts by weight: 100 parts of methyl phenyl vinyl silicone oil, 2-4 parts of catalyst, 4-12 parts of heat-resistant additive processed by a silane coupling agent, and 400-500 parts of auxiliary packing processed by the silane coupling agent; the component B is prepared from the following ingredients in parts by weight: 100 parts of methyl phenyl vinyl silicone oil, 1.8-2.5 parts of cross-linkingagent, 0.1-0.15 parts of inhibitor, 4-12 parts of heat-resistant additive processed by the silane coupling agent, and 400-500 parts of auxiliary packing processed by the silane coupling agent; and the components A and B are evenly mixed according to the equal mass ratio, defoamed in vacuum and cured to prepare the addition-type heat-resistant silicon rubber. The heat-resisting temperature of the addition-type heat-resistant silicon rubber disclosed by the invention can achieve 460 DEG C; and the heat-resisting requirements of the fields such as aeronautics and astronautics, ignition cable protecting bushes of automobiles, and high-temperature sealing elements on the silicon rubber can be met.

Owner:HEFEI UNIV OF TECH

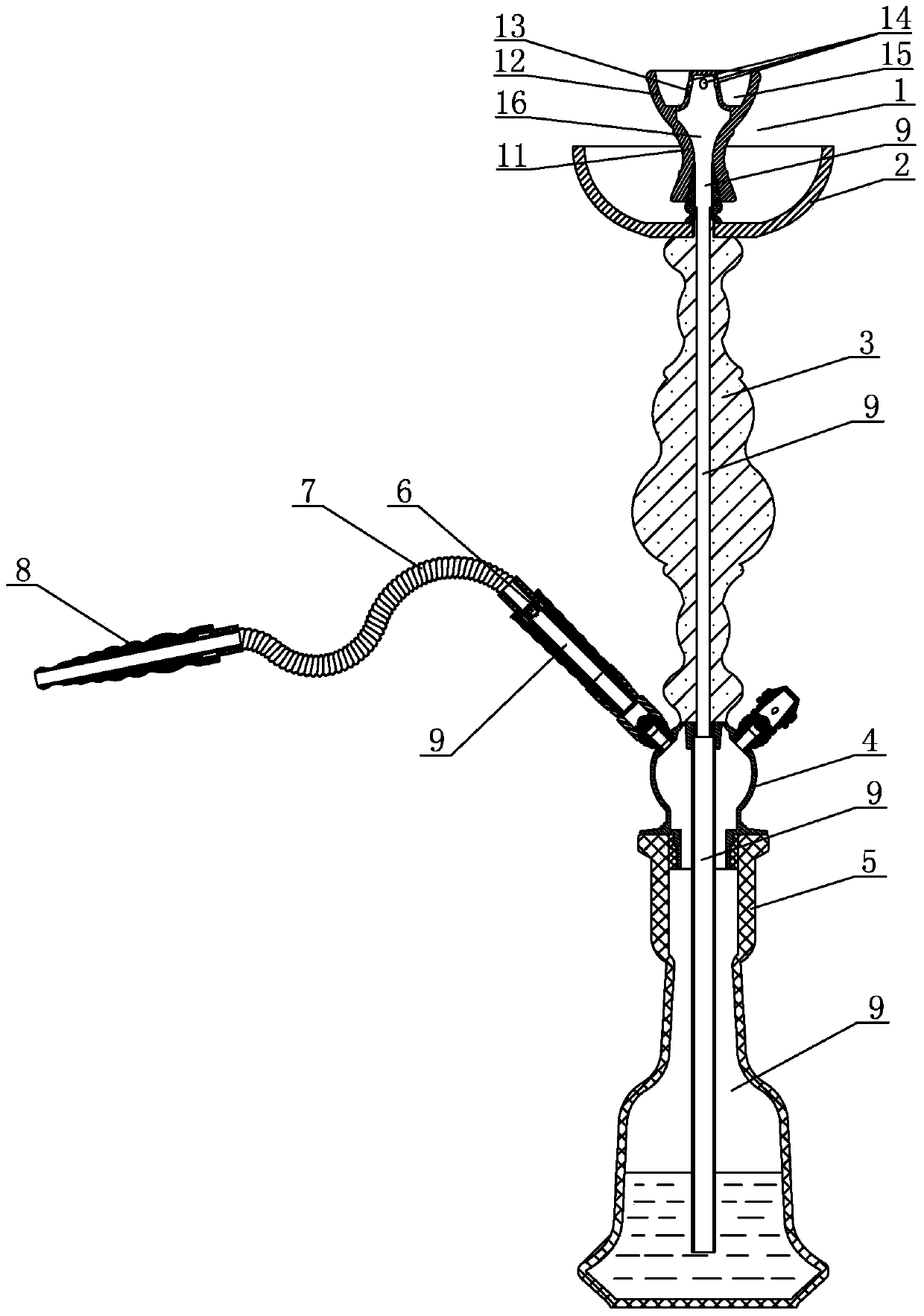

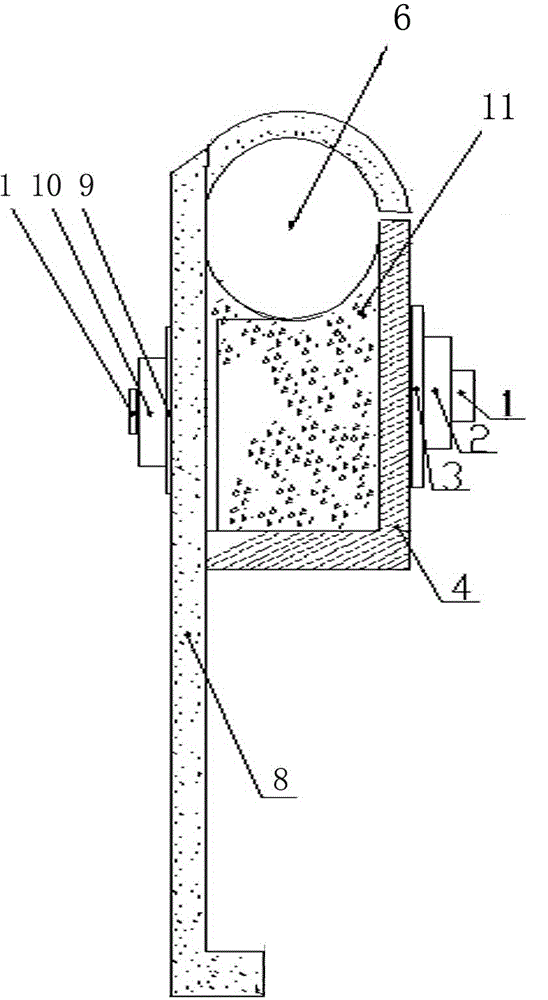

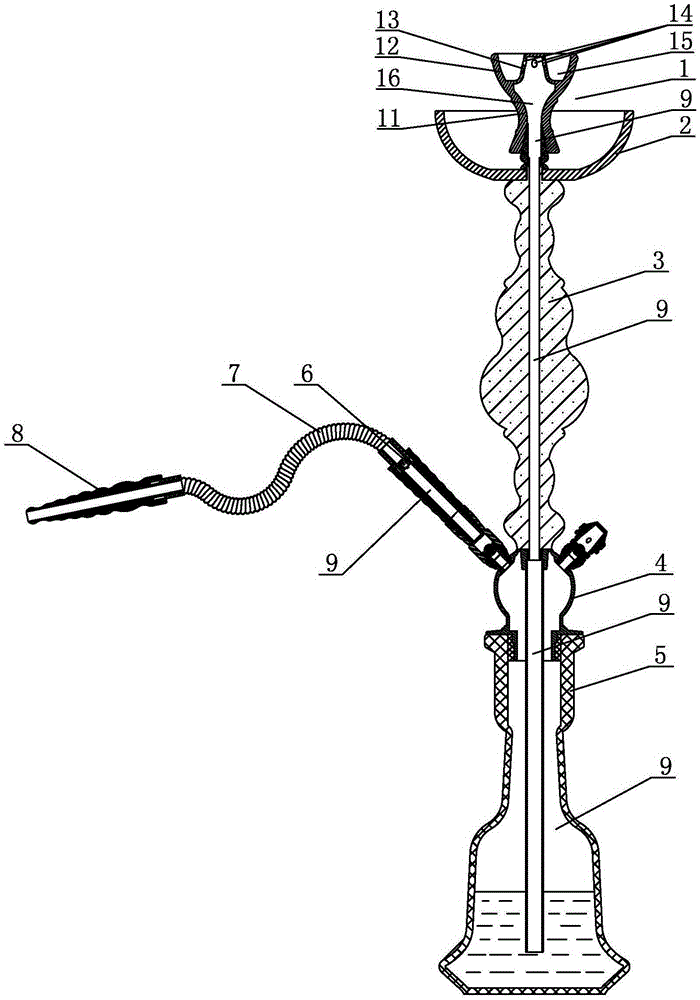

Hookah

The invention discloses a hookah which comprises a smoke pan head, a tray, a smoke pipe, a smoke discharging barrel and a smoke bottle which are communicated in sequence from top to bottom, wherein the smoke discharging barrel is connected with a hose; a suction nozzle is arranged at the end part of the hose; a hookah pipeline is formed between the smoke pan head and the suction nozzle; the smoke pan head is made of heat-resistant halogen-free flame-resistant silicone rubber and consists of a base, a smoke pan and a cap body; a plurality of smoke outlet holes are formed in the cap body; an opening is formed in the lower part of the cap body; a concave cavity for containing cigarette tobaccos is formed between the inner wall of the smoke pan and the outer wall of the cap body; a smoke cavity is formed in the base and is communicated with the concave cavity through a plurality of smoke outlet holes; the bottom of the smoke cavity is a taper with a small upper part and a large lower part. The smoke pan head is made of the heat-resistant halogen-free flame-resistant silicone rubber, is breakage-proof, has good handfeel and can meet a requirement on heat resistance; the service life of the smoke pan head can be prolonged; the bottom of the smoke cavity is the taper with the small upper part and the large lower part, so that the smoke cavity is conveniently connected with the smoke pipes with different sizes, and the smoke pipe and the smoke cavity are tightly connected during connection, so that air leakage can be avoided.

Owner:宁波市海曙拓睿工艺品有限公司

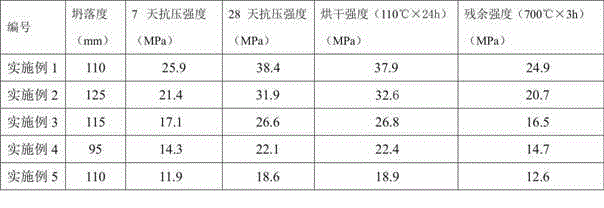

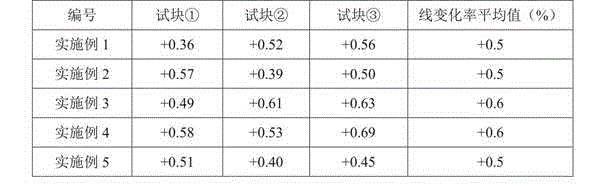

Heat-resistant concrete

InactiveCN103553651AReduce manufacturing costMeet heat resistance requirementsMining engineeringSlag

The invention relates to heat-resistant concrete. The heat-resistant concrete is prepared by using fly ash ceramsite as a coarse aggregate and blast furnace water quenched slag as a fine aggregate. The heat-resistant concrete can fully replace igneous rock coarse and fine aggregates to prepare the heat-resistant concrete in the prior art. Detected indexes fit various performance indexes required by the heat-resistant concrete.

Owner:CHINA FIRST METALLURGICAL GROUP

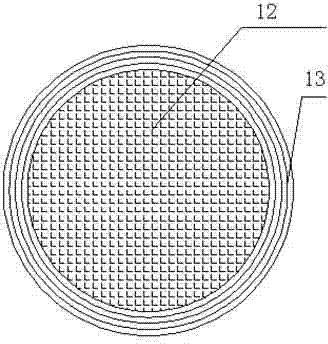

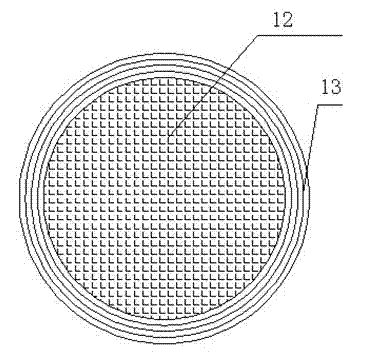

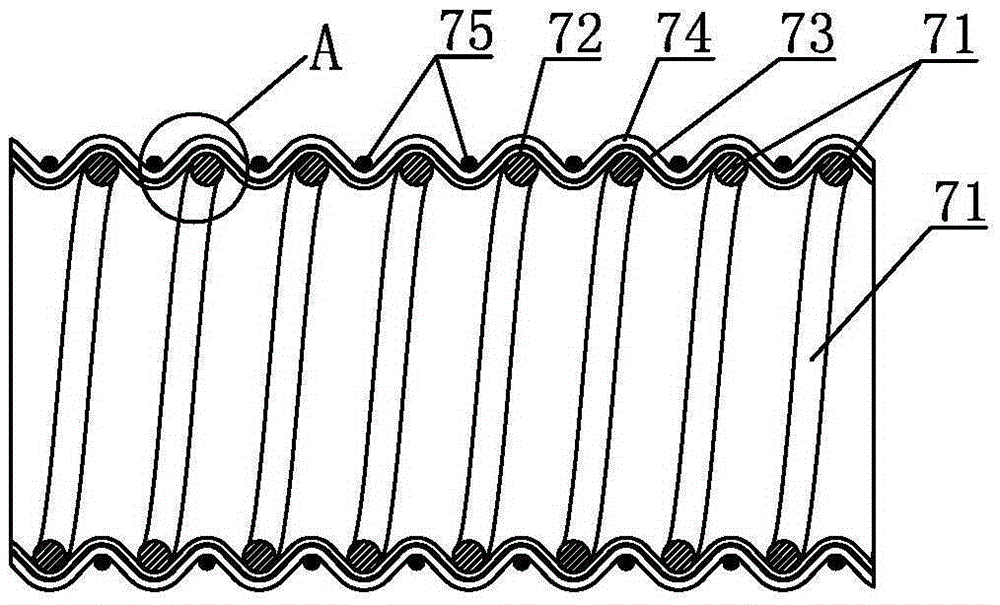

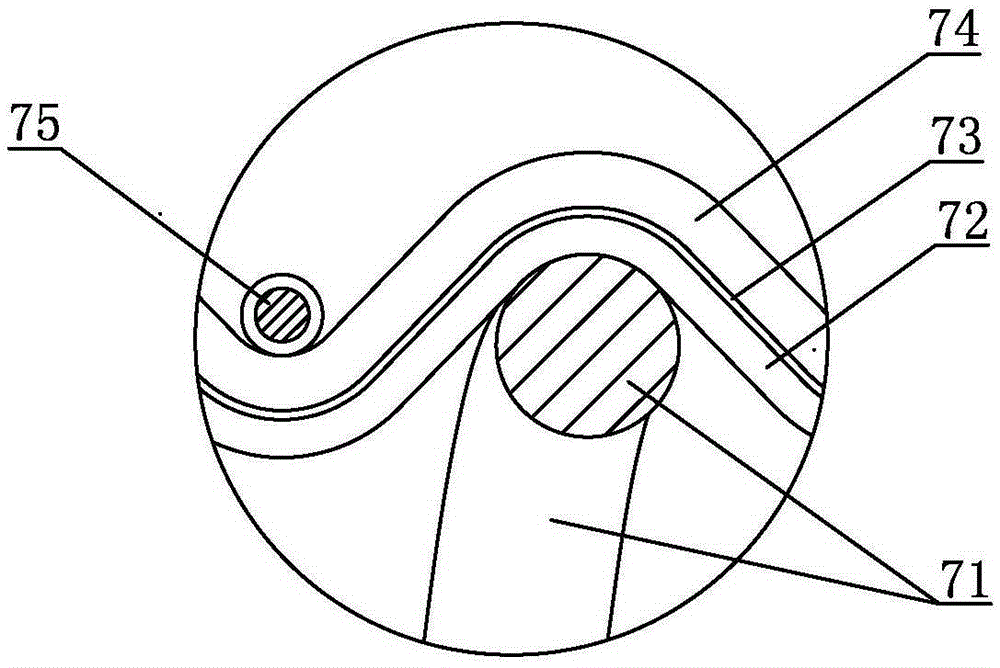

Cable core of carbon fiber composites

ActiveCN103093888AImprove mechanical propertiesExtend working lifeInsulated cablesInsulated conductorsGlass fiberEpoxy

The invention relates to a cable core of carbon fiber composites. The cable core of the carbon fiber composites comprises a bearing core (12) and a protective layer (13), and the protective layer (13) covers the outer portion of the bearing core (12) through a winding process. The cable core is characterized in that the bearing core (12) is the composite of epoxy resin and carbon fibers, wherein the epoxy resin is heat resisting and high in mechanical property, and the protective layer (13) is the composite of epoxy resin and glass fibers, wherein the epoxy resin is high temperature resisting and weather resisting. Due to the fact that the bearing core and the protective layer are chosen to be different epoxy resin systems, the high mechanical property of the epoxy resin system of the bearing core cannot be influenced by the epoxy resin system of the outer protective layer, the good weather resisting property of the outer protective layer protects the bearing core from being damaged by outer environment, and the combination property of the cable core is greatly improved.

Owner:CHANGJI POWER SUPPLY COMPANY STATE GRID XINJIANGELECTRIC POWER +1

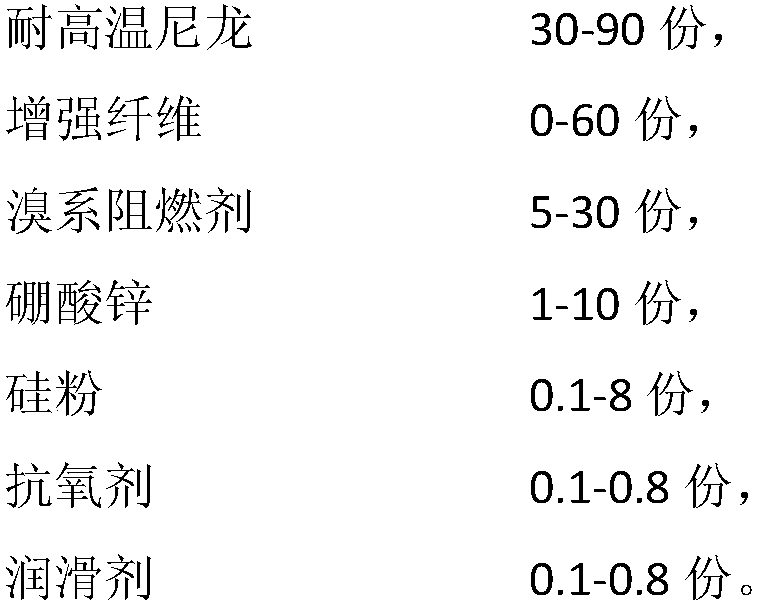

Anticorrosion high temperature resistant and flame-retardant nylon composite material and preparation method thereof

The invention provides an anticorrosion high temperature resistant and flame-retardant nylon composite material and a preparation method thereof. The composite material includes: 30-90 parts of high temperature resistant nylon, 0-60 parts of reinforcement fiber, 5-30 parts of a brominated flame retardant, 1-10 parts of zinc borate, 0.1-8 parts of silicon powder, 0.1-0.8 part of an antioxidant, and0.1-0.8 part of a lubricant. The method includes: mixing dry high temperature resistant nylon, the brominated flame retardant, zinc borate, silicon powder, the antioxidant and the lubricant to obtaina mixture; adding the mixture into a twin-screw extruder from a main feed port, adding the reinforcement fiber into the twin-screw extruder from a side feed port, and conducting drawing, cooling, grain cutting and drying, thus obtaining the anticorrosion high temperature resistant and flame-retardant nylon composite material. The anticorrosion high temperature resistant and flame-retardant nyloncomposite material provided by the invention has a high comparative tracking index, and can avoid generation of methane gas at high temperature, thus reducing corrosion of a mold surface.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

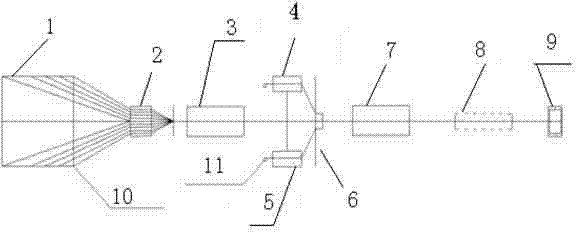

Manufacture method of cable core

InactiveCN103093897AImprove mechanical propertiesExtend working lifeCable/conductor manufactureGlass fiberEpoxy

The invention relates to a manufacture method of a cable core. The manufacture cost of the cable core comprises the following steps: carbon fibers are led out of a creel, gum dipping is carried out to the carbon fibers after entering a first gum dipping area, and used epoxy resin is epoxy resin with heat-resisting high mechanical property; the carbon fibers after gum dipping enter a first curing oven to be precured, carbon fiber composite core are manufactured, the diameter of each carbon fiber composite core is 5mm to 12mm, and a curing degree reaches more than 85% by adjusting temperature; glass fibers on two sides are led out and respectively enter a second gum dipping area and a third gum dipping area, and used epoxy resin is high temperature resistant and weather resistant; the glass fibers after gum dipping pass through a winding area and are wound and cover the outer layers of the carbon fiber cores, the thickness of single side is 0.5mm to 2mm, and winding speed is synchronous with pultrusion speed by being controlled by a servo motor; and the carbon fiber composite cores and the glass fiber protective layers pass through the second curing oven after being compounded, and are fully cured by adjusting temperature. Composite material cable core products pass through a dragger and are wound up on the position of a winding disc.

Owner:STATE GRID CORP OF CHINA +1

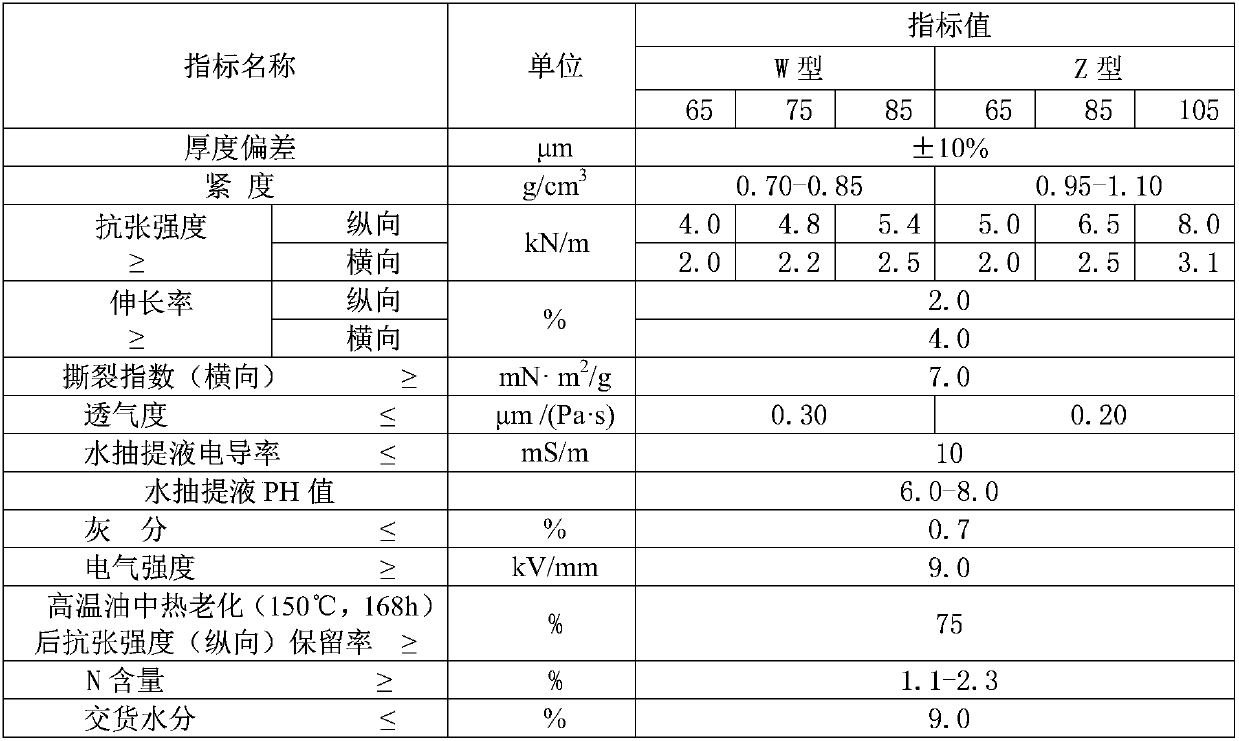

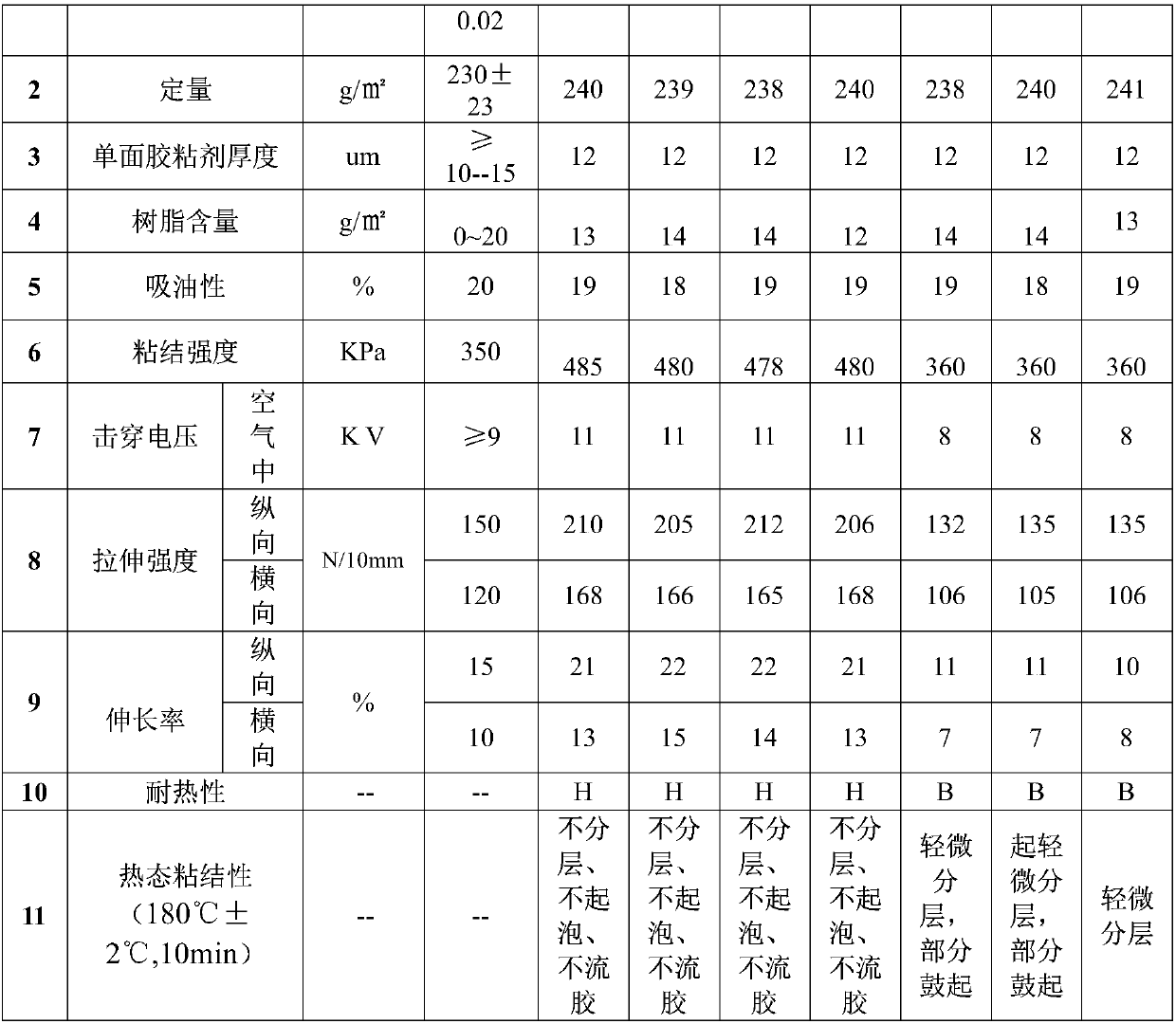

Dispensing insulation paper suitable for wind power and solar transformers, and application thereof

InactiveCN107901556AMeet heat resistance requirementsSmall sizeLamination ancillary operationsSynthetic resin layered productsElectricityTransformer

The invention discloses a dispensing insulation paper suitable for wind power and solar transformers, and an application thereof. The dispensing insulation paper comprises a first heatproof insulationpaper, a middle layer formed by a polyimide film and a second heatproof insulation paper which are sequentially stacked, the first insulation paper and the middle layer are bonded through an adhesive, and the second insulation paper and the middle layer are bonded through the adhesive, wherein the adhesive is a composite adhesive, and the composite adhesive includes a PU adhesive and an epoxy adhesive, and a mass ratio of the PU adhesive to the epoxy adhesive is (8-10):1; the epoxy adhesive includes modified epoxy resin and an epoxy resin curing agent according to a mass ratio is (4-8):1; andthe modified epoxy resin comprises liquid epoxy resin and solid epoxy resin according to a mass ratio of (0.5-2):1, and the adhesive is dispensed on the outer surfaces of the first and second heatproof insulation papers. The invention also discloses the application of the dispensing insulation paper in the wind power transformers and solar transformers. The dispensing insulation paper has the advantages of high heatproof grade, good mechanical strength and good breakdown voltage, and is extremely suitable for the interlayer insulation of the wind power and solar transformers.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Antifriction heat-resistant cobalt-based alloy material used for laser composite manufacturing of large and medium proximate matter rollers

InactiveCN106756256AHeat fatigue resistantHigh temperature corrosion resistanceMetallic material coating processesHigh pressureLaser

The invention discloses antifriction heat-resistant cobalt-based alloy powder used for laser composite manufacturing of large and medium proximate matter rollers. The antifriction heat-resistant cobalt-based alloy powder is characterized in that the components of the cobalt-based alloy powder material comprise, by weight, 0.55-1.25% of C, 20.00-27.00% of Cr, 1.00-1.30% of Si, 10.00-15.00% of Ni, 0.20-0.50% of Mn, 5.50-11.50% of W, 1.00-1.50% of Fe, 3.00-5.00% of B, 2.50-5.20% of N and the balance Co. By optimizing the matching of the laser cladding powder material, the antifriction heat-resistant material suitable for the large and medium proximate matter rollers is designed, and cladding layers are manufactured on the surfaces of the large and medium proximate matter rollers through the laser cladding technology, so that the abrasion resistance requirement of the rollers under the high temperature and high pressure conditions is met.

Owner:沈阳大陆激光工程技术有限公司

Heat-resistant aluminum alloy conductor material with electric conductivity of 62 percent and preparation method for heat-resistant aluminum alloy conductor material

InactiveCN104561674AImprove heat resistanceImprove conductivityMetal/alloy conductorsCable/conductor manufactureMechanical propertyYttrium

The invention discloses a heat-resistant aluminum alloy conductor material with the electric conductivity of 62 percent and a preparation method for the heat-resistant aluminum alloy conductor material, and belongs to the technical field of conductor materials for overhead transmission lines. The material comprises the following elements in percentage by mass: 0.31 to 0.50 percent of erbium, 0.20 to 0.40 percent of yttrium, 0.02 to 0.05 percent of boron, less than or equal to 0.06 percent of silicon impurities, less than or equal to 0.20 percent of iron impurities, less than or equal to 0.012 percent of impurities of chromium, manganese, vanadium and titanium, and the balance of aluminum, wherein the mass ratio of the erbium to the boron is greater than or equal to 10 and less than or equal to 15. The aluminum alloy conductor material disclosed by the invention is prepared into the lines in the required specifications by smelting, casting, cold machining and hot machining. The aluminum alloy conductor material disclosed by the invention has the tensile strength of greater than or equal to 160 MPa, the elongation rate of greater than or equal to 2.0 percent and the electric conductivity of greater than or equal to 62 percent according to IACS. The mechanical properties and the electrical properties at room temperature reach or even exceed those of an LY9-L2 high-conductivity hard aluminum conductor material; the heat resistance meets the requirement on the heat resistance of the heat-resistant aluminum alloy conductor material; compared with a heat-resistant aluminum alloy line with the electric conductivity of 60 percent according to IACS, the line loss can be reduced by 3 percent; remarkable economic benefits can be achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

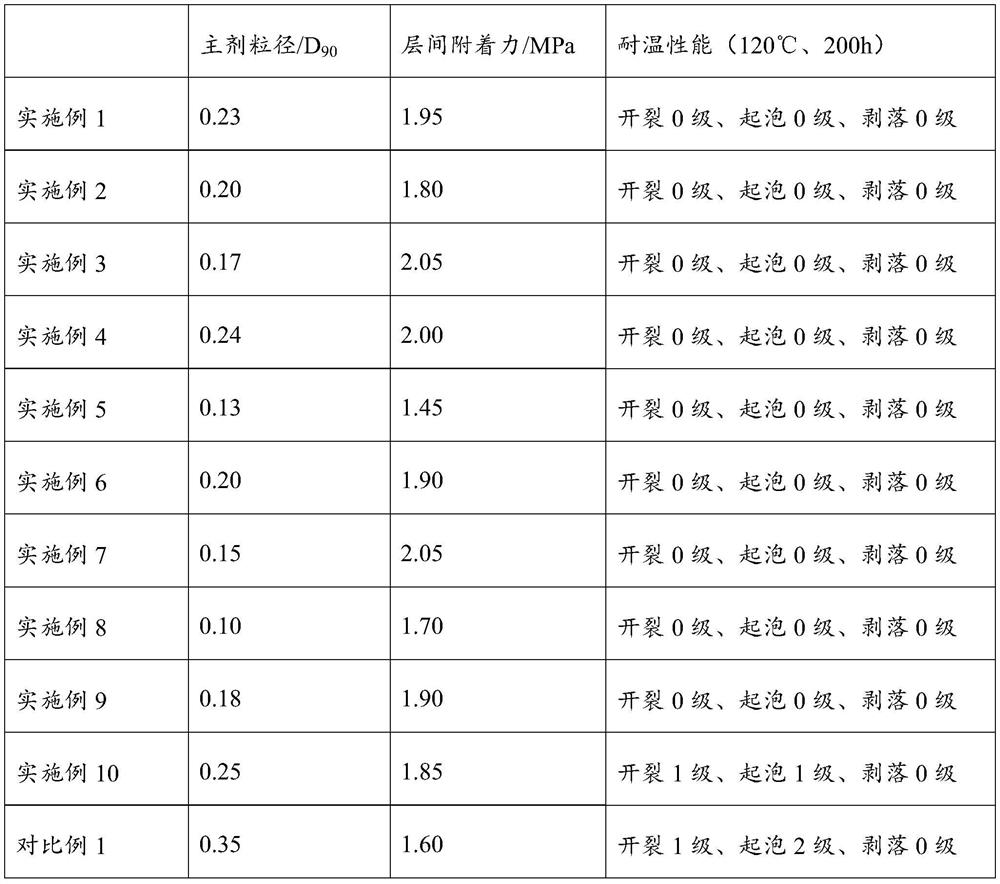

Concrete laitance enhancer and preparation method and application thereof

The invention belongs to the technical field of functional polymer materials, and particularly relates to a concrete laitance enhancer and a preparation method and application thereof. The concrete laitance enhancer is a graft copolymerization epoxy type concrete laitance reinforcer containing polyfunctional groups, the main agent is submicron grafted multifunctional resin with the particle size of 0.05-0.25 mu m, the silanol structural unit of the main agent has excellent permeability to laitance and the interior, and the silanol structural unit is coupled with surface OH to enhance the strength of a laitance substrate, the tensile cohesion strength of laitance on the surface of concrete is improved, the construction coating also has good strength when the laitance does not need to be polished clean in engineering application, the enhancer has good wetting adhesiveness to a concrete substrate and a subsequent coating, the adhesive force of the matched protective coating is larger than or equal to 1.5 MPa, meanwhile, the enhancer is a thermosetting coating film obtained through crosslinking, the heat resistance, temperature change creep resistance and heat resistance of the reinforcer are improved, and the coating temperature resistance requirement of 200 hours at the temperature of 120 DEG C can be met.

Owner:T&H NOVEL MATERIALS (SUZHOU) CO LTD +2

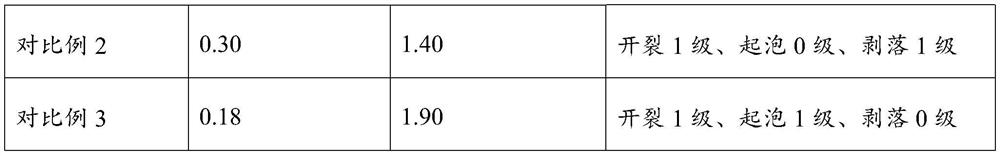

Liquid organic silicon doping hexagonal boron nitride material and automatic preparation and industrial application method thereof

InactiveCN105670300ALow conductivity and heat dissipation coefficientReduce toughnessHydrogenHexagonal boron nitride

The invention discloses a liquid organic silicon-doped hexagonal boron nitride material and its automatic preparation and industrial application methods. The material is composed of component A composed of vinyl silicone oil, surface-activated hexagonal boron nitride, inhibitor and catalyst, and group B composed of vinyl silicone oil, hydrogen-containing silicone oil and surface-activated hexagonal boron nitride grouped. Its automatic preparation and industrial application method, the steps are as follows: 1) A and B components are automatically transported and mixed, and then enter the precision injection system; 2) At the same time, the silver-plated stone black ene composite metal sheet is automatically transported to the mold setting 3) Then after glue injection, curing, wrapping, slicing, chip sticking, gold wire connection, potting glue potting, it is transformed into components such as LED light source and IC patch. The liquid organic silicon-doped hexagonal boron nitride material prepared by the invention has excellent characteristics such as high and low temperature resistance, high molding efficiency, good sealing performance, and low cost, and can be widely used in various fields of optoelectronic components.

Owner:DONG GUAN CHI MING ELECTRONICS TECH CO LTD

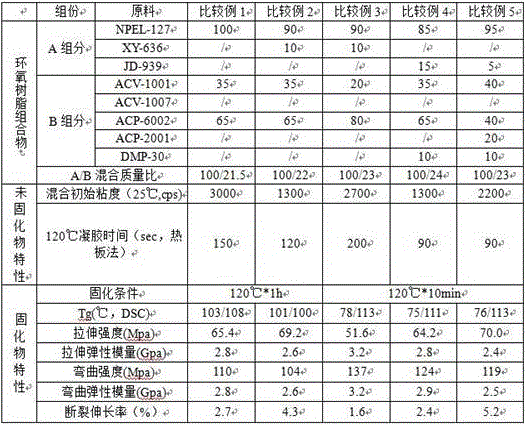

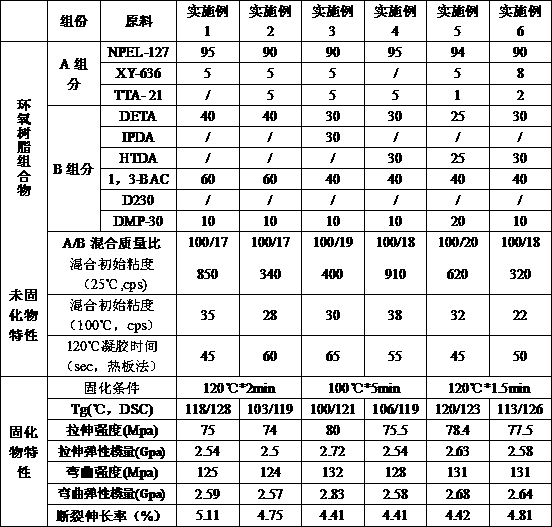

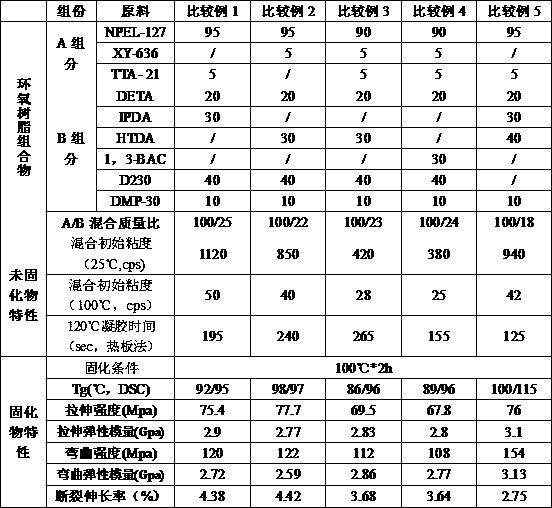

Epoxy resin composition for rapid forming of fiber-reinforced automobile parts, preparation method and recycling method

ActiveCN106632996AMeet heat resistance requirementsImprove mechanical propertiesPlastic recyclingFiberFatty amine

The invention discloses an epoxy resin composition for rapid forming of fiber-reinforced automobile parts, a preparation method and a recycling method. The epoxy resin composition is prepared from a component A and a component B, wherein the component A is prepared from bisphenol A epoxy resin 127, triglycidyl p-aminophenol JD-939 and a trifunctional glycidyl ether diluent XY636; the component B is prepared from a degradable fatty amine curing agent ACV-1001, a degradable fatty amine curing agent ACV-1007, a degradable hydrazide amine curing agent ACP-6002, a degradable aromatic amine curing agent ACP-2001 and an accelerant of phenol. The epoxy resin composition disclosed by the invention can be rapidly cured at 110 to 120 DEG C, the viscosity is ultra low at 110 to 120 DEG C, reinforced fiber can be rapidly infiltrated, the epoxy resin composition is suitable for rapid molding technologies of HP-RTM (High Pressure-Resin Transfer Molding) and WCM (Wet Compression Molding), and the molding period of epoxy composite automobile parts can be shortened to 5 to 10 minutes.

Owner:芜湖天道绿色新材料有限公司

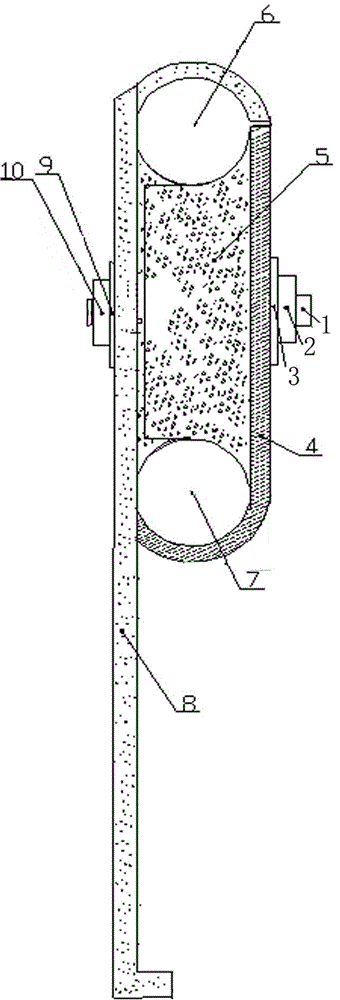

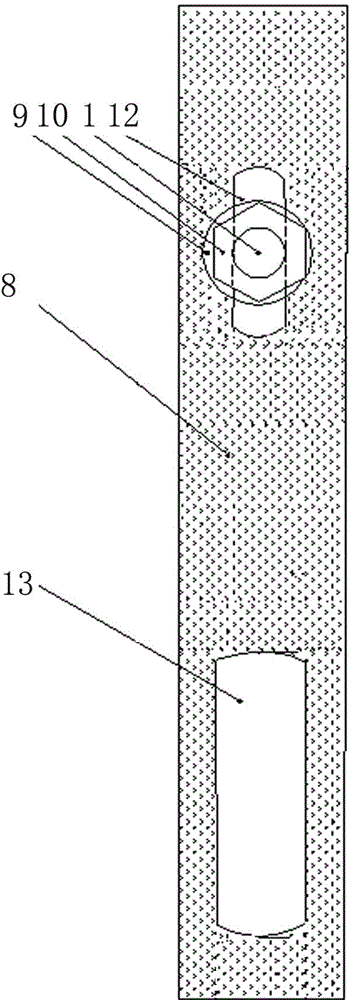

Span adjustable grounding wire head clamp device

ActiveCN102683922BMeet conductivityMeet heat resistance requirementsElectric connection structural associationsClamped/spring connectionsHeat resistanceGrounding line

The invention relates to the technical field of a span adjustable grounding wire head clamp device. The device is characterized in that an upper retaining ring, a concave pillar and a lower retaining ring and a wire hanging plate thereof are connected by screws; and an adjustable retaining hole and a ground wire hanging groove are also arranged at the bottom of the lower retaining ring and the wire hanging plate thereof. The device has the following beneficial effects that the problem of installation of grounding wires of overhead single conductors with current-carrying capacities being above 879A and wire diameter areas being above 400mm<2> and overhead composite conductors with current-carrying capacities being above 1620A and wire diameter areas being above 400mm<2>*2 and the problem that the grounding wires are difficult to install in the places needing installation of the grounding wires due to various reasons are solved; and the device meets the requirements of electrical conductivity and heat resistance, has simple structure and can not only appropriately adjust the span to meet the installation requirement according to the overhead wire diameters on the site but also be suitable for various grounding wire conductor terminal joints.

Owner:SHENYANG POWER SUPPLY LIAONING POWER +1

a hookah

The invention discloses a hookah which comprises a smoke pan head, a tray, a smoke pipe, a smoke discharging barrel and a smoke bottle which are communicated in sequence from top to bottom, wherein the smoke discharging barrel is connected with a hose; a suction nozzle is arranged at the end part of the hose; a hookah pipeline is formed between the smoke pan head and the suction nozzle; the smoke pan head is made of heat-resistant halogen-free flame-resistant silicone rubber and consists of a base, a smoke pan and a cap body; a plurality of smoke outlet holes are formed in the cap body; an opening is formed in the lower part of the cap body; a concave cavity for containing cigarette tobaccos is formed between the inner wall of the smoke pan and the outer wall of the cap body; a smoke cavity is formed in the base and is communicated with the concave cavity through a plurality of smoke outlet holes; the bottom of the smoke cavity is a taper with a small upper part and a large lower part. The smoke pan head is made of the heat-resistant halogen-free flame-resistant silicone rubber, is breakage-proof, has good handfeel and can meet a requirement on heat resistance; the service life of the smoke pan head can be prolonged; the bottom of the smoke cavity is the taper with the small upper part and the large lower part, so that the smoke cavity is conveniently connected with the smoke pipes with different sizes, and the smoke pipe and the smoke cavity are tightly connected during connection, so that air leakage can be avoided.

Owner:宁波市海曙拓睿工艺品有限公司

Epoxy resin composition for high heat-resisting aluminum substrate as well as preparation method and application of epoxy resin composition

InactiveCN108192291AImprove heat resistanceMeet heat resistance requirementsCircuit susbtrate materialsDiluentRaw material

The invention discloses an epoxy resin composition for a high heat-resisting aluminum substrate as well as a preparation method and application of the epoxy resin composition. The epoxy resin composition for the high heat-resisting aluminum substrate is prepared from the following raw material components in parts by weight: 55 to 65 parts of phenolicepoxy resin, 20 to 24 parts of phenolic resin and 17 to 21 parts of a diluent. An LED (Light-Emitting Diode) aluminum substrate circuit board prepared by the epoxy resin composition for the high heat-resisting aluminum substrate has the advantagesof higher heat resistance, and the capabilities of meeting the requirement of welding processing on heat resistance and ensuring the reliability of welding.

Owner:纽宝力精化(广州)有限公司

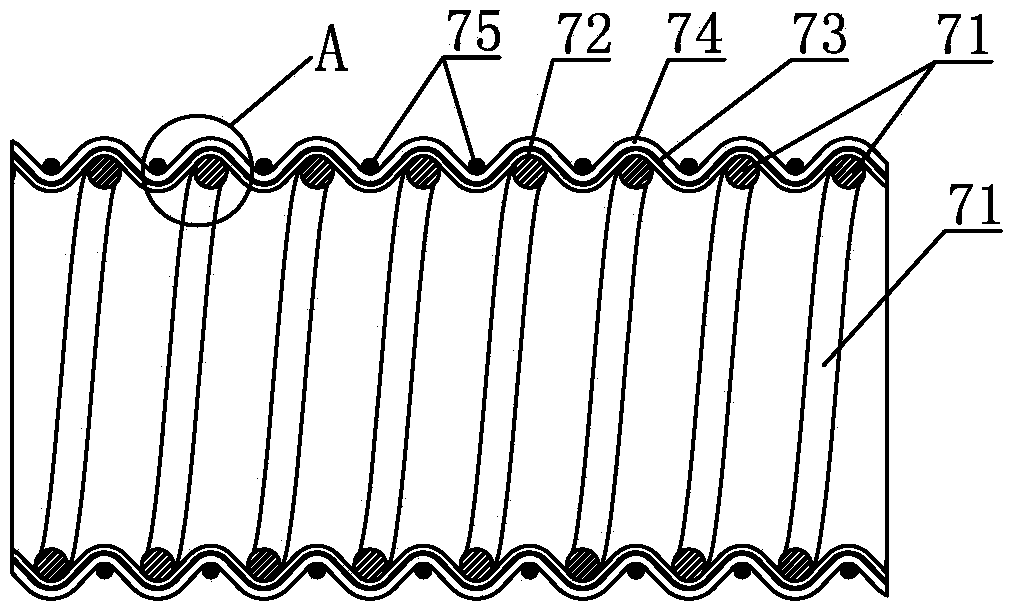

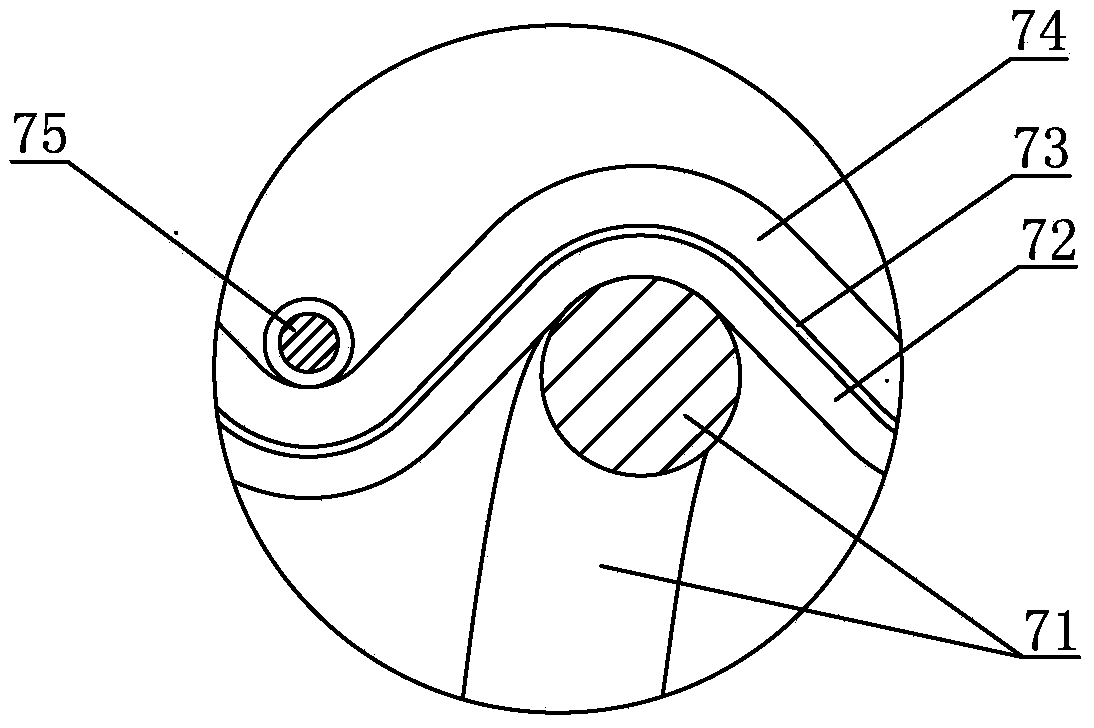

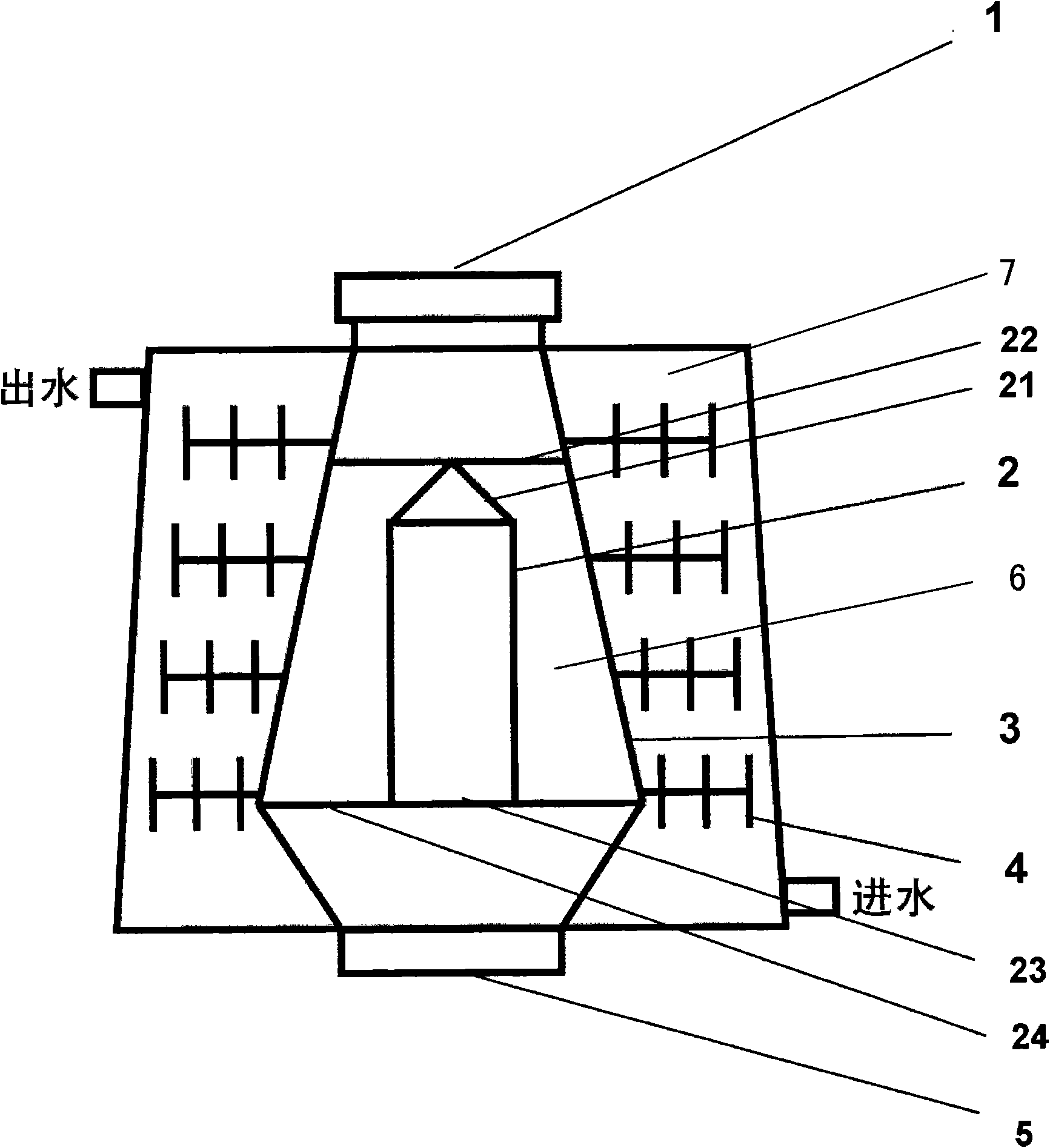

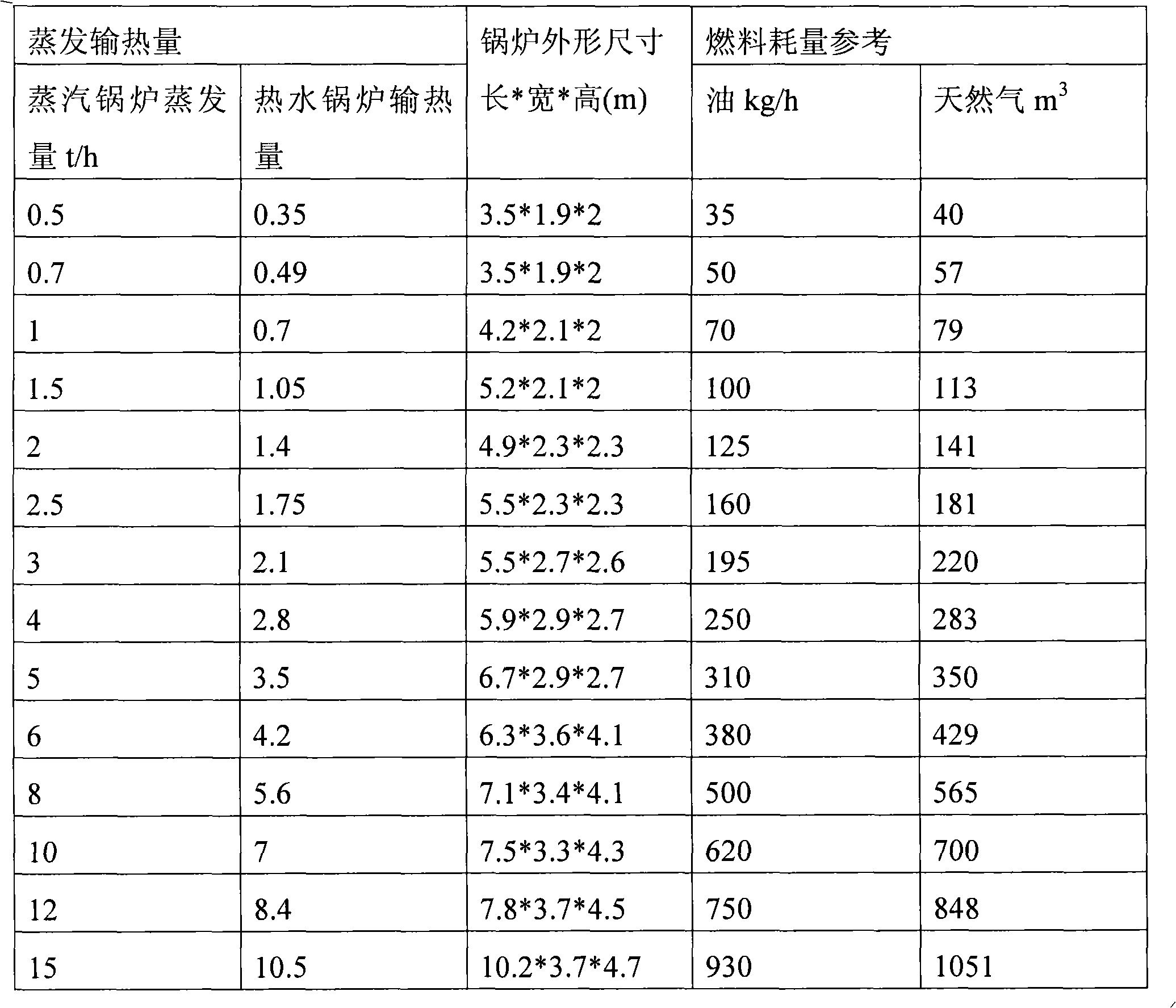

Environmentally-friendly energy-saving device of boiler

InactiveCN101598382AReduce weightReach weightEnergy efficient heating/coolingAir heatersFlue gasProcess engineering

The invention provides an environmentally-friendly energy-saving device of a boiler. The device comprises a flue gas pipeline and a heat transfer unit, wherein the lower part of the flue gas pipeline is provided with a flue gas inlet communicated with a boiler flue gas port, and the upper part of the glue gas pipeline is provided with an outlet; the heat transfer unit is arranged on the periphery of the pipe wall of the flue gas pipeline; and between the flue gas inlet and the outlet, a heat insulation expander is arranged in the glue gas pipeline along the direction of gas flow so as to ensure that the cross sectional area of the flue gas pipeline is reduced. The energy-saving device cannot be limited by a site, has simple structure, low cost and easy popularization and greatly improves the energy-saving effect of the boiler.

Owner:徐卫国

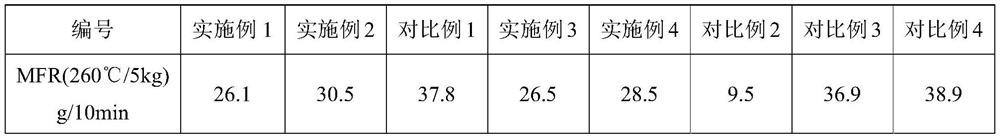

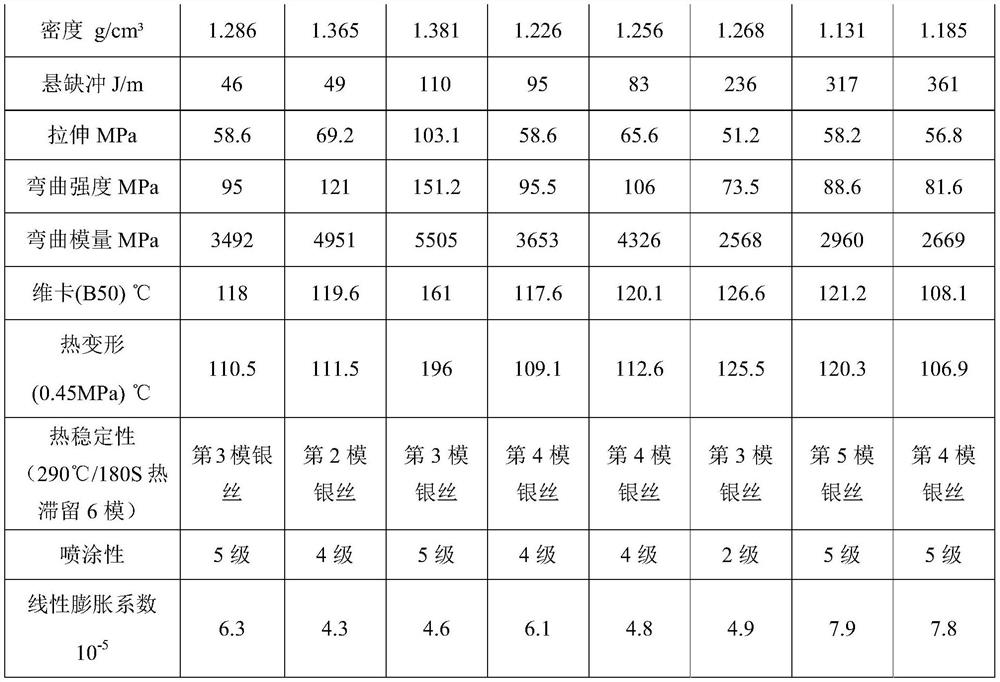

Easy-to-spray high-rigidity alloy material and preparation method thereof

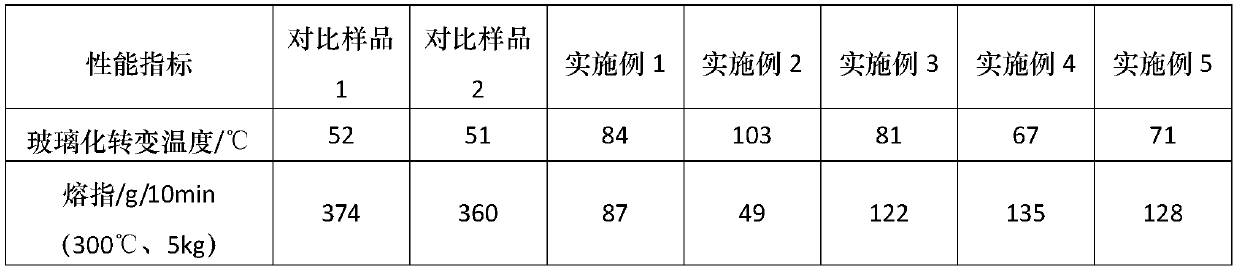

The invention discloses an easy-to-spray high-rigidity alloy material and a preparation method thereof, and relates to the technical field of high polymer materials. The alloy material is prepared from the following components in parts by weight: 5 to 30 parts of aromatic polyester, 20 to 70 parts of polycarbonate, 5 to 30 parts of a styrene-acrylonitrile copolymer, 2 to 8 parts of a flexibilizer, 10 to 30 parts of a filler, 0.5 to 2 parts of a heat stabilizer, 1 part of a coloring agent, 0.4 to 1 part of an antioxidant, 0.2 to 0.5 part of a lubricant and 0.1 to 0.5 part of an ester exchange inhibitor. The easy-to-spray high-rigidity alloy composition provided by the invention has the characteristics of high flowability, high rigidity, good dimensional stability, low linear expansion coefficient, corrosion resistance and easy spraying; the alloy material is especially suitable for replacing a metal material to be applied to the field of interior and exterior decoration coating with high strength requirements, such as skylight decoration strips, and also has a good application effect in the field of frameworks with high requirements for material rigidity and dimensional stability.

Owner:ORINKO NEW MATERIAL CO LTD

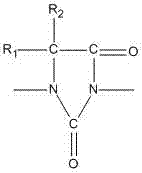

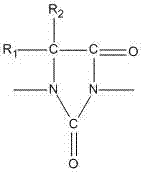

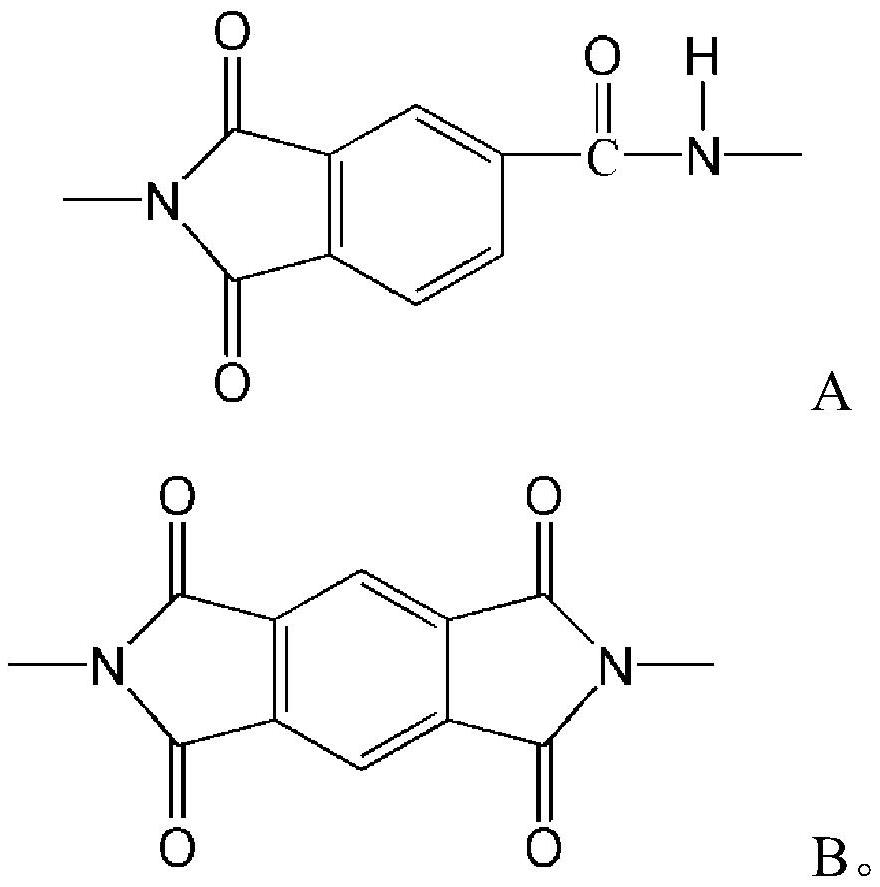

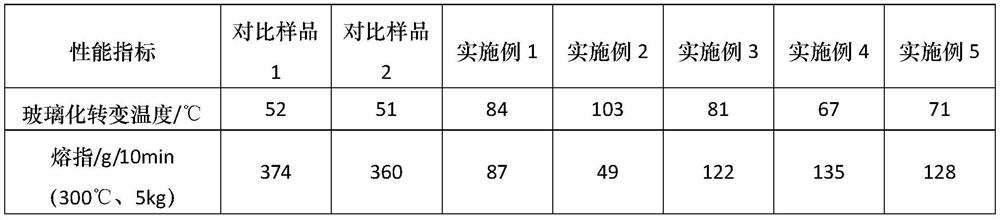

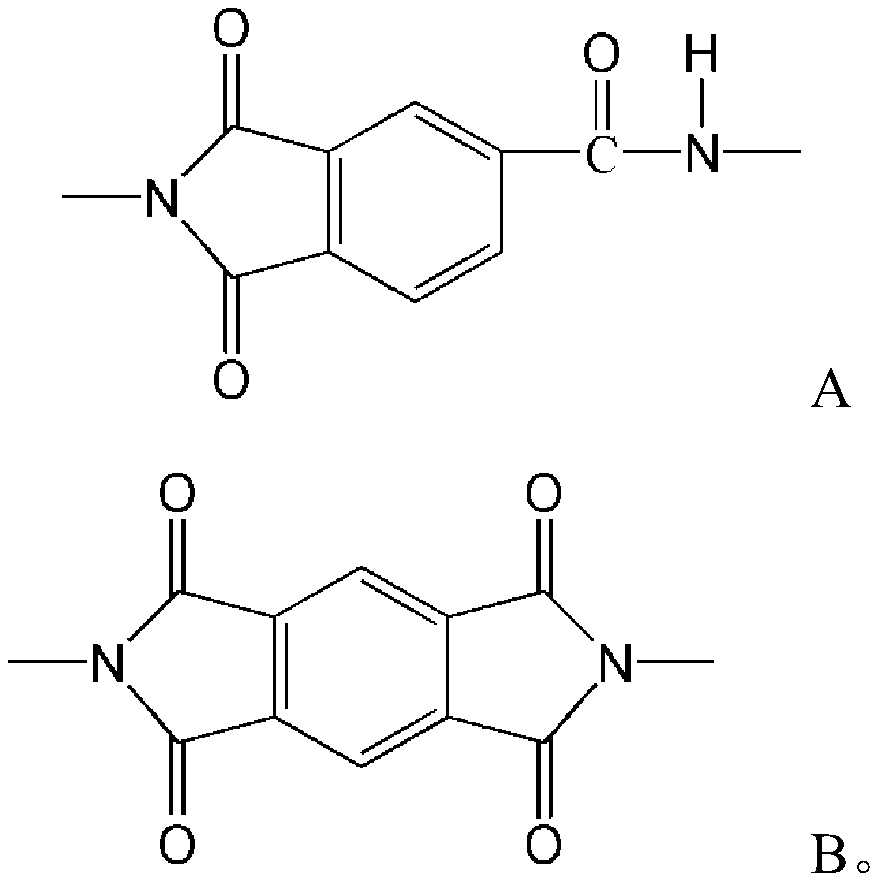

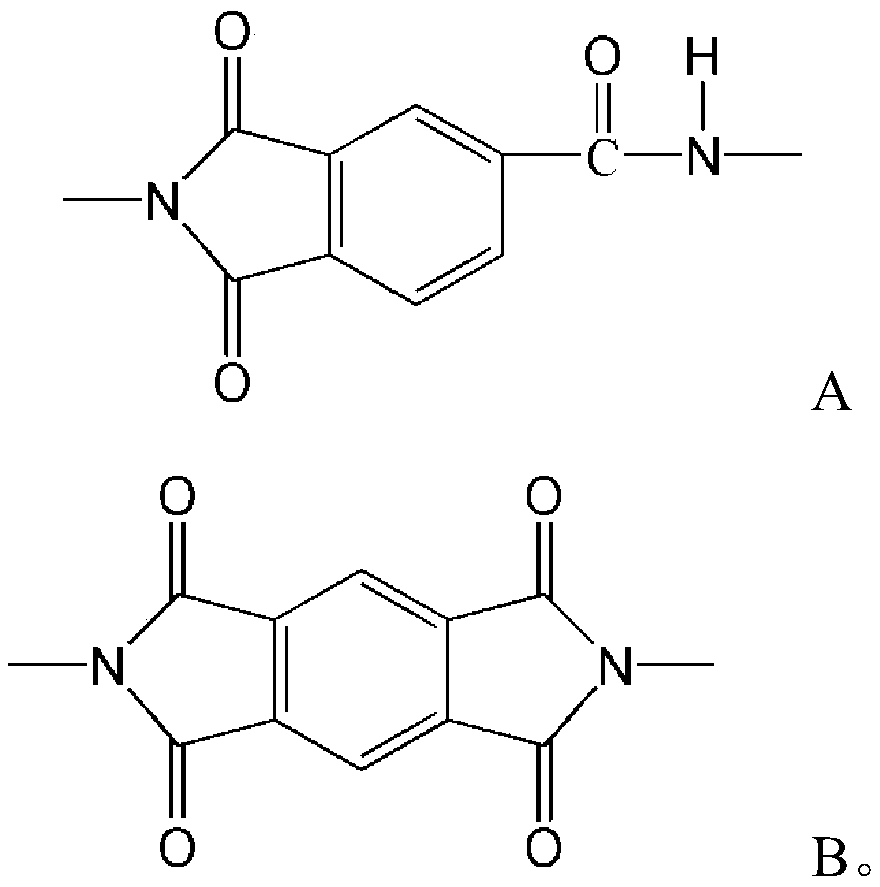

A kind of polyamide resin and its preparation method and application

The present invention relates to a polyamide resin and its preparation method and use. The polyamide resin contains aliphatic polyamide molecular chain segments, and aromatic imide units and aromatic imide units are embedded in the aliphatic polyamide molecular chain segments. amide unit. The polyamide resin is prepared by controlling the polymerization reaction conditions and combining precipitation, washing and drying. The polymerization reaction temperature of the polyamide resin in the invention is relatively low, the reaction process is easy to control, and is suitable for large-scale production and application. The product has excellent heat resistance, which can meet the heat resistance requirements of electronic and electrical reflow soldering (SMT) process and the periphery of automobile engine for plastic products.

Owner:ZHONGLUN PLASTIC IND FUJIAN

A kind of method utilizing lignin to prepare heat-resistant epoxy resin

ActiveCN106008917BHigh glass transition temperatureImprove heat resistanceChemical recyclingFermentationMolecular sievePolymer science

The invention belongs to the technical field of epoxy resin synthesis, and in particular relates to a method for preparing heat-resistant epoxy resin by using lignin. The method for preparing heat-resistant epoxy resin described in the present invention uses common industrial by-product lignin as raw material processing, carries out enzyme modification treatment through the enzyme preparation solution containing at least catalase and β-glucosidase, and selects The HY-type molecular sieve catalyst is used to catalyze the epoxidation reaction, not only the catalyst is easy to obtain and can be recycled, but also the yield of the prepared epoxy resin can reach more than 99%, and the epoxy value of the product and the viscosity of the product are both high. and the prepared epoxy resin has higher glass transition temperature and better heat resistance, which is obviously higher than that of products prepared from general lignin in the prior art and bisphenol A type epoxy resin products, It can meet the heat resistance requirements of epoxy resin in some special fields.

Owner:HUANGSHAN HUIZHOU TIANMA CHEM

Polyamide resin as well as preparation method and application thereof

The invention relates to a polyamide resin as well as a preparation method and application thereof. The polyamide resin comprises an aliphatic polyamide molecular chain segment, wherein an aromatic imide unit and an aromatic amide unit are embedded into the aliphatic polyamide molecular chain segment. The polyamide resin is prepared by controlling polymerization reaction conditions together with precipitation, cleaning and drying treatment. The polyamide resin provided by the invention is low in polymerization reaction temperature, easy in reaction process control and applicable to large-scaleproduction and application. The product has very good thermal resistance, and is capable of meeting requirements of electronic and electrical reflow soldering (SMT) processes and automobile engine accessories on thermal resistance of plastic products.

Owner:ZHONGLUN PLASTIC IND FUJIAN

Epoxy resin composition for rapid prototyping of fiber-reinforced auto parts, preparation method and recycling method

ActiveCN106632996BMeet heat resistance requirementsImprove mechanical propertiesPlastic recyclingFiberTransfer molding

The invention discloses an epoxy resin composition for rapid forming of fiber-reinforced automobile parts, a preparation method and a recycling method. The epoxy resin composition is prepared from a component A and a component B, wherein the component A is prepared from bisphenol A epoxy resin 127, triglycidyl p-aminophenol JD-939 and a trifunctional glycidyl ether diluent XY636; the component B is prepared from a degradable fatty amine curing agent ACV-1001, a degradable fatty amine curing agent ACV-1007, a degradable hydrazide amine curing agent ACP-6002, a degradable aromatic amine curing agent ACP-2001 and an accelerant of phenol. The epoxy resin composition disclosed by the invention can be rapidly cured at 110 to 120 DEG C, the viscosity is ultra low at 110 to 120 DEG C, reinforced fiber can be rapidly infiltrated, the epoxy resin composition is suitable for rapid molding technologies of HP-RTM (High Pressure-Resin Transfer Molding) and WCM (Wet Compression Molding), and the molding period of epoxy composite automobile parts can be shortened to 5 to 10 minutes.

Owner:芜湖天道绿色新材料有限公司

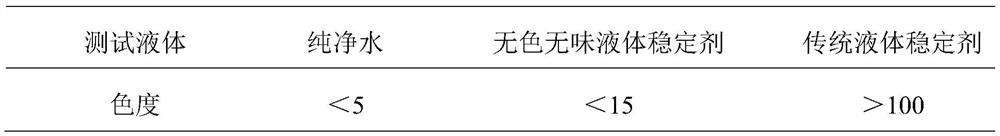

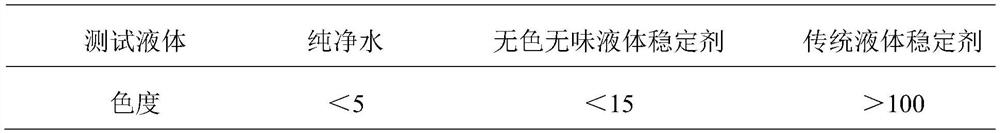

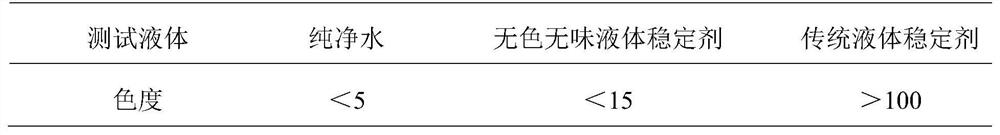

Colorless and odorless environment-friendly liquid stabilizer for transparent hose

PendingCN112898632AReduces pungent odorsMeet heat resistance requirementsActivated carbonCalcium hydroxide

The invention relates to the technical field of heat stabilizer preparation, in particular to a colorless and odorless environment-friendly liquid stabilizer for a transparent hose. The liquid stabilizer comprises the following components in parts by weight: 30-40 parts of a D80 solvent, 5-15 parts of fatty acid, 5-15 parts of aromatic acid, 1-5 parts of zinc oxide, 5-10 parts of calcium hydroxide, 1-5 parts of an antioxidant, 20-30 parts of an auxiliary stabilizer and 1-5 parts of an odor masking agent. Compared with a traditional liquid stabilizer, the liquid stabilizer prepared through preferable material is basically colorless and transparent, meanwhile, the heat-resistant requirement of transparent hose processing is met, activated carbon is introduced for deodorization, a proper amount of smell masking agent is added, so that the liquid stabilizer has less pungent odor, and greenness of the production process and the processed finished product is ensured.

Owner:嘉兴若天新材料科技有限公司

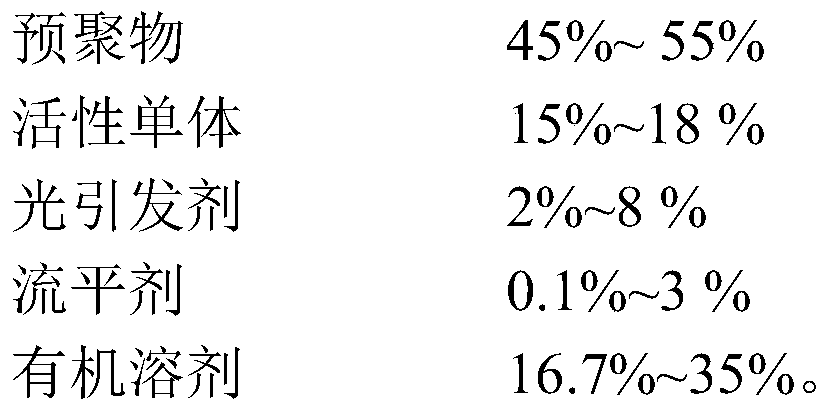

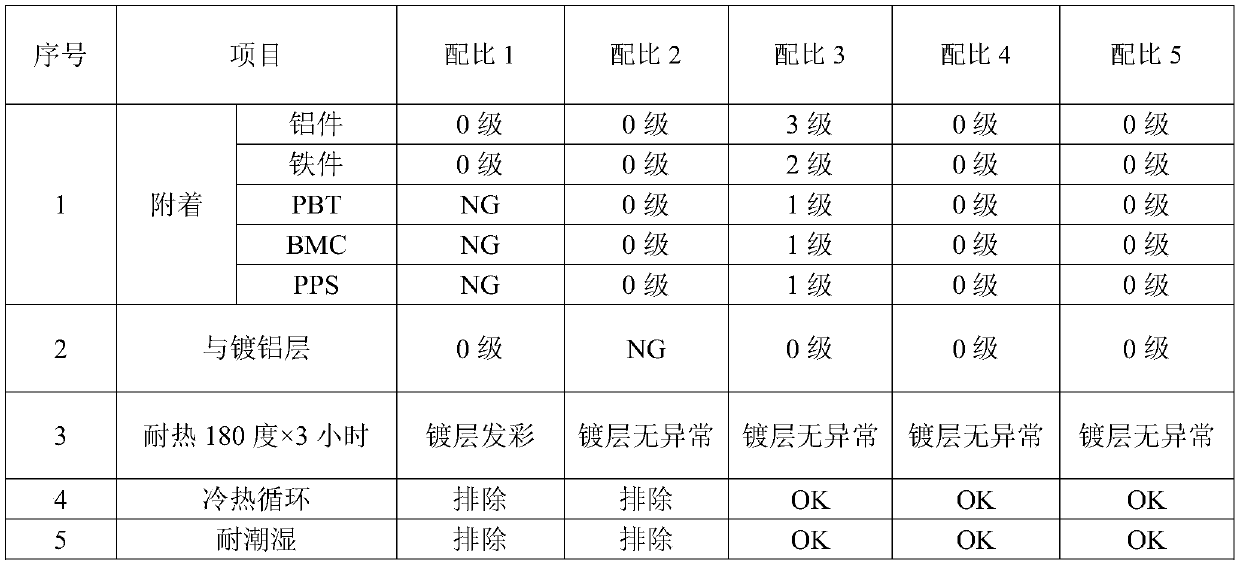

A kind of high temperature resistant vacuum electroplating uv coating and its preparation method and application

ActiveCN105368297BMeet heat resistance requirementsAdhesionPolyurea/polyurethane coatingsEpoxy resin coatingsOrganic solventPhotoinitiator

The invention provides a high-temperature resistant UV (Ultraviolet) coating material for vacuum plating. The high-temperature resistant UV coating material is prepared from the following ingredients in percentage by mass: 45-65% of prepolymer, 10-25% of reactive monomer, 2-8% of photoinitiator, 0.1-3% of leveling agent and 10-35% of organic solvent. Correspondingly, the invention also provides a preparation method for the coating material. The preparation method comprises the following steps: (a) isolating ultraviolet rays, and carrying out lighting by adopting a yellow-light lamp; (b) thoroughly dissolving the initiator with the organic solvent, and carrying out uniform stirring; and (c) sequentially adding the monomer of a formula amount, the prepolymer of a formula amount and the leveling agent of a formula amount in order under the condition of keeping stirring, and then, carrying out uniform stirring, thereby completing the preparation of the UV coating material. The invention further provides application of the high-temperature resistant UV coating material for vacuum plating. The coating material is coated on a base material, leveling is carried out for 1-2 minutes so as to thoroughly spread and level a coating film, infrared preheating is carried out for 3-5 minutes at the preheating temperature of 50 to 120 DEG C, then, UV irradiation curing is carried out, and the light radiation energy is 2,000-3,500mJ / cm<2>.

Owner:JIANGMEN LING YUN PAINT CO LTD

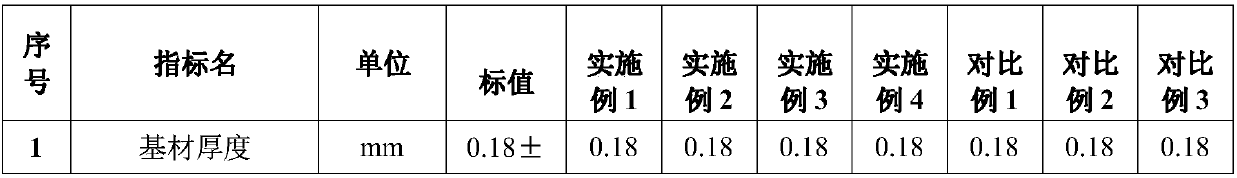

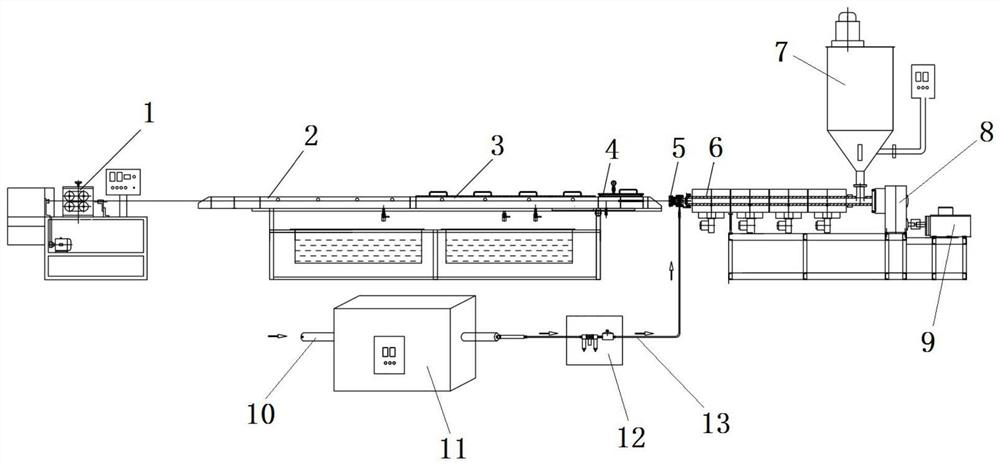

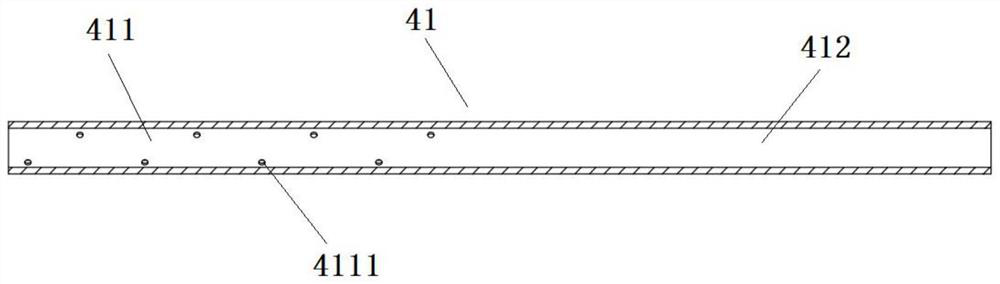

Production method and production equipment of PLA heat-resistant suction pipes

PendingCN114030166AProlong crystal setting timeImprove cooling and crystallization effectFood contactProcess engineering

Owner:江西禾尔斯环保科技有限公司

Epoxy resin composition for rapid prototyping of fiber-reinforced auto parts and preparation method thereof

ActiveCN106674900BMeet heat resistance requirementsPromote infiltrationGlycidyl ethersDiethylenetriamine

Owner:芜湖天道绿色新材料有限公司

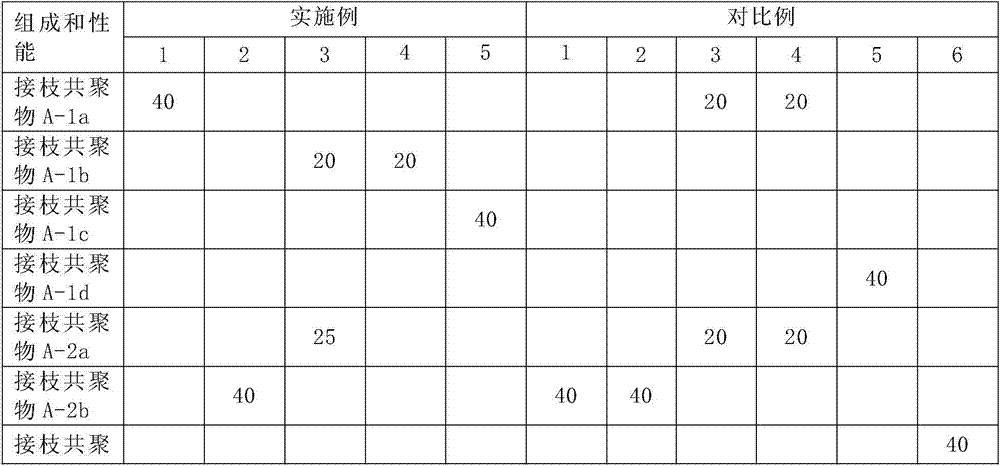

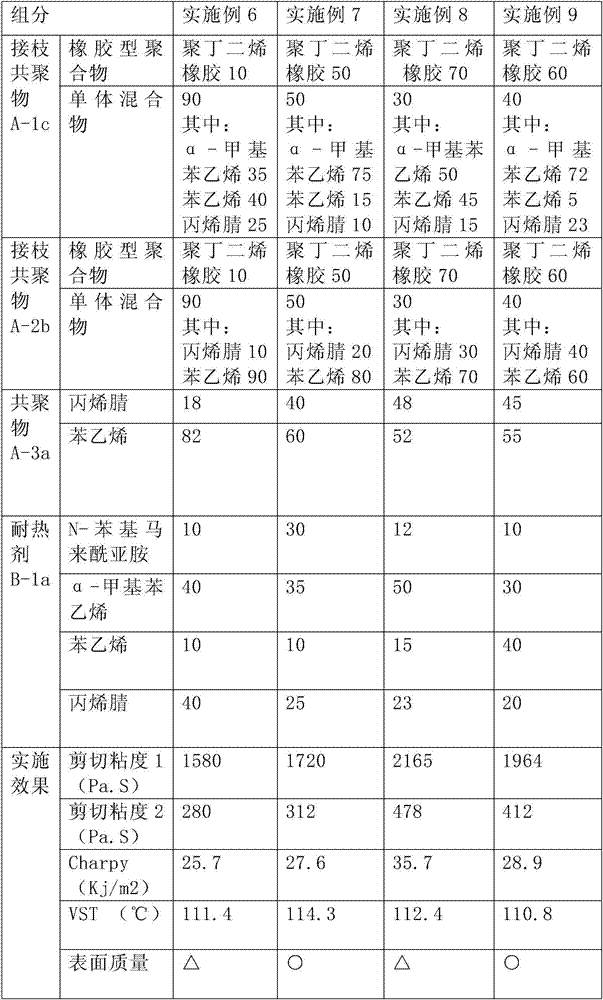

High heat-resistant abs resin composition suitable for blow molding and preparation method thereof

The present invention relates to a heat-resistant ABS resin composition formed by blow molding and a preparation method therefor. The composition comprises styrene resin composition A in 100 parts by weight and a heat-resistant agent B in 20 to 40 parts by weight, the heat-resistant agent B being N-phenylmaleimide-α-methylstyrene-acrylonitrile-styrene quadripolymer. The preparation method for the ABS resin composition comprises the following steps: weighing the components in parts by weight; thoroughly mixing the components in a high-speed mixer, to obtain a mixture; the mixture entering a double-screw extruder from a main feed port, and undergoing melt extrusion, cooling, drying, and dicing, to obtain the ABS resin composition. A product prepared by blow molding in the present invention has desirable surface quality and heat-resistant performance, the vicat softening temperature reaches above 110°C, and therefore, the product can meet the heat-resistance requirement of the paint-spraying post-processing technique for auto parts and can be used in a harsh environment; moreover, the product prepared by blow molding is highly impact-resistant.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Brick for fireplace and preparation method of brick

The invention discloses a brick for a fireplace. The brick comprises 10-30% of magnesite powder, 5-10% of dolomite powder, 5-20% of quartz sand, 5-20% of plant stalk powder, 25-40% of residual soil and garbage powder, 2-15% of a binding agent, 0.3-3% of a curing agent and 5-15% of cement. The invention also provides a preparation method of the brick for the fireplace. The brick has the advantages that the raw materials of the brick are adopted, so that waste recovery can be realized, the aim of changing waste materials into things of value can be achieved, the area of land occupied by garbage in a city can be reduced, and the surrounding environment of the city can be improved; in addition, no any poisonous substances are discharged after the brick is molded, so that the environment is protected; meanwhile, the heat resistance of the material is relatively good, so that the heat-resistant requirement of the fireplace is met; and the process steps of the preparation method are relatively simple, and the quality of the obtained product is relatively good.

Owner:ANHUI POPULAR SCI PROD ENG RES CENT

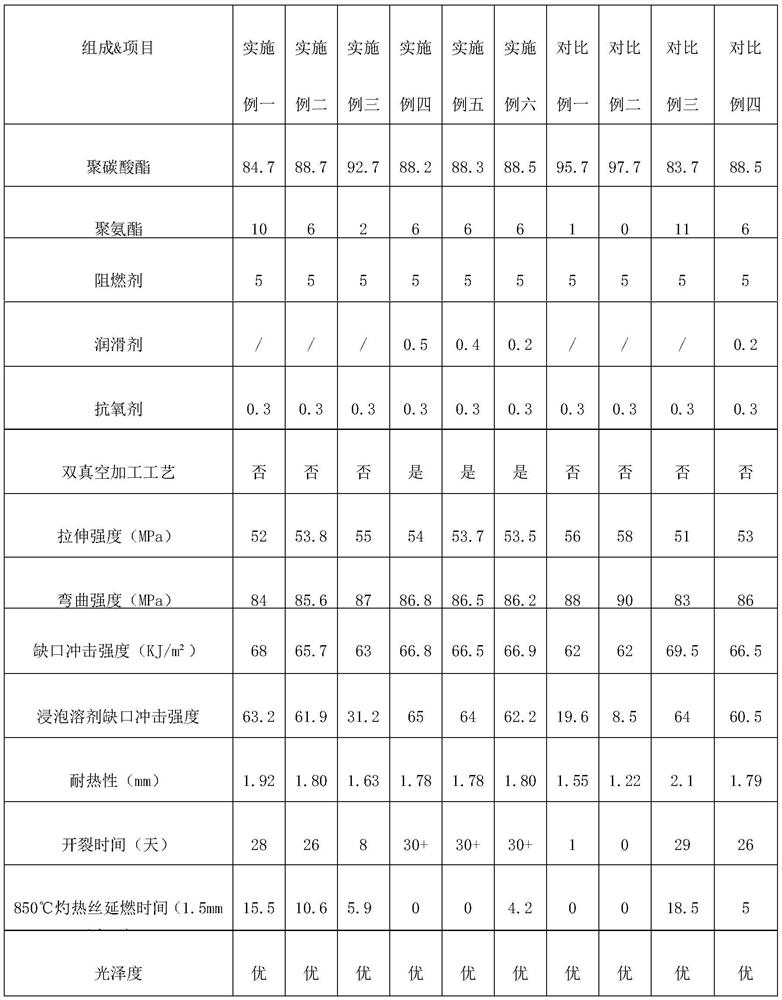

A kind of high-gloss long-lasting solvent-resistant polycarbonate material and its preparation method

The invention discloses a high-gloss and long-lasting solvent-resistant polycarbonate material. The raw materials include the following components in mass percentages: polycarbonate 81-94%, polyurethane 2-10%, flame retardant 2-8%, Antioxidant 0.1-0.5%, lubricant 0.2-0.5%; the invention adopts polyester polyurethane (TPU) to not only improve the impact strength of polycarbonate (PC) material, but also improve the long-term solvent resistance of the material, And the addition of an appropriate proportion has no obvious effect on the heat resistance of polycarbonate (PC) materials, which can meet the heat resistance requirements of electrical products.

Owner:BULL GRP CO LTD

Addition-type heat-resistant silicon rubber and preparation method thereof

InactiveCN103087532BMeet heat resistance requirementsIncrease productivityPtru catalystMethyl benzene

The invention discloses addition-type heat-resistant silicon rubber and a preparation method thereof. The heat-resistant silicon rubber comprises a component A and a component B, wherein the component A is prepared from the following ingredients in parts by weight: 100 parts of methyl phenyl vinyl silicone oil, 2-4 parts of catalyst, 4-12 parts of heat-resistant additive processed by a silane coupling agent, and 400-500 parts of auxiliary packing processed by the silane coupling agent; the component B is prepared from the following ingredients in parts by weight: 100 parts of methyl phenyl vinyl silicone oil, 1.8-2.5 parts of cross-linkingagent, 0.1-0.15 parts of inhibitor, 4-12 parts of heat-resistant additive processed by the silane coupling agent, and 400-500 parts of auxiliary packing processed by the silane coupling agent; and the components A and B are evenly mixed according to the equal mass ratio, defoamed in vacuum and cured to prepare the addition-type heat-resistant silicon rubber. The heat-resisting temperature of the addition-type heat-resistant silicon rubber disclosed by the invention can achieve 460 DEG C; and the heat-resisting requirements of the fields such as aeronautics and astronautics, ignition cable protecting bushes of automobiles, and high-temperature sealing elements on the silicon rubber can be met.

Owner:HEFEI UNIV OF TECH

Polyester-polycarbonate copolymer, polyester product, its preparation method and application

ActiveCN111808273BGood temperature characteristicsImprove flame retardant propertiesSynthetic resin layered productsMonocomponent polyesters artificial filamentPolymer scienceCarbonate ester

The invention discloses a polyester-polycarbonate copolymer, a polyester product, a preparation method and application thereof. The preparation method comprises: copolymerizing phosphorus-containing glycol with dimethyl carbonate / diphenyl carbonate, dibasic acid and glycol to prepare polyester-polycarbonate copolymer. The present invention uses phosphorus-containing aromatic diols as comonomers and introduces them into polyesters through polymerization, which can significantly improve the glass transition temperature and flame-retardant properties of existing polyesters. Further, through the combination of polycarbonate and polyester Copolymerization also increases the ester bond density of the copolymer, greatly increasing its heat resistance. The polyester-polycarbonate of the present invention has excellent high temperature resistance and flame retardancy, and its glass transition temperature can reach above 100°C, which can fully meet the heat resistance requirements of fire-fighting equipment, kitchen appliances, electronic products, automobile manufacturing, etc. , It also effectively protects the life and property safety of users with its excellent flame retardant properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com