Colorless and odorless environment-friendly liquid stabilizer for transparent hose

A liquid stabilizer and auxiliary stabilizer technology, which is applied in the field of heat stabilizer preparation, can solve the problems of unpleasant smell, pungent odor residue in transparent hoses, and easy generation of irritating smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 30 parts of D80 solvent, 5 parts of fatty acid, 5 parts of aromatic acid, 1 part of zinc oxide, and 5 parts of calcium hydroxide, put them into the reaction kettle in turn, raise the temperature to 105 ° C for 3 hours, turn on the vacuum pump for 0.5 hours after the reaction is completed, and remove In addition to the moisture generated by the reaction, then add 1 part of antioxidant, 20 parts of auxiliary stabilizer, 1 part of odor masking agent, keep warm at 80 ° C for 0.5 hours, add activated carbon for decolorization and deodorization, and then add filter aid for filtration. Just repack.

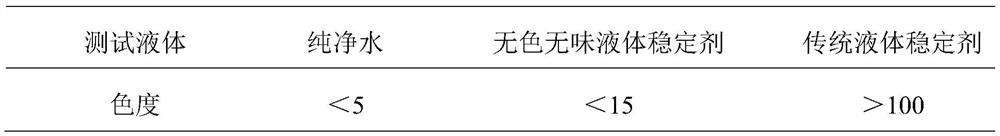

[0034] The colorless and odorless liquid stabilizer that present embodiment obtains is carried out chromaticity test with traditional product, and result is as shown in table 1:

[0035] Table 1 Chroma table of pure water, colorless and odorless liquid stabilizer, traditional liquid stabilizer

[0036]

[0037] Compared with the traditional liquid stabilizer, the colorle...

Embodiment 2

[0039] Weigh 40 parts of D80 solvent, 15 parts of fatty acid, 15 parts of aromatic acid, 5 parts of zinc oxide, and 10 parts of calcium hydroxide, put them into the reaction kettle in turn, raise the temperature to 105 ° C for 3 hours, turn on the vacuum pump for 0.5 hours after the reaction is completed, and remove Remove the moisture generated by the reaction, then add 5 parts of antioxidant, 30 parts of auxiliary stabilizer, 5 parts of odor masking agent, keep warm at 80°C for 0.5 hours, add activated carbon for decolorization and deodorization, and then add filter aid for filtration. Just repack.

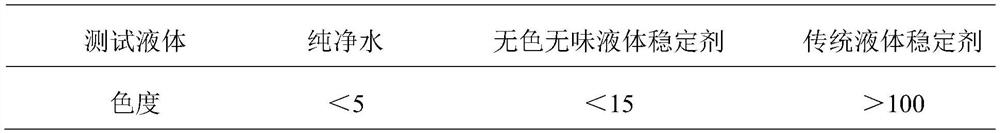

[0040] The colorless and odorless liquid stabilizer that present embodiment obtains and traditional product are carried out chromaticity test, and result is as shown in table 2:

[0041] Table 2 Chroma table of purified water, colorless and odorless liquid stabilizer, traditional liquid stabilizer

[0042]

[0043] Compared with the traditional liquid stabilizer, the colorle...

Embodiment 3

[0045] Weigh 35 parts of D80 solvent, 10 parts of fatty acid, 10 parts of aromatic acid, 3 parts of zinc oxide, and 7 parts of calcium hydroxide, put them into the reaction kettle in turn, raise the temperature to 105 ° C for 3 hours, turn on the vacuum pump for 0.5 hours after the reaction is completed, and remove Remove the moisture generated by the reaction, then add 3 parts of antioxidant, 25 parts of auxiliary stabilizer, 3 parts of odor masking agent, keep warm at 80°C for 0.5 hours, add activated carbon for decolorization and deodorization, and then add filter aid for filtration. Just repack.

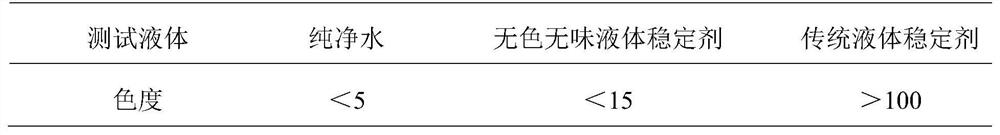

[0046] The colorless and odorless liquid stabilizer that present embodiment obtains is carried out chromaticity test with traditional product, and result is as shown in table 3:

[0047] Table 3 Chroma table of purified water, colorless and odorless liquid stabilizer, and traditional liquid stabilizer

[0048]

[0049] Compared with the traditional liquid stabilizer, the colorl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com