Low-halogen rotation UV (Ultraviolet) environment-friendly ink and preparation method thereof

An environmentally friendly, ink technology, used in inks, household appliances, applications, etc., can solve problems such as damage to the health of operators, volatile, pollution of the production and use environment, etc., to improve alcohol resistance and eraser resistance. Test performance, good adhesion, and the effect of reducing the irritating odor of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

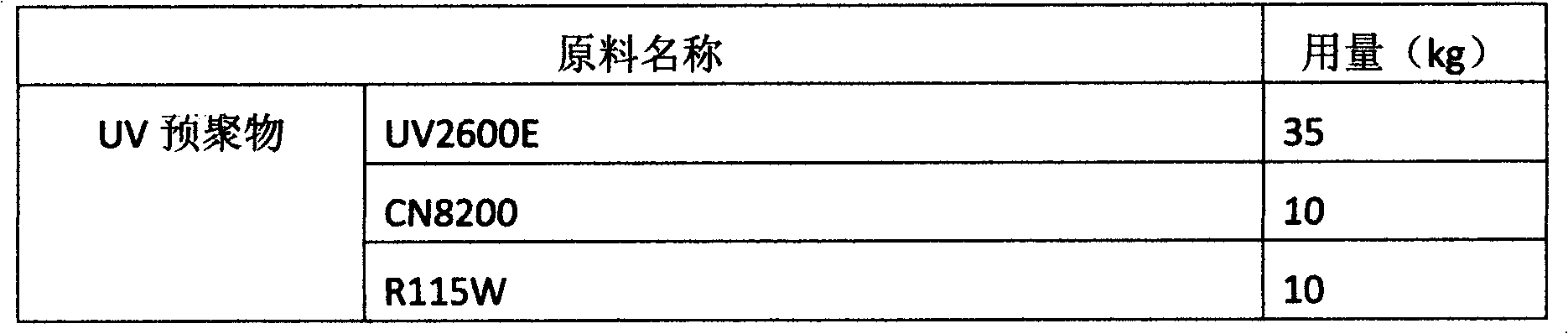

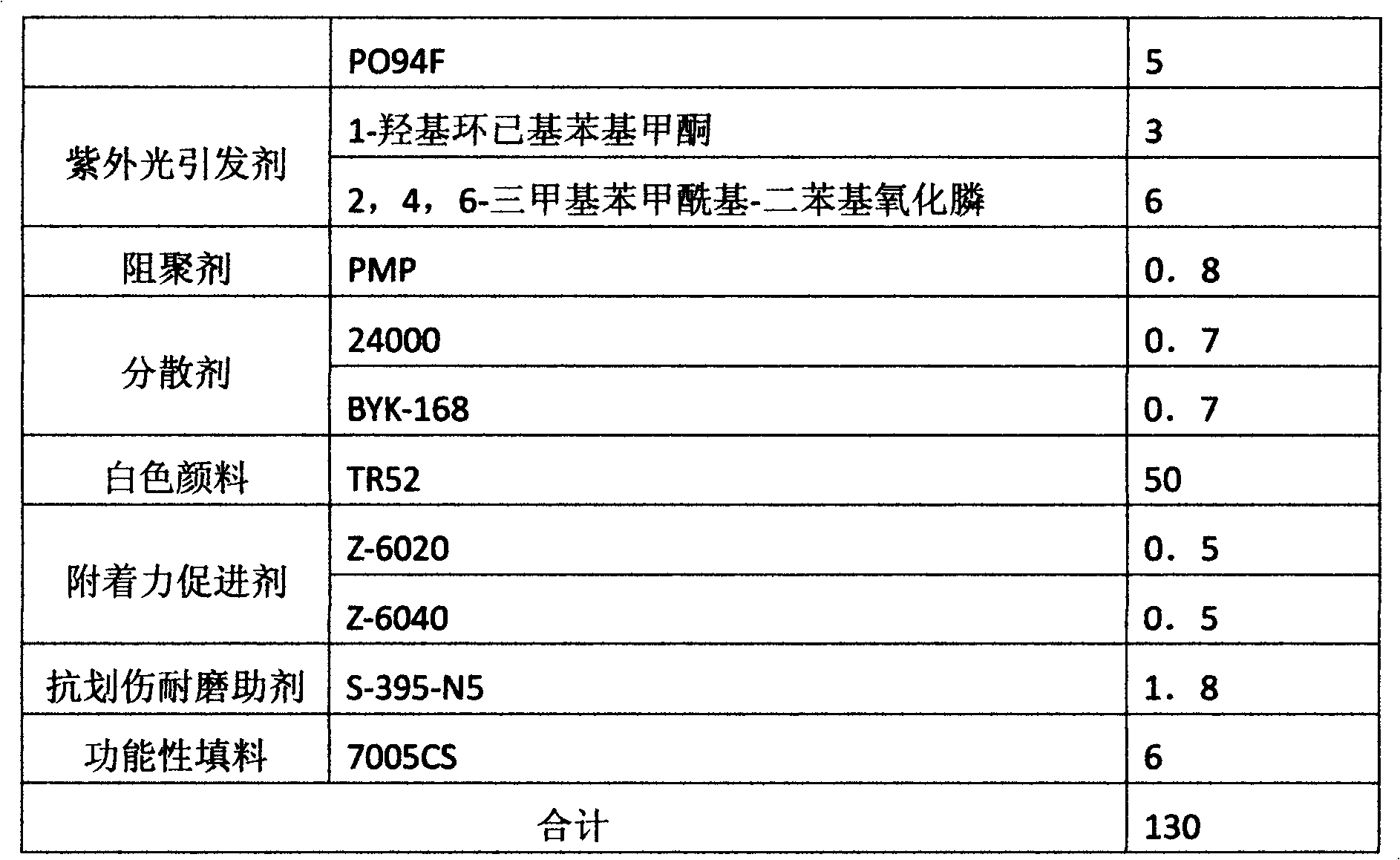

[0025] Embodiment 1: the preparation of white ink

[0026] (1), ink formula

[0027]

[0028]

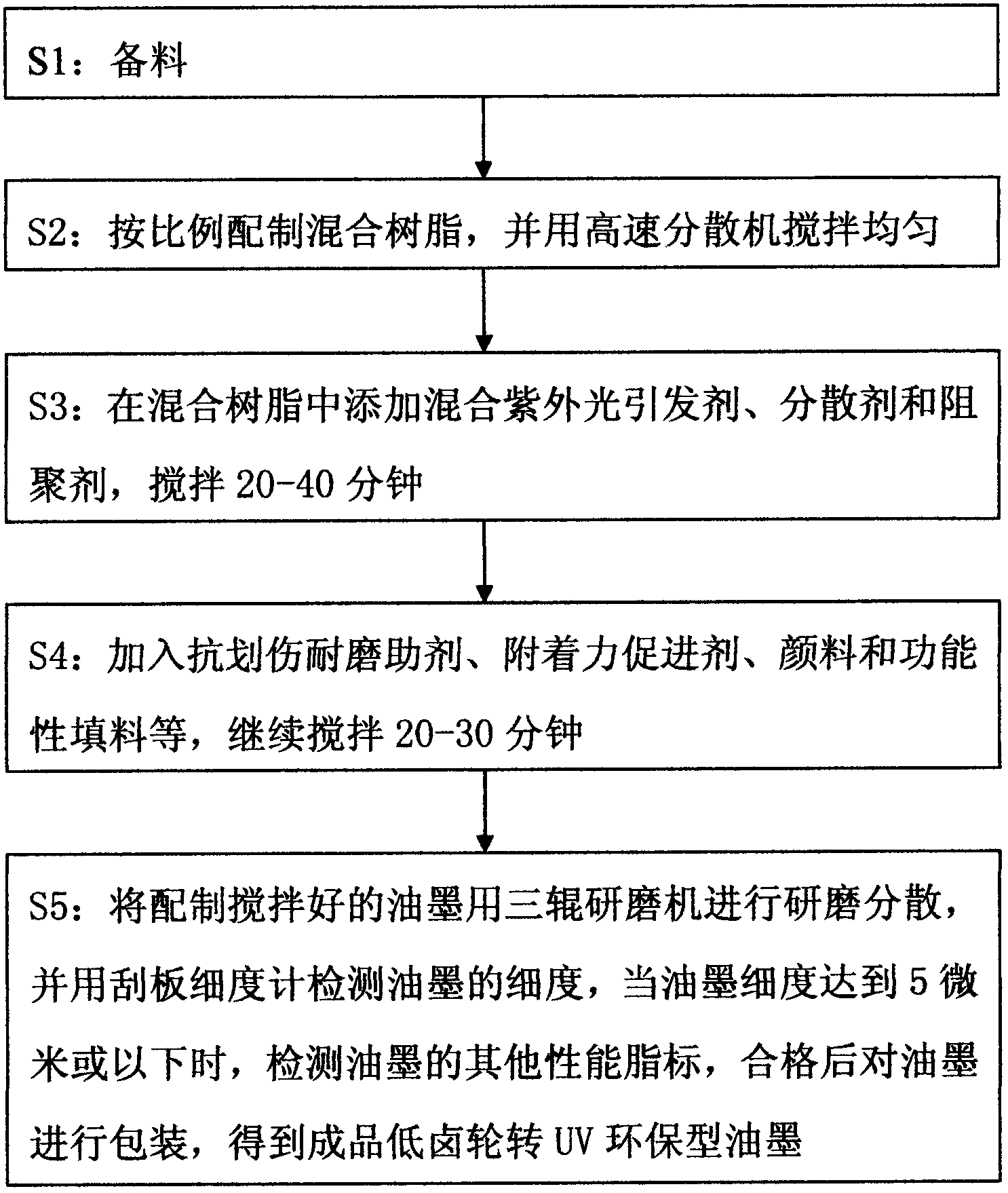

[0029] (2) Ink preparation is carried out under light-shielding conditions: (because it is a specific embodiment, so the following conditions in each preparation process such as rotating speed, temperature, pressure, time, etc. should be changed to a specific value, as long as it is in the original data Data values within the range will do)

[0030]Prepare the mixed resin in proportion, control the temperature at 50°C, stir the mixed resin into a uniform slurry with a high-speed disperser, control the speed of the high-speed disperser at 600 rpm, and the time is 15 minutes; then add mixed ultraviolet light Initiator, dispersant and polymerization inhibitor, continue to stir for 30 minutes, and the speed is controlled at 800 rpm, so that the mixed ultraviolet photoinitiator and polymerization inhibitor are completely dissolved, and the dispersant is completely and evenly dis...

Embodiment 2

[0031] Embodiment 2: the preparation of four-color yellow ink

[0032] (1), ink formula

[0033]

[0034]

[0035] (2) Ink preparation is carried out under dark conditions:

[0036] Prepare the mixed resin in proportion, control the temperature at 50°C, stir the mixed resin into a uniform slurry with a high-speed disperser, control the speed of the high-speed disperser at 600 rpm, and the time is 15 minutes; then add mixed ultraviolet light Initiator, dispersant and polymerization inhibitor, continue to stir for 30 minutes, and the speed is controlled at 800 rpm, so that the mixed ultraviolet photoinitiator and polymerization inhibitor are completely dissolved, and the dispersant is completely and evenly dispersed in the mixed resin; Add the remaining anti-scratch and wear-resistant additives, adhesion promoters, yellow pigments and functional fillers, etc., and continue to stir for 20 minutes. The temperature is controlled at 50 ° C, and the speed is controlled at 800 ...

Embodiment 3

[0036] Prepare the mixed resin in proportion, control the temperature at 50°C, stir the mixed resin into a uniform slurry with a high-speed disperser, control the speed of the high-speed disperser at 600 rpm, and the time is 15 minutes; then add mixed ultraviolet light Initiator, dispersant and polymerization inhibitor, continue to stir for 30 minutes, and the speed is controlled at 800 rpm, so that the mixed ultraviolet photoinitiator and polymerization inhibitor are completely dissolved, and the dispersant is completely and evenly dispersed in the mixed resin; Add the remaining anti-scratch and wear-resistant additives, adhesion promoters, yellow pigments and functional fillers, etc., and continue to stir for 20 minutes. The temperature is controlled at 50 ° C, and the speed is controlled at 800 rpm. The agent is fully dispersed in the resin; then the prepared and stirred ink is ground and dispersed with a three-roll mill. The temperature of the cooling water of the three-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com