Epoxy resin composition for rapid prototyping of fiber-reinforced auto parts and preparation method thereof

A technology of auto parts and epoxy resin, which is applied in the field of epoxy resin composition and its preparation, can solve the problems of long molding cycle, cannot meet the requirements of high efficiency and low cost of automobile production line, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

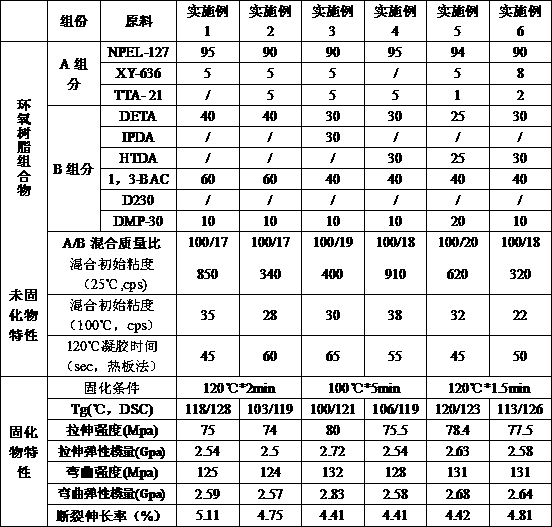

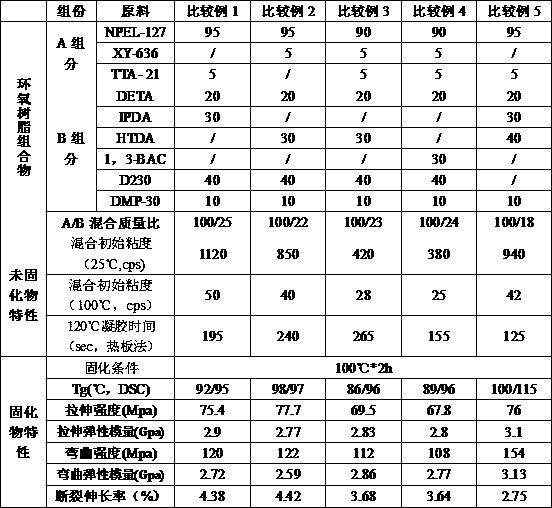

Examples

preparation example Construction

[0022] The present invention also provides the preparation method of the above-mentioned epoxy resin composition for the rapid prototyping of fiber-reinforced auto parts, comprising:

[0023] 1) Preheat bisphenol A epoxy resin 127, then add trifunctional glycidyl ether diluent XY636, cycloaliphatic epoxy resin TTA21 and stir under vacuum to prepare component A;

[0024] 2) Diethylenetriamine DETA, isophoronediamine IPDA, methylcyclohexanediamine HTDA, 1,3-cyclohexanedimethylamine 1,3-BAC and 2,4,6-tri(dimethyl Aminomethyl)phenol DMP-30 was stirred to obtain component B;

[0025] 3) Mixing component A and component B to obtain an epoxy resin composition for rapid prototyping of fiber-reinforced auto parts;

[0026] Among them, the weight ratio of component A to component B is 100:15-25; based on the total weight of component A, the amount of bisphenol A epoxy resin 127 is 80-95% by weight, trifunctional glycidol The amount of ether diluent XY636 is 0-10% by weight, the amount o...

Embodiment 1

[0034] 1) Preheat the bisphenol A epoxy resin NPEL-127 to 50-55°C; then add the preheated bisphenol A epoxy resin NPEL-127 and various additives into the reactor; then add the trifunctional Glycidyl ether diluent XY636 and cycloaliphatic epoxy resin TTA21 were added to the reaction kettle in sequence; then in a vacuum environment, the agitator was turned on and stirred at a speed of 20-25rpm for 28-32min and then stopped; finally, the vacuum was stopped and the Return to normal pressure in the reactor to obtain the A component;

[0035] 2) The curing agent diethylenetriamine DETA, isophoronediamine IPDA, methylcyclohexanediamine HTDA, m-cyclohexanedimethylamine 1, 3-BAC and accelerator three-(dimethylaminomethyl ) Phenol DMP-30 into another reaction kettle; then turn on the agitator, stir at a speed of 20-25rpm for 18-22min and then stop to obtain the B component (according to the nominal tank barrel, nitrogen protection when filling the barrel gas)

[0036] 3) Mix the A com...

Embodiment 2

[0039] Carry out epoxy resin composition C2 according to the method for embodiment 1, difference is, the weight ratio of bisphenol A type epoxy resin 127, trifunctional glycidyl ether diluent XY636 and alicyclic epoxy resin TTA21 is 90:5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com