Anticorrosion high temperature resistant and flame-retardant nylon composite material and preparation method thereof

A technology of flame-retardant nylon and composite materials, which is applied in the field of modified nylon composite materials and its preparation, which can solve the problems of recycling materials that affect the beauty of products, limit the application range of products, shorten the service life of molds, etc., and improve the production environment of the workshop , Improve product competitiveness and improve appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053]

[0054] A method for preparing a corrosion-resistant and high-temperature-resistant flame-retardant nylon composite material, comprising the following steps:

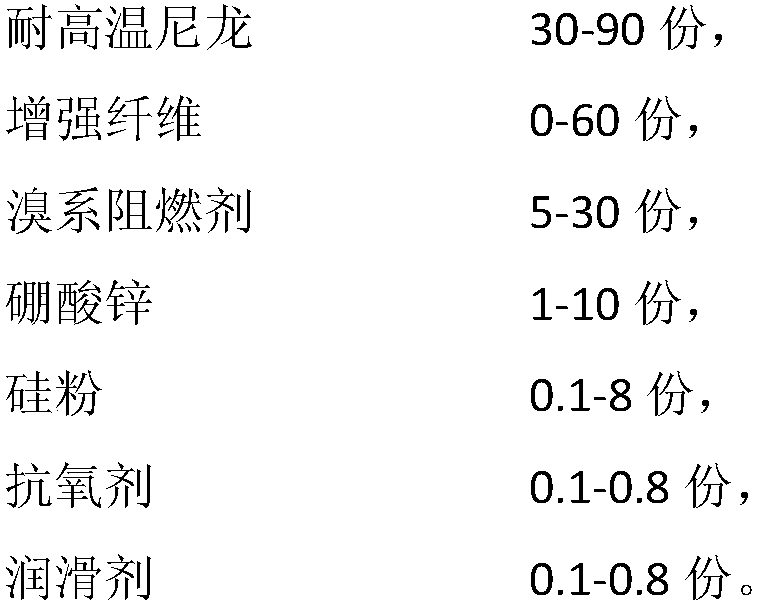

[0055] (1), 30-90 parts of dry high-temperature resistant nylon, 5-30 parts of brominated flame retardant, 1-10 parts of zinc borate, 0.1-8 parts of silicon powder, 0.1-0.8 parts of antioxidant, 0.1-0.8 parts lubricant mixed to obtain a mixture;

[0056] (2) Add the mixture into the twin-screw extruder from the main feeding port of the twin-screw extruder, and add 0-60 parts of reinforcing fibers to the twin-screw extruder from the side feeding port of the twin-screw extruder. After exiting the machine, after drawing, cooling, pelletizing and drying, the corrosion-resistant, high-temperature, flame-retardant nylon composite material is obtained.

[0057] Among them, the dry high-temperature-resistant nylon in step (1) is obtained by air-drying high-temperature-resistant nylon at 80-120°C for 4-8 hours. Becaus...

Embodiment 1

[0065] This example provides a modified corrosion-resistant and high-temperature-resistant flame-retardant nylon composite material, the raw materials of which include the following components:

[0066]

[0067]

[0068] This embodiment also provides a method for preparing a corrosion-resistant and high-temperature-resistant flame-retardant nylon composite material, which includes the following steps:

[0069] (1), drying high temperature resistant nylon (PA6T / 66) in a drying oven at 120°C for 4 hours to obtain dry high temperature resistant nylon (PA6T / 66);

[0070] (2), 40 parts of dry high temperature resistant nylon (PA6T / 66), 15 parts of brominated flame retardant (HP3010), 4 parts of zinc borate, 1 part of silicon powder, 0.4 parts of antioxidant (H10), 0.4 parts The lubricant (A-C540A) is mixed in a high-speed mixer, the speed of the high-speed mixer is 600rpm, the mixing time is 4min, and the mixture is obtained after mixing;

[0071] (3) Add the mixture into th...

Embodiment 2

[0074] This example provides a modified corrosion-resistant and high-temperature-resistant flame-retardant nylon composite material, the raw materials of which include the following components:

[0075]

[0076] This embodiment also provides a method for preparing a corrosion-resistant and high-temperature-resistant flame-retardant nylon composite material, which includes the following steps:

[0077] (1), drying high temperature resistant nylon (PA6T / 6) in a drying oven at 80°C for 8 hours to obtain dry high temperature resistant nylon (PA6T / 6);

[0078] (2), 30 parts of dry high temperature resistant nylon (PA6T / 6), 30 parts of brominated flame retardant (PBS-64HW), 10 parts of zinc borate, 8 parts of silicon powder, 0.8 parts of antioxidant (0.4 parts of 1098 Mix with 0.4 part of 168), 0.8 part of lubricant (P12) in high-speed mixer, the rotating speed of high-speed mixer is 800rpm, the time of mixing is 2min, obtain mixture after mixing;

[0079] (3), the mixture is ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com