A kind of high-gloss long-lasting solvent-resistant polycarbonate material and its preparation method

A polycarbonate and solvent-resistant technology, which is applied in the field of high-gloss and long-term solvent-resistant polycarbonate materials and its preparation, can solve the influence of the surface gloss of the material, the flame retardant performance, heat resistance and impact strength of alloy materials. The problem of high oxygen index can improve the long-term solvent resistance, meet the heat resistance requirements, and improve the impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

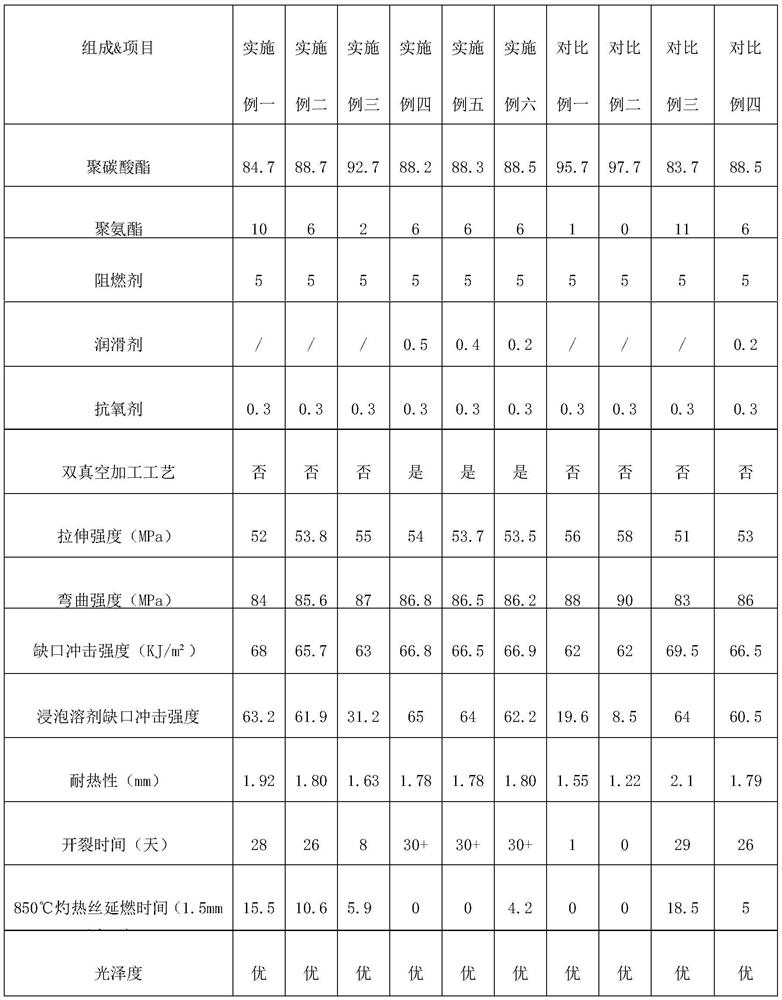

Examples

Embodiment 1

[0023] Embodiment 1: The mass ratio of each component of the formula is: polycarbonate accounts for 84.7%, polyurethane accounts for 10%, flame retardant accounts for 5%, and antioxidant accounts for 0.3%.

Embodiment 2

[0024] Embodiment 2: The mass ratio of each component of the formula is: polycarbonate accounts for 88.7%, polyurethane accounts for 6%, flame retardant accounts for 5%, and antioxidant accounts for 0.3%.

Embodiment 3

[0025] Embodiment 3: The mass ratio of each component of the formula is: polycarbonate accounts for 92.7%, polyurethane accounts for 2%, flame retardant accounts for 5%, and antioxidant accounts for 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com