Patents

Literature

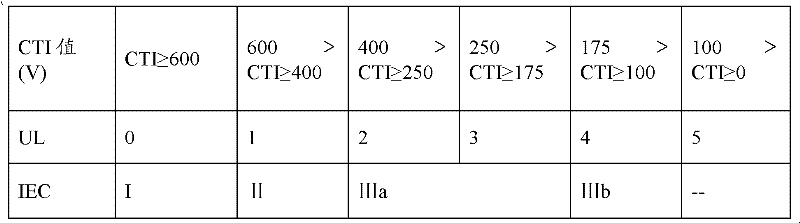

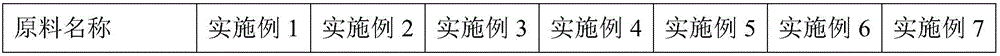

80results about How to "High CTI value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

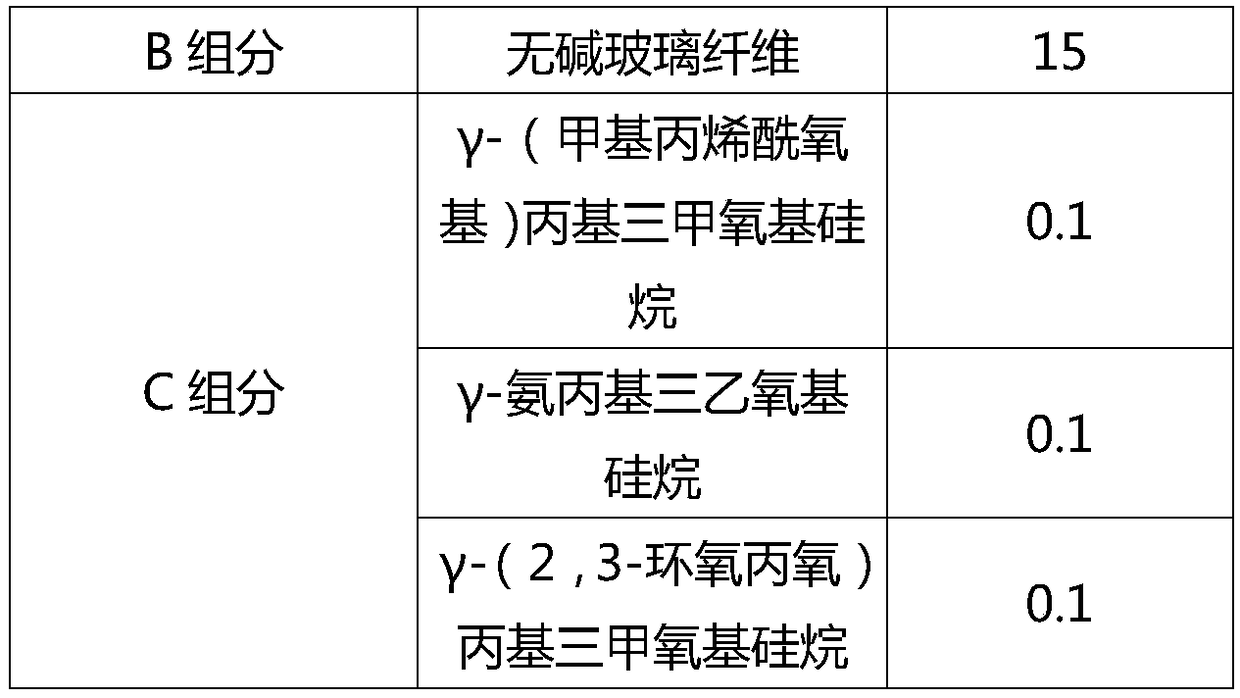

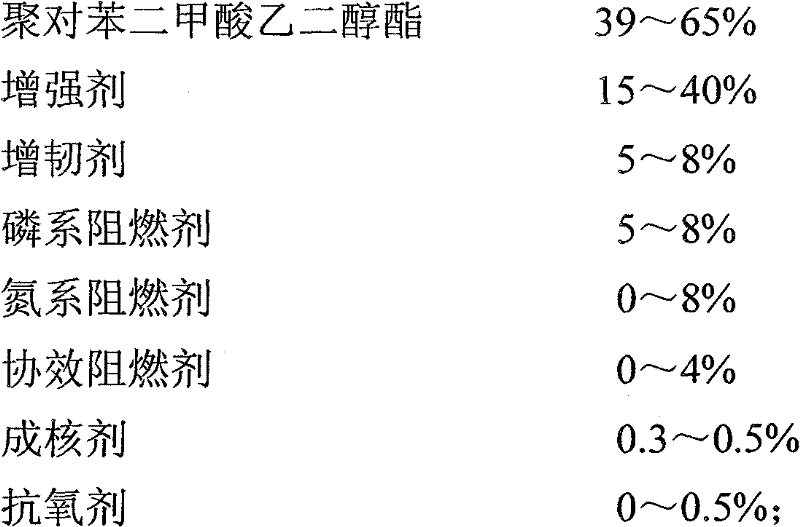

Halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and method for preparing same

The invention discloses halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and a method for preparing the same. The plastics consist of the following components in percentage by weight: 39 to 65 percent of polydiethylene terephthalate, 15 to 40 percent of reinforcing agent, 0 to 8 percent of toughening agent, 5 to 8 percent of phosphorus flame retardant, 0 to 8 percent of nitrogen flame retardant, 0 to 4 percent of synergetic flame retardant, 0 to 0.5 percent of nucleating agent and 0 to 0.5 percent of antioxidant. In the preparation method, the phosphorus-nitrogen antiflaming system is combined with the nanometer clay, so that while the halogen-free stibium-free flame retardation of the compound material is realized, the higher CTI value of the antiflaming material is ensured; the plastics are applicable in the field of electric appliances; and the method for preparing the material is simple and avoids adopting mould temperature forming processing, and the compound material possesses excellent thermal stability and therefore can be recycled.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and high CTI (comparative tracking index) value and method for preparing flame-retardant glass fiber reinforced PBT

InactiveCN105647134ARaise the ignition temperatureImprove mechanical propertiesAntioxidantPolyethylene terephthalate

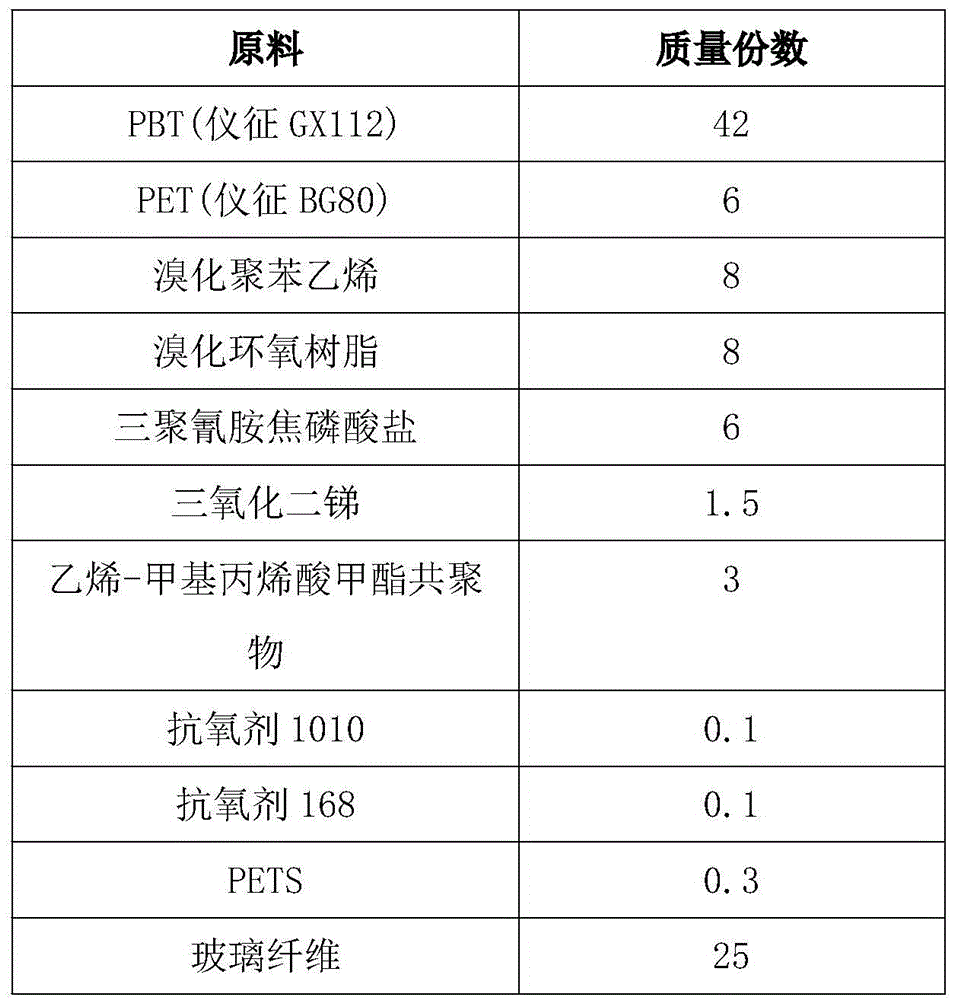

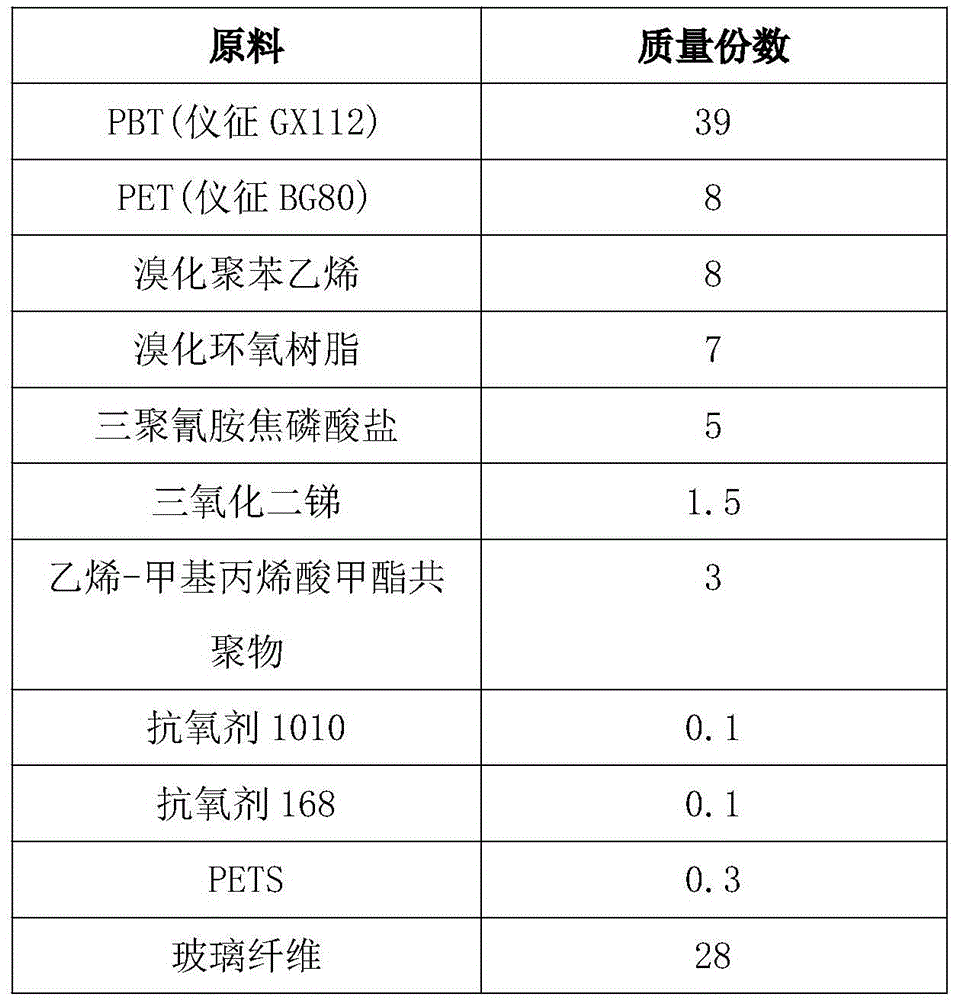

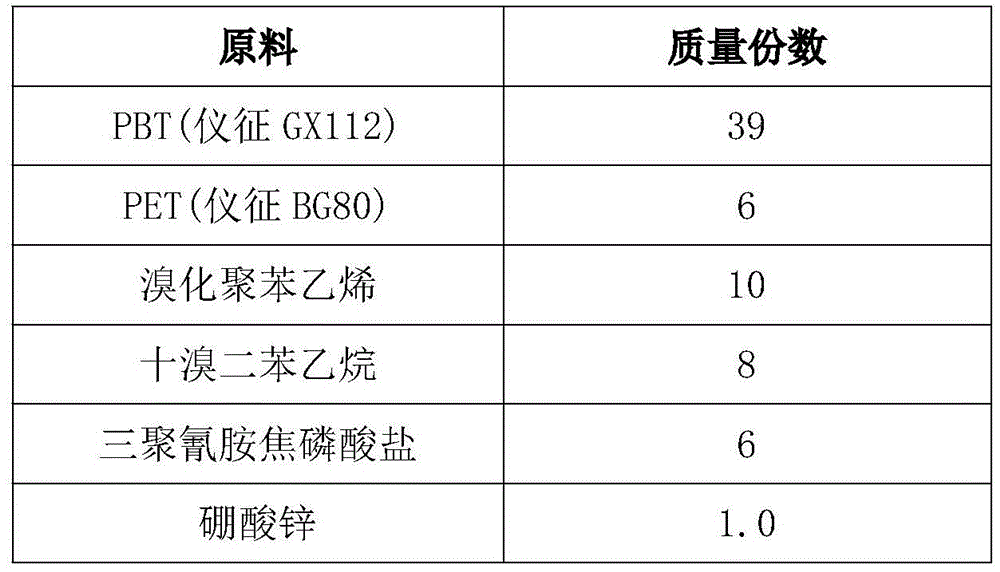

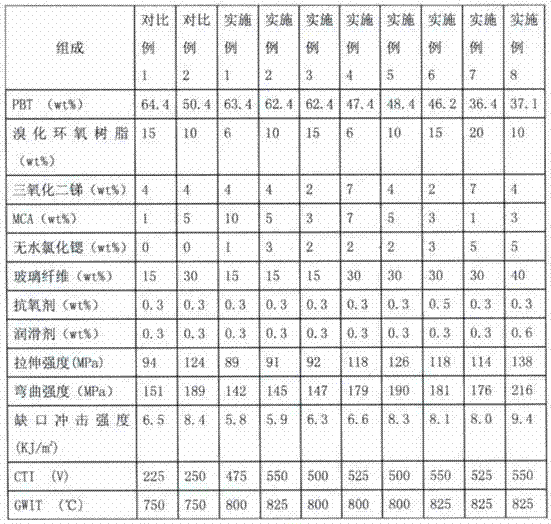

The invention discloses a flame-retardant glass fiber reinforced PBT (polybutylene terephthalate) with high glow wires and a high CTI (comparative tracking index) value and a method for preparing the flame-retardant glass fiber reinforced PBT. The flame-retardant glass fiber reinforced PBT comprises, by weight, 38-45 parts of PBT, 5-8 parts of PET (polyethylene terephthalate), 15-18 parts of flame retardants A, 0.5-1.5 parts of flame retardants B, 5-8 parts of flame retardants C, 2-4 parts of toughening agents, 0.2-0.4 part of antioxidants, 0.3-0.6 part of lubricants and 25-30 parts of glass fibers. The flame-retardant glass fiber reinforced PBT and the method have the advantages that the glow wire ignition temperature (GWIT) of the flame-retardant glass fiber reinforced PBT can be increased and reaches 850 DEG C, and a comparative tracking index (CTI) of the flame-retardant glass fiber reinforced PBT can reach 400 V; the mechanical performance and the machining performance of the flame-retardant glass fiber reinforced PBT can be prevented from being damaged or only is damaged at low level.

Owner:贝克兰(厦门)新材料有限公司

High CTI brominated flame-retardant reinforced PBT material and preparation method thereof

The invention provides a high CTI brominated flame-retardant reinforced PBT material and a preparation method thereof. The brominated flame-retardant reinforced PBT material comprises the following ingredients: 35-65 wt% of PBT resin, 6-20 wt% of brominated fire retardant, 2-7 wt% of fire-resisting synergistic agent, 1-10 wt% of nitrogen containing compound, 1-5 wt% of strontium compound, 15-40 wt% of glass fiber, 0.1-1 wt% of antioxidant and 0.1-1 wt% of lubricant. The brominated flame-retardant reinforced PBT material disclosed in the invention has high CTI value, high flame resistance, excellent mechanical property, simultaneously has superior characteristics of no precipitation and high GWIT value.

Owner:SHANGHAI KINGFA SCI & TECH +1

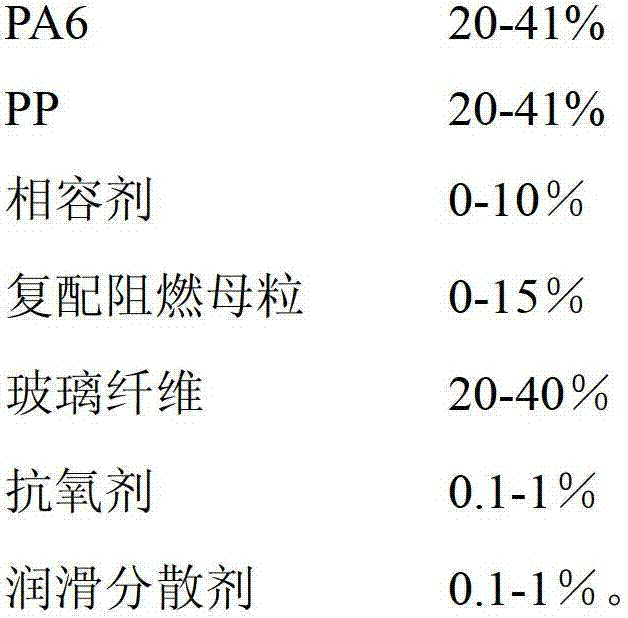

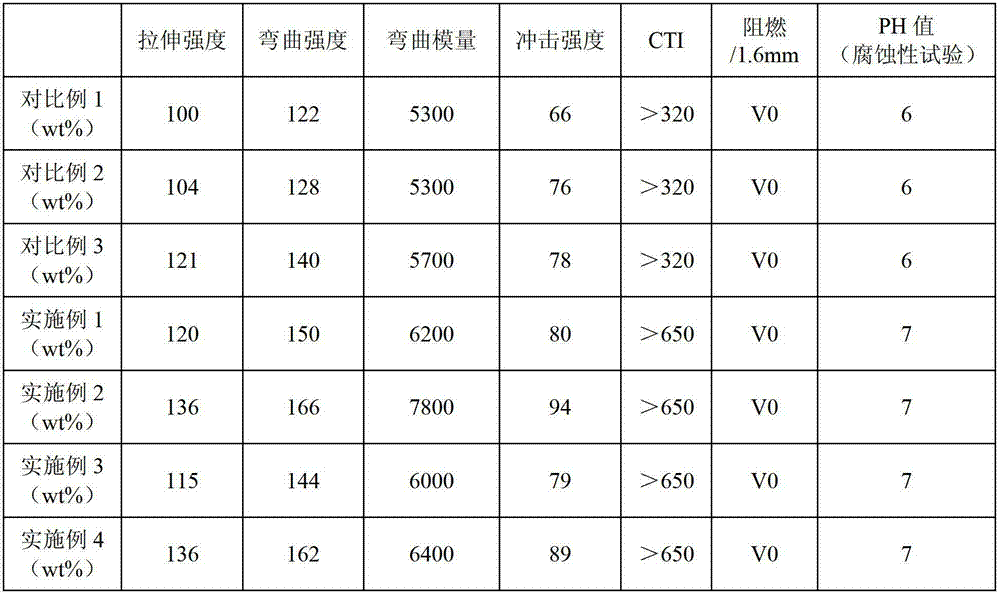

Flame-retardant glass fiber reinforced polyamide 6/polypropylene (PA6/PP) alloy composite and preparation method thereof

InactiveCN102775771AImprove mechanical propertiesCTI improvementMasterbatchComparative Tracking Index

The invention relates to a flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite and a preparation method of the flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite. The composite comprises the following components in percentage by weight: 20-40 percent of polyamide 6 (PA6), 20-41 percent of polypropylene (PP), 0-10 percent of a compatilizer, 0-15 percent of compound flame-retardant masterbatch, 20-40 percent of glass fiber, 0.1-1 percent of an antioxygen and 0.1-1 percent of a lubricant dispersing agent. The preparation method of the composite comprises the following steps of: weighing each component according to the weight proportions; putting the components into a high mixing machine to mix for 2-5 minutes; discharging; and extruding and pelleting by a twin-screw extruder to process at the temperature of 200-225 DEG C under the condition of screw revolution of 30-40HZ. Compared with the prior art, the composite has the advantages of high comparative tracking index (CTI) value, low flame-retardant precipitation property, halogen-free environment friendliness, comprehensive performance equalization and the like, and can be widely applied to products of contacts, leakage protectors, circuit breaker shells and the like in the electronics field.

Owner:SHANGHAI SUNNY

Environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952379AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PBT, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PBT material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in composite material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

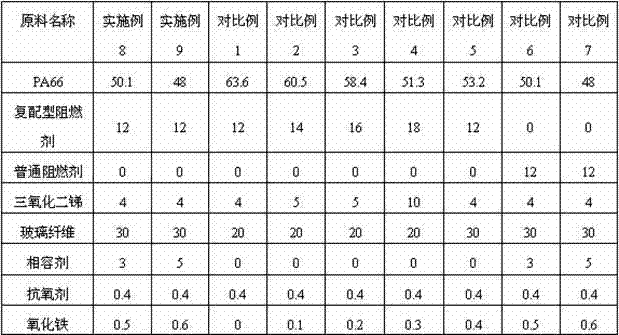

Environment-friendly flame retardant glass fiber reinforced polyamide 66 (PA66) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952399AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly flame retardant glass fiber reinforced polyamide 66 (PA66) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PA66, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PA66 material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

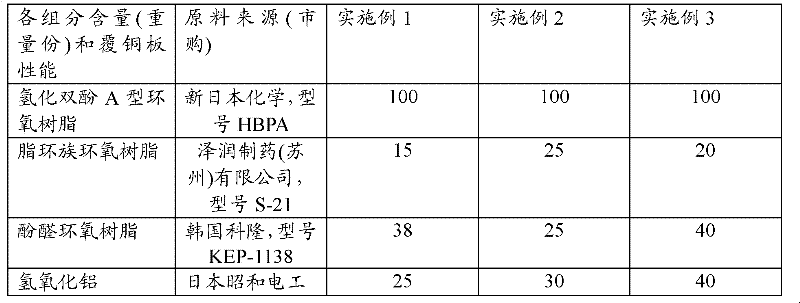

Halogen-free resin composition and copper clad plate prepared from composition

ActiveCN102286190AHigh CTI valueReduce dosageCircuit susbtrate materialsMetal layered productsOrganic solventComparative Tracking Index

The invention discloses a halogen-free resin composition. The composition is prepared by fully mixing hydrogenated bisphenol A type epoxy resin, alicyclic epoxy resin, novolac epoxy resin curing agent, aluminum hydroxide serving as an inorganic filler and organic solvent uniformly. The invention also discloses a copper clad plate prepared from the halogen-free resin composition. The copper clad plate has good thermal stability and creepage tracing property. The halogen-free resin with high comparative tracking index (CTI) resin is adopted, and the consumption of the aluminum hydroxide servingas the inorganic filler is reduced, so that the composition has high CTI value, avoids series problems caused by using excessive aluminum hydroxide and simultaneously realizes halogen-free and environment-friendly properties.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

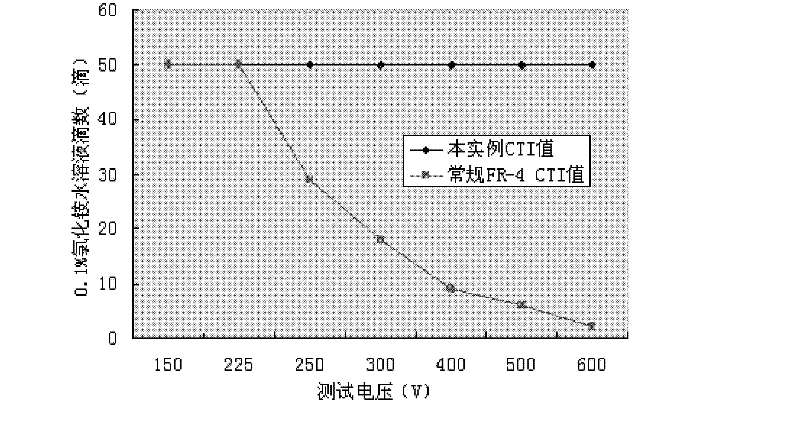

Making method for high thermal conductive, high heat resistant and high CTI FR-4 copper-clad plate

InactiveCN104002524AImprove thermal conductivityImprove heat resistanceSynthetic resin layered productsLaminationEpoxyHeat conducting

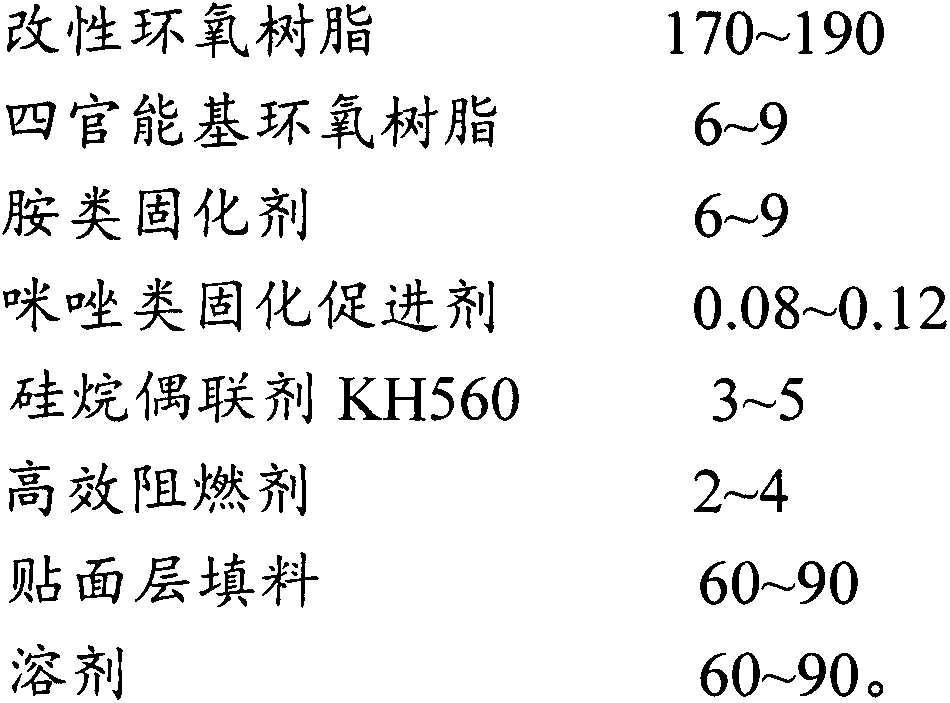

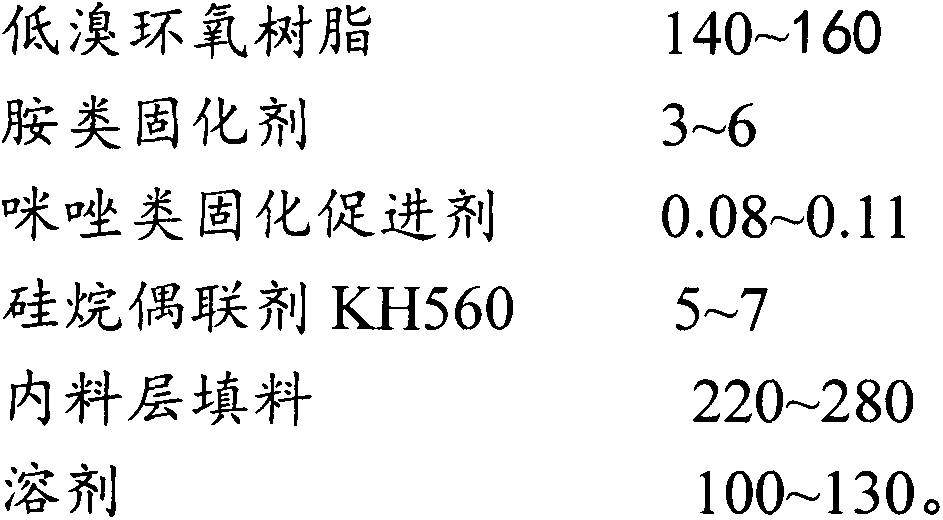

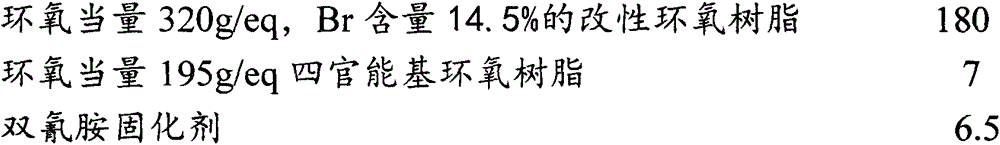

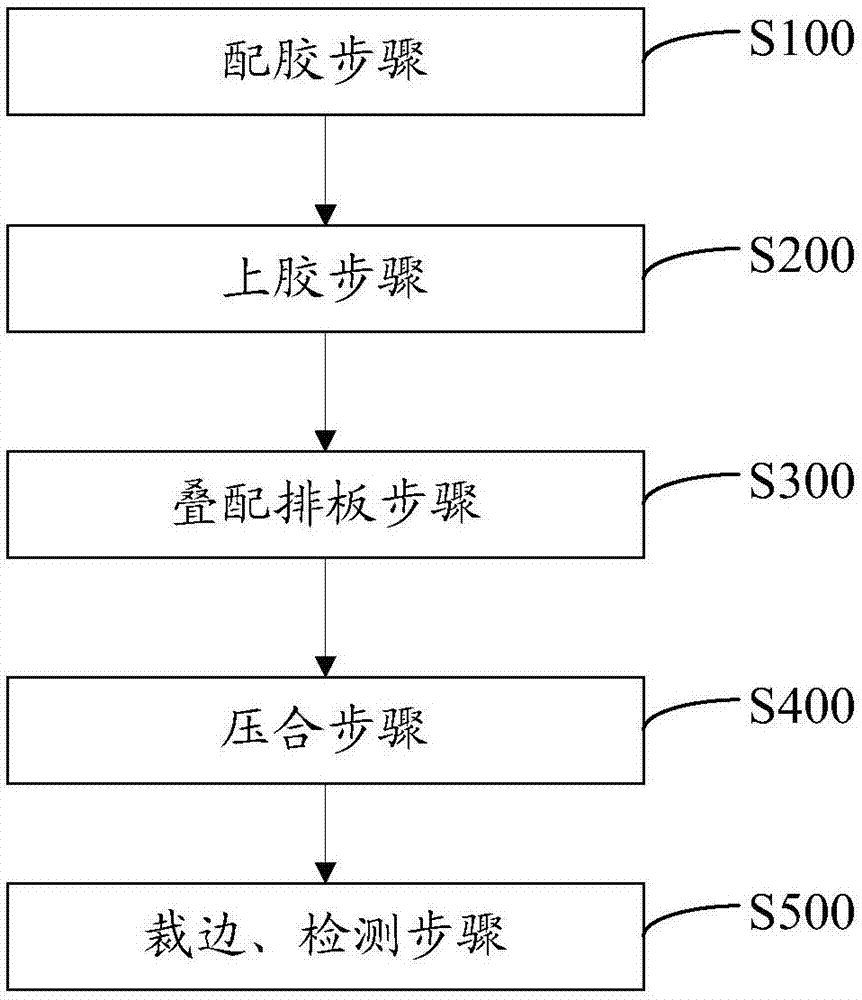

The invention discloses a making method for a high thermal conductive, high heat resistant and high CTI FR-4 copper-clad plate. The method comprises the steps of: preparation of a veneer layer glue solution and an inner material layer glue solution respectively, cementing, superimposition, and hot pressing. The veneer layer glue solution comprises the ingredients of: modified epoxy resin, tetrafunctional epoxy resin, an amine curing agent, an imidazole curing accelerator, a silane coupling agent KH560, an efficient flame retardant and a veneer layer filler; and any one of or a composition of over one of acetone, butanone, and dimethylformamide is taken as the solvent for preparation. The inner material layer glue solution comprises the ingredients of: low bromine epoxy resin, an amine curing agent, an imidazole curing accelerator, a silane coupling agent KH560, and an inner material layer filler; and any one of or a composition of over one of acetone, butanone, and dimethylformamide is taken as the solvent for preparation. The copper-clad plate prepared by the method provided by the invention has a CTI value of greater than or equal to 600V, efficient heat-conducting property, and thermal conductivity of greater than or equal to 1.7W / mk, thus meeting the use requirements of LED products for higher security. At the same time, the copper-clad plate also has excellent heat resistance.

Owner:NANTONG RODA ELECTRON

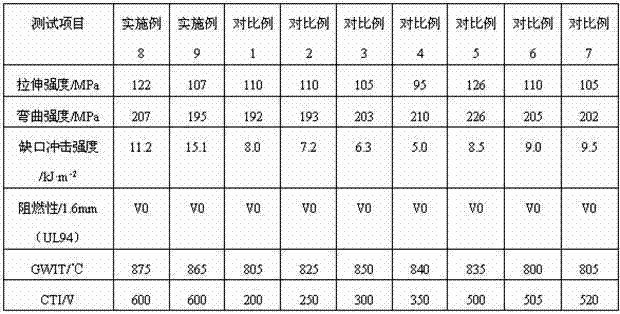

Flame retardant glass fiber reinforced PA6 (Polyamide 6)/PPO (Poly-p-Phenylene Oxide) alloy composite and preparation method thereof

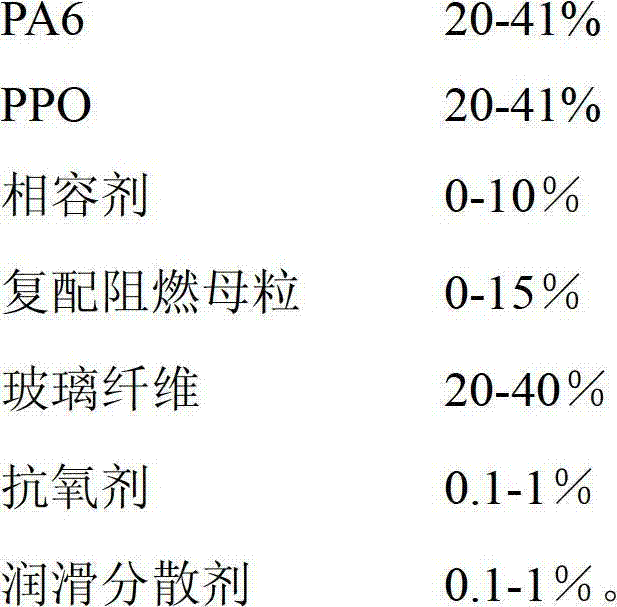

The invention relates to a flame retardant glass fiber reinforced PA6 (Polyamide 6) / PPO(Poly-p-Phenylene Oxide) alloy composite and a preparation method thereof. The compound comprises the components by weight as follows: 20-41% of PA6, 20-41% of PPO, 0-10% of compatilizer, 0-15% of compound flame retardant master batch, 20-40% of glass fiber, 0.1-1% of antioxidant, and 0.1-1% of lubricating dispersant. The preparation method comprises the steps of weighing the components by weight percentage, placing the components in a high mixing machine to mix for 2-5 minutes; discharging; and then extruding and pelleting by a double-screw extruder, wherein the processing temperature is 245-270 DEG C and revolution of the screw is 30-40HZ. Compared with the prior art, the alloy composite provided by the invention has the advantages of high CTI (Comparative Tracking Index) value, low separation of flame retardant, no halogen and environment-friendliness, balanced comprehensive performance and the like, and can be widely applied to products in the field of electronics such as contactor, leakage protector and circuit breaker shell.

Owner:SHANGHAI SUNNY

High CTI value halogen free flame-retardant reinforced PBT composite material and preparation method thereof

The invention relates to a PBT composite material, in particular to a high CTI value halogen free flame-retardant reinforced PBT composite material and a preparation method thereof. The PBT composite material comprises the following components in parts by weight: 48-64 parts of PBT, 20-30 parts of glass fibre, 16-22 parts of flame retardant, 0.1-0.5 part of CTI synergist, 0.3-0.8 part of anti-oxidant, and 0.5-0.8 part lubricant; wherein the flame retardant is prepared by comprising one or more components comprising methyl phenyl phosphate, methyl phenyl phosphate ester and methyl phenyl phosphite ester; the CTI synergist is prepared by comprising at least one of components comprising calcium oxide, magnesium oxide, and barium oxide; the anti-oxidant is prepared by comprising 1010 or 168; and the lubricant is prepared by comprising at least one of the components comprising EBS, oxidized lignite wax and oxidized polyethylene wax. The PBT composite material has the advantages of high CTI, environmental protection, high performance and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

High-CTI (comparative tracking index)-value brominated flame-retardant HIPS (high impact polystyrene) material and preparation method thereof

The invention relates to the field of high-polymer materials, and discloses a high-CTI (comparative tracking index)-value brominated flame-retardant HIPS (high impact polystyrene) material. The brominated flame-retardant HIPS material comprises the following raw materials in parts by weight: 51-66 parts of HIPS resin, 10-20 parts of brominated flame retardant, 2-5 parts of flame-retardant synergist, 10-20 parts of magnesium-containing compound, 5-10 parts of toughener, 0.4-1 part of antioxidant and 0.5-1 part of lubricant. The invention also discloses a preparation method of the brominated flame-retardant HIPS material. The brominated flame-retardant HIPS material provided by the invention has high CTI value and favorable tracking resistance; the flame retardancy is stable and can be up to the V-0 level; and the brominated flame-retardant HIPS material has excellent mechanical property and fine processability. Thus, the brominated flame-retardant HIPS material can be widely used for electronic / electrical equipment manufacturing.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value and preparation method of halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value

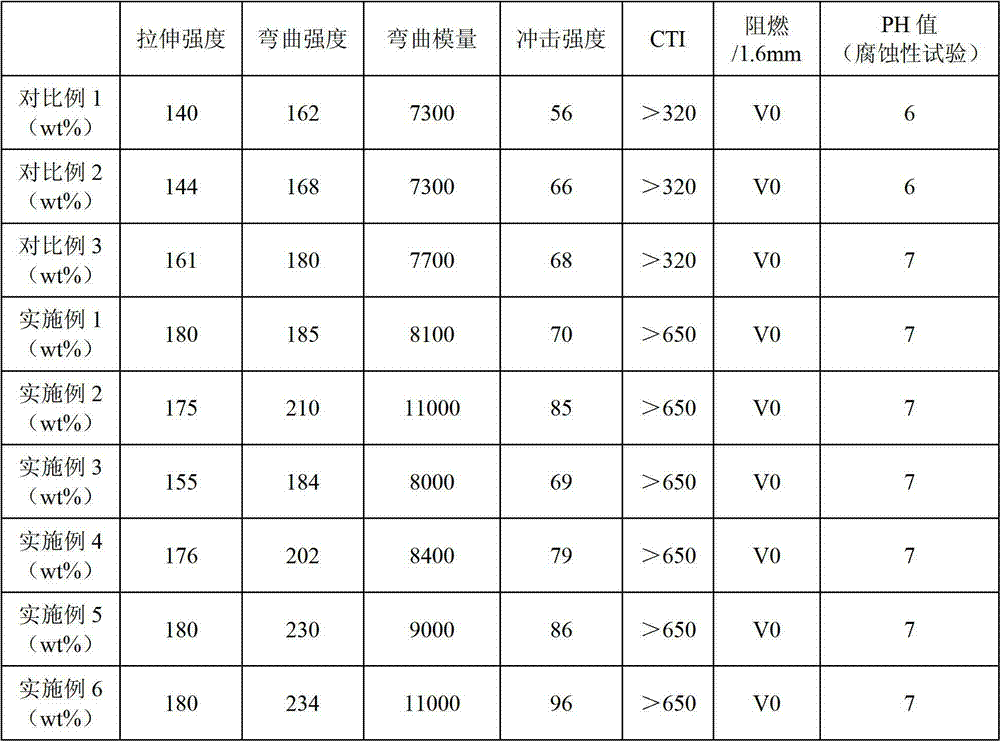

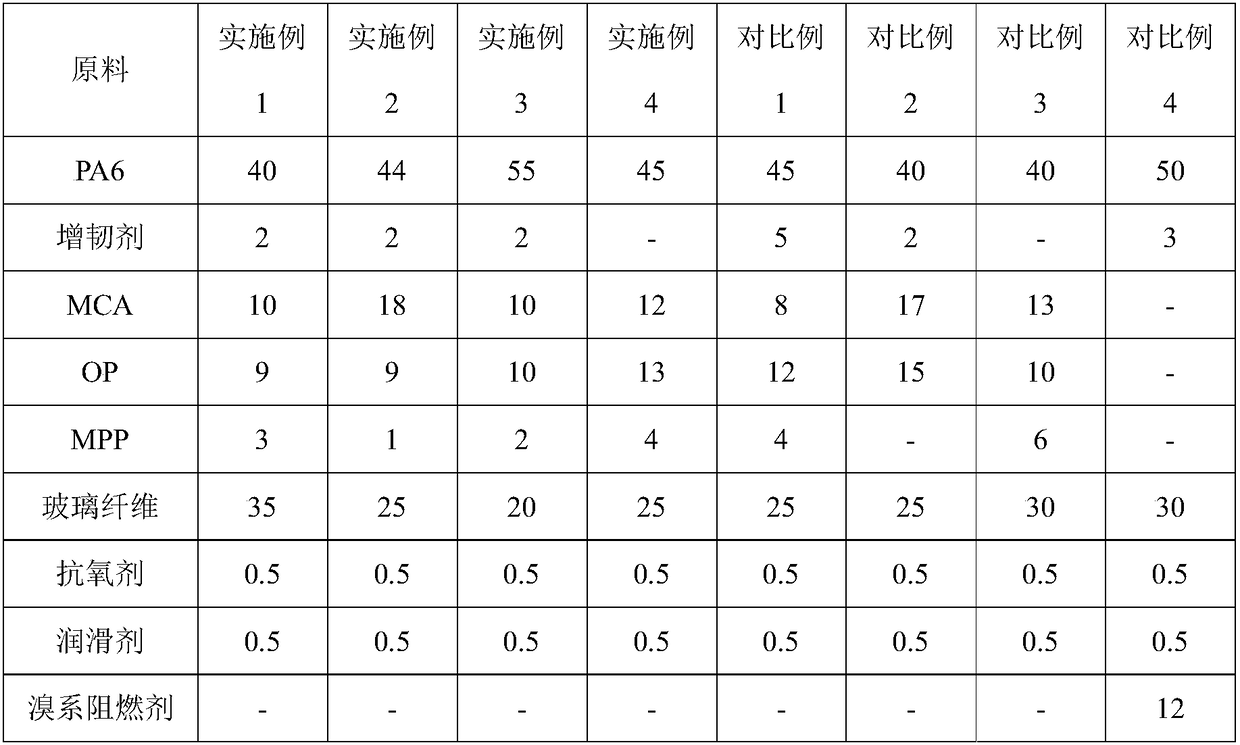

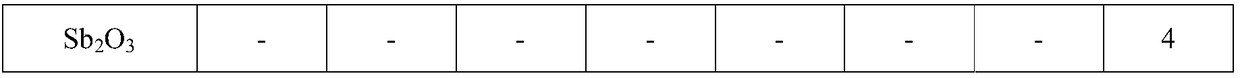

The invention discloses a halogen-free flame-retardant glass fiber-reinforced PA6 composite material with a high-ignition-temperature glow wire and a high CTI value and a preparation method of the PA6composite material. The PA6 composite material is composed of the following raw materials of: in parts by mass, 40-55 parts of PA6 resin, 0-5 parts of a toughening agent, 10-18 parts of melamine cyanurate flame retardant, 9-13 parts of aluminum hypophosphite flame retardant, 1-4 parts of melamine polyphosphate flame retardant, 20-35 parts of glass fiber, 0.3-0.5 part of an antioxidant and 0.3-1 part of a lubricant. Meanwhile, the invention discloses the preparation method of the halogen-free flame-retardant glass fiber-reinforced PA6 composite material with the high-ignition-temperature glowwire and the high CTI value. The halogen-free flame-retardant glass fiber-reinforced PA6 composite material with the high-ignition-temperature glow wire and the high CTI value has excellent flame retardant performance, high ignition temperature of the glow wire and high anti-tracking performance, and meanwhile the prepared composite material has excellent comprehensive mechanical properties and asimple preparation process, and is worthy of popularization and application.

Owner:GUANGDONG JUSHI CHEM CO LTD

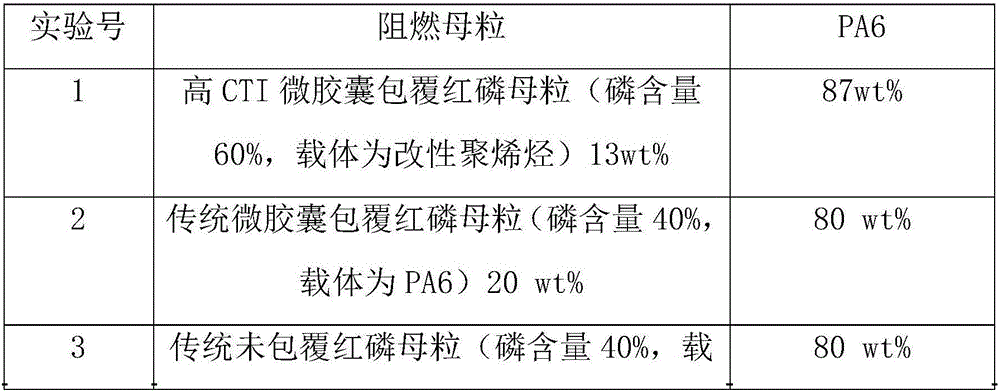

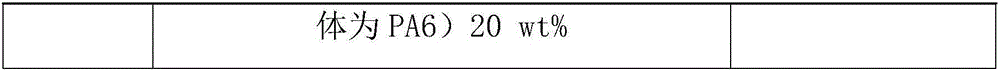

High CTI microcapsule coated red phosphorus fire retardant master batch and preparation method thereof

InactiveCN106220936AEasy to useThe risk of storage and transportation is reducedPolyolefinMelamine formaldehyde resin

The invention discloses high-CTI microcapsule coated red phosphorus fire retardant master batch and a preparation method thereof. The high-CTI microcapsule coated red phosphorus fire retardant master batch is prepared from coated red phosphorus, a modified polyolefin carrier and kaolin synergist which are granulated. The high-CTI microcapsule coated red phosphorus fire retardant master batch is prepared from the coated red phosphorus, the modified polyolefin carrier and the kaolin synergist by weight percent: 55 to 65% of the coated red phosphorus, 15 to 25% of the modified polyolefin carrier and 15 to 25% of the kaolin synergist. The preparation method of the high-CTI microcapsule coated red phosphorus fire retardant master batch comprises the steps of preprocessing red phosphorus, physically removing iron, preparing melamine-formaldehyde resin prepolymer, performing red phosphorus microencapsulation, filtering, washing, drying and granulating. The high-CTI microcapsule coated red phosphorus fire retardant master batch can improve the flame-retardant efficiency of red phosphorus flame retardant, the compatibility of the red phosphorus flame retardant with a base material and the CTI value of the red phosphorus flame retardant products.

Owner:广州银塑阻燃新材料股份有限公司

Oil fume resistant polycarbonate material, preparation method and application thereof

The invention discloses an oil fume resistant polycarbonate material, a preparation method and application thereof. The oil fume resistant polycarbonate material is prepared from the following components by mass: 70-90% of polycarbonate; 5-20% of modified nitrile butadiene rubber; 4-15% of a flame retardant; 0.3-3% of an antioxidant, and 0.4%-3% of a lubricating agent. The modified nitrile butadiene rubber is prepared from nitrile butadiene rubber and an ethylene-methyl acrylate copolymer in a mass ratio of 2-5:1. The material has excellent impact toughness, good flame retardant properties and electrical insulation properties, also has well improved oil fume cracking resistance, and is very suitable for preparation of kitchen wall switches and other products. The preparation method of the oil fume resistant polycarbonate material disclosed in the invention adopts existing equipment, the preparation is simple and is easy for industrial production, thus having broad application prospects.

Owner:中广核俊尔(浙江)新材料有限公司 +2

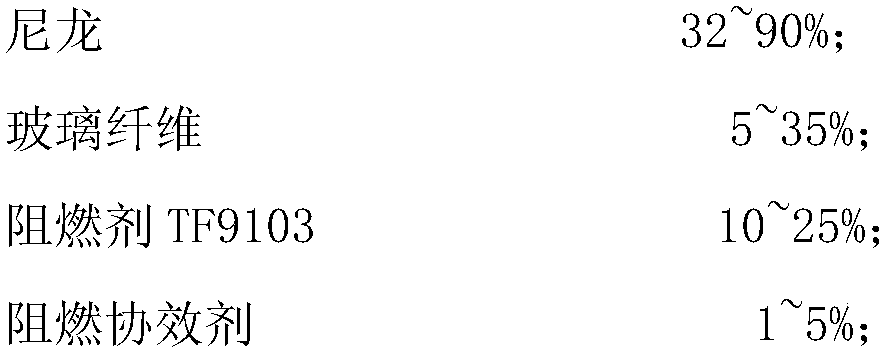

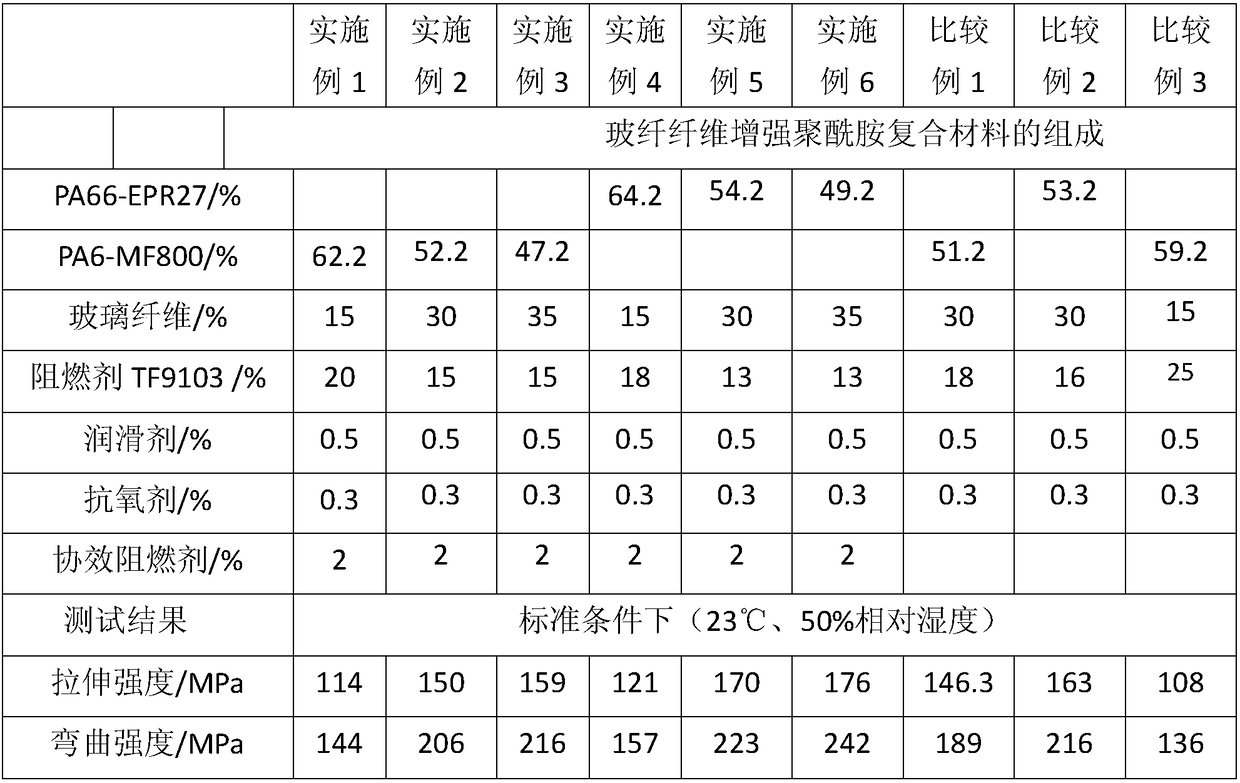

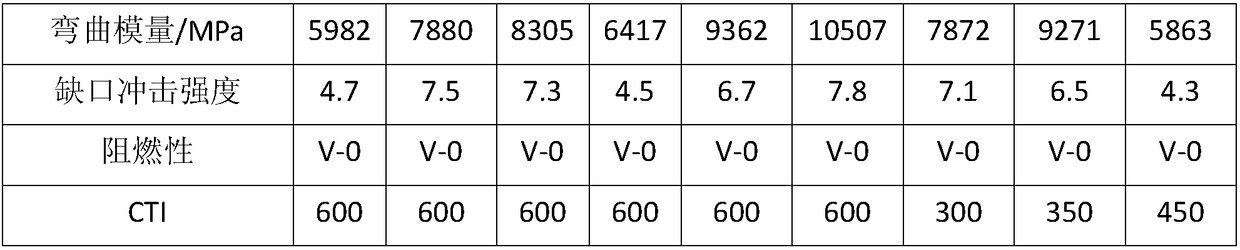

Environment-friendly, high-performance and high-CTI flame retardancy enhanced nylon material and preparation method thereof

The invention discloses an environment-friendly, high-performance and high-CTI flame retardancy enhanced nylon material and a preparation method thereof. The material is prepared from the following components in percentage by weight: 32-90% of a nylon raw material, 5-35% of glass fiber, 10-25% of a flame retardant TF9103, 0-5% of a flame-retardant synergist, 0-1% of a lubricating agent and 0-1% ofan antioxidant. The material and the preparation method thereof disclosed by the invention have the beneficial effects that the prepared environment-friendly and high-CTI flame retardancy enhanced nylon material meeting the environmental protection requirements has excellent mechanical properties and flame retardancy and meets requirements of ROHS and WEEE instructions; and by adding a home-madeefficient flame-retardant synergist, the dosage of the flame retardant can be effectively reduced, the CTI value can be increased, the reduction of the content of the flame retardant has positive significance for improving processability and saving cost, and the high CTI value can increase the application of composite materials and meet application requirements of more products; and the material can be applied to electronic and electrical equipment such as contactors and breaker shells.

Owner:CHONGQNG PRET NEW MATERIAL +4

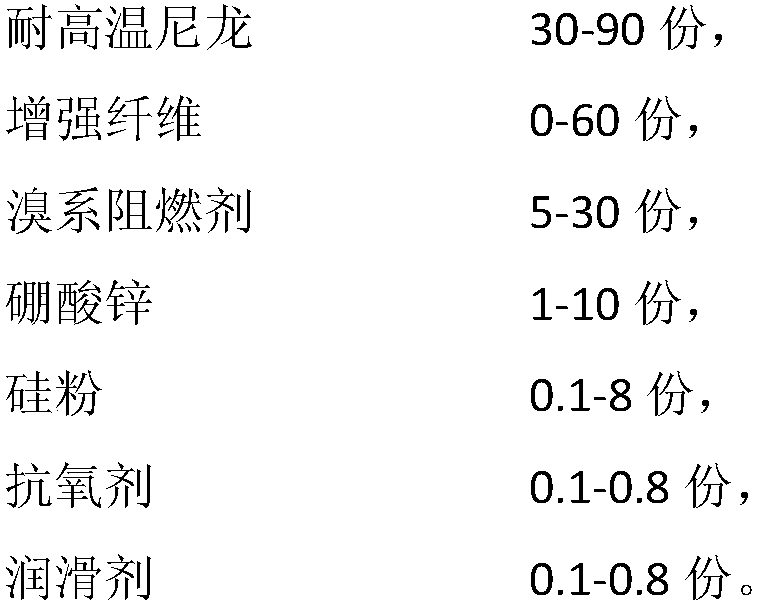

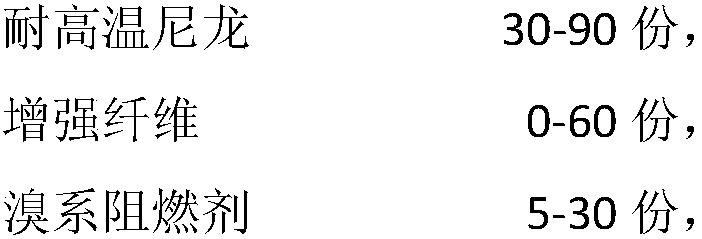

Anticorrosion high temperature resistant and flame-retardant nylon composite material and preparation method thereof

The invention provides an anticorrosion high temperature resistant and flame-retardant nylon composite material and a preparation method thereof. The composite material includes: 30-90 parts of high temperature resistant nylon, 0-60 parts of reinforcement fiber, 5-30 parts of a brominated flame retardant, 1-10 parts of zinc borate, 0.1-8 parts of silicon powder, 0.1-0.8 part of an antioxidant, and0.1-0.8 part of a lubricant. The method includes: mixing dry high temperature resistant nylon, the brominated flame retardant, zinc borate, silicon powder, the antioxidant and the lubricant to obtaina mixture; adding the mixture into a twin-screw extruder from a main feed port, adding the reinforcement fiber into the twin-screw extruder from a side feed port, and conducting drawing, cooling, grain cutting and drying, thus obtaining the anticorrosion high temperature resistant and flame-retardant nylon composite material. The anticorrosion high temperature resistant and flame-retardant nyloncomposite material provided by the invention has a high comparative tracking index, and can avoid generation of methane gas at high temperature, thus reducing corrosion of a mold surface.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

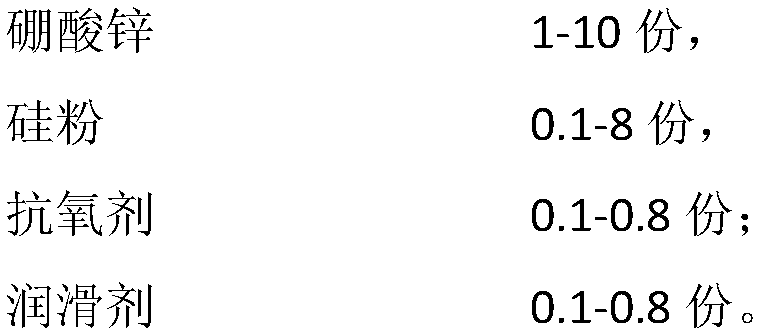

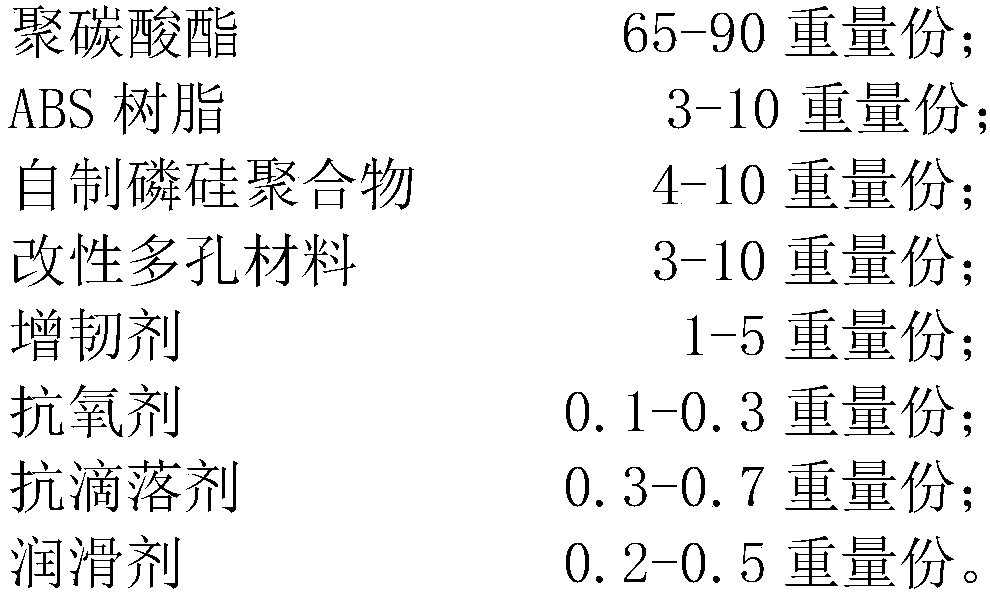

High-CTI, high-heat-resistance, halogen-free and flame-retardant PC/ ABS composition and preparation method thereof

The invention discloses a high-CTI, high-heat-resistance, halogen-free and flame-retardant PC / ABS composition and a preparation method thereof. The composition comprises the following raw materials in parts by weight: 65-90 parts of polycarbonate, 3-10 parts of ABS resin, 4-10 parts of self-made phosphosilicate polymer, 3-10 parts of modified porous material, 1-5 parts of thickening agent, 0.1-0.3 part of antioxygen, 0.3-0.7 part of anti-dripping agent, and 0.2-0.5 part of lubricating agent. According to the high-CTI, high-heat-resistance, halogen-free and flame-retardant PC / ABS composition,the defects of low CTI, high dosage of phosphorus based flame retardant, low flame retarding performance and low thermal deformation temperature of a traditional halogen-free flame-retardant PC / ABSresin are solved; the complex system of the self-made phosphosilicate polymer and the porous material is selected, and a continuous net shaped carbon layer structure is formed through an electric field and electrolyte, so that the resin is high in CTI, and high in thermal deformation temperature; the thermal deformation temperature of the prepared PC / ABS composition is up to 113 DEG C, and the CTI is up to 450V.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Resin composition, copper-clad board, circuit board and manufacturing method

InactiveCN107189347AHigh CTI valueImprove heat resistanceSynthetic resin layered productsElectrical equipmentEpoxyHeat resistance

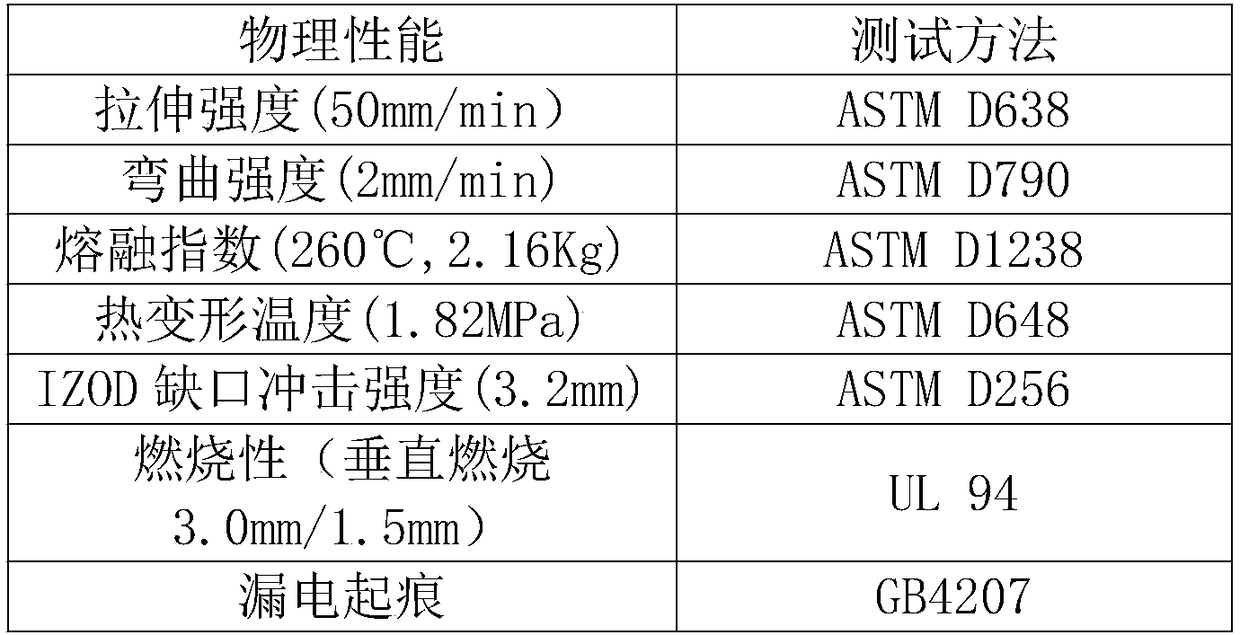

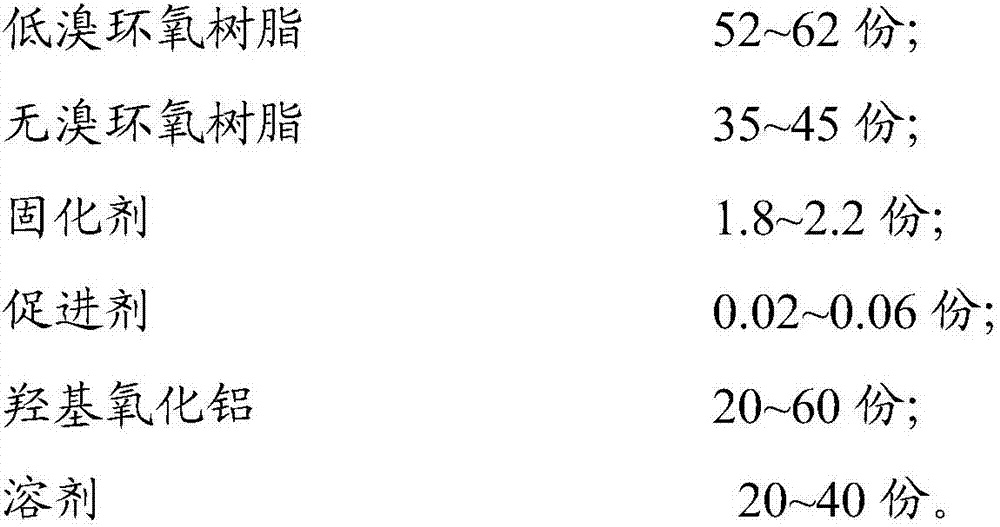

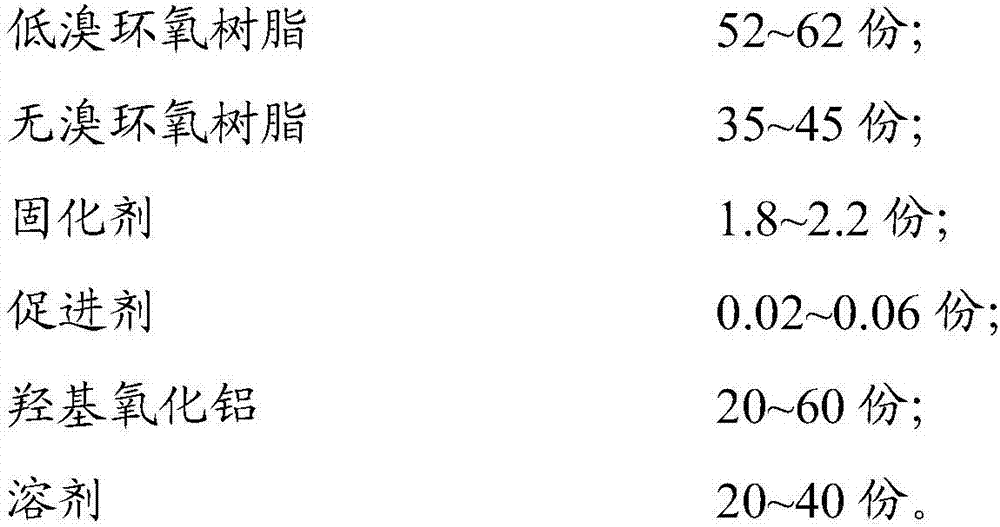

The invention discloses a resin composition, a copper-clad board, a circuit board and a manufacturing method. The resin composition comprises, by weight, 52-62 parts of low-bromine epoxy resin, 35-45 parts of bromine-free epoxy resin, 1.8-2.2 parts of curing agents, 0.02-0.06 part of accelerators, 20-60 parts of hydroxyl aluminum oxide and 20-40 parts of solvents. The resin composition, the copper-clad board, the circuit board and the manufacturing method have the advantages that hydroxyl aluminum oxide inorganic fillers are added to the resin composition, accordingly, a CTI (comparative tracking index) value of copper-clad board can be increased, the heat resistance, the acid and alkali resistance and the peel strength of the copper-clad board can be greatly improved, and application spaces of the prepared copper-clad board can be effectively expanded.

Owner:建滔覆铜板(深圳)有限公司

Environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene)/PA (polyamide) 11 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value and preparation method thereof

The invention relates to an environment-friendly and flame-retardant glass fiber reinforced PP (polypropylene) / PA (polyamide) 11 alloy material with high CTI (comparative tracking index) value and high GWIT (glow-wire ignition temperature) value. The alloy material is prepared from the following raw materials in percentage by weight: 23-41% of PP, 22-41% of PA11, 6-20% of compound flame retardant, 3-15% of antimony trioxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide. The invention also provides a preparation method of the alloy material. The alloy material has high GWIT and high CTI, is environment-friendly, has balanced overall performances and can be widely applied to low-voltage electronic capacitor shells, load break switches, carbon brush brackets and moulded case circuit breakers.

Owner:SHANGHAI SUNNY

Environment-friendly flame retardant glass fiber reinforced polyethylene terephthalate (PET) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952380AHigh GWIT valueImprove impact performancePolymer sciencePolyethylene terephthalate glycol

The invention discloses an environment-friendly flame retardant glass fiber reinforced polyethylene terephthalate (PET) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PET, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PET material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in composite material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

Halogen-free flame-retardant polypropylene composite for auto fuse holder, preparation method and application

InactiveCN102604221AImprove flame retardant performanceHigh CTI valuePolypropylene compositesHeat deflection temperature

The invention discloses a halogen-free flame-retardant polypropylene composite for an auto fuse holder, a preparation method and application. The polypropylene composite is prepared by 32-83% of polypropylene, 0-1% of heat stabilizer, 0-1% of processing agent, 10-30% of halogen-free intumescent flame retardant, 2-6% of compatilizer and 5-30% of reinforcing filler, wherein the halogen-free intumescent flame retardant refers to phosphorus-nitrogen halogen-free intumescent flame retardant. The halogen-free flame-retardant polypropylene composite for the auto fuse holder has excellent flame-retardant effect, high CTI (comparative tracking index) value, good comprehensive mechanical property, excellent folding resistance and high heat distortion temperature, the flame retardant property can reach 1.6mm V0, tensile strength is larger than or equal to 30MPa, bending modulus is larger than or equal to 2000MPa, CTI is larger than or equal to 500V, hinge folding times are larger than or equal to 106, notch impact strength is larger than or equal to 3.5KJ / m2, and heat distortion temperature (0.45MPa) is larger than or equal to 120 DEG C.

Owner:KINGFA SCI & TECH CO LTD +2

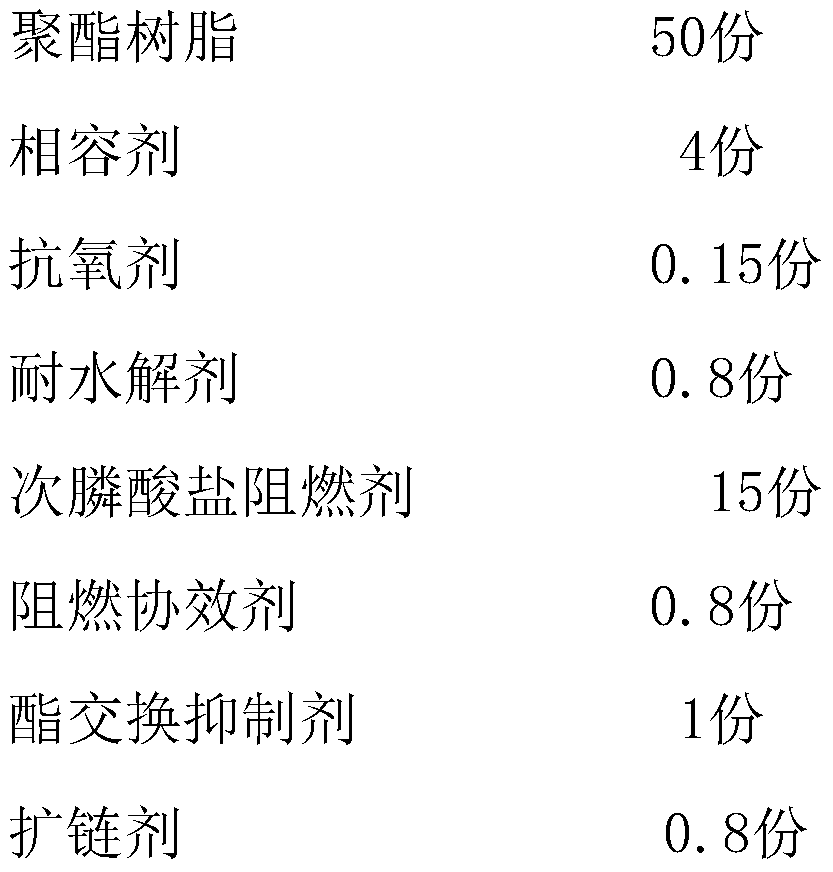

High-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite material, and preparation method thereof

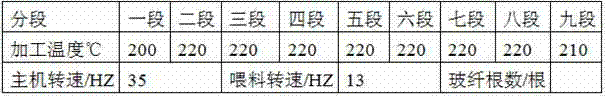

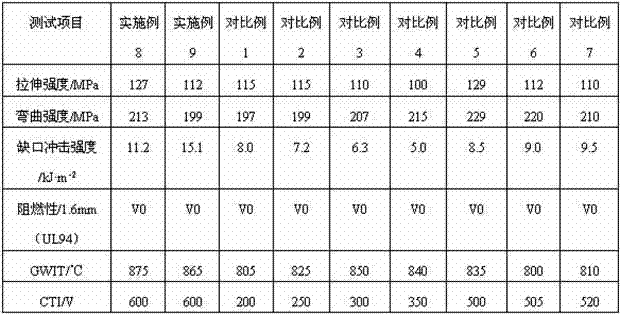

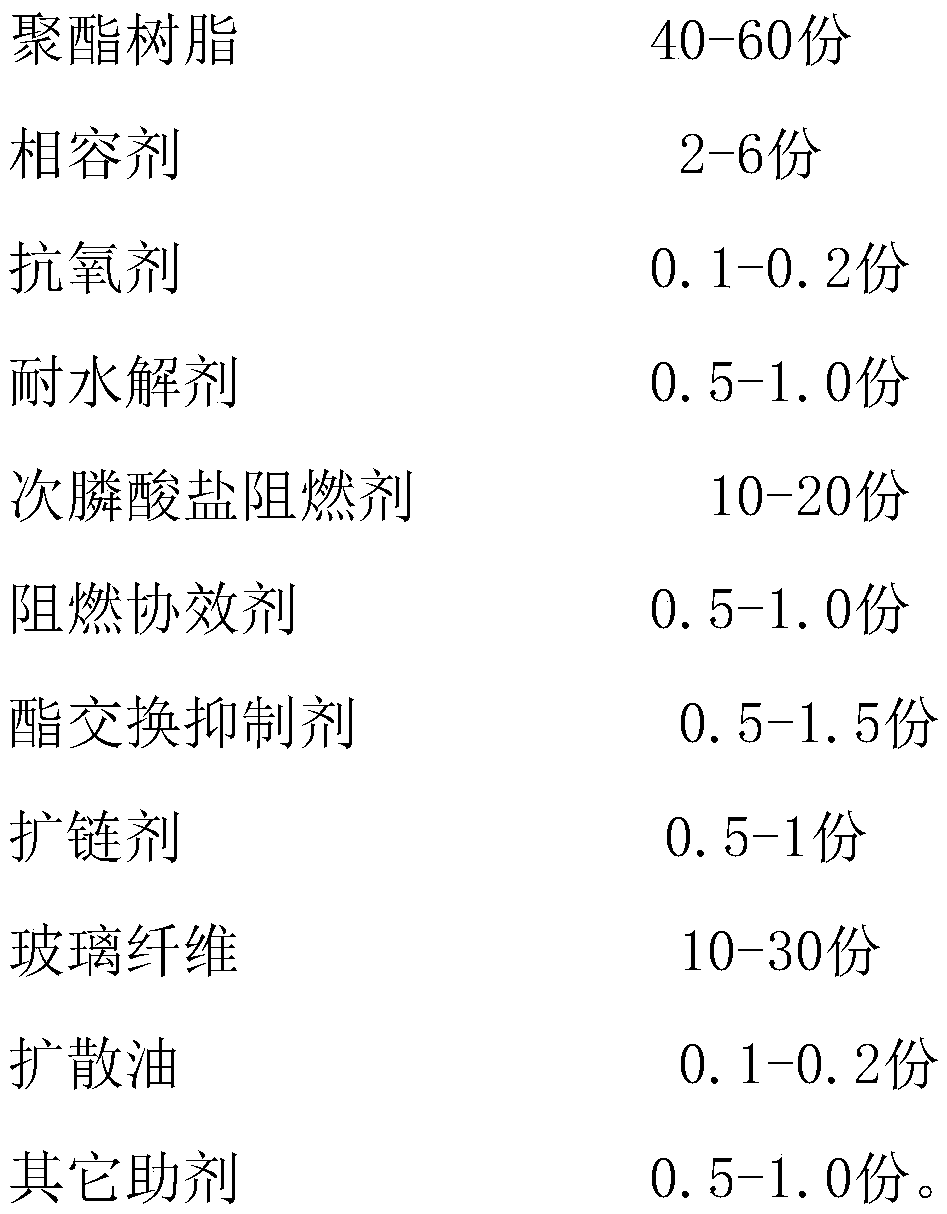

The invention belongs to the technical field of polyester materials used for charging piles, and more specifically relates to a high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite material, and a preparation method thereof. The high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite material comprises following raw materials, by weight, 40 to 60 parts of a polyester resin, 2 to 6 parts of a compatibilizer, 0.1 to 0.2 part of an antioxidant, 0.5 to 1.0 part of a hydrolysis inhibitor, 10 to 20 parts of aphosphinate flame retardant, 0.5 to 1.0 part of a flame retardant synergistic agent, 0.5 to 1.5 parts of an ester interchange inhibitor, 0.5 to 1 part of a chain extender, 10 to 30 parts of glass fiber, and 0 .5 to 1.0 part of other additives. Under double 85 test conditions, in 1000h, the high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite materialpossesses high CTI characteristics, the material mechanical properties are relatively stable, flame resistance is maintained, and no precipitate is generated on the surface of the high-temperature-resistant high-moisture-resistant halogen-free flame-retardant polyester composite material.

Owner:东莞市东翔塑胶有限公司

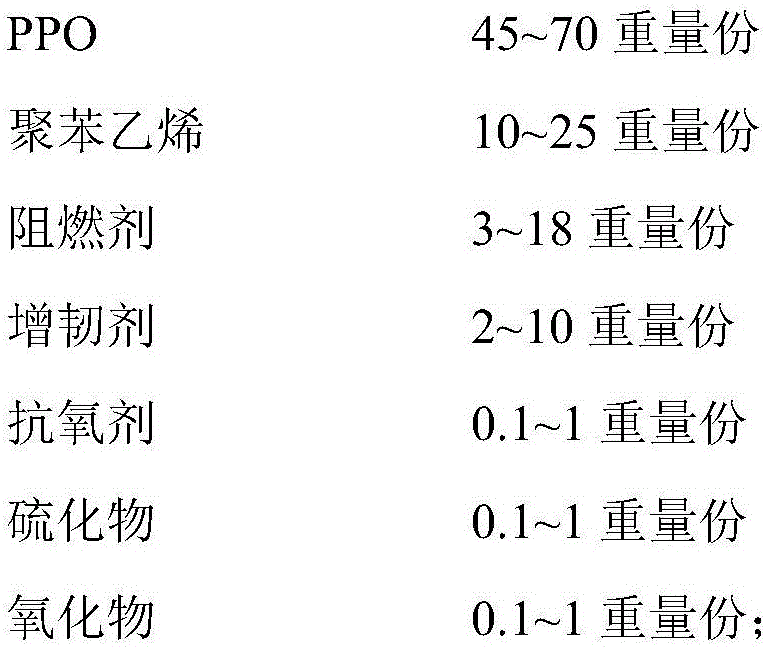

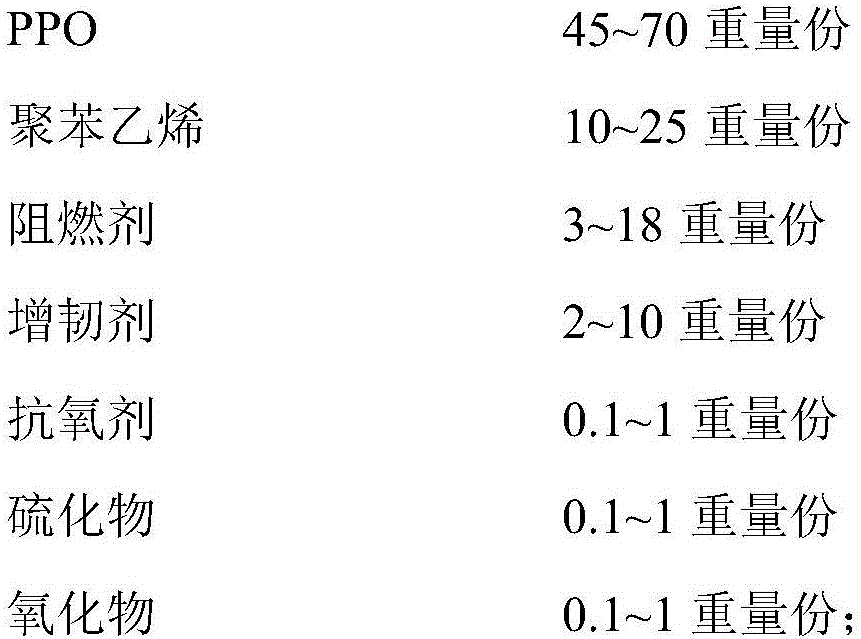

MPPO (modified polyphenylene oxide) composite material and preparation method thereof

The invention discloses an MPPO (modified polyphenylene oxide) composite material which comprises, by weight, 45-70 parts of PPO (polyphenylene oxide), 10-25 parts of polystyrene, 3-18 parts of flame retardants, 2-10 parts of toughening agents, 0.1-1 part of antioxidant, 0.1-1 part of sulfide and 0.1-1 part of oxide. The viscosity of the PPO is 40-45dl / g. The invention further provides a preparation method of an MPPO material which is high in impact strength, heat resistance and CTI (comparative tracking index) and good in halogen-free flame retardant effect. The composite material can pass a 125 DEG C ball indentation test, is uniform in comprehensive performance and can be widely applicable to the electronic and electrical appliance fields such as shells of electronic products and glue filling boxes of computer control systems.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

High-CTI and high-strength flame-retardant polyamide material and preparation method thereof

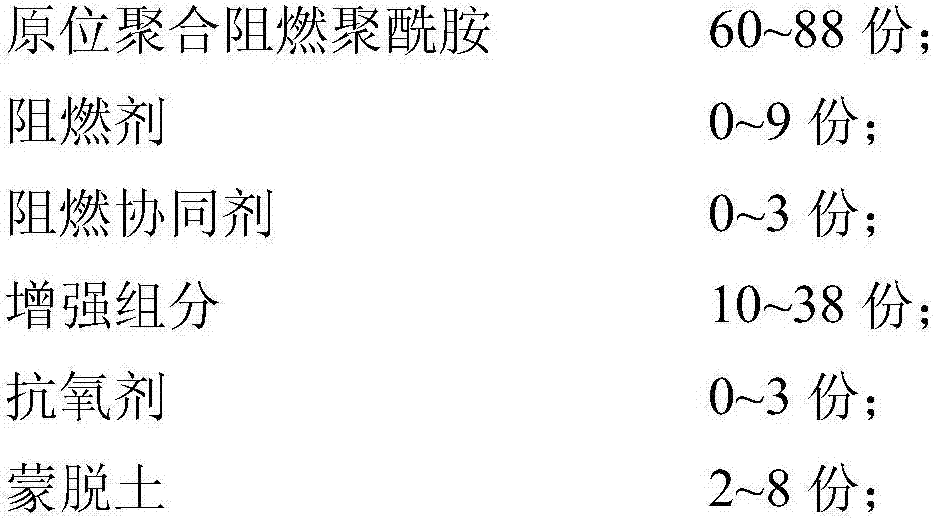

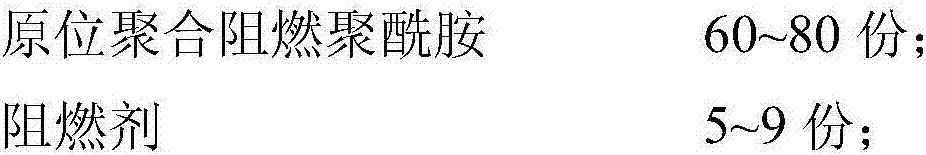

The invention discloses a high-CTI and high-strength flame-retardant polyamide material and a preparation method thereof. The high-CTI and high-strength flame-retardant polyamide material is prepared from the following components in parts by weight: 60-88 parts of in-situ polymerized polyamide, 10-38 an enhanced component and 2-8 montmorillonite; the in-situ polymerized polyamide is a phosphorus-containing flame-retardant copolymer and is obtained through copolymerization of a reactive flame retardant and polyamide; and the content of phosphorus in the in-situ polymerized polyamide is 3500-8000ppm. The adopted polyamide is the in-situ polymerized polyamide, so that the polyamide material has a good flame-retardant characteristic, and a product can reach the V-0 flame-retardant effect of a UL94 test under the condition of adding a little of flame retardant and montmorillonite or not adding the flame retardant or the montmorillonite. The enhanced component has better compatibility with the polyamide through chemical surface modification, so that the high-CTI value and high-mechanical strength flame-retardant polyamide material is prepared. The high-CTI and high-strength flame-retardant polyamide material is extruded and pelletized by adopting an existing twin-screw extruder, and is simple in method, low in cost and suitable for massive production.

Owner:THE QUARTERMASTER EQUIP INST OF THE LOGISTICAL SUPPORT DEPT CMC

Halogen-free flame-retardant PBT material and preparation process thereof

PendingCN112724616AHigh CTI valueGood physical propertiesHollow article cleaningPolytetramethylene terephthalateGlass fiber

The invention relates to a halogen-free flame-retardant PBT material and a preparation process thereof. The halogen-free flame-retardant PBT material is prepared from the following six components in percentage by weight: polybutylene terephthalate, halogen-free flame retardant, antioxidant, compatilizer, silicate and glass fiber. The percentage of the content of the six components is as follows: 50-70% of polybutylene terephthalate; 18%-25% of the halogen-free flame retardant; 0.5%-1% of the antioxidant; 1%-5% of the compatilizer; 0.5%-1% of silicate; 0-30% of glass fiber. According to the halogen-free flame-retardant PBT material and the preparation process thereof, through reasonable improvement of a production line, waste is avoided, the raw material utilization rate is higher, and the product performance is better.

Owner:JIANGYIN JIHUA NEW MATERIAL

High-CTI-value high-flame-retardant composite film and preparation method thereof

InactiveCN112606504AImprove flame retardant performanceHigh CTI valueSynthetic resin layered productsLaminationPolymer scienceComposite film

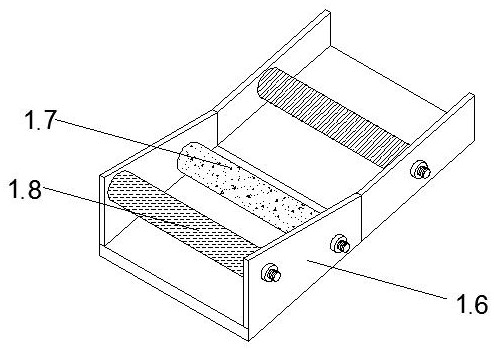

The invention discloses a high-CTI-value high-flame-retardant composite film and a preparation method thereof. The high-CTI-value high-flame-retardant composite film comprises a modified PC material layer and two modified PPO material layers, the modified PC material layer serves as a base material layer, the two modified PPO material layers are compounded on the upper surface and the lower surface of the modified PC material layer in a co-extrusion mode to form a three-extrusion composite film; through a multi-layer co-extrusion preparation method, a high-flame-retardant PPO material and a high-flame-retardant PC material are adopted, PC serves as a main base material, the PPO material with high flame retardance and a high CTI value is co-extruded on the surface of the PC, so that a 0.5 mm film reaches the flame retardant grade of UL94-V0, meanwhile, the PPO material on the double-sided surface layer has a function of CTI being 0, and high CTI value.

Owner:苏州奥美材料科技有限公司

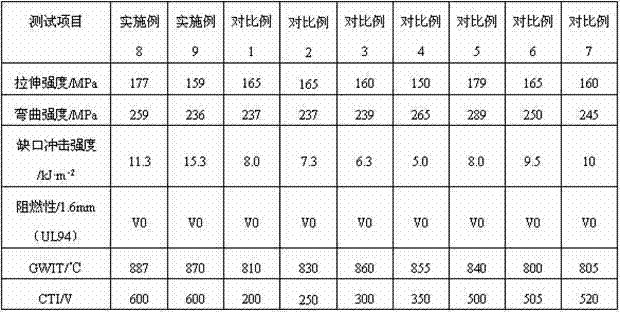

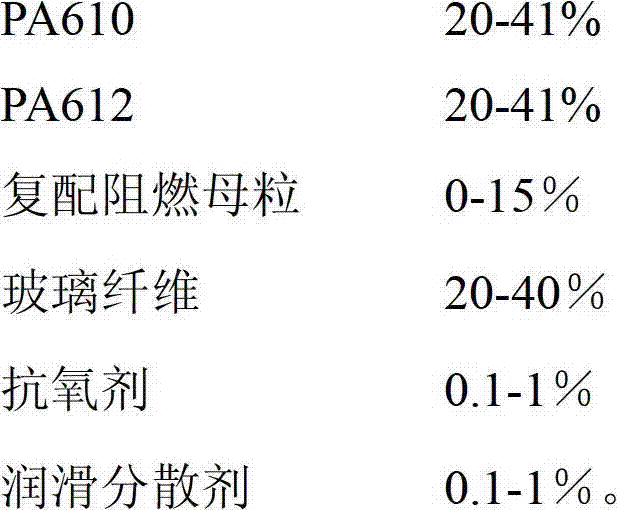

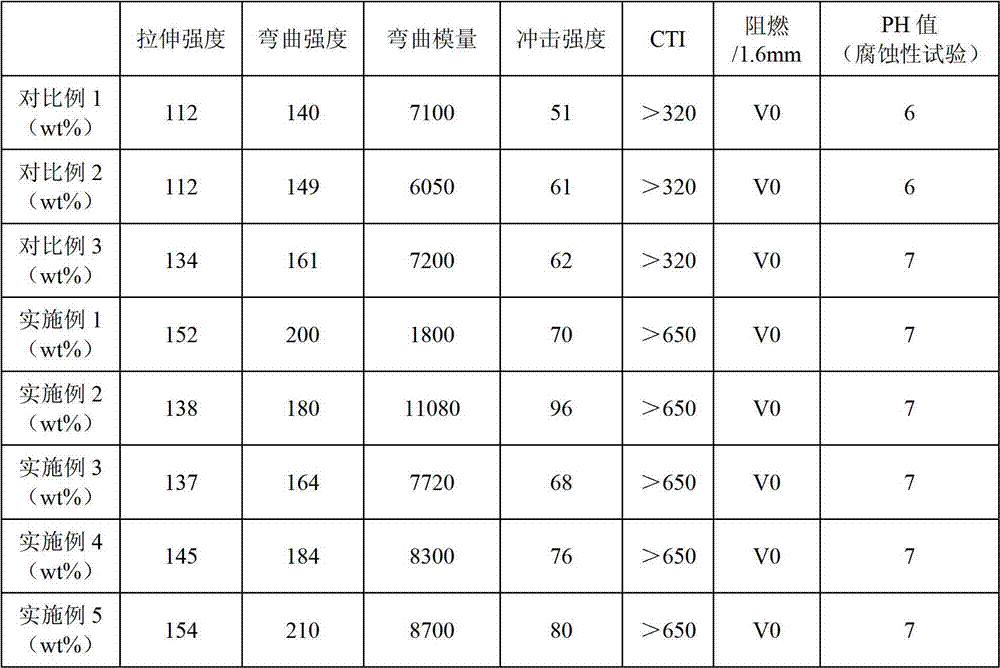

Flame-retardant glass fiber reinforced polyamide 610/polyamide 612 (PA610/PA612) alloy composite and preparation method thereof

InactiveCN102775781AImprove mechanical propertiesCTI improvementMasterbatchComparative Tracking Index

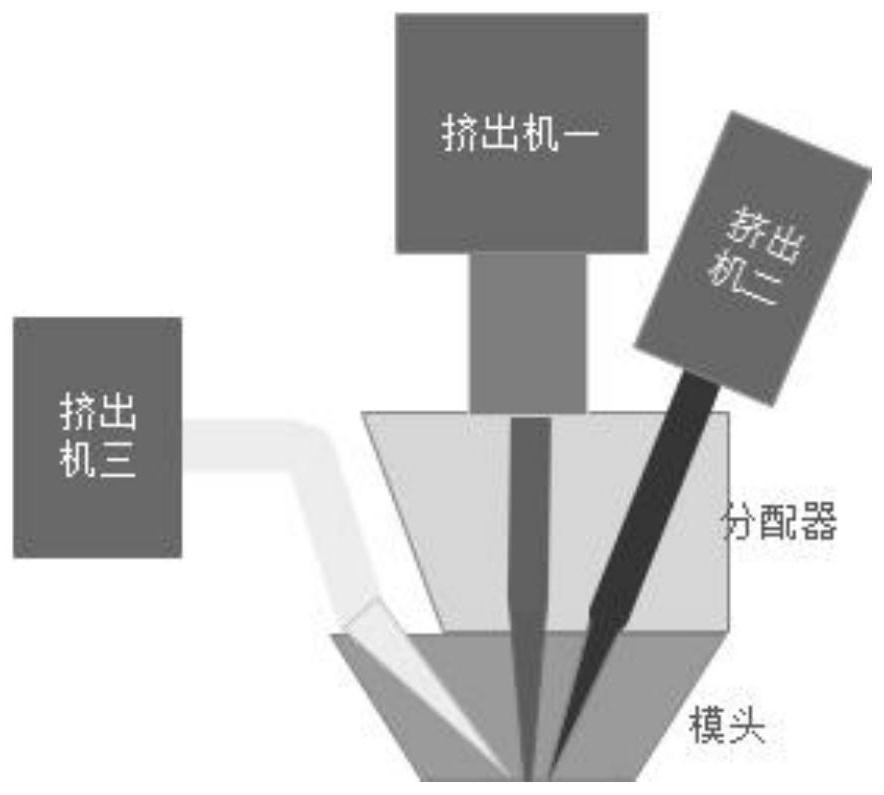

The invention relates to a flame-retardant glass fiber reinforced polyamide 610 / polyamide 612 (PA610 / PA612) alloy composite and a preparation method thereof. The composite comprises the following components in percentage by weight: 20-41 percent of polyamide 610 (PA610), 20-41 percent of polyamide 612 (PA612), 0-15 percent of compound flame-retardant masterbatch, 20-40 percent of glass fiber, 0.1-1 percent of an antioxygen and 0.1-1 percent of a lubricant dispersing agent. The preparation method of the composite comprises the following steps of: weighing each component according to the weight proportions; putting the components into a high mixing machine to mix for 2-5 minutes; discharging; and extruding and pelleting by a twin-screw extruder to process at the temperature of 235-260 DEG C under the condition of screw revolution of 30-40HZ. Compared with the prior art, the composite has the advantages of high comparative tracking index (CTI) value, low flame-retardant precipitation property, halogen-free environment friendliness, comprehensive performance equalization and the like, and can be widely applied to products of contacts, leakage protectors, circuit breaker shells and the like in the electronics field.

Owner:SHANGHAI SUNNY

Halogen-free flame-retardant PBT resin with high CTI and preparation method of halogen-free flame-retardant PBT resin

InactiveCN109337305AComply with RoHS environmental directiveHigh flame retardant levelAntioxidantPre treatment

The invention provides halogen-free flame-retardant PBT resin with high CTI and a preparation method of the halogen-free flame-retardant PBT resin. The halogen-free flame-retardant PBT resin is prepared from components in parts by weight as follows: 40-70 parts of PBT resin, 18-24 parts of a composite flame retardant, 1-5 parts of a CTI synergist, 10-30 parts of reinforcing filler, 0.4-2 parts ofa lubricant, 0.2-1 part of an antioxidant and 0.2-2 parts of a coupling agent. The method comprises the following steps: (1) the reinforcing filler is subjected to pretreatment: 10-30 parts by weightof the reinforcing filler is weighed and subjected to surface treatment with the coupling agent mainly in a manner that the compound coupling agent and the reinforcing filler are premixed in a high-speed mixer for 10-30 min; (2) 40-70 parts of the PBT resin, 18-24 parts of the composite flame retardant, 1-5 parts of the CTI synergist, 10-30 parts of the reinforcing filler, 0.4-2 parts of the lubricant and 0.2-1 part of the antioxidant are added to the mixture in step (1) and mixed at a high speed for 5-8 min, the mixture is subjected to extrusion and granulation by a twin-screw extruder at 190-230 DEG C, and halogen-free flame-retardant PBT resin with high CTI is obtained; (3) injection molding is performed by an injection molding machine at 190-230 DEG C.

Owner:浙江富丽新材料有限公司

Halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and method for preparing same

The invention discloses halogen-free stibium-free antiflaming polydiethylene terephthalate engineering plastics and a method for preparing the same. The plastics consist of the following components in percentage by weight: 39 to 65 percent of polydiethylene terephthalate, 15 to 40 percent of reinforcing agent, 0 to 8 percent of toughening agent, 5 to 8 percent of phosphorus flame retardant, 0 to 8 percent of nitrogen flame retardant, 0 to 4 percent of synergetic flame retardant, 0 to 0.5 percent of nucleating agent and 0 to 0.5 percent of antioxidant. In the preparation method, the phosphorus-nitrogen antiflaming system is combined with the nanometer clay, so that while the halogen-free stibium-free flame retardation of the compound material is realized, the higher CTI value of the antiflaming material is ensured; the plastics are applicable in the field of electric appliances; and the method for preparing the material is simple and avoids adopting mould temperature forming processing, and the compound material possesses excellent thermal stability and therefore can be recycled.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com