Environment-friendly, high-performance and high-CTI flame retardancy enhanced nylon material and preparation method thereof

A green and high-performance technology, applied in the field of flame retardant reinforced nylon materials, can solve problems such as harming human health, polluting the environment, and large heat, and achieve the effect of increasing the barrier performance, increasing the CTI value, and increasing the amount of carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

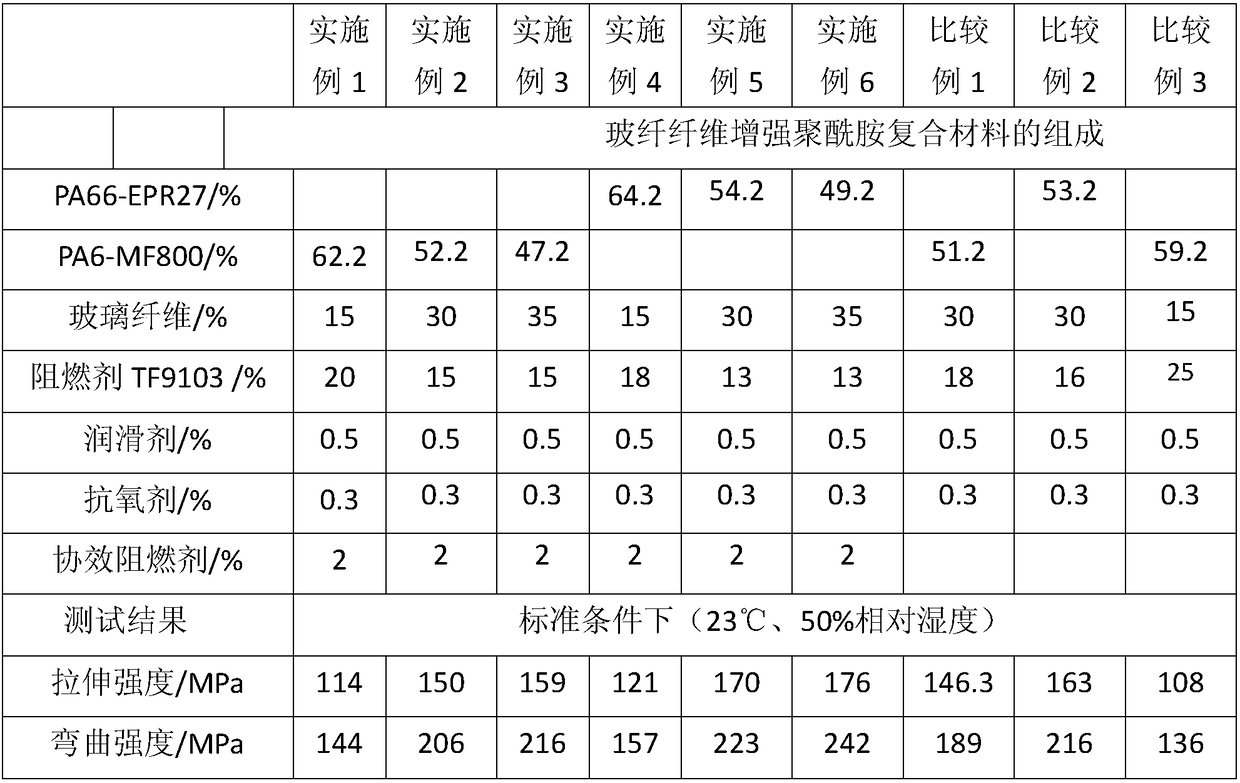

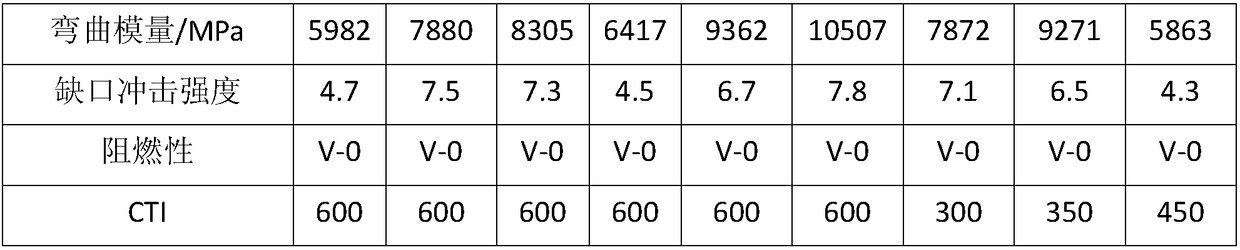

Examples

Embodiment 1

[0038] Weigh 3.11kg of PA6-MF800, dry at 100°C for 4 hours, weigh 0.15kg of toughening agent, 15g of antioxidant H318, and 25g of lubricant and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0039] Weigh 0.75 kg of alcoholysis-resistant glass fiber and set aside.

[0040] Weigh 1kg of flame retardant TF9103, 100g of synergistic flame retardant, mix evenly, set aside

[0041] The resin mixture obtained above is added to the twin-screw extruder through the main feeding port of the twin-screw extruder (the screw diameter is 35mm, and the length-to-diameter ratio is L / D=40), and the glass fiber is fed through the rear end side. (close to the machine head), add the flame retardant through the front feeding port, and control the temperature of each section of the twin-screw extruder (from the feeding port to the machine head outlet) to 170°C, 190°C, 200°C, 200°C, 200°C ℃, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed of the twin-screw extruder is 320r / m...

Embodiment 2

[0044] Weigh 2.61kg of PA6-MF800, dry at 100°C for 4 hours, weigh 0.15kg of toughening agent, 15g of antioxidant H318, and 25g of lubricant and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0045] Weigh 1.5 kg of alcoholysis-resistant glass fiber and set aside.

[0046] Weigh 0.75kg of flame retardant TF9103, 100g of synergistic flame retardant, mix evenly, set aside

[0047]The resin mixture obtained above is added to the twin-screw extruder through the main feeding port of the twin-screw extruder (the screw diameter is 35mm, and the length-to-diameter ratio is L / D=40), and the glass fiber is fed through the rear end side. (close to the machine head), add the flame retardant through the front feeding port, and control the temperature of each section of the twin-screw extruder (from the feeding port to the machine head outlet) to 170°C, 190°C, 200°C, 200°C, 200°C ℃, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed of the twin-screw extruder is 320r / ...

Embodiment 3

[0050] Weigh 2.36kg of PA6-MF800, dry at 100°C for 4 hours, weigh 0.15kg of toughening agent, 15g of antioxidant H318, and 25g of lubricant and mix them uniformly in a high-speed mixer to obtain a resin mixture;

[0051] Weigh 1.75kg of alcoholysis-resistant glass fiber and set aside.

[0052] Weigh 0.75kg of flame retardant TF9103, 100g of synergistic flame retardant, mix evenly, set aside

[0053] The resin mixture obtained above is added to the twin-screw extruder through the main feeding port of the twin-screw extruder (the screw diameter is 35mm, and the length-to-diameter ratio is L / D=40), and the glass fiber is fed through the rear end side. (close to the machine head), add the flame retardant through the front feeding port, and control the temperature of each section of the twin-screw extruder (from the feeding port to the machine head outlet) to 170°C, 190°C, 200°C, 200°C, 200°C ℃, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed of the twin-screw extruder is 320r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com